Comprehensive Evaluation of Rice Qualities under Different Nitrogen Levels in South China

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Cultivars and Site

2.2. Experimental Design

2.3. Evaluation of Appearance Quality and Milling Quality

2.4. Sensory Evaluation of Eating Quality of Rice

2.5. Statistical Analyses

3. Results

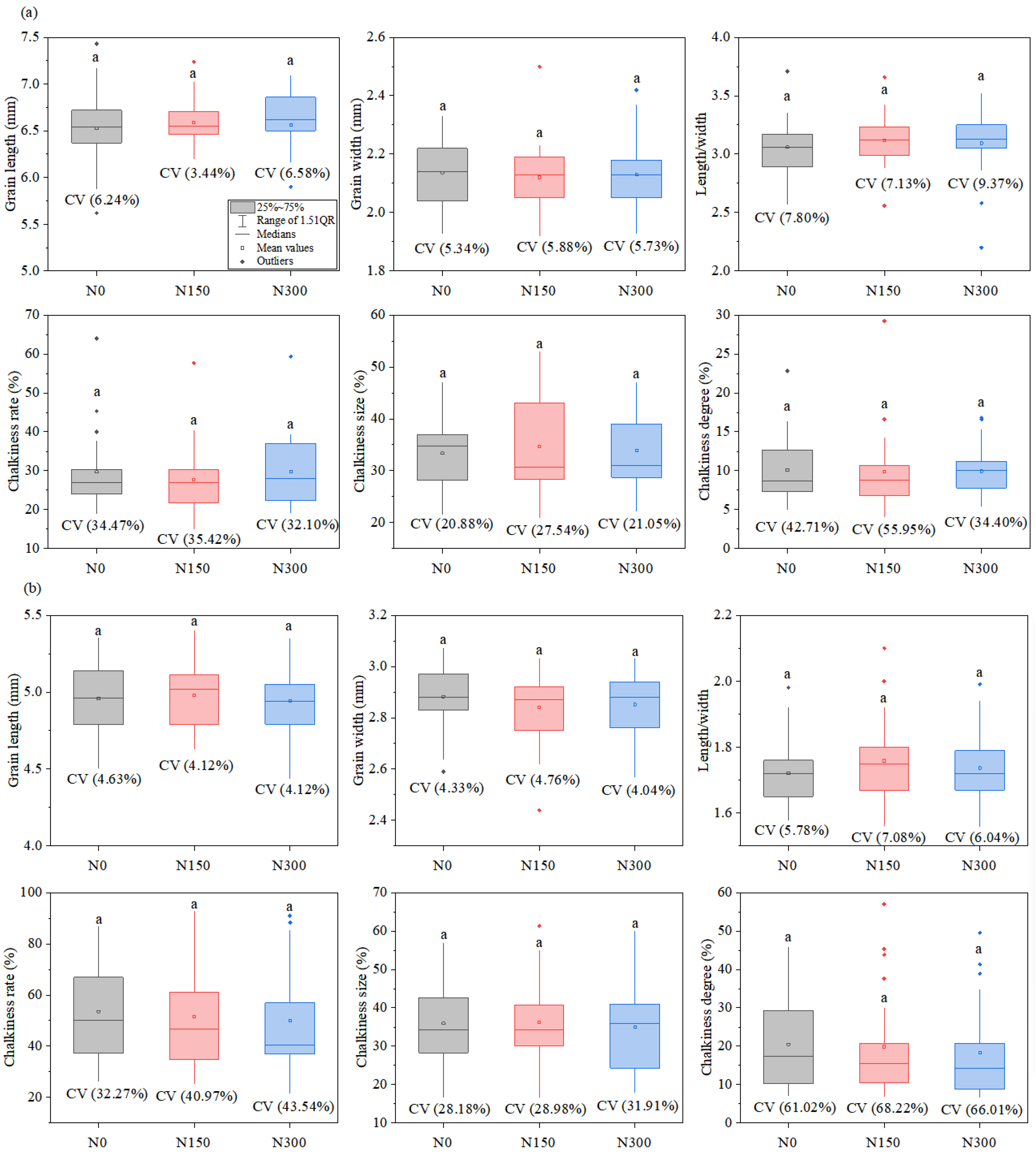

3.1. Trait Variations among Varieties and Nitrogen Levels

3.2. Comprehensive Evaluation of Rice Quality of Different Varieties under Different Nitrogen Levels

3.3. Cluster Analysis on the Quality of Different Rice Varieties

4. Discussion

4.1. Difference in Rice Qualities among Varieties

4.2. Nitrogen Effects on Rice Qualities

4.3. Comprehensive Evaluation of Rice Quality

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- National Bureau of Statistics of the People’s Republic of China. In China Statistical Yearbook; Statistics Press: Beijing, China, 2021.

- Li, X.K.; Wu, L.; Geng, X.; Xia, X.H.; Wang, X.H.; Xu, Z.J.; Xu, Q. Deciphering the environmental impacts on rice quality for different rice cultivated areas. Rice 2018, 11, 7. [Google Scholar] [CrossRef]

- Cui, Y.; Zhu, M.M.; Xu, Z.J.; Chen, W.F. The breeding of japonica rice in northern China: An eleven-year study (2006–2016). Journal of Integrative Agriculture 2020, 19, 1941–1946. [Google Scholar] [CrossRef]

- Ma, H.Z.; Chen, X.Y.; Wang, Z.J.; Zhu, Y.; Jiang, W.Q.; Ren, G.L.; Ma, Z.T.; Wei, H.Y.; Zhang, H.C.; Liu, G.D. Analysis on appearance and cooking taste quality characteristics of some high quality japonica rice in China. Sci. Agric. Sin. 2021, 54, 1338–1353, (In Chinese with English Abstract). [Google Scholar]

- Wang, C.L.; Zhang, Y.D.; Zhu, Z.; Chen, T.; Zhao, Q.Y.; Zhong, W.G.; Yang, J.; Yao, S.; Zhou, L.H.; Zhao, L.; et al. Research progress on the breeding of japonica super rice varieties in Jiangsu Province, China. J. Integr. Agric. 2017, 16, 992–999. [Google Scholar] [CrossRef]

- Cheng, F.; Xu, Q.; Xu, Z.J.; Chen, W.F. Effect of rice breeding process on improvement of yield and quality in china. Rice Sci. 2020, 27, 363–367. [Google Scholar] [CrossRef]

- GB/T17891-2017; High Quality Paddy. Standardization Administration of the People’s Republic of China. China National Standardization Management Committee: Beijing, China, 2017.

- Zhang, Y.D.; Chen, T.; Zhao, Q.Y.; Zhu, Z.; Zhou, L.H.; Yao, S.; Zhao, L.; Wang, C.L. Establishment and application of evaluation method for eating quality of rice. Jiangsu Agric. Sci. 2011, 39, 350–352, (In Chinese with English Abstract). [Google Scholar]

- Meng, Q.H.; Li, X.H.; Sanshang, L.S.; Heye, Y.X.; Lu, S.W.; Chen, A.H.; Yao, X.M.; Guan, H.T. Predicting eating quality of short grain rice by using visible and near infrared spectroscopy. J. Chin. Creals Oils Assoc. 2010, 25, 90–99, (In Chinese with English Abstract). [Google Scholar]

- Xu, Y.J.; Ying, Y.N.; Ouyang, S.H.; Duan, X.L.; Sun, H.; Jiang, S.K.; Sun, S.C.; Bao, J.S. Factors Affecting Sensory Quality of Cooked japonica Rice. Rice Sci. 2018, 25, 330–339. [Google Scholar]

- Zhao, C.F.; Yue, H.L.; Huang, S.J.; Zhou, L.H.; Zhao, L.; Chen, T.; Zhu, Z.; Zhao, Q.Y.; Yao, S.; Liang, W.H.; et al. Eating quality and physicochemical properties in nanjing rice varieties. Sci. Agric. Sin. 2019, 52, 909–920, (In Chinese with English Abstract). [Google Scholar]

- Huang, M.; Hu, L.Q.; Cao, J.L.; Zhang, R.C.; Chen, J.N.; Cao, F.B.; Liu, L.S.; Fang, S.L.; Zhang, M. Texture and digestion properties of hybrid rice: A comparison between two cultivars released 18 years apart. Food Chem. X 2022, 13, 100215. [Google Scholar] [CrossRef] [PubMed]

- Chen, N.; Yang, S.H.; Xie, L.H.; Daun, B.W. Differences in sensory evaluation of cooked rice in indica rice growing region in China. China Jounal Rice Sci. 2011, 25, 413–419, (In Chinese with English Abstract). [Google Scholar]

- Lu, H.; Yuan, Y.J.; Zhang, S.Q.; Chen, H.; Chen, D.; Zhong, X.Y.; Li, B.; Deng, F.; Chen, Y.; Li, G.Y.; et al. Evaluation of rice eating quality and optimization of varieties of Southwest indica hybrid rice based on three taste evaluation methods. Sci. Agric. Sin. 2021, 54, 1243–1257, (In Chinese with English Abstract). [Google Scholar]

- Chen, H.; Chen, D.; He, L.H.; Wang, T.; Lu, H.; Yang, F.; Deng, F.; Chen, Y.; Tao, Y.F.; Li, M.; et al. Correlation of taste values with chemical compositions and Rapid Visco Analyser profiles of 36 indica rice (Oryza sativa L.) varieties. Food Chem. 2021, 349, 129176. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Xiong, N.; Liu, H.; Wu, L.; Meng, H.; Liu, L.; Wu, L.L. Establishment of models to evaluate the eating quality and comprehensive quality of indica rice. Food Sci. 2016, 37, 97–103, (In Chinese with English Abstract). [Google Scholar]

- Jiang, X.J.; Zhou, J.M.; Huang, M.; Duan, G.J.; Luo, H.G.; Ou, L.J.; Ni, X.L. Evaluation of rice quality of new rice varieties in Hunan Province based on principal component and cluster Analysis. China Rice 2009, 15, 33–35, (In Chinese with English Abstract). [Google Scholar]

- Jing, Z.Y.; Wei, J.Q.; Wang, L.Y.; Song, W.M.; Zheng, J.P.; Guo, Y.X. Comprehensive quality evaluation of different rice varieties based on principal component analysis. Food Sci. 2020, 41, 179–184, (In Chinese with English Abstract). [Google Scholar]

- Chen, Y.Y.; Hu, X.X.; Chen, J.D.; Yang, X.; Ma, Q.; Chen, Q.; Ge, M.J.; Dai, Q.G. Effect of Nitrogen Fertilizer Application on Eating Quality of Early-Maturing Late Japonica Rice in Jiangsu and Its Difference among Varieties. Acta Agron. Sin. 2012, 38, 2086–2092, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Liao, S.; Deng, F.; Tian, Q.L.; Li, W.; Hu, H.; Pu, S.L.; Li, S.X.; Ren, W.J. Response of major restore lines for hybrid rice to nitrogen rate in Sichuan Province. J. Plant Nutr. Fertil. 2018, 24, 71–81, (In Chinese with English Abstract). [Google Scholar]

- Xu, F.X.; Xiong, H.; Zhang, L.; Guo, X.Y.; Zhu, Y.C.; Zhou, X.B.; Liu, M. Effect factor and predict model of rice quality variation for mid-season hybrid rice at different ecological sites and nitrogen application levels. Chin. J. Rice Sci. 2012, 26, 438–444, (In Chinese with English Abstract). [Google Scholar]

- Wei, H.Y.; Zhu, Y.; Qiu, S.; Han, C.; Hu, L.; Xu, D.; Zhou, N.B.; Xing, Z.P.; Hu, Y.J.; Cui, P.Y.; et al. Combined effect of shading time and nitrogenlevel on grain filling and grain quality in japonica super rice. J. Integr. Agric. 2018, 17, 2405–2417. [Google Scholar] [CrossRef]

- Yang, X.Y.; Lin, Z.M.; Liu, Z.H.; Alim, M.A.; Bi, J.G.; Li, G.H.; Wang, Q.S.; Wang, S.H.; Ding, Y.F. Physicochemical and sensory properties of japonica rice varied with production areas in china. J. Integr. Agric. 2013, 12, 1748–1756. [Google Scholar] [CrossRef]

- Yao, D.P.; Wu, J.; Luo, Q.H.; Shen, H.; Zhuang, W.; Xiao, G.; Li, J.W.; Li, Y.G.; Deng, Q.Y.; Lei, D.Y.; et al. Comprehensive evaluation of high temperature tolerance of six rice varieties during grain-filling period based on key starch physicochemical indexs. LWT-Food Sci. Technol. 2021, 148, 111804. [Google Scholar] [CrossRef]

- Lv, F.; Yang, F.; Fan, T.; Liu, J.; Li, Q.; Wang, L.G.; Long, X.B. Analysis of rice variety approval data from 1977 to 2018. Chin. Seed Ind. 2019, 2, 29–40, (In Chinese with English Abstract). [Google Scholar]

- Zhang, H.; Tan, G.L.; Sun, X.L.; Liu, L.J.; Yang, J.C. Changes in grain quality during the evolution of mid-season indica rice cultivars in Jiangsu province. Acta Agron. Sin. 2009, 35, 2037–2044, (In Chinese with English Abstract). [Google Scholar]

- Gu, J.F.; Chen, J.; Chen, L.; Wang, Z.Q.; Zhang, H.; Yang, J.C. Grain quality changes and responses to nitrogen fertilizer of japonica rice cultivars released in the Yangtze River Basin from the 1950s to 2000s. Crop J. 2015, 3, 285–297. [Google Scholar] [CrossRef]

- Hu, X.Q.; Zhang, W.X.; Shao, Y.F.; Yu, Y.H.; Lu, L.; Chen, M.X. Analysis on high quality rate of rice in China during recent 20 years. China Rice 2021, 27, 84–87, (In Chinese with English Abstract). [Google Scholar]

- Zeng, Y.H.; Tan, X.M.; Zeng, Y.J.; Xie, X.B.; Pan, X.H.; Shi, Q.H.; Zhang, J. Changes in the rice grain quality of different high-quality rice varieties released in southern China from 2007 to 2017. J. Cereal Sci. 2019, 87, 111–116. [Google Scholar] [CrossRef]

- Feng, F.; Li, Y.J.; Qin, X.L.; Liao, Y.C.; Siddique, K.H.M. Changes in rice grain quality of indica and japonica type varieties released in China from 2000 to 2014. Front. Plant Sci. 2017, 8, 1863. [Google Scholar] [CrossRef]

- Zhu, D.W.; Zhang, L.P.; Chen, M.X.; Fang, C.Y.; Yu, Y.H.; Zheng, X.L.; Shao, Y.F. Characteristics of high-quality rice varieties and taste sensory evaluation values in China. Sci. Agric. Sin. 2022, 55, 1271–1283, (In Chinese with English Abstract). [Google Scholar]

- Ma, Q.; Zhang, H.C.; Dai, Q.G.; Wei, H.Y.; Huo, Z.Y.; Xu, K.; Yin, C.Y.; Hang, J.; Zhang, S.F.; Zhang, Q. Effects of Nitrogen Application Rate and Growth-Development Type on Milling Quality in Japonica Rice. Acta Agron. Sin. 2009, 35, 1282–1289, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Zhou, L.J.; Liang, S.S.; Ponce, K.; Marundon, S.; Ye, G.Y.; Zhao, X.Q. Factors affecting head rice yield and chalkiness in indica rice. Field Crops Res. 2015, 172, 1–10. [Google Scholar] [CrossRef]

- Meng, T.Y.; Zhang, X.B.; Chen, X.; Ge, J.L.; Zhou, G.S.; Wei, H.H.; Dai, Q.G. Trends in grain quality and responses to nitrogen application of japonica inbred rice released after the 1980s in east China. Cereal Chem. 2022, 99, 503–519. [Google Scholar] [CrossRef]

- Tang, J.; Tang, C.; Guo, B.W.; Zhang, C.X.; Zhang, Z.Z.; Wang, K.; Zhang, H.C.; Chen, H.; Sun, M.Z. Effect of nitrogen application on yield and rice quality of mechanical transplanting high quality late rice. Acta Agron. Sin. 2020, 46, 117–130, (In Chinese with English abstract). [Google Scholar] [CrossRef]

- Tao, J.; Qian, X.C.; Jv, C.X.; Liu, L.J.; Zhang, H.; Gu, J.F.; Wang, Z.Q.; Yang, J.C. Grain quality and its response to nitrogen fertilizer in mid-season indica rice varieties planted in different decades from 1950s to 2010s. Acta Agron. Sin. 2016, 42, 1352–1362, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Zhang, Q.; Guo, B.W.; Hu, Y.J.; Zhang, H.C.; Xu, Y.F.; Xu, X.J.; Zhu, B.H.; Xu, J.F.; Niu, Z.Y.; Tu, R.W. Differences in yield and rice quality of soft japonica rice with high quality and high yield under different nitrogen levels. Chin. J. Rice Sci. 2021, 35, 606–616, (In Chinese with English Abstract). [Google Scholar]

- Zhu, D.W.; Zhang, H.C.; Guo, B.W.; Xu, K.; Dai, Q.G.; Wei, H.Y.; Gao, H.; Hu, Y.J.; Cui, P.Y.; Huo, Z.Y. Effects of nitrogen level on yield and quality of japonica soft super rice. J. Integr. Agric. 2017, 16, 1018–1027. [Google Scholar] [CrossRef]

- Huang, S.J.; Zhao, C.F.; Zhu, Z.; Zhou, L.H.; Zheng, Q.H.; Wang, C.L. Characterization of eating quality and starch properties of two Wx alleles japonica rice cultivars under different nitrogen treatments. J. Integr. Agric. 2020, 19, 988–998. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Y.Y.; Song, N.Y.; Chen, Q.L.; Sun, H.Z.; Peng, T.; Huang, S.; Zhao, Q.Z. Response of grain-filling rate and grain quality of mid-season indica rice to nitrogen application. J. Integr. Agric. 2021, 20, 1465–1473. [Google Scholar] [CrossRef]

- Xiong, R.Y.; Tan, X.M.; Yang, T.T.; Pan, X.H.; Zeng, Y.J.; Huang, S.; Shang, Q.Y.; Zhang, J.; Zeng, Y.H. Relation of cooked rice texture to starch structure and physicochemical properties under different nitrogen managements. Carbohydr. Polym. 2022, 295, 119882. [Google Scholar] [CrossRef]

- Zhou, T.Y.; Zhou, Q.; Li, E.P.; Yuan, L.M.; Wang, W.L.; Zhang, H.; Liu, L.J.; Wang, Z.Q.; Yang, J.C.; Gu, J.F. Effects of nitrogen fertilizer on structure and physicochemical properties of ‘super’ rice starch. Carbohydr. Polym. 2020, 239, 116237. [Google Scholar] [CrossRef]

- Shi, S.J.; Wang, E.T.; Li, C.X.; Zhou, H.; Cai, M.L.; Cao, C.G.; Jiang, Y. Comprehensive evaluation of 17 qualities of 84 types of rice based on principal component analysis. Foods 2021, 10, 2883. [Google Scholar] [CrossRef] [PubMed]

| Quality Traits | Hybrid Indica Rice | Inbred Japonica Rice | ||||

|---|---|---|---|---|---|---|

| V | N | V × N | V | N | V × N | |

| Grain length (mm) | ** | ns | ns | ** | ns | ns |

| Grain width (mm) | ** | ns | ns | ** | ns | ns |

| Length/width | ** | ns | ns | ** | ns | ns |

| Brown rice percentage (%) | * | ** | ns | * | ** | ns |

| Mild rice percentage (%) | * | * | ns | * | * | ns |

| Head rice percentage (%) | * | ** | ns | ** | ns | ns |

| Chalkiness rate (%) | ** | ns | ** | ** | ns | ** |

| Chalkiness size (%) | ** | ns | * | ** | ns | ns |

| Chalkiness degree (%) | ** | ns | ** | ** | ns | ns |

| Appearance | * | ns | * | ** | ns | ns |

| Aroma | ** | ns | ns | ** | ns | ns |

| Taste | ** | * | ns | ** | ns | ns |

| Texture | ** | * | ** | ** | * | * |

| Retrogradation | ** | ns | ns | ** | * | ** |

| Overall eating quality | ** | * | * | ** | ** | * |

| Traits | PC1 | PC2 | PC3 | PC4 | PC5 |

|---|---|---|---|---|---|

| Grain length | 0.1795 | 0.0618 | 0.0384 | 0.6309 | 0.2444 |

| Grain width | −0.2582 | 0.3504 | 0.2056 | −0.1808 | 0.0972 |

| length/width | 0.2821 | −0.1943 | −0.1126 | 0.5546 | 0.0892 |

| Brown rice percentage | 0.0502 | 0.4340 | −0.3094 | 0.1385 | −0.1573 |

| Mild rice percentage | 0.0577 | 0.4621 | −0.3377 | 0.0508 | −0.0509 |

| Head rice percentage | −0.0328 | 0.3856 | −0.4229 | 0.0275 | −0.0704 |

| Chalkiness rate | −0.3661 | 0.2167 | 0.1745 | 0.1119 | 0.1687 |

| Chalkiness size | −0.1842 | −0.0158 | 0.1995 | 0.2449 | −0.4473 |

| Chalkiness degree | −0.3794 | 0.1728 | 0.2446 | 0.2258 | −0.0943 |

| Appearance | −0.0958 | 0.1943 | 0.3518 | 0.2578 | 0.0145 |

| Smell | 0.0438 | 0.1270 | −0.0018 | −0.1190 | 0.7708 |

| Taste | 0.2845 | 0.2229 | 0.3686 | −0.0470 | 0.0474 |

| Texture | 0.3602 | 0.2306 | 0.2861 | −0.1046 | −0.1015 |

| Retrogradation | 0.3842 | 0.0751 | 0.0357 | −0.1381 | −0.2071 |

| Overall eating quality | 0.3652 | 0.2138 | 0.2866 | −0.0536 | −0.0590 |

| Eigenvalue | 4.0828 | 3.1141 | 2.1377 | 1.6626 | 1.0080 |

| Contributive ratio (%) | 27.2187 | 20.7605 | 14.2513 | 11.0836 | 6.7199 |

| Cumulative (%) | 27.2187 | 47.9792 | 62.2305 | 73.3142 | 80.0341 |

| Traits | PC1 | PC2 | PC3 | PC4 | PC5 |

|---|---|---|---|---|---|

| Grain length | −0.0728 | 0.2654 | −0.1763 | 0.3058 | 0.7037 |

| Grain width | 0.2231 | 0.0543 | 0.2978 | −0.3500 | 0.4141 |

| length/width | −0.2157 | 0.1415 | −0.3356 | 0.4709 | 0.1813 |

| Brown rice percentage | −0.0227 | 0.2734 | 0.4554 | 0.1874 | −0.1644 |

| Mild rice percentage | 0.0367 | 0.2200 | 0.4433 | 0.3671 | −0.0468 |

| Head rice percentage | 0.1417 | 0.3196 | 0.3985 | 0.1414 | −0.0032 |

| Chalkiness rate | 0.2593 | −0.3786 | 0.0400 | 0.1637 | 0.0868 |

| Chalkiness size | 0.2292 | −0.2566 | 0.0237 | 0.4174 | −0.1488 |

| Chalkiness degree | 0.2731 | −0.4029 | 0.0358 | 0.2701 | −0.0315 |

| Appearance | 0.1197 | 0.3878 | −0.2309 | −0.1766 | −0.2567 |

| Smell | 0.0465 | 0.2735 | −0.2926 | 0.2033 | −0.3801 |

| Taste | 0.3985 | 0.1737 | −0.1562 | 0.0309 | −0.0616 |

| Texture | 0.4212 | 0.0960 | −0.0886 | −0.1316 | 0.1545 |

| Retrogradation | 0.3958 | 0.0011 | −0.1002 | 0.0788 | 0.0485 |

| Overall eating quality | 0.4157 | 0.2127 | −0.1424 | −0.0376 | 0.0126 |

| Eigenvalue | 4.3386 | 3.0768 | 2.4791 | 1.7693 | 0.9703 |

| Contributive ratio (%) | 28.9239 | 20.5122 | 16.5271 | 11.7952 | 6.4686 |

| Cumulative (%) | 28.9239 | 49.4361 | 65.9632 | 77.7584 | 84.2270 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, C.; Xu, C.; Lu, B.; Zhu, X.; Luo, X.; He, B.; Elidio, C.; Liu, Z.; Ding, Y.; Yang, J.; et al. Comprehensive Evaluation of Rice Qualities under Different Nitrogen Levels in South China. Foods 2023, 12, 697. https://doi.org/10.3390/foods12040697

Ding C, Xu C, Lu B, Zhu X, Luo X, He B, Elidio C, Liu Z, Ding Y, Yang J, et al. Comprehensive Evaluation of Rice Qualities under Different Nitrogen Levels in South China. Foods. 2023; 12(4):697. https://doi.org/10.3390/foods12040697

Chicago/Turabian StyleDing, Chao, Congshan Xu, Bo Lu, Xuhui Zhu, Xikun Luo, Bin He, Cambula Elidio, Zhenghui Liu, Yanfeng Ding, Jie Yang, and et al. 2023. "Comprehensive Evaluation of Rice Qualities under Different Nitrogen Levels in South China" Foods 12, no. 4: 697. https://doi.org/10.3390/foods12040697