Whey Protein Isolate-Mesona chinensis Polysaccharide Conjugate: Characterization and Its Applications in O/W Emulsions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation and Characterization of WPI-MCP Conjugate

2.2.1. Preparation

2.2.2. FT-IR

2.2.3. Chemical Bonds Measurement

2.2.4. Surface Hydrophobicity

2.3. Preparation and Characterization of WPI-MCP Emulsion

2.3.1. Preparation

2.3.2. Microstructure Analysis

2.3.3. Rheological Properties

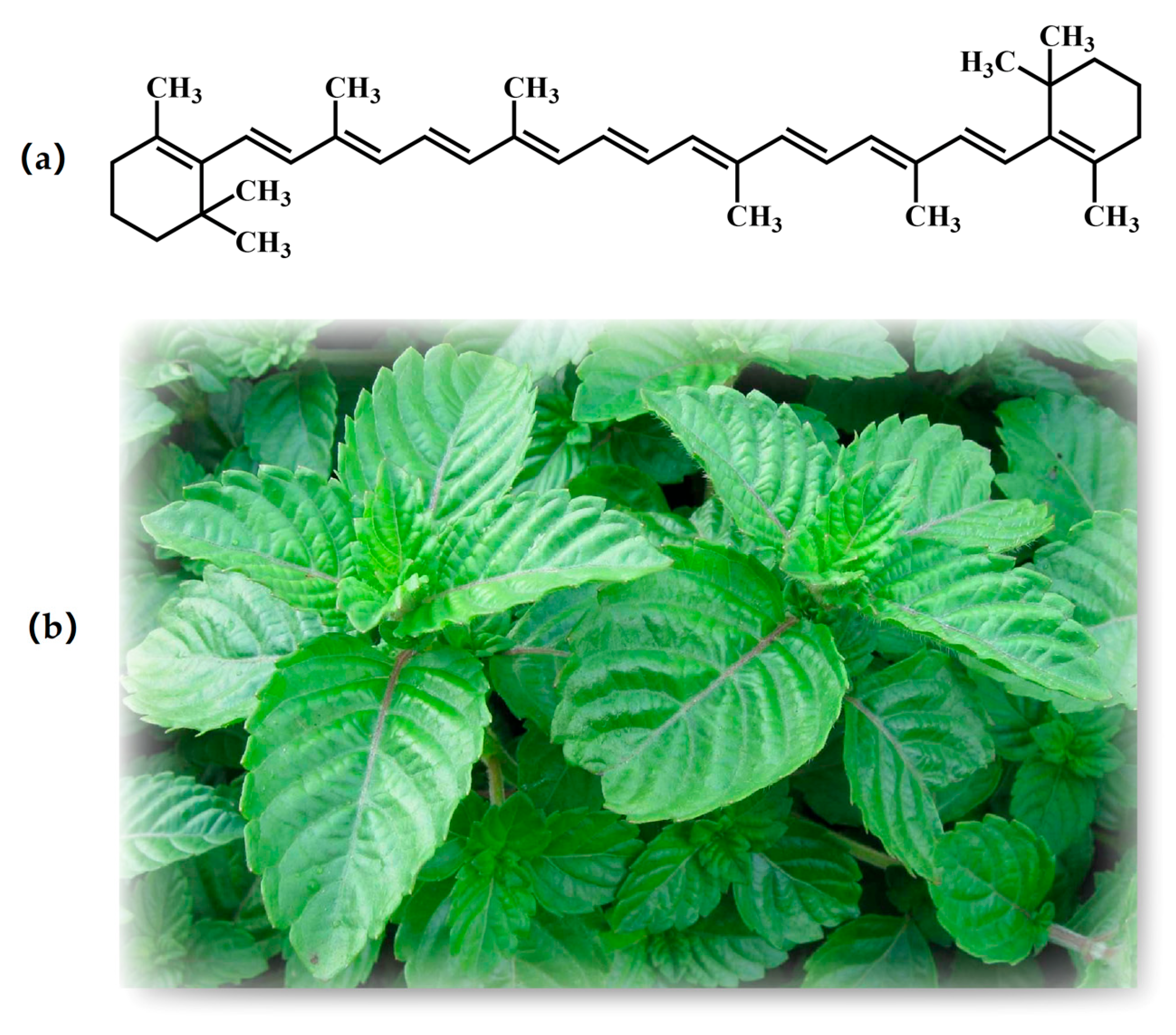

2.4. Preparation and Characterization of β-Carotene-Loaded WPI-MCP Emulsion

2.4.1. Preparation

2.4.2. Particle Size and Zeta Potential Determinations

2.4.3. EE

2.4.4. Oxidative Stability Assessment

2.5. Chemical Stability Analysis

2.6. Statistical Analysis

3. Results and Discussion

3.1. FT-IR

3.2. Surface Hydrophobicity

3.3. Chemical Bonds Measurement

3.4. Morphology

3.5. Rheological Property

3.6. Size, Zeta Potential and EE of β-Carotene Emulsions

3.7. Oxidative Stability

3.8. Chemical Stability of β-Carotene

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jing, X.; Chen, B.; Liu, T.; Cai, Y.; Zhao, Q.; Deng, X.; Zhao, M. Formation and stability of Pickering emulsion gels by insoluble soy peptide aggregates through hydrophobic modification. Food Chem. 2022, 387, 132897. [Google Scholar] [CrossRef] [PubMed]

- Rawal, K.; Annamalai, P.K.; Bhandari, B.; Prakash, S. Oat flour as a novel stabiliser for designing plant-based Pickering emulsion. J. Food Eng. 2023, 340, 111300. [Google Scholar] [CrossRef]

- Shen, C.; Chen, W.; Li, C.; Chen, X.; Cui, h.; Lin, L. Pickering emulsion stabilized by gliadin/soybean polysaccharide composite colloidal nanoparticle: Physicochemical properties and its application on washing of fresh-cut cabbage. Food Res. Int. 2022, 161, 111886. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Lv, K.; Mu, W.; Zhou, S.; Yang, Y. Encapsulation of α-tocopherol in whey protein isolate/chitosan particles using oil-in-water emulsion with optimal stability and bioaccessibility. LWT Food Sci. Technol. 2021, 148, 111724. [Google Scholar] [CrossRef]

- Liu, G.; Li, W.; Qin, X.; Zhong, Q. Pickering emulsions stabilized by amphiphilic anisotropic nanofibrils of glycated whey proteins. Food Hydrocoll. 2020, 101, 105503. [Google Scholar] [CrossRef]

- Chang, C.; Wang, T.; Hu, Q.; Luo, Y. Caseinate-zein-polysaccharide complex nanoparticles as potential oral delivery vehicles for curcumin: Effect of polysaccharide type and chemical cross-linking. Food Hydrocoll. 2017, 72, 254–262. [Google Scholar] [CrossRef]

- Dai, L.; Wei, Y.; Sun, C.; Mao, L.; McClements, D.J.; Gao, Y. Development of protein-polysaccharide-surfactant ternary complex particles as delivery vehicles for curcumin. Food Hydrocoll. 2018, 85, 75–85. [Google Scholar] [CrossRef]

- Yang, J.; Lin, J.; Chen, X.; Rong, L.; Shen, M.; Wang, Y.; Xie, J. Mesona chinensis polysaccharide/zein nanoparticles to improve the bioaccesibility and in vitro bioactivities of curcumin. Carbohydr. Polym. 2022, 295, 119875. [Google Scholar] [CrossRef] [PubMed]

- Xiao, W.; Li, J.; Shen, M.; Yu, Q.; Chen, Y.; Xie, J. Mesona chinensis polysaccharide accelerates the short-term retrogradation of debranched waxy corn starch. Curr. Res. Food Sci. 2022, 5, 1649–1659. [Google Scholar] [CrossRef]

- Huang, S.; Huang, W.; Gu, Q.; Luo, J.; Wang, K.; Du, B.; Li, P. Thermally reversible Mesona chinensis polysaccharide hydrogel. Food Hydrocoll. 2023, 134, 108087. [Google Scholar] [CrossRef]

- Hong, Y.; Shen, M.; Yu, Q.; Chen, Y.; Xie, J. UPLC-Q-TOF/MS-based metabolomics reveals modulatory effects of Mesona chinensis Benth polysaccharide in liver injury mice induced by cyclophosphamide. Food Sci. Hum. Wellness. 2023, 12, 584–595. [Google Scholar] [CrossRef]

- Schendel, S.; Berg, T.; Scherfling, M.; Drößer, C.; Ptok, S.; Weißenborn, A.; Lindtner, O.; Sarvan, I. Results of the BfR MEAL Study: Highest levels of retinol found in animal livers and of beta-carotene in yellow-orange and green leafy vegetables. Food Chem. X 2022, 16, 100458. [Google Scholar] [CrossRef] [PubMed]

- Xiang, H.; Zhong, A.; Wang, H.; Xiao, L.; Deng, T.; Hu, T.; Wen, P. Fabrication of alkali lignin-based emulsion electrospun nan ofibers for the nanoencapsulation of beta-carotene and the enhanced antioxidant property. Int. J. Biol. Macromol. 2022, 218, 739–750. [Google Scholar] [CrossRef] [PubMed]

- Lino, R.C.; de Carvalho, S.M.; Noronha, C.M.; Sganzerla, W.G.; da Rosa, C.G.; Nunes, M.R.; D’Avila, R.F.; Zambiazi, R.C.; Barreto, P.L.M. Production of methylcellulose films functionalized with poly-epsilon-caprolactone nanocapsules entrapped beta-carotene for food packaging application. Food Res. Int. 2022, 160, 111750. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Lin, Y.; Yao, K.; Xiao, J.; Cao, Y. Increasing β-carotene bioavailability and bioactivity in spinach demonstrated using excipient nanoemulsions—Especially those of long-chain triglycerides. Food Chem. 2023, 404, 134194. [Google Scholar] [CrossRef] [PubMed]

- Kawata, A.; Murakami, Y.; Suzuki, S.; Fujisawa, S. Anti-inflammatory Activity of beta-Carotene, Lycopene and Tri-n-butylborane, a Scavenger of Reactive Oxygen Species. Vivo 2018, 32, 255–264. [Google Scholar] [CrossRef] [Green Version]

- Honarbakhsh, M.; Malta, K.; Ericsson, A.; Holloway, C.; Kim, Y.-K.; Hammerling, U.; Quadro, L. beta-carotene improves fecal dysbiosis and intestinal dysfunctions in a mouse model of vitamin A deficiency. Biochim. Biophys. Acta (BBA)—Mol. Cell Biol. Lipids 2022, 1867, 159122. [Google Scholar] [CrossRef]

- Miller, A.P.; Coronel, J.; Amengual, J. The role of beta-carotene and vitamin A in atherogenesis: Evidences from preclinical and clinical studies. Biochim. Biophys. Acta Mol. Cell Biol. Lipids 2020, 1865, 158635. [Google Scholar] [CrossRef]

- Harvey, P.J.; Ben-Amotz, A. Towards a sustainable Dunaliella salina microalgal biorefinery for 9-cis β-carotene production. Algal Res. 2020, 50, 102002. [Google Scholar] [CrossRef]

- Singh, R.V.; Sambyal, K. An overview of β-carotene production: Current status and future prospects. Food Biosci. 2022, 47, 101717. [Google Scholar] [CrossRef]

- Zhang, H.; Tan, S.; Gan, H.; Zhang, H.; Xia, N.; Jiang, L.; Ren, H.; Zhang, X. Investigation of the formation mechanism and beta-carotene encapsulation stability of emulsion gels based on egg yolk granules and sodium alginate. Food Chem. 2023, 400, 134032. [Google Scholar] [CrossRef]

- Lin, L.; Xie, J.; Liu, S.; Shen, M.; Tang, W.; Xie, M. Polysaccharide from Mesona chinensis: Extraction optimization, physicochemical characterizations and antioxidant activities. Int. J. Biol. Macromol. 2017, 99, 665–673. [Google Scholar] [CrossRef]

- Deng, C.; Shao, Y.; Xu, M.; Yao, Y.; Wu, N.; Hu, H.; Zhao, Y.; Tu, Y. Effects of metal ions on the physico-chemical, microstructural and digestion characteristics of alkali-induced egg white gel. Food Hydrocoll. 2020, 107, 105956. [Google Scholar] [CrossRef]

- Dong, W.; Zhang, X.; Ding, L.; Liu, C.; Ai, M.; Jin, Y.; Isobe, K.; Handa, A.; Cai, Z. Enhancement of emulsification properties by modulation of egg white protein fibril structure with different heating times. Food Hydrocoll. 2023, 135, 108203. [Google Scholar] [CrossRef]

- Yuan, Y.W.; Chen, Y.W.; Cai, W.Q.; Dong, X.P.; Wang, Y.R.; Zheng, L.L. Effects of sodium erythorbate and sodium tripolyphosphate on the lipid oxidation of Russian sturgeon with sous-vide cooking. J. Food Compos. Anal. 2022, 106, 104345. [Google Scholar] [CrossRef]

- Chen, Y.-W.; Cai, W.-Q.; Shi, Y.-G.; Dong, X.-P.; Bai, F.; Shen, S.-K.; Jiao, R.; Zhang, X.-Y.; Zhu, X. Effects of different salt concentrations and vacuum packaging on the shelf-stability of Russian sturgeon (Acipenser gueldenstaedti) stored at 4 °C. Food Control. 2020, 109, 106865. [Google Scholar] [CrossRef]

- Wang, L.; Wu, M.; Liu, H.M. Emulsifying and physicochemical properties of soy hull hemicelluloses-soy protein isolate conjugates. Carbohydr. Polym. 2017, 163, 181–190. [Google Scholar] [CrossRef] [PubMed]

- Tirgarian, B.; Farmani, J.; Farahmandfar, R.; Milani, J.M.; Bockstaele, F. Ultra-stable high internal phase emulsions stabilized by protein-anionic polysaccharide Maillard conjugates. Food Chem. 2022, 393, 133427. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Zhao, R.; Hu, J.; Wei, Z.; McClements, D.J.; Liu, S.; Li, B.; Li, Y. One-Step Dynamic Imine Chemistry for Preparation of Chitosan-Stabilized Emulsions Using a Natural Aldehyde: Acid Trigger Mechanism and Regulation and Gastric Delivery. J. Agric. Food Chem. 2020, 68, 5412–5425. [Google Scholar] [CrossRef] [PubMed]

- Tang, S.; Li, J.; Huang, G.; Yan, L. Predicting Protein Surface Property with its Surface Hydrophobicity. Protein Pept Lett. 2021, 28, 938–944. [Google Scholar] [CrossRef]

- Liu, Q.; Cui, H.; Muhoza, B.; Hayat, K.; Hussain, S.; Tahir, M.U.; Zhang, X.; Ho, C.-T. Whey protein isolate-dextran conjugates: Decisive role of glycation time dependent conjugation degree in size control and stability improvement of colloidal nanoparticles. LWT Food Sci. Technol. 2021, 148, 111766. [Google Scholar] [CrossRef]

- Moro, A.; Gatti, C.; Delorenzi, N. Hydrophobicity of whey protein concentrates measured by fluorescence quenching and its relation with surface functional properties. J. Agric. Food Chem. 2001, 49, 4784–4789. [Google Scholar] [CrossRef]

- Hu, Q.; Wu, Y.; Zhong, L.; Ma, N.; Zhao, L.; Ma, G.; Cheng, N.; Nakata, P.A.; Xu, J. In vitro digestion and cellular antioxidant activity of β-carotene-loaded emulsion stabilized by soy protein isolate-Pleurotus eryngii polysaccharide conjugates. Food Hydrocoll. 2021, 112, 105340. [Google Scholar] [CrossRef]

- Huang, Y.; Lin, J.; Tang, X.; Wang, Z.; Yu, S. Grape seed proanthocyanidin-loaded gel-like W/O/W emulsion stabilized by genipin-crosslinked alkaline soluble polysaccharides-whey protein isolate conjugates: Fabrication, stability, and in vitro digestion. Int. J. Biol. Macromol. 2021, 186, 759–769. [Google Scholar] [CrossRef] [PubMed]

- Rong, L.; Shen, M.; Wen, H.; Xiao, W.; Li, J.; Xie, J. Effects of xanthan, guar and Mesona chinensis Benth gums on the pasting, rheological, texture properties and microstructure of pea starch gels. Food Hydrocoll. 2022, 125, 107391. [Google Scholar] [CrossRef]

- PerezMateos, M.; Lourenco, H.; Montero, P.; Borderias, A.J. Rheological and biochemical characteristics of high-pressure- and heat-Induced gels from blue whiting (micromesistius poutassou) muscle proteins. J. Agric. Food Chem. 1997, 45, 44–49. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Yang, J.; Shen, M.; Chen, Y.; Yu, Q.; Xie, J. Structure, function and advance application of microwave-treated polysaccharide: A review. Trends Food Sci. Technol. 2022, 123, 198–209. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Z.; Dai, C.; Wang, Y.; Chen, W.; Ju, X.; Yuan, J.; He, R. Physical stability and microstructure of rapeseed protein isolate/gum Arabic stabilized emulsions at alkaline pH. Food Hydrocoll. 2019, 88, 50–57. [Google Scholar] [CrossRef]

- Guo, B.; Hu, X.; Wu, J.; Chen, R.; Dai, T.; Liu, Y. Soluble starch/whey protein isolate complex-stabilized high internal phase emulsion: Interaction and stability. Food Hydrocoll. 2021, 111, 106377. [Google Scholar] [CrossRef]

- Jiang, L.; Ren, Y.; Xiao, Y.; Liu, S.; Zhang, J.; Yu, Q.; Chen, Y.; Xie, J. Effects of Mesona chinensis polysaccharide on the thermostability, gelling properties, and molecular forces of whey protein isolate gels. Carbohydr. Polym. 2020, 242, 116424. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, Y.; Wang, R.; Li, J.; Pan, W.; Zhang, X.; Xiao, W.; Wen, H.; Xie, J. Chestnut starch modification with dry heat treatment and addition of xanthan gum: Gelatinization, structural and functional properties. Food Hydrocoll. 2022, 124, 107205. [Google Scholar] [CrossRef]

- Lv, P.; Wang, D.; Chen, Y.; Zhu, S.; Zhang, J.; Mao, L. Pickering emulsion gels stabilized by novel complex particles of high-pressure-induced WPI gel and chitosan: Fabrication, characterization and encapsulation. Food Hydrocoll. 2020, 108, 105992. [Google Scholar] [CrossRef]

- Wang, C.; Wang, H.; Sun, X.; Sun, Y.; Guo, M. Heat-Induced Interactions between Whey Protein and Inulin and Changes in Physicochemical and Antioxidative Properties of the Complexes. Int. J. Mol. Sci. 2019, 20, 4089. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lu, Q.; Li, D.C.; Jiang, J.G. Preparation of a tea polyphenol nanoliposome system and its physicochemical properties. J. Agric. Food Chem. 2011, 59, 13004–13011. [Google Scholar] [CrossRef] [PubMed]

- Niu, F.; Zhou, J.; Niu, D.; Wang, C.; Liu, Y.; Su, Y.; Yang, Y. Synergistic effects of ovalbumin/gum arabic complexes on the stability of emulsions exposed to environmental stress. Food Hydrocoll. 2015, 47, 14–20. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Y.; Wang, Y.; Luo, X.; Li, Y.; Li, B.; Wang, J.; Liu, S. Surface modification of cellulose nanofibrils with protein nanoparticles for enhancing the stabilization of O/W pickering emulsions. Food Hydrocoll. 2019, 97, 105180. [Google Scholar] [CrossRef]

- Siems, W.; Wiswedel, I.; Salerno, C.; Crifo, C.; Augustin, W.; Schild, L.; Langhans, C.D.; Sommerburg, O. Beta-carotene breakdown products may impair mitochondrial functions--potential side effects of high-dose beta-carotene supplementation. J. Nutr. Biochem. 2005, 16, 385–397. [Google Scholar] [CrossRef] [PubMed]

- Pénicaud, C.; Achir, N.; Dhuique-Mayer, C.; Dornier, M.; Bohuon, P. Degradation of β-carotene during fruit and vegetable pro cessing or storage: Reaction mechanisms and kinetic aspects: A review. Fruits 2011, 66, 417–440. [Google Scholar] [CrossRef] [Green Version]

| Sample | Surface Hydrophobicity | R2 |

|---|---|---|

| WPI | 29.57 ± 0.93 e | 0.9925 |

| MCP | 3.07 ± 0.03 a | 0.9879 |

| WPI-MCP0.05 | 20.60 ± 0.11 d | 0.9914 |

| WPI-MCP0.1 | 11.68 ± 0.70 c | 0.9867 |

| WPI-MCP0.2 | 9.07 ± 1.05 b | 0.9706 |

| WPI-MCP0.3 | 8.53 ± 0.20 b | 0.9890 |

| Emulsifiers | Size (nm) | PDI | Zeta Potential (mV) | EE (%) |

|---|---|---|---|---|

| WPI | 175.5 ± 2.79 a | 0.29 ± 0.02 a | −32.93 ± 1.05 b | 86.68 ± 2.45 a |

| WPI-MCP | 235.0 ± 2.03 b | 0.29 ± 0.04 a | −37.87 ± 0.95 a | 87.18 ± 0.67 a |

| Systems | β-carotene Retention Rate at Different Storage Times (%) | |||||

|---|---|---|---|---|---|---|

| 0 Day | 7 Day | 14 Day | 21 Day | 28 Day | ||

| WPI β-carotene emulsion | stored at 4 °C | 100 a | 97.36 ± 0.3 a | 90.73 ± 11.98 ab | 89.13 ± 12.53 ab | 78.7 ± 14.03 ab |

| stored at 25 °C | 100 a | 98.53 ± 0.51 b | 88.1 ± 1.75 a | 80.93 ± 3.4 a | 71.8 ± 4.42 a | |

| WPI-MCP β-carotene emulsion | stored at 4 °C | 100 a | 97.1 ± 0.2 a | 96.3 ± 3.96 b | 98.03 ± 0.06 b | 86.33 ± 6.44 b |

| stored at 25 °C | 100 a | 98.07 ± 0.75 ab | 99 ± 6.05 b | 78.8 ± 1.8 a | 73.57 ± 3.46 a | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, M.; Qi, X.; Zhang, J.; Wang, C.; Xie, J. Whey Protein Isolate-Mesona chinensis Polysaccharide Conjugate: Characterization and Its Applications in O/W Emulsions. Foods 2023, 12, 1068. https://doi.org/10.3390/foods12051068

Yao M, Qi X, Zhang J, Wang C, Xie J. Whey Protein Isolate-Mesona chinensis Polysaccharide Conjugate: Characterization and Its Applications in O/W Emulsions. Foods. 2023; 12(5):1068. https://doi.org/10.3390/foods12051068

Chicago/Turabian StyleYao, Meixiang, Xin Qi, Jiahui Zhang, Chengyuan Wang, and Jianhua Xie. 2023. "Whey Protein Isolate-Mesona chinensis Polysaccharide Conjugate: Characterization and Its Applications in O/W Emulsions" Foods 12, no. 5: 1068. https://doi.org/10.3390/foods12051068

APA StyleYao, M., Qi, X., Zhang, J., Wang, C., & Xie, J. (2023). Whey Protein Isolate-Mesona chinensis Polysaccharide Conjugate: Characterization and Its Applications in O/W Emulsions. Foods, 12(5), 1068. https://doi.org/10.3390/foods12051068