Recent Trends in Improving the Oxidative Stability of Oil-Based Food Products by Inhibiting Oxidation at the Interfacial Region

Abstract

:1. Introduction

2. Lipid Oxidation Mechanism in the Oil-Based Food Products

2.1. Bulk Oil

2.1.1. Role of Association Colloids on Bulk Oil Peroxidation

2.1.2. Effect of Association Colloids on the Efficiency of Antioxidants

2.2. O/W Emulsion

2.2.1. Physicochemical Properties of the Interfacial Region

2.2.2. Oil and Aqueous Phase Components

2.2.3. Size of Oil Droplets

2.2.4. Transfer of Oxidants and Antioxidants between Oil Droplets

2.2.5. Surfactant Micelles

2.2.6. pH

3. Recent Advances in Reducing the Oxidation Rate of Bulk Oil

3.1. Esterifying Antioxidants

3.2. Combining Antioxidants with Surface-Active Compounds

4. Recent Advances in Reducing the Oxidation Rate of O/W Emulsions

4.1. Formation of Thick Coatings around the Oil Droplets

4.1.1. Enhancing the Layers of the Interfacial Membrane

4.1.2. Applying Pickering Particles to Stabilize Emulsions

4.2. Entrapping Emulsified Oil Droplets in a Gel Matrix

4.3. Applying Surface-Active Biopolymers with Antioxidant Property

4.3.1. Proteins and Peptides

4.3.2. Polysaccharides

4.3.3. Protein-Polysaccharide

4.3.4. Protein-Polyphenol

4.3.5. Protein-Saponin

4.3.6. Protein-Polysaccharide-Polyphenol

4.4. Increasing the Fraction of Antioxidants at the Interfacial Region

4.4.1. Lipophilization of Hydrophilic Antioxidants

4.4.2. Conjugating Antioxidants with Surfactants

4.4.3. Entrapping Antioxidants into the Pickering Particles

5. Conclusions and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Duxbury, D. Omega-3s offer solutions to trans fat substitution problems. Food Technol. 2005, 59, 34–39. [Google Scholar]

- Laguerre, M.; Bayrasy, C.; Panya, A.; Weiss, J.; McClements, D.J.; Lecomte, J.; Decker, E.A.; Villeneuve, P. What makes good antioxidants in lipid-based systems? The next theories beyond the polar paradox. Crit. Rev. Food Sci. Nutr. 2015, 55, 183–201. [Google Scholar] [CrossRef]

- Mansouri, H.; Farhoosh, R.; Rezaie, M. Interfacial performance of gallic acid and methyl gallate accompanied by lecithin in inhibiting bulk phase oil peroxidation. Food Chem. 2020, 328, 127128. [Google Scholar] [CrossRef]

- Keramat, M.; Golmakani, M.-T.; Niakousari, M. Effect of polyglycerol polyricinoleate on the inhibitory mechanism of sesamol during bulk oil oxidation. Sci. Rep. 2022, 12, 11946. [Google Scholar] [CrossRef]

- Zhu, W.; Zheng, F.; Song, X.; Ren, H.; Gong, H. Influence of formulation parameters on lipid oxidative stability of Pickering emulsion stabilized by hydrophobically modified starch particles. Carbohydr. Polym. 2020, 246, 116649. [Google Scholar] [CrossRef]

- Meng, R.; Wu, Z.; Xie, Q.-T.; Zhang, B.; Li, X.-L.; Liu, W.-J.; Tao, H.; Li, P.-J. Zein/carboxymethyl dextrin nanoparticles stabilized pickering emulsions as delivery vehicles: Effect of interfacial composition on lipid oxidation and in vitro digestion. Food Hydrocoll. 2020, 108, 106020. [Google Scholar] [CrossRef]

- Chen, B.; Han, A.; Laguerre, M.; McClements, D.J.; Decker, E.A. Role of reverse micelles on lipid oxidation in bulk oils: Impact of phospholipids on antioxidant activity of α-tocopherol and Trolox. Food Funct. 2011, 2, 302–309. [Google Scholar] [CrossRef]

- Budilarto, E.S.; Kamal-Eldin, A. The supramolecular chemistry of lipid oxidation and antioxidation in bulk oils. Eur. J. Lipid Sci. Technol. 2015, 117, 1095–1137. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Q.; Wang, M.; Zhang, W.; Zhao, W.; Yang, R. Impact of phosphatidylcholine and phosphatidylethanolamine on the oxidative stability of stripped peanut oil and bulk peanut oil. Food Chem. 2020, 311, 125962. [Google Scholar] [CrossRef] [PubMed]

- Kittipongpittaya, K.; Panya, A.; McClements, D.J.; Decker, E.A. Impact of free fatty acids and phospholipids on reverse micelles formation and lipid oxidation in bulk oil. J. Am. Oil Chem. Soc. 2014, 91, 453–462. [Google Scholar] [CrossRef]

- Kiralan, S.S.; Dogŭ-Baykut, E.; Kittipongpittaya, K.; McClements, D.J.; Decker, E.A. Increased antioxidant efficacy of tocopherols by surfactant solubilization in oil-in-water emulsions. J. Agric. Food Chem. 2014, 62, 10561–10566. [Google Scholar] [CrossRef]

- Homma, R.; Suzuki, K.; Cui, L.; McClements, D.J.; Decker, E.A. Impact of association colloids on lipid oxidation in triacylglycerols and fatty acid ethyl esters. J. Agric. Food Chem. 2015, 63, 10161–10169. [Google Scholar] [CrossRef] [PubMed]

- Jo, S.; Lee, J. Evaluation of the effects of aldehydes on association colloid properties and oxidative stability in bulk oils. Food Chem. 2021, 338, 127778. [Google Scholar] [CrossRef] [PubMed]

- Mancuso, J.R.; McClements, D.J.; Decker, E.A. The effects of surfactant type, pH, and chelators on the oxidation of salmon oil-in-water emulsions. J. Agric. Food Chem. 1999, 47, 4112–4116. [Google Scholar] [CrossRef]

- Min, D.; Boff, J. Chemistry and reaction of singlet oxygen in foods. Compr. Rev. Food Sci. Food Saf. 2002, 1, 58–72. [Google Scholar] [CrossRef] [PubMed]

- Waraho, T.; Cardenia, V.; Rodriguez-Estrada, M.T.; McClements, D.J.; Decker, E.A. Prooxidant mechanisms of free fatty acids in stripped soybean oil-in-water emulsions. J. Agric. Food Chem. 2009, 57, 7112–7117. [Google Scholar] [CrossRef]

- Chen, B.; McClements, D.J.; Decker, E.A. References. In Lipid Oxidation: Challenge in Food System; Logan, A., Nienaber, A., Pan, X., Eds.; AOCS Press: Urbana, IL, USA, 2013; pp. 129–154. ISBN 978-0-9830791-6-3. [Google Scholar]

- Jayasinghe, C.; Gotoh, N.; Wada, S. Pro-oxidant/antioxidant behaviours of ascorbic acid, tocopherol, and plant extracts in n-3 highly unsaturated fatty acid rich oil-in-water emulsions. Food Chem. 2013, 141, 3077–3084. [Google Scholar] [CrossRef]

- Iannone, A.; Rota, C.; Bergamini, S.; Tomasi, A.; Canfield, L.M. Antioxidant activity of carotenoids: An electron-spin resonance study on β-carotene and lutein interaction with free radicals generated in a chemical system. J. Biochem. Mol. Toxicol. 1998, 12, 299–304. [Google Scholar] [CrossRef]

- Laguerre, M.; Chen, B.; Lecomte, J.; Villeneuve, P.; McClements, D.J.; Decker, E.A. Antioxidant properties of chlorogenic acid and its alkyl esters in stripped corn oil in combination with phospholipids and/or water. J. Agric. Food Chem. 2011, 59, 10361–10366. [Google Scholar] [CrossRef]

- Rokosik, E.; Siger, A.; Rudzińska, M.; Dwiecki, K. Antioxidant activity and synergism of canolol and α-tocopherol in rapeseed oil is affected by the presence of phospholipid association colloids. LWT-Food Sci. Technol. 2020, 133, 110095. [Google Scholar] [CrossRef]

- Waraho, T.; McClements, D.J.; Decker, E.A. Mechanisms of lipid oxidation in food dispersions. Trends Food Sci. Technol. 2011, 22, 3–13. [Google Scholar] [CrossRef]

- Mao, L.; Xu, D.; Yang, J.; Yuan, F.; Gao, Y.; Zhao, J. Effects of small and large molecule emulsifiers on the characteristics of β-carotene nanoemulsions prepared by high pressure homogenization. Food Technol. Biotechnol. 2009, 47, 336–342. [Google Scholar]

- Riesz, P.; Kondo, T. Free radical formation induced by ultrasound and its biological implications. Free Radic. Biol. Med. 1992, 13, 247–270. [Google Scholar] [CrossRef] [PubMed]

- Laguerre, M.; Bily, A.; Roller, M.; Birtić, S. Mass transport phenomena in lipid oxidation and antioxidation. Annu. Rev. Food Sci. Technol. 2017, 8, 391–411. [Google Scholar] [CrossRef]

- McClements, D.J.; Decker, E.A. Lipid oxidation in oil-in-water emulsions: Impact of molecular environment on chemical reactions in heterogeneous food systems. J. Food Sci. 2000, 65, 1270–1282. [Google Scholar] [CrossRef]

- Villeneuve, P.; Bourlieu-Lacanal, C.; Durand, E.; Lecomte, J.; McClements, D.J.; Decker, E.A. Lipid oxidation in emulsions and bulk oils: A review of the importance of micelles. Crit. Rev. Food Sci. Nutr. 2021. online ahead of print. [Google Scholar] [CrossRef]

- McClements, D.J.; Decker, E. Interfacial antioxidants: A review of natural and synthetic emulsifiers and coemulsifiers that can inhibit lipid oxidation. J. Agric. Food Chem. 2018, 66, 20–35. [Google Scholar] [CrossRef]

- Berton-Carabin, C.C.; Schroën, K. Pickering emulsions for food applications: Background, trends, and challenges. Annu. Rev. Food Sci. Technol. 2015, 6, 263–297. [Google Scholar] [CrossRef]

- Zhou, F.-Z.; Huang, X.-N.; Wu, Z.-L.; Yin, S.-W.; Zhu, J.-H.; Tang, C.-H.; Yang, X.-Q. Fabrication of zein/pectin hybrid particle-stabilized pickering high internal phase emulsions with robust and ordered interface architecture. J. Agric. Food Chem. 2018, 66, 11113–11123. [Google Scholar] [CrossRef]

- Shaw, L.A.; McClements, D.J.; Decker, E.A. Spray-dried multilayered emulsions as a delivery method for ω-3 fatty acids into food systems. J. Agric. Food Chem. 2007, 55, 3112–3119. [Google Scholar] [CrossRef]

- Klinkesorn, U.; Sophanodora, P.; Chinachoti, P.; McClements, D.J.; Decker, E.A. Increasing the oxidative stability of liquid and dried tuna oil-in-water emulsions with electrostatic layer-by-layer deposition technology. J. Agric. Food Chem. 2005, 53, 4561–4566. [Google Scholar] [CrossRef]

- Djordjevic, D.; Cercaci, L.; Alamed, J.; McClements, D.J.; Decker, E.A. Chemical and physical stability of citral and limonene in sodium dodecyl sulfate-chitosan and gum arabic-stabilized oil-in-water emulsions. J. Agric. Food Chem. 2007, 55, 3585–3591. [Google Scholar] [CrossRef]

- Charoen, R.; Jangchud, A.; Jangchud, K.; Harnsilawat, T.; Decker, E.A.; McClements, D.J. Influence of interfacial composition on oxidative stability of oil-in-water emulsions stabilized by biopolymer emulsifiers. Food Chem. 2012, 131, 1340–1346. [Google Scholar] [CrossRef]

- Dai, L.; Zhan, X.; Wei, Y.; Sun, C.; Mao, L.; McClements, D.J.; Gao, Y. Composite zein-propylene glycol alginate particles prepared using solvent evaporation: Characterization and application as Pickering emulsion stabilizers. Food Hydrocoll. 2018, 85, 281–290. [Google Scholar] [CrossRef]

- Cardenia, V.; Waraho, T.; Rodriguez-Estrada, M.T.; McClements, D.J.; Decker, E.A. Antioxidant and prooxidant activity behavior of phospholipids in stripped soybean oil-in-water emulsions. J. Am. Oil Chem. Soc. 2011, 88, 1409–1416. [Google Scholar] [CrossRef]

- Matsumura, Y.; Egami, M.; Satake, C.; Maeda, Y.; Takahashi, T.; Nakamura, A.; Mori, T. Inhibitory effects of peptide-bound polysaccharides on lipid oxidation in emulsions. Food Chem. 2003, 83, 107–119. [Google Scholar] [CrossRef]

- Berton-Carabin, C.C.; Ropers, M.H.; Genot, C. Lipid oxidation in oil-in-water emulsions: Involvement of the interfacial layer. Compr. Rev. Food Sci. Food Saf. 2014, 13, 945–977. [Google Scholar] [CrossRef]

- Nakaya, K.; Ushio, H.; Matsukawa, S.; Shimizu, M.; Ohshima, T. Effects of droplet size on the oxidative stability of oil-in-water emulsions. Lipids 2005, 40, 501–507. [Google Scholar] [CrossRef]

- Keramat, M.; Niakousari, M.; Golmakani, M.-T. Comparing the antioxidant activity of gallic acid and its alkyl esters in emulsion gel and non-gelled emulsion. Food Chem. 2023, 407, 135078. [Google Scholar] [CrossRef]

- Laguerre, M.; Tenon, M.; Bily, A.; Birtić, S. Toward a spatiotemporal model of oxidation in lipid dispersions: A hypothesis-driven review. Eur. J. Lipid Sci. Technol. 2020, 122, 1900209. [Google Scholar] [CrossRef] [Green Version]

- Raudsepp, P.; Brüggemann, D.A.; Andersen, M.L. Evidence for transfer of radicals between oil-in-water emulsion droplets as detected by the probe (E, E)-3, 5-bis (4-phenyl-1, 3-butadienyl)-4, 4-difluoro-4-bora-3a, 4a-diaza-s-indacene, BODIPY665/676. J. Agric. Food Chem. 2014, 62, 12428–12435. [Google Scholar] [CrossRef] [PubMed]

- Raudsepp, P.; Brüggemann, D.A.; Knudsen, J.C.; Andersen, M.L. Localized lipid autoxidation initiated by two-photon irradiation within single oil droplets in oil-in-water emulsions. Food Chem. 2016, 199, 760–767. [Google Scholar] [CrossRef] [PubMed]

- Nuchi, C.D.; Hernandez, P.; McClements, D.J.; Decker, E.A. Ability of lipid hydroperoxides to partition into surfactant micelles and alter lipid oxidation rates in emulsions. J. Agric. Food Chem. 2002, 50, 5445–5449. [Google Scholar] [CrossRef]

- Richards, M.P.; Chaiyasit, W.; McClements, D.J.; Decker, E.A. Ability of surfactant micelles to alter the partitioning of phenolic antioxidants in oil-in-water emulsions. J. Agric. Food Chem. 2002, 50, 1254–1259. [Google Scholar] [CrossRef] [PubMed]

- Cho, Y.-J.; Chun, S.-S.; Decker, E.A. Effect of surfactant micelles on lipid oxidation in oil-in-water emulsion containing soybean oil. Korean J. Food Sci. Technol. 2002, 34, 770–774. [Google Scholar]

- Panya, A.; Laguerre, M.; Bayrasy, C.; Lecomte, J.; Villeneuve, P.; McClements, D.J.; Decker, E.A. An investigation of the versatile antioxidant mechanisms of action of rosmarinate alkyl esters in oil-in-water emulsions. J. Agric. Food Chem. 2012, 60, 2692–2700. [Google Scholar] [CrossRef]

- Mozuraityte, R.; Kristinova, V.; Rustad, T.; Storrø, I. The role of iron in peroxidation of PUFA: Effect of pH and chelators. Eur. J. Lipid Sci. Technol. 2016, 118, 658–668. [Google Scholar] [CrossRef]

- Mozuraityte, R.; Rustad, T.; Storrø, I. Oxidation of cod phospholipids in liposomes: Effects of salts, pH and zeta potential. Eur. J. Lipid Sci. Technol. 2006, 108, 944–950. [Google Scholar] [CrossRef]

- Li, R.; Dai, T.; Zhou, W.; Fu, G.; Wan, Y.; McClements, D.J.; Li, J. Impact of pH, ferrous ions, and tannic acid on lipid oxidation in plant-based emulsions containing saponin-coated flaxseed oil droplets. Food Res. Int. 2020, 136, 109618. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Liu, W.; Luo, L.; Liu, C.; McClements, D.J. Influence of anionic polysaccharides on the physical and oxidative stability of hydrolyzed rice glutelin emulsions: Impact of polysaccharide type and pH. Food Hydrocoll. 2017, 72, 185–194. [Google Scholar] [CrossRef]

- Akanbi, T.O.; Marshall, S.N.; Barrow, C.J. Polydatin-fatty acid conjugates are effective antioxidants for stabilizing omega 3-containing bulk fish oil and fish oil emulsions. Food Chem. 2019, 301, 125297. [Google Scholar] [CrossRef]

- Cumming, H.; Marshall, S.N. Lipase-catalysed synthesis of mono-and di-acyl esters of glyceryl caffeate in propylene carbonate and their antioxidant properties in tuna oil. J. Biotechnol. 2021, 325, 217–225. [Google Scholar] [CrossRef] [PubMed]

- Oh, W.Y.; Shahidi, F. Antioxidant activity of resveratrol ester derivatives in food and biological model systems. Food Chem. 2018, 261, 267–273. [Google Scholar] [CrossRef]

- Zhong, Y.; Shahidi, F. Lipophilized epigallocatechin gallate (EGCG) derivatives as novel antioxidants. J. Agric. Food Chem. 2011, 59, 6526–6533. [Google Scholar] [CrossRef] [PubMed]

- Farhoosh, R.; Nyström, L. Antioxidant potency of gallic acid, methyl gallate and their combinations in sunflower oil triacylglycerols at high temperature. Food Chem. 2018, 244, 29–35. [Google Scholar] [CrossRef]

- Keramat, M.; Golmakani, M.T.; Toorani, M.R. Effect of interfacial activity of eugenol and eugenol esters with different alkyl chain lengths on inhibiting sunflower oil oxidation. Eur. J. Lipid Sci. Technol. 2021, 123, 2000367. [Google Scholar] [CrossRef]

- Toorani, M.R.; Golmakani, M.-T. Investigating relationship between water production and interfacial activity of γ-oryzanol, ethyl ferulate, and ferulic acid during peroxidation of bulk oil. Sci. Rep. 2021, 11, 17026. [Google Scholar] [CrossRef]

- Katsuda, M.S.; McClements, D.; Miglioranza, L.H.; Decker, E.A. Physical and oxidative stability of fish oil-in-water emulsions stabilized with β-lactoglobulin and pectin. J. Agric. Food Chem. 2008, 56, 5926–5931. [Google Scholar] [CrossRef]

- Gudipati, V.; Sandra, S.; McClements, D.J.; Decker, E.A. Oxidative stability and in vitro digestibility of fish oil-in-water emulsions containing multilayered membranes. J. Agric. Food Chem. 2010, 58, 8093–8099. [Google Scholar] [CrossRef]

- Kartal, C.; Unal, M.K.; Otles, S. Flaxseed oil-in-water emulsions stabilized by multilayer membranes: Oxidative stability and the effects of pH. J. Dispers. Sci. Technol. 2016, 37, 1683–1691. [Google Scholar] [CrossRef]

- Julio, L.M.; Copado, C.N.; Diehl, B.W.; Ixtaina, V.Y.; Tomás, M.C. Chia bilayer emulsions with modified sunflower lecithins and chitosan as delivery systems of omega-3 fatty acids. LWT-Food Sci. Technol. 2018, 89, 581–590. [Google Scholar] [CrossRef]

- Tamm, F.; Härter, C.; Brodkorb, A.; Drusch, S. Functional and antioxidant properties of whey protein hydrolysate/pectin complexes in emulsions and spray-dried microcapsules. LWT-Food Sci. Technol. 2016, 73, 524–527. [Google Scholar] [CrossRef]

- Jiménez-Martín, E.; Gharsallaoui, A.; Pérez-Palacios, T.; Carrascal, J.R.; Rojas, T.A. Suitability of using monolayered and multilayered emulsions for microencapsulation of ω-3 fatty acids by spray drying: Effect of storage at different temperatures. Food Bioprocess Technol. 2015, 8, 100–111. [Google Scholar] [CrossRef]

- Chen, B.; Li, H.; Ding, Y.; Rao, J. Improvement of physicochemical stabilities of emulsions containing oil droplets coated by non-globular protein–beet pectin complex membranes. Food Res. Int. 2011, 44, 1468–1475. [Google Scholar] [CrossRef]

- Lomova, M.V.; Sukhorukov, G.B.; Antipina, M.N. Antioxidant coating of micronsize droplets for prevention of lipid peroxidation in oil-in-water emulsion. ACS Appl. Mater. Interfaces 2010, 2, 3669–3676. [Google Scholar] [CrossRef]

- Xu, D.; Aihemaiti, Z.; Cao, Y.; Teng, C.; Li, X. Physicochemical stability, microrheological properties and microstructure of lutein emulsions stabilized by multilayer membranes consisting of whey protein isolate, flaxseed gum and chitosan. Food Chem. 2016, 202, 156–164. [Google Scholar] [CrossRef]

- Fustier, P.; Achouri, A.; Taherian, A.R.; Britten, M.; Pelletier, M.; Sabik, H.; Villeneuve, S.; Mondor, M. Protein–protein multilayer oil-in-water emulsions for the microencapsulation of flaxseed oil: Effect of whey and fish gelatin concentration. J. Agric. Food Chem. 2015, 63, 9239–9250. [Google Scholar] [CrossRef]

- Kargar, M.; Fayazmanesh, K.; Alavi, M.; Spyropoulos, F.; Norton, I.T. Investigation into the potential ability of Pickering emulsions (food-grade particles) to enhance the oxidative stability of oil-in-water emulsions. J. Colloid Interface Sci. 2012, 366, 209–215. [Google Scholar] [CrossRef]

- Kargar, M.; Spyropoulos, F.; Norton, I.T. The effect of interfacial microstructure on the lipid oxidation stability of oil-in-water emulsions. J. Colloid Interface Sci. 2011, 357, 527–533. [Google Scholar] [CrossRef]

- Hosseini, R.S.; Rajaei, A. Potential Pickering emulsion stabilized with chitosan-stearic acid nanogels incorporating clove essential oil to produce fish-oil-enriched mayonnaise. Carbohydr. Polym. 2020, 241, 116340. [Google Scholar] [CrossRef] [PubMed]

- Atarian, M.; Rajaei, A.; Tabatabaei, M.; Mohsenifar, A.; Bodaghi, H. Formulation of Pickering sunflower oil-in-water emulsion stabilized by chitosan-stearic acid nanogel and studying its oxidative stability. Carbohydr. Polym. 2019, 210, 47–55. [Google Scholar] [CrossRef] [PubMed]

- Angkuratipakorn, T.; Sriprai, A.; Tantrawong, S.; Chaiyasit, W.; Singkhonrat, J. Fabrication and characterization of rice bran oil-in-water Pickering emulsion stabilized by cellulose nanocrystals. Colloids Surf. A Physicochem. Eng. Asp. 2017, 522, 310–319. [Google Scholar] [CrossRef]

- Nasrabadi, M.N.; Goli, S.A.H.; Doost, A.S.; Dewettinck, K.; Van der Meeren, P. Bioparticles of flaxseed protein and mucilage enhance the physical and oxidative stability of flaxseed oil emulsions as a potential natural alternative for synthetic surfactants. Colloids Surf. B Biointerfaces 2019, 184, 110489. [Google Scholar] [CrossRef] [PubMed]

- Zeng, T.; Wu, Z.-L.; Zhu, J.-Y.; Yin, S.-W.; Tang, C.-H.; Wu, L.-Y.; Yang, X.-Q. Development of antioxidant Pickering high internal phase emulsions (HIPEs) stabilized by protein/polysaccharide hybrid particles as potential alternative for PHOs. Food Chem. 2017, 231, 122–130. [Google Scholar] [CrossRef] [PubMed]

- Ruan, Q.; Zeng, L.; Ren, J.; Yang, X. One-step formation of a double Pickering emulsion via modulation of the oil phase composition. Food Funct. 2018, 9, 4508–4517. [Google Scholar] [CrossRef]

- Lim, S.H.; Kim, H.R.; Choi, S.J.; Moon, T.W. Lipid oxidation of sodium caseinate-stabilized emulsion-gels prepared using microbial transglutaminase. Food Sci. Biotechnol. 2015, 24, 2023–2026. [Google Scholar] [CrossRef]

- Chen, J.; Ren, Y.; Zhang, K.; Qu, J.; Hu, F.; Yan, Y. Phosphorylation modification of myofibrillar proteins by sodium pyrophosphate affects emulsion gel formation and oxidative stability under different pH conditions. Food Funct. 2019, 10, 6568–6581. [Google Scholar] [CrossRef]

- Poyato, C.; Astiasarán, I.; Barriuso, B.; Ansorena, D. A new polyunsaturated gelled emulsion as replacer of pork back-fat in burger patties: Effect on lipid composition, oxidative stability and sensory acceptability. LWT-Food Sci. Technol. 2015, 62, 1069–1075. [Google Scholar] [CrossRef] [Green Version]

- Sato, A.; Moraes, K.; Cunha, R. Development of gelled emulsions with improved oxidative and pH stability. Food Hydrocoll. 2014, 34, 184–192. [Google Scholar] [CrossRef]

- Li, S.; Wang, K.; Huang, Q.; Geng, F. Microwave pretreatment enhanced the properties of ovalbumin-inulin-oil emulsion gels and improved the storage stability of pomegranate seed oil. Food Hydrocoll. 2021, 113, 106548. [Google Scholar] [CrossRef]

- Nasirpour-Tabrizi, P.; Azadmard-Damirchi, S.; Hesari, J.; Heshmati, M.K.; Savage, G.P. Rheological and physicochemical properties of novel low-fat emulgels containing flaxseed oil as a rich source of ω-3 fatty acids. LWT-Food Sci. Technol. 2020, 133, 110107. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Y.; Wang, Y.; Luo, X.; Li, Y.; Li, B.; Wang, J.; Liu, S. Surface modification of cellulose nanofibrils with protein nanoparticles for enhancing the stabilization of O/W pickering emulsions. Food Hydrocoll. 2019, 97, 105180. [Google Scholar] [CrossRef]

- Liu, C.; Pei, R.; Peltonen, L.; Heinonen, M. Assembling of the interfacial layer affects the physical and oxidative stability of faba bean protein-stabilized oil-in-water emulsions with chitosan. Food Hydrocoll. 2020, 102, 105614. [Google Scholar] [CrossRef]

- Farjami, T.; Madadlou, A. Fabrication methods of biopolymeric microgels and microgel-based hydrogels. Food Hydrocoll. 2017, 62, 262–272. [Google Scholar] [CrossRef]

- Li, Y.; Wang, D.; Lu, S.; Zeng, L.; Wang, Y.; Song, W.; Liu, J. Pramipexole nanocrystals for transdermal permeation: Characterization and its enhancement micro-mechanism. Eur. J. Pharm. Sci. 2018, 124, 80–88. [Google Scholar] [CrossRef]

- Sun, C.; Gunasekaran, S.; Richards, M.P. Effect of xanthan gum on physicochemical properties of whey protein isolate stabilized oil-in-water emulsions. Food Hydrocoll. 2007, 21, 555–564. [Google Scholar] [CrossRef]

- Zhou, F.; Sun, W.; Zhao, M. Controlled formation of emulsion gels stabilized by salted myofibrillar protein under malondialdehyde (MDA)-induced oxidative stress. J. Agric. Food Chem. 2015, 63, 3766–3777. [Google Scholar] [CrossRef]

- Nourbehesht, N.; Shekarchizadeh, H.; Soltanizadeh, N. Investigation of stability, consistency, and oil oxidation of emulsion filled gel prepared by inulin and rice bran oil using ultrasonic radiation. Ultrason. Sonochem. 2018, 42, 585–593. [Google Scholar] [CrossRef] [PubMed]

- Berton, C.; Ropers, M.-H.; Viau, M.; Genot, C. Contribution of the interfacial layer to the protection of emulsified lipids against oxidation. J. Agric. Food Chem. 2011, 59, 5052–5061. [Google Scholar] [CrossRef]

- Yi, J.; Ning, J.; Zhu, Z.; Cui, L.; Decker, E.A.; McClements, D.J. Impact of interfacial composition on co-oxidation of lipids and proteins in oil-in-water emulsions: Competitive displacement of casein by surfactants. Food Hydrocoll. 2019, 87, 20–28. [Google Scholar] [CrossRef]

- Qiu, C.; Zhao, M.; Decker, E.A.; McClements, D.J. Influence of protein type on oxidation and digestibility of fish oil-in-water emulsions: Gliadin, caseinate, and whey protein. Food Chem. 2015, 175, 249–257. [Google Scholar] [CrossRef] [PubMed]

- Gumus, C.E.; Decker, E.A.; McClements, D.J. Impact of legume protein type and location on lipid oxidation in fish oil-in-water emulsions: Lentil, pea, and faba bean proteins. Food Res. Int. 2017, 100, 175–185. [Google Scholar] [CrossRef]

- Hu, M.; McClements, D.J.; Decker, E.A. Lipid oxidation in corn oil-in-water emulsions stabilized by casein, whey protein isolate, and soy protein isolate. J. Agric. Food Chem. 2003, 51, 1696–1700. [Google Scholar] [CrossRef]

- Fernandez-Avila, C.; Trujillo, A. Ultra-High Pressure Homogenization improves oxidative stability and interfacial properties of soy protein isolate-stabilized emulsions. Food Chem. 2016, 209, 104–113. [Google Scholar] [CrossRef]

- Padial-Domínguez, M.; Espejo-Carpio, F.J.; García-Moreno, P.J.; Jacobsen, C.; Guadix, E.M. Protein derived emulsifiers with antioxidant activity for stabilization of omega-3 emulsions. Food Chem. 2020, 329, 127148. [Google Scholar] [CrossRef]

- Zhao, Q.; Wu, C.; Yu, C.; Bi, A.; Xu, X.; Du, M. High stability of bilayer nano-emulsions fabricated by Tween 20 and specific interfacial peptides. Food Chem. 2021, 340, 127877. [Google Scholar] [CrossRef] [PubMed]

- Shi, M.-J.; Wang, F.; Jiang, H.; Qian, W.-W.; Xie, Y.-Y.; Wei, X.-Y.; Zhou, T. Effect of enzymatic degraded polysaccharides from Enteromorpha prolifera on the physical and oxidative stability of fish oil-in-water emulsions. Food Chem. 2020, 322, 126774. [Google Scholar] [CrossRef]

- Yao, X.; Xiang, S.; Nie, K.; Gao, Z.; Zhang, W.; Fang, Y.; Nishinari, K.; Phillips, G.O.; Jiang, F. Whey protein isolate/gum arabic intramolecular soluble complexes improving the physical and oxidative stabilities of conjugated linoleic acid emulsions. RSC Adv. 2016, 6, 14635–14642. [Google Scholar] [CrossRef]

- Zha, F.; Dong, S.; Rao, J.; Chen, B. Pea protein isolate-gum Arabic Maillard conjugates improves physical and oxidative stability of oil-in-water emulsions. Food Chem. 2019, 285, 130–138. [Google Scholar] [CrossRef] [PubMed]

- Meng, X.; Liu, H.; Xia, Y.; Hu, X. A family of chitosan-peptide conjugates provides broad HLB values, enhancing emulsion’s stability, antioxidant and drug release capacity. Carbohydr. Polym. 2021, 258, 117653. [Google Scholar] [CrossRef] [PubMed]

- Quan, T.H.; Benjakul, S. Duck egg albumen hydrolysate-epigallocatechin gallate conjugates: Antioxidant, emulsifying properties and their use in fish oil emulsion. Colloids Surf. A Physicochem. Eng. Asp. 2019, 579, 123711. [Google Scholar] [CrossRef]

- Liu, H.; Li, Y.; Diao, X.; Kong, B.; Liu, Q. Effect of porcine bone protein hydrolysates on the emulsifying and oxidative stability of oil-in-water emulsions. Colloids Surf. A Physicochem. Eng. Asp. 2018, 538, 757–764. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, F.; Xie, B.; Sun, Z.; McClements, D.J.; Deng, Q. Fabrication and characterization of whey protein isolates-lotus seedpod proanthocyanin conjugate: Its potential application in oxidizable emulsions. Food Chem. 2021, 346, 128680. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Dai, T.; Tan, Y.; Fu, G.; Wan, Y.; Liu, C.; McClements, D.J. Fabrication of pea protein-tannic acid complexes: Impact on formation, stability, and digestion of flaxseed oil emulsions. Food Chem. 2020, 310, 125828. [Google Scholar] [CrossRef] [PubMed]

- Ba, C.; Fu, Y.; Niu, F.; Wang, M.; Jin, B.; Li, Z.; Chen, G.; Zhang, H.; Li, X. Effects of environmental stresses on physiochemical stability of β-carotene in zein-carboxymethyl chitosan-tea polyphenols ternary delivery system. Food Chem. 2020, 311, 125878. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Zhang, M.; Hong, X.; Liu, Y.; Li, J. Application of ultrasound in stabilizing of Antarctic krill oil by modified chickpea protein isolate and ginseng saponin. LWT-Food Sci. Technol. 2021, 149, 111803. [Google Scholar] [CrossRef]

- Chai, K.F.; Voo, A.Y.H.; Chen, W.N. Bioactive peptides from food fermentation: A comprehensive review of their sources, bioactivities, applications, and future development. Compr. Rev. Food Sci. Food Saf. 2020, 19, 3825–3885. [Google Scholar] [CrossRef] [PubMed]

- Sabet, S.; Rashidinejad, A.; Melton, L.D.; McGillivray, D.J. Recent advances to improve curcumin oral bioavailability. Trends Food Sci. Technol. 2021, 110, 253–266. [Google Scholar] [CrossRef]

- Yang, Y.; Cui, S.; Gong, J.; Miller, S.S.; Wang, Q.; Hua, Y. Stability of citral in oil-in-water emulsions protected by a soy protein–polysaccharide Maillard reaction product. Food Res. Int. 2015, 69, 357–363. [Google Scholar] [CrossRef]

- Evans, M.; Ratcliffe, I.; Williams, P.A. Emulsion stabilisation using polysaccharide–protein complexes. Curr. Opin. Colloid Interface Sci. 2013, 18, 272–282. [Google Scholar] [CrossRef] [Green Version]

- Lee, Y.Y.; Tang, T.K.; Phuah, E.T.; Alitheen, N.B.M.; Tan, C.P.; Lai, O.M. New functionalities of Maillard reaction products as emulsifiers and encapsulating agents, and the processing parameters: A brief review. J. Sci. Food Agric. 2017, 97, 1379–1385. [Google Scholar] [CrossRef] [PubMed]

- Xu, D.; Yuan, F.; Gao, Y.; McClements, D.J.; Decker, E.A. Influence of pH, metal chelator, free radical scavenger and interfacial characteristics on the oxidative stability of β-carotene in conjugated whey protein–pectin stabilised emulsion. Food Chem. 2013, 139, 1098–1104. [Google Scholar] [CrossRef]

- Nakamura, S.; Kato, A.; Kobayashi, K. Enhanced antioxidative effect of ovalbumin due to covalent binding of polysaccharides. J. Agric. Food Chem. 1992, 40, 2033–2037. [Google Scholar] [CrossRef]

- Nakamura, S.; Kato, A. Multi-functional biopolymer prepared by covalent attachment of galactomannan to egg-white proteins through naturally occurring Maillard reaction. Food/Nahrung 2000, 44, 201–206. [Google Scholar] [CrossRef]

- Quan, T.H.; Benjakul, S.; Sae-leaw, T.; Balange, A.K.; Maqsood, S. Protein–polyphenol conjugates: Antioxidant property, functionalities and their applications. Trends Food Sci. Technol. 2019, 91, 507–517. [Google Scholar] [CrossRef]

- Czubinski, J.; Dwiecki, K. A review of methods used for investigation of protein–phenolic compound interactions. Int. J. Food Sci. Technol. 2017, 52, 573–585. [Google Scholar] [CrossRef]

- Sun, J.; Jing, H.; Mu, Y.; McClements, D.J.; Dong, S.; Xu, B. Fabrication of antioxidant emulsifiers from natural ingredients: Conjugation of egg white proteins with catechin and chlorogenic acid. Food Hydrocoll. 2020, 108, 106019. [Google Scholar] [CrossRef]

- Jiang, J.; Zhang, Z.; Zhao, J.; Liu, Y. The effect of non-covalent interaction of chlorogenic acid with whey protein and casein on physicochemical and radical-scavenging activity of in vitro protein digests. Food Chem. 2018, 268, 334–341. [Google Scholar] [CrossRef]

- Cao, Y.; Xiong, Y.L. Chlorogenic acid-mediated gel formation of oxidatively stressed myofibrillar protein. Food Chem. 2015, 180, 235–243. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Liu, H.; Liu, Q.; Kong, B.; Diao, X. Effects of zein hydrolysates coupled with sage (salvia officinalis) extract on the emulsifying and oxidative stability of myofibrillar protein prepared oil-in-water emulsions. Food Hydrocoll. 2019, 87, 149–157. [Google Scholar] [CrossRef]

- Dai, T.; Chen, J.; McClements, D.J.; Hu, P.; Ye, X.; Liu, C.; Li, T. Protein–polyphenol interactions enhance the antioxidant capacity of phenolics: Analysis of rice glutelin–procyanidin dimer interactions. Food Funct. 2019, 10, 765–774. [Google Scholar] [CrossRef] [PubMed]

- Ma, B.; Zhu, J.; Zhao, A.; Zhang, J.; Wang, Y.; Zhang, H.; Zhang, L.; Zhang, Q. Raddeanin A, a natural triterpenoid saponin compound, exerts anticancer effect on human osteosarcoma via the ROS/JNK and NF-κB signal pathway. Toxicol. Appl. Pharmacol. 2018, 353, 87–101. [Google Scholar] [CrossRef]

- Zhang, S.; Tian, L.; Yi, J.; Zhu, Z.; Decker, E.A.; McClements, D.J. Mixed plant-based emulsifiers inhibit the oxidation of proteins and lipids in walnut oil-in-water emulsions: Almond protein isolate-camellia saponin. Food Hydrocoll. 2020, 109, 106136. [Google Scholar] [CrossRef]

- Liu, R.; Yan, X.; Liu, Z.; McClements, D.J.; Liu, F.; Liu, X. Fabrication and characterization of functional protein–polysaccharide–polyphenol complexes assembled from lactoferrin, hyaluronic acid and (−)-epigallocatechin gallate. Food Funct. 2019, 10, 1098–1108. [Google Scholar] [CrossRef] [PubMed]

- Jin, B.; Zhou, X.; Zheng, Z.; Liang, Y.; Chen, S.; Zhang, S.; Li, Q. Investigating on the interaction behavior of soy protein hydrolysates/β-glucan/ferulic acid ternary complexes under high-technology in the food processing: High pressure homogenization versus microwave treatment. Int. J. Biol. Macromol. 2020, 150, 823–830. [Google Scholar] [CrossRef] [PubMed]

- Villeneuve, P.; Durand, E.; Decker, E.A. The need for a new step in the study of lipid oxidation in heterophasic systems. J. Agric. Food Chem. 2018, 66, 8433–8434. [Google Scholar] [CrossRef]

- Laguerre, M.; Bayrasy, C.; Lecomte, J.; Chabi, B.; Decker, E.A.; Wrutniak-Cabello, C.; Cabello, G.; Villeneuve, P. How to boost antioxidants by lipophilization? Biochimie 2013, 95, 20–26. [Google Scholar] [CrossRef]

- Medina, I.; Lois, S.; Alcántara, D.; Lucas, R.; Morales, J.C. Effect of lipophilization of hydroxytyrosol on its antioxidant activity in fish oils and fish oil-in-water emulsions. J. Agric. Food Chem. 2009, 57, 9773–9779. [Google Scholar] [CrossRef] [PubMed]

- Almeida, J.; Losada-Barreiro, S.; Costa, M.; Paiva-Martins, F.; Bravo-Diaz, C.; Romsted, L.S. Interfacial concentrations of hydroxytyrosol and its lipophilic esters in intact olive oil-in-water emulsions: Effects of antioxidant hydrophobicity, surfactant concentration, and the oil-to-water ratio on the oxidative stability of the emulsions. J. Agric. Food Chem. 2016, 64, 5274–5283. [Google Scholar] [CrossRef] [PubMed]

- Laguerre, M.; López Giraldo, L.J.; Lecomte, J.; Figueroa-Espinoza, M.-C.; Barea, B.; Weiss, J.; Decker, E.A.; Villeneuve, P. Chain length affects antioxidant properties of chlorogenate esters in emulsion: The cutoff theory behind the polar paradox. J. Agric. Food Chem. 2009, 57, 11335–11342. [Google Scholar] [CrossRef]

- Laguerre, M.; Lopez Giraldo, L.J.; Lecomte, J.; Figueroa-Espinoza, M.-C.; Baréa, B.; Weiss, J.; Decker, E.A.; Villeneuve, P. Relationship between hydrophobicity and antioxidant ability of “phenolipids” in emulsion: A parabolic effect of the chain length of rosmarinate esters. J. Agric. Food Chem. 2010, 58, 2869–2876. [Google Scholar] [CrossRef]

- Alemán, M.; Bou, R.; Guardiola, F.; Durand, E.; Villeneuve, P.; Jacobsen, C.; Sørensen, A.-D.M. Antioxidative effect of lipophilized caffeic acid in fish oil enriched mayonnaise and milk. Food Chem. 2015, 167, 236–244. [Google Scholar] [CrossRef] [Green Version]

- Sørensen, A.D.M.; Villeneuve, P.; Jacobsen, C. Alkyl caffeates as antioxidants in O/W emulsions: Impact of emulsifier type and endogenous tocopherols. Eur. J. Lipid Sci. Technol. 2017, 119, 1600276. [Google Scholar] [CrossRef] [Green Version]

- Da Silveira, T.F.F.; Cajaíba, L.M.; Valentin, L.; Baréa, B.; Villeneuve, P.; Castro, I.A. Effect of sinapic acid ester derivatives on the oxidative stability of omega-3 fatty acids rich oil-in-water emulsions. Food Chem. 2020, 309, 125586. [Google Scholar] [CrossRef]

- Da Silveira, T.F.F.; Laguerre, M.; Bourlieu-Lacanal, C.; Lecomte, J.; Durand, E.; Figueroa-Espinoza, M.C.; Baréa, B.; Barouh, N.; Castro, I.A.; Villeneuve, P. Impact of surfactant concentration and antioxidant mode of incorporation on the oxidative stability of oil-in-water nanoemulsions. LWT-Food Sci. Technol. 2021, 141, 110892. [Google Scholar] [CrossRef]

- Yesiltas, B.; Sørensen, A.-D.M.; García-Moreno, P.J.; Anankanbil, S.; Guo, Z.; Jacobsen, C. Modified phosphatidylcholine with different alkyl chain length and covalently attached caffeic acid affects the physical and oxidative stability of omega-3 delivery 70% oil-in-water emulsions. Food Chem. 2019, 289, 490–499. [Google Scholar] [CrossRef] [Green Version]

- Yesiltas, B.; García-Moreno, P.J.; Sørensen, A.-D.M.; Anankanbil, S.; Guo, Z.; Jacobsen, C. Effects of modified DATEMs with different alkyl chain lengths on improving oxidative and physical stability of 70% fish oil-in-water emulsions. J. Agric. Food Chem. 2018, 66, 12512–12520. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yesiltas, B.; García-Moreno, P.J.; Sørensen, A.-D.M.; Caindec, A.M.S.; Hyldig, G.; Anankanbil, S.; Guo, Z.; Jacobsen, C. Enrichment of mayonnaise with a high fat fish oil-in-water emulsion stabilized with modified DATEM C14 enhances oxidative stability. Food Chem. 2021, 341, 128141. [Google Scholar] [CrossRef]

- Niu, H.; Chen, W.; Chen, W.; Yun, Y.; Zhong, Q.; Fu, X.; Chen, H.; Liu, G. Preparation and characterization of a modified-β-cyclodextrin/β-carotene inclusion complex and its application in Pickering emulsions. J. Agric. Food Chem. 2019, 67, 12875–12884. [Google Scholar] [CrossRef] [PubMed]

- Schröder, A.; Laguerre, M.; Sprakel, J.; Schroën, K.; Berton-Carabin, C.C. Pickering particles as interfacial reservoirs of antioxidants. J. Colloid Interface Sci. 2020, 575, 489–498. [Google Scholar] [CrossRef]

| Pro-Oxidant Compound | Mechanism of Pro-Oxidant Effect | Reference |

|---|---|---|

| Transition metals (copper and iron) | Decomposing lipid hydroperoxides into free radicals | Mancuso et al. [14] |

| Singlet Oxygen | Directly attaching to the double bonds of unsaturated fatty acids to form lipid hydroperoxides | Min and Boff [15] |

| Free fatty acids | Attracting transition metals to the oil droplet surface when the pH of the emulsion is higher than the pKa of free fatty acids | Waraho et al. [16] |

| Phospholipids | Attracting transition metals to the emulsion droplet surface | Chen et al. [17] |

| Ascorbic acid | Donating an electron to Fe3+ to form Fe2+ [18] | Jayasinghe et al. [18] |

| Carotenoids | Reaction of carotene peroxy radical with 3O2 and lipid molecules to produce lipid alkyl radicals | Iannone et al. [19] |

| Oil Type | First Layer | Second Layer | Third Layer | Oxidation Test | Result | Reference |

|---|---|---|---|---|---|---|

| Flaxseed Oil | Sodium caseinate | Pectin | - | PV and TBARS * | Positive effect of multilayer structure on improving physical and oxidative stabilities of conventional emulsions | Kartal et al. [61] |

| Chia oil | Modified sunflower lecithin | Chitosan | - | PV and TBARS | Higher oxidative stability of double-layer emulsions than monolayer ones | Julio et al. [62] |

| Fish oil | β-lactoglobulin or its hydrolysates | Pectin | - | PV | High oxidative stability of bilayer microcapsules | Tamm et al. [63] |

| Fish oil | Lecithin | Chitosan | - | TBARS | Great protective effect of multilayered microcapsules against lipid oxidation | Jiménez-Martín et al. [64] |

| Corn oil | Silk fibroin | Beet pectin | - | PV and hexanal formation | Better oxidative stability of double-layer emulsion than monolayer one | Chen et al. [65] |

| Fish oil | Citrem | Chitosan | Alginate | PV and TBARS | Better oxidative stability of Citrem/chitosan than Citrem alone or Citrem/chitosan/alginate | Gudipati et al. [60] |

| Linseed oil | Bovine serum albumin | Polyarginine | Dextran sulfate or tannic acid | TBARS | Efficient protection of oil droplets against oxidation by multilayer shell containing tannic acid | Lomova et al. [66] |

| Biopolymer Type | Oil Type | Oxidation Test | Result | Reference |

|---|---|---|---|---|

| Pickering emulsion | ||||

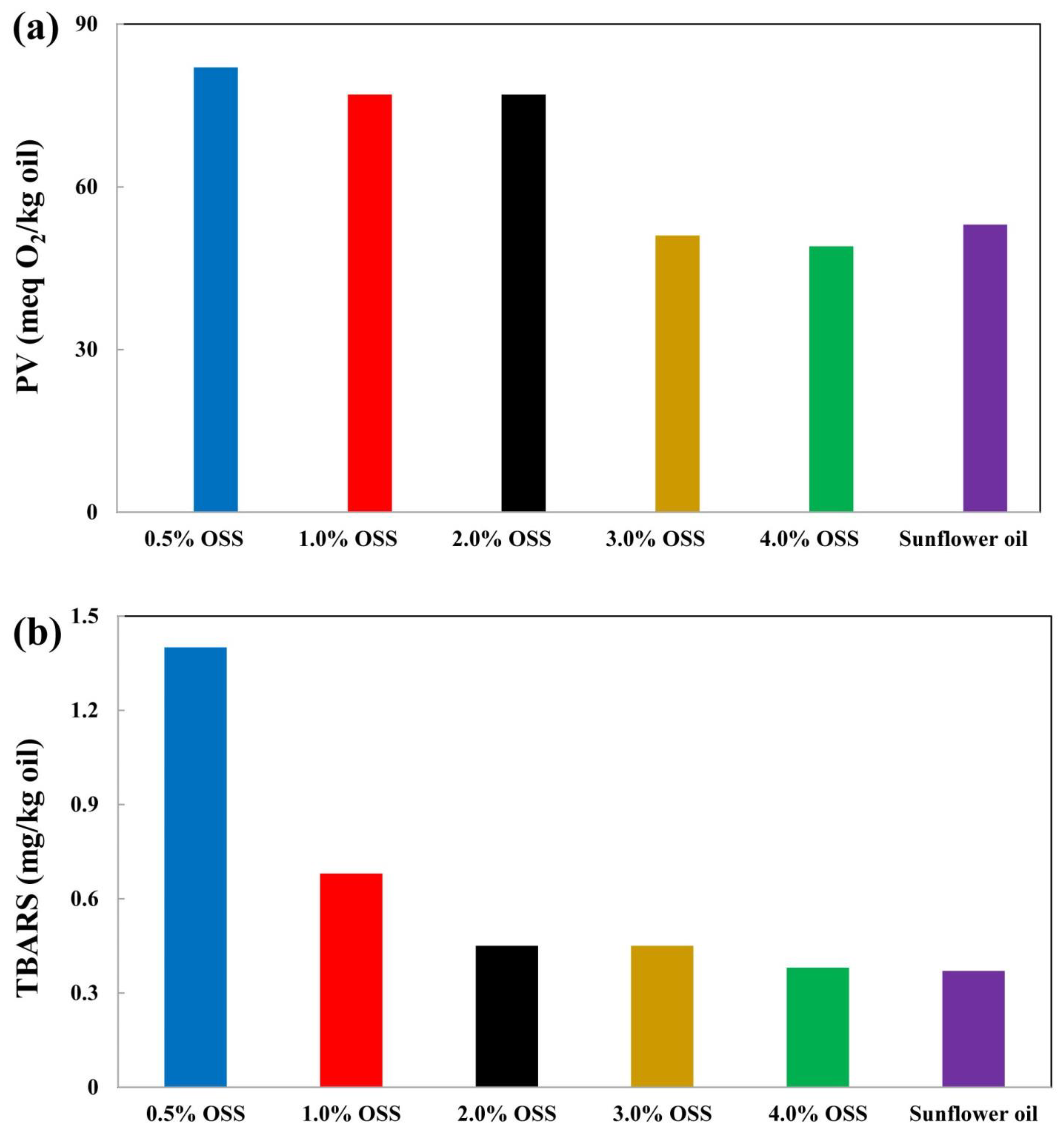

| Chitosan-stearic acid nanogel | Sunflower oil | PV and TBARS * | Higher oxidative stability of emulsion stabilized by chitosan-stearic acid nanogel than emulsion stabilized by Tween 80 | Atarian et al. [72] |

| Octenyl succinic anhydride modified rice starch | Sunflower oil | PV and TBARS | High oxidative stability of emulsion at pH 6–7 | Zhu et al. [5] |

| Silica particles | Sunflower oil | PV and AV | Higher oxidative stability of emulsions stabilized with silica particles than emulsions stabilized with surfactants alone | Kargar et al. [70] |

| Cellulose nanocrystals | Rice bran oil | PV | Cellulose nanocrystals inhibited the formation of hydroperoxides in unsaturated fatty acids of rice bran oil phase | Angkuratipakorn, et al. [73] |

| Flaxseed protein and mucilage | Flaxseed oil | PV and TBARS | High oxidative stability of emulsions stabilized by flaxseed protein and mucilage complex particles | Nasrabadi et al. [74] |

| Gliadin/chitosan | Corn oil | PV and TBARS | Lower content of primary oxidation products in Pickering high internal phase emulsions (HIPEs) than in bulk oil | Zeng et al. [75] |

| Corn-peptide-functionalized calcium phosphate | Algal oil | PV and hexanal and volatile components formation | Water-in-oil-in-water Pickering emulsion stabilized by corn-peptide-functionalized calcium phosphate particles showed higher oxidative stability than emulsion prepared by bare calcium phosphate | Ruan et al. [76] |

| Emulsion gel | ||||

| Sodium caseinate | Sunflower oil | PV, hexanal, and 1-octen-3-ol formation | Higher oxidative stability of emulsion gel than conventional emulsion | Lim et al. [77] |

| Myofibrillar protein modified by sodium pyrophosphate | Soybean oil | PV | High oxidative stability of emulsion gels at pH 6 and 7 | Chen et al. [78] |

| Carrageenan | Sunflower oil | TBARS and cholesterol oxidation products | Higher oxidative stability of burger patties containing emulsion gel as pork-back-fat replacer than control (burger patties containing pork back fat) | Poyato et al. [79] |

| Gelatin, alginate, or their mixture | Olive oil | PV and AV | Higher oxidative stability of alginate-gelatin mixed emulsions than systems produced with only one biopolymer | Sato et al. [80] |

| Ovalbumin, inulin, and carrageenan | Pomegranate seed oil | PV | High oxidative stability of emulsion gel | Li et al. [81] |

| locust bean, κ-carrageenan, xanthan, and maltodextrin | Flaxseed oil | PV, TBARS, and acid value | High oxidative stability of emulsion gels during storage period | Nasirpour-Tabrizi et al. [82] |

| Surface-Active Compound | Oil Type | Results | Oxidation Test | Reference |

|---|---|---|---|---|

| Proteins and peptides | ||||

| β-Casein, β-lactoglobulin, and bovine serum albumin | Rapeseed oil | Lower efficiency of protein-stabilized interfaces than Tween 20 or Tween 80-stabilized interfaces at inhibiting lipid oxidation | Oxygen uptake, CD, and volatile compound formation * | Berton et al. [90] |

| Sodium caseinate | Walnut oil | Slow lipid oxidation but rapid protein oxidation of emulsions stabilized solely by sodium caseinate | PV and TBARS | Yi et al. [91] |

| Gliadin, sodium caseinate, and whey protein isolate | Fish oil | Higher efficiency of gliadin and whey protein isolate than sodium caseinate at inhibiting lipid oxidation | PV and TBARS | Qiu et al. [92] |

| Legume protein (lentil, pea, and faba bean) | Fish oil | Higher antioxidant activity of pea and faba bean proteins than whey proteins in washed emulsions | PV and TBARS | Gumus et al. [93] |

| Casein, whey protein isolate, and soy protein isolate | Corn oil | Higher antioxidant activity of casein than whey protein isolate and soy protein isolate | PV and headspace hexanal formation | Hu et al. [94] |

| Soy protein isolate | Soybean oil | Higher oxidative stability of emulsions treated with ultra-high-pressure homogenization than untreated emulsions | PV and TBARS | Fernandez-Avila and Trujillo [95] |

| Whey protein hydrolysate, soy protein hydrolysate, and blue whiting | Fish oil | Higher antioxidant activity of whey protein hydrolysate than soy protein hydrolysate and blue whiting | PV, AV, and volatile compounds | Padial-Domínguez et al. [96] |

| Cod bone peptides | Soybean oil | High oxidative stability of emulsions added with cod bone peptides | TBARS | Zhao et al. [97] |

| Polysaccharides | ||||

| Microcrystalline cellulose and modified starch | Sunflower oil | Higher oxidative stability of emulsions stabilized by microcrystalline cellulose than modified starch | PV and AV | Kargar et al. [69] |

| Modified starch and gum Arabic | Rice bran oil | Higher oxidative stability of emulsions containing modified starch than those emulsions containing gum Arabic | PV and hexanal formation | Charoen et al. [34] |

| Enzymatic degraded polysaccharides from Enteromorpha prolifra | Fish oil | High physical and oxidative stabilities of fish oil emulsion system (5% oil, 1% Enzymatic degraded polysaccharides, and 1% Tween 80) | PV and TBARS | Shi et al. [98] |

| Proteins-polysaccharides | ||||

| Whey protein isolate-gum Arabic | Conjugated linoleic acid | Nano-sized whey protein isolate/gum Arabic intramolecular soluble complexes significantly improved the oxidative stability of emulsions in comparison with individual protein or polysaccharide | Oxygen consumption measurement | Yao et al. [99] |

| Pea protein isolate-gum Arabic conjugate | Corn oil | Effective prevention of lipid oxidation by pea protein isolate-gum Arabic conjugates | PV and hexanal formation | Zha et al. [100] |

| Chitosan-peptide conjugate | Soybean oil | Higher antioxidant activity of chitosan-peptide conjugates than peptide, chitosan, and mixture of peptide-chitosan | TBARS | Meng et al. [101] |

| Proteins-polyphenols | ||||

| Duck egg albumen hydrolysate-epigallocatechin gallate conjugates | Fish oil | High efficiency of duck egg albumen hydrolysate in improving oxidative stability of emulsion | PV and TBARS | Quan and Benjakul [102] |

| Porcine bone protein hydrolysates-rutin conjugates | Soybean oil | Emulsions coated by Porcine bone protein hydrolysates and Porcine bone protein hydrolysates-rutin conjugates exhibited a high oxidative stability | PV and TBARS | Liu et al. [103] |

| Whey protein isolates-lotus seedpod proanthocyanin conjugate | Flaxseed oil | Higher antioxidant activity of conjugate than pure protein | CD and malondialdehyde | Chen et al. [104] |

| Pea protein-tannic acid complex | Flaxseed oil | High efficiency of pea protein-tannic acid complex in enhancing oxidative stability of emulsion | CD and TBARS | Li et al. [105] |

| Proteins-saponins | ||||

| Almond protein isolate-camellia saponin | Walnut oil | Higher resistant of almond protein isolate-camellia saponin-coated droplets to oxidation than almond protein isolate-coated droplets | PV and TBARS | Ba et al. [106] |

| Chickpea protein isolate-saponin isolated from ginseng | Antarctic krill oil | Ultrasound treatment improved antioxidant activity of chicken protein isolate-saponin isolated from ginseng complex | PV and TBARS | Xu et al. [107] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Keramat, M.; Ehsandoost, E.; Golmakani, M.-T. Recent Trends in Improving the Oxidative Stability of Oil-Based Food Products by Inhibiting Oxidation at the Interfacial Region. Foods 2023, 12, 1191. https://doi.org/10.3390/foods12061191

Keramat M, Ehsandoost E, Golmakani M-T. Recent Trends in Improving the Oxidative Stability of Oil-Based Food Products by Inhibiting Oxidation at the Interfacial Region. Foods. 2023; 12(6):1191. https://doi.org/10.3390/foods12061191

Chicago/Turabian StyleKeramat, Malihe, Elham Ehsandoost, and Mohammad-Taghi Golmakani. 2023. "Recent Trends in Improving the Oxidative Stability of Oil-Based Food Products by Inhibiting Oxidation at the Interfacial Region" Foods 12, no. 6: 1191. https://doi.org/10.3390/foods12061191