Comparative Study of Sensory and Physicochemical Characteristics of Green-Tea-Fortified Cupcakes upon Air Frying and Oven Baking

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Reagents

2.2. Preparation of Green Tea Powder and Extract

2.3. Preparation of Cupcakes

2.4. Sensory Evaluation of Cupcakes

2.5. Color Measurement of Cupcakes

2.6. Firmness Measurement of Cupcakes

2.7. Weight Loss Determination of Cupcakes

2.8. Determination of Fluorescent AGEs in Cupcakes

2.9. Chromatographic Analysis of Green Tea Components

2.10. Statistical Analysis

3. Results and Discussion

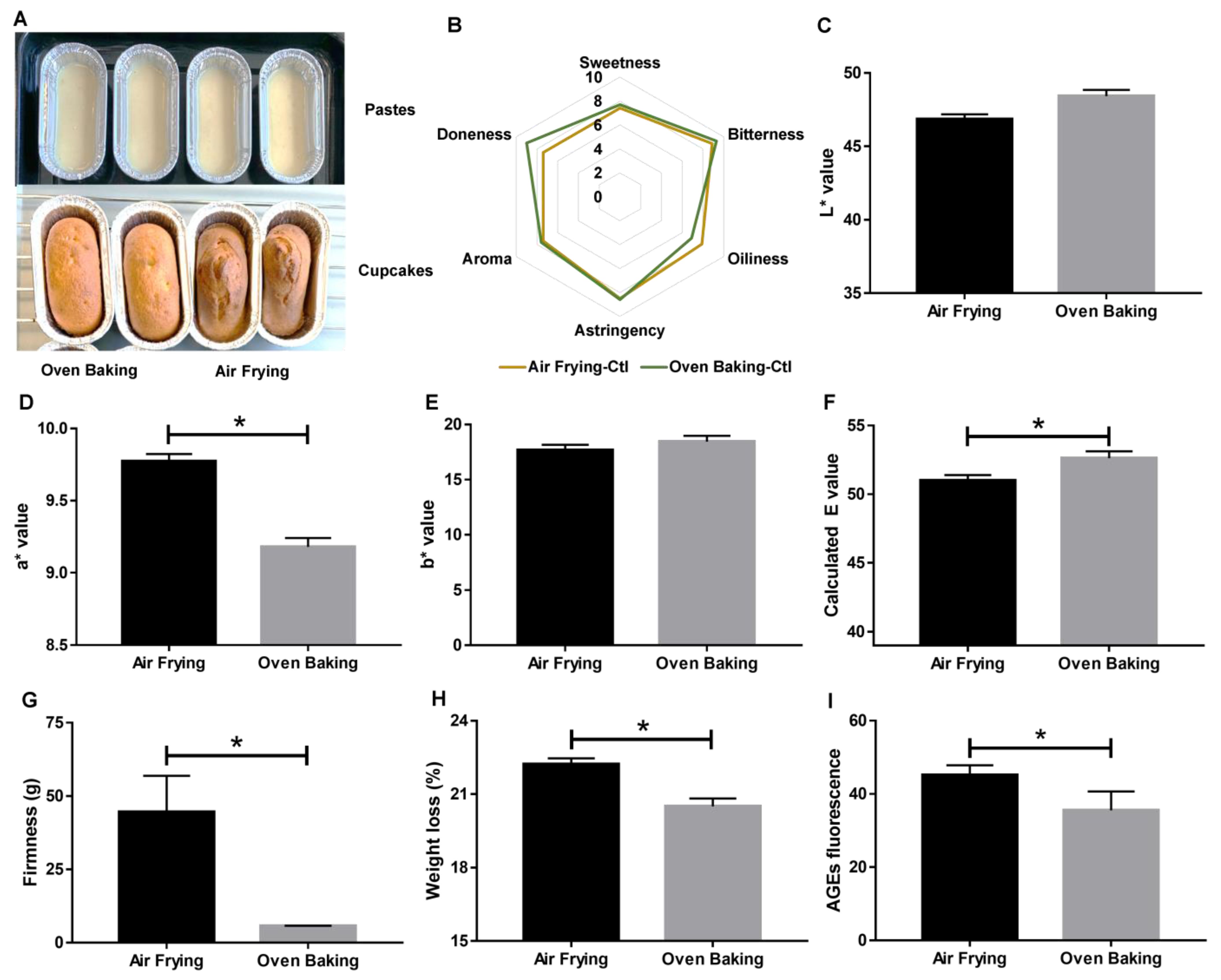

3.1. The Impact of Air Frying and Oven Baking on the Characteristics of Cupcakes

3.2. Green Tea Fortification Reduced the Characteristic Differences between Oven-Baked and Air-Fried Cupcakes

3.3. The Change of Green Tea Components in Cupcakes upon Air Frying and Oven Baking

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zaghi, A.N.; Barbalho, S.M.; Guiguer, E.L.; Otoboni, A.M. Frying process: From conventional to air frying technology. Food Rev. Int. 2019, 35, 763–777. [Google Scholar] [CrossRef]

- Ismail, S.R.; Maarof, S.K.; Ali, S.S.; Ali, A. Systematic review of palm oil consumption and the risk of cardiovascular disease. PLoS ONE 2018, 13, e0193533. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Devi, S.; Zhang, M.; Ju, R.; Bhandari, B. Recent development of innovative methods for efficient frying technology. Crit. Rev. Food Sci. Nutr. 2020, 61, 3709–3724. [Google Scholar] [CrossRef] [PubMed]

- Ghaitaranpour, A.; Koocheki, A.; Mohebbi, M.; Ngadi, M.O. Effect of deep fat and hot air frying on doughnuts physical properties and kinetic of crust formation. J. Cereal Sci. 2018, 83, 25–31. [Google Scholar] [CrossRef]

- Gouyo, T.; Rondet, É.; Mestres, C.; Hofleitner, C.; Bohuon, P. Microstructure analysis of crust during deep-fat or hot-air frying to understand French fry texture. J. Food Eng. 2021, 298, 110484. [Google Scholar] [CrossRef]

- Gouyo, T.; Mestres, C.; Maraval, I.; Fontez, B.; Hofleitner, C.; Bohuon, P. Assessment of acoustic-mechanical measurements for texture of French fries: Comparison of deep-fafrying and air frying. Food Res. Int. 2020, 131, 108947. [Google Scholar] [CrossRef]

- Erickson, C.S. Air Fryer. US4817509A, 17 February 1987. [Google Scholar]

- Azmi, M.M.Z.; Taip, F.S.; Kamal, S.M.M.; Chin, N.L. Effects of temperature and time on the physical characteristics of moist cakes baked in air fryer. J. Food Sci. Technol. 2019, 56, 4616–4624. [Google Scholar] [CrossRef]

- Shahapuzi, N.S.; Taip, F.S.; Ab Aziz, N.; Ahmedov, A. Effect of oven temperature profile and different baking conditions on final cake quality. Int. J. Food Sci. Technol. 2014, 50, 723–729. [Google Scholar] [CrossRef]

- Sani, N.A.; Taip, F.S.; Kamal, S.M.M.; Aziz, N. Effects of temperature and airflow on volume development during baking and its influence on quality of cake. J. Eng. Sci. Technol. 2014, 9, 303–313. [Google Scholar]

- Haddarah, A.; Naim, E.; Dankar, I.; Sepulcre, F.; Pujolà, M.; Chkeir, M. The effect of borage, ginger and fennel extracts on acrylamide formation in French fries in deep and electric air frying. Food Chem. 2021, 350, 129060. [Google Scholar] [CrossRef]

- McKay, D.L.; Blumberg, J.B. The role of tea in human health: An update. J. Am. Coll. Nutr. 2002, 21, 1–3. [Google Scholar] [CrossRef] [PubMed]

- Chao, J.; Leung, Y.; Wang, M.; Chang, R.C. Nutraceuticals and their preventive or potential therapeutic value in Parkinson’s disease. Nutr. Rev. 2012, 70, 373–386. [Google Scholar] [CrossRef] [PubMed]

- Huo, C.; Wan, S.B.; Lam, W.H.; Li, L.; Wang, Z.; Landis-Piwowar, K.R.; Chen, D.; Dou, Q.P.; Chan, T.H. The challenge of developing green tea polyphenols as therapeutic agents. Inflammopharmacology 2008, 16, 248–252. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mandel, S.A.; Amit, T.; Kalfon, L.; Reznichenko, L.; Youdim, M.B.H. Targeting multiple neurodegenerative diseases etiologies with multimodal-acting green tea catechins. J. Nutr. 2008, 138, S1578–S1583. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhong, Y.; Shahidi, F. Lipophilized epigallocatechin gallate (EGCG) derivatives as novel antioxidants. J. Agric. Food Chem. 2011, 59, 6526–6533. [Google Scholar] [CrossRef] [PubMed]

- Mildner-Szkudlarz, S.; Siger, A.; Szwengiel, A.; Przygoński, K.; Wojtowicz, E.; Zawirska-Wojtasiak, R. Phenolic compounds reduce formation of Nε-(carboxymethyl) lysine and pyrazines formed by Maillard reactions in a model bread system. Food Chem. 2017, 231, 175–184. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Xu, W.; Wu, X.; Zhang, X.; Zhang, Y. Addition of antioxidant from bamboo leaves as an effective way to reduce the formation of acrylamide in fried chicken wings. Food Addit. Contam. 2007, 24, 242–251. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, J.; Zhang, X.; Wu, X.; Zhang, Y. Addition of antioxidant of bamboo leaves (AOB) effectively reduces acrylamide formation in potato crisps and French fries. J. Agric. Food Chem. 2007, 55, 523–528. [Google Scholar] [CrossRef]

- Cheng, K.-W.; Zeng, X.; Tang, Y.S.; Wu, J.-J.; Liu, Z.; Sze, K.-H.; Chu, I.K.; Chen, F.; Wang, M. Inhibitory mechanism of naringenin against carcinogenic acrylamide formation and nonenzymatic browning in Maillard model reactions. Chem. Res. Toxicol. 2009, 22, 1483–1489. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, F.; Wang, M. Antioxidant and antiglycation activity of selected dietary polyphenols in a cookie model. J. Agric. Food Chem. 2014, 62, 1643–1648. [Google Scholar] [CrossRef]

- Zhu, Q.; Liang, C.-P.; Cheng, K.-W.; Peng, X.; Lo, C.-Y.; Shahidi, F.; Chen, F.; Ho, C.-T.; Wang, M. Trapping effects of green and black tea extracts on peroxidation-derived carbonyl substances of seal blubber oil. J. Agric. Food Chem. 2009, 57, 1065–1069. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Q.; Wang, L.; Liu, B.; Xiao, J.; Cheng, K.-W.; Chen, F.; Wang, M. Tricoumaroylspermidine from rose exhibits inhibitory activity against ethanol-induced apoptosis in HepG2 cells. Food Funct. 2021, 12, 5892–5902. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Sun, Y.; Li, L.; Zhou, Q.; Wang, M. The antiglycative effect of apple flowers in fructose/glucose-BSA models and cookies. Food Chem. 2020, 330, 127170. [Google Scholar] [CrossRef] [PubMed]

- Trégoat, V.; Brohée, M.; Cordeiro, F.; van Hengel, A.J. Immunofluorescence detection of advanced glycation end products (AGEs) in cookies and its correlation with acrylamide content and antioxidant activity. Food Agric. Immunol. 2009, 20, 253–268. [Google Scholar] [CrossRef]

- Sharma, A.; Zhou, W. A stability study of green tea catechins during the biscuit making process. Food Chem. 2011, 126, 568–573. [Google Scholar] [CrossRef]

- Zhou, Q.; Cheng, K.-W.; Xiao, J.; Wang, M. The multifunctional roles of flavonoids against the formation of advanced glycation end products (AGEs) and AGEs-induced harmful effects. Trends Food Sci. Technol. 2020, 103, 333–347. [Google Scholar] [CrossRef]

- Giovanelli, G.; Torri, L.; Sinelli, N.; Buratti, S. Comparative study of physico-chemical and sensory characteristics of French fries prepared from frozen potatoes using different cooking systems. Eur. Food Res. Technol. 2017, 243, 1619–1631. [Google Scholar] [CrossRef]

- Uribarri, J.; Woodruff, S.; Goodman, S.; Cai, W.; Chen, X.; Pyzik, R.; Yong, A.; Striker, G.E.; Vlassara, H. Advanced glycation end products in foods and a practical guide to their reduction in the diet. J. Am. Diet. Assoc. 2010, 110, 911–916.e12. [Google Scholar] [CrossRef] [Green Version]

- Kozłowska, M.; Żbikowska, A.; Szpicer, A.; Półtorak, A. Oxidative stability of lipid fractions of sponge-fat cakes after green tea extracts application. J. Food Sci. Technol. 2019, 56, 2628–2638. [Google Scholar] [CrossRef] [Green Version]

- Wang, R.; Zhou, W.; Isabelle, M. Comparison study of the effect of green tea extract (GTE) on the quality of bread by instrumental analysis and sensory evaluation. Food Res. Int. 2007, 40, 470–479. [Google Scholar] [CrossRef]

- Weinreb, O.; Mandel, S.; Amit, T.; Youdim, M.B. Neurological mechanisms of green tea polyphenols in Alzheimer’s and Parkinson’s diseases. J. Nutr. Biochem. 2004, 15, 506–516. [Google Scholar] [CrossRef] [PubMed]

- Kovacs, E.M.R.; Lejeune, M.P.G.M.; Nijs, I.; Westerterp-Plantenga, M.S. Effects of green tea on weight maintenance after body-weight loss. Br. J. Nutr. 2004, 91, 431–437. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, Z.-Y.; Zhu, Q.Y.; Tsang, D.; Huang, Y. Degradation of green tea catechins in tea drinks. J. Agric. Food Chem. 2000, 49, 477–482. [Google Scholar] [CrossRef] [PubMed]

- Liang, H.; Liang, Y.; Dong, J.; Lu, J. Tea extraction methods in relation to control of epimerization of tea catechins. J. Sci. Food Agric. 2007, 87, 1748–1752. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ngan, H.-L.; Ip, S.-Y.; Wang, M.; Zhou, Q. Comparative Study of Sensory and Physicochemical Characteristics of Green-Tea-Fortified Cupcakes upon Air Frying and Oven Baking. Foods 2023, 12, 1266. https://doi.org/10.3390/foods12061266

Ngan H-L, Ip S-Y, Wang M, Zhou Q. Comparative Study of Sensory and Physicochemical Characteristics of Green-Tea-Fortified Cupcakes upon Air Frying and Oven Baking. Foods. 2023; 12(6):1266. https://doi.org/10.3390/foods12061266

Chicago/Turabian StyleNgan, Hiu-Lok, Shu-Yu Ip, Mingfu Wang, and Qian Zhou. 2023. "Comparative Study of Sensory and Physicochemical Characteristics of Green-Tea-Fortified Cupcakes upon Air Frying and Oven Baking" Foods 12, no. 6: 1266. https://doi.org/10.3390/foods12061266