Developments of Plant-Based Emulsion-Type Sausage by Using Grey Oyster Mushrooms and Chickpeas

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Mushroom Preparation

2.3. Determination of Total Dietary Fiber (TDF) of GOM Powder

2.4. Functional Properties of GOM Powder

2.4.1. Water-Holding Capacity (WHC)

2.4.2. Oil-Holding Capacity (OHC)

2.4.3. Swelling Capacity (SC)

2.4.4. Emulsion Activity (EA) and Emulsion Stability (ES)

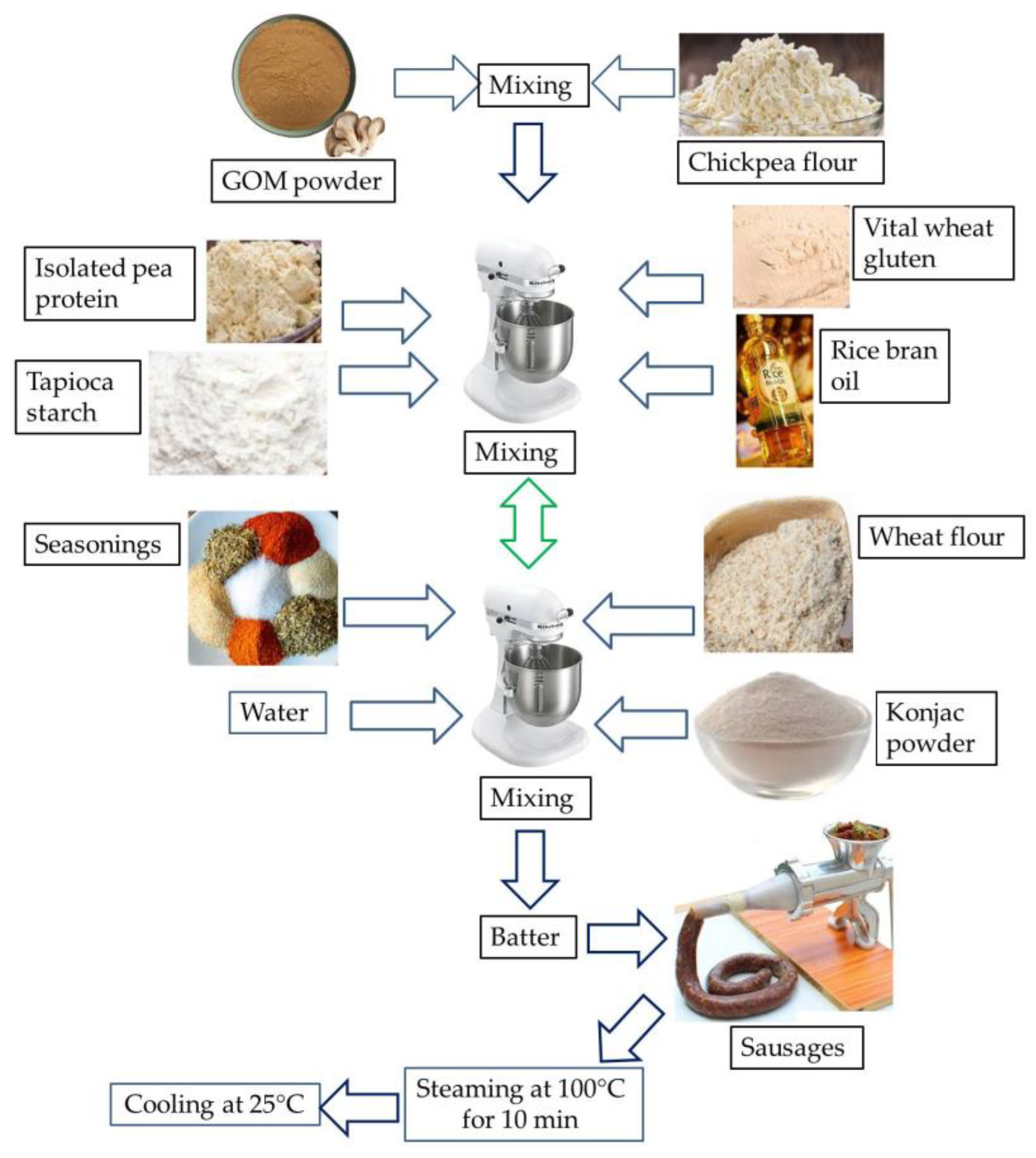

2.5. Processing of Emulsion-Type Sausage (ES)

- (i)

- To find the suitable concentration of GOM powder, and CF for the processing of ES, the following ratios of GOM powder and CF were used: 20:20, 25:15, 30:10 (w/w). Other ingredients, e.g., vital wheat gluten (15% w/w), canola oil (5% w/w), wheat flour (5% w/w), pea protein isolate (5% w/w), seasoning (5% w/w), tapioca starch (10% w/w), konjac powder (5% w/w), and water were added to the mixture (Table 1). To prepare the batter for the sausage, first, different concentrations of GOM powder and CF were mixed properly in a mixer machine (5KPM5EWH, KITCHENAID®, St. Joseph, MI, USA) at a speed of 150 rpm. Thereafter, 50% of other ingredients were added to the mixer machine and mixed properly. The rest of the 50% ingredients were added to the mixer machine and mixed for 10 min. The batter was stuffed into cellulose casings and steamed for 10 min at 100 °C, followed by cooling at 25 °C. For the suitable formula, a concentration of GOM powder and CF was chosen based on the texture profile analysis (TPA), protein content, and consumer acceptability. The developed ES was compared with the commercial plant-based sausage.

- (ii)

- To find the suitable hydrocolloids (5% w/w), konjac powder (KP), xanthan gum (XG), and carrageenan (CN) were used in this study to quantify the quality attributes of the sausage. To find the suitable formulation, the developed sausages were compared with commercial sausages based on the textural profile analysis and sensory attributes.

- (iii)

- To find the suitable source of edible oil (5% w/w), rice bran oil (RBO), olive oil (OL), and canola oil (CO) were used to find the quality attributes of the sausage. To find the suitable formulation concentration of GOM powder, CF, type of hydrocolloids, and sources of oil, the formulated sausages were subjected to a sensory analysis by panelists regarding appearance and taste.

2.6. Determination of Physical Characteristics of GOM-Based Emulsion-Type Sausages

2.6.1. Texture Profile Analysis (TPA)

2.6.2. Expressible Moisture

2.6.3. Emulsion Stability

2.6.4. Purge Loss

2.6.5. Cooking Loss

2.6.6. Color Determination

2.7. Determination of Chemical Characteristics of GOM-Based Emulsion-Type Sausages

2.7.1. Proximate Composition Analysis

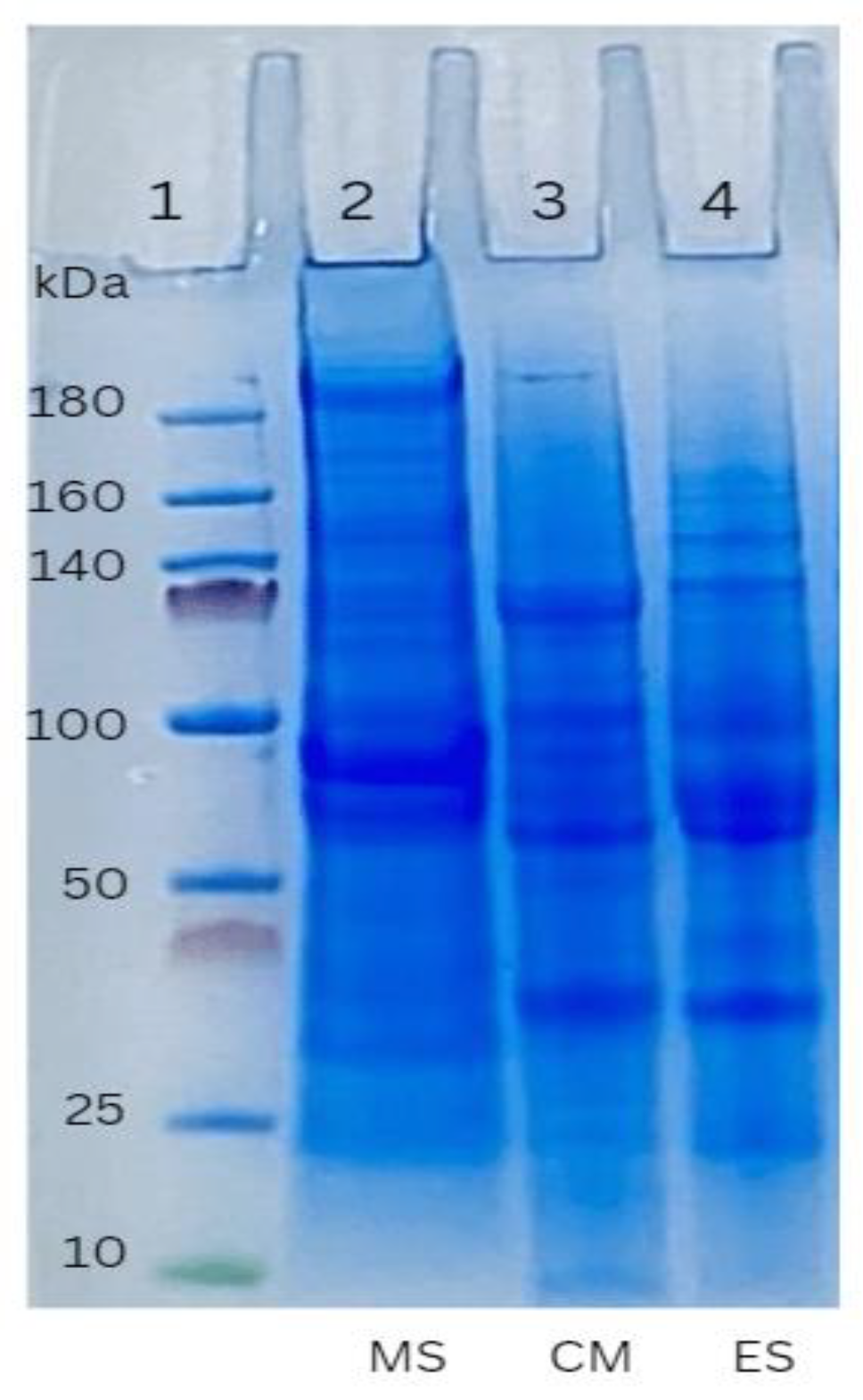

2.7.2. SDS-Polyacrylamide Gel Electrophoresis (SDS-PAGE)

2.8. Sensory Evaluation

2.9. Statistical Analysis

3. Results and Discussion

3.1. Effect of Concentration of GOM Powder and CF on the Protein, TPA, and Sensory Quality of ES

3.1.1. Texture Profile Analysis of GOM-Based ES

3.1.2. Sensory Evaluation

3.2. The Effect of Different Hydrocolloids on Quality Attributes of GOM-Based ES

3.2.1. Effect of Hydrocolloids on Emulsion Stability of ES

3.2.2. Effect of Hydrocolloids on Purge Loss of ES

3.2.3. Effect of Hydrocolloids on the Cooking Qualities of ES

3.2.4. Effect of Hydrocolloids on Textural Properties of ES

3.2.5. Effect of Hydrocolloids on Sensory Attributes of ES

3.3. The Effect of Oil on Quality Attributes of GOM-Based ES

3.4. Analysis of GOM-Based ES

3.4.1. Sensory Attributes of GOM-Based ES

3.4.2. Physical and Chemical Properties of GOM-Based ES

Physical Properties

3.5. Protein Patterns

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Choudhury, D.; Singh, S.; Seah, J.S.H.; Yeo, D.C.L.; Tan, L.P. Commercialization of plant-based meat alternatives. Trends Plant Sci. 2020, 25, 1055–1058. [Google Scholar] [CrossRef]

- Plant-Based Meat Market to Cross $15.7 Billion by 2027—Exclusive Report by Markets and Markets™. Available online: https://www.globenewswire.com/news-release/2022/12/21/2577964/0/en/Plant-based-Meat-Market-to-Cross-15-7-Billion-by-2027-Exclusive-Report-by-MarketsandMarkets.html (accessed on 17 February 2023).

- Hughes, G.J.; Ryan, D.J.; Mukherjea, R.; Schasteen, C.S. Protein digestibility-corrected amino acid scores (PDCAAS) for soy protein isolates and concentrate: Criteria for evaluation. J. Agric. Food Chem. 2011, 59, 12707–12712. [Google Scholar] [CrossRef] [PubMed]

- Sun, C.; Ge, J.; He, J.; Gan, R.; Fang, Y. Processing, quality, safety, and acceptance of meat analogue products. Engineering 2021, 7, 674–678. [Google Scholar] [CrossRef]

- Martínez-Villaluenga, C.; Gulewicz, P.; Frias, J.; Gulewicz, K.; Vidal-Valverde, C. Assessment of protein fractions of three cultivars of Pisum sativum L.: Effect of germination. Eur. Food Res. Tech. 2008, 226, 1465–1478. [Google Scholar] [CrossRef]

- Chang, S.T. Development of the culinary-medicinal mushrooms industry in China: Past, present and future. Int. J. Med. Mushrooms 2006, 8, 1–17. [Google Scholar] [CrossRef]

- Moore, D.; Chiu, S.W. Filamentous fungi as food. In Exploitation of Filamentous Fungi, 1st ed.; Pointing, S.B., Hyde, K.D., Eds.; Fungal Diversity Press: Hong Kong, China, 2001. [Google Scholar]

- Panuthut, C. Thai Mushroom, 1st ed.; New Thammada Press: Bangkok, Thailand, 2001. [Google Scholar]

- Chirinang, P.; Intarapichet, K.O. Amino acids and antioxidant properties of the oyster mushrooms, Pleurotus ostreatus and Pleurotus sajor-caju. Sci. Asia 2009, 35, 326–331. [Google Scholar] [CrossRef]

- Gallotti, F.; Lavelli, V.; Turchiuli, C. Application of Pleurotus ostreatus β-glucans for oil–in–water emulsions encapsulation in powder. Food Hydrocoll. 2020, 105, 105841. [Google Scholar] [CrossRef]

- Jung, D.Y.; Lee, H.J.; Shin, D.J.; Kim, C.H.; Jo, C. Mechanism of improving emulsion stability of emulsion-type sausage with oyster mushroom (Pleurotus ostreatus) powder as a phosphate replacement. Meat Sci. 2022, 194, 108993. [Google Scholar] [CrossRef]

- Boukid, F. Chickpea (Cicer arietinum L.) protein as a prospective plant-based ingredient: A review. Int. J. Food Sci. Tech. 2021, 56, 5435–5444. [Google Scholar] [CrossRef]

- McArdle, R.; Hamill, R. Utilisation of hydrocolloids in processed meat systems. In Processed Meats Improving Safety, Nutrition and Quality; Wood head Publishing Series in Food Science; Technology and Nutrition: Cambridge, UK, 2011; pp. 243–269. [Google Scholar]

- Goff, H.D.; Guo, Q. The role of hydrocolloids in the development of food structure. In Food Chemistry, Function and Analysis Handbook of Food Structure Development, 1st ed.; Spyropoulos, F., Lazidis, A., Norton, I., Eds.; Royal Society of Chemistry: London, UK, 2019; pp. 1–28. [Google Scholar]

- Saha, D.; Bhattacharya, S. Hydrocolloids as thickening and gelling agents in food: A critical review. J. Food Sci. Tech. 2010, 47, 587–597. [Google Scholar] [CrossRef]

- Arora, B.; Kamal, S.; Sharma, V.P. Effect of binding agents on quality characteristics of mushroom based sausage analogue. J. Food Process. Preserv. 2017, 41, e13134. [Google Scholar] [CrossRef]

- Bayram, M.; Bozkurt, H. The use of bulgur as a meat replacement: Bulgur-sucuk (a vegetarian dry-fermented sausage). J. Sci. Food Agric. 2007, 87, 411–419. [Google Scholar] [CrossRef]

- Sakai, K.; Sato, Y.; Okada, M.; Yamaguchi, S. Improved functional properties of meat analogs by laccase catalyzed protein and pectin crosslinks. Sci. Rep. 2021, 11, 16631. [Google Scholar] [CrossRef]

- Lee, E.J.; Hong, G.P. Effects of microbial transglutaminase and alginate on the water-binding, textural and oil absorption properties of soy patties. Food Sci. Biotechnol. 2020, 29, 777–782. [Google Scholar] [CrossRef] [PubMed]

- Ran, X.; Lou, X.; Zheng, H.; Gu, Q.; Yang, H. Improving the texture and rheological qualities of a plant-based fishball analogue by using konjac glucomannan to enhance crosslinks with soy protein. Innov. Food Sci. Emerg. Tech. 2022, 75, 102910. [Google Scholar] [CrossRef]

- Hsing, Y.-l.; Chern, C.-G.; Fan, M.-J.; Lu, P.-C.; Chen, K.-T.; Lo, S.-F.; Sun, P.-K.; Ho, S.-L.; Lee, K.-W.; Wang, Y.-C.; et al. A rice gene activation/knockout mutant resource for high throughput functional genomics. Plant Mol. Biol. 2007, 63, 351–364. [Google Scholar] [CrossRef] [PubMed]

- Mazlan, M.M.; Talib, R.A.; Chin, N.L.; Shukri, R.; Taip, F.S.; Nor, M.Z.M.; Abdullah, N. Physical and microstructure properties of oyster mushroom-soy protein meat analog via single-screw extrusion. Foods 2020, 9, 1023. [Google Scholar] [CrossRef]

- Bakhsh, A.; Lee, S.-J.; Lee, E.-Y.; Sabikun, N.; Hwang, Y.-H.; Joo, S.-T. A Novel approach for tuning the physicochemical, textural, and sensory characteristics of plant-based meat analogs with different levels of methylcellulose concentration. Foods 2021, 10, 560. [Google Scholar] [CrossRef] [PubMed]

- Bakhsh, A.; Lee, S.-J.; Lee, E.-Y.; Hwang, Y.-H.; Joo, S.-T. Evaluation of rheological and sensory characteristics of plant-based meat analog with comparison to beef and pork. Food Sci. Anim. Resour. 2021, 41, 983–996. [Google Scholar]

- Ali, A.; Devarajan, S. Nutritional and Health Benefits of Rice Bran Oil; Springer Cham: Manhattan, NY, USA, 2017; pp. 135–158. [Google Scholar]

- Lai, O.-M.; Jacoby, J.J.; Leong, W.-F.; Lai, W.-T. Chapter 2—Nutritional studies of rice bran oil. In Rice Bran and Rice Bran Oil, 1st ed.; Cheong, L.-Z., Xu, X., Eds.; AOCS Press: Urbana, IL, USA, 2019; pp. 19–54. [Google Scholar]

- Ghosh, S.K.; Pal, T. Interparticle coupling effect on the surface plasmon resonance of gold nanoparticles: From theory to applications. Chem. Rev. 2007, 107, 4797–4862. [Google Scholar] [CrossRef]

- Putnik, P.; Kovačević, D.B. Meat consumption: Theory, practice and future prospects. Theor. Prac. Meat Proc. 2021, 6, 335–342. [Google Scholar] [CrossRef]

- Peng, W.; Xu, X.L.; Zhou, G.H. Effects of meat and phosphate level on water-holding capacity and texture of emulsion-type sausage during storage. Agric. Sci. China 2009, 8, 1475–1481. [Google Scholar]

- Zinia, S.A.; Rahim, A.; Jony, A.L.; Begum, A.A.; Mazumder, M.A.R. The roles of okara powder on the processing and nutrient content of roti and paratha. Int. J. Agric. Environ. Sci. 2019, 6, 18–22. [Google Scholar]

- AOAC International, Official Method 985.29. Total Dietary Fiber in Foods, 21st ed.; AOAC International: Gaithersburg, MD, USA, 2019. [Google Scholar]

- Mesías, M.; Morales, F.J. Effect of different flours on the formation of hydroxymethylfurfural, furfural, and dicarbonyl compounds in heated glucose/flour systems. Foods 2017, 4, 14. [Google Scholar] [CrossRef]

- Sosulski, F.W.; Humbert, E.; Bui, S.K.; Jones, J.O. Functional properties of rapeseed flour concentrates and isolate. J. Food Sci. 1996, 41, 1349–1352. [Google Scholar] [CrossRef]

- Elaveniya, E.; Jayamuthungai, J. Functional, physicochemical and antioxidant properties of dehydrated banana blossom powder and its incorporation in biscuits. Int. J. Chem. Tech. Res. 2014, 6, 4446–4454. [Google Scholar]

- Sathe, S.K.; Deshpande, S.S.; Salunkhe, D.K. Functional properties of black gram (Phaseolus mungo L.) proteins. Lebensm.-Wiss. Technol. 1983, 16, 69–72. [Google Scholar]

- Aguirre, M.E.; Owens, C.M.; Miller, R.K.; Alvarado, C.Z. Descriptive sensory and instrumental texture profile analysis of woody breast in marinated chicken. Poult. Sci. 2018, 97, 1456–1461. [Google Scholar] [CrossRef]

- Wang, X.; Wang, S.J.; Nan, Y.; Liu, G.Q. The effects of oil type and crystallization temperature on the physical properties of vitamin C-loaded oleogels prepared by an emulsion-templated approach. Food Func. 2020, 11, 8028–8037. [Google Scholar] [CrossRef]

- Hughes, E.; Cofrades, S.; Troy, D.J. Effect of fat level, oat fiber and carrageenan on frankfurters formulated with 5, 12 and 30% fat. Meat Sci. 1997, 45, 273–281. [Google Scholar] [CrossRef]

- Cheetangdee, N. Characteristics of sausages as influenced by partial replacement of pork back-fat using pre-emulsified soybean oil stabilized by fish proteins isolate. Agric. Nat. Resour. 2017, 51, 310–318. [Google Scholar] [CrossRef]

- Lee, J.-S.; Oh, H.; Choi, I.; Yoon, C.S.; Han, J. Physico-chemical characteristics of rice protein-based novel textured vegetable proteins as meat analogues produced by low-moisture extrusion cooking technology. LWT 2022, 157, 113056. [Google Scholar] [CrossRef]

- AOAC International, Official Method 950.46. Moisture in Meat and Meat Products, 21st ed.; AOAC International: Gaithersburg, MD, USA, 2019. [Google Scholar]

- AOAC International, Official Method 920.153. Ash in Meat and Meat Products, 21st ed.; AOAC International: Gaithersburg, MD, USA, 2019. [Google Scholar]

- AOAC International, Official Method 981.10. Crude Protein in Meat and Meat Products, 21st ed.; AOAC International: Gaithersburg, MD, USA, 2019. [Google Scholar]

- AOAC International, Official Method 922.06. Fat in Grain and Flour, 21st ed.; AOAC International: Gaithersburg, MD, USA, 2019. [Google Scholar]

- Food and Agriculture Organization. Food Energy—Methods of Analysis and Conversion Factors. Available online: https://www.fao.org/uploads/media/FAO_2003_Food_Energy_02.pdf (accessed on 5 February 2023).

- Wichchukit, S.; O’Mahony, M. The 9-point hedonic scale and hedonic ranking in food science: Some reappraisals and alternatives. J. Sci. Food Agric. 2015, 95, 2167–2178. [Google Scholar] [CrossRef]

- Lopera-Cardona, S.; Gallardo, C.; Umañ-Gallego, J.; Gil, L.M. Comparative study of the physicochemical, compositional and functional properties of eight flours obtained from different plant materials found in Colombia. Food Sci. Tech. Int. 2016, 22, 699–707. [Google Scholar] [CrossRef]

- Raghavendra, S.N.; Ramachandra Swamy, S.R.; Rastogi, N.K.; Raghavarao, K.S.M.S.; Kumar, S.; Tharanathan, R.N. Grinding characteristics and hydration properties of coconut residue: A source of dietary fiber. J. Food Eng. 2006, 72, 281–286. [Google Scholar] [CrossRef]

- Yegrem, L.; Mengestu, D.; Legesse, O.; Abebe, W.; Girma, N. Nutritional compositions and functional properties of New Ethiopian chickpea varieties: Effects of variety, grown environment and season. Int. J. Food Proper. 2022, 25, 1485–1497. [Google Scholar] [CrossRef]

- Grigelmo-Miguel, N.; Martín-Belloso, O. Comparison of dietary fibre from by-products of processing fruits and greens and from cereals. LWT-Food Sci. Tech. 1999, 32, 503–508. [Google Scholar] [CrossRef]

- Lan, G.; Chen, H.; Chen, S.; Tian, J. Chemical composition and physicochemical properties of dietary fiber from Polygonatum odoratum as affected by different processing methods. Food Res. Int. 2012, 49, 406–410. [Google Scholar] [CrossRef]

- Guillon, F.; Champ, M. Structural and physical properties of dietary fibres, and consequences of processing on human physiology. Food Res. Int. 2000, 33, 233–245. [Google Scholar] [CrossRef]

- Viuda-Martos, M.; Ruiz-Navajas, Y.; Martin-Sánchez, A.; Sánchez-Zapata, E.; Fernández-López, J.; Sendra, E.; Sayas-Barberá, E.; Navarro, C.; Pérez-Álvarez, J.A. Chemical, physico-chemical and functional properties of pomegranate (Punica granatum L.) bagasses powder coproduct. J. Food Eng. 2012, 110, 220–224. [Google Scholar] [CrossRef]

- Kaushal, P.; Kumar, V.; Sharma, H.K. Comparative study of physicochemical, functional, anti-nutritional and pasting properties of taro (Colocasia Esculenta), rice (Oryza Sativa), pegion pea (Cajanus Cajan) flour and their Blends. LWT Food Sci. Technol. 2012, 48, 59–68. [Google Scholar] [CrossRef]

- Khalifa, G.K.; Eljack, A.E.; Mohammed, M.I.; Elamin, O.M.; Mohamed, E.S. Yield stability in common bean genotypes (Phaseolus Vulgaris L.) in the Sudan. J. Plant Breed. Crop Sci. 2013, 5, 203–208. [Google Scholar] [CrossRef]

- Khan, T.N.; Meldrum, A.; Croser, J.S. Pea: Overview; Elsevier: Melbourne, Australia, 2016; Volume 1, pp. 324–333. [Google Scholar]

- Drummen, M.; Tischmann, L.; Gatta-Cherifi, B.; Adam, T.; Westerterp-Plantenga, M. Dietary protein and energy balance in relation to obesity and co-morbidities. Front. Endocrinol. 2018, 9, 443. [Google Scholar] [CrossRef] [PubMed]

- Institute of Medicine, Food and Nutrition Board. Dietary Reference Intakes for Calcium, Phosphorus, Magnesium, Witamin D, and Fluorid; National Academies Press: Washington, DC, USA, 1997. [Google Scholar]

- Verma, M.M.; Ledward, D.A.; Lawrie, R.A. Utilization of chickpea flour in sausages. Meat Sci. 1984, 11, 109–121. [Google Scholar] [CrossRef]

- Kilinççeker, O.; Kurt, Ş. Effects of chickpea (Cicer arietinum) flour on quality of deep-fat fried chicken nugget. J. Food Agric. Environ. 2010, 8, 47–50. [Google Scholar]

- Verma, A.K.; Banarjee, R.; Sharma, B.D. Quality of low fat chicken nuggets: Effect of sodium chloride replacement and added chickpea (Cicer arietinum L.) hull flour. Asian-Aust. J. Anim. Sci. 2012, 25, 291–298. [Google Scholar] [CrossRef]

- Jukantil, A.K.; Gaur, P.M.; Gowda, C.L.L.; Chibbar, R.N. Nutritional quality and health benefits of chickpea (Cicer arietinum L.): A review. Br. J. Nutr. 2012, 108, S11–S26. [Google Scholar] [CrossRef]

- Webb, D.; Plattner, B.J.; Donald, E.; Funk, D.; Plattner, B.S.; Alavi, S. Role of chickpea flour in texturization of extruded pea protein. J. Food Sci. 2020, 85, 4180–4187. [Google Scholar] [CrossRef]

- Why You Should Buy a Bag of Chickpea Flour. Available online: https://www.epicurious.com/ingredients/how-to-cook-and-bake-with-chickpea-flour-article (accessed on 21 February 2023).

- Sharima-Abdullah, N.; Hassan, C.Z.; Arifin, N.; Huda-Faujan, N. Physicochemical propertiesand consumer preference of imitation chickennuggets produced from chickpea flour and texturedvegetable protein. Int. Food Res. J. 2018, 25, 1016–1025. [Google Scholar]

- Osen, R.; Toelstede, S.; Eisner, P.; Schweiggert-Weisz, U. Effect of high moisture extrusion cooking on protein-protein interactions of pea (Pisum sativum L.) protein isolates. Int. J. Food Sci. Tech. 2015, 50, 1390–1396. [Google Scholar] [CrossRef]

- Mohammed, I.; Ahmed, A.R.; Senge, B. Dough rheology and bread quality of wheat-chickpea flour blends. Ind. Crop. Prod. 2012, 36, 196–202. [Google Scholar] [CrossRef]

- Ismail Yılmaz, I.; Orhan Dağlıoğlu, O. The effect of replacing fat with oat bran on fatty acid composition and physicochemical properties of meatballs. Meat Sci. 2003, 65, 819–823. [Google Scholar] [CrossRef]

- Sarıçoban, C.; Yılmaz, M.T.; Karakaya, M. Response surface methodology study on the optimization of effects of fat, wheat bran and salt onchemical, textural and sensory properties of patties. Meat Sci. 2009, 83, 610–619. [Google Scholar] [CrossRef]

- Wan Rosli, W.I.; Solihah, M.A.; Aishah, M.; NikFakurudin, N.A.; Mohsin, S.S.J. Colour, textural properties, cooking characteristics and fibre content of chicken patty added with oyster mushroom (Pleurotus sajor-caju). Int. Food Res. J. 2011, 18, 621–627. [Google Scholar]

- Ding, Y. Process for Creating a Thermo-Irreversible Konjac Gel Food. U.S. Patent 11/228,984, 17 September 2005. [Google Scholar]

- Candogan, K.; Kolsarici, N. The effects of carrageenan and pectin on some quality characteristics of low fat beef frankfurters. Meat Sci. 2003, 64(2), 199–206. [Google Scholar] [CrossRef]

- Shand, P.J.; Sofos, J.N.; Schmidt, G.R. Kappa-carrageenan, sodium chloride and temperature affect yield and texture of structured beef Rolls. J. Food Sci. 1994, 59, 282–287. [Google Scholar] [CrossRef]

- Han, M.; Bertram, C. Designing healthier comminuted meat products: Effect of dietary fibers on water distribution and texture of a fat-reduced meat model system. Meat Sci. 2017, 133, 159–165. [Google Scholar] [CrossRef]

- Cornet, S.H.V.; Edwards, D.; van der Goot, A.J.; van der Sman, R.G.M. Water release kinetics from soy protein gels and meat analogues as studied with confined compression. Innov. Food Sci. Emerg. Technol. 2020, 66, 102528. [Google Scholar] [CrossRef]

- Schreuders, F.K.G.; Dekkers, B.L.; Bodnár, I.; Erni, P.; Boom, R.M.; Jan, A.; Goot, V.D. Comparing structuring potential of pea and soy protein with gluten for meat analogue preparation. J. Food Eng. 2019, 261, 32–39. [Google Scholar] [CrossRef]

- Wi, G.; Bae, J.; Kim, H.; Cho, Y.; Choi, M.-J. Evaluation of the Physicochemical and Structural Properties and the Sensory Characteristics of Meat Analogues Prepared with Various Non-Animal Based Liquid Additives. Foods 2020, 9, 461. [Google Scholar] [CrossRef]

- Pietrasik, Z.; Duda, Z. Effect of fat content and soy protein/carragenan mix on the quality characteristics of comminuted, scalded sausages. Meat Sci. 2000, 64, 181–188. [Google Scholar] [CrossRef] [PubMed]

- Carballo, J.; Barreto, G.; Colmenero, F.J. Starch and egg white influence on properties of bologna sausage as related to fat content. J. Food Sci. 1995, 60, 673–677. [Google Scholar] [CrossRef]

- Grigelmo-Miguel, N.; Martin-Belloso, O. Peach dietary fiber as a food Ingredient. IFT Book Abstr. 1997, 13C–29, 36. [Google Scholar]

- Grigelmo-Miguel, N.; Abadias-Seros, M.I.; Martin-Belloso, O. Characterization of low-fat high dietary fibre frankfurters. Meat Sci. 1999, 52, 247–256. [Google Scholar] [CrossRef] [PubMed]

- Egbert, R.W.; Huffman, D.L.; Chen, C.; Dylewski, D.P. Development of low-fat ground beef. Food Technol. 1991, 45, 64–73. [Google Scholar]

- Candogan, K.; Kolsarici, N. Storage stability of low-fat beef frankfurters formulated with carrageenan or carrageenan with pectin. Meat Sci. 2003, 64, 207–214. [Google Scholar] [CrossRef]

- Traynham, T.L.; Myers, D.J.; Carriquiry, A.L.; Johnson, L.A. Evaluation of water-holding capacity for wheat-soy flour blends. J. Am. Oil Chem. Soc. 2007, 84, 151–155. [Google Scholar] [CrossRef]

- Wang, Z.; Liang, J.; Jiang, L.; Li, Y.; Wang, J.; Zhang, H.; Li, D.; Han, F.; Li, Q.; Wang, R.; et al. Effect of the interaction between myofibrillar protein and heat-induced soy protein isolates on gel properties. CyTA J. Food 2015, 13, 527–534. [Google Scholar] [CrossRef]

- Cornet, S.H.; Snel, S.J.; Lesschen, J.; van der Goot, A.J.; van der Sman, R.G. Enhancing the water holding capacity of model meat analogues through marinade composition. J. Food Eng. 2021, 290, 110283. [Google Scholar] [CrossRef]

- Lin, K.W.; Keeton, J.T. Textural and physicochemical properties of low-fat, precooked ground beef patties containing carrageenan and sodium alginate. J. Food Sci. 1998, 63, 571–574. [Google Scholar] [CrossRef]

- Kang, Y.; Siegel, P.M.; Shu, W.; Drobnjak, M.; Kakonen, S.M.; Cordón-Cardo, C.; Guise, T.A.; Massagué, J. A multigenic program mediating breast cancer metastasis to bone. Cancer Cell 2003, 3, 537–549. [Google Scholar] [CrossRef]

- Dai, F.C.; Lee, C.F.; Ngai, Y.Y. Landslide risk assessment and management: An overview. Eng. Geol. 2002, 64, 65–87. [Google Scholar] [CrossRef]

- Draget, K.I.; Bræk, G.S.; Smidsrød, O. Alginic acid gels: The effect of alginate chemical composition and molecular weight. Carbohydr. Polym. 1994, 25, 31–38. [Google Scholar] [CrossRef]

- Park, J.; Park, J.; Jang, S.; Kim, S.; Kong, S.; Choi, J.; Ahn, K.; Kim, J.; Lee, S.; KIm, S.; et al. FTFD: An informatics pipeline supporting phylogenomic analysis of fungal transcription factors. Bioinformatics 2008, 24, 1024–1025. [Google Scholar] [CrossRef]

- Nair, M.S.; Tomar, M.; Punia, S.; Kukula-Koch, W.; Kumar, M. Enhancing the functionality of chitosan-and alginate-based active edible coatings/films for the preservation of fruits and vegetables: A review. Int. J. Biol. Macromol. 2020, 164, 304–320. [Google Scholar] [CrossRef]

- Selani, M.M.; Bianchini, A.; Ratnayake, W.S.; Flores, R.A.; Massarioli, A.P.; de Alencar, S.M.; Canniatti Brazaca, S.G. Physicochemical, functional and antioxidant properties of tropical fruits co-products. Plant Foods Hum. Nutr. 2016, 71, 137–144. [Google Scholar] [CrossRef]

- Ahmad, H.; Chohan, T.A.; Mudassir, J.; Mehta, P.; Yousef, B.; Zaman, A.; Ali, A.; Qutachi, O.; Chang, M.-W.; Fatouros, D.; et al. Evaluation of sustained-release in-situ injectable gels, containing naproxen sodium, using in vitro, in silico and in vivo analysis. Int. J. Pharm. 2022, 616, 121512. [Google Scholar] [CrossRef]

- Cîrstea (Lazăr), N.; Nour, V.; Boruzi, A.I. Effects of Pork Backfat Replacement with Emulsion Gels Formulated with a Mixture of Olive, Chia and Algae Oils on the Quality Attributes of Pork Patties. Foods 2023, 12, 519. [Google Scholar] [CrossRef]

- Kim, G.D.; Seo, J.K.; Yum, H.W.; Jeong, J.Y.; Yang, H.S. Protein markers for discrimination of meat species in raw beef, pork and poultry and their mixtures. Food Chem. 2017, 217, 163–170. [Google Scholar] [CrossRef]

- Zeraatkar, D.; Han, M.A.; Guyatt, G.H.; Vernooij, R.W.; El Dib, R.; Cheung, K.; Milio, K.; Zworth, M.; Bartoszko, J.; Valli, C.; et al. Red and processed meat consumption and risk for all-cause mortality and cardiometabolic outcomes: A systematic review and meta-analysis of cohort studies. Ann. Int. Medic. 2019, 171, 703–710. [Google Scholar] [CrossRef]

- Giangiaconmo, R.; Messina, G. Determinazione oggetiva del colore del latte alimentare mediante colorimetria tristimolo. Sci. E Tec. Latt.-Casearia 1988, 39, 20–39. [Google Scholar]

- Petracci, M.; Mudalal, S.; Bonfiglio, A.; Cavani, C. Occurrence of white striping under commercial conditions and its impact on breast meat quality in broiler chickens. Poult. Sci. 2013, 92, 1670–1675. [Google Scholar] [CrossRef] [PubMed]

- Botella-Martínez, C.; Viuda-Martos, M.; Fernández-López, J.A.; Pérez-Alvarez, J.A.; Fernández-López, J. Development of plant-based burgers using gelled emulsions as fat source and beetroot juice as colorant: Effects on chemical, physicochemical, appearance and sensory characteristics. LWT 2022, 172, 114193. [Google Scholar] [CrossRef]

- Webb, D.; Li, Y.; Alavi, S. Chemical and physicochemical features of common plant proteins and their extrudates for use in plant-based meat. Trends Food Sci. Technol. 2023, 131, 129–138. [Google Scholar] [CrossRef]

- Kyriakopoulou, K.; Dekkers, B.; van der Goot, A.J. Chapter 6—Plant-based meat analogues. In Sustainable Meat Production and Processing; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 103–126. [Google Scholar]

- Samard, S.; Ryu, G.-H. Physicochemical and functional characteristics of plant protein-based meat analogs. J. Food Proc. Preserv. 2019, 43, e14123. [Google Scholar] [CrossRef]

| Formulation | GOM (%) | CF (%) | Tapioca Starch (%) | Wheat Gluten (%) | Wheat Flour (%) | Pea Protein Isolate (%) | Hydro- Colloids (%) | Canolo Oil (%) | Seasoning (%) | Water (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| MR20 | 20 | 20 | 10 | 15 | 5 | 5 | 5 | 5 | 5 | 15 |

| MR25 | 25 | 15 | 10 | 15 | 5 | 5 | 5 | 5 | 5 | 15 |

| MR30 | 30 | 10 | 10 | 15 | 5 | 5 | 5 | 5 | 5 | 15 |

| Components/Functional Properties | GOM | CF |

|---|---|---|

| Nutritional composition | ||

| Moisture (%) | 6.92 ± 0.10 b | 7.95 ± 0.50 a |

| Ash (%) | 7.15 ± 0.55 a | 2.72 ± 0.29 b |

| Protein (%) | 23.10 ± 0.75 a | 22.0.5 ± 1.55 b |

| Fat (%) | 2.52 ± 0.60 b | 4.61 ± 0.44 a |

| Carbohydrate (%) | 60.31 | 62.62 |

| Dietary fiber (%) | 55.12 ± 1.0 a | 10.80 ± 0.95 b |

| Appearance |  |  |

| Functional properties | ||

| Water-holding capacity (g/g) | 12.75 ± 0.35 a | 9.16 ± 0.52 b |

| Oil-holding capacity (mL/g) | 7.82 ± 0.12 a | 3.97 ± 0.77 b |

| Swelling capacity (g/g) | 18.50 ± 0.25 a | 9.28 ± 0.35 b |

| Emulsifying ability (%) | 50.55 ± 0.75 a | 36.44 ± 0.25 b |

| Emulsion stability (%) | 96.10 ± 0.22 a | 90.15 ± 0.92 b |

| Formulation | C | MR20 | MR25 | MR30 |

|---|---|---|---|---|

| Protein content (%) | 33.23 ± 0.74 b | 39.87 ± 0.58 a | 38.07 ± 0.96 b | 36.95 ± 0.17 c |

| ||||

| Hardness (N) | 4475.33 ± 470.34 c | 5485.79 ± 752.04 a | 5191 ± 1092.63 b | 5028.14 ± 886.52 b |

| Springiness (mm) | 0.95 ± 0.02 a | 0.79 ± 0.01 b | 0.90 ± 0.02 a | 0.83 ± 0.05 b |

| Cohesiveness | 0.70 ± 0.05 a | 0.61 ± 0.03 a | 0.67 ± 0.02 a | 0.61 ± 0.06 a |

| Chewiness (N) | 2961.37 ± 286.10 a | 2630.04 ± 333.26 a | 3124.69 ± 627.27 a | 3584.62 ± 734.56 a |

| Gumminess (N) | 3110.69 ± 299.01 a | 3321.68 ± 451.99 a | 3464.55 ± 727.34 a | 3404.29 ± 703.14 a |

| ||||

| Overall acceptability | - | 5.7 ± 1.39 b | 5.8 ± 1.35 a | 5.67 ± 1.75 b |

| Texture | - | 5.77 ± 1.79 a | 6.03 ± 1.55 a | 5.1 ± 2.06 a |

| Taste | - | 5.87 ± 1.74 a | 5.07 ± 2 a | 5.3 ± 2.03 a |

| Formulation | KP | XG | CN |

|---|---|---|---|

| Expressible moisture (%) | 0.49 ± 0.08 b | 0.61 ± 0.02 a | 0.58 ± 0.06 a |

| 2.30 ± 0.07 a | 4.87 ± 0.01 a | 3.68 ± 0.09 b |

| 3.25 ± 0.17 a | 5.05 ± 0.27 c | 4.32 ± 0.10 b |

| 4.44 ± 0.05 a | 6.97 ± 0.03 c | 5.79 ± 0.07 b |

|  |  |  |

| |||

| 5528.16 ± 46.45 a | 5462.78 ± 69.78 a | 5435.03 ± 34.67 a |

| 0.89 ± 0.03 a | 0.84 ± 0.05 a | 0.87 ± 0.04 a |

| 0.67 ± 0.02 a | 0.63 ± 0.02 a | 0.64 ± 0.01 a |

| 3515.45 ± 0.14 a | 3213.63 ± 0.02 a | 3426.03 ± 0.02 a |

| 5340.01 ± 238.88 a | 5704.48 ± 321.46 a | 5527.8 ± 287.22 a |

| |||

| 6.53 ± 1.80 a | 6.33 ± 1.97 a | 6.37 ± 1.63 a |

| 6.23 ± 1.96 a | 6.03 ± 2.20 a | 6.1 ± 1.81 a |

| 6.13 ± 1.94 a | 5.97 ± 2.24 a | 6.0 ± 1.72 a |

| 40.00 | 33.30 | 26.70 |

| Formulation | RBO | OL | CL |

|---|---|---|---|

| 6.47 ± 1.76 a | 6.17 ± 1.63 a | 6.43 ± 1.29 a |

| 6.5 ± 2.01 a | 5.7 ± 1.52 a | 6.37 ± 1.64 a |

| 5.27 ± 2.08 a | 5.63 ± 1.59 a | 5.97 ± 1.81 a |

| 6.73 ± 1.72 a | 6.1 ± 1.83 a | 6.37 ± 1.81 ab |

| 43.30 | 20.00 | 36.70 |

|  |  |  |

| Attributes | Samples | |

|---|---|---|

| ES | C | |

| 6.43 ± 1.59 a | 6.57 ± 1.57 a |

| 6.07 ± 1.68 a | 6.3 ± 2.07 a |

| 6.83 ± 1.60 a | 7.03 ± 1.64 a |

| 5.47 ± 1.57 ab | 6.33 ± 1.73 a |

| 6.10 ± 1.70 a | 6.27 ± 2.05 a |

| 6.80 ± 1.52 ab | 7.00 ± 1.31 a |

| Attributes | Composition/Values | |

|---|---|---|

| ES | C | |

| Nutritional value (dry basis) | ||

| Moisture content (%) | 48.05 ±0.77 a | 48.85 ± 0.55 a |

| Protein content (%) | 36.92 ± 0.52 a | 33.23 ± 0.74 b |

| Ash content (%) | 2.25 ± 0.89 a | 2.40 ± 0.33 a |

| Fat content (%) | 8.23 ± 0.09 b | 9.79 ± 0.88 a |

| Carbohydrate (%) by difference | 4.55 | 5.73 |

| Energy (cal/100 g) | 239.95 | 243.95 |

| Appearance (cooked sausages) |  |  |

| ||

| 5542.83 ± 345.00 a | 4475.33 ± 470.34 b |

| 0.67 ± 0.04 b | 0.95 ± 0.02 a |

| 0.69 ± 0.02 a | 0.70 ± 0.03 a |

| 2963.99 ± 378.20 a | 2961.37 ± 286.10 a |

| 4156.07 ± 770.34 a | 3110.69 ± 299.01 b |

| Color parameter (cooked sausages) | ||

| 37.65 ± 1.45 | 36.22 ± 1.10 |

| 28.44 ± 0.88 | 27.65 ± 0.55 |

| 42.60 ± 0.45 a | 41.60 ± 0.84 a |

| 13.52 ± 0.33 a | 12.95 ± 0.59 a |

| 20.98 ± 0.73 a | 22.18 ± 0.14 a |

| Physical properties | ||

| 4.08 ± 1.77 b | 6.08 ± 1.05 a |

| 2.50 ± 0.39 b | 4.25 ± 0.66 a |

| 3.45 ± 0.77 b | 4.05 ± 0.93 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mazumder, M.A.R.; Sujintonniti, N.; Chaum, P.; Ketnawa, S.; Rawdkuen, S. Developments of Plant-Based Emulsion-Type Sausage by Using Grey Oyster Mushrooms and Chickpeas. Foods 2023, 12, 1564. https://doi.org/10.3390/foods12081564

Mazumder MAR, Sujintonniti N, Chaum P, Ketnawa S, Rawdkuen S. Developments of Plant-Based Emulsion-Type Sausage by Using Grey Oyster Mushrooms and Chickpeas. Foods. 2023; 12(8):1564. https://doi.org/10.3390/foods12081564

Chicago/Turabian StyleMazumder, Md. Anisur Rahman, Naphat Sujintonniti, Pranchalee Chaum, Sunantha Ketnawa, and Saroat Rawdkuen. 2023. "Developments of Plant-Based Emulsion-Type Sausage by Using Grey Oyster Mushrooms and Chickpeas" Foods 12, no. 8: 1564. https://doi.org/10.3390/foods12081564

APA StyleMazumder, M. A. R., Sujintonniti, N., Chaum, P., Ketnawa, S., & Rawdkuen, S. (2023). Developments of Plant-Based Emulsion-Type Sausage by Using Grey Oyster Mushrooms and Chickpeas. Foods, 12(8), 1564. https://doi.org/10.3390/foods12081564