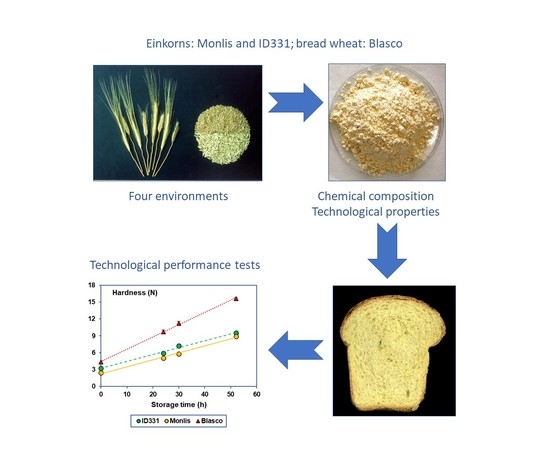

Breadmaking Performance of Elite Einkorn (Triticum monococcum L. subsp. monococcum) Lines: Evaluation of Flour, Dough and Bread Characteristics

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Kernels

2.2.2. Flour and Dough

2.2.3. Bread

2.2.4. Statistical Analysis

3. Results

3.1. Kernels

3.2. Flour and Dough

3.3. Bread

3.3.1. Characteristics

3.3.2. Changes during Storage

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brandolini, A.; Hidalgo, A.; Moscaritolo, S. Chemical composition and pasting properties of einkorn (Triticum monococcum L. subsp. monococcum) whole meal flour. J. Cereal Sci. 2008, 47, 599–609. [Google Scholar] [CrossRef]

- Hidalgo, A.; Brandolini, A. Protein, ash, lutein and tocols distribution in einkorn (Triticum monococcum L. subsp. monococcum) seed fractions. Food Chem. 2008, 107, 444–448. [Google Scholar] [CrossRef]

- Afzal, M.; Longin, F.; Pfleger, F.; Huintjes, N.; Ruhrländer, M.; Akel, W. Agronomy and Processing Quality of 148 Einkorn Varieties Compared to Wheat. 2023. Available online: https://www.uni-hohenheim.de/fileadmin/uni_hohenheim/Aktuelles/Uni-News/Pressemitteilungen/GrossesEinkornProjekt_engl.pdf (accessed on 30 March 2023).

- Abdel-Aal, E.S.M.; Young, J.C.; Wood, P.J.; Rabalski, I.; Hucl, P.; Falk, D.; Fregeau-Reid, J. Einkorn: A potential candidate for developing high lutein wheat. Cereal Chem. 2002, 79, 455–457. [Google Scholar] [CrossRef]

- Hidalgo, A.; Brandolini, A.; Pompei, C.; Piscozzi, R. Carotenoids and tocols of einkorn (Triticum monococcum). J. Cereal Sci. 2006, 44, 182–193. [Google Scholar] [CrossRef]

- Borghi, B.; Castagna, R.; Corbellini, M.; Heun, M.; Salamini, F. Breadmaking quality of einkorn wheat (Triticum monoccoccum ssp. monococcum). Cereal Chem. 1996, 73, 208–214. [Google Scholar]

- Corbellini, M.; Empilli, S.; Vaccino, P.; Brandolini, A.; Borghi, B.; Heun, M.; Salamini, F. Einkorn (Triticum monococcum) characterization for bread and biscuit production in relation to protein subunit composition. Cereal Chem. 1999, 76, 727–733. [Google Scholar] [CrossRef]

- Brandolini, A.; Hidalgo, A.; Plizzari, L.; Erba, D. Impact of genetic and environmental factors on einkorn wheat (Triticum monococcum L. subsp. monococcum) polysaccharides. J. Cereal Sci. 2011, 53, 65–72. [Google Scholar] [CrossRef]

- Belcar, J.; Sobczyk, A.; Sekutowski, T.R.; Stankowski, S.; Gorzelany, J. Evaluation of flours from ancient varieties of wheat (einkorn, emmer, spelt) used in production of bread. Acta Univ. Cibiniensis. Ser. E Food Technol. 2021, 25, 53–66. [Google Scholar] [CrossRef]

- Șerban, L.R.; Păucean, A.; Man, S.M.; Chiş, M.S.; Mureşan, V. Ancient wheat species: Biochemical profile and impact on sourdough bread characteristics—A review. Processes 2021, 9, 2008. [Google Scholar] [CrossRef]

- Hidalgo, A.; Fongaro, L.; Brandolini, A. Wheat flour granulometry determines colour perception. Food Res. Int. 2014, 64, 363–370. [Google Scholar] [CrossRef] [PubMed]

- Hidalgo, A.; Brandolini, A. Lipoxygenase activity in whole meal flours from Triticum monococcum, Triticum turgidum and Triticum aestivum. Food Chem. 2012, 131, 1499–1503. [Google Scholar] [CrossRef]

- Hidalgo, A.; Brusco, M.; Plizzari, L.; Brandolini, A. Polyphenol oxidase, alpha-amylase and beta-amylase activities of Triticum monococcum, Triticum turgidum and Triticum aestivum: A two-year study. J. Cereal Sci. 2013, 58, 51–58. [Google Scholar] [CrossRef]

- Hidalgo, A.; Brandolini, A. Kinetics of carotenoids degradation during the storage of einkorn (Triticum monococcum L. ssp. monococcum) and breadwheat (Triticum aestivum L. ssp. aestivum) flours. J. Agric. Food Chem. 2008, 56, 11300–11305. [Google Scholar] [CrossRef] [PubMed]

- Hidalgo, A.; Brandolini, A.; Pompei, C. Kinetics of tocols degradation during the storage of einkorn (Triticum monococcum L. ssp. monococcum) and breadwheat (Triticum aestivum L. ssp. aestivum) flours. Food Chem. 2009, 116, 821–827. [Google Scholar] [CrossRef]

- Hidalgo, A.; Brandolini, A.; Pompei, C. Carotenoids evolution during pasta, bread and water biscuit preparation from wheat flours. Food Chem. 2010, 121, 746–751. [Google Scholar] [CrossRef]

- Hidalgo, A.; Brandolini, A. Tocols stability during bread, water biscuit and pasta processing from wheat flours. J. Cereal Sci. 2010, 52, 254–259. [Google Scholar] [CrossRef]

- Hidalgo, A.; Brandolini, A. Evaluation of heat damage, sugars, amylases and colour in breads from einkorn, durum and bread wheat flour. J. Cereal Sci. 2011, 54, 90–97. [Google Scholar] [CrossRef]

- Vaccino, P.; Becker, H.A.; Brandolini, A.; Salamini, F.; Kilian, B. A catalogue of Triticum monococcum genes encoding toxic and immunogenic peptides for celiac disease patients. Mol. Genet. Genom. 2009, 281, 289–300. [Google Scholar] [CrossRef]

- Zanini, B.; Basche, R.; Ferraresi, A.; Ricci, C.; Lanzarotto, F.; Marullo, M.; Villanacci, V.; Hidalgo, A.; Lanzini, A. Randomised clinical study: Gluten challenge induces symptom recurrence in only a minority of patients who meet clinical criteria for non-coeliac gluten sensitivity. Aliment. Pharmacol. Ther. 2015, 42, 968–976. [Google Scholar] [CrossRef]

- Zanini, B.; Villanacci, V.; De Leo, L.; Lanzini, A. Triticum monococcum in patients with celiac disease: A phase II open study on safety of prolonged daily administration. Eur. J. Nutr. 2015, 54, 1027–1029. [Google Scholar] [CrossRef] [PubMed]

- Bo, S.; Seletto, M.; Choc, A.; Ponzo, V.; Lezo, A.; Demagistris, A.; Evangelista, A.; Ciccone, G.; Bertolino, M.; Cassader, M.; et al. The acute impact of the intake of four types of bread on satiety and blood concentrations of glucose, insulin, free fatty acids, triglyceride and acylated ghrelin. A randomized controlled cross-over trial. Food Res. Int. 2017, 92, 40–47. [Google Scholar] [CrossRef]

- Barone, F.; Laghi, L.; Gianotti, A.; Ventrella, D.; Taneyo Saa, D.L.; Bordoni, A.; Forni, M.; Brigidi, P.; Bacci, M.L.; Turroni, S. In vivo effects of einkorn wheat (Triticum monococcum) bread on the intestinal microbiota, metabolome, and on the glycemic and insulinemic response in the pig model. Nutrients 2018, 11, 16. [Google Scholar] [CrossRef] [PubMed]

- Antognoni, F.; Mandrioli, R.; Bordoni, A.; Di Nunzio, M.; Viadel, B.; Gallego, E.; Villalba, M.P.; Tomás-Cobos, L.; Taneyo Saa, D.L.; Gianotti, A. Integrated evaluation of the potential health benefits of einkorn-based breads. Nutrients 2017, 9, 1232. [Google Scholar] [CrossRef]

- AACC International—American Association of Cereal Chemists. AACC official methods 08-03.01, 10-05.01, 10-10B, 14-50.01, 38-12.02, 44-15.02, 46-10.01, 56-81.03. In Approved Methods of the American Association of Cereal Chemists; AACC International: Minneapolis, MN, USA, 1995. [Google Scholar]

- Preston, K.R.; March, P.R.; Tipples, K.H. An assessment of the SDS-sedimentation test for the prediction of Canadian bread wheat quality. Can. J. Plant Sci. 1982, 62, 545–553. [Google Scholar] [CrossRef]

- Hashimoto, S.; Shogren, M.D.; Pomeranz, Y. Cereal pentosans: Their estimation and significance. I. Pentosans in wheat and milled wheat products. Cereal Chem. 1987, 64, 30–34. [Google Scholar]

- ICC—International Association for Cereal Science and Technology. ICC official method 115/1. In ICC Standard Methods; ICC: Wien, Austria, 1992. [Google Scholar]

- Mariotti, M.; Lucisano, M.; Pagani, M.A.; Iametti, S. Macromolecular interaction and rheological properties of buckwheat-based dough obtained from differently processed grains. J. Agric. Food Chem. 2008, 56, 4258–4267. [Google Scholar] [CrossRef]

- Mariotti, M.; Lucisano, M.; Pagani, M.A.; Ng, P.K.W. The role of corn starch, amaranth flour, pea isolate, and Psyllium flour on the rheological properties and the ultrastructure of gluten-free dough. Food. Res. Int. 2009, 42, 963–975. [Google Scholar] [CrossRef]

- Turnbull, K.M.; Rahman, S. Endosperm texture in wheat. J. Cereal Sci. 2002, 36, 327–337. [Google Scholar] [CrossRef]

- D’Egidio, M.G.; Nardi, S.; Vallega, V. Grain, flour, and dough characteristics of selected strains of diploid wheat, Triticum monococcum L. Cereal Chem. 1993, 70, 298–303. [Google Scholar]

- Abdel-Aal, E.; Hucl, P.; Sosulski, F.W.; Bhirud, P.R. Kernel, milling and baking properties of spring-type spelt and einkorn wheats. J. Cereal Sci. 1997, 26, 363–370. [Google Scholar] [CrossRef]

- Abdel-Aal, E.; Hucl, P.; Sosulski, F.W. Compositional and nutritional characteristics of spring einkorn and spelt wheats. Cereal Chem. 1995, 72, 621–624. [Google Scholar]

- Løje, H.; Moller, B.; Lausten, A.M.; Hansen, A. Chemical composition, functional properties and sensory profiling of einkorn (Triticum monococcum L.). J. Cereal Sci. 2003, 37, 231–240. [Google Scholar] [CrossRef]

- Acquistucci, R.; D’Egidio, M.G.; Vallega, V. Amino acid composition of selected strains of diploid wheat, Triticum monococcum L. ssp. monococcum. Cereal Chem. 1995, 72, 213–216. [Google Scholar]

- Galterio, G.; Borghi, B.; Bucarelli, F.; Cannella, C.; Salamini, F. Breadmaking quality, protein subunits and amino-acid composition of einkorn (Triticum monococcum) compared with other wheat species. In Proceedings of the Conference Cereals for Human Health and Preventive Nutrition, Brno, Czech Republic, 7–11 July 1998; Mendelova Zemedelska a Lesnicka Univerzita: Černá Pole, Czech Republic, 1998. [Google Scholar]

- Estivi, L.; Pellegrino, L.; Hogenboom, J.A.; Brandolini, A.; Hidalgo, A. Antioxidants of amaranth, quinoa and buckwheat wholemeals and heat-damage development in pseudocereal-enriched einkorn water biscuits. Molecules 2022, 27, 7541. [Google Scholar] [CrossRef] [PubMed]

- Meuser, F.; Suckow, P. Nonstarch polysaccharides. In Chemistry and Physics of Baking; Blanshard, J.M.V., Frazier, P.J., Galliard, T., Eds.; The Royal Society of Chemistry: London, UK, 1986; pp. 42–61. [Google Scholar]

- Pomeranz, Y. Wheat: Chemistry and Technology; AACC Inc.: St. Paul, MN, USA, 1988; pp. 100–118. [Google Scholar]

- Wang, M.; Sapirstein, H.D.; Machet, A.S.; Dexter, J.E. Composition and distribution of pentosans in millstreams of different hard spring wheats. Cereal Chem. 2006, 83, 161–168. [Google Scholar] [CrossRef]

- Westerlund, E.; Andersson, R.; Åman, P.; Theander, O. Effects of baking on water-soluble non-starch polysaccharides in white bread fractions. J. Cereal Sci. 1990, 12, 33–42. [Google Scholar] [CrossRef]

- Kim, S.K.; D’Appolonia, B.L. Bread staling studies. III. Effect of pentosans on dough, bread, and bread staling rate. Cereal Chem. 1977, 54, 225–229. [Google Scholar]

- Martini, D.; Taddei, F.; Ciccoritti, R.; Pasquini, M.; Nicoletti, I.; Corradini, D.; D’Egidio, M.G. Variation of total antioxidant activity and of phenolic acid, total phenolics and yellow-coloured pigments in durum wheat (Triticum turgidum L. var. durum) as a function of genotype, crop year and growing area. J. Cereal Sci. 2015, 65, 175–185. [Google Scholar] [CrossRef]

- Lunn, G.D.; Kettlewell, P.S.; Major, B.J.; Scott, R.K. Effects of pericarp alpha-amylase activity on wheat (Triticum aestivum) Hagberg falling number. Ann. Appl. Biol. 2001, 138, 207–214. [Google Scholar] [CrossRef]

- Buchanan, A.M.; Nicholas, E.M. Sprouting, alpha-amylase, and breadmaking quality. Cereal Res. Commun. 1980, 8, 23–28. [Google Scholar]

- Empilli, S.; Castagna, R.; Brandolini, A. Morpho-agronomic variability of the diploid wheat Triticum monococcum L. Plant Genet. Res. 2000, 124, 36–40. [Google Scholar]

- Stoddard, F.L. Survey of starch particle-size distribution in wheat and related species. Cereal Chem. 1999, 76, 145–149. [Google Scholar] [CrossRef]

- Steffe, J.F. Rheological Methods in Food Processing Engineering; Freeman Press: East Lansing, MI, USA, 1996; 418p. [Google Scholar]

- Gao, J.; Wang, Y.; Dong, Z.; Zhou, W. Structural and mechanical characteristics of bread and their impact on oral processing: A review. Int. J. Food Sci. Technol. 2018, 53, 858–872. [Google Scholar] [CrossRef]

- Lucisano, M.; Pagani, M.A. Cereali e derivati. In Gli Alimenti. Aspetti Tecnologici e Nutrizionali; Daghetta, A., Ed.; Istituto Danone: Torino, Italy, 1997; pp. 7–67. [Google Scholar]

- Amigo, J.M.; Del Olmo Alvarez, A.; Engelsen, M.M.; Lundkvist, H.; Engelsen, S.B. Staling of white wheat bread crumb and effect of maltogenic α-amylases. Part 1: Spatial distribution and kinetic modeling of hardness and resilience. Food Chem. 2016, 208, 318–325. [Google Scholar] [CrossRef] [PubMed]

- Amigo, J.M.; Del Olmo Alvarez, A.; Engelsen, M.M.; Lundkvist, H.; Engelsen, S.B. Staling of white wheat bread crumb and effect of maltogenic α-amylases. Part 2: Monitoring the staling process by using near infrared spectroscopy and chemometrics. Food Chem. 2019, 297, 124946. [Google Scholar] [CrossRef] [PubMed]

- Taglieri, I.; Macaluso, M.; Bianchi, A.; Sanmartin, C.; Quartacci, M.F.; Zinnai, A.; Venturi, F. Overcoming bread quality decay concerns: Main issues for bread shelf life as a function of biological leavening agents and different extra ingredients used in formulation. A review. J. Sci. Food Agric. 2021, 101, 1732–1743. [Google Scholar] [CrossRef] [PubMed]

| ID331 | MONLIS | BLASCO | |

|---|---|---|---|

| Kernel * | |||

| Hectolitre weight (kg/hL) | 76.6 ± 1.1 | 75.8 ± 1.4 | 85.3 ± 1.4 |

| Flour yield (g/100 g) | 61.8 ± 0.7 | 59.8 ± 1.1 | 54.0 ± 2.5 |

| Flour <125 μm (g/100 g) | 85.3 ±1.6 | 86.6 ± 1.8 | 57.8 ± 2.9 |

| Flour | |||

| Moisture (g/100 g) | 14.5 ±0.4 | 14.3 ± 0.4 | 14.5 ± 0.3 |

| Ash (g/100 g DM) | 0.60 b ± 0.02 | 0.67 a ± 0.01 | 0.59 c ± 0.01 |

| Protein (g/100 g DM) | 16.7 a ± 1.5 | 16.2 b ± 1.3 | 10.5 c ± 0.8 |

| Starch (g/100 g DM) | 69.3 b ± 1.3 | 68.7 b ± 1.8 | 79.1 a ± 1.1 |

| Amylose (g/100 g starch) | 25.3 b ± 0.1 | 26.9 a ± 0.3 | 26.8 a ± 0.3 |

| Total pentosans (g/100 g DM) | 2.49 ± 0.01 | 2.66 ± 0.08 | 2.52 ± 0.05 |

| Soluble pentosans (g/100 g DM) | 0.95 b ± 0.04 | 1.10 a ± 0.03 | 0.82 c ± 0.01 |

| Yellow pigment (mg/kg DM) | 8.7 b ± 0.6 | 11.3 a ± 0.7 | 1.0 c ± 0.1 |

| Dry gluten (g/100 g DM) | 1.58 a ±0.13 | 1.49 a ± 0.08 | 1.15 b ± 0.03 |

| Falling number (s) | 358 b ± 16 | 365 b ± 11 | 431 a ± 13 |

| α-amylase activity (CU/g DM) | 0.19 a ± 0.02 | 0.20 a ± 0.01 | 0.15 b ± 0.01 |

| ID331 | MONLIS | BLASCO | |

|---|---|---|---|

| SDS sedimentation volume (mL) | 91 a ± 0.9 | 88 a ± 2 | 66 b ± 7 |

| Brabender farinograph * | |||

| Water absorption (%) | 52.7 ± 1.5 | 52.4 ± 0.8 | 58.8 ± 0.6 |

| Development time (s) | 144 ± 15 | 168 ± 23 | 195 ± 107 |

| Stability time (s) | 387 ± 226 | 305 ± 122 | 429 ± 234 |

| Degree of softening (BU) | 65 ± 20 | 85 ± 15 | 56 ± 22 |

| Rheofermentograph * | |||

| Dough max height (mm) | 72.3 ± 5.3 | 73.8 ± 4.8 | 63.0 ± 3.6 |

| Time to max height (min) | 121.8 ± 10.8 | 119.8 ± 20.5 | 175.0 ± 4.4 |

| CO2 total (mL) | 1136 ± 89 | 1168 ± 107 | 1713 ± 79 |

| CO2 lost (mL) | 12 ± 5 | 15 ± 5 | 193 ± 26 |

| CO2 retained (mL) | 1124 ± 85 | 1154 ±103 | 1523 ± 85 |

| Retention coefficient (%) | 99.0 ± 0.4 | 99.3 ± 0.1 | 88.7 ± 1.6 |

| Strain sweep test | |||

| LVR limit for G′ (%) | 0.70 a ± 0.03 | 0.69 a ± 0.02 | 0.33 b ± 0.02 |

| LVR limit for G″ (%) | 0.82 a ± 0.03 | 0.79 a ± 0.01 | 0.48 b ± 0.02 |

| Frequency sweep test | |||

| G′ (Pa) (0.10% strain, 1 Hz) | 9216 b ± 822 | 10,748 a ± 860 | 7764 c ± 605 |

| G″ (Pa) (0.10% strain, 1 Hz) | 4403 b ± 270 | 5131 a ± 565 | 2933 c ± 151 |

| Damping factor G″/G′ | 0.48 a ± 0.02 | 0.48 a ± 0.02 | 0.38 b ± 0.02 |

| Bread | |||

| Volume (cm3) | 732 a ± 128 | 740 a ± 107 | 671 b ± 43 |

| Height (cm) | 102 ab ± 12 | 104 a ± 10 | 99 b ± 3 |

| Specific volume (cm3/kg) | 5.23 ab ± 0.97 | 5.40 a ± 0.77 | 4.55 b ± 0.29 |

| ID331 | Monlis | Blasco | ||

|---|---|---|---|---|

| Crust | L* | 46.1 ± 3.1 | 45.7 ± 2.6 | 46.1 ± 2.7 |

| a* | 17.3 ab ± 0.5 | 17.0 b ± 0.4 | 17.7 a ± 0.7 | |

| b* | 26.7 ± 2.7 | 26.8 ± 2.2 | 25.4 ± 1.5 | |

| Crumb | L* | 79.6 ± 0.9 | 79.2 ± 0.5 | 79.6 ± 1.8 |

| a* | −2.6 b ± 0.1 | −2.9 c ± 0.1 | 0.2 a ± 0.08 | |

| b* | 35.2 a ± 0.6 | 35.8 a ± 0.2 | 15.5 b ± 0.4 | |

| R | 234 a ± 5 | 232 a ± 7 | 219 b ± 4 | |

| G | 216 a ± 5 | 214 a ± 7 | 207 b ± 3 | |

| B | 130 b ± 3 | 126 c ± 4 | 172 a ± 3 | |

| N° Pores | N° Pores (%) | Pores Area (mm2) | Pores Area (%) | Mean Pores Area (mm2) | Mean Pores Diametre (mm) | Pores Shape | ||

|---|---|---|---|---|---|---|---|---|

| C1 | ID331 | 647 ± 34 | 75.7 ± 2.8 | 237.5 a ± 13.1 | 32.6 ± 3.6 | 0.37 ± 0.01 | 0.64 b ± 0.01 | 1.78 ± 0.03 |

| Monlis | 611 ± 30 | 73.9 ± 2.8 | 219.6 b ± 11.4 | 27.9 ± 4.3 | 0.36 ± 0.01 | 0.64 b ± 0.01 | 1.89 ± 0.05 | |

| Blasco | 652 ± 32 | 72.7 ± 1.6 | 243.5 a ± 12.6 | 30.1 ± 2.2 | 0.37 ± 0.01 | 0.65 a ± 0.01 | 1.89 ± 0.04 | |

| C2 | ID331 | 193 b ± 32 | 22.5 ± 2.9 | 377.8 b ± 63.2 | 51.2 b ± 4.5 | 1.96 ± 0.08 | 1.55 ± 0.04 | 1.98 b ± 0.05 |

| Monlis | 195 b ± 23 | 23.6 ± 2.2 | 388.0 b ± 57.2 | 48.5 b ± 0.8 | 1.98 ± 0.08 | 1.57 ± 0.03 | 2.16 a ± 0.08 | |

| Blasco | 229 a ± 14 | 25.6 ± 1.2 | 454.9 a ± 31.7 | 56.2 a ± 2.3 | 1.98 ± 0.05 | 1.58 ± 0.02 | 2.12 a ± 0.09 | |

| C3 | ID331 | 15 b ± 3 | 1.8 b ± 0.5 | 118.1 b ± 28.1 | 16.1 b ± 3.6 | 7.97 b ± 0.59 | 2.93 ± 0.16 | 2.34 ± 0.34 |

| Monlis | 21 a ± 6 | 2.5 a ± 0.7 | 191.4 a ± 51.0 | 23.6 a ± 3.9 | 9.21 a ± 0.94 | 3.09 ± 0.18 | 2.39 ± 0.38 | |

| Blasco | 15 b ± 4 | 1.7 b ± 0.4 | 112.2 b ± 35.5 | 13.7 b ± 3.9 | 7.37 b ± 0.95 | 2.86 ± 0.13 | 2.60 ± 0.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brandolini, A.; Lucisano, M.; Mariotti, M.; Estivi, L.; Hidalgo, A. Breadmaking Performance of Elite Einkorn (Triticum monococcum L. subsp. monococcum) Lines: Evaluation of Flour, Dough and Bread Characteristics. Foods 2023, 12, 1610. https://doi.org/10.3390/foods12081610

Brandolini A, Lucisano M, Mariotti M, Estivi L, Hidalgo A. Breadmaking Performance of Elite Einkorn (Triticum monococcum L. subsp. monococcum) Lines: Evaluation of Flour, Dough and Bread Characteristics. Foods. 2023; 12(8):1610. https://doi.org/10.3390/foods12081610

Chicago/Turabian StyleBrandolini, Andrea, Mara Lucisano, Manuela Mariotti, Lorenzo Estivi, and Alyssa Hidalgo. 2023. "Breadmaking Performance of Elite Einkorn (Triticum monococcum L. subsp. monococcum) Lines: Evaluation of Flour, Dough and Bread Characteristics" Foods 12, no. 8: 1610. https://doi.org/10.3390/foods12081610

APA StyleBrandolini, A., Lucisano, M., Mariotti, M., Estivi, L., & Hidalgo, A. (2023). Breadmaking Performance of Elite Einkorn (Triticum monococcum L. subsp. monococcum) Lines: Evaluation of Flour, Dough and Bread Characteristics. Foods, 12(8), 1610. https://doi.org/10.3390/foods12081610