A Comparative Analysis of Thin-Layer Microwave and Microwave/Convective Dehydration of Chokeberry

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Microwave Dehydration

2.2.2. Models of Thin-Layer Dehydration

2.2.3. Determination of Effective Moisture Diffusivity

2.2.4. Determination of Activation Energy

2.2.5. Determination of Energy Consumption of Dehydration Processes

2.2.6. Water-Holding Capacity

2.2.7. Sensory Evaluation

2.2.8. Statistical Methods

3. Results and Discussion

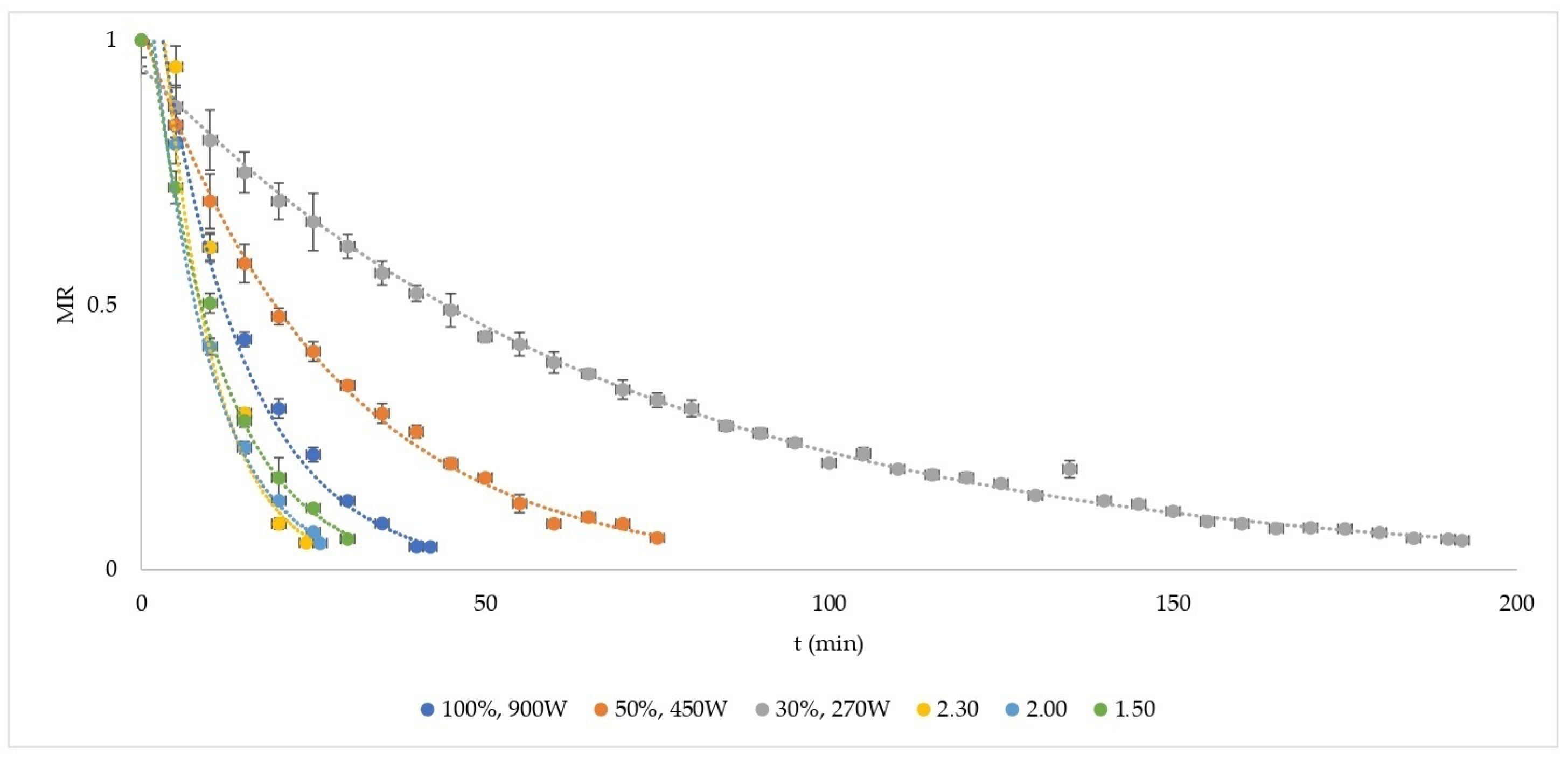

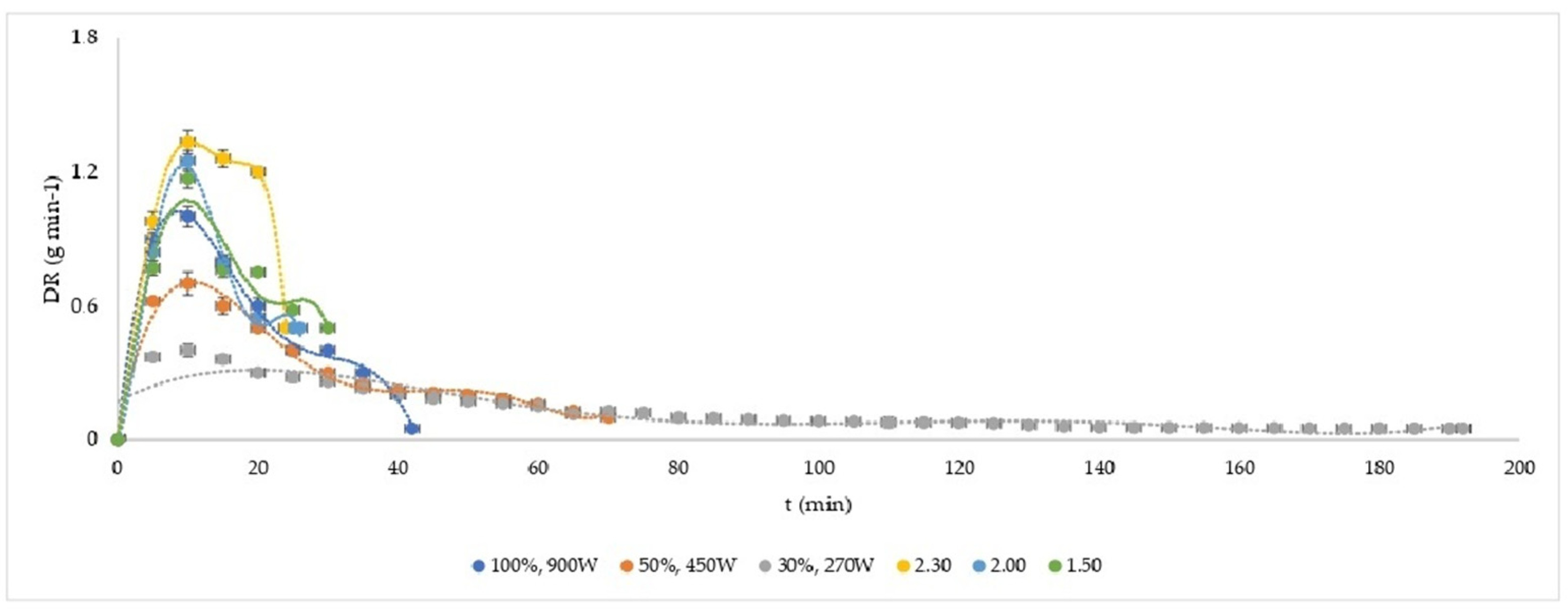

3.1. Models of Thin-Layer Dehydration

3.2. Determination of Effective Moisture Diffusivity

3.3. Determination of Activation Energy

3.4. Determination of Energy Consumption of Dehydration Processes

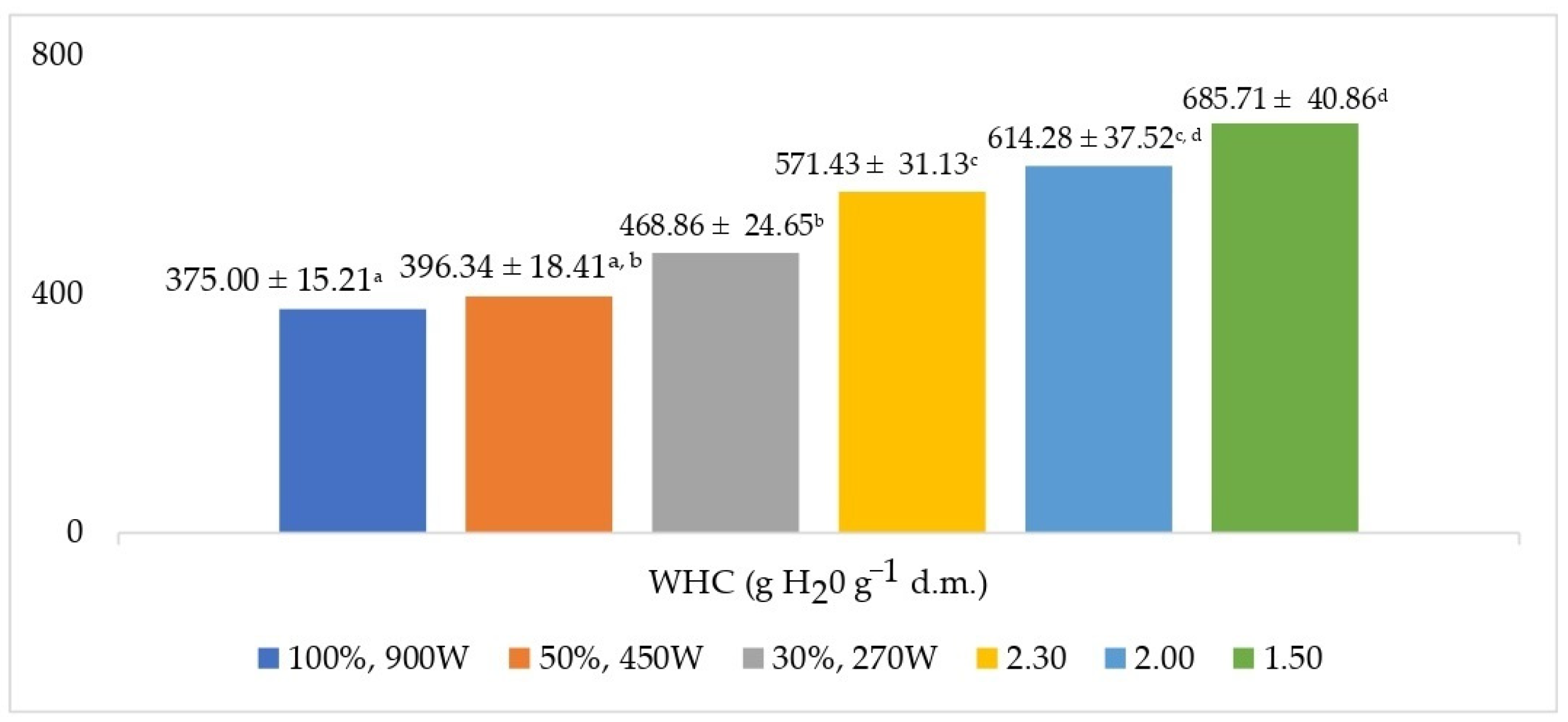

3.5. Water-Holding Capacity

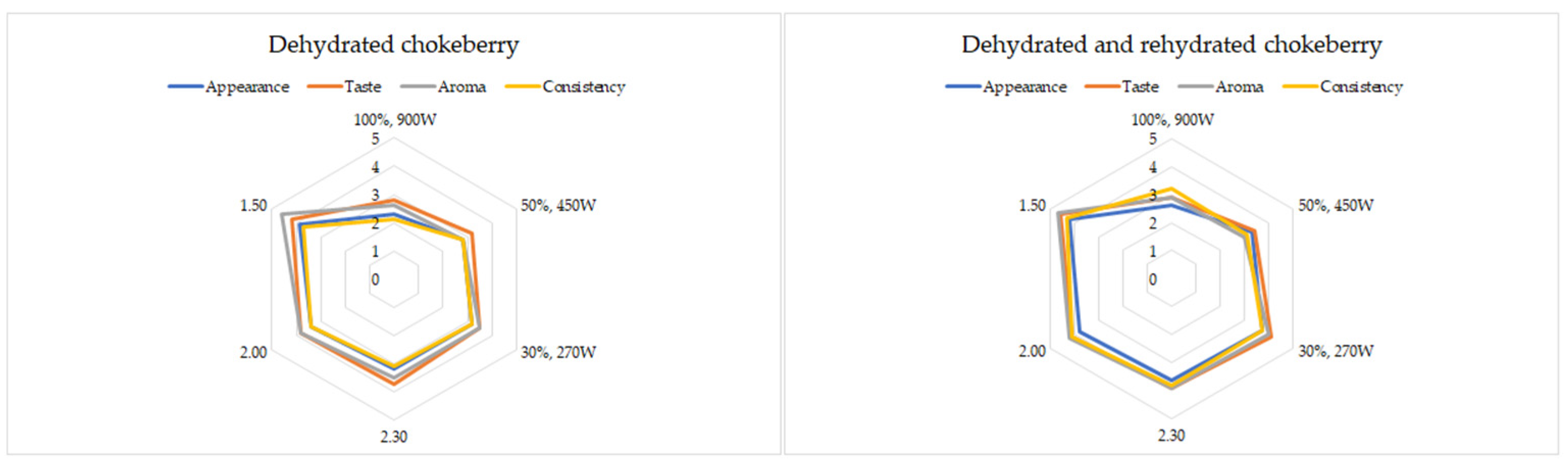

3.6. Sensory Evaluation

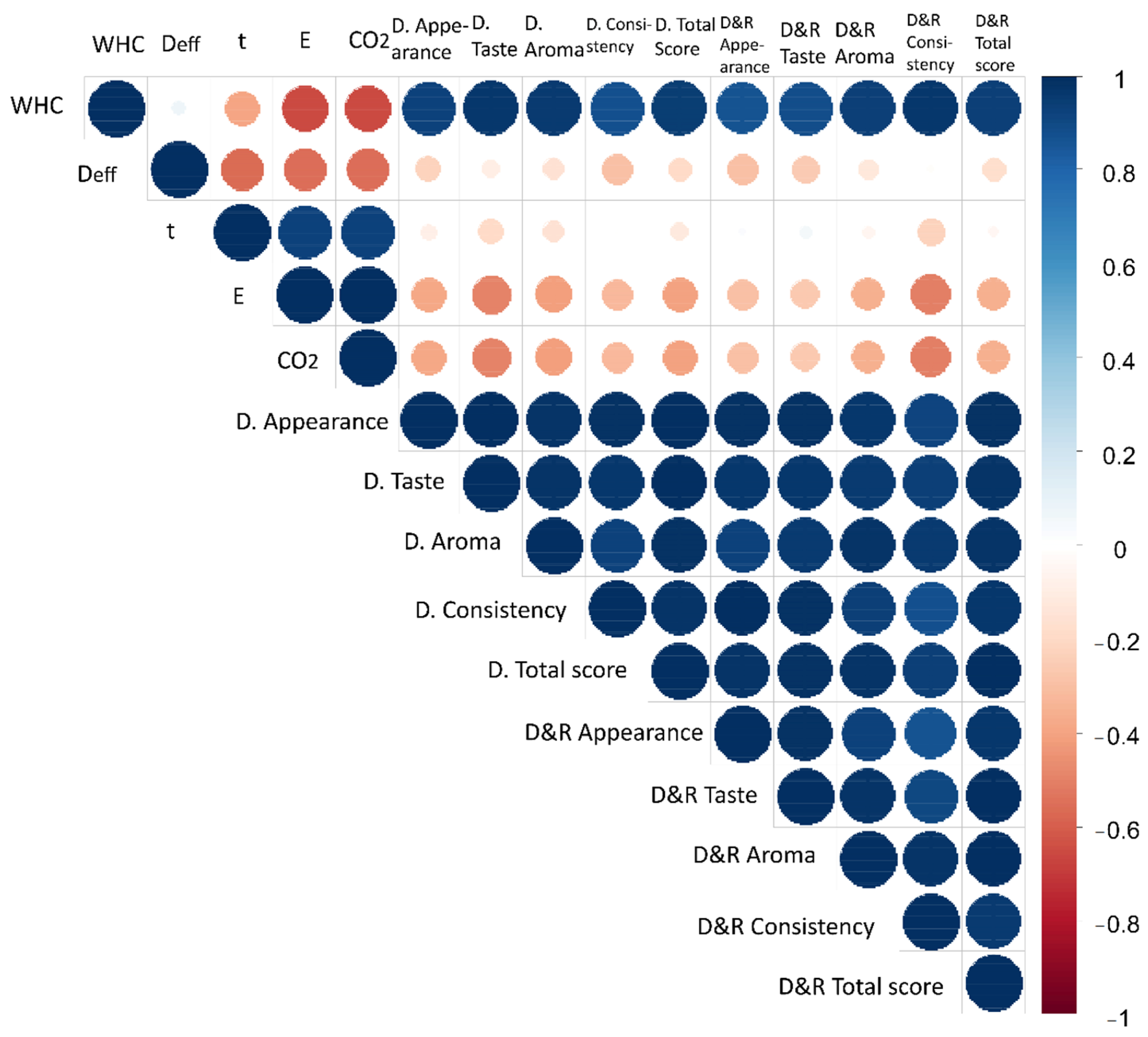

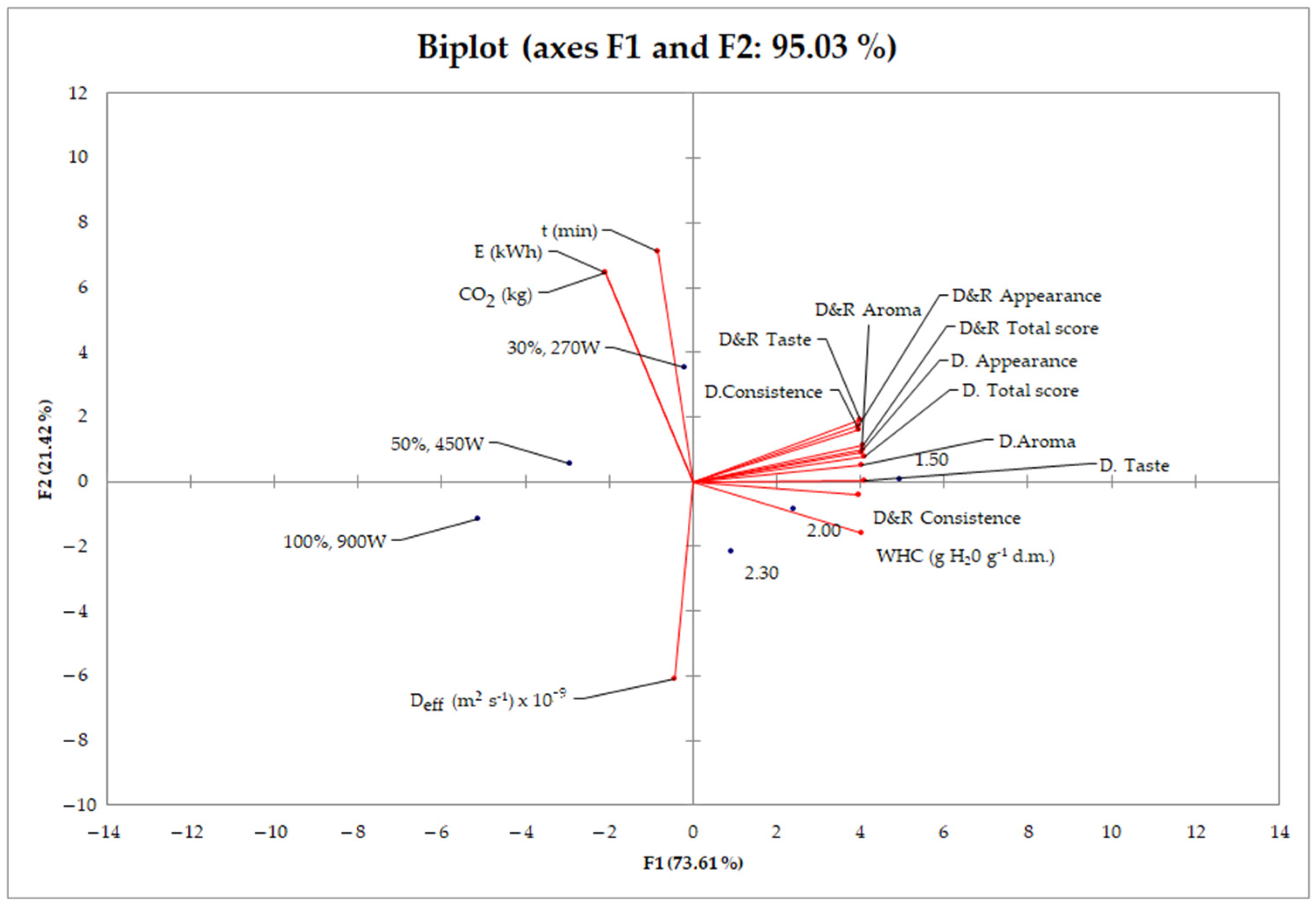

3.7. Statistical Methods

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Simić, V.M.; Rajković, K.M.; Stojičević, S.S.; Veličković, D.T.; Nikolić, N.Č.; Lazić, M.L.; Karabegović, I.T. Optimization of microwave-assisted extraction of total polyphenolic compounds from chokeberries by response surface methodology and artificial neural network. Sep. Purif. Technol. 2016, 160, 89–97. [Google Scholar] [CrossRef]

- De Oliveira, G.B. Processing of Berries-Effects on Functionality, Stability and Bioactivity of Anthocyanins. Ph.D. Thesis, Food and Nutrition Science, Department of Biology and Biological Engineering, Chalmers University of Technology, Gothenburg, Sweden, 17 December 2019. [Google Scholar]

- Jurikova, T.; Mlcek, J.; Skrovankova, S.; Sumczynski, D.; Sochor, J.; Hlavacova, I.; Snopek, L.; Orsavova, J. Fruits of Black Chokeberry Aronia melanocarpa in the Prevention of Chronic Diseases. Molecules 2017, 22, 944. [Google Scholar] [CrossRef] [PubMed]

- Calín-Sánchez, Á.; Kharaghani, A.; Lech, K.; Figiel, A.; Carbonell-Barrachina, Á.A.; Tsotsas, E. Drying Kinetics and Microstructural and SensoryProperties of Black Chokeberry (Aronia melanocarpa) as Affected by Drying Method. Food Bioprocess Technol. 2014, 8, 63–74. [Google Scholar] [CrossRef]

- Filipović, V.; Filipović, J.; Petković, M.; Filipović, I.; Miletić, N.; Đurović, I.; Lukyanov, A. Modeling convective thin-layer drying of carrot slices and quality parameters. Therm. Sci. 2022, 26, 2187–2198. [Google Scholar] [CrossRef]

- Rojas, M.L.; Augusto, P.E.D. Ethanol pre-treatment improves vegetable drying and rehydration: Kinetics, mechanisms and impact on viscoelastic properties. J. Food Eng. 2018, 233, 17–27. [Google Scholar] [CrossRef]

- Petković, M.; Filipović, V.; Filipović, J.; Đurović, I.; Miletić, N.; Radovanović, J. Chemical, antioxidative and sensory characteristics of wheat bread partially substituted with black chokeberry (Aronia melanocarpa L.) powder. J. Food Process. Preserv. 2020, 45, e15027. [Google Scholar] [CrossRef]

- Babu, A.K.; Kumaresan, G.; Raj, V.A.A.; Velraj, R. Review of leaf drying: Mechanism and influencing parameters, drying methods, nutrient preservation, and mathematical models. Renew. Sustain. Energy Rev. 2018, 90, 536–556. [Google Scholar] [CrossRef]

- Feng, L.; Zhang, M.; Adhikari, B. Effect of Water on the Quality of Dehydrated Products: A Review of Novel Characterization Methods and Hybrid Drying Technologies. Dry. Technol. 2014, 32, 1872–1884. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, M.; Mujumdar, A. Berry Drying: Mechanism, Pretreatment, Drying Technology, Nutrient Preservation, and Mathematical Models. Food Eng. Rev. 2019, 11, 61–77. [Google Scholar] [CrossRef]

- Cao, X.; Zhang, M.; Mujumdar, A.S.; Zhong, Q.; Wang, Z. Effect of microwave freeze drying on quality and energy supply in drying of barley grass. J. Sci. Food Agric. 2017, 98, 1599–1605. [Google Scholar] [CrossRef]

- Hossan, M.R.; Byun, D.; Dutta, P. Analysis of microwave heating for cylindrical shaped objects. Int. J. Heat Mass Transf. 2010, 53, 5129–5138. [Google Scholar] [CrossRef]

- Zheng, X.; Liu, C.; Mu, Y.; Liu, H.; Song, X.; Lin, Z.; Liu, D.; Weerasooriya, G.V.T.V. Analysis of Puffing Characteristics Using a Sigmodal Function for the Berry Fruit Snack Subjected to Microwave Vacuum Conditions. Dry. Technol. 2012, 30, 494–504. [Google Scholar] [CrossRef]

- Kowalski, S.J.; Musielak, G.; Banaszak, J. Heat and mass transfer during microwave-convective drying. AICHE J. 2009, 56, 24–35. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, S. Recent developments in radio frequency drying of food and agricultural products: A review. Dry. Technol. 2018, 37, 271–286. [Google Scholar] [CrossRef]

- Zhang, M.; Chen, H.; Mujumdar, A.S.; Tang, J.; Miao, S.; Wang, Y. Recent developments in high-quality drying of vegetables, fruits, and aquatic products. Crit. Rev. Food Sci. Nutr. 2015, 57, 1239–1255. [Google Scholar] [CrossRef] [PubMed]

- Petković, M.; Lukyanov, A.; Rudoy, D.; Kurćubić, V.; Đurović, I.; Miletić, N.; Safarov, J. Potato thin layer convective dehydration model and energy efficiency estimation. In Proceedings of the E3S Web of Conferences, Rostov-on-Don, Russia, 24–26 February 2021. [Google Scholar] [CrossRef]

- Petković, M.; Miletić, N.; Kurćubić, V.; Lukyanov, A.; Đurović, I.; Filipović, V.; Mladenović, V. Energy consumption and dehydration parameters of microwave drying of carrot. Acta Agric. Serb. 2022, 27, 137–142. [Google Scholar] [CrossRef]

- Onwude, D.I.; Hanshim, N.; Janius, R.B.; Nawi, N.M.; Abdan, K. Modeling the Thin Layer Drying of Fruits and Vegetables: A Review. Compr. Rev. Food Sci. Food Saf. 2016, 15, 599–618. [Google Scholar] [CrossRef]

- Szychowski, P.J.; Lech, K.; Sendra-Nadal, E.; Hernández, F.; Figiel, A.; Wojdyło, A.; Carbonell-Barrachina, Á.A. Kinetics, biocompounds, antioxidant activity, and sensory attributes of quinces as affected by drying method. Food Chem. 2018, 255, 157–164. [Google Scholar] [CrossRef]

- Rosell, C.M.; Santos, E.; Collar, C. Physico-chemical properties of commercial fibres from different sources: A comparative approach. Food Res. Int. 2009, 42, 176–184. [Google Scholar] [CrossRef]

- AOAC. Official Method of Analysis, Association of Official Analytical Chemists, 16th ed.; No 934.01; AOAC: Arlington, VA, USA, 1995. [Google Scholar]

- Mitrović, O.; Popović, B.; Kandić, M.; Leposavić, A.; Miletić, N. The effects of drying temperature and dipping on prune quality. Acta Hortic. 2021, 1308, 241–248. [Google Scholar] [CrossRef]

- Nićetin, M.; Pezo, L.; Pergal, M.; Lončar, B.; Filipović, V.; Knežević, V.; Demir, H.; Filipović, J.; Manojlović, D. Celery Root Phenols Content, Antioxidant Capacities and Their Correlations after Osmotic Dehydration in Molasses. Foods 2022, 11, 1945. [Google Scholar] [CrossRef]

- Lončar, B.; Filipović, V.; Nićetin, M.; Knežević, V.; Filipović, J.; Pezo, L.; Šuput, D. Mass transfer rate and osmotic treatment efficiency of peaches. Acta Univ. Sapientiae Aliment. 2022, 15, 1–10. [Google Scholar] [CrossRef]

- Zhao, Y.; Bi, J.; Yi, J.; Njoroge, D.M.; Peng, J.; Hou, C. Comparison of dynamic water distribution and microstructure formation of shiitake mushrooms during hot air and far infrared radiation drying by low-field nuclear magnetic resonance and scanning electron microscopy. J. Sci. Food Agric. 2019, 99, 2826–2834. [Google Scholar] [CrossRef] [PubMed]

- Khiari, R.; Zemni, H.; Mihoubi, D. Raisin processing: Physicochemical, nutritional and microbiological quality characteristics as affected by drying process. Food Rev. Int. 2019, 35, 246–298. [Google Scholar] [CrossRef]

- Cortez, R.E.; Gonzalez de Mejia, E. Blackcurrants (Ribes nigrum): A review on chemistry, processing, and health benefits. J. Food Sci. 2019, 84, 2387–2401. [Google Scholar] [CrossRef] [PubMed]

- Petković, M.; Đurović, I.; Miletić, N.; Radovanović, J. Effect of Convective Drying Method of Chokeberry (Aronia melanocarpa L.) on Drying Kinetics, Bioactive Components and Sensory Characteristics of Bread with Chokeberry Powder. Period. Polytech. Chem. Eng. 2019, 63, 600–608. [Google Scholar] [CrossRef]

- Wang, Z.; Yu, C.; Huang, H.; Guo, W.; Yu, J.; Qiu, J. Carbon-enabled microwave chemistry: From interaction mechanisms to nanomaterial manufacturing. Nano Energy 2021, 85, 106027. [Google Scholar] [CrossRef]

- Azimi-Nejadian, H.; Hoseini, S.S. Study the effect of microwave power and slices thickness on drying characteristics of potato. Heat Mass Transf. 2019, 55, 2921–2930. [Google Scholar] [CrossRef]

- Filipović, V.; Petković, M.; Filipović, J.; Miletić, N.; Đurović, I.; Radovanović, J.; Lukyanov, A. Chokeberry thin layer convective drying process modeling and energy efficiency estimation. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Rostov-on-Don, Russia, 16–17 June 2020. [Google Scholar] [CrossRef]

- Radovanović, J. The Influence of the Kinetics of Aronia Drying (Aronia melanocarpa L.) on the Quality of Flour and Bread Obtained from Chokeberry. Master’s Thesis, Food Department, Faculty of Agronomy Čačak, University of Kragujevac, Kragujevac, Serbia, 11 July 2019. [Google Scholar]

- Sadowska, A.; Świderski, F.; Rakowska, R.; Hallmann, E. The Functional Properties of Chokeberry and Kale Powders Obtained by an Innovative Method of Fluidised-Bed Jet Milling with Drying Compared to Freeze Drying. Int. J. Food Eng. 2017, 13, 20160310. [Google Scholar] [CrossRef]

- Ghinea, C.; Prisacaru, A.E.; Leahu, A. Physico-Chemical and Sensory Quality of Oven-Dried and Dehydrator-Dried Apples of the Starkrimson, Golden Delicious and Florina Cultivars. Appl. Sci. 2022, 12, 2350. [Google Scholar] [CrossRef]

- Pallas, L.A.; Pegg, R.B.; Kerr, W.L. Quality factors, antioxidant activity, and sensory properties of jet-tube dried rabbiteye blueberries. J. Sci. Food Agric. 2012, 93, 1887–1897. [Google Scholar] [CrossRef] [PubMed]

- Fotirić Akšić, M.; Nešović, M.; Ćirić, I.; Tešić, Ž.; Pezo, L.; Tosti, T.; Gašić, U.; Dojčinović, B.; Lončar, B.; Meland, M. Chemical fruit profiles of different raspberry cultivars grown in specific Norwegian agroclimatic conditions. Horticulturae 2022, 8, 765. [Google Scholar] [CrossRef]

- Ćurčić, L.; Lončar, B.; Pezo, L.; Stojić, N.; Prokić, D.; Filipović, V.; Pucarević, M. Chemometric Approach to Pesticide Residue Analysis in Surface Water. Water 2022, 14, 4089. [Google Scholar] [CrossRef]

| Model | T (min) | Deff (m2 s−1) | Henderson and Pabis Model | Polynomial Model | E (kWh) | CO2 (kg) |

|---|---|---|---|---|---|---|

| 100%, 900 W | 42 ± 4 a | 4.4891 × 10−10 ± 4.4518 × 10−12, f | y = 1.1181 × e−0.0730 × x R2 = 0.9881 MSE = 0.0025 | y = 2.5657 × 10−7 × x5 − 3. 3384 × 10−5 × x4 + 1.6315 × 10−3 × x3 − 3.6273 × 10−2 × x2 + 0.3231 × x + 0.0850 R2 = 0.9706 MSE = 0.0165 | 0.624 ± 0.059 b | 0.623 ± 0.059 b |

| 50%, 450 W | 75 ± 6 b | 1.7492 × 10−10 ± 2.0241 × 10−12, e | y = 1.0134 × e−0.0366 × x R2 = 0.9999 MSE = 0.0002 | y = 1.5705 × 10−8 × x5 − 3.6291 × 10−4 × x4 + 3.0319 × 10−3 × x3 − 1.0989 × 10−2 × x2 + 0,1513 × x + 0.0029 R2 = 0.9950 MSE = 0.0059 | 0.640 ± 0.062 b | 0.638 ± 0.062 b |

| 30%, 270 W | 192 ± 15 c | 3.6891 × 10−9 ± 3.3214 × 10−11, a | y = 0.9432 × e−0.0147 × x R2 = 0.9979 MSE = 0.0001 | y = 3.4667 × 10−10 × x5 − 1.5067 × 10−7 × x4 + 2.3610 × 10−5 × x3 − 1.5861 × 10−3 × x2 + 0.0394 × x + 0.0393 R2 = 0.848 MSE = 0.0069 | 0.866 ± 0.081 c | 0.865 ± 0.081 c |

| 2.30 | 24 ± 2 a | 6.0768 × 10−9 ± 5.9815 × 10−11, b | y = 1.3174 × e−0.1795 × x R2 = 0.9338 MSE = 0.0344 | y = 1.8931 × 10−5 × x5 − 1.0469 × 10−3 × x4 + 0,0186 × x3 − 0,1157 × x2 + 0,2901 × x + 3.2426 × 10−10 R2 = 0.9999 MSE = 0.0893 | 0.382 ± 0.036 a | 0.381 ± 0.357 a |

| 2.00 | 26 ± 2 a | 1.5412 × 10−9 ± 1.5374 × 10−11, d | y = 1.2133 × e−0.1167 × x R2 = 0.9560 MSE = 0.005 | y = 1.1634 × 10−6 × x5 + 9 × 10−5 × x4 − 1.8603 × 10−3 × x3 + 0.0042 × x2 + 0.1998 × x − 0.0030 R2 = 0.9970 MSE = 0.1205 | 0.396 ± 0.036 a | 0.395 ± 0.363 a |

| 1.50 | 30 ± 3 a | 1.3565 × 10−9 ± 1.2355 × 10−11, c | y = 1.1058 × e−0.0948 × x R2 = 0.9872 MSE = 0.0014 | y = 1.3537 × 10−6 × x5 − 1.2626 × 10−3 × x4 + 0.0044 × x3 − 0.0709 × x2 + 0.4884 × x − 0.0010 R2 = 0.9917 MSE = 0.6254 | 0.451 ± 0.048 a | 0.450 ± 0.447 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petković, M.; Filipović, V.; Lončar, B.; Filipović, J.; Miletić, N.; Malešević, Z.; Jevremović, D. A Comparative Analysis of Thin-Layer Microwave and Microwave/Convective Dehydration of Chokeberry. Foods 2023, 12, 1651. https://doi.org/10.3390/foods12081651

Petković M, Filipović V, Lončar B, Filipović J, Miletić N, Malešević Z, Jevremović D. A Comparative Analysis of Thin-Layer Microwave and Microwave/Convective Dehydration of Chokeberry. Foods. 2023; 12(8):1651. https://doi.org/10.3390/foods12081651

Chicago/Turabian StylePetković, Marko, Vladimir Filipović, Biljana Lončar, Jelena Filipović, Nemanja Miletić, Zoranka Malešević, and Darko Jevremović. 2023. "A Comparative Analysis of Thin-Layer Microwave and Microwave/Convective Dehydration of Chokeberry" Foods 12, no. 8: 1651. https://doi.org/10.3390/foods12081651

APA StylePetković, M., Filipović, V., Lončar, B., Filipović, J., Miletić, N., Malešević, Z., & Jevremović, D. (2023). A Comparative Analysis of Thin-Layer Microwave and Microwave/Convective Dehydration of Chokeberry. Foods, 12(8), 1651. https://doi.org/10.3390/foods12081651