Impact of Lavender Flower Powder as a Flavoring Ingredient on Volatile Composition and Quality Characteristics of Gouda-Type Cheese during Ripening

Abstract

1. Introduction

2. Materials and Methods

2.1. Manufacturing of Gouda-Type Cheese

2.2. Proximate Composition Analysis of Cheese and Calculation of Total Carbohydrate Content, Fat in Dry Matter Content, and Energy Value

2.3. Determination of Sodium Chloride Content, pH, and Titratable Acidity of the Cheese

2.4. Texture Profile Analysis of Cheese

2.5. Microbiological Analysis of Cheese

2.6. Analysis of Volatile Compounds in Cheese

2.7. Sensory Analysis of Cheese and Determination of Consumers’ Acceptance and Purchase Intention

2.8. Statistical Analysis

3. Results and Discussion

3.1. Nutritional Properties of Gouda-Type Cheese

3.2. Textural Properties of Gouda-Type Cheese

3.3. Microbiological Properties of Gouda-Type Cheese

3.4. Volatile Compounds in Gouda-Type Cheese

| Crt.No. | Volatile Compound | MSS (%) | Odor Descriptor | Reference | CC | Control Cheese | Lavender Cheese | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| µg/kg Cheese | |||||||||||

| T1 | T2 | T3 | T1 | T2 | T3 | ||||||

| 1 | Methyl acetate | 96 | Fruity, solvent, blackcurrant-like | [48] | Es | 38.56 ± 4.199bB | 67.26 ± 2.948bB | 111.20 ± 26.935aA | 53.50 ± 1.607bA | 115.42 ± 25.312aA | 61.89 ± 5.974bB |

| 2 | Isopropanol | 97 | Sharp musty | [49] | Alc | 221.75 ± 46.558cB | 722.34 ± 89.846bB | 1155.17 ± 222.182aA | 599.38 ± 75.037bA | 1047.99 ± 120.237aA | 590.10 ± 7.424bB |

| 3 | Methyl butyrate | 96 | Fruity, apple-like | [50] | Es | 54.21 ± 11.983bB | 114.20 ± 17.312aB | 153.96 ± 31.418aA | 180.06 ± 25.014aA | 222.23 ± 34.620aA | 170.39 ± 1.721aA |

| 4 | Acetonitrile | 98 | - | - | CyAlka | 275.86 ± 51.660cB | 1083.19 ± 169.607bA | 1636.99 ± 279.534aA | 575.97 ± 89.883cA | 1495.49 ± 197.115aA | 1022.22 ± 52.569bB |

| 5 | Chloroform | 77 | Ether-like | [49] | HoAlka | 1068.81 ± 206.553cB | 3527.63 ± 402.152bA | 5590.37 ± 1139.680aA | 2176.24 ± 339.353bA | 4329.89 ± 565.593aA | 4329.89 ± 565.593aA |

| 6 | Toluene | 94 | Nutty, bitter, almonds, paint; fruity | [51,52] | AH | 23.03 ± 3.945b | 51.99 ± 9.667abA | 65.66 ± 18.515aA | n.d. | 68.95 ± 22.883aA | 41.11 ± 5.903aA |

| 7 | Ethyl butyrate (isomer) | 95 | Fruity, pineapple, acetone, caramel | [48] | Es | n.d. | n.d. | n.d. | 39.08 ± 2.587a | 50.16 ± 15.106a | 28.71 ± 12.886a |

| 8 | Butyl acetate | 94 | Fruity | [49] | Es | 15.34 ± 3.106aB | 25.07 ± 3.967aA | 23.29 ± 5.877aA | 27.71 ± 2.459aA | 22.75 ± 2.323bA | 13.80 ± 0.133cB |

| 9 | Hexanal | 95 | Cut grass | [53] | Ald | 16.51 ± 5.051aA | 6.68 ± 2.494bA | n.d. | 31.52 ± 20.601aA | 6.86 ± 2.523aA | 19.44 ± 0.720a |

| 10 | Isobutanol | 91 | Choking alcohol | [49] | Alc | 6.31 ± 1.424bB | 24.40 ± 3.487aB | 28.14 ± 8.926aA | 12.67 ± 3.009cA | 34.31 ± 1.756aA | 20.10 ± 3.050bA |

| 11 | Isoamyl acetate | 97 | Banana, chewing gum | [48] | Es | n.d. | n.d. | n.d. | n.d. | 62.98 ± 10.744a | 52.95 ± 4.624a |

| 12 | 1-Butanol | 97 | Medicinal, fruity | [51] | Alc | 201.21 ± 41.648cB | 640.06 ± 83.138bA | 950.89 ± 166.505aA | 505.86 ± 71.458aA | 638.14 ± 80.605aA | 319.35 ± 28.604bB |

| 13 | β-Myrcene | 93 | Balsamic, spice | [54] | Te&Ts | n.d. | n.d. | n.d. | 29.92 ± 9.055b | 62.30 ± 6.066a | 38.28 ± 2.828b |

| 14 | Pyridine | 92 | - | - | Pyr | 12.38 ± 3.015bA | 50.35 ± 9.850aA | 63.41 ± 11.766aA | 21.12 ± 6.264aA | 21.45 ± 2.673aB | 10.31 ± 1.399bB |

| 15 | 2-Heptanone | 88 | Fruity | [52] | Ket | 6.17 ± 1.257cA | 13.62 ± 2.483bB | 23.78 ± 1.680aA | 10.71 ± 2.732bA | 30.92 ± 3.245aA | 27.73 ± 2.546aA |

| 16 | Heptanal | 80 | Sour milk/dairy | [52] | Ald | 5.94 ± 1.317 | n.d. | n.d. | n.d. | n.d. | n.d. |

| 17 | Methyl hexanoate | 96 | Fruity, ester-like | [50] | Es | 141.11 ± 25.302bB | 288.30 ± 40.965aB | 321.42 ± 53.508aA | 428.97 ± 58.989aA | 496.81 ± 69.633aA | 279.30 ± 29.445bA |

| 18 | 1,8-Cineole | 97 | Floral, minty, fruity | [54] | Te&Ts | n.d. | n.d. | n.d. | 370.96 ± 56.128b | 678.05 ± 61.261a | 356.96 ± 17.757b |

| 19 | Isoamyl alcohol | 97 | Banana | [55] | Alc | 194.44 ± 43.626bB | 750.88 ± 94.873aB | 831.51 ± 172.253aA | 433.41 ± 95.289cA | 1284.59 ± 151.738aA | 758.69 ± 54.400bA |

| 20 | Ethyl butyrate (isomer) | 96 | Pineapple-like | [49] | Es | 8.62 ± 2.144bB | 14.59 ± 2.407bB | 29.48 ± 7.633aA | 79.59 ± 8.303aA | 74.89 ± 2.553aA | 54.02 ± 9.024bB |

| 21 | trans-β-Ocimene | 82 | Mushroom-like | [56] | Te&Ts | 21.33 ± 4.752cA | 50.26 ± 4.803bB | 66.13 ± 7.807aB | 97.95 ± 13.079bB | 158.27 ± 8.496aA | 90.65 ± 9.332bA |

| 22 | ɣ-Terpinene | 83 | Unpleasant | [57] | Te&Ts | 5.57 ± 0.261bB | 13.84 ± 1.000aB | 14.45 ± 1.618aA | 17.75 ± 2.660bA | 30.85 ± 2.920aA | 16.42 ± 1.305bA |

| 23 | Styrene | 87 | Sweet smell | [49] | AH | 15.76 ± 1.719bB | 42.52 ± 7.501abB | 66.04 ± 17.135aA | 32.90 ± 3.271bA | 61.74 ± 5.802aA | 35.94 ± 4.774bB |

| 24 | 3-Octanone * | 89 | Mushroom-like/buttery | [58] | Ket | n.d. | n.d. | n.d. | 192.64 ± 49.231b | 400.72 ± 37.208a | 181.33 ± 18.574b |

| 25 | β-Ocimene | 87 | Sweet, herb | [54] | Te&Ts | 18.66 ± 2.322b | 34.83 ± 9.189a | 42.49 ± 4.247a | n.d. | n.d. | n.d. |

| 26 | o-Cymene | 96 | Gasoline, citrus | [54,59] | Te&Ts | 56.15 ± 11.023bB | 153.78 ± 18.436aA | 151.50 ± 28.686aA | 94.46 ± 15.536bA | 172.38 ± 21.329aA | 86.03 ± 15.595bB |

| 27 | Isoamyl butyrate | 90 | Green, fruity | [60] | Es | n.d. | n.d. | n.d. | 25.73 ± 5.723b | 66.30 ± 16.486a | 55.30 ± 5.393a |

| 28 | Acetoin | 96 | Sour milk | [51] | Ket | 185.42 ± 44.259cB | 484.17 ± 63.701aB | 331.24 ± 59.406bA | 439.72 ± 24.064bA | 1026.19 ± 125.392aA | 283.79 ± 6.800bA |

| 29 | 3-Methylacetoin | 87 | - | - | Ket | 6.87 ± 0.932bB | 13.14 ± 0.796aA | 8.24 ± 1.433bB | 18.18 ± 2.239aA | 17.12 ± 4.537aA | 17.12 ± 4.537aA |

| 30 | 1-Butoxy-2-propanol | 94 | - | - | Alc | 7.00 ± 1.595bB | 33.38 ± 5.554aB | 25.65 ± 4.623aA | 33.53 ± 4.275bA | 58.20 ± 7.734aA | 28.39 ± 3.179bA |

| 31 | 1-Hexanol | 96 | Sweet, green | [49] | Alc | 28.91 ± 5.329aB | 62.36 ± 46.499aB | 95.27 ± 14.049aB | 623.90 ± 309.213aA | 552.70 ± 159.944aA | 528.37 ± 238.769aA |

| 32 | 1-Octenyl acetate | 95 | - | - | Es | n.d. | n.d. | n.d. | 426.19 ± 57.704b | 775.69 ± 80.136a | 402.63 ± 25.727b |

| 33 | 3-Octanol | 84 | Mushroom, cheese | [54] | Alc | n.d. | n.d. | n.d. | 52.82 ± 5.691b | 89.54 ± 9.653a | 67.24 ± 10.446b |

| 34 | Hexyl butyrate | 93 | Fruity, green | [61] | Es | n.d. | n.d. | n.d. | 17.50 ± 2.985b | 34.34 ± 1.539a | 19.27 ± 3.282b |

| 35 | Acetic acid | 95 | Vinegar, sour, sharp, peppery, green | [51] | CA | 92.92 ± 21.149bB | 445.64 ± 79.887aA | 605.66 ± 92.910aA | 226.10 ± 45.177cA | 562.83 ± 68.060aA | 363.00 ± 28.421bB |

| 36 | trans-Linalool oxide (isomer) | 95 | - | - | Te&Ts | n.d. | n.d. | n.d. | 638.94 ± 108.438b | 1247.76 ± 186.259a | 633.61 ± 60.692b |

| 37 | 1-Octen-3-ol | 97 | Mushroom, metallic | [54] | Alc | 5.90 ± 1.212bB | 10.13 ± 0.379abB | 11.35 ± 2.807aB | 84.88 ± 9.979bA | 160.27 ± 25.469aA | 82.59 ± 2.777bA |

| 38 | trans-2-Pinanol | 86 | - | - | Te&Ts | n.d. | n.d. | n.d. | 17.53 ± 1.531b | 30.69 ± 3.142a | 19.49 ± 3.055b |

| 39 | trans-Linalool oxide (isomer) | 97 | - | - | Te&Ts | n.d. | n.d. | n.d. | 327.46 ± 49.616b | 558.54 ± 25.266a | 305.77 ± 29.301b |

| 40 | Linalyl acetate | 72 | Flower, fruit, lavender | [54] | Te&Ts | n.d. | n.d. | n.d. | 6.97 ± 0.964b | 10.38 ± 0.517a | 6.33 ± 0.437b |

| 41 | 2-Ethyl-1-hexanol | 90 | Mild, oily, sweet, slightly floral odor reminiscent of rose | [49] | Alc | n.d. | n.d. | n.d. | 11.11 ± 1.098a | 11.17 ± 1.211a | 10.57 ± 1.624a |

| 42 | Camphor | 93 | Camphor | [54] | Te&Ts | n.d. | n.d. | n.d. | 61.08 ± 7.291b | 101.92 ± 6.717a | 54.25 ± 4.126b |

| 43 | Benzaldehyde | 97 | Almonds, sugar, burnt | [51] | Ald | 49.32 ± 11.585bB | 116.58 ± 14.396aB | 115.88 ± 24.301aB | 211.96 ± 12.459aA | 271.88 ± 66.353aA | 266.70 ± 52.937aA |

| 44 | 2,3-Butanediol (optical isomer) | 95 | Fruity, onions | [51] | Alc | 28.42 ± 9.483cA | 77.80 ± 11.120bB | 145.40 ± 24.605aA | 39.73 ± 5.638bA | 156.05 ± 25.139aA | 119.33 ± 23.194aA |

| 45 | Linalool | 86 | Flower, lavender | [54,62] | Te&Ts | 9.49 ± 1.481abB | 8.77 ± 0.928bB | 15.56 ± 3.930aB | 2416.24 ± 313.723bA | 4130.24 ± 295.527aA | 2371.14 ± 188.355bA |

| 46 | Isobutyric acid | 94 | Cheesy, butter, rancid | [51] | CA | 12.31 ± 1.076c | 81.03 ± 16.303b | 142.94 ± 26.383a | n.d. | n.d. | n.d. |

| 47 | Linalyl isobutyrate ** | 87 | Cheesy, butter, rancid | [51] | Te&Ts | n.d. | n.d. | n.d. | 2143.98 ± 264.564b | 3817.29 ± 361.877a | 2297.54 ± 183.074b |

| 48 | 2,3-Butanediol (meso isomer) | 97 | Fruity, onions | [51] | Alc | 81.21 ± 31.384cA | 175.49 ± 32.577bB | 307.94 ± 34.889aA | 98.55 ± 13.951bA | 478.83 ± 157.897aA | 215.29 ± 86.648bA |

| 49 | 4-Terpineol *** | 86 | Green, liquorice, moldy | [48] | Te&Ts | n.d. | n.d. | n.d. | 237.05 ± 30.071b | 373.97 ± 35.340a | 258.37 ± 31.058b |

| 50 | Methyl decanoate | 89 | - | - | Es | 13.02 ± 1.438c | 30.64 ± 4.524b | 40.91 ± 4.701a | n.d. | n.d. | n.d. |

| 51 | Lavandulyl acetate | 93 | Floral odor reminiscent of lavender | [63] | Te&Ts | n.d. | n.d. | n.d. | 211.16 ± 29.910b | 355.30 ± 35.686a | 216.28 ± 19.026b |

| 52 | Butyric acid | 93 | Parmesan cheese, vomit, butanoic acid | [48] | CA | 81.43 ± 21.084cB | 212.27 ± 56.676bB | 389.59 ± 64.874aA | 469.11 ± 26.717aA | 643.62 ± 144.232aA | 506.19 ± 81.424aA |

| 53 | Phenylacetaldehyde | 94 | Floral, rosy, sweet, hyacinth-like | [62] | Ald | n.d. | n.d. | n.d. | 20.02 ± 1.922a | 23.38 ± 1.934a | 12.98 ± 3.641b |

| 54 | Isovaleric acid | 94 | Sweet, rancid, rotten, cheesy, Swiss cheese | [51] | CA | 64.68 ± 6.667cB | 373.42 ± 17.242bB | 537.57 ± 30.138aB | 207.08 ± 13.678cA | 553.87 ± 37.967bA | 702.86 ± 33.921aA |

| 55 | α-Terpineol | 83 | Oil, anise, mint | [54] | Te&Ts | n.d. | n.d. | n.d. | 20.99 ± 2.956b | 31.51 ± 2.595a | 18.49 ± 3.808b |

| 56 | Borneol | 95 | Camphor | [54] | Te&Ts | n.d. | n.d. | n.d. | 155.76 ± 21.932b | 250.67 ± 27.919a | 145.19 ± 32.109b |

| 57 | cis-Geranyl acetate | 86 | Rose, fruity, flower | [54] | Te&Ts | n.d. | n.d. | n.d. | 34.31 ± 3.226b | 56.58 ± 6.103a | 34.09 ± 6.532b |

| 58 | Linalool oxide (isomer) | 77 | Floral, honey-like | [61] | Te&Ts | n.d. | n.d. | n.d. | 10.48 ± 2.264b | 15.63 ± 1.521a | 9.73 ± 2.250b |

| 59 | Caproic acid | 93 | Bad breath, popcorn, goaty | [51] | CA | 185.93 ± 46.042bB | 403.05 ± 90.032aB | 451.28 ± 36.396aB | 807.79 ± 45.073bA | 1133.32 ± 206.390aA | 722.20 ± 16.136bA |

| 60 | 2,6-dimethyl-3,7-octadien-2,6-diol | 83 | - | - | Alc | n.d. | n.d. | n.d. | 37.95 ± 6.169b | 65.88 ± 5.583a | 43.95 ± 2.542b |

| 61 | Caryophyllene oxide | 87 | Terpene notes, weak woody–spicy | [64] | Te&Ts | n.d. | n.d. | n.d. | 26.76 ± 3.983b | 47.81 ± 1.866a | 31.78 ± 4.108b |

| 62 | Caprylic acid | 97 | Sweaty, rancid | [51] | CA | 76.51 ± 7.885bB | 188.50 ± 28.549aB | 192.79 ± 32.975aA | 193.80 ± 21.998bA | 342.19 ± 29.252aA | 240.40 ± 41.430bA |

| TOTAL, of which: | 3337.08 | 10,392.16 | 14,743.17 | 16,366.71 | 29,619.78 | 19,695.86 | |||||

| Alc | 775.14 | 2496.84 | 3551.32 | 2533.80 | 4577.67 | 2783.98 | |||||

| Ald | 71.77 | 123.26 | 115.88 | 263.50 | 302.12 | 299.12 | |||||

| AH | 38.79 | 94.52 | 131.71 | 32.90 | 130.69 | 77.05 | |||||

| CA | 513.79 | 1703.91 | 2319.84 | 1903.87 | 3235.83 | 2534.65 | |||||

| CyAlka | 275.86 | 1083.19 | 1636.99 | 575.97 | 1495.49 | 1022.22 | |||||

| Es | 270.86 | 540.06 | 680.26 | 1278.34 | 1921.57 | 1138.26 | |||||

| HoAlka | 1068.81 | 3527.63 | 5590.37 | 2176.24 | 4329.89 | 4329.89 | |||||

| Ket | 198.46 | 510.93 | 363.26 | 661.25 | 1474.94 | 509.98 | |||||

| Pyr | 12.38 | 50.35 | 63.41 | 21.12 | 21.45 | 10.31 | |||||

| Te&Ts | 111.21 | 261.48 | 290.13 | 6919.72 | 12130.13 | 6990.40 | |||||

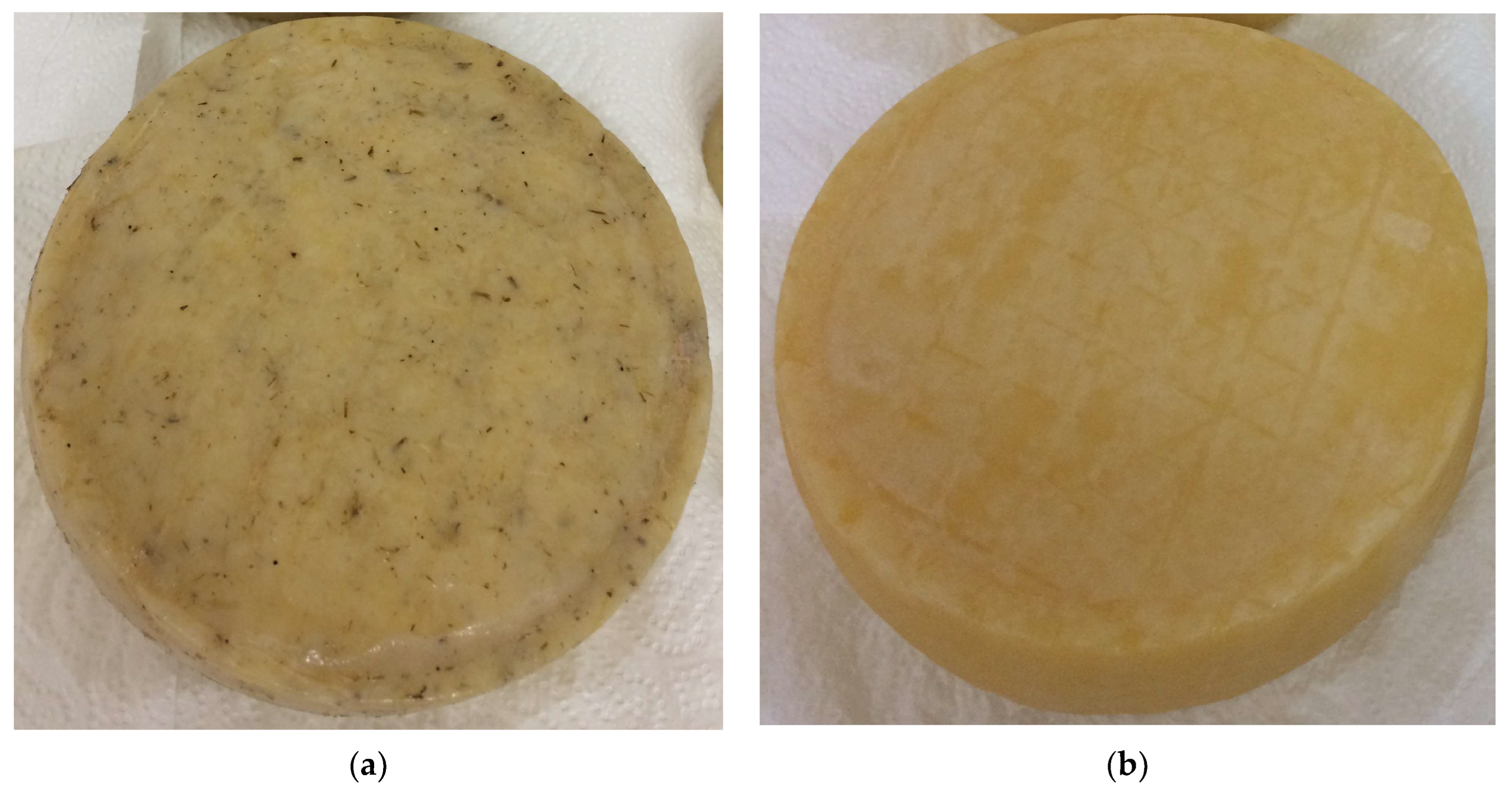

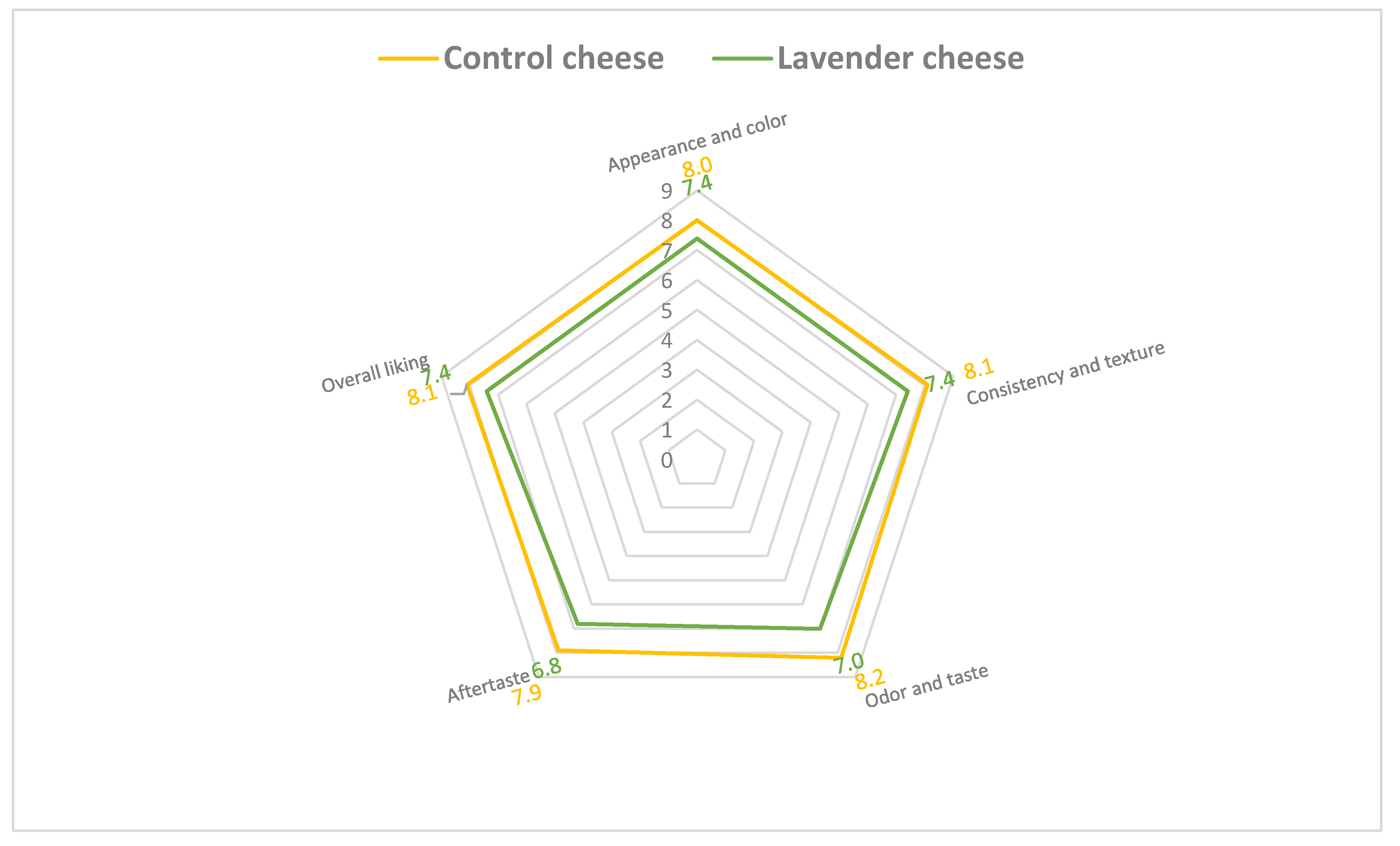

3.5. Sensory Properties of Gouda-Type Cheese and Consumers’ Acceptance and Purchase Intention

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Codex Alimentarius Commission. Standard for Gouda CXS 266-1966. Available online: https://www.fao.org/fao-who-codexalimentarius/sh-proxy/en/?lnk=1&url=https%253A%252F%252Fworkspace.fao.org%252Fsites%252Fcodex%252FStandards%252FCXS%2B266-1966%252FCXS_266e.pdf (accessed on 11 February 2023).

- Chen, C.; Tian, T.; Yu, H.; Yuan, H.; Wang, B.; Xu, Z.; Tian, H. Characterisation of the key volatile compounds of commercial Gouda cheeses and their contribution to aromas according to Chinese consumers’ preferences. Food Chem. X 2022, 15, 100416. [Google Scholar] [CrossRef] [PubMed]

- Choi, H.Y.; Yang, C.J.; Choi, K.S.; Bae, I. Characteristics of Gouda cheese supplemented with fruit liquors. J. Anim. Sci. Technol. 2015, 57, 15. [Google Scholar] [CrossRef]

- Semeniuc, C.A.; Zăpârţan, L.; Stan, L.; Pop, C.R.; Borş, M.D.; Rotar, A.M. Physicochemical and sensory properties of whey cheese with pine nuts. Bull. UASVM Food Sci. Technol. 2015, 72, 177–181. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Guo, H.Y.; Zhao, L.; Sun, W.F.; Zeng, S.S.; Lu, X.M.; Cao, X.; Ren, F.Z. Sensory profile and Beijing youth preference of seven cheese varieties. Food Qual. Prefer. 2011, 22, 101–109. [Google Scholar] [CrossRef]

- Semeniuc, C.A.; Mandrioli, M.; Socaci, B.S.; Socaciu, M.-I.; Fogarasi, M.; Podar, A.S.; Michiu, D.; Jimborean, A.M.; Mureşan, V.; Ionescu, S.R.; et al. Changes in lipid composition and oxidative status during ripening of Gouda-type cheese as influenced by addition of lavender flower powder. Int. Dairy J. 2022, 133, 105427. [Google Scholar] [CrossRef]

- Taherkhani, P.; Noori, N.; Akhondzadeh Basti, A.; Gandomi, H.; Alimohammadi, M. Antimicrobial effects of Kermanian black cumin (Bunium persicum Boiss.) essential oil in Gouda cheese matrix. J. Med. Plants 2015, 14, 76–85. [Google Scholar]

- Kim, Y.K.; Nam, M.S.; Bae, H.C. Characteristics of Gouda cheese supplemented with chili pepper extract microcapsules. Korean J. Food Sci. Anim. Resour. 2017, 37, 833–839. [Google Scholar] [PubMed]

- Düsterhöft, E.M.; Engels, W.; Huppertz, T. Dutch-type cheeses. In Global Cheesemaking Technology: Cheese Quality and Characteristics, 1st ed.; Papademas, P., Bintsis, T., Eds.; John Wiley & Sons, Ltd.: Chichester, UK, 2018; pp. 326–335. [Google Scholar]

- Majdik, A. Experimental Studies on Changes Made to Pre Press for Gouda Cheese with Spices. In Proceedings of the International Multidisciplinary Scientific GeoConference: SGEM, Varna, Bulgaria, 16–22 June 2013. [Google Scholar]

- Agboola, S.O.; Radovanovic-Tesic, M. Influence of Australian native herbs on the maturation of vacuum-packed cheese. LWT-Food Sci. Technol. 2002, 35, 575–583. [Google Scholar] [CrossRef]

- Park, W.; Yoo, J.; Oh, S.; Ham, J.S.; Jeong, S.G.; Kim, Y. Microbiological characteristics of Gouda cheese manufactured with pasteurized and raw milk during ripening using next generation sequencing. Food Sci. Anim. Resour. 2019, 39, 585. [Google Scholar] [CrossRef]

- Open Universiteit; Thames Polytechnic. Starter cultures for cheese production. In CIP: Biotechnological Innovations in Food Processing; Open Universiteit, Thames Polytechnic, Eds.; Butterworth-Heinemann: Oxford, UK, 1991; pp. 77–112. [Google Scholar]

- ISO 5534:2004|IDF 4:2004; Cheese and Processed Cheese—Determination of the Total Solids Content (Reference Method). ISO: Geneva, Switzerland, 2004.

- ISO 8968-1:2014|IDF 20-1:2014; Milk and Milk Products—Determination of Nitrogen Content—Part 1: Kjeldahl Principle and Crude Protein Calculation. ISO: Geneva, Switzerland, 2014.

- ISO 3433:2008|IDF 222:2008; Cheese—Determination of Fat Content—Van Gulik Method. ISO: Geneva, Switzerland, 2008.

- Nagy, M.; Semeniuc, C.A.; Socaci, S.A.; Pop, C.R.; Rotar, A.M.; Sălăgean, C.D.; Tofană, M. Utilization of brewer’s spent grain and mushrooms in fortification of smoked sausages. Food Sci. Technol. 2017, 37, 315–320. [Google Scholar] [CrossRef][Green Version]

- ISO 5943:2006|IDF 88:2006; Cheese and Processed Cheese Product—Determination of Chloride Conten—Potentiometric Titration Method. ISO: Geneva, Switzerland, 2006.

- STAS 6353-85; Milk and Milk Products—Determination of Acidity. ASRO: Bucharest, Romania, 1985.

- Ong, L.; Dagastine, R.R.; Kentish, S.E.; Gras, S.L. The effect of pH at renneting on the microstructure, composition and texture of Cheddar cheese. Food Res. Int. 2012, 48, 119–130. [Google Scholar] [CrossRef]

- Socaciu, M.I.; Fogarasi, M.; Simon, E.L.; Semeniuc, C.A.; Socaci, S.A.; Podar, A.S.; Vodnar, D.C. Effects of whey protein isolate-based film incorporated with tarragon essential oil on the quality and shelf-life of refrigerated brook trout. Foods 2021, 10, 401. [Google Scholar] [CrossRef]

- ISO 7889:2003|IDF 117:2003; Yogurt—Enumeration of Characteristic Microorganisms—Colony-Count Technique at 37 °C. ISO: Geneva, Switzerland, 2003.

- Cozzolino, R.; Martignetti, A.; De Giulio, B.; Malorni, L.; Addeo, F.; Picariello, G. SPME GC-MS monitoring of volatile organic compounds to assess typicity of Pecorino di Carmasciano ewe-milk cheese. Int. J. Dairy Technol. 2021, 74, 383–392. [Google Scholar] [CrossRef]

- Lignou, S.; Oloyede, O.O. Consumer acceptability and sensory profile of sustainable paper-based packaging. Foods 2021, 10, 990. [Google Scholar] [CrossRef]

- dos Reis Santos, J.; Gomes Hafemann, S.P.; Giani Pieretti, G.; Antigo, J.L.; Soares dos Santos Pozza, M.; da Silva Scapim, M.R.; Scaramal Madrona, G. Sensorial, microbiological, and physico-chemical analysis of Minas frescal cheese with oregano essential oil (Origanum vulgare) addition. Int. J. Food Sci. Nutr. Eng. 2014, 4, 86–90. [Google Scholar]

- Wang, Y.; Wu, J.; Lv, M.; Shao, Z.; Hungwe, M.; Wang, J.; Bai, X.; Xie, J.; Wang, Y.; Geng, W. Metabolism characteristics of lactic acid bacteria and the expanding applications in food industry. Front. Bioeng. Biotechnol. 2021, 9, 612285. [Google Scholar] [CrossRef]

- Mureşan, C.C.; Marc Vlaic, R.A.; Semeniuc, C.A.; Socaci, A.S.; Fărcaş, A.; Francisc, D.; Pop, C.R.; Rotar, A.; Dodan, A.; Mureşan, V.; et al. Changes in physicochemical and microbiological properties, fatty acid and volatile compound profiles of Apuseni cheese during ripening. Foods 2021, 10, 258. [Google Scholar] [CrossRef]

- Kanawjia, S.K.; Rajesh, P.; Sabikhi, L.; Singh, S. Flavour, chemical and textural profile changes in accelerated ripened Gouda cheese. LWT-Food Sci. Technol. 1995, 28, 577–583. [Google Scholar] [CrossRef]

- Ivanov, G.; Bogdanova, A.; Zsivanovits, G. Effect of ripening temperature on the texture of cow milk Kashkaval cheese. Prog. Agri. Eng. Sci. 2018, 14, 69–78. [Google Scholar] [CrossRef]

- Zheng, Y.; Liu, Z.; Mo, B. Texture profile analysis of sliced cheese in relation to chemical composition and storage temperature. J. Chem. 2016, 2016, 8690380. [Google Scholar] [CrossRef]

- Pinho, O.; Mendes, E.; Alves, M.M.; Ferreira, I.M.P.L.V.O. Chemical, physical, and sensorial characteristics of “Terrincho” ewe cheese: Changes during ripening and intravarietal comparison. J. Dairy Sci. 2004, 87, 249–257. [Google Scholar] [CrossRef]

- Librán, C.M.; Moro, A.; Zalacain, A.; Molina, A.; Carmona, M.; Berruga, M.I. Potential application of aromatic plant extracts to prevent cheese blowing. World J. Microbiol. Biotechnol. 2013, 29, 1179–1188. [Google Scholar] [CrossRef] [PubMed]

- Öztürk, H.İ.; Aydın, S.; Akın, N. Effect of lavender powder on microbial, physicochemical, sensory and functional properties of yoghurt. Int. J. Second. Metab. 2017, 4, 94–102. [Google Scholar] [CrossRef]

- Kınık, O.; Kesenkaş, H.; Ergönül, P.G.; Akan, E. The effect of using pro and prebiotics on the aromatic compounds, textural and sensorial properties of symbiotic goat cheese. Mljekarstvo 2017, 67, 71–85. [Google Scholar]

- Hayaloglu, A.A.; Karabulut, I. SPME/GC-MS characterization and comparison of volatiles of eleven varieties of Turkish cheeses. Int. J. Food Prop. 2013, 16, 1630–1653. [Google Scholar] [CrossRef]

- Gómez-Ruiz, J.Á.; Ballesteros, C.; González Viñas, M.Á.; Cabezas, L.; Martínez-Castro, I. Relationships between volatile compounds and odour in Manchego cheese: Comparison between artisanal and industrial cheeses at different ripening times. Lait 2002, 82, 613–628. [Google Scholar] [CrossRef][Green Version]

- Resch, P.; Guthy, K. Chloroform in milk and dairy products. Part A: Analysis of chloroform using static headspace gaschromatography. Dtsch Leb. Rundsch 1999, 95, 418–423. [Google Scholar]

- Van Leuven, I.; Van Caelenberg, T.; Dirinck, P. Aroma characterisation of Gouda-type cheeses. Int. Dairy J. 2008, 18, 790–800. [Google Scholar] [CrossRef]

- Van Hoorde, K.; Van Leuven, I.; Dirinck, P.; Heyndrickx, M.; Coudijzer, K.; Vandamme, P.; Huys, G. Selection, application and monitoring of Lactobacillus paracasei strains as adjunct cultures in the production of Gouda-type cheeses. Int. J. Food Microbiol. 2010, 144, 226–235. [Google Scholar] [CrossRef] [PubMed]

- Ordiales, E.; Martín, A.; Benito, M.J.; Hernández, A.; Ruiz-Moyano, S.; de Guía Córdoba, M. Role of the microbial population on the flavor of the soft-bodied cheese Torta del Casar. J. Dairy Sci. 2013, 96, 5477–5486. [Google Scholar] [CrossRef]

- Aminifar, M.; Hamedi, M.; Emam-Djomeh, Z.; Mehdinia, A. Investigation on proteolysis and formation of volatile compounds of Lighvan cheese during ripening. J. Food Sci. Technol. 2014, 51, 2454–2462. [Google Scholar] [CrossRef] [PubMed]

- Jung, H.J.; Ganesan, P.; Lee, S.J.; Kwak, H.S. Comparative study of flavor in cholesterol-removed Gouda cheese and Gouda cheese during ripening. J. Dairy Sci. 2013, 96, 1972–1983. [Google Scholar] [CrossRef] [PubMed]

- Ruyssen, T.; Janssens, M.; Van Gasse, B.; Van Laere, D.; Van der Eecken, N.; De Meerleer, M.; Vermeiren, L.; Van Hoorde, K.; Martins, J.C.; Uyttendaele, M.; et al. Characterisation of Gouda cheeses based on sensory, analytical and high-field 1H nuclear magnetic resonance spectroscopy determinations: Effect of adjunct cultures and brine composition on sodium-reduced Gouda cheese. Int. Dairy J. 2013, 33, 142–152. [Google Scholar] [CrossRef]

- Shiota, M.; Iwasawa, A.; Suzuki-Iwashima, A.; Iida, F. Effects of flavor and texture on the sensory perception of Gouda-type cheese varieties during ripening using multivariate analysis. J. Food Sci. 2015, 80, C2740–C2750. [Google Scholar] [CrossRef]

- Jo, Y.; Benoist, D.M.; Ameerally, A.; Drake, M.A. Sensory and chemical properties of Gouda cheese. J. Dairy Sci. 2017, 101, 1967–1989. [Google Scholar] [CrossRef] [PubMed]

- Sýkora, M.; Vítová, E.; Jeleń, H.H. Application of vacuum solid-phase microextraction for the analysis of semi-hard cheese volatiles. Eur. Food Res. Technol. 2020, 246, 573–580. [Google Scholar] [CrossRef]

- Semeniuc, C.A.; Mandrioli, M.; Rodriguez-Estrada, M.T.; Muste, S.; Lercker, G. Thiobarbituric acid reactive substances in flavored phytosterol-enriched drinking yogurts during storage: Formation and matrix interferences. Eur. Food Res. Technol. 2016, 242, 431–439. [Google Scholar] [CrossRef]

- Varming, C.; Petersen, M.A.; Poll, L. Comparison of isolation methods for the determination of important aroma compounds in black currant (Ribes nigrum L.) juice, using nasal impact frequency profiling. J. Agric. Food Chem. 2004, 52, 1647–1652. [Google Scholar] [CrossRef]

- PubChem. Available online: https://pubchem.ncbi.nlm.nih.gov/ (accessed on 12 February 2023).

- Zheng, L.-Y.; Sun, G.-M.; Liu, Y.-G.; Lv, L.-L.; Yang, W.-X.; Zhao, W.-F.; Wei, C.-B. Aroma volatile compounds from two fresh pineapple varieties in China. Int. J. Mol. Sci. 2012, 13, 7383–7392. [Google Scholar] [CrossRef]

- Lacroix, N.; St-Gelais, D.; Champagne, C.P.; Fortin, J.; Vuillemard, J.-C. Characterization of aromatic properties of old-style cheese starters. J. Dairy Sci. 2010, 93, 3427–3441. [Google Scholar] [CrossRef]

- O’Riordan, P.J.; Delahunty, C.M. Comparison of volatile compounds released during the consumption of Cheddar cheese with compounds extracted by vacuum distillation using gas chromatography–olfactometry. Flavour. Fragr. J. 2001, 16, 425–434. [Google Scholar] [CrossRef]

- Karagul Yuceer, Y.; Tuncel, B.; Guneser, O.; Engin, B.; Isleten, M.; Yasar, K.; Mendes, M. Characterization of aroma-active compounds, sensory properties, and proteolysis in Ezine cheese. J. Dairy Sci. 2009, 92, 4146–4157. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Z.; Li, Q.; Niu, Y.; Zhou, X.; Liu, J.; Xu, Y.; Xu, Z. Odor-active compounds of different lavender essential oils and their correlation with sensory attributes. Ind. Crop. Prod. 2017, 108, 748–755. [Google Scholar] [CrossRef]

- Gómez-Míguez, M.J.; Cacho, J.F.; Ferreira, V.; Vicario, I.M.; Heredia, F.J. Volatile components of Zalema white wines. Food Chem. 2007, 100, 1464–1473. [Google Scholar] [CrossRef]

- Song, H.S.; Sawamura, M.; Ito, T.; Ido, A.; Ukeda, H. Quantitative determination and characteristic flavour of daidai (Citrus aurantium L. var. cyathifera Y. Tanaka) peel oil. Flavour. Fragr. J. 2000, 15, 323–328. [Google Scholar] [CrossRef]

- Senoussi, A.; Rapisarda, T.; Schadt, I.; Chenchouni, H.; Saoudi, Z.; Senoussi, S.; Zidoune, O.A.; Zidoune, M.N.; Carpino, S. Formation and dynamics of aroma compounds during manufacturing-ripening of Bouhezza goat cheese. Int. Dairy J. 2022, 129, 105349. [Google Scholar] [CrossRef]

- Cho, I.H.; Namgung, H.-J.; Choi, H.-K.; Kim, Y.-S. Volatiles and key odorants in the pileus and stipe of pine-mushroom (Tricholoma matsutake Sing.). Food Chem. 2008, 106, 71–76. [Google Scholar] [CrossRef]

- Semeniuc, C.A.; Rotar, A.; Stan, L.; Pop, C.R.; Socaci, S.; Mireşan, V.; Muste, S. Characterization of pine bud syrup and its effect on physicochemical and sensory properties of kefir. CyTA-J. Food 2016, 14, 213–218. [Google Scholar] [CrossRef]

- Tsouli Sarhir, S.; Amanpour, A.; Bouseta, A.; Selli, S. Potent odorants and sensory characteristics of the soft white cheese “Jben”: Effect of salt content. Flavour. Fragr. J. 2022, 37, 243–253. [Google Scholar] [CrossRef]

- Guo, X.; Ho, C.-T.; Wan, X.; Zhu, H.; Liu, Q.; Wen, Z. Changes of volatile compounds and odor profiles in Wuyi rock tea during processing. Food Chem. 2021, 341, 128230. [Google Scholar] [CrossRef]

- Zhu, M.; Sun, J.; Zhao, H.; Wu, F.; Xue, X.; Wu, L.; Cao, W. Volatile compounds of five types of unifloral honey in Northwest China: Correlation with aroma and floral origin based on HS-SPME/GC–MS combined with chemometrics. Food Chem. 2022, 384, 132461. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Wang, P. Aroma characteristics of lavender extract and essential oil from Lavandula angustifolia Mill. Molecules 2020, 25, 5541. [Google Scholar] [CrossRef] [PubMed]

- Bail, S.; Buchbauer, G.; Schmidt, E.; Wanner, J.; Slavchev, A.; Stoyanova, A.; Denkova, Z.; Geissler, M.; Jirovetz, L. GC-MS-analysis, antimicrobial activities and olfactory evaluation of essential davana (Artemisia pallens Wall. ex DC) oil from India. Nat. Prod. Commun. 2008, 3, 1057–1062. [Google Scholar] [CrossRef]

| Parameter/Energy Value | Control Cheese | Lavender Cheese | ||||

|---|---|---|---|---|---|---|

| T1 | T2 | T3 | T1 | T2 | T3 | |

| Moisture (%) | 36.84 ± 0.270aA | 35.80 ± 0.060abA | 34.97 ± 0.064bA | 37.87 ± 0.282aA | 36.57 ± 0.630abA | 35.48 ± 0.165bA |

| Protein (%) | 21.13 ± 0.191cA | 22.11 ± 0.014bA | 23.17 ± 0.212aB | 21.55 ± 0.078cA | 22.39 ± 0.134bA | 24.90 ± 0.113aA |

| Fat (%) | 28.25 ± 0.354cA | 29.50 ± 0.0bA | 30.75 ± 0.354aA | 29.25 ± 0.354aA | 29.25 ± 0.354aA | 29.75 ± 0.354aA |

| Fat in dry matter (%) | 44.73 ± 0.057cB | 45.95 ± 0.042bA | 47.29 ± 0.495aA | 47.08 ± 0.354aA | 46.11 ± 0.099aA | 46.11 ± 0.431aA |

| Ash (%) | 4.28 ± 0.014bA | 4.49 ± 0.156bA | 5.45 ± 0.014aA | 4.25 ± 0.007bA | 4.31 ± 0.035bA | 5.06 ± 0.028aB |

| Total carbohydrate (%) | 9.51 ± 0.700aA | 8.10 ± 0.205aA | 5.66 ± 0.488bA | 7.09 ± 0.0aB | 7.50 ± 0.177aA | 4.82 ± 0.106bA |

| Sodium chloride (%) | 2.37 ± 0.028cA | 2.60 ± 0.021bB | 2.71 ± 0.007aB | 2.26 ± 0.028cA | 2.91 ± 0.028bA | 3.28 ± 0.071aA |

| pH | 4.87 ± 0.014aB | 4.73 ± 0.007bA | 4.60 ± 0.0cA | 4.99 ± 0.007aA | 4.83 ± 0.092abA | 4.65 ± 0.042bA |

| Titratable acidity (°T) | 85.2 ± 0.566cA | 90.6 ± 0.849bA | 95.0 ± 0.283aA | 79.8 ± 0.283cB | 83.8 ± 0.283bB | 92.0 ± 0.0aB |

| Energy value (kcal/100 g) | 377 ± 4.950bA | 387 ± 0.707abA | 393 ± 2.121aA | 378 ± 2.828aA | 383 ± 4.243aA | 387 ± 2.121aA |

| Texture Attribute | Control Cheese | Lavender Cheese | ||||

|---|---|---|---|---|---|---|

| T1 | T2 | T3 | T1 | T2 | T3 | |

| Hardness (N) | 35.43 ± 2.456bA | 36.52 ± 5.547bA | 53.07 ± 10.105aA | 24.72 ± 3.534bB | 40.56 ± 10.605aA | 41.51 ± 9.777aA |

| Cohesiveness | 0.46 ± 0.066aA | 0.37 ± 0.047bA | 0.24 ± 0.028cA | 0.44 ± 0.061aA | 0.29 ± 0.036bB | 0.24 ± 0.030bA |

| Springiness index | 0.83 ± 0.026aA | 0.79 ± 0.061aA | 0.54 ± 0.076bA | 0.82 ± 0.088aA | 0.80 ± 0.048aA | 0.68 ± 0.019bA |

| Gumminess (N) | 16.09 ± 2.530aA | 19.90 ± 6.244aA | 8.94 ± 2.153bA | 10.72 ± 0.987aB | 11.72 ± 2.580aB | 10.17 ± 3.366aA |

| Chewiness index (N) | 13.35 ± 2.229aA | 15.71 ± 5.299aA | 4.90 ± 1.587bA | 8.57 ± 1.121aB | 9.43 ± 2.914aB | 6.96 ± 1.060bA |

| Parameter | Control Cheese | Lavender Cheese | ||||

|---|---|---|---|---|---|---|

| T1 | T2 | T3 | T1 | T2 | T3 | |

| Lactobacilli count | 9.5 ± 0.007cB | 9.7 ± 0.009bB | 9.8 ± 0.004aB | 9.7 ± 0.005cA | 9.8 ± 0.004bA | 9.9 ± 0.006aA |

| Streptococci count | 8.7 ± 0.011cB | 9.2 ± 0.011bB | 9.3 ± 0.016aB | 9.0 ± 0.024cA | 9.5 ± 0.012bA | 9.6 ± 0.013aA |

| Total lactic acid bacteria count | 18.2 ± 0.004cB | 18.9 ± 0.002bB | 19.1 ± 0.020aB | 18.7 ± 0.019cA | 19.3 ± 0.008bA | 19.5 ± 0.020aA |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Semeniuc, C.A.; Mandrioli, M.; Tura, M.; Socaci, B.S.; Socaciu, M.-I.; Fogarasi, M.; Michiu, D.; Jimborean, A.M.; Mureşan, V.; Ionescu, S.R.; et al. Impact of Lavender Flower Powder as a Flavoring Ingredient on Volatile Composition and Quality Characteristics of Gouda-Type Cheese during Ripening. Foods 2023, 12, 1703. https://doi.org/10.3390/foods12081703

Semeniuc CA, Mandrioli M, Tura M, Socaci BS, Socaciu M-I, Fogarasi M, Michiu D, Jimborean AM, Mureşan V, Ionescu SR, et al. Impact of Lavender Flower Powder as a Flavoring Ingredient on Volatile Composition and Quality Characteristics of Gouda-Type Cheese during Ripening. Foods. 2023; 12(8):1703. https://doi.org/10.3390/foods12081703

Chicago/Turabian StyleSemeniuc, Cristina Anamaria, Mara Mandrioli, Matilde Tura, Beatrice Sabrina Socaci, Maria-Ioana Socaciu, Melinda Fogarasi, Delia Michiu, Anamaria Mirela Jimborean, Vlad Mureşan, Simona Raluca Ionescu, and et al. 2023. "Impact of Lavender Flower Powder as a Flavoring Ingredient on Volatile Composition and Quality Characteristics of Gouda-Type Cheese during Ripening" Foods 12, no. 8: 1703. https://doi.org/10.3390/foods12081703

APA StyleSemeniuc, C. A., Mandrioli, M., Tura, M., Socaci, B. S., Socaciu, M.-I., Fogarasi, M., Michiu, D., Jimborean, A. M., Mureşan, V., Ionescu, S. R., Rotar, M. A., & Gallina Toschi, T. (2023). Impact of Lavender Flower Powder as a Flavoring Ingredient on Volatile Composition and Quality Characteristics of Gouda-Type Cheese during Ripening. Foods, 12(8), 1703. https://doi.org/10.3390/foods12081703