Incorporation of Buckwheat Flour at Different Particle Sizes and Distinctive Doses in Wheat Flour to Manufacture an Improved Wheat Bread

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Preparation of Optimal Composite Flour

2.3. Dough and Bread-Making Procedure

2.4. Proximate Analysis of Samples

2.5. Minerals Content Determination

2.6. Total Free Amino Acid Content Determination

2.7. Dough Rheological Test

2.8. Bread Physical and Textural Characteristics Determination

2.9. Sensory Evaluation of Breads

2.10. Statistical Analysis

3. Results

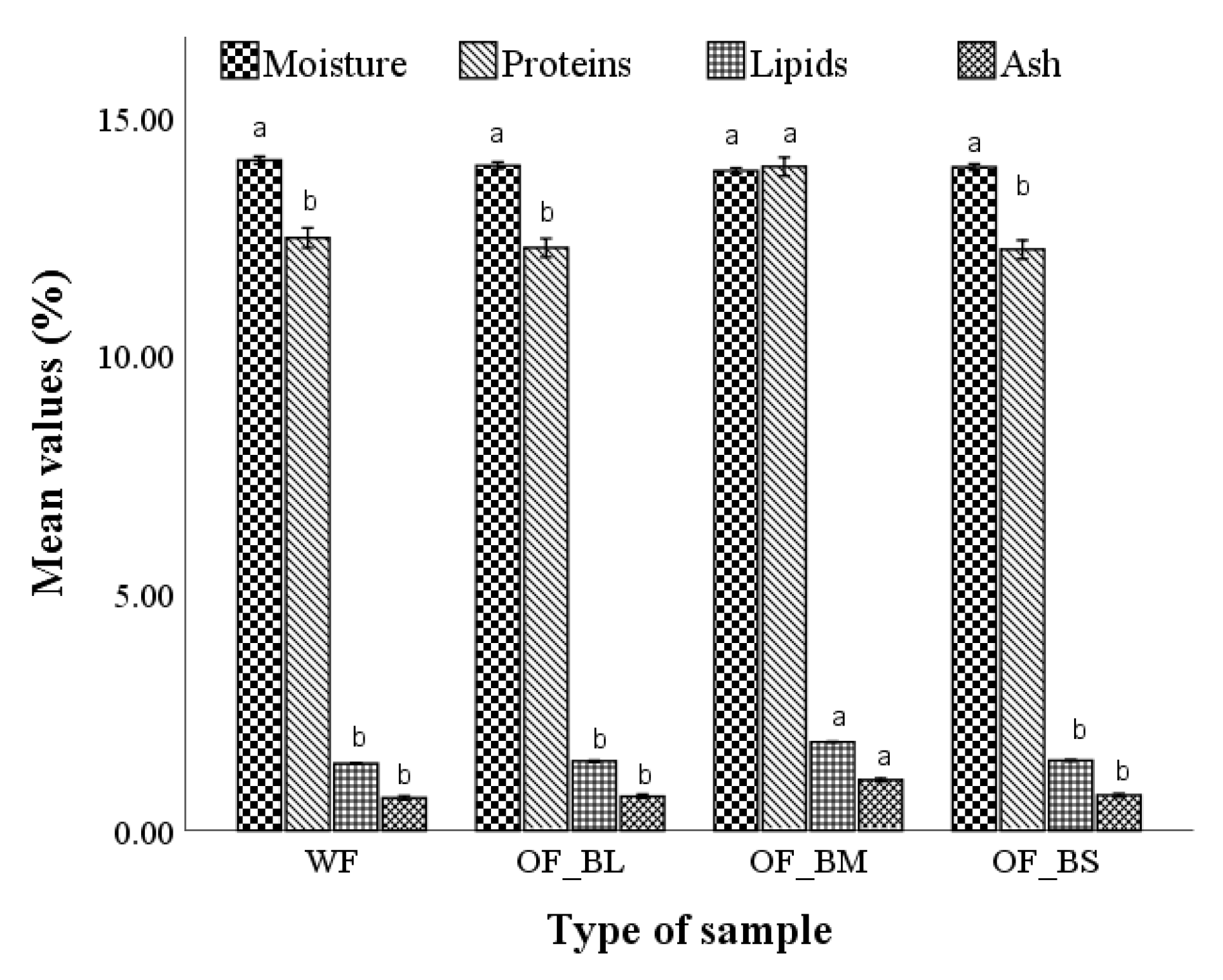

3.1. Physico-Chemical Parameters of Wheat Flour and Optimal Composite Flours

3.2. Wheat–Buckwheat Composite Flour and Bread Characterization

3.3. Advanced Characterization of the Optimal Breads

3.3.1. The Physical Characteristics of the Optimal Breads

3.3.2. Optimal Bread Texture

3.3.3. Nutritional Composition and Energy Value of Optimal Breads

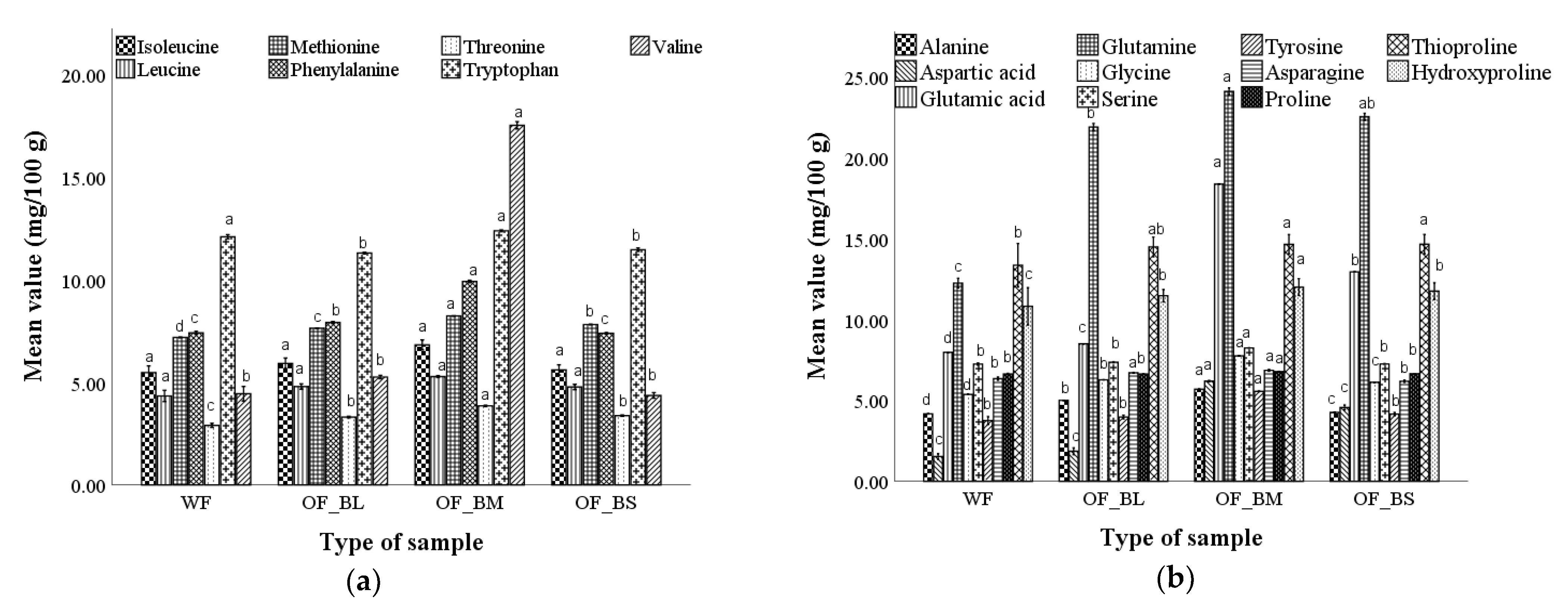

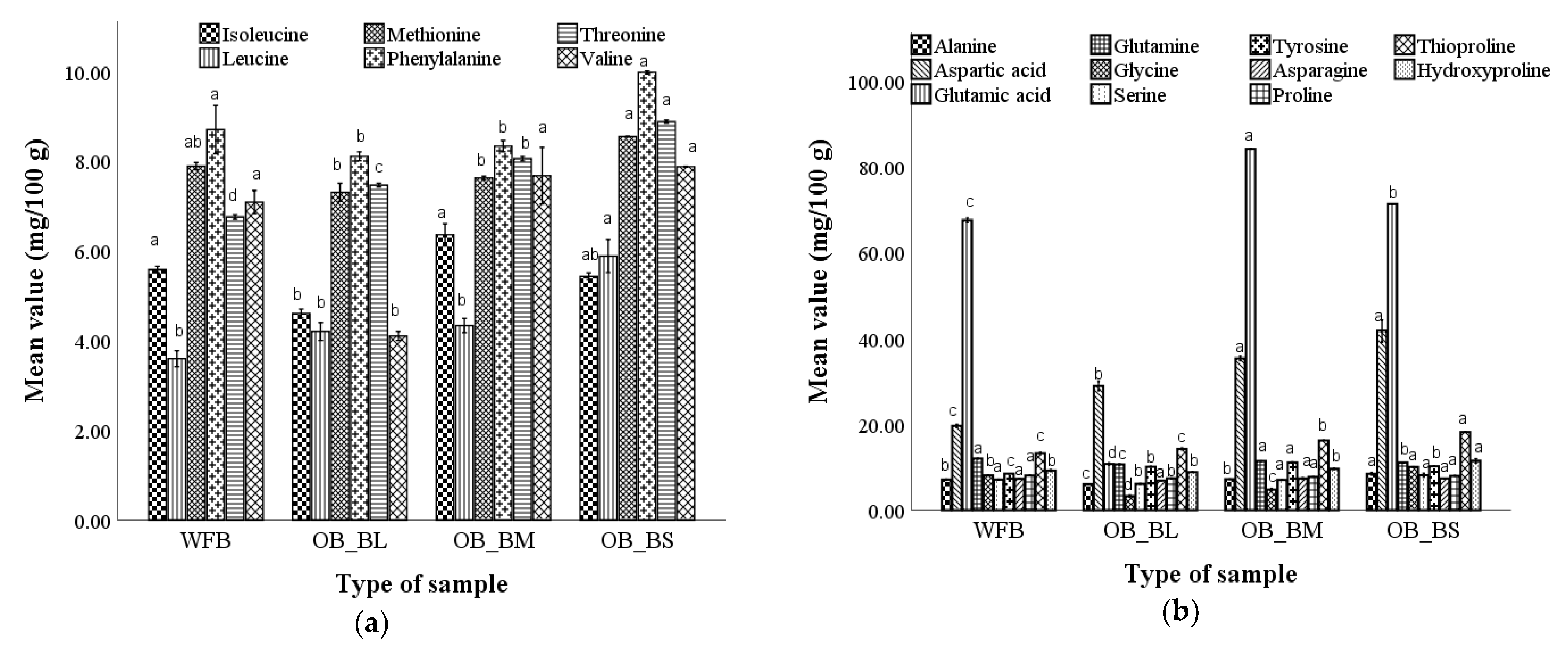

3.3.4. Amino Acid Profile of Optimal Bread Samples

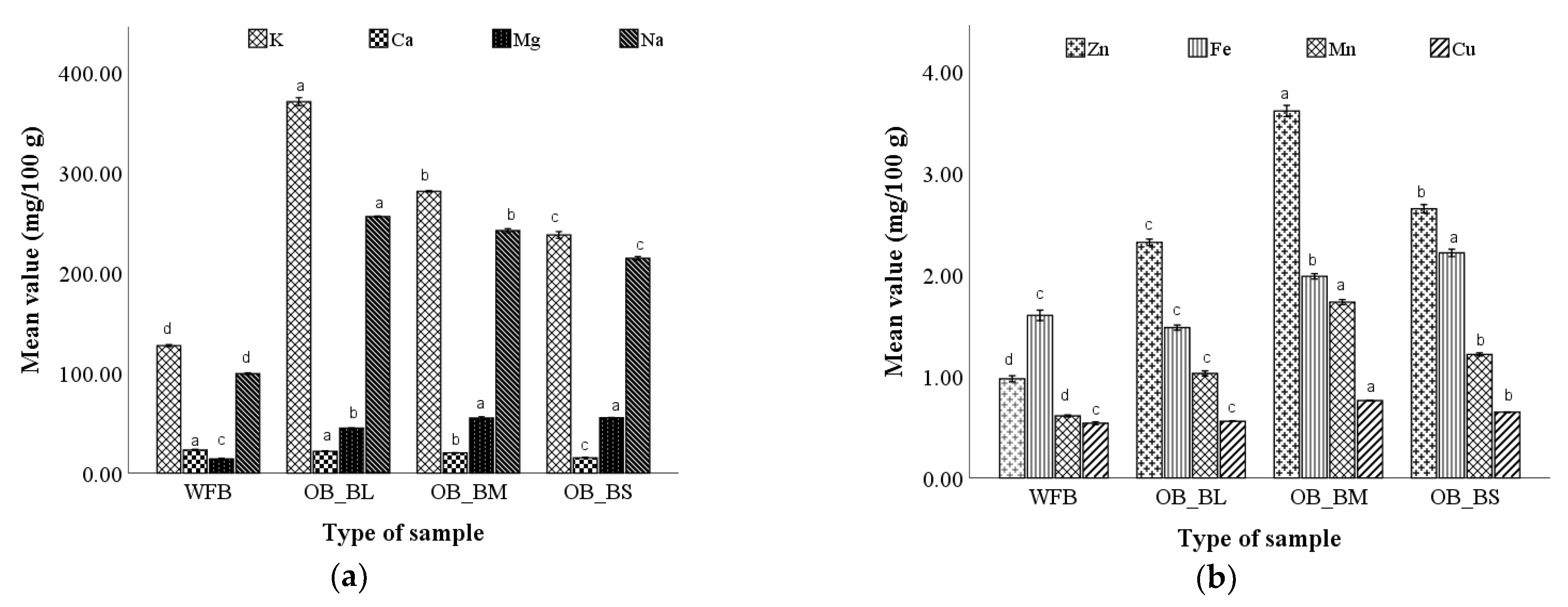

3.3.5. Minerals Content of Optimal Bread Samples

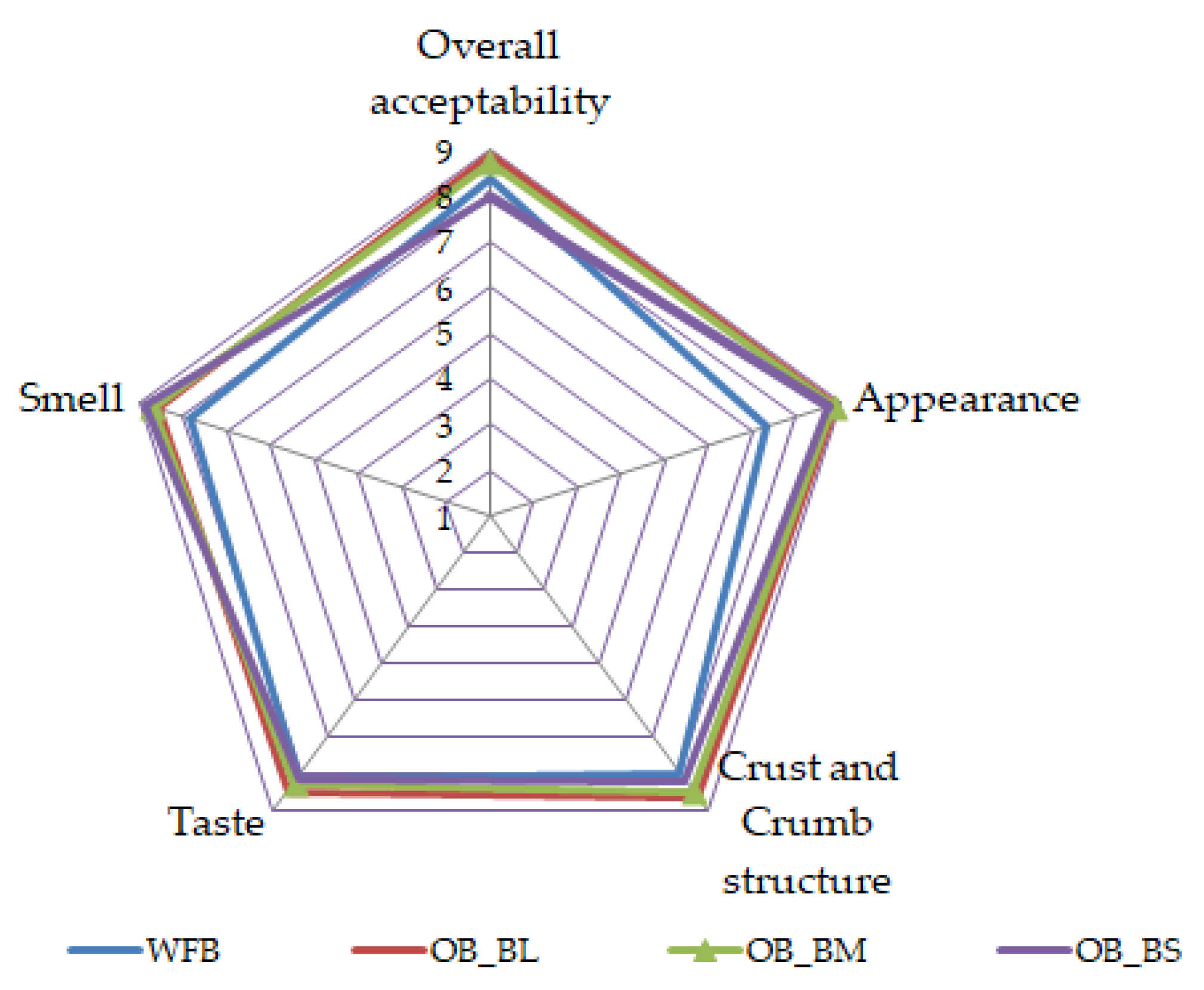

3.3.6. Sensory Evaluation of the Optimal Breads

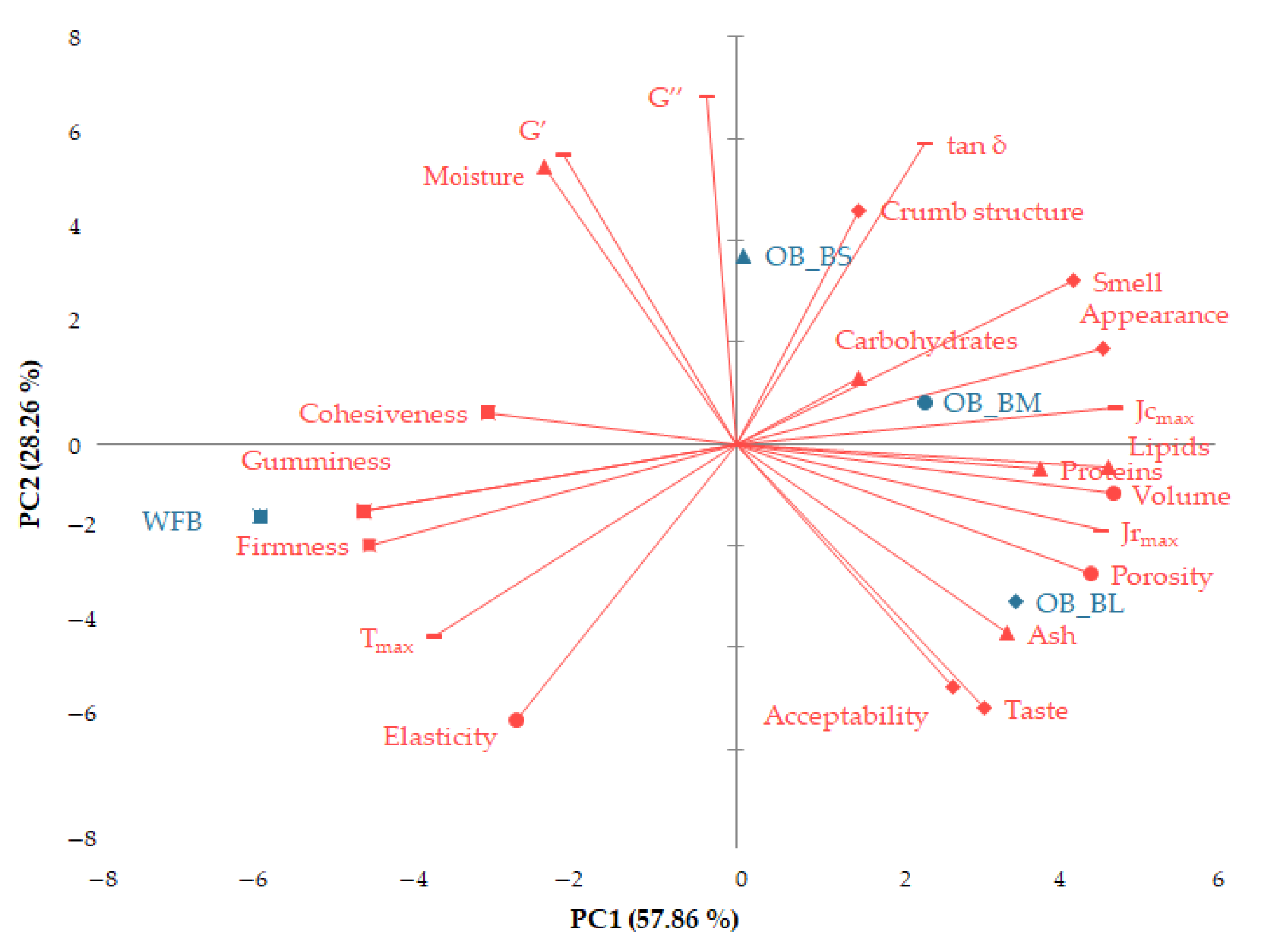

3.3.7. Evaluating Relationships between Variables

4. Discussion

4.1. Nutritional Characteristics of Optimal Wheat–Buckwheat Composition Flour

4.2. The Technological Behavior of the Optimal Wheat–Buckwheat Composite Flour and the Bread Baking Parameters

4.3. Complex Characterization of the Optimal Bread Samples

4.4. The Comprehensive Overview of Dough and Bread Characteristics

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dyner, L.; Drago, S.R.; Piñeiro, A.; Sánchez, H.; González, R.; Villaamil, E.; Valencia, M.E. Composition and potential contribution of iron, calcium and zinc of bread and pasta made with wheat and amaranth flours. Arch. Latinoam Nutr. 2007, 57, 69–77. [Google Scholar] [PubMed]

- Coțovanu, I.; Stroe, S.-G.; Ursachi, F.; Mironeasa, S. Addition of Amaranth Flour of Different Particle Sizes at Established Doses in Wheat Flour to Achieve a Nutritional Improved Wheat Bread. Foods 2023, 12, 133. [Google Scholar] [CrossRef] [PubMed]

- Ungureanu-Iuga, M.; Atudorei, D.; Codină, G.G.; Mironeasa, S. Rheological Approaches of Wheat Flour Dough Enriched with Germinated Soybean and Lentil. Appl. Sci. 2021, 11, 11706. [Google Scholar] [CrossRef]

- Coţovanu, I.; Mironeasa, S. Effects of molecular characteristics and microstructure of amaranth particle sizes on dough rheology and wheat bread characteristics. Sci. Rep. 2022, 12, 7883. [Google Scholar] [CrossRef] [PubMed]

- Raczyk, M.; Kruszewski, B.; Zachariasz, E. Effect of Tomato, Beetroot and Carrot Juice Addition on Physicochemical, Antioxidant and Texture Properties of Wheat Bread. Antioxidants 2022, 11, 2178. [Google Scholar] [CrossRef]

- Coțovanu, I.; Mironeasa, S. Impact of Different Amaranth Particle Sizes Addition Level on Wheat Flour Dough Rheology and Bread Features. Foods 2021, 10, 1539. [Google Scholar] [CrossRef]

- Coţovanu, I.; Mironeasa, S. Features of Bread Made from Different Amaranth Flour Fractions Partially Substituting Wheat Flour. Appl. Sci. 2022, 12, 897. [Google Scholar] [CrossRef]

- Rollán, G.C.; Gerez, C.L.; LeBlanc, J.G. Lactic Fermentation as a Strategy to Improve the Nutritional and Functional Values of Pseudocereals. Front. Nutr. 2019, 6, 98. [Google Scholar] [CrossRef]

- Haros, C.M.; Sanz-Penella, J.M. Food uses of whole pseudocereals. In Pseudocereals: Chemistry and Technology; John Wiley & Sons: Hoboken, NJ, USA, 2017; pp. 163–192. [Google Scholar]

- Paucar-Menacho, L.M.; Simpalo-López, W.D.; Castillo-Martínez, W.E.; Esquivel-Paredes, L.J.; Martínez-Villaluenga, C. Improving Nutritional and Health Benefits of Biscuits by Optimizing Formulations Based on Sprouted Pseudocereal Grains. Foods 2022, 11, 1533. [Google Scholar] [CrossRef]

- Sanz-Penella, J.; Wronkowska, M.; Soral-Smietana, M.; Haros, M. Effect of whole amaranth flour on bread properties and nutritive value. LWT Food Sci. Technol. 2013, 50, 679–685. [Google Scholar] [CrossRef]

- Miranda-Ramos, K.C.; Sanz-Ponce, N.; Haros, C.M. Evaluation of technological and nutritional quality of bread enriched with amaranth flour. LWT 2019, 114, 108418. [Google Scholar] [CrossRef]

- Sciarini, L.S.; Steffolani, M.E.; Fernández, A.; Paesani, C.; Pérez, G.T. Gluten-free breadmaking affected by the particle size and chemical composition of quinoa and buckwheat flour fractions. Food Sci. Technol. Int. 2020, 26, 321–332. [Google Scholar] [CrossRef] [PubMed]

- Demin, M.; Vučelić-Radović, B.; Banjac, N.; Tipsina, N.N.; Milovanović, M.M. Buckwheat and quinoa seeds as supplements in wheat bread production. Hem. Ind. 2013, 67, 115–121. [Google Scholar] [CrossRef]

- Coţovanu, I.; Mironeasa, S. Influence of Buckwheat Seed Fractions on Dough and Baking Performance of Wheat Bread. Agronomy 2022, 12, 137. [Google Scholar] [CrossRef]

- Coţovanu, I.; Mironeasa, C.; Mironeasa, S. Insights into the Potential of Buckwheat Flour Fractions in Wheat Bread Dough. Appl. Sci. 2022, 12, 2302. [Google Scholar] [CrossRef]

- Buresova, I.; Tokar, M.; Marecek, J.; Hivna, L.; Famera, O.; Sottníkova, V. The comparison of the effect of added amaranth, buckwheat, chickpea, corn, millet and quinoa flour on rice dough rheological characteristics, textural and sensory quality of bread. J. Cereal Sci. 2017, 75, 158–164. [Google Scholar] [CrossRef]

- Sinkovič, L.; Deželak, M.; Meglič, V. Macro/microelements, nutrients and bioactive components in common and Tartary buckwheat (Fagopyrum spp.) grain and stone-milling fractions. LWT 2022, 161, 113422. [Google Scholar] [CrossRef]

- Lin, L.Y.; Hsieh, Y.J.; Liu, H.M.; Lee, C.C.; Mau, J.L. Flavor components in buckwheat bread. J. Food Process Preserv. 2009, 33, 814–826. [Google Scholar] [CrossRef]

- Yildiz, G.; Bilgicli, N. Effects of whole buckwheat flour on physical, chemical, and sensory properties of flat bread, lavas. Czech J. Food Sci. 2012, 30, 534–540. [Google Scholar] [CrossRef]

- Yildiz, G.; Bilgicli, N. Utilisation of buckwheat flour in leavened and unleavened Turkish flat breads. Qual. Assur. Saf. Crops Foods 2015, 7, 207–215. [Google Scholar] [CrossRef]

- Skrabanja, V.; Liljeberg Elmståhl, H.G.; Kreft, I.; Björck, I.M. Nutritional properties of starch in buckwheat products: Studies in vitro and in vivo. J. Agric. Food Chem. 2001, 49, 490–496. [Google Scholar] [CrossRef] [PubMed]

- Chlopicka, J.; Pasko, P.; Gorinstein, S. Total phenolic and total flavonoid content, antioxidant activity and sensory evaluation of pseudocereal breads. LWT Food Sci. Technol. 2012, 46, 548–555. [Google Scholar] [CrossRef]

- Moroni, A.V.; Dal Bello, F.; Zannini, E.; Arendt, E.K. Impact of sourdough on buckwheat flour, batter and bread: Biochemical, rheological and textural insights. J. Cereal Sci. 2011, 54, 195–202. [Google Scholar] [CrossRef]

- Moroni, A.V.; Zannini, E.; Sensidoni, G.; Arendt, E.K. Exploitation of buckwheat sourdough for the production of wheat bread. Eur. Food Res. Technol. 2012, 235, 659–668. [Google Scholar] [CrossRef]

- Taylor, J.R.; Taylor, J.; Campanella, O.H.; Hamaker, B.R. Functionality of the storage proteins in gluten-free cereals and pseudocereals in dough systems. J. Cereal Sci. 2016, 67, 22–34. [Google Scholar] [CrossRef]

- Taylor, J.R.N.; Parker, M.L. Quinoa. In Pseudocereals and Less Common Cereals: Grain Properties and Utilization; Belton, P.S., Taylor, J.R.N., Eds.; Springer: Berlin, Germany, 2002; pp. 93–122. [Google Scholar]

- El-Sohaimy, S.A.; Shehata, M.G.; Toshev, A.D.; Teha, M.; Zeitoun, M.A.; Zeitoun, A.M. Development and characterization of functional pan bread supplemented with quinoa flour. J. Food Process. Preserv. 2021, 45, e15180. [Google Scholar] [CrossRef]

- Graziano, S.; Agrimonti, C.; Marmiroli, N.; Gullì, M. Utilisation and limitations of pseudocereals (quinoa, amaranth, and buckwheat) in food production: A review. Trends Food Sci. Technol. 2022, 125, 154–165. [Google Scholar] [CrossRef]

- Kurek, M.A.; Sokolova, N. Optimization of bread quality with quinoa flour of different particle size and degree of wheat flour replacement. Food Sci. Technol. 2019, 40, 307–314. [Google Scholar] [CrossRef]

- de la Hera, E.; Talegón, M.; Caballero, P.; Gómez, M. Influence of maize flour particle size on gluten-free breadmaking. J. Sci. Food Agric. 2013, 93, 924–932. [Google Scholar] [CrossRef]

- Coțovanu, I.; Mironeasa, S. Buckwheat Seeds: Impact of Milling Fractions and Addition Level on Wheat Bread Dough Rheology. Appl. Sci. 2021, 11, 1731. [Google Scholar] [CrossRef]

- Coțovanu, I.; Batariuc, A.; Mironeasa, S. Characterization of Quinoa Seeds Milling Fractions and Their Effect on the Rheological Properties of Wheat Flour Dough. Appl. Sci. 2020, 10, 7225. [Google Scholar] [CrossRef]

- ICC. Standard Methods of the International Association for Cereal Chemistry. Methods 110/1, 105/2, 136, 104/1; 173 International Association for Cereal Chemistry: Vienna, Austria, 2010. [Google Scholar]

- Raczyk, M.; Kruszewski, B.; Michałowska, D. Effect of Coconut and Chestnut Flour Supplementations on Texture, Nutritional and Sensory Properties of Baked Wheat Based Bread. Molecules 2021, 26, 4641. [Google Scholar] [CrossRef] [PubMed]

- Coţovanu, I.; Mironeasa, C.; Mironeasa, S. Nutritionally Improved Wheat Bread Supplemented with Quinoa Flour of Large, Medium and Small Particle Sizes at Typical Doses. Plants 2023, 12, 698. [Google Scholar] [CrossRef]

- Chetrariu, A.; Ursachi, V.F.; Dabija, A. Evaluation of the fatty acids and amino acids profiles in spent grain from brewing and malt whisky. Sci. Study Res. Chem. Chem. Eng. Biotechnol. Food Ind. 2022, 23, 167–177. [Google Scholar]

- Oroian, M.; Dranca, F.; Ursachi, F. Characterization of Romanian Bee Pollen—An Important Nutritional Source. Foods 2022, 11, 2633. [Google Scholar] [CrossRef] [PubMed]

- Mironeasa, S.; Iuga, M.; Zaharia, D.; Mironeasa, C. Rheological Analysis of Wheat Flour Dough as Influenced by Grape Peels of Different Particle Sizes and Addition Levels. Food Bioprocess Technol. 2018, 12, 228–245. [Google Scholar] [CrossRef]

- Hu, Y.; Sjoberg, S.M.; Chen, C.; Hauvermale, A.L.; Morris, C.F.; Delwiche, S.R.; Zhang, Z. As the number falls, alternatives to the Hagberg–Perten falling number method: A review. Compr. Rev. Food Sci. Food Saf. 2022, 21, 2105–2117. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC International, 19th ed.; AOAC: Washington, DC, USA, 2005. [Google Scholar]

- SR 90:2007; Wheat Flour. Analysis Method. Romanian Standards Association: Bucharest, Romania, 2007.

- SR ISO 11035:2007; Sensory Analysis—Identification and Selection of Descriptors for Establishing a Sensory Profile by a Multidimensional Approach. International Organization for Standardization: Geneva, Switzerland, 1994.

- Martín-García, B.; Pasini, F.; Verardo, V.; Gómez-Caravaca, A.M.; Marconi, E.; Caboni, M.F. Distribution of Free and Bound Phenolic Compounds in Buckwheat Milling Fractions. Foods 2019, 8, 670. [Google Scholar] [CrossRef]

- Han, L.; Cheng, Y.; Qiu, S.; Tatsumi, E.; Shen, Q.; Lu, Z.; Li, L. The effects of vital wheat gluten and transglutaminase on the thermomechanical and dynamic rheological properties of buckwheat dough. Food Bioprocess Technol. 2013, 6, 561–569. [Google Scholar] [CrossRef]

- Shevkani, K.; Singh, N.; Kaur, A.; Rana, J.C. Physicochemical, pasting, and functional properties of amaranth seed flours: Effects of lipids removal. J. Food Sci. 2014, 79, C1271–C1277. [Google Scholar] [CrossRef]

- Siwatch, M.; Yadav, R.B.; Yadav, B.S. Chemical, physicochemical, pasting and microstructural properties of amaranth (Amaranthus hypochondriacus) flour as affected by different processing treatments. Qual. Assur. Saf. Crops Foods 2019, 11, 3–13. [Google Scholar] [CrossRef]

- Alarcón-García, M.A.; Perez-Alvarez, J.A.; López-Vargas, J.H.; Pagán-Moreno, M.J. Techno-Functional Properties of New Andean Ingredients: Maca (Lepidium meyenii) and Amaranth (Amaranthus caudatus). Proceedings 2021, 70, 74. [Google Scholar] [CrossRef]

- Golijan, J.; Milinčić, D.D.; Petronijević, R.; Pešić, M.B.; Barać, M.B.; Sečanski, M.; Kostić, A. Ž. The fatty acid and triacylglycerol profiles of conventionally and organically produced grains of maize, spelt and buckwheat. J. Cereal Sci. 2019, 90, 102845. [Google Scholar] [CrossRef]

- Prego, I.; Maldonado, S.; Otegui, M. Seed structure and localization of reserves in Chenopodium quinoa. Ann. Bot. 1998, 82, 481–488. [Google Scholar] [CrossRef]

- Bonafaccia, G.; Marocchini, M.; Kreft, I. Composition and technological properties of the flour and bran from common and tartary buckwheat. Food Chem. 2003, 80, 9–15. [Google Scholar] [CrossRef]

- Ahmed, A.; Khalid, N.; Ahmad, A.; Abbasi, N.A.; Latif, M.S.Z.; Randhawa, M.A. Phytochemicals and biofunctional properties of buckwheat: A review. J. Agric. Sci. 2014, 152, 349–369. [Google Scholar] [CrossRef]

- Li, S.Q.; Zhang, H.Q. Advances in the development of functional foods from buckwheat. Crit. Rev. Food Sci. Nutr. 2001, 41, 451–464. [Google Scholar] [CrossRef]

- Gamel, T.H.; Mesallam, A.S.; Damir, A.A.; Shekib, L.A.; Linssen, J.P. Characterization of amaranth seed oils. J. Food Lipids 2007, 14, 323–334. [Google Scholar] [CrossRef]

- Joshi, D.C.; Chaudhari, G.V.; Sood, S.; Kant, L.; Pattanayak, A.; Zhang, K.; Zhou, M. Revisiting the versatile buckwheat: Reinvigorating genetic gains through integrated breeding and genomics approach. Planta 2019, 250, 783–801. [Google Scholar] [CrossRef]

- Kowalski, S.; Mikulec, A.; Mickowska, B.; Buksa, K. Nutritional properties and amino acid profile of buckwheat bread. J. Food Sci. Technol. 2022, 59, 3020–3030. [Google Scholar] [CrossRef]

- Mota, C.; Santos, M.; Mauro, R.; Samman, N.; Matos, A.S.; Torres, D.; Castanheira, I. Protein content and amino acids profle of pseudocereals. Food Chem. 2016, 193, 55–61. [Google Scholar] [CrossRef]

- Skrabanja, V.; Kreft, I.; Golob, T.; Modic, M.; Ikeda, S.; Ikeda, K.; Kosmelj, K. Nutrient Content in Buckwheat Milling Fractions. Cereal Chem. 2004, 81, 172–176. [Google Scholar] [CrossRef]

- Rombouts, I.; Lagrain, B.; Brijs, K.; Delcour, J.A. Cross-linking of wheat gluten proteins during production of hard pretzels. Amino Acids 2012, 42, 2429–2438. [Google Scholar] [CrossRef] [PubMed]

- Psodorov, Đ.B.; Vujić, Đ.N.; Ačanski, M.M.; Pastor, K.A.; Razmovski, R.N.; Kravić, S.Ž. The content of buckwheat flour in wheat bread. Acta Period. Technol. 2014, 45, 79–87. [Google Scholar] [CrossRef]

- Diowksz, A.; Sadowska, A. Impact of sourdough and transglutaminase on gluten-free buckwheat bread quality. Food Biosci. 2021, 43, 101309. [Google Scholar] [CrossRef]

- Lin, L.Y.; Wang, H.E.; Lin, S.D.; Liu, H.M.; Mau, J.L. Changes in buckwheat bread during storage. J. Food Process. Preserv. 2013, 37, 285–290. [Google Scholar] [CrossRef]

- Coţovanu, I.; Mironeasa, S. An Evaluation of the Dough Rheology and Bread Quality of Replacement Wheat Flour with Different Quinoa Particle Sizes. Agronomy 2022, 12, 2271. [Google Scholar] [CrossRef]

- Bilgiçl, N.; İbanoğlu, Ş. Effect of pseudo cereal flours on some physical, chemical and sensory properties of bread. J. Food Sci. Technol. 2015, 52, 7525–7529. [Google Scholar] [CrossRef]

| Elements (mg/100 g) | WF | OF_BL | OF_BM | OF_BS |

|---|---|---|---|---|

| K | 108.50 ± 2.12 b | 108.50 ± 2.12 b | 139.78 ± 34.64 a | 108.05 ± 10.59 b |

| Ca | 24.80 ± 0.10 a | 24.20 ± 0.19 b | 23.73 ± 0.02 c | 24.13 ± 0.01 b |

| Mg | 155.50 ± 0.65 a | 156.66 ± 0.42 ab | 157.42 ± 0.07 ab | 156.47 ± 0.03 ab |

| Na | 7.33 ± 0.11 a | 7.60 ± 0.95 a | 7.72 ± 1.10 a | 7.62 ± 0.18 a |

| Fe | 1.80 ± 0.06 b | 2.22 ± 0.56 ab | 2.55 ± 0.05 a | 1.99 ± 0.01 ab |

| Zn | 3.02 ± 0.25 a | 3.46 ± 0.07 ab | 3.58 ± 0.07 ab | 3.20 ± 0.19 a |

| Mn | 1.59 ± 0.10 a | 1.98 ± 0.41 a | 2.25 ± 0.52 a | 1.64 ± 0.02 a |

| Cu | 0.56 ± 0.01 b | 0.65 ± 0.21 ab | 0.68 ± 0.07 a | 0.60 ± 0.01 ab |

| Characteristic | WF | OF_BL | OF_BM | OF_BS |

|---|---|---|---|---|

| FN (s) Mixolab | 312.00 ± 5.25 axA | 317.22 ± 5.25 b | 316.52 ± 8.15 y | 352.01 ± 9.38 B |

| WA (%) | 58.50 ± 0.02 axA | 59.50 ± 0.25 a | 58.55 ± 0.50 x | 59.20 ± 0.17 A |

| DT (min) | 1.69 ± 0.75 axB | 2.85 ± 0.55 b | 2.95 ± 0.50 y | 1.45 ± 0.80 A |

| ST (min) | 9.96 ± 0.65 byB | 9.25 ± 0.66 a | 9.50 ± 2.15 x | 8.90 ± 0.96 A |

| C1-2 (N·m) | 0.61 ± 0.02 axA | 0.63 ± 0.25 a | 0.64 ± 0.02 x | 0.65 ± 0.03 A |

| C3-2 (N·m) | 1.41 ± 0.03 axB | 1.35 ± 0.03 a | 1.40 ± 0.01 x | 1.42 ± 0.0 A |

| C3-4 (N·m) | 0.05 ± 0.04 axA | 0.12 ± 0.02 b | 0.11 ± 0.01 y | 0.05 ± 0.03 A |

| C5-4 (N·m) Alveograph | 1.15 ± 0.01 byB | 0.95 ± 0.01 a | 0.92 ± 2.01 x | 0.89 ± 0.07 A |

| P (mm H2O) | 87.00 ± 5.75 byB | 80.52 ± 10.15 a | 82.05 ± 3.57 x | 84.23 ± 4.57 A |

| L (mm) | 91.00 ± 10.50 byB | 51.55 ± 9.50 a | 52.50 ± 8.52 x | 48.81 ± 12.42 A |

| W (10−4 J) | 253.00 ± 20.14 byB | 130.58 ± 15.10 a | 127.58 ± 5.58 x | 138.01 ± 18.22 A |

| P/L (adim.) Rheofermentometer | 0.95 ± 0.05 axA | 1.47 ± 0.50 b | 0.97 ± 0.52 x | 1.79 ± 0.49 A |

| H′m (mm) | 62.00 ± 4.25 axA | 75.25 ± 2.25 b | 71.25 ± 6.23 y | 70.75 ± 2.50 B |

| VT (mL) | 1168.00 ± 89.56 axA | 1345.05 ± 85.25 b | 1295.45 ± 120.40 y | 1346.88 ± 100.58 B |

| VR (mL) | 991.20 ± 85.25 axA | 1200.45 ± 85.25 b | 1128.50 ± 595.70 y | 1221.78 ± 64.25 B |

| CR (%) Rheometer | 84.20 ± 2.50 axA | 91.45 ± 1.45 b | 90.85 ± 4.75 y | 91.94 ± 5.58 B |

| G′ (Pa) | 26,370.00 ± 10.00 axA | 26,952.25 ± 214.78 a | 26,950.15 ± 265.45 y | 27,087.10 ± 1763.00 B |

| G″ (Pa) | 9488.00 ± 74.58 bxA | 9647.25 ± 685.45 b | 9850.45 ± 456.52 y | 10,636.45 ± 681.85 B |

| tan δ (adim.) | 0.3610 ± 0.02 bxB | 0.3580 ± 0.01 a | 0.3600 ± 0.05 x | 0.3801 ± 0.01 B |

| Tmax (°C) | 83.24 ± 0.55 byB | 80.25 ± 1.00 a | 81.25 ± 0.52 x | 79.42 ± 0.91 A |

| Jcmax (10−5 Pa−1) | 24.50 ± 4.50 bxB | 23.25 ± 2.25 a | 22.80 ± 1.50 x | 22.56 ± 2.75 A |

| Jrmax (10−5 Pa−1) | 16.62 ± 2.40 bxA | 15.55 ± 1.50 a | 16.75 ± 1.50 x | 15.66 ± 5.25 A |

| Bread Sample | Bread Volume (cm3) | Specific Volume (cm3/g) | Porosity (%) | Elasticity (%) |

|---|---|---|---|---|

| WFB | 352.20 ± 15.25 d | 2.45 ± 0.25 c | 64.22 ± 5.62 c | 91.70 ± 6.52 d |

| OB_BL | 373.19 ± 22.25 a | 2.76 ± 0.35 a | 73.75 ± 5.85 a | 94.28 ± 8.45 a |

| OB_BM | 370.25 ± 25.45 b | 2.70 ± 0.10 b | 72.79 ± 4.78 b | 93.58 ± 5.52 b |

| OB_BS | 362.51 ± 58.70 c | 2.55 ± 0.52 b | 72.57 ± 2.75 b | 92.41 ± 4.78 c |

| Bread Sample | Crust Color Parameters | Crumb Color Parameters | ||||

|---|---|---|---|---|---|---|

| L* | a* | b* | L* | a* | b* | |

| WFB | 70.35 ± 0.91 a | −1.33 ± 0.22 d | 32.27 ± 0.28 c | 73.94 ± 0.27 a | −4.48 ± 0.03 b | 20.02 ± 0.23 a |

| OB_BL | 63.25 ± 0.99 b | 3.83 ± 0.55 c | 33.82 ± 0.37 bc | 60.71 ± 0.48 b | −3.20 ± 0.11 a | 16.15 ± 0.02 c |

| OB_BM | 57.47 ± 0.83 c | 6.59 ± 0.43 a | 35.24 ± 0.83 ab | 61.63 ± 2.12 b | −2.63 ± 0.11 a | 17.41 ± 0.28 b |

| OB_BS | 63.92 ± 0.67 b | 4.88 ± 0.03 b | 37.40 ± 0.90 a | 63.28 ± 0.48 b | −3.91 ± 0.01 b | 16.16 ± 0.29 c |

| Bread Sample | Firmness (N) | Springiness (Adim.) | Cohesiveness (Adim.) | Gumminess (N) | Resilience (Adim.) | Masticability (N) |

|---|---|---|---|---|---|---|

| WFB | 5.71 ± 0.02 a | 1.3457 ± 0.27 a | 0.8575 ± 0.01 a | 499.73 ± 4.63 a | 1.8278 ± 0.00 a | 499.73 ± 4.63 a |

| OB_BL | 3.68 ± 0.06 b | 1.1196 ± 0.00 b | 0.8492 ± 0.03 a | 212.33 ± 17.70 c | 1.9335 ± 0.17 a | 212.33 ± 17.70 b |

| OB_BM | 3.64 ± 0.26 b | 1.0157 ± 0.00 bc | 0.8376 ± 0.03 a | 221.58 ± 12.54 c | 1.9323 ± 0.07 a | 221.58 ± 12.54 b |

| OB_BS | 3.78 ± 0.02 b | 0.8115 ± 0.00 c | 0.8570 ± 0.00 a | 253.19 ± 13.00 b | 1.8114 ± 0.06 a | 253.19 ± 13.00 b |

| Bread Sample | Moisture (%) | Proteins (%) | Lipids (%) | Ash (%) | Carbohydrates (%) | Energetic Value (kcal) |

|---|---|---|---|---|---|---|

| WFB | 43.12 ± 0.03 b | 8.35 ± 0.13 c | 0.01 ± 0.00 c | 0.72 ± 0.02 b | 47.81 ± 0.11 a | 230.31 ± 0.22 a |

| OB_BL | 43.23 ± 0.03 a | 9.31 ± 0.25 b | 0.15 ± 0.02 a | 0.85 ± 0.02 a | 46.46 ± 0.18 b | 230.05 ± 0.12 a |

| OB_BM | 40.21 ± 0.07 c | 10.00 ± 0.14 a | 0.22 ± 0.02 a | 0.85 ± 0.01 a | 48.71 ± 0.10 a | 242.75 ± 0.15 ab |

| OB_BS | 43.64 ± 0.19 a | 9.70 ± 0.13 b | 0.14 ± 0.02 b | 0.69 ± 0.03 b | 45.84 ± 0.06 a | 229.01 ± 1.00 bc |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Coţovanu, I.; Mironeasa, C.; Mironeasa, S. Incorporation of Buckwheat Flour at Different Particle Sizes and Distinctive Doses in Wheat Flour to Manufacture an Improved Wheat Bread. Foods 2023, 12, 1730. https://doi.org/10.3390/foods12081730

Coţovanu I, Mironeasa C, Mironeasa S. Incorporation of Buckwheat Flour at Different Particle Sizes and Distinctive Doses in Wheat Flour to Manufacture an Improved Wheat Bread. Foods. 2023; 12(8):1730. https://doi.org/10.3390/foods12081730

Chicago/Turabian StyleCoţovanu, Ionica, Costel Mironeasa, and Silvia Mironeasa. 2023. "Incorporation of Buckwheat Flour at Different Particle Sizes and Distinctive Doses in Wheat Flour to Manufacture an Improved Wheat Bread" Foods 12, no. 8: 1730. https://doi.org/10.3390/foods12081730

APA StyleCoţovanu, I., Mironeasa, C., & Mironeasa, S. (2023). Incorporation of Buckwheat Flour at Different Particle Sizes and Distinctive Doses in Wheat Flour to Manufacture an Improved Wheat Bread. Foods, 12(8), 1730. https://doi.org/10.3390/foods12081730