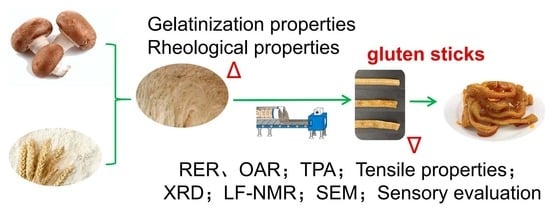

Lentinus edodes Powder Improves the Quality of Wheat Flour Gluten Sticks

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

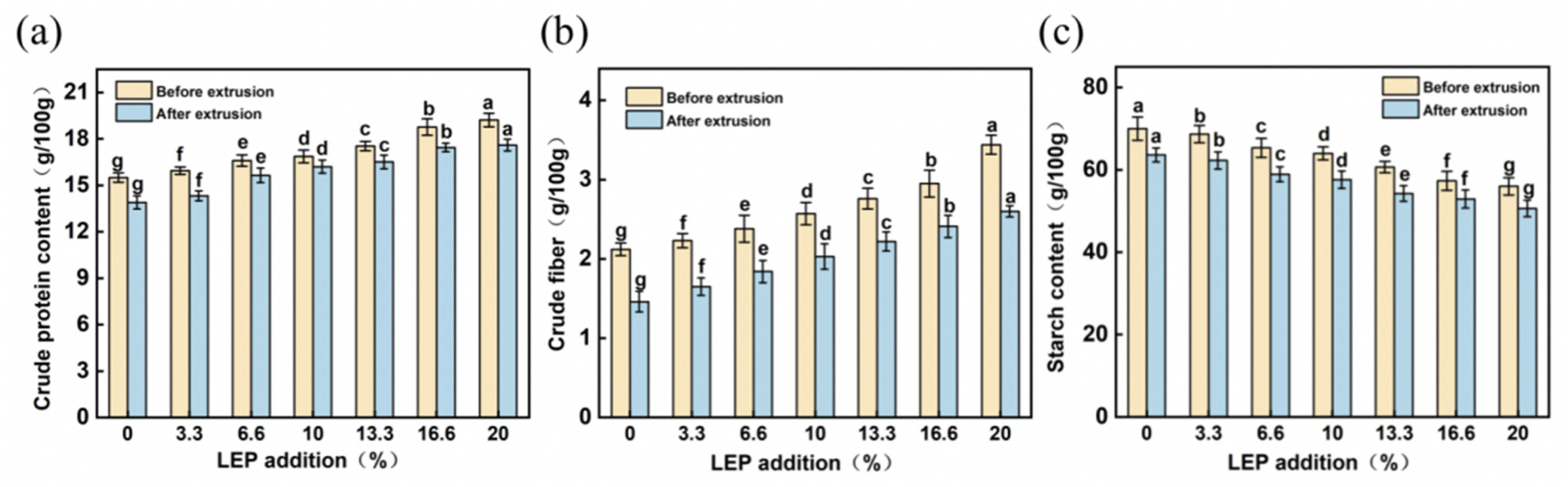

2.2. Nutrient Composition Analysis

2.3. Gelatinization Properties

2.4. Extrusion Process

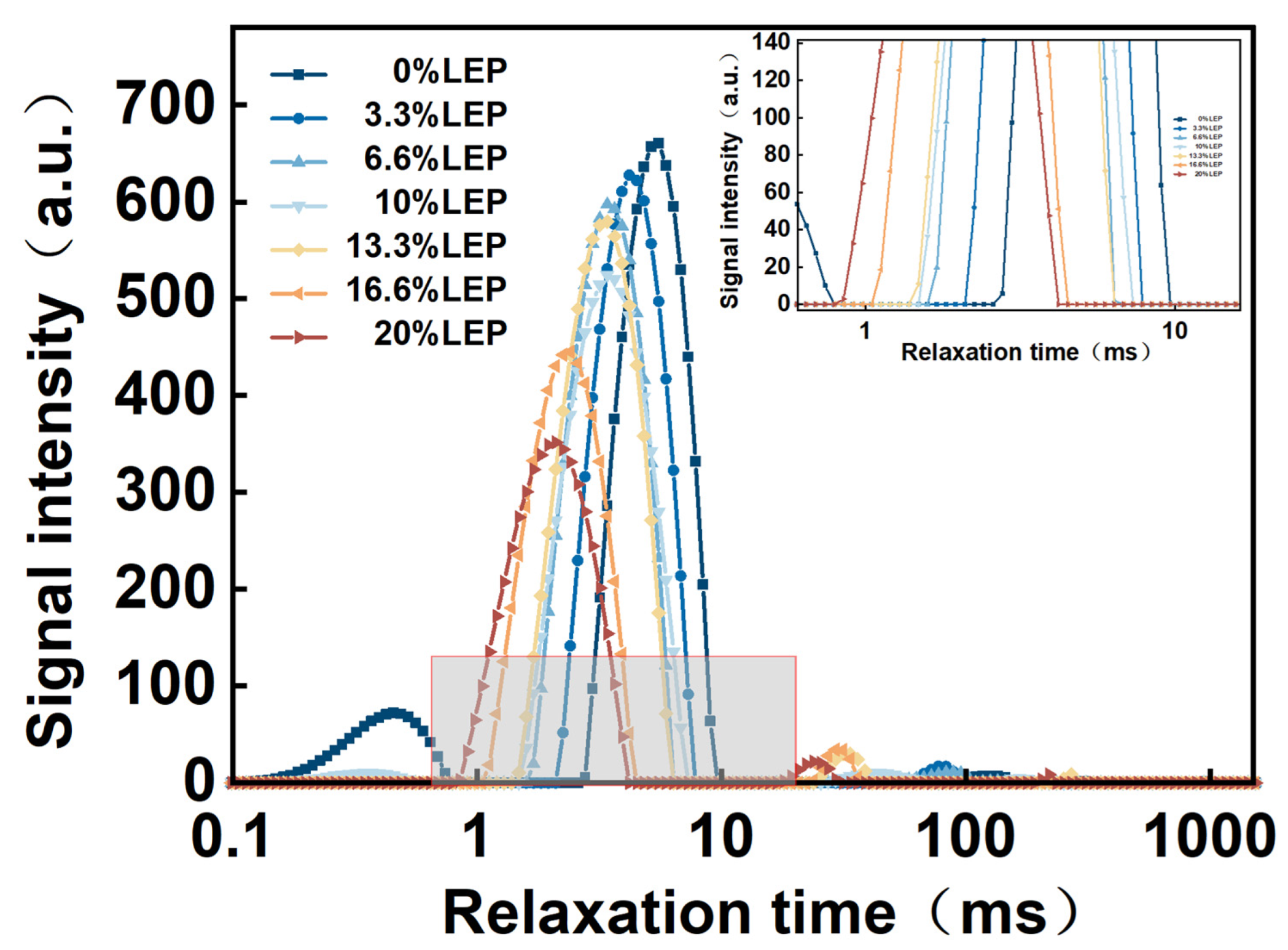

2.5. Radical Expansion Rate (RER) and Oil Absorption Rate (OAR)

2.6. Texture Profile Analysis (TPA)

2.7. X-ray Diffraction Pattern (XRD)

2.8. Low Field Nuclear Magnetic Resonance (LF-NMR)

2.9. Scanning Electron Microscope (SEM)

2.10. Sensory Evaluation

2.11. Statistical Analysis

3. Results and Discussion

3.1. Nutrient Composition Analysis

3.2. Gelatinization Properties

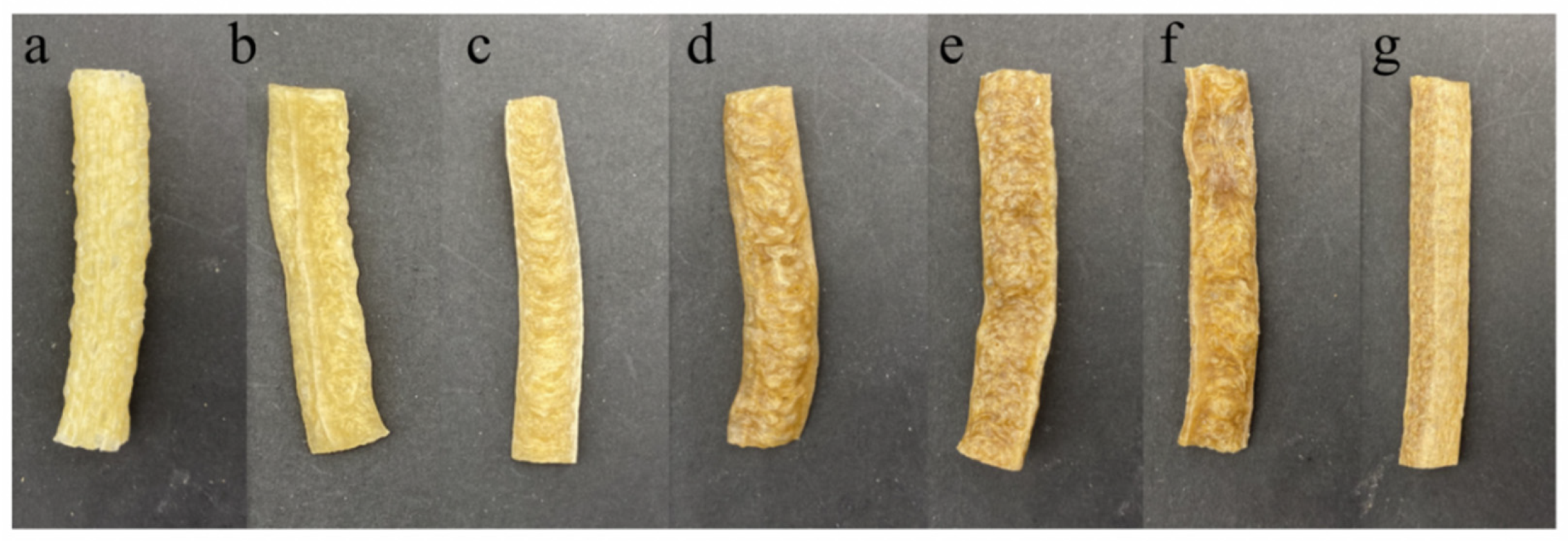

3.3. Extruded Materials

3.4. Radial Expansion Rate (RER) and Oil Absorption Rate (OAR)

3.5. Texture Profile Analysis (TPA)

3.6. X-ray Diffraction Pattern (XRD)

3.7. Low Field Nuclear Magnetic Resonance (LF-NMR)

3.8. Scanning Electron Microscope (SEM)

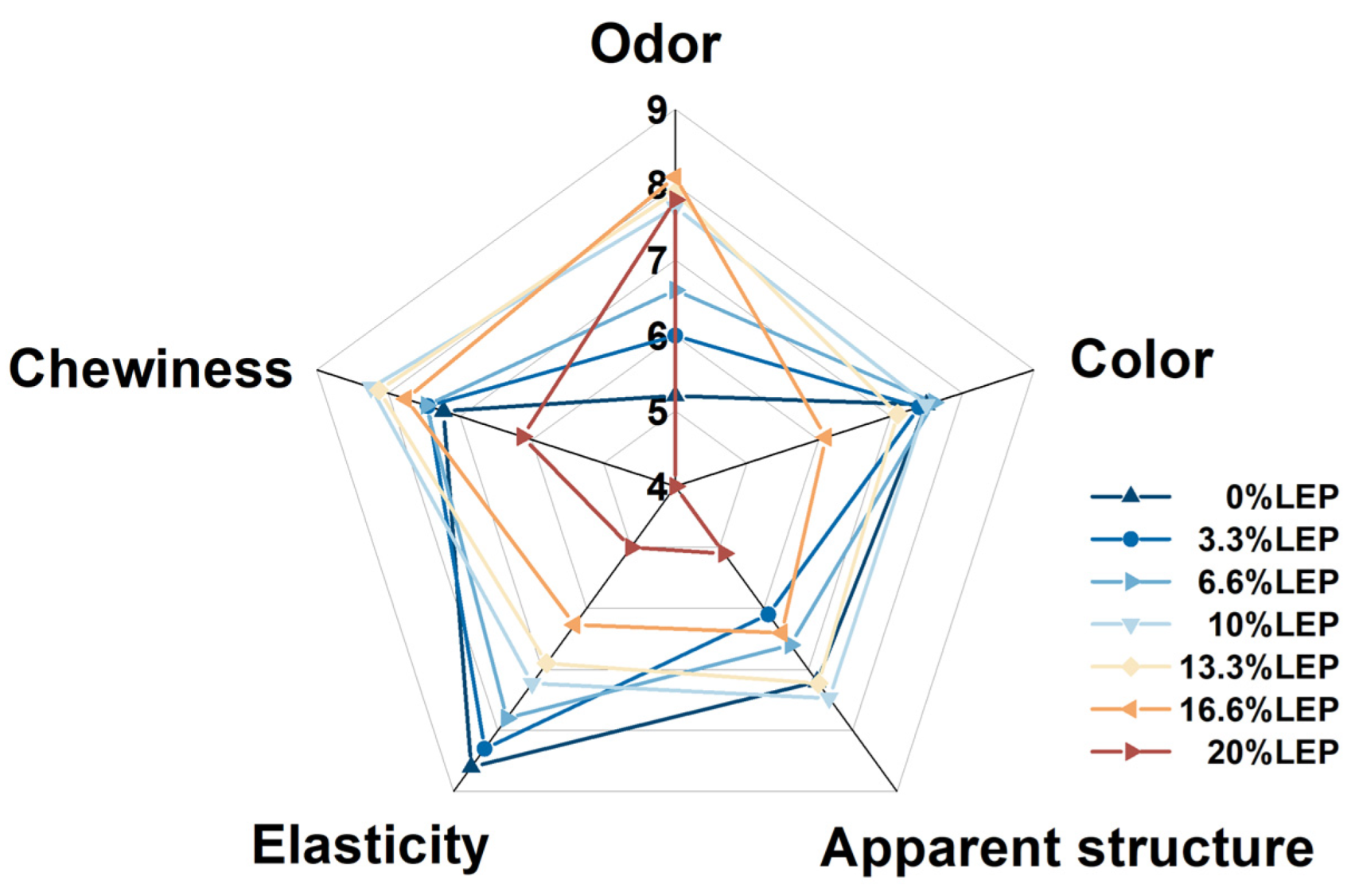

3.9. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- White, G. Defining the true meaning of snacks. Food Technol. Int. Eur. 1994, 2, 115–117. [Google Scholar]

- Brncic, M.; Tripalo, B.; Rimac Brncic, S.; Karlovic, S.; Zupan, A.U.P.A.N.; Herceg, Z. Evaluation of textural properties for whey enriched direct extruded and puffed corn based products. Bulg. J. Agric. Sci. 2009, 15, 204–214. [Google Scholar] [CrossRef]

- Hashempour-Baltork, F.; Torbati, M.; Azadmard-Damirchi, S.; Savage, G.P. Quality properties of puffed corn snacks incorporated with sesame seed powder. Food Sci. Nutr. 2017, 6, 85–93. [Google Scholar] [CrossRef] [PubMed]

- Veronica, A.O.; Olusola, O.O.; Adebowale, E.A. Qualities of extruded puffed snacks from maize/soybean mixture. J. Food Process. Eng. 2006, 29, 149–161. [Google Scholar] [CrossRef]

- Nwabueze, T.U. Effect of process variables on trypsin inhibitor activity (TIA), phytic acid and tannin content of extruded African breadfruit–corn–soy mixtures: A response surface analysis. LWT-Food Sci. Technol. 2007, 40, 21–29. [Google Scholar] [CrossRef]

- Shaviklo, A.R.; Azaribeh, M.; Moradi, Y.; Zangeneh, P. Formula optimization and storage stability of extruded puffed corn-shrimp snacks. LWT-Food Sci. Technol. 2015, 63, 307–314. [Google Scholar] [CrossRef]

- Huang, R.-C.; Peng, J.; Lu, F.; Lui, W.-B.; Lin, J. The study of optimum operating conditions of extruded snack food with tomato powder. J. Food Process. Eng. 2006, 29, 1–21. [Google Scholar] [CrossRef]

- Lobato, L.; Anibal, D.; Lazaretti, M.; Grossmann, M. Extruded puffed functional ingredient with oat bran and soy flour. LWT 2011, 44, 933–939. [Google Scholar] [CrossRef]

- Athar, N.; Hardacre, A.; Taylor, G.; Clark, S.; Harding, R.; McLaughlin, J. Vitamin retention in extruded food products. J. Food Compos. Anal. 2006, 19, 379–383. [Google Scholar] [CrossRef]

- Alves, R.M.L.; Grossmann, M.V.E. Parâmetros de estrusão para produção de “snacks” de farinha de cará (Dioscorea alata). Food Sci. Technol. 2002, 22, 32–38. [Google Scholar] [CrossRef]

- Bisen, P.S.; Baghel, R.K.; Sanodiya, B.S.; Thakur, G.S.; Prasad, G.B. Lentinus edodes: A Macrofungus with Pharmacological Activities. Curr. Med. Chem. 2010, 17, 2419–2430. [Google Scholar] [CrossRef] [PubMed]

- Vetter, J. Mineralstoff- und Aminosäuregehalte des eßbaren, kultivierten Pilzes Shii-take (Lentinus edodes). Z. Lebensm.-Unters. Und-Forsch. 1995, 201, 17–19. [Google Scholar] [CrossRef] [PubMed]

- Ming, J.; Chen, L.; Hong, H.; Li, J. Effect of superfine grinding on the physico-chemical, morphological and thermogravimetric properties of Lentinus edodes mushroom powders. J. Sci. Food Agric. 2014, 95, 2431–2437. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.F.; Yan, H.D.; Tang, J.; Chen, J.; Zhang, X.W. Polysaccharides in Lentinus edodes: Isolation, structure, immunomodulating activity and future prospective. Crit. Rev. Food Sci. Nutr. 2014, 54, 474–487. [Google Scholar] [CrossRef]

- Kaur, K.; Grewal, S.K.; Gill, P.S.; Singh, S. Comparison of cultivated and wild chickpea genotypes for nutritional quality and antioxidant potential. J. Food Sci. Technol. 2019, 56, 1864–1876. [Google Scholar] [CrossRef] [PubMed]

- Xia, D.; Zhou, H.; Wang, Y.; Ao, Y.; Li, Y.; Huang, J.; Wu, B.; Li, X.; Wang, G.; Xiao, J.; et al. qFC6, a major gene for crude fat content and quality in rice. Theor. Appl. Genet. 2022, 135, 2675–2685. [Google Scholar] [CrossRef] [PubMed]

- Fan, L.; Ren, J.; Yang, Y.; Zhang, L. Comparative Analysis on Essential Nutrient Compositions of 23 Wild Hazelnuts (Corylus heterophylla) Grown in Northeast China. J. Food Qual. 2020, 2020, 9475961. [Google Scholar] [CrossRef]

- Lu, C.-M.; Hou, M.-L.; Lin, L.-C.; Tsai, T.-H. Chemical and Physical Methods to Analyze a Multicomponent Traditional Chinese Herbal Prescription Using LC-MS/MS, Electron Microscope, and Congo Red Staining. Evid.-Based Complement. Altern. Med. 2013, 2013, 952796. [Google Scholar] [CrossRef]

- Sekhon, J.; Grewal, S.K.; Singh, I.; Kaur, J. Evaluation of nutritional quality and antioxidant potential of pigeonpea genotypes. J. Food Sci. Technol. 2017, 54, 3598–3611. [Google Scholar] [CrossRef]

- Li, H.; Xie, S.; Cao, S.; Hu, L.; Xu, D.; Zhang, J.; Mo, H.; Liu, Z. Bioconversion of High-Calorie Potato Starch to Low-Calorie β-Glucan via 3D Printing Using Pleurotus eryngii Mycelia. Foods 2022, 11, 1443. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, L.; Wang, H.; Ai, L.; Xiong, W. Insight into protein-starch ratio on the gelatinization and retrogradation characteristics of reconstituted rice flour. Int. J. Biol. Macromol. 2020, 146, 524–529. [Google Scholar] [CrossRef] [PubMed]

- Yang, K.; Luo, X.; Zhai, Y.; Liu, J.; Chen, K.; Shao, X.; Wu, X.; Li, Y.; Chen, Z. Influence of sodium alginate on the gelatinization, rheological, and retrogradation properties of rice starch. Int. J. Biol. Macromol. 2021, 185, 708–715. [Google Scholar] [CrossRef] [PubMed]

- Jia, Z.; Yang, H.; Zhang, Y.; Ding, W.; Shuang, Y.; Fu, Y.; Xie, Q.; Dong, T.; Wu, Y.; Wang, X. Effects of isomalt on the quality of wheat flour dough and spicy wheat gluten sticks. Int. J. Food Sci. Technol. 2022, 57, 2310–2320. [Google Scholar] [CrossRef]

- Li, Q.-Q.; Wang, Y.-S.; Chen, H.-H.; Liu, S.; Li, M. Retardant effect of sodium alginate on the retrogradation properties of normal cornstarch and anti-retrogradation mechanism. Food Hydrocoll. 2017, 69, 1–9. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, M.; Bhandari, B.; Yang, P. Intelligent detection of flavor changes in ginger during microwave vacuum drying based on LF-NMR. Food Res. Int. 2019, 119, 417–425. [Google Scholar] [CrossRef]

- Santosh, O.; Bajwa, H.K.; Bisht, S.M.; Chongtham, N. Antioxidant activity and sensory evaluation of crispy salted snacks fortifified with bamboo shoot rich in bioactive compounds. Appl. Food Res. 2021, 1, 100018. [Google Scholar] [CrossRef]

- Dereje, B. Composition, morphology and physicochemical properties of starches derived from indigenous Ethiopian tuber crops: A review. Int. J. Biol. Macromol. 2021, 187, 911–921. [Google Scholar] [CrossRef]

- Jing, Y.; Chi, Y.-J. Effects of twin-screw extrusion on soluble dietary fibre and physicochemical properties of soybean residue. Food Chem. 2013, 138, 884–889. [Google Scholar] [CrossRef]

- Chen, B.-R.; Wen, Q.-H.; Zeng, X.-A.; Abdul, R.; Roobab, U.; Xu, F.-Y. Pulsed electric field assisted modification of octenyl succinylated potato starch and its influence on pasting properties. Carbohydr. Polym. 2020, 254, 117294. [Google Scholar] [CrossRef]

- Liu, Q.; Donner, E.; Yin, Y.; Huang, R.; Fan, M. The physicochemical properties and in vitro digestibility of selected cereals, tubers and legumes grown in China. Food Chem. 2006, 99, 470–477. [Google Scholar] [CrossRef]

- Vandeputte, G.; Derycke, V.; Geeroms, J.; Delcour, J. Rice starches. II. Structural aspects provide insight into swelling and pasting properties. J. Cereal Sci. 2003, 38, 53–59. [Google Scholar] [CrossRef]

- Ma, Y.-S.; Pan, Y.; Xie, Q.-T.; Li, X.-M.; Zhang, B.; Chen, H.-Q. Evaluation studies on effects of pectin with different concentrations on the pasting, rheological and digestibility properties of corn starch. Food Chem. 2018, 274, 319–323. [Google Scholar] [CrossRef] [PubMed]

- Mulye, V.; Zofair, S. Utilization of croaker (Johnius dussumieri) to develop ready to eat puff snack product using extrusion technology. Food Sci. Res. J. 2015, 6, 184–191. [Google Scholar] [CrossRef]

- Rahman, M.S.; Al-Farsi, S.A. Instrumental texture profile analysis (TPA) of date flesh as a function of moisture content. J. Food Eng. 2005, 66, 505–511. [Google Scholar] [CrossRef]

- Dankar, I.; Haddarah, A.; Omar, F.E.L.; Pujolà, M.; Sepulcre, F. Characterization of food additive-potato starch complexes by FTIR and X-ray diffraction. Food Chem. 2018, 260, 7–12. [Google Scholar] [CrossRef] [PubMed]

- Primo-Martín, C.; van Nieuwenhuijzen, N.; Hamer, R.; van Vliet, T. Crystallinity changes in wheat starch during the bread-making process: Starch crystallinity in the bread crust. J. Cereal Sci. 2007, 45, 219–226. [Google Scholar] [CrossRef]

- Zhu, L.-J.; Liu, Q.-Q.; Wilson, J.D.; Gu, M.-H.; Shi, Y.-C. Digestibility and physicochemical properties of rice (Oryza sativa L.) flours and starches differing in amylose content. Carbohydr. Polym. 2011, 86, 1751–1759. [Google Scholar] [CrossRef]

- Hansen, C.L.; Thybo, A.K.; Bertram, H.C.; Viereck, N.; Berg, F.V.D.; Engelsen, S.B. Determination of Dry Matter Content in Potato Tubers by Low-Field Nuclear Magnetic Resonance (LF-NMR). J. Agric. Food Chem. 2010, 58, 10300–10304. [Google Scholar] [CrossRef]

| Component | Crude Protein | Crude Fat | Crude Fiber | Water | Total Sugars | Total Ash | Starch |

|---|---|---|---|---|---|---|---|

| LEP | 21.2 ± 1.56 a | 2.9 ± 0.22 a | 7.5 ± 0.68 a | 8.6 ± 0.81 a | 52 ± 5.72 | 4.9 ± 0.53 a | No measured |

| Wheat flour | 9.5 ± 0.95 b | 1.5 ± 0.11 b | 2.1 ± 0.19 b | 10.5 ± 0.98 a | No measured | 1.2 ± 0.23 b | 68 ± 5.23 |

| Samples a | Viscosity (cP) | ||||

|---|---|---|---|---|---|

| Peak | Trough | Final | Breakdown | Setback | |

| 0% | 454 ± 8.12 a | 285 ± 7.84 a | 666 ± 9.52 a | 169 ± 6.71 a | 381 ± 8.42 a |

| 3.3% | 345 ± 7.63 b | 215 ± 9.02 b | 520 ± 6.81 b | 130 ± 7.23 b | 305 ± 9.07 b |

| 6.6% | 301 ± 6.68 c | 201 ± 8.61 c | 493 ± 7.95 c | 100 ± 9.86 c | 292 ± 7.41 c |

| 10% | 295 ± 9.17 d | 196 ± 6.73 d | 476 ± 8.69 d | 99 ± 5.41 c | 280 ± 7.80 d |

| 13.3% | 292 ± 5.93 e | 193 ± 5.89 e | 449 ± 9.36 e | 99 ± 7.04 c | 256 ± 8.53 e |

| 16.6% | 270 ± 9.16 f | 173 ± 8.05 f | 388 ± 6.82 f | 97 ± 9.36 d | 215 ± 5.94 f |

| 20% | 251 ± 7.44 g | 155 ± 9.08 g | 366 ± 8.97 g | 96 ± 6.63 d | 211 ± 6.58 g |

| Samples | RER | OAR (%) |

|---|---|---|

| 0% | 1.131 ± 0.0173 d | 5.124 ± 1.2003 f |

| 3.3% | 1.189 ± 0.0507 c | 5.291 ± 0.9346 f |

| 6.6% | 1.264 ± 0.0287 b | 5.673 ± 0.7577 e |

| 10% | 1.388 ± 0.0289 a | 12.436 ± 0.6744 d |

| 13.3% | 1.128 ± 0.0326 d | 13.917 ± 1.1726 c |

| 16.6% | 0.974 ± 0.0533 e | 14.156 ± 1.4752 b |

| 20% | 0.833 ± 0.0243 f | 14.852 ± 1.0925 a |

| Samples | Hardness (g) | Chewiness | Springiness |

|---|---|---|---|

| 0% | 1148.898 ± 32.32 f | 1010.393 ± 56.28 g | 1.055 ± 0.028 a |

| 3.3% | 1293.307 ± 24.45 e | 1182.01 ± 49.01 f | 0.942 ± 0.011 b |

| 6.6% | 1488.048 ± 45.38 d | 1266.978 ± 61.31 e | 0.845 ± 0.014 c |

| 10% | 1661.984 ± 26.71 c | 1366.23 ± 53.27 d | 0.799 ± 0.026 d |

| 13.3% | 2055.741 ± 33.9 b | 1400.88 ± 42.12 c | 0.739 ± 0.021 e |

| 16.6% | 2163.826 ± 45.38 a | 1565.4 ± 47.35 a | 0.702 ± 0.017 f |

| 20% | 2055.492 ± 54.59 b | 1499.233 ± 32.81 b | 0.612 ± 0.031 g |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, S.; Li, H.; Li, N.; Liu, Z.; Xu, D.; Hu, L.; Mo, H. Lentinus edodes Powder Improves the Quality of Wheat Flour Gluten Sticks. Foods 2023, 12, 1755. https://doi.org/10.3390/foods12091755

Xie S, Li H, Li N, Liu Z, Xu D, Hu L, Mo H. Lentinus edodes Powder Improves the Quality of Wheat Flour Gluten Sticks. Foods. 2023; 12(9):1755. https://doi.org/10.3390/foods12091755

Chicago/Turabian StyleXie, Suya, Hongbo Li, Na Li, Zhenbin Liu, Dan Xu, Liangbin Hu, and Haizhen Mo. 2023. "Lentinus edodes Powder Improves the Quality of Wheat Flour Gluten Sticks" Foods 12, no. 9: 1755. https://doi.org/10.3390/foods12091755