Exploration of Convective and Infrared Drying Effect on Image Texture Parameters of ‘Mejhoul’ and ‘Boufeggous’ Date Palm Fruit Using Machine Learning Models

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Date Fruit Drying

2.2.1. Convective Drying

2.2.2. Infrared Drying

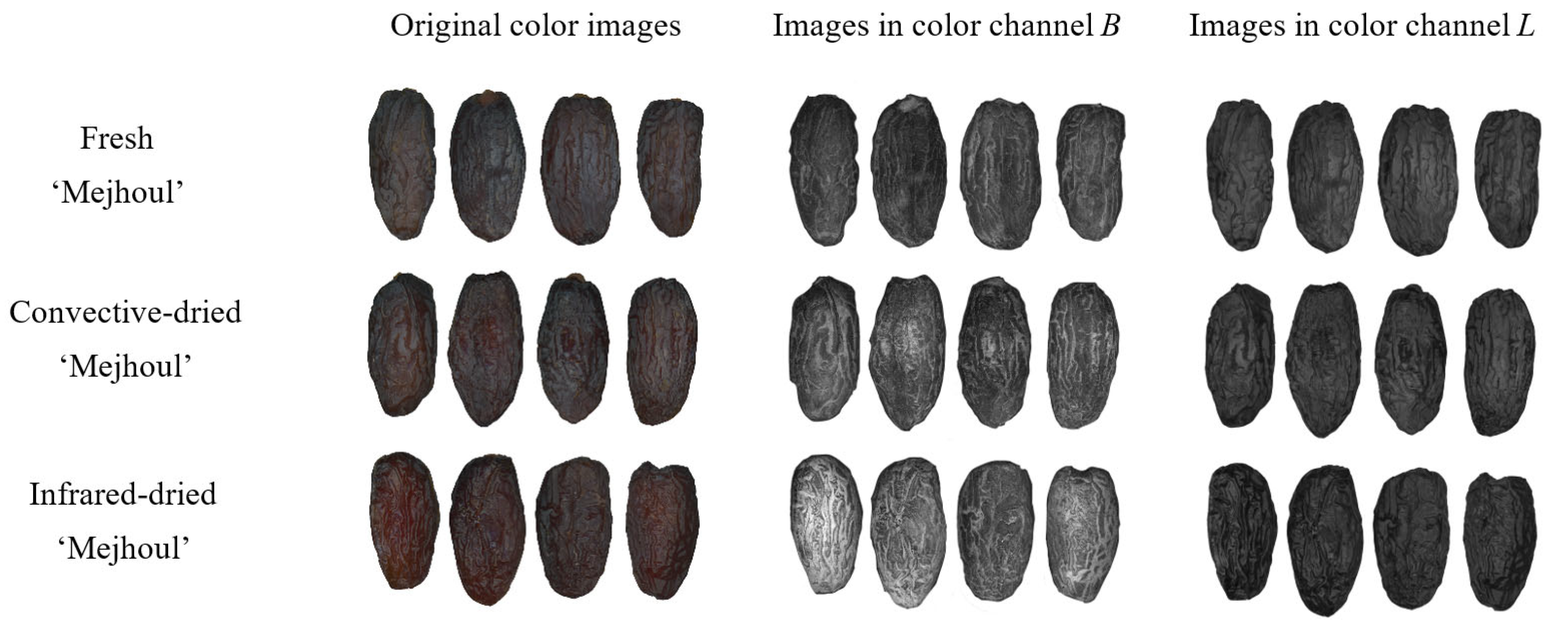

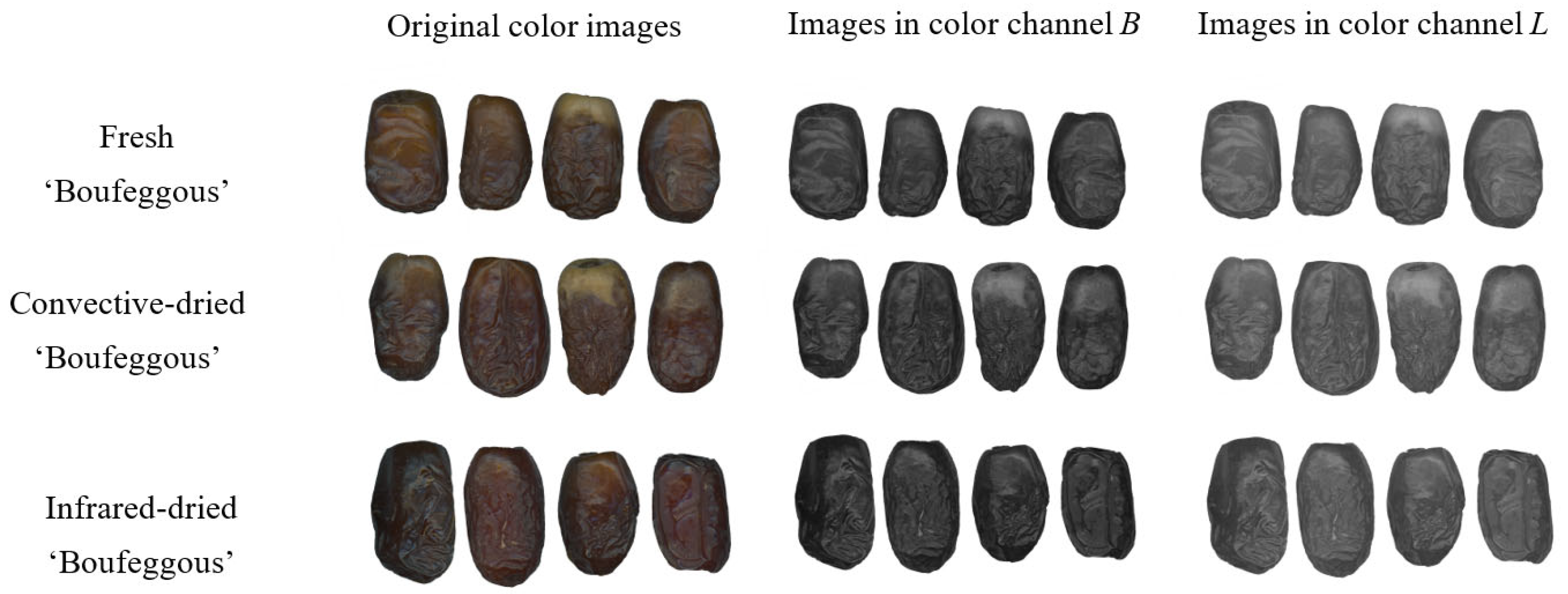

2.3. Image Analysis

2.4. Mean Comparison of Selected Image Textures

2.5. Machine Learning Models for Distinguishing Fresh, Convective, and Infrared-Dried Date Fruit

3. Results and Discussion

3.1. ‘Mejhoul’: Discrimination between Fresh, Convective, and Infrared Dried Fruit Based on Machine Learning Models and Selected Image Texture Parameters

3.2. ‘Boufeggous’: Discrimination between Fresh, Convective, and Infrared Dried Fruit Based on Machine Learning Models and Selected Texture Parameters

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alsmairat, N.; Othman, Y.; Ayad, J.; Al-Ajlouni, M.; Sawwan, J.; El-Assi, N. Anatomical Assessment of Skin Separation in Date Palm (Phoenix dactylifera L. var. Mejhoul) Fruit during Maturation and Ripening Stages. Agriculture 2023, 13, 38. [Google Scholar] [CrossRef]

- Rakesh Reddy, S.V.; Singh, R.S.; Meena, R.; Berwal, M.K.; Sarolia, D.K.; Palpandian, P. Impact of Hot Water Pre-Treatments on the Drying Efficiency and Quality of Dates cv. Medjool. Horticulturae 2023, 9, 784. [Google Scholar] [CrossRef]

- Uchoi, J.; Nikhumbhe, P.H.; Kumar, A.; Patidar, A.; Harish, G.D. Impact of inclined solar drier for dehydration quality in khadrawy dates during doka maturity stage at north western arid India. Int. J. Curr. Microbiol. Appl. Sci. 2020, 9, 119–125. [Google Scholar] [CrossRef]

- Muñoz-Bas, C.; Muñoz-Tebar, N.; Candela-Salvador, L.; Pérez-Alvarez, J.A.; Lorenzo, J.M.; Viuda-Martos, M.; Fernández-López, J. Quality Characteristics of Fresh Date Palm Fruits of “Medjoul” and “Confitera” cv. from the Southeast of Spain (Elche Palm Grove). Foods 2023, 12, 2659. [Google Scholar] [CrossRef] [PubMed]

- Noutfia, Y.; Ropelewska, E. What can artificial intelligence approaches bring to an improved and efficient harvesting and postharvest handling of date fruit (Phoenix dactylifera L.)? A review. Postharvest Biol. Technol. 2024, 213, 112926. [Google Scholar] [CrossRef]

- Bassey, E.J.; Cheng, J.H.; Sun, D.W. Novel nonthermal and thermal pretreatments for enhancing drying performance and improving quality of fruits and vegetables. Trends Food Sci. Technol. 2021, 112, 137–148. [Google Scholar] [CrossRef]

- Alsmairat, N.; Al-Qudah, T.; El-Assi, N.; Mehyar, G.; Gammoh, I.; Othman, Y.; Araj, S.; Al-Antary, T. Effect of drying process on physical and chemical properties of ‘Medjool’ date palm fruits. Fresenius Environ. Bull. 2019, 28, 1552–1559. [Google Scholar]

- Özlem, E.; Yeliz, I. Modeling of drying processes of dates (Phoenix, Arecaceae) with oven or TGA and microbiological properties of fresh and dried dates. Int. J. Fruit Sci. 2020, 20, S1530–S1538. [Google Scholar]

- Elwakeel, A.E.; Tantawy, A.A.; Alsebiey, M.M.; Elliby, A.K. The date fruit drying systems: Acritical over review. Al-Azhar J. Agric. Eng. 2022, 3, 26–36. [Google Scholar] [CrossRef]

- Falade, K.O.; Abbo, E.S. Air-drying and rehydration characteristics of date palm (Phoenix dactylifera L.) fruits. J. Food Eng. 2007, 79, 724–730. [Google Scholar] [CrossRef]

- Shahdadi, F.; Mirzaei, H.O.; Daraei Garmakhany, A. Study of phenolic compound and antioxidant activity of date fruit as a function of ripening stages and drying process. J. Food Sci. Technol. 2015, 52, 1814–1819. [Google Scholar] [CrossRef] [PubMed]

- İzli, G. Total phenolics, antioxidant capacity, colour and drying characteristics of date fruit dried with different methods. Food Sci. Technol. 2016, 37, 139–147. [Google Scholar] [CrossRef]

- Noutfia, Y.; Benali, A.; Alem, C.; Zegzouti, Y.F. Design of a solar dryer for small-farm level use and studying fig quality. Acta Sci. Pol. Technol. Aliment. 2018, 17, 359–365. [Google Scholar] [CrossRef] [PubMed]

- Elghazali, M.N.; Tawfeuk, H.Z.; Gomaa, R.A.; Tantawy, A.A. Technological Studies on Aswan Dry Dates Products After Dehydration. Assiut J. Agric. Sci. 2020, 51, 32–49. [Google Scholar]

- Tireki, S. Effective diffusivity determination of date (Phoenix dactylifera L.) leather in infrared drying: Effect of cooking time. NOHU J. Eng. Sci. 2023, 12, 1558–1565. [Google Scholar] [CrossRef]

- Noutfia, Y.; Ropelewska, E. Innovative models built based on image textures using traditional machine learning algorithms for distinguishing different varieties of Moroccan date palm fruit (Phoenix dactylifera L.). Agriculture 2022, 13, 26. [Google Scholar] [CrossRef]

- Noutfia, Y.; Ropelewska, E. Comprehensive characterization of date palm fruit ‘Mejhoul’ (Phoenix dactylifera L.) using image analysis and quality attribute measurements. Agriculture 2022, 13, 74. [Google Scholar] [CrossRef]

- Szczypiński, P.M.; Strzelecki, M.; Materka, A. Mazda-a software for texture analysis. In Proceedings of the 2007 International Symposium on Information Technology Convergence (ISITC 2007), Jeonju, Republic of Korea, 23–24 November 2007; pp. 245–249. [Google Scholar]

- Szczypiński, P.M.; Strzelecki, M.; Materka, A.; Klepaczko, A. MaZda—A software package for image texture analysis. Comput. Methods Programs Biomed. 2009, 94, 66–76. [Google Scholar] [CrossRef] [PubMed]

- Strzelecki, M.; Szczypiński, P.; Materka, A.; Klepaczko, A. A software tool for automatic classification and segmentation of 2D/3D medical images. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2013, 702, 137–140. [Google Scholar] [CrossRef]

- Witten, I.H.; Frank, E. Data Mining: Practical Machine Learning Tools and Techniques, 2nd ed.; Elsevier: San Francisco, CA, USA, 2005. [Google Scholar]

- Bouckaert, R.R.; Frank, E.; Hall, M.; Kirkby, R.; Reutemann, P.; Seewald, A.; Scuse, D. WEKA Manual for Version 3-9-1; University of Waikato: Hamilton, New Zealand, 2016. [Google Scholar]

- Frank, E.; Hall, M.A.; Witten, I.H. The WEKA Workbench. In Data Mining: Practical Machine Learning Tools and Techniques, 4th ed.; Online Appendix; Morgan Kaufmann: Burlington, MA, USA, 2016. [Google Scholar]

- Ropelewska, E. Diversity of Plum Stones Based on Image Texture Parameters and Machine Learning Algorithms. Agronomy 2022, 12, 762. [Google Scholar] [CrossRef]

- Sabanci, K.; Aslan, M.F.; Ropelewska, E.; Unlersen, M.F. A convolutional neural network-based comparative study for pepper seed classification: Analysis of selected deep features with support vector machine. J. Food Process Eng. 2022, 45, e13955. [Google Scholar] [CrossRef]

- Cinar, I.; Koklu, M. Classification of Rice Varieties Using Artificial Intelligence Methods. Int. J. Intell. Syst. Appl. Eng. 2019, 7, 188–194. [Google Scholar] [CrossRef]

- Ropelewska, E. Distinguishing lacto-fermented and fresh carrot slice images using the Multilayer Perceptron neural network and other machine learning algorithms from the groups of Functions, Meta, Trees, Lazy, Bayes and Rules. Eur Food Res Technol 2022, 248, 2421–2429. [Google Scholar] [CrossRef]

- Vaishnav, D.; Rao, B.R. Comparison of machine learning algorithms and fruit classification using orange data mining tool. In Proceedings of the 2018 3rd International Conference on Inventive Computation Technologies (ICICT), Coimbatore, India, 15–16 November 2018; pp. 603–607. [Google Scholar]

- Koklu, M.; Kursun, R.; Taspinar, Y.S.; Cinar, I. Classification of date fruits into genetic varieties using image analysis. Math. Probl. Eng. 2021, 2021, 4793293. [Google Scholar] [CrossRef]

- Ramadan, B.R.; EL-Rify, M.N.A.; Abd El-Hamid, A.A.; Abd El-Majeed, M.H. Effect of some treatments on chemical composition and quality properties of Saidy date fruit (Phoenix dactylifera L.) during storage. Assiut J. Agric. Sci. 2016, 47, 107–124. [Google Scholar]

- Tang, Z.X.; Shic, L.E.; Aleid, S.M. Date fruit: Chemical composition, nutritional and medicinal values, products. J. Sci. Food Agric. 2013, 93, 2351–2361. [Google Scholar] [CrossRef] [PubMed]

- Juhaimi, F.A.; Ghafoor, K.; Özcan, M.M. Physical and chemical properties, antioxidant activity, total phenol and mineral profile of seeds of seven different date fruit (Phoenix dactylifera L.) varieties. Int. J Food Sci. Nutr. 2012, 63, 84–89. [Google Scholar] [CrossRef] [PubMed]

- AL Juhaimi, F.; Ghafoor, K.; Özcan, M.M. Physicochemical properties and mineral contents of seven different date fruit (Phoenix dactylifera L.) varieties growing from Saudi Arabia. Environ. Monit. Assess. 2014, 186, 2165–2170. [Google Scholar] [CrossRef]

- Hadibi, T.; Mennouche, D.; Boubekri, A.; Arıcı, M.; Wang, Y.; Li, M.; Hassanien, R.H.E.; Shirkole, S.S. Experimental investigation, performance analysis, and optimization of hot air convective drying of date fruits via response surface methodology. Renew. Energy 2024, 226, 120404. [Google Scholar] [CrossRef]

- Sansaniwal, S.K.; Kumar, M.; Kumar Sahdev, R.; Bhutani, V.; Manchanda, H. Toward natural convection solar drying of date palm fruits (Phoenix dactylifera L.): An experimental study. Environ. Prog. Sustain. Energy 2022, 41, e13862. [Google Scholar] [CrossRef]

- Al-Awaadh, A.M.; Hassan, B.H.; Ahmed, K.M.A. Hot Air Drying Characteristics of Sukkari Date (Phoenix dactylifera L.) and Effects of Drying Condition on Fruit Color and Texture. Int. J. Food Eng. 2015, 11, 421–434. [Google Scholar] [CrossRef]

- Kumar, M.; Shimpy, M.; Sahdev, R.K.; Sansaniwal, S.K.; Bhutani, V.; Manchanda, H. Experimental forced convection greenhouse and indirect cabinet drying of date fruits: A comparative study. J. Therm. Anal. Calorim. 2023, 148, 5437–5454. [Google Scholar] [CrossRef]

- Boubekri, A.; Benmoussa, H.; Mennouche, D. Solar drying kinetics of date palm fruits assuming a step-wise air temperature change. J. Eng. Sci. Technol. 2009, 4, 292–304. [Google Scholar]

- Raihen, M.N.; Akter, S. Prediction modeling using deep learning for the classification of grape-type dried fruits. Int. J. Math. Comput. Eng. 2024, 2, 1–12. [Google Scholar] [CrossRef]

- Sağlam, C.; Çetin, N. Machine learning algorithms to estimate drying characteristics of apples slices dried with different methods. J. Food Process. Preserv. 2022, 46, e16496. [Google Scholar] [CrossRef]

- Çetin, N.; Sağlam, C. Rapid detection of total phenolics, antioxidant activity and ascorbic acid of dried apples by chemometric algorithms. Food Biosci. 2022, 47, 101670. [Google Scholar] [CrossRef]

- Al-Mashhadany, S.A.; Hasan, H.A.; Al-Sammarraie, M.A.J. Using Machine Learning Algorithms to Predict the Sweetness of Bananas at Different Drying Times. J. Ecol. Eng. 2024, 25, 231–238. [Google Scholar] [CrossRef]

| Image Texture Parameter | Fresh ‘Mejhoul’ | Convective-Dried ‘Mejhoul’ | Infrared-Dried ‘Mejhoul’ |

|---|---|---|---|

| RHMean | 70.35 a | 70.08 ab | 69.44 b |

| GHMean | 59.65 a | 57.44 b | 55.54 c |

| BHMean | 55.51 a | 53.45 b | 51.60 c |

| LHMean | 91.94 a | 90.28 b | 88.77 c |

| aHMean | 130.02 a | 130.79 b | 131.24 c |

| bHMean | 130.46 a | 130.73 b | 130.91 b |

| XHMean | 12.74 a | 12.41 b | 11.85 c |

| YHMean | 12.58 a | 12.08 b | 11.40 c |

| ZHMean | 10.56 a | 10.07 b | 9.30 c |

| Algorithm | Predicted Class (Number of Cases) | Actual Class | Average Accuracy (%) | ||

|---|---|---|---|---|---|

| Fresh ‘Mejhoul’ | Convective-Dried ‘Mejhoul’ | Infrared-Dried ‘Mejhoul’ | |||

| trees Random Forest | 400 | 0 | 0 | Fresh ‘Mejhoul’ | 99.33 |

| 6 | 393 | 1 | Convective-dried ‘Mejhoul’ | ||

| 0 | 1 | 399 | Infrared-dried ‘Mejhoul’ | ||

| rules PART | 399 | 1 | 0 | Fresh ‘Mejhoul’ | 97.83 |

| 23 | 376 | 1 | Convective-dried ‘Mejhoul’ | ||

| 0 | 1 | 399 | Infrared-dried ‘Mejhoul’ | ||

| meta Logit Boost | 394 | 6 | 0 | Fresh ‘Mejhoul’ | 98.42 |

| 12 | 387 | 1 | Convective-dried ‘Mejhoul’ | ||

| 0 | 0 | 400 | Infrared-dried ‘Mejhoul’ | ||

| lazy IBk | 400 | 0 | 0 | Fresh ‘Mejhoul’ | 99.25 |

| 8 | 391 | 1 | Convective-dried ‘Mejhoul’ | ||

| 0 | 0 | 400 | Infrared-dried ‘Mejhoul’ | ||

| functions Multilayer Perceptron | 397 | 3 | 0 | Fresh ‘Mejhoul’ | 98.67 |

| 13 | 387 | 0 | Convective-dried ‘Mejhoul’ | ||

| 0 | 0 | 400 | Infrared-dried ‘Mejhoul’ | ||

| Bayes Bayes Net | 391 | 9 | 0 | Fresh ‘Mejhoul’ | 98.42 |

| 9 | 390 | 1 | Convective-dried ‘Mejhoul’ | ||

| 0 | 0 | 400 | Infrared-dried ‘Mejhoul’ | ||

| Algorithm | Class | TPR | FPR | Precision | Recall | F-Measure | MCC | ROC Area | PRC Area |

|---|---|---|---|---|---|---|---|---|---|

| trees Random Forest | Fresh ‘Mejhoul’ | 1.000 | 0.008 | 0.985 | 1.000 | 0.993 | 0.989 | 1.000 | 1.000 |

| Convective-dried ‘Mejhoul’ | 0.983 | 0.001 | 0.997 | 0.983 | 0.990 | 0.985 | 0.998 | 0.998 | |

| Infrared-dried ‘Mejhoul’ | 0.998 | 0.001 | 0.998 | 0.998 | 0.998 | 0.996 | 1.000 | 1.000 | |

| rules PART | Fresh ‘Mejhoul’ | 0.998 | 0.029 | 0.945 | 0.998 | 0.971 | 0.956 | 0.985 | 0.939 |

| Convective-dried ‘Mejhoul’ | 0.940 | 0.003 | 0.995 | 0.940 | 0.967 | 0.951 | 0.966 | 0.970 | |

| Infrared-dried ‘Mejhoul’ | 0.998 | 0.001 | 0.998 | 0.998 | 0.998 | 0.996 | 0.998 | 0.994 | |

| meta Logit Boost | Fresh ‘Mejhoul’ | 0.985 | 0.015 | 0.970 | 0.985 | 0.978 | 0.966 | 0.999 | 0.998 |

| Convective-dried ‘Mejhoul’ | 0.968 | 0.008 | 0.985 | 0.968 | 0.976 | 0.964 | 0.996 | 0.996 | |

| Infrared-dried ‘Mejhoul’ | 1.000 | 0.001 | 0.998 | 1.000 | 0.999 | 0.998 | 0.999 | 0.998 | |

| lazy IBk | Fresh ‘Mejhoul’ | 1.000 | 0.010 | 0.980 | 1.000 | 0.990 | 0.985 | 0.991 | 0.966 |

| Convective-dried ‘Mejhoul’ | 0.978 | 0.000 | 1.000 | 0.978 | 0.989 | 0.983 | 0.981 | 0.985 | |

| Infrared-dried ‘Mejhoul’ | 1.000 | 0.001 | 0.998 | 1.000 | 0.999 | 0.998 | 0.999 | 0.998 | |

| functions Multilayer Perceptron | Fresh ‘Mejhoul’ | 0.993 | 0.016 | 0.968 | 0.993 | 0.980 | 0.970 | 0.996 | 0.990 |

| Convective-dried ‘Mejhoul’ | 0.968 | 0.004 | 0.992 | 0.968 | 0.980 | 0.970 | 0.992 | 0.974 | |

| Infrared-dried ‘Mejhoul’ | 1.000 | 0.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | |

| Bayes Bayes Net | Fresh date fruit | 0.978 | 0.011 | 0.978 | 0.978 | 0.978 | 0.966 | 0.999 | 0.998 |

| Convective-dried date fruit | 0.975 | 0.011 | 0.977 | 0.975 | 0.976 | 0.964 | 0.997 | 0.996 | |

| Infrared-dried date fruit | 1.000 | 0.001 | 0.998 | 1.000 | 0.999 | 0.998 | 0.999 | 0.998 |

| Image Texture Parameter | Fresh ‘Boufeggous’ | Convective-Dried ‘Boufeggous’ | Infrared-Dried ‘Boufeggous’ |

|---|---|---|---|

| RHMean | 65.32 a | 65.25 a | 63.70 b |

| GHMean | 56.54 a | 56.18 a | 53.20 b |

| BHMean | 49.58 a | 51.53 b | 48.22 c |

| LHMean | 88.10 a | 88.04 a | 85.40 b |

| aHMean | 129.06 a | 129.58 b | 130.07 c |

| bHMean | 131.64 a | 130.59 b | 131.01 c |

| XHMean | 11.56 a | 11.47 a | 10.81 b |

| YHMean | 11.61 a | 11.60 a | 10.74 b |

| ZHMean | 9.08 a | 9.72 b | 8.84 c |

| Algorithm | Predicted Class (Number of Cases) | Actual Class | Average Accuracy (%) | ||

|---|---|---|---|---|---|

| Fresh ‘Boufeggous’ | Convective-Dried ‘Boufeggous’ | Infrared-Dried ‘Boufeggous’ | |||

| trees Random Forest | 377 | 22 | 1 | Fresh ‘Boufeggous’ | 94.33 |

| 42 | 356 | 2 | Convective-dried ‘Boufeggous’ | ||

| 0 | 1 | 399 | Infrared-dried ‘Boufeggous’ | ||

| rules PART | 361 | 38 | 1 | Fresh ‘Boufeggous’ | 92.25 |

| 48 | 348 | 4 | Convective-dried ‘Boufeggous’ | ||

| 0 | 2 | 398 | Infrared-dried ‘Boufeggous’ | ||

| meta Logit Boost | 367 | 31 | 2 | Fresh ‘Boufeggous’ | 94.25 |

| 35 | 365 | 0 | Convective-dried ‘Boufeggous’ | ||

| 0 | 1 | 399 | Infrared-dried ‘Boufeggous’ | ||

| lazy IBk | 352 | 47 | 1 | Fresh ‘Boufeggous’ | 91.00 |

| 57 | 342 | 1 | Convective-dried ‘Boufeggous’ | ||

| 1 | 1 | 398 | Infrared-dried ‘Boufeggous’ | ||

| functions Multilayer Perceptron | 370 | 26 | 4 | Fresh ‘Boufeggous’ | 93.92 |

| 41 | 359 | 0 | Convective-dried ‘Boufeggous’ | ||

| 1 | 1 | 398 | Infrared-dried ‘Boufeggous’ | ||

| Bayes Bayes Net | 373 | 26 | 1 | Fresh ‘Boufeggous’ | 93.67 |

| 43 | 357 | 0 | Convective-dried ‘Boufeggous’ | ||

| 1 | 5 | 394 | Infrared-dried ‘Boufeggous’ | ||

| Algorithm | Class | TPR | FPR | Precision | Recall | F-Measure | MCC | ROC Area | PRC Area |

|---|---|---|---|---|---|---|---|---|---|

| trees Random Forest | Fresh ‘Boufeggous’ | 0.943 | 0.053 | 0.900 | 0.943 | 0.921 | 0.880 | 0.990 | 0.980 |

| Convective-dried ‘Boufeggous’ | 0.890 | 0.029 | 0.939 | 0.890 | 0.914 | 0.873 | 0.990 | 0.980 | |

| Infrared-dried ‘Boufeggous’ | 0.998 | 0.004 | 0.993 | 0.998 | 0.995 | 0.993 | 1.000 | 1.000 | |

| rules PART | Fresh ‘Boufeggous’ | 0.903 | 0.060 | 0.883 | 0.903 | 0.892 | 0.838 | 0.961 | 0.938 |

| Convective-dried ‘Boufeggous’ | 0.870 | 0.050 | 0.897 | 0.870 | 0.883 | 0.826 | 0.967 | 0.927 | |

| Infrared-dried ‘Boufeggous’ | 0.995 | 0.006 | 0.988 | 0.995 | 0.991 | 0.987 | 0.995 | 0.984 | |

| meta Logit Boost | Fresh ‘Boufeggous’ | 0.918 | 0.044 | 0.913 | 0.918 | 0.915 | 0.873 | 0.988 | 0.975 |

| Convective-dried ‘Boufeggous’ | 0.913 | 0.040 | 0.919 | 0.913 | 0.916 | 0.874 | 0.987 | 0.978 | |

| Infrared-dried ‘Boufeggous’ | 0.998 | 0.003 | 0.995 | 0.998 | 0.996 | 0.994 | 0.999 | 0.999 | |

| lazy IBk | Fresh ‘Boufeggous’ | 0.880 | 0.073 | 0.859 | 0.880 | 0.869 | 0.803 | 0.905 | 0.800 |

| Convective-dried ‘Boufeggous’ | 0.855 | 0.060 | 0.877 | 0.855 | 0.866 | 0.800 | 0.899 | 0.804 | |

| Infrared-dried ‘Boufeggous’ | 0.995 | 0.003 | 0.995 | 0.995 | 0.995 | 0.993 | 0.996 | 0.992 | |

| functions Multilayer Perceptron | Fresh ‘Boufeggous’ | 0.925 | 0.053 | 0.898 | 0.925 | 0.911 | 0.866 | 0.973 | 0.948 |

| Convective-dried ‘Boufeggous’ | 0.898 | 0.034 | 0.930 | 0.898 | 0.913 | 0.872 | 0.979 | 0.963 | |

| Infrared-dried ‘Boufeggous’ | 0.995 | 0.005 | 0.990 | 0.995 | 0.993 | 0.989 | 0.998 | 0.995 | |

| Bayes Bayes Net | Fresh ‘Boufeggous’ | 0.933 | 0.055 | 0.894 | 0.933 | 0.913 | 0.869 | 0.982 | 0.964 |

| Convective-dried ‘Boufeggous’ | 0.893 | 0.039 | 0.920 | 0.893 | 0.906 | 0.860 | 0.981 | 0.966 | |

| Infrared-dried ‘Boufeggous’ | 0.985 | 0.001 | 0.997 | 0.985 | 0.991 | 0.987 | 1.000 | 0.999 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Noutfia, Y.; Ropelewska, E. Exploration of Convective and Infrared Drying Effect on Image Texture Parameters of ‘Mejhoul’ and ‘Boufeggous’ Date Palm Fruit Using Machine Learning Models. Foods 2024, 13, 1602. https://doi.org/10.3390/foods13111602

Noutfia Y, Ropelewska E. Exploration of Convective and Infrared Drying Effect on Image Texture Parameters of ‘Mejhoul’ and ‘Boufeggous’ Date Palm Fruit Using Machine Learning Models. Foods. 2024; 13(11):1602. https://doi.org/10.3390/foods13111602

Chicago/Turabian StyleNoutfia, Younes, and Ewa Ropelewska. 2024. "Exploration of Convective and Infrared Drying Effect on Image Texture Parameters of ‘Mejhoul’ and ‘Boufeggous’ Date Palm Fruit Using Machine Learning Models" Foods 13, no. 11: 1602. https://doi.org/10.3390/foods13111602

APA StyleNoutfia, Y., & Ropelewska, E. (2024). Exploration of Convective and Infrared Drying Effect on Image Texture Parameters of ‘Mejhoul’ and ‘Boufeggous’ Date Palm Fruit Using Machine Learning Models. Foods, 13(11), 1602. https://doi.org/10.3390/foods13111602