Artificial Rainfall on Grain Quality and Baking Characteristics of Winter Wheat Cultivars in Korea

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Materials

2.2. Artificial Rain Treatments

2.3. Flour Sample Preparation

2.4. Color Measurements

2.5. Measurement of Flour Quality

2.6. Alpha-Amylase Assay and Falling Number

2.7. Baking Quality

2.8. Statistical Analysis

3. Results and Discussion

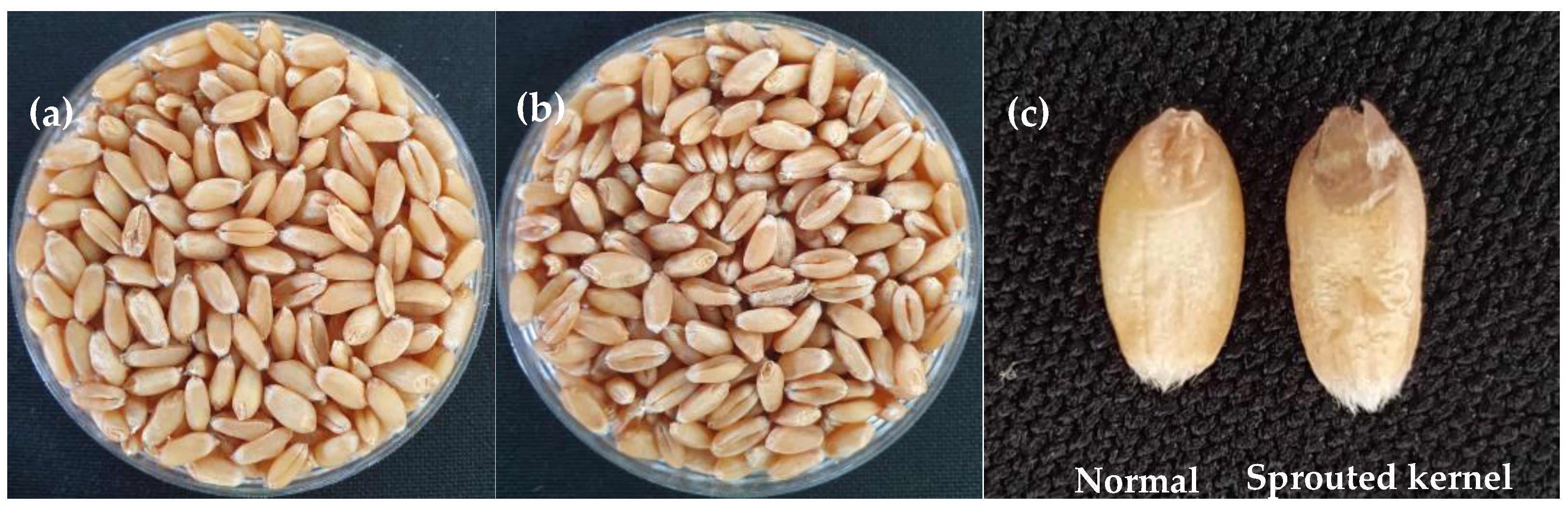

3.1. Kernel Quality Characteristics

3.2. Starch Characteristics

3.3. Flour Quality

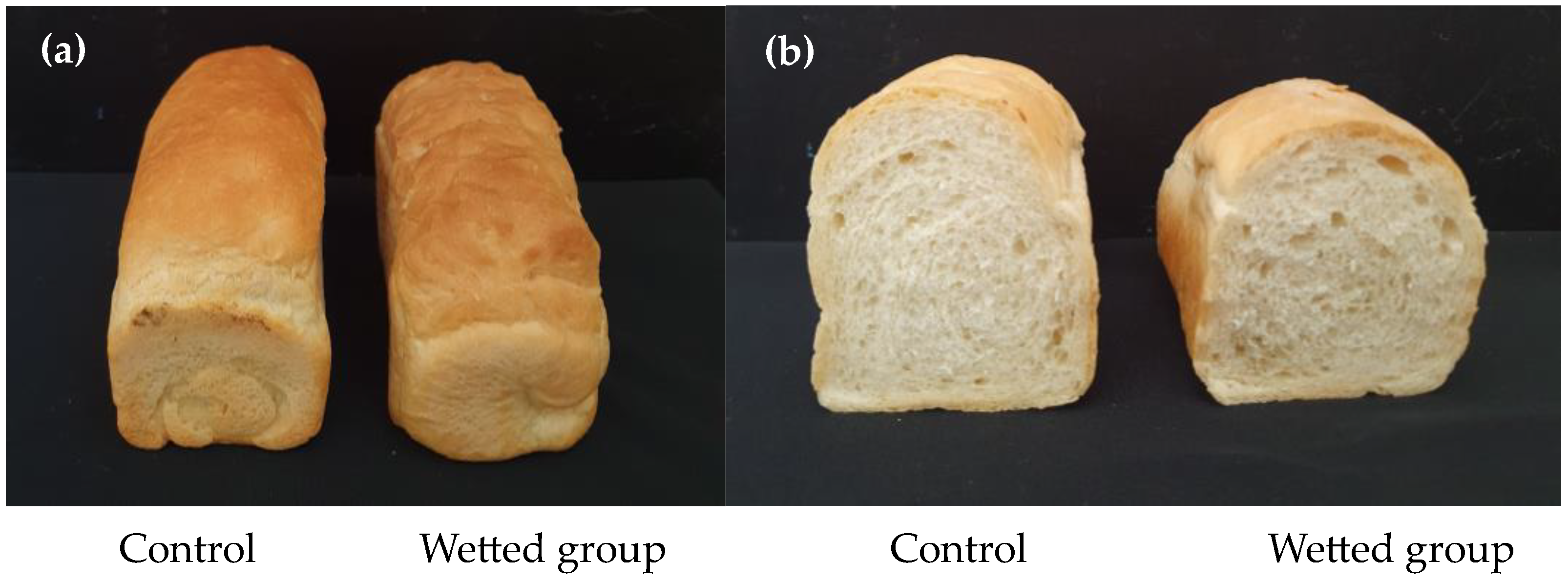

3.4. Dough and Baking Quality

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tilman, D.; Balzer, C.; Hill, J.; Befort, B.L. Global food demand and the sustainable intensification of agriculture. Proc. Natl. Acad. Sci. USA 2011, 108, 20260–20264. [Google Scholar] [CrossRef] [PubMed]

- Asseng, S.; Guarin, J.R.; Raman, M.; Monje, O.; Kiss, G.; Despommier, D.D.; Meggers, F.M.; Gauthier, P.P. Wheat yield potential in controlled-environment vertical farms. Proc. Natl. Acad. Sci. USA 2020, 117, 19131–19135. [Google Scholar] [CrossRef] [PubMed]

- Boyer, J.S. Plant productivity and environment. Science 1982, 218, 443–448. [Google Scholar] [CrossRef] [PubMed]

- Hughes, N.; Galeano, D.; Hatfield-Dodds, S. The effects of drought and climate variability on Australian farms. ABARES 2019, 11. Available online: https://apo.org.au/sites/default/files/resource-files/2019-12/apo-nid272176.pdf (accessed on 2 March 2024).

- Food and Agricultural Organization of the United Nations (FAO). FAOSTAT. 2020. Available online: http://www.fao.org/faostat/en/#home (accessed on 21 January 2021).

- Labuschagne, M.; Elago, O.; Koen, E. The influence of temperature extremes on some quality and starch characteristics in bread, biscuit and durum wheat. J. Cereal Sci. 2009, 49, 184–189. [Google Scholar] [CrossRef]

- Li, Y.F.; Wu, Y.; Hernandez-Espinosa, N.; Pena, R.J. Comparing small-scale testing methods for predicting wheat gluten strength across environments. Cereal Chem. 2015, 92, 231–235. [Google Scholar] [CrossRef]

- Vetch, J.M.; Stougaard, R.N.; Martin, J.M.; Giroux, M.J. Revealing the genetic mechanisms of pre-harvest sprouting in hexaploid wheat (Triticum aestivum L.). Plant Sci. 2019, 281, 180–185. [Google Scholar] [CrossRef] [PubMed]

- Fowler, D.; Brydon, J.; Darroch, B.; Entz, M.; Johnston, A. Environment and genotype influence on grain protein concentration of wheat and rye. Agronomy 1990, 82, 655–664. [Google Scholar] [CrossRef]

- Jiang, G.-L.; Xiao, S. Factorial cross analysis of pre-harvest sprouting resistance in white wheat. Field Crops Res. 2005, 91, 63–69. [Google Scholar] [CrossRef]

- Sorenson, B.; Wiersma, J. Sprout damaged wheat, crop insurance and quality concerns. Minn. Crop News Arch. 2004. Available online: http://www.extension.umn.edu/cropEnews/2004/04MNCN31.htm (accessed on 2 February 2024).

- Wahl, T.I.; Desmond O’Rourke, A. The economics of sprout damage in wheat. Agribusiness 1994, 10, 27–41. [Google Scholar] [CrossRef]

- Hatcher, D.; Symons, S. Influence of sprout damage on oriental noodle appearance as assessed by image analysis. Cereal Chem. 2000, 77, 380–387. [Google Scholar] [CrossRef]

- Lin, M.; Liu, S.; Zhang, G.; Bai, G. Effects of TaPHS1 and TaMKK3-A genes on wheat pre-harvest sprouting resistance. Agronomy 2018, 8, 210. [Google Scholar] [CrossRef]

- Groos, C.; Gay, G.; Perretant, M.-R.; Gervais, L.; Bernard, M.; Dedryver, F.; Charmet, G. Study of the relationship between pre-harvest sprouting and grain color by quantitative trait loci analysis in a white× red grain bread-wheat cross. Theor. Appl. Genet. 2002, 104, 39–47. [Google Scholar] [CrossRef]

- Kruger, J. Biochemistry of preharvest sprouting in cereals. In Preharvest Field Sprouting in Cereals; CRC Press: Boca Raton, FL, USA, 2018; pp. 1–14. [Google Scholar]

- King, R.; von Wettstein-Knowles, P. Epicuticular waxes and regulation of ear wetting and pre-harvest sprouting in barley and wheat. Euphytica 2000, 112, 157–166. [Google Scholar] [CrossRef]

- Peery, S.R.; Carle, S.W.; Wysock, M.; Pumphrey, M.O.; Steber, C.M. LMA or vivipary? Wheat grain can germinate precociously during grain maturation under the cool conditions used to induce late maturity alpha-amylase (LMA). Front. Plant Sci. 2023, 14, 1156784. [Google Scholar] [CrossRef]

- Mares, D. Temperature dependence of germinability of wheat (Triticum aestivum L.) grain in relation to pre-harvest sprouting. Aust. J. Agric. Res. 1984, 35, 115–128. [Google Scholar] [CrossRef]

- Cannon, A.E.; Marston, E.J.; Kiszonas, A.M.; Hauvermale, A.L.; See, D.R. Late-maturity α-amylase (LMA): Exploring the underlying mechanisms and end-use quality effects in wheat. Planta 2022, 255, 2. [Google Scholar] [CrossRef]

- Fincher, G.B. Molecular and cellular biology associated with endosperm mobilization in germinating cereal grains. Annu. Rev. Plant Biol. 1989, 40, 305–346. [Google Scholar] [CrossRef]

- Perten, H. Application of the falling number method for evaluating alpha-amylase activity. Cereal Chem. 1964, 41, 127–140. [Google Scholar]

- Steber, C.M. Avoiding problems in wheat with low falling numbers. Crops Soils 2017, 50, 22–25. [Google Scholar] [CrossRef]

- Newberry, M.; Zwart, A.B.; Whan, A.; Mieog, J.C.; Sun, M.; Leyne, E.; Pritchard, J.; Daneri-Castro, S.N.; Ibrahim, K.; Diepeveen, D. Does late maturity alpha-amylase impact wheat baking quality? Front. Plant Sci. 2018, 9, 1356. [Google Scholar] [CrossRef]

- Kaur, A.; Shevkani, K.; Katyal, M.; Singh, N.; Ahlawat, A.K.; Singh, A.M. Physicochemical and rheological properties of starch and flour from different durum wheat varieties and their relationships with noodle quality. J. Food Sci. Technol. 2016, 53, 2127–2138. [Google Scholar] [CrossRef]

- Simsek, S.; Ohm, J.-B.; Lu, H.; Rugg, M.; Berzonsky, W.; Alamri, M.S.; Mergoum, M. Effect of pre-harvest sprouting on physicochemical properties of starch in wheat. Foods 2014, 3, 194–207. [Google Scholar] [CrossRef]

- Park, H.; Cha, J.-K.; Lee, S.-M.; Kwon, Y.; Choi, J.; Oh, K.-W.; Lee, J.-H. Influence of Artificial Rainfall on Wheat Grain Quality During Ripening by Using the Speed-breeding System. Korean J. Crop. Sci. 2023, 68, 188–196. [Google Scholar]

- RDA. Wheat Cultivation Guidelines; Rural Development Administration: Jeonju, Republic of Korea, 2020. [Google Scholar]

- Kweon, M.; Martin, R.; Souza, E. Effect of tempering conditions on milling performance and flour functionality. Cereal Chem. 2009, 86, 12–17. [Google Scholar] [CrossRef]

- Romano, G.; Baranyai, L.; Gottschalk, K.; Zude, M. An approach for monitoring the moisture content changes of drying banana slices with laser light backscattering imaging. Food Bioprocess Technol. 2008, 1, 410–414. [Google Scholar] [CrossRef]

- Cereals & Grains Association. Approved Methods of Analysis. Methods, 46-30.01. Crude Protein-Combustion Method; 26-50.01. Brabender Quadrumat Jr.(Quadruplex) Method; 54-40.02. Mixograph Method; 38-12.02. Wet Gluten, Dry Gluten, Water-Binding Capacity, and Gluten Index; 66-50.01. Pasta and Noodle Cooking Quality-Firmness; Cereals & Grains Association: St. Paul, MN, USA, 2010. [Google Scholar]

- Delwiche, S.R.; Vinyard, B.T.; Bettge, A.D. Repeatability precision of the falling number procedure under standard and modified methodologies. Cereal Chem. 2015, 92, 177–184. [Google Scholar] [CrossRef]

- Oury, F.-X.; Lasme, P.; Michelet, C.; Rousset, M.; Abecassis, J.; Lullien-Pellerin, V. Relationships between wheat grain physical characteristics studied through near-isogenic lines with distinct puroindoline-b allele. Theor. Appl. Genet. 2015, 128, 913–929. [Google Scholar] [CrossRef]

- Baasandorj, T.; Ohm, J.B.; Simsek, S. Effect of dark, hard, and vitreous kernel content on protein molecular weight distribution and on milling and breadmaking quality characteristics for hard spring wheat samples from diverse growing regions. Cereal Chem. 2015, 92, 570–577. [Google Scholar] [CrossRef]

- Weightman, R.M.; Millar, S.; Alava, J.; Foulkes, M.J.; Fish, L.; Snape, J.W. Effects of drought and the presence of the 1BL/1RS translocation on grain vitreosity, hardness and protein content in winter wheat. J. Cereal Sci. 2008, 47, 457–468. [Google Scholar] [CrossRef]

- Johansson, E.; Malik, A.H.; Hussain, A.; Rasheed, F.; Newson, W.R.; Plivelic, T.; Hedenqvist, M.S.; Gällstedt, M.; Kuktaite, R. Wheat gluten polymer structures: The impact of genotype, environment, and processing on their functionality in various applications. Cereal Chem. 2013, 90, 367–376. [Google Scholar] [CrossRef]

- Dong, K.; Ge, P.; Ma, C.; Wang, K.; Yan, X.; Gao, L.; Li, X.; Liu, J.; Ma, W.; Yan, Y. Albumin and globulin dynamics during grain development of elite Chinese wheat cultivar Xiaoyan 6. J. Cereal Sci. 2012, 56, 615–622. [Google Scholar] [CrossRef]

- Wei, C.; Zhang, J.; Chen, Y.; Zhou, W.; Xu, B.; Wang, Y.; Chen, J. Physicochemical properties and development of wheat large and small starch granules during endosperm development. Acta Physiol. Plant 2010, 32, 905–916. [Google Scholar] [CrossRef]

- Shang, J.; Li, L.; Zhao, B.; Liu, M.; Zheng, X. Comparative studies on physicochemical properties of total, A-and B-type starch from soft and hard wheat varieties. Int. J. Biol. Macromol. 2020, 154, 714–723. [Google Scholar] [CrossRef]

- Ichinose, Y.; Takata, K.; Kuwabara, T.; Iriki, N.; Abiki, T.; Yamauchi, H. Effects of increase in α-amylase and endo-protease activities during germination on the breadmaking quality of wheat. Food Sci. Technol. Res. 2001, 7, 214–219. [Google Scholar] [CrossRef]

- Barnard, A. Genetic diversity of South African winter wheat cultivars in relation to preharvest sprouting and falling number. In Proceedings of the Wheat in a Global Environment: Proceedings of the 6th International Wheat Conference, Budapest, Hungary, 5–9 June 2000; pp. 237–242. [Google Scholar]

- Rakita, S.M.; Torbica, A.M.; Dokić, L.P.; Tomić, J.M.; Pojić, M.M.; Hadnađev, M.S.; Hadnađev, D.T.R. Alpha-amylase activity in wheat flour and breadmaking properties in relation to different climatic conditions. Food Feed Res. 2015, 42, 91–99. [Google Scholar] [CrossRef]

- Flintham, J.E. Different genetic components control coat-imposed and embryo-imposed dormancy in wheat. Seed Sci. Res. 2000, 10, 43–50. [Google Scholar] [CrossRef]

- Shorinola, O.; Bird, N.; Simmonds, J.; Berry, S.; Henriksson, T.; Jack, P.; Werner, P.; Gerjets, T.; Scholefield, D.; Balcárková, B. The wheat Phs-A1 pre-harvest sprouting resistance locus delays the rate of seed dormancy loss and maps 0.3 cM distal to the PM19 genes in UK germplasm. J. Exp. Bot 2016, 67, 4169–4178. [Google Scholar] [CrossRef]

- Hirano, J. Effects of rain in ripening period on the grain quality of wheat. JARQ Ibaraki 1976, 10, 168–173. [Google Scholar]

- Bonfil, D.J.; Abbo, S.; Svoray, T. Sowing date and wheat quality as determined by gluten index. Crop. sci. 2015, 55, 2294–2306. [Google Scholar] [CrossRef]

- Cesevičienė, J.; Butkutė, B. Comparison of Gluten Parameters When Gluten is Determined by the Glutomatic and Hand Washing Methods. 2012. Available online: https://www.researchgate.net/profile/Jurgita-Ceseviciene/publication/236132092_Comparison_of_gluten_parameters_when_gluten_is_determined_by_the_glutomatic_and_hand_washing_methods/links/5834492c08ae138f1c0d696d/Comparison-of-gluten-parameters-when-gluten-is-determined-by-the-glutomatic-and-hand-washing-methods.pdf (accessed on 15 February 2024).

- Wahlund, K.-G.; Gustavsson, M.; MacRitchie, F.; Nylander, T.; Wannerberger, L. Size characterisation of wheat proteins, particularly glutenin, by asymmetrical flow field-flow fractionation. J. Cereal Sci. 1996, 23, 113–119. [Google Scholar] [CrossRef]

- Chaudhary, N.; Dangi, P.; Khatkar, B.S. Assessment of molecular weight distribution of wheat gluten proteins for chapatti quality. Food Chem. 2016, 199, 28–35. [Google Scholar] [CrossRef]

- Uthayakumaran, S.; Gras, P.; Stoddard, F.; Bekes, F. Effect of varying protein content and glutenin-to-gliadin ratio on the functional properties of wheat dough. Cereal Chem. 1999, 76, 389–394. [Google Scholar] [CrossRef]

- Chung, O.; Ohm, J.; Caley, M.; Seabourn, B. Prediction of baking characteristics of hard winter wheat flours using computer-analyzed mixograph parameters. Cereal Chem. 2001, 78, 493–497. [Google Scholar] [CrossRef]

- Gras, P.; O’brien, L. Application of a 2-gram mixograph to early generation selection for dough strength. Cereal Chem. 1992, 69, 254–257. [Google Scholar]

- Khatkar, B.S.; Bell, A.E.; Schofield, J.D. A comparative study of the inter-relationships between mixograph parameters and bread-making qualities of wheat flours and glutens. J. Sci. Food Agric. 1996, 72, 71–85. [Google Scholar] [CrossRef]

| Treatment 1 | L* | a* | b* | ΔE*ab |

|---|---|---|---|---|

| Control | 48.38 ± 0.23 b | 9.42 ± 0.15 a | 23.46 ± 0.25 b | - |

| Wetted | 49.41 ± 0.31 a | 9.19 ± 0.22 b | 23.72 ± 0.18 a | 1.40 ± 0.29 |

| Cultivar | Treatment | Alpha-Amylase Activity (CU(%d.b.)) | Falling Number (s) |

|---|---|---|---|

| Jokyoung | Control | 0.243 b | 415 |

| Wetted | 0.430 a | 368 | |

| Hwanggeumal | Control | 0.173 b | 432 |

| Wetted | 0.363 a | 424 |

| Cultivar | Treatment | Protein Content (%) | Amylose Content (%) | Moisture (%) | SDS -Sedimentation (mL) |

|---|---|---|---|---|---|

| Jokyoung | Control | 11.0 | 16.4 | 13.1 | 58.0 |

| Wetted | 11.5 | 14.3 | 13.1 | 56.3 | |

| Hwanggeumal | Control | 12.2 | 13.0 | 13.4 | 58.5 |

| Wetted | 13.9 | 13.0 | 13.2 | 57.5 |

| Treatment 1 | Ash Content (%) | Gluten Content (g) | Gluten Index |

|---|---|---|---|

| Control | 0.345 b | 10.3 b | 87.3 a |

| Wetted | 0.432 a | 11.9 a | 82.2 b |

| Cultivar | Treatment | MPTi (min.) | MPV (%) | MPW (%) | MTxV (%) | MTxW (%) |

|---|---|---|---|---|---|---|

| Jokyoung | Control | 5.4 b | 49.4 | 15.7 a | 40.9 b | 8.4 |

| Wetted | 6.7 a | 47.0 | 14.4 b | 42.9 a | 8.5 | |

| Hwanggeumal | Control | 4.4 b | 49.4 | 14.5 a | 39.5 b | 7.3 |

| Wetted | 4.5 a | 48.7 | 13.2 b | 40.6 a | 7.5 |

| Cultivar | Treatment | Loaf Characteristics | Color Values | ||||

|---|---|---|---|---|---|---|---|

| Mixing Time (min.) | Loaf Volume (mL) | L* | a* | b* | ΔE*ab | ||

| Jokyoung | Control | 3:25 | 800 a | 80.18 a | 0.41 b | 18.56 a | - |

| Wetted | 3:06 | 670 b | 79.37 b | 0.76 a | 17.50 b | 1.38 | |

| Hwanggeumal | Control | 2:53 | 600 a | 78.77 a | 0.63 b | 17.55 b | - |

| Wetted | 2:51 | 580 b | 76.77 b | 0.87 a | 18.13 a | 2.10 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, H.; Cha, J.-K.; Lee, S.-M.; Kwon, Y.; Choi, J.; Lee, J.-H. Artificial Rainfall on Grain Quality and Baking Characteristics of Winter Wheat Cultivars in Korea. Foods 2024, 13, 1679. https://doi.org/10.3390/foods13111679

Park H, Cha J-K, Lee S-M, Kwon Y, Choi J, Lee J-H. Artificial Rainfall on Grain Quality and Baking Characteristics of Winter Wheat Cultivars in Korea. Foods. 2024; 13(11):1679. https://doi.org/10.3390/foods13111679

Chicago/Turabian StylePark, Hyeonjin, Jin-Kyung Cha, So-Myeong Lee, Youngho Kwon, Jisu Choi, and Jong-Hee Lee. 2024. "Artificial Rainfall on Grain Quality and Baking Characteristics of Winter Wheat Cultivars in Korea" Foods 13, no. 11: 1679. https://doi.org/10.3390/foods13111679

APA StylePark, H., Cha, J.-K., Lee, S.-M., Kwon, Y., Choi, J., & Lee, J.-H. (2024). Artificial Rainfall on Grain Quality and Baking Characteristics of Winter Wheat Cultivars in Korea. Foods, 13(11), 1679. https://doi.org/10.3390/foods13111679