Impact of pH and High-Pressure Pasteurization on the Germination and Development of Clostridium perfringens Spores under Hyperbaric Storage versus Refrigeration

Abstract

1. Introduction

2. Materials and Methods

2.1. Culture Media and Chemicals

2.2. Spores’ Production, Harvesting, Storage, and Inoculation

2.3. HPP Pasteurization

2.4. Storage Conditions

2.5. Determination of Spores’ Germination and Inactivation

2.6. Spore Inactivation Kinetics Modelling

2.6.1. First-Order Kinetic Model

2.6.2. Weibull Model

2.7. Statistical Analysis

3. Results and Discussion

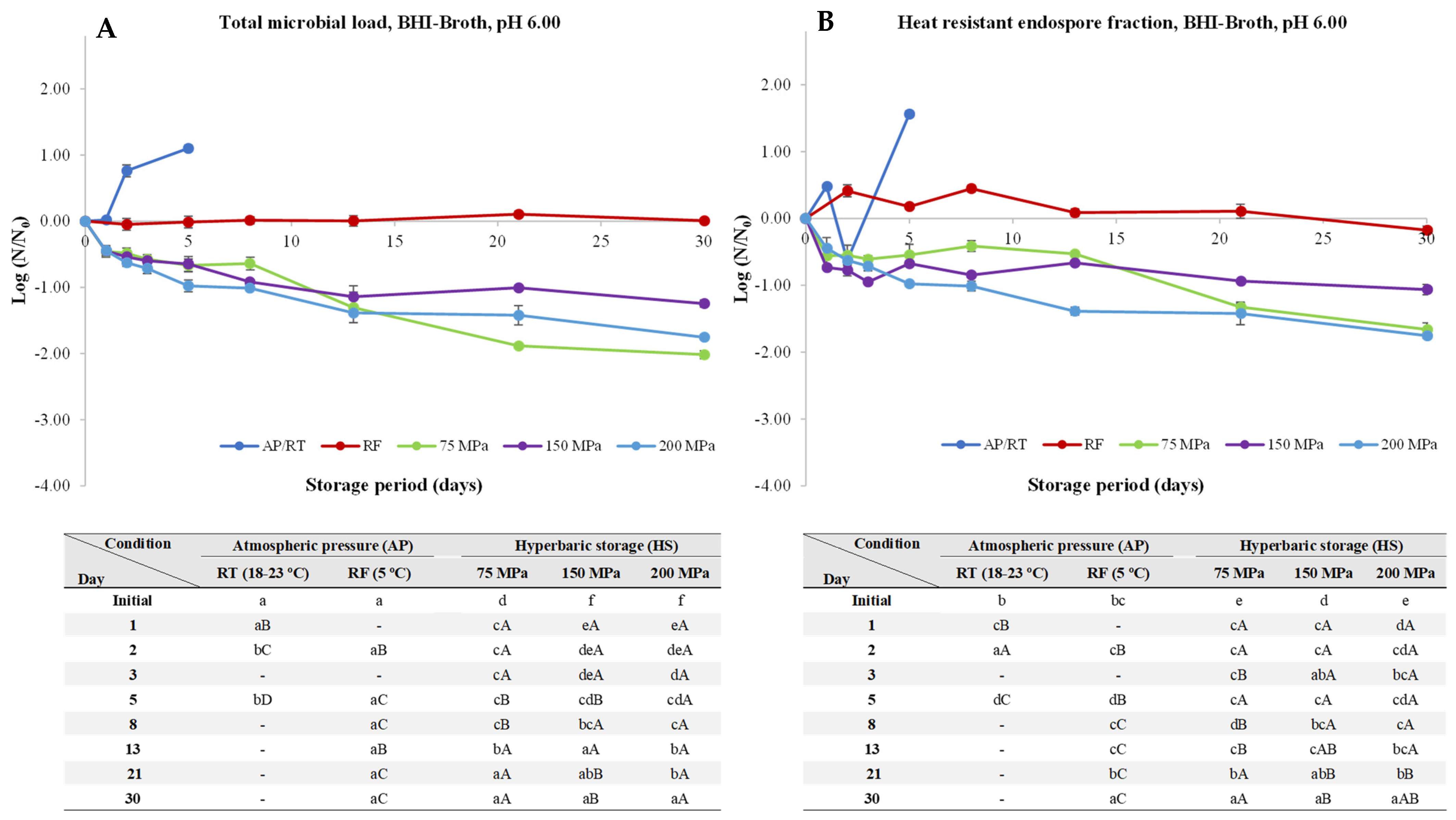

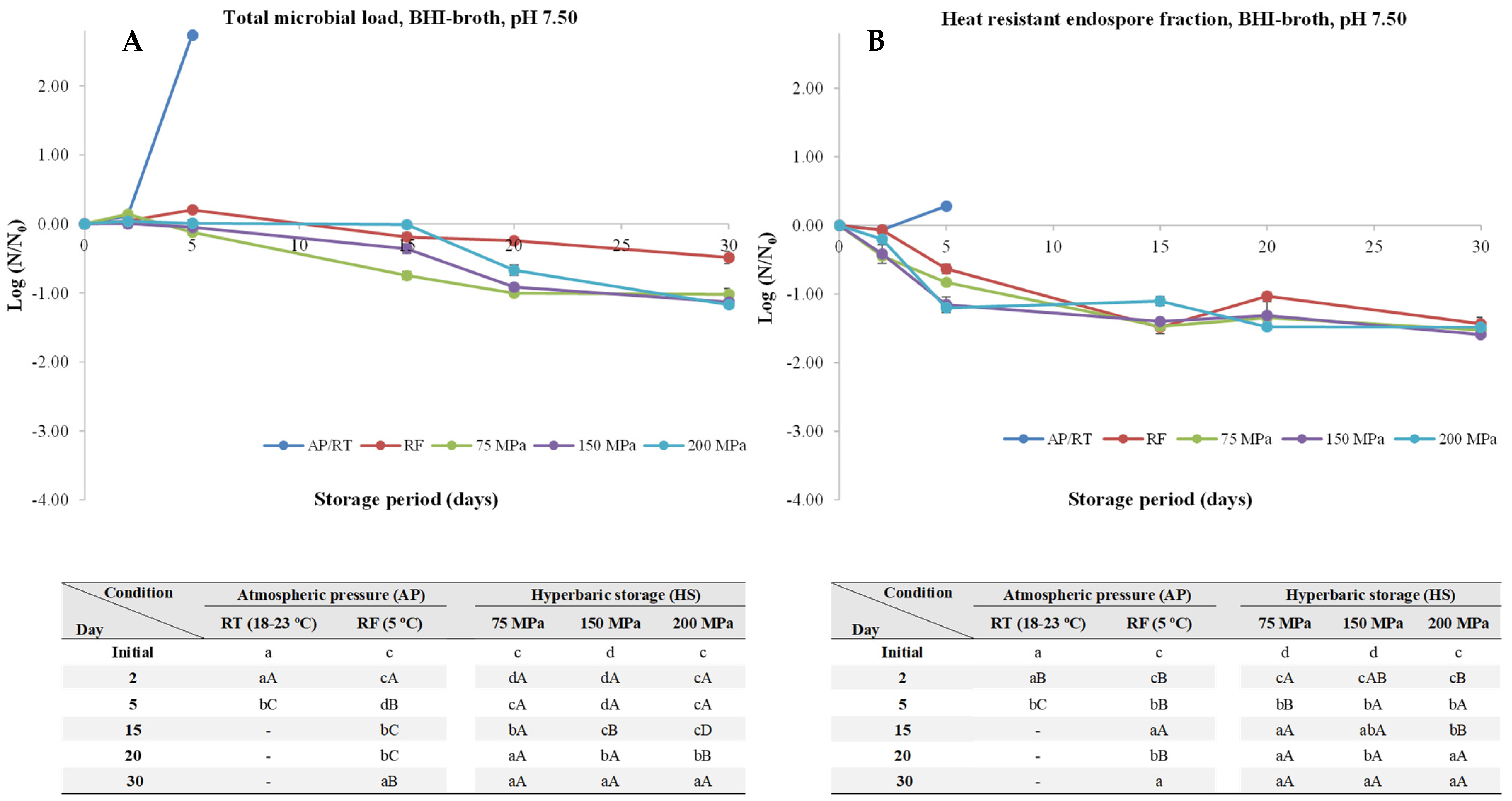

3.1. Impact of pH on the C. perfringens Spores’ Behavior under HS

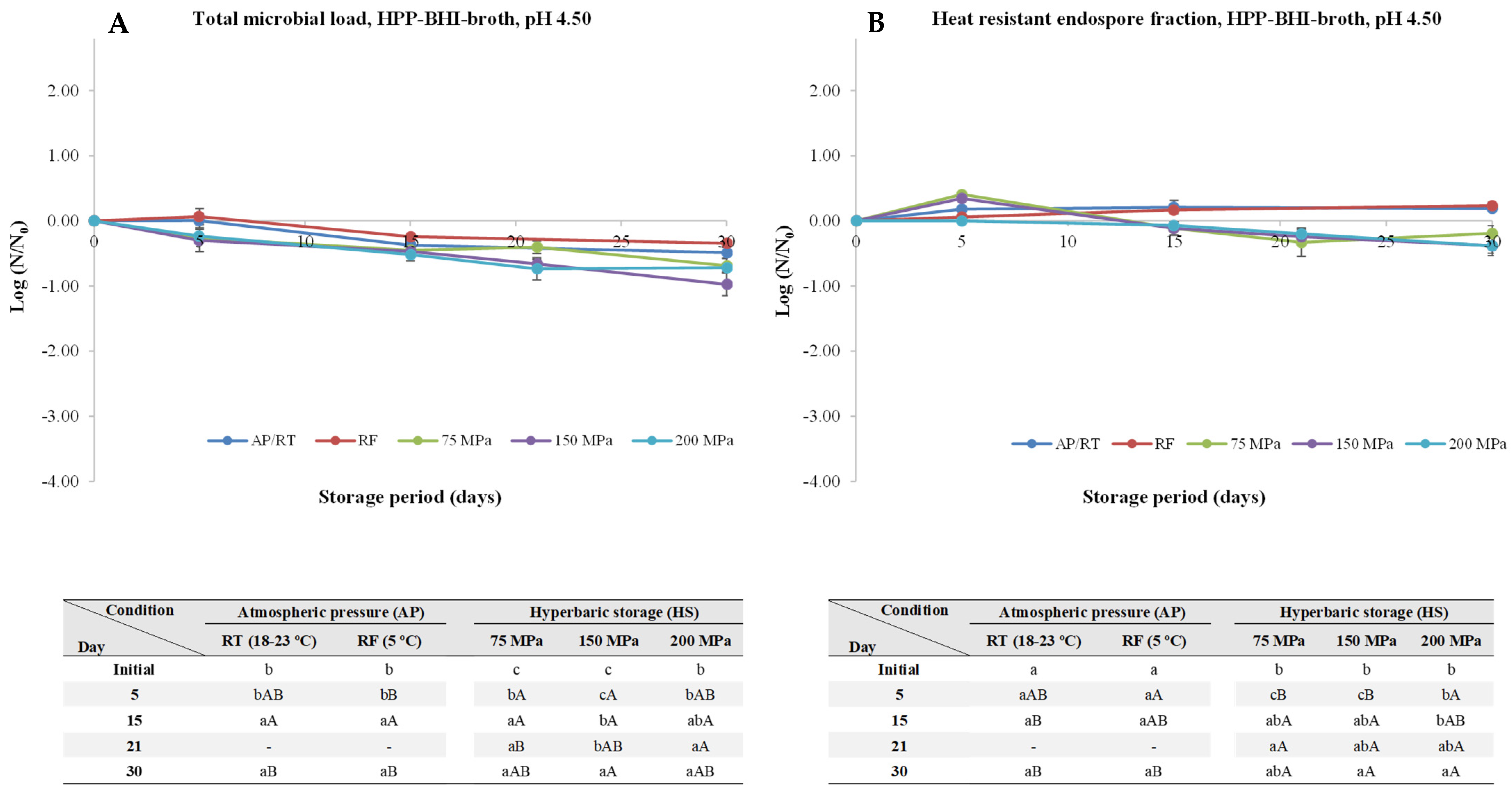

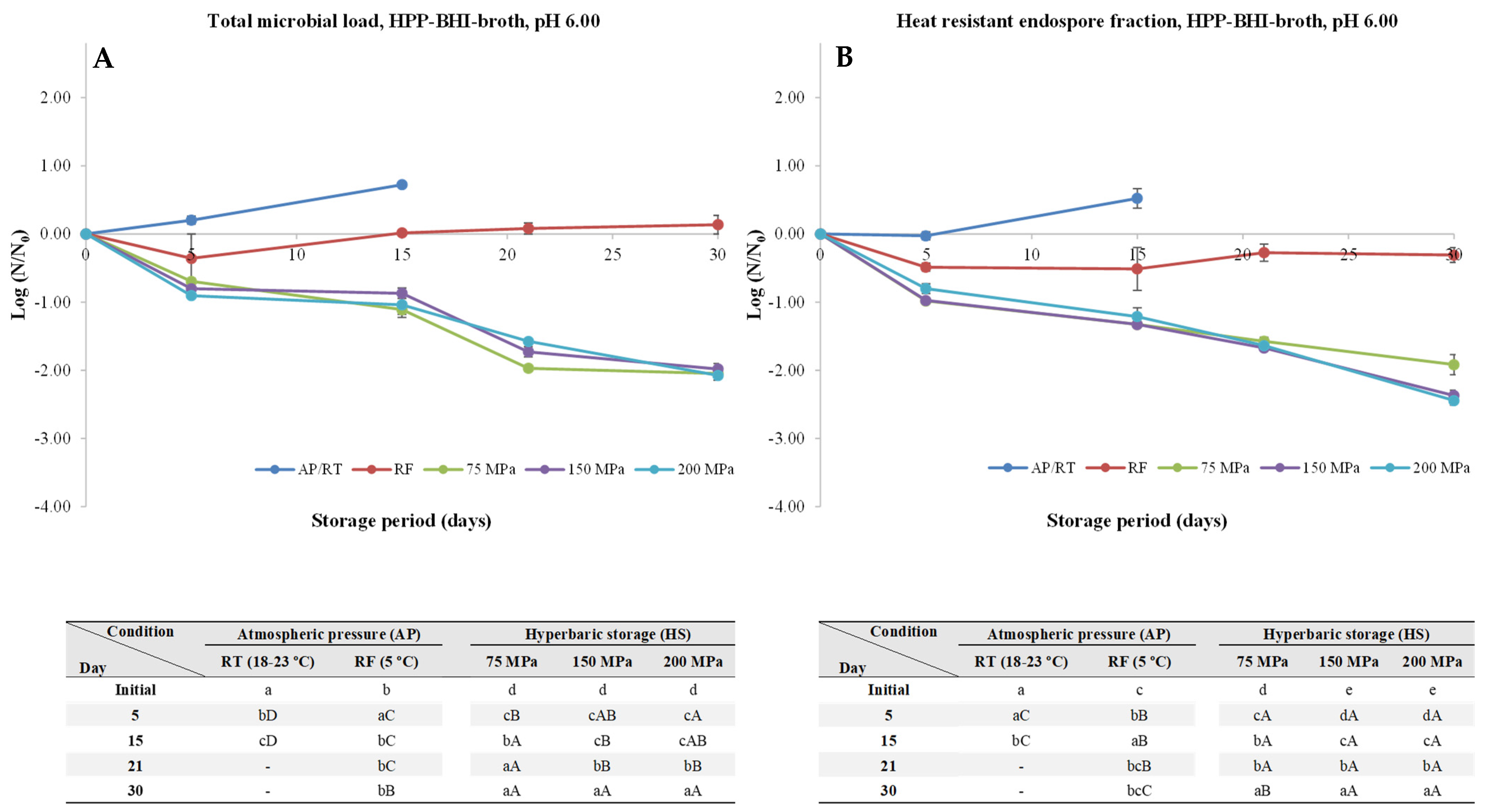

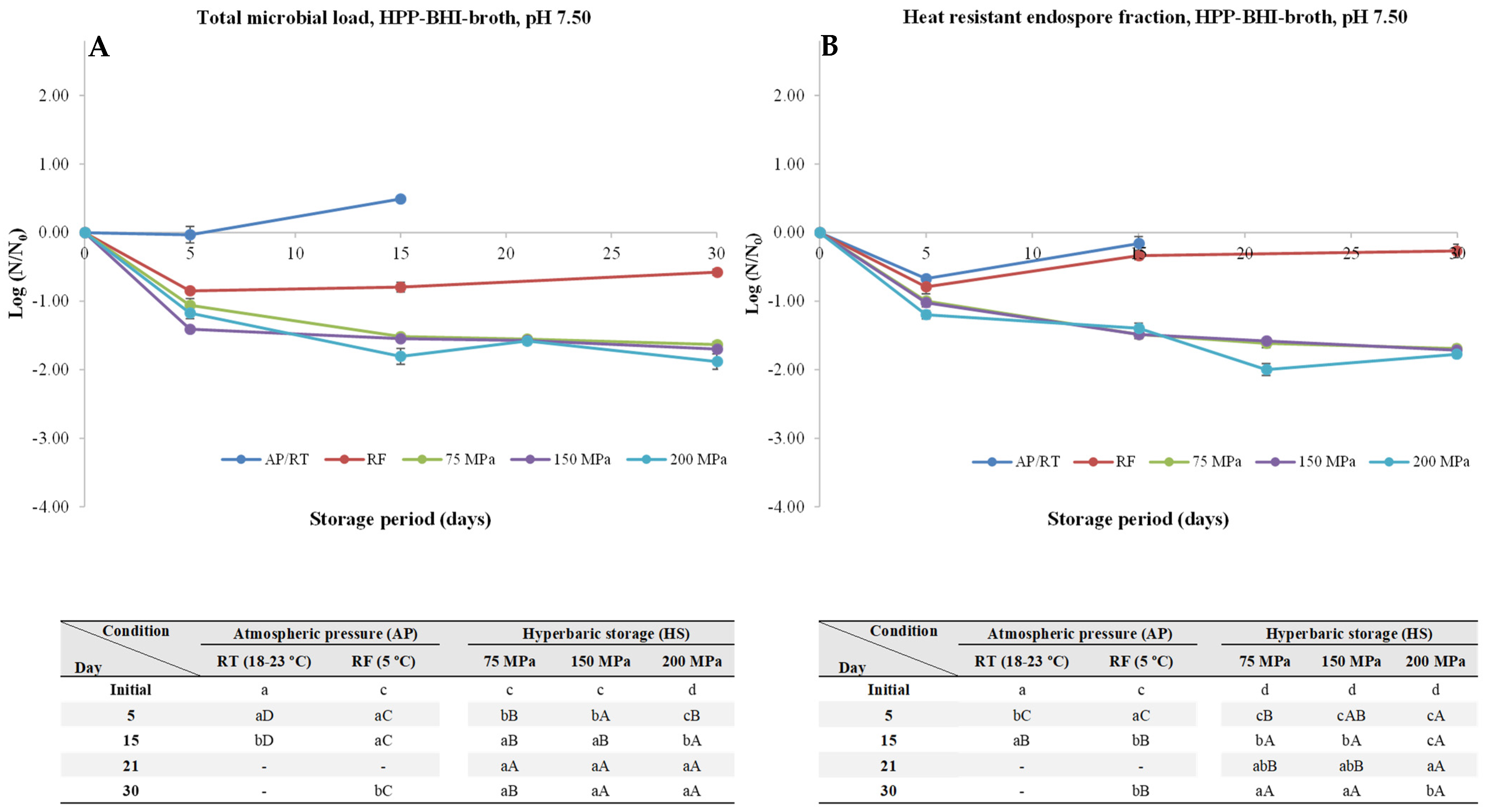

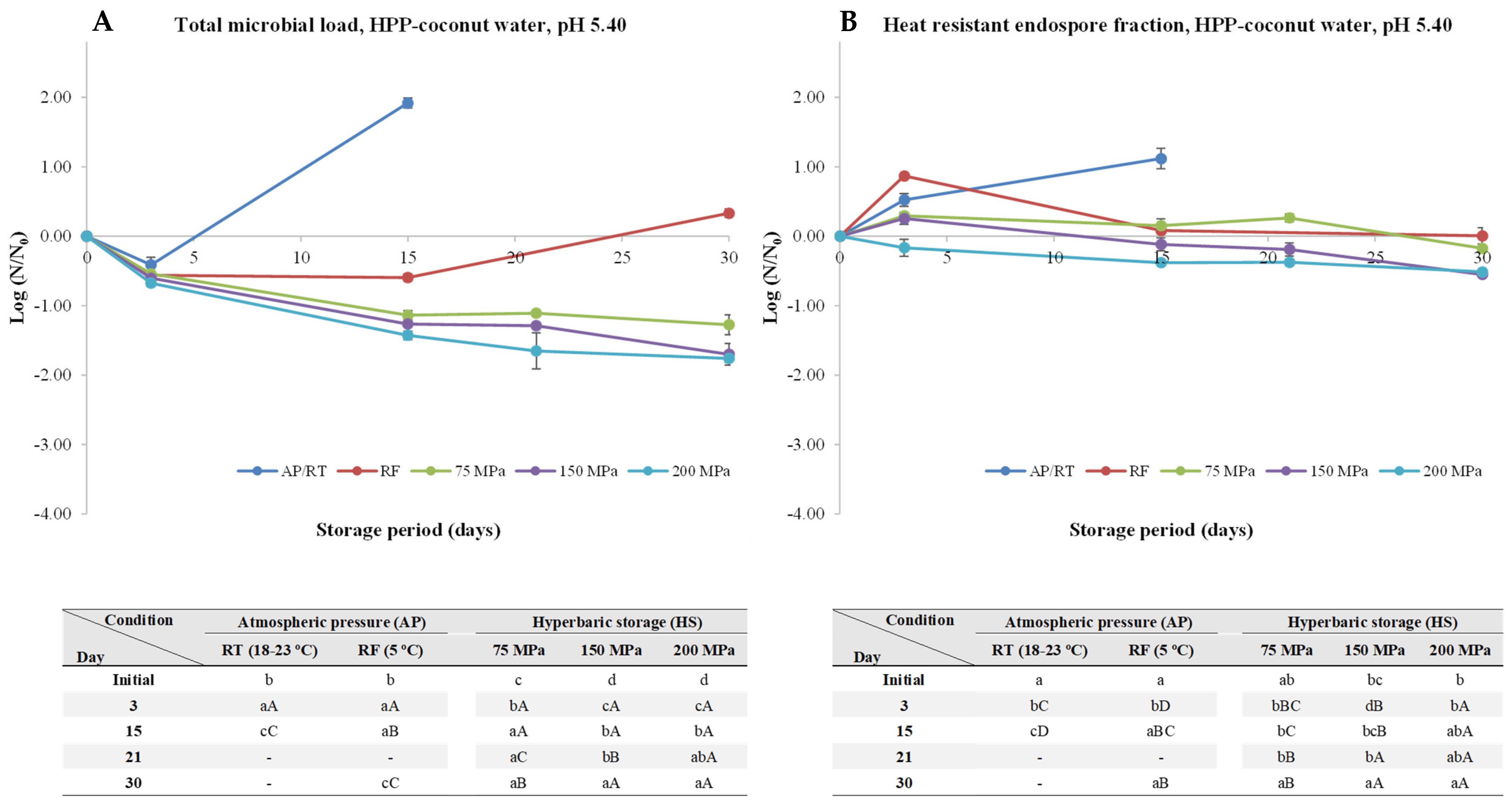

3.2. Impact of HPP and pH on the C. perfringens Spores Behavior under HS Conditions

3.3. Effect of HS on the Inactivation Kinetic Parameters

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- McClane, B.A.; Robertson, S.L.; Li, J. Clostridium Perfringens. In Food Microbiology; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2012; pp. 465–489. ISBN 978-1-68367-058-2. [Google Scholar]

- Rood, J.I.; Adams, V.; Lacey, J.; Lyras, D.; McClane, B.A.; Melville, S.B.; Moore, R.J.; Popoff, M.R.; Sarker, M.R.; Songer, J.G.; et al. Expansion of the Clostridium Perfringens Toxin-Based Typing Scheme. Anaerobe 2018, 53, 5–10. [Google Scholar] [CrossRef] [PubMed]

- Grass, J.E.; Gould, L.H.; Mahon, B.E. Epidemiology of Foodborne Disease Outbreaks Caused by Clostridium Perfringens, United States, 1998-2010. Foodborne Pathog. Dis. 2013, 10, 131–136. [Google Scholar] [CrossRef]

- Fua’di, M.T.; Er, B.; Lee, S.; Chan, P.P.; Khoo, J.; Tan, D.; Li, H.; Muhammad, I.R.; Raj, P.; Kurupatham, L.; et al. Characteristics of Gastroenteritis Outbreaks Investigated in Singapore: 2018–2021. Int. J. Environ. Res. Public Health 2024, 21, 64. [Google Scholar] [CrossRef]

- Li, J.; Paredes-Sabja, D.; Sarker, M.R.; McClane, B.A. Clostridium Perfringens Sporulation and Sporulation-Associated Toxin Production. Microbiol. Spectr. 2016, 4. [Google Scholar] [CrossRef]

- Banawas, S.; Paredes-Sabja, D.; Korza, G.; Li, Y.; Hao, B.; Setlow, P.; Sarker, M.R. The Clostridium Perfringens Germinant Receptor Protein GerKC Is Located in the Spore Inner Membrane and Is Crucial for Spore Germination. J. Bacteriol. 2013, 195, 5084–5091. [Google Scholar] [CrossRef]

- Paredes-Sabja, D.; Torres, J.A.; Setlow, P.; Sarker, M.R. Clostridium Perfringens Spore Germination: Characterization of Germinants and Their Receptors. J. Bacteriol. 2008, 190, 1190–1201. [Google Scholar] [CrossRef] [PubMed]

- García, S.; Heredia, N. Clostridium Perfringens: A Dynamic Foodborne Pathogen. Food Bioprocess. Technol. 2011, 4, 624–630. [Google Scholar] [CrossRef]

- Talukdar, P.K.; Udompijitkul, P.; Hossain, A.; Sarker, M.R. Inactivation Strategies for Clostridium Perfringens Spores and Vegetative Cells. Appl. Environ. Microbiol. 2017, 83, e02731-16. [Google Scholar] [CrossRef]

- Silva, F.V.M.; Evelyn, E. Pasteurization of Food and Beverages by High Pressure Processing (HPP) at Room Temperature: Inactivation of Staphylococcus Aureus, Escherichia Coli, Listeria Monocytogenes, Salmonella, and Other Microbial Pathogens. Appl. Sci. 2023, 13, 1193. [Google Scholar] [CrossRef]

- Ma, Y.; Xu, L.; Wang, S.; Xu, Z.; Liao, X.; Cheng, Y. Comparison of the Quality Attributes of Coconut Waters by High-pressure Processing and High-temperature Short Time during the Refrigerated Storage. Food Sci. Nutr. 2019, 7, 1512–1519. [Google Scholar] [CrossRef]

- Kannangara, A.C.; Chandrajith, V.G.G.; Ranaweera, K. Comparative Analysis of Coconut Water in Four Different Maturity Stages. J. Pharmacogn. Phytochem. 2018, 7, 1814–1817. [Google Scholar]

- Awua, A.K.; Doe, E.D.; Agyare, R. Exploring the Influence of Sterilisation and Storage on Some Physicochemical Properties of Coconut (Cocos Nucifera L.) Water. BMC Res. Notes 2011, 4, 451. [Google Scholar] [CrossRef]

- Burns, D.T.; Johnston, E.-L.; Walker, M.J. Authenticity and the Potability of Coconut Water—A Critical Review. J. AOAC Int. 2020, 103, 800–806. [Google Scholar] [CrossRef]

- Kwiatkowski, A.; Clemente, E.; Scarcelli, A.; Vida, J.B. Quality of Coconut Water ‘in Natura’ Belonging to Green Dwarf Fruit Variety in Different Stages of Development, in Plantation on the Northwest Area of Paraná, Brazil. J. Food Agric. Environ. 2008, 6, 102–105. [Google Scholar]

- Prithviraj, V.; Pandiselvam, R.; Babu, A.C.; Kothakota, A.; Manikantan, M.R.; Ramesh, S.V.; Beegum, P.P.S.; Mathew, A.C.; Hebbar, K.B. Emerging Non-Thermal Processing Techniques for Preservation of Tender Coconut Water. LWT 2021, 149, 111850. [Google Scholar] [CrossRef]

- Raghubeer, E.V.; Phan, B.N.; Onuoha, E.; Diggins, S.; Aguilar, V.; Swanson, S.; Lee, A. The Use of High-Pressure Processing (HPP) to Improve the Safety and Quality of Raw Coconut (Cocos Nucifera L) Water. Int. J. Food Microbiol. 2020, 331, 108697. [Google Scholar] [CrossRef]

- González-Angulo, M.; Clauwers, C.; Harastani, R.; Tonello, C.; Jaime, I.; Rovira, J.; Michiels, C.W. Evaluation of Factors Influencing the Growth of Non-Toxigenic Clostridium Botulinum Type E and Clostridium Sp. in High-Pressure Processed and Conditioned Tender Coconut Water from Thailand. Food Res. Int. 2020, 134, 109278. [Google Scholar] [CrossRef]

- Salehy, Y.; Hoang, H.-M.; Cluzel, F.; Leroy, Y.; Delahaye, A.; Fournaison, L.; Yannou, B. Energy Performances Assessment for Sustainable Design Recommendations: Case Study of a Supermarket’s Refrigeration System. In Proceedings of the LCE2020, Grenoble, France, 12–15 May 2020; Elsevier: Grenoble, France, 2020; Volume 90, pp. 328–333. [Google Scholar]

- Pinto, C.A.; Santos, M.D.; Fidalgo, L.G.; Delgadillo, I.; Saraiva, J.A. Enhanced Control of Bacillus Subtilis Endospores Development by Hyperbaric Storage at Variable/Uncontrolled Room Temperature Compared to Refrigeration. Food Microbiol. 2018, 74, 125–131. [Google Scholar] [CrossRef]

- Pinto, C.A.; Martins, A.P.; Santos, M.D.; Fidalgo, L.G.; Delgadillo, I.; Saraiva, J.A. Growth Inhibition and Inactivation of Alicyclobacillus Acidoterrestris Endospores in Apple Juice by Hyperbaric Storage at Ambient Temperature. Innov. Food Sci. Emerg. Technol. 2019, 52, 232–236. [Google Scholar] [CrossRef]

- Evelyn; Silva, F.V.M. Use of Power Ultrasound to Enhance the Thermal Inactivation of Clostridium Perfringens Spores in Beef Slurry. Int. J. Food Microbiol. 2015, 206, 17–23. [Google Scholar] [CrossRef]

- Lenz, C.A.; Vogel, R.F. Differential Effects of Sporulation Temperature on the High Pressure Resistance of Clostridium Botulinum Type E Spores and the Interconnection with Sporulation Medium Cation Contents. Food Microbiol. 2015, 46, 434–442. [Google Scholar] [CrossRef] [PubMed]

- Juneja, V.K.; Novak, J.S.; Huang, L.; Eblen, B.S. Increased Thermotolerance of Clostridium Perfringens Spores Following Sublethal Heat Shock. Food Control 2003, 14, 163–168. [Google Scholar] [CrossRef]

- Miles, A.A.; Misra, S.S.; Irwin, J.O. The Estimation of the Bactericidal Power of the Blood. J. Hyg. 1938, 38, 732–749. [Google Scholar] [CrossRef] [PubMed]

- Reineke, K.; Mathys, A. Endospore Inactivation by Emerging Technologies: A Review of Target Structures and Inactivation Mechanisms. Annu. Rev. Food Sci. Technol. 2020, 11, 51632. [Google Scholar] [CrossRef] [PubMed]

- Wuytack, E.Y.; Michiels, C.W. A Study on the Effects of High Pressure and Heat on Bacillus Subtilis Spores at Low pH. Int. J. Food Microbiol. 2001, 64, 333–341. [Google Scholar] [CrossRef] [PubMed]

- Stanbury, P.F.; Whitaker, A.; Hall, S.J. Chapter 5—Sterilization. In Principles of Fermentation Technology, 3rd ed.; Stanbury, P.F., Whitaker, A., Hall, S.J., Eds.; Butterworth-Heinemann: Oxford, UK, 2017; pp. 273–333. ISBN 978-0-08-099953-1. [Google Scholar]

- Evelyn; Silva, F.V.M. High Pressure Thermal Processing for the Inactivation of Clostridium Perfringens Spores in Beef Slurry. Innov. Food Sci. Emerg. Technol. 2016, 33, 26–31. [Google Scholar] [CrossRef]

- Sevenich, R.; Reineke, K.; Hecht, P.; Fröhling, A.; Rauh, C.; Schlüter, O.; Knorr, D. Impact of Different Water Activities (Aw) Adjusted by Solutes on High Pressure High Temperature Inactivation of Bacillus Amyloliquefaciens Spores. Front. Microbiol. 2015, 6, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Valero, A.; Olague, E.; Medina-Pradas, E.; Garrido-Fernández, A.; Romero-Gil, V.; Cantalejo, M.J.; García-Gimeno, R.M.; Pérez-Rodríguez, F.; Posada-Izquierdo, G.D.; Arroyo-López, F.N. Influence of Acid Adaptation on the Probability of Germination of Clostridium Sporogenes Spores Against pH, NaCl and Time. Foods 2020, 9, 127. [Google Scholar] [CrossRef] [PubMed]

- Mao, L.; Jiang, S.; Wang, B.; Chen, L.; Yao, Q.; Chen, K. Protein Profile of Bacillus Subtilis Spore. Curr. Microbiol. 2011, 63, 198–205. [Google Scholar] [CrossRef]

- Jaakkola, K.; Virtanen, K.; Lahti, P.; Keto-Timonen, R.; Lindström, M.; Korkeala, H. Comparative Genome Analysis and Spore Heat Resistance Assay Reveal a New Component to Population Structure and Genome Epidemiology within Clostridium Perfringens Enterotoxin-Carrying Isolates. Front. Microbiol. 2021, 12, 717176. [Google Scholar] [CrossRef]

- Doona, C.J.; Feeherry, F.E.; Setlow, B.; Wang, S.; Li, W.; Nichols, F.C.; Talukdar, P.K.; Sarker, M.R.; Li, Y.Q.; Shen, A.; et al. Effects of High-Pressure Treatment on Spores of Clostridium Species. Appl. Environ. Microbiol. 2016, 82, 5287–5297. [Google Scholar] [CrossRef] [PubMed]

- Delbrück, A.I.; Zhang, Y.; Hug, V.; Trunet, C.; Mathys, A. Isolation, Stability, and Characteristics of High-Pressure Superdormant Bacillus Subtilis Spores. Int. J. Food Microbiol. 2021, 343, 109088. [Google Scholar] [CrossRef] [PubMed]

- Aoyama, Y.; Shigeta, Y.; Okazaki, T.; Hagura, Y.; Suzuki, K. Growth Inhibition of Microorganisms by Hydrostatic Pressure. Food Sci. Technol. Res. 2004, 10, 268–272. [Google Scholar] [CrossRef]

- Kocatepe, D.; Turan, H.; Altan, C.O.; Keskïn, İ.; Ceylan, A.; Kösteklï, B.; Candan, C. Influence of Different Essential Oils on Marinated Anchovy (Engraulis Encrasicolus L. 1758) during Refrigerated Storage. Food Sci. Technol 2019, 39, 255–260. [Google Scholar] [CrossRef]

- Shim, K.; Mok, J.S.; Jeong, Y.; Park, K.; Jang, M.-S. Effect of Organic Acids on the Formation of Biogenic Amines in Fermented Anchovy Sauce Comprising Raw Anchovy Materials with Different Levels of Freshness. J. Food Sci. Technol. 2022, 59, 703. [Google Scholar] [CrossRef] [PubMed]

- Paidhungat, M.; Setlow, B.; Daniels, W.B.; Hoover, D.; Papafragkou, E.; Setlow, P. Mechanisms of Induction of Germination of Bacillus Subtilis Spores by High Pressure. Appl. Environ. Microbiol. 2002, 68, 3172–3175. [Google Scholar] [CrossRef]

- Shen, A.; Edwards, A.N.; Sarker, M.R.; Paredes-Sabja, D. Sporulation and Germination in Clostridial Pathogens. Microbiol. Spectr. 2019, 7. [Google Scholar] [CrossRef]

| Pasteurization Process | Matrix | pH | Pressure (MPa) | First Order Model Parameters | Weibull Model Parameters | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D-Value (Days) | R2 | Adj-R2 | MSRE | b | n | R2 | Adj-R2 | MSRE | ||||

| No pasteurization | BHI-broth | 4.50 | 75 | * | * | |||||||

| 150 | ||||||||||||

| 200 | ||||||||||||

| 6.00 | 75 | 15.53 ± 1.97 | 0.9135 | 0.9100 | 0.1999 | 0.275 ± 0.073 | 0.595 ± 0.090 | 0.9355 | 0.9329 | 0.1726 | ||

| 150 | * | 0.448 ± 0.065 | 0.302 ± 0.055 | 0.9253 | 0.9223 | 0.1063 | ||||||

| 200 | 0.490 ± 0.050 | 0.372 ± 0.037 | 0.9735 | 0.9725 | 0.0874 | |||||||

| 7.50 | 75 | * | * | |||||||||

| 150 | 24.16 ± 3.35 | 0.9359 | 0.9318 | 0.1232 | 0.014 ± 0.016 | 1.305 ± 0.349 | 0.9393 | 0.9355 | 0.1199 | |||

| 200 | * | 0.001 ± 0.002 | 2.333 ± 0.728 | 0.9194 | 0.9143 | 0.1392 | ||||||

| Coconut water | 5.40 | 75 | * | 0.275 ± 0.052 | 0.489 ± 0.063 | 0.9821 | 0.9810 | 0.0693 | ||||

| 150 | 0.655 ± 0.199 | 0.356 ± 0.105 | 0.9332 | 0.9290 | 0.2084 | |||||||

| 200 | 1.208 ± 0.233 | 0.232 ± 0.069 | 0.9571 | 0.9544 | 0.1977 | |||||||

| High pressure processing (600 MPa, 3 min, 17 °C) | BHI-broth | 4.50 | 75 | * | * | |||||||

| 150 | 0.060 ± 0.057 | 0.807 ± 0.301 | 0.9009 | 0.8932 | 0.1155 | |||||||

| 200 | 0.108 ± 0.077 | 0.580 ± 0.231 | 0.9083 | 0.9012 | 0.0954 | |||||||

| 6.00 | 75 | 14.49 ± 2.56 | 0.9198 | 0.9136 | 0.2363 | 0.226 ± 0.131 | 0.661 ± 0.186 | 0.9475 | 0.9434 | 0.1912 | ||

| 150 | * | 0.210 ± 0.158 | 0.656 ± 0.241 | 0.9108 | 0.9039 | 0.2284 | ||||||

| 200 | 16.19 ± 3.04 | 0.9108 | 0.9039 | 0.2242 | 0.278 ± 0.152 | 0.573 ± 0.177 | 0.9397 | 0.9350 | 0.1844 | |||

| 7.50 | 75 | * | 0.757 ± 0.113 | 0.235 ± 0.095 | 0.9889 | 0.9880 | 0.0693 | |||||

| 150 | 1.193 ± 0.090 | 0.098 ± 0.026 | 0.9962 | 0.9959 | 0.0420 | |||||||

| 200 | 0.846 ± 0.237 | 0.235 ± 0.095 | 0.9622 | 0.9593 | 0.1447 | |||||||

| Coconut water | 5.40 | 75 | * | 0.401 ± 0.108 | 0.346 ± 0.089 | 0.9562 | 0.9528 | 0.1082 | ||||

| 150 | 0.369 ± 0.117 | 0.440 ± 0.104 | 0.9699 | 0.9676 | 0.1128 | |||||||

| 200 | 0.462 ± 0.132 | 0.405 ± 0.094 | 0.9721 | 0.9700 | 0.1212 | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pinto, C.A.; Mousakhani Ganjeh, A.; Barba, F.J.; Saraiva, J.A. Impact of pH and High-Pressure Pasteurization on the Germination and Development of Clostridium perfringens Spores under Hyperbaric Storage versus Refrigeration. Foods 2024, 13, 1832. https://doi.org/10.3390/foods13121832

Pinto CA, Mousakhani Ganjeh A, Barba FJ, Saraiva JA. Impact of pH and High-Pressure Pasteurization on the Germination and Development of Clostridium perfringens Spores under Hyperbaric Storage versus Refrigeration. Foods. 2024; 13(12):1832. https://doi.org/10.3390/foods13121832

Chicago/Turabian StylePinto, Carlos A., Alireza Mousakhani Ganjeh, Francisco J. Barba, and Jorge A. Saraiva. 2024. "Impact of pH and High-Pressure Pasteurization on the Germination and Development of Clostridium perfringens Spores under Hyperbaric Storage versus Refrigeration" Foods 13, no. 12: 1832. https://doi.org/10.3390/foods13121832

APA StylePinto, C. A., Mousakhani Ganjeh, A., Barba, F. J., & Saraiva, J. A. (2024). Impact of pH and High-Pressure Pasteurization on the Germination and Development of Clostridium perfringens Spores under Hyperbaric Storage versus Refrigeration. Foods, 13(12), 1832. https://doi.org/10.3390/foods13121832