The Light-Intensity-Affected Aroma Components of Green Tea during Leaf Spreading

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fresh Tea Leaves

2.2. External Light Source

2.3. Withering Experiment with Different Light Conditions

2.4. Tea Sample Preparation

2.5. Tea Samples’ Sensory Evaluation

2.6. Volatile Compound Extraction and Identification in Tea Samples

2.7. Data Processing and Statistical Analysis

3. Results

3.1. Green Tea’s Sensory Qualities in Relation to Various Light-Intensity Treatments

3.2. Volatile Compound Production According to Different Light-Intensity Treatments

3.2.1. Classification of Volatile Components

3.2.2. Analysis of Total Content and VENE of Volatile Substances

3.3. Green Tea Odor Profiles during Spreading under Different Light-Intensity Treatments

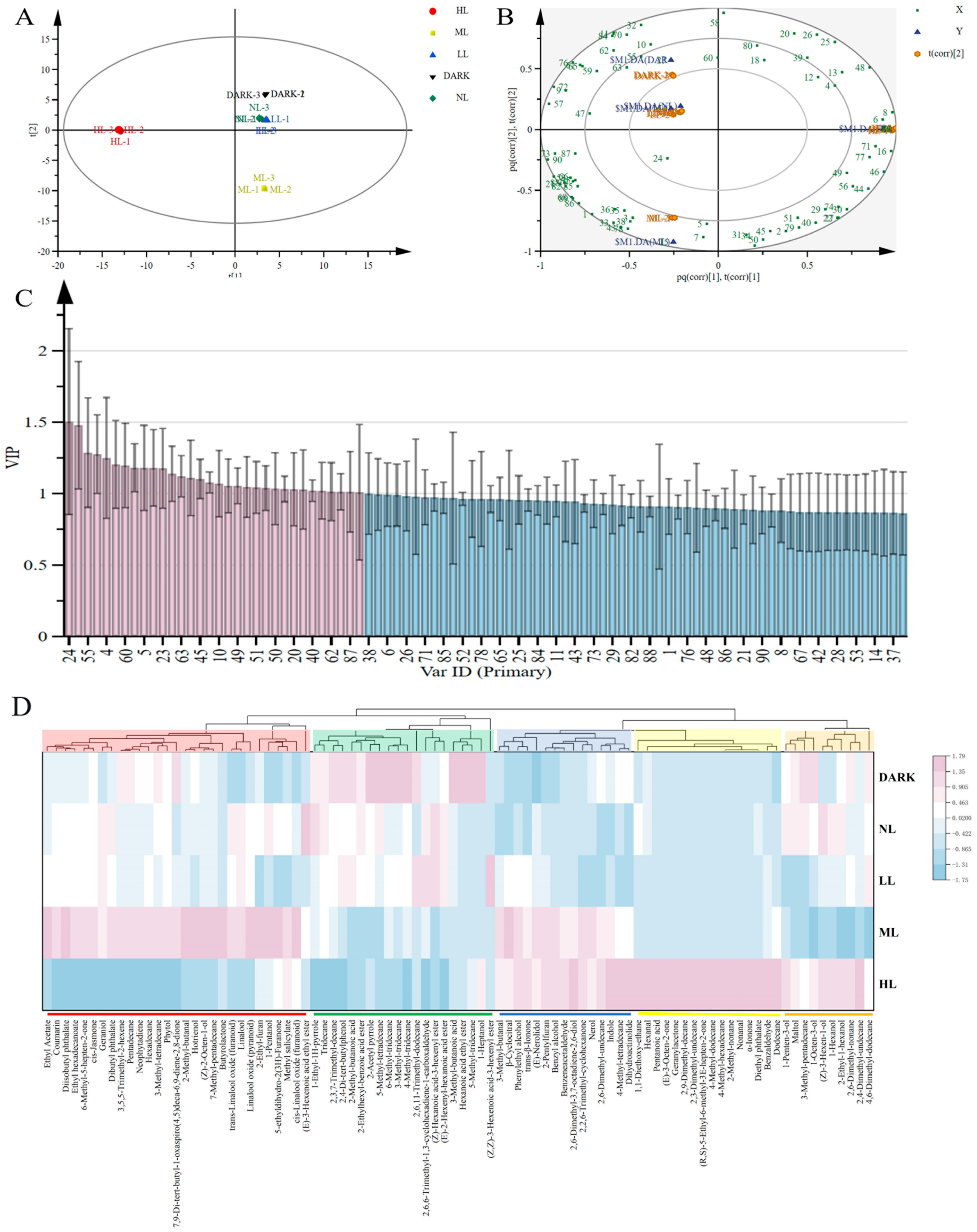

3.3.1. Principal Component Analysis

3.3.2. Orthogonal Partial Least Squares Discriminant Analysis

3.3.3. Heatmap Cluster Analysis of Green Tea under Different Light-Intensity Treatments

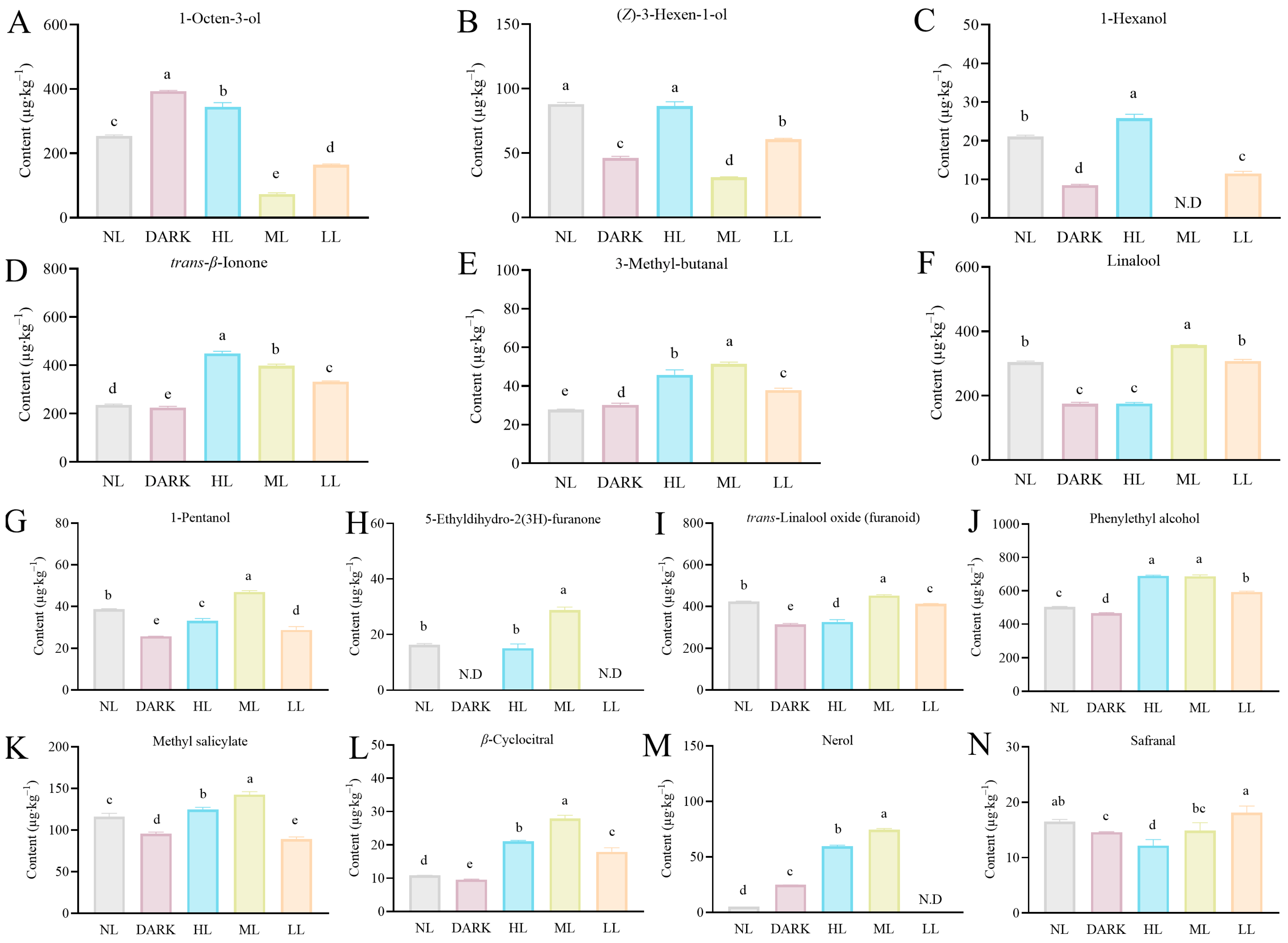

3.3.4. Validation of the Fourteen Important Differential Compounds under Different Light-Intensity Treatments

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sarma, A.; Bania, R.; Das, M.K. Green Tea: Current Trends and Prospects in Nutraceutical and Pharmaceutical Aspects. J. Herb. Med. 2023, 41, 100694. [Google Scholar] [CrossRef]

- Chaturvedula, V.S.P.; Prakash, I. The aroma, taste, color and bioactive constituents of tea. J. Med. Plants Res. 2011, 5, 2110–2124. [Google Scholar]

- Chen, M.; Fang, D.; Gou, H.; Wang, S.; Yue, W. Quantitative Measurement Reveals Dynamic Volatile Changes and Potential Biochemical Mechanisms during Green Tea Spreading Treatment. ACS Omega 2022, 7, 40009–40020. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Yang, C.; Luo, X.; Hu, B.; Dong, C. Research on the Online Rapid Sensing Method of Moisture Content in Famous Green Tea Spreading. J. Food Process Eng. 2021, 44, e13853. [Google Scholar] [CrossRef]

- Chen, Q.; Shi, J.; Mu, B.; Chen, Z.; Dai, W.; Lin, Z. Metabolomics Combined with Proteomics Provides a Novel Interpretation of the Changes in Nonvolatile Compounds during White Tea Processing. Food Chem. 2020, 332, 127412. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zheng, P.-C.; Liu, P.-P.; Song, X.-W.; Guo, F.; Li, Y.-Y.; Ni, D.-J.; Jiang, C.-J. Novel Insight into the Role of Withering Process in Characteristic Flavor Formation of Teas Using Transcriptome Analysis and Metabolite Profiling. Food Chem. 2019, 272, 313–322. [Google Scholar] [CrossRef] [PubMed]

- Qiao, D.; Mi, X.; An, Y.; Xie, H.; Cao, K.; Chen, H.; Chen, M.; Liu, S.; Chen, J.; Wei, C. Integrated Metabolic Phenotypes and Gene Expression Profiles Revealed the Effect of Spreading on Aroma Volatiles Formation in Postharvest Leaves of Green Tea. Food Res. Int. 2021, 149, 110680. [Google Scholar] [CrossRef]

- Yang, Z.; Baldermann, S.; Watanabe, N. Recent Studies of the Volatile Compounds in Tea. Food Res. Int. 2013, 53, 585–599. [Google Scholar] [CrossRef]

- Lin, J.; Tu, Z.; CHen, L. The Effect of Red Light Withering on the Volatile Components of Tea Leaves and the Quality of Black Tea Product. J. Tea Sci. 2021, 41, 393–405. [Google Scholar] [CrossRef]

- Liu, J.J.; Zhang, J.Y.; Peng, Y. Effects of Light Waves on the Aroma Substances of Tea Shoots during Withering and the Final Quality of Green Tea. J. Tea Sci. 2022, 42, 500–514. [Google Scholar] [CrossRef]

- Fu, X.; Chen, Y.; Mei, X.; Katsuno, T.; Kobayashi, E.; Dong, F.; Watanabe, N.; Yang, Z. Regulation of Formation of Volatile Compounds of Tea (Camellia sinensis) Leaves by Single Light Wavelength. Sci. Rep. 2015, 5, 16858. [Google Scholar] [CrossRef]

- Zheng, C.; Ma, J.; Ma, C.; Shen, S.; Liu, Y.; Chen, L. Regulation of Growth and Flavonoid Formation of Tea Plants (Camellia sinensis) by Blue and Green Light. J. Agric. Food Chem. 2019, 67, 2408–2419. [Google Scholar] [CrossRef]

- Huang, F.; Chen, L.; Zhou, X.; Ye, Y.; Zhu, H. Effect of red and bule light exposure during withering on amino acid and catechin contents of congou black tea. Fujian J. Agric. Sci. 2015, 30, 509–515. [Google Scholar] [CrossRef]

- Ai, Z.; Zhang, B.; Chen, Y.; Yu, Z.; Chen, H.; Ni, D. Impact of Light Irradiation on Black Tea Quality during Withering. J. Food Sci. Technol. 2017, 54, 1212–1227. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; He, C.; Yu, X.; Zhou, J.; Ntezimana, B.; Yu, Z.; Chen, Y.; Ni, D. Study on Improving Aroma Quality of Summer-Autumn Black Tea by Red-Light Irradiation during Withering. LWT 2022, 154, 112597. [Google Scholar] [CrossRef]

- He, Y.; Li, J.; Mei, H.; Zhuang, J.; Zhao, Z.; Jeyaraj, A.; Wang, Y.; Chen, X.; Li, X.; Liu, Z. Effects of Leaf-Spreading on the Volatile Aroma Components of Green Tea under Red Light of Different Intensities. Food Res. Int. 2023, 168, 112759. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.-Q.; Yin, H.-X.; Yuan, H.-B.; Jiang, Y.-W.; Dong, C.-W.; Deng, Y.-L. Characterization of the Volatile Components in Green Tea by IRAE-HS-SPME/GC-MS Combined with Multivariate Analysis. PLoS ONE 2018, 13, e0193393. [Google Scholar] [CrossRef]

- Su, D.; He, J.J.; Zhou, Y.Z.; Li, Y.L.; Zhou, H.J. Aroma Effects of Key Volatile Compounds in Keemun Black Tea at Different Grades: HS-SPME-GC-MS, Sensory Evaluation, and Chemometrics. Food Chem. 2022, 373, 131587. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Ho, C.-T.; Wan, X.; Zhu, H.; Liu, Q.; Wen, Z. Changes of Volatile Compounds and Odor Profiles in Wuyi Rock Tea during Processing. Food Chem. 2021, 341, 128230. [Google Scholar] [CrossRef]

- Guo, X.; Schwab, W.; Ho, C.-T.; Song, C.; Wan, X. Characterization of the Aroma Profiles of Oolong Tea Made from Three Tea Cultivars by Both GC–MS and GC-IMS. Food Chem. 2022, 376, 131933. [Google Scholar] [CrossRef]

- Ho, C.-T.; Zheng, X.; Li, S. Tea Aroma Formation. Food Sci. Hum. Wellness 2015, 4, 9–27. [Google Scholar] [CrossRef]

- Wang, H.; Hua, J.; Jiang, Y.; Yang, Y.; Wang, J.; Yuan, H. Influence of Fixation Methods on the Chestnut-like Aroma of Green Tea and Dynamics of Key Aroma Substances. Food Res. Int. 2020, 136, 109479. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.-J.; Ma, H.-Y.; Zhuang, J. iTRAQ-Based Proteomics Monitors the Withering Dynamics in Postharvest Leaves of Tea Plant (Camellia sinensis). Mol. Genet. Genom. 2018, 293, 45–59. [Google Scholar] [CrossRef] [PubMed]

- Dou, H.; Niu, G.; Gu, M.; Masabni, J. Effects of Light Quality on Growth and Phytonutrient Accumulation of Herbs under Controlled Environments. Horticulturae 2017, 3, 36. [Google Scholar] [CrossRef]

- Wang, D.; Kubota, K.; Kobayashi, A.; Juan, I.-M. Analysis of Glycosidically Bound Aroma Precursors in Tea Leaves. 3. Change in the Glycoside Content of Tea Leaves during the Oolong Tea Manufacturing Process. J. Agric. Food Chem. 2001, 49, 5391–5396. [Google Scholar] [CrossRef] [PubMed]

- Huang, F.; Liu, F.; Tang, X.; Luo, F. Research progress on the effect of light on tea withering. J. Tea Sci. 2019, 46, 402–408. [Google Scholar]

- Zhou, Z.-W.; Wu, Q.-Y.; Yang, Y.; Hu, Q.-C.; Wu, Z.-J.; Huang, H.-Q.; Lin, H.-Z.; Lai, Z.-X.; Sun, Y. The Dynamic Change in Fatty Acids during the Postharvest Process of Oolong Tea Production. Molecules 2022, 27, 4298. [Google Scholar] [CrossRef] [PubMed]

- Sasaki, K.; Takase, H.; Matsuyama, S.; Kobayashi, H.; Matsuo, H.; Ikoma, G.; Takata, R. Effect of Light Exposure on Linalool Biosynthesis and Accumulation in Grape Berries. Biosci. Biotechnol. Biochem. 2016, 80, 2376–2382. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.; Zhai, X.; Guo, D.; Du, W.; Gao, T.; Zhou, J.; Schwab, W.G.; Song, C. Characterization of Key Odorants in Xinyang Maojian Green Tea and Their Changes During the Manufacturing Process. J. Agric. Food Chem. 2021, 70, 279–288. [Google Scholar] [CrossRef]

- Kumazawa, K.; Masuda, H. Identification of Potent Odorants in Different Green Tea Varieties Using Flavor Dilution Technique. J. Agric. Food Chem. 2002, 50, 5660–5663. [Google Scholar] [CrossRef]

- Guo, X.; Ho, C.-T.; Schwab, W.; Song, C.; Wan, X. Aroma Compositions of Large-Leaf Yellow Tea and Potential Effect of Theanine on Volatile Formation in Tea. Food Chem. 2019, 280, 73–82. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Lv, H.-P.; Shao, C.-Y.; Kang, S.; Zhang, Y.; Guo, L.; Dai, W.-D.; Tan, J.-F.; Peng, Q.-H.; Lin, Z. Identification of Key Odorants Responsible for Chestnut-like Aroma Quality of Green Teas. Food Res. Int. 2018, 108, 74–82. [Google Scholar] [CrossRef] [PubMed]

- Nie, C.N.; Gao, Y.; Du, X.; Bian, J.L.; Li, H.; Zhang, X.; Wang, C.M.; Li, S.Y. Characterization of the Effect of Cis-3-Hexen-1-Ol on Green Tea Aroma. Sci. Rep. 2020, 10, 15506. [Google Scholar] [CrossRef] [PubMed]

- Deng, W.-W.; Wang, R.; Yang, T.; Jiang, L.; Zhang, Z.-Z. Functional Characterization of Salicylic Acid Carboxyl Methyltransferase from Camellia sinensis, Providing the Aroma Compound of Methyl Salicylate during the Withering Process of White Tea. J. Agric. Food Chem. 2017, 65, 11036–11045. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Qin, D.; Huang, G.; Jiang, X.; Fang, K.; Wang, Q.; Ni, E.; Li, B.; Pan, C.; Li, H.; et al. Identification and Characterization of the Key Volatile Flavor Compounds in Black Teas from Distinct Regions Worldwide. J. Food Sci. 2022, 87, 3433–3446. [Google Scholar] [CrossRef]

- Zhu, J.; Niu, Y.; Xiao, Z. Characterization of the Key Aroma Compounds in Laoshan Green Teas by Application of Odour Activity Value (OAV), Gas Chromatography-Mass Spectrometry-Olfactometry (GC-MS-O) and Comprehensive Two-Dimensional Gas Chromatography Mass Spectrometry (GC × GC-qMS). Food Chem. 2021, 339, 128136. [Google Scholar] [CrossRef]

| Light Condition | Aroma | Taste | Liquor Color | Appearance of Waste Leaves | Comprehensive Sensory Evaluation |

|---|---|---|---|---|---|

| HL | 88.00 ± 2.00 b | 88.33 ± 2.08 c | 89.00 ± 4.00 a | 84.67 ± 4.04 a | 89.62 ± 1.11 c |

| ML | 94.00 ± 1.73 a | 95.67 ± 0.58 a | 94.00 ± 3.00 a | 90.33 ± 4.51 a | 94.38 ± 0.78 a |

| LL | 90.00 ± 1.00 b | 92.33 ± 1.53 b | 92.33 ± 3.06 a | 89.67 ± 2.08 a | 92.15 ± 0.57 b |

| DARK | 90.00 ± 0.00 b | 91.33 ± 1.15 b | 92.00 ± 1.00 a | 89.33 ± 0.58 a | 91.78 ± 0.31 b |

| NL | 90.00 ± 2.00 b | 93.33 ± 1.53 ab | 92.00 ± 2.00 a | 89.33 ± 1.15 a | 92.38 ± 0.15 b |

| Compound Name | Odor Characteristic | OTs (µg∙kg−1) | OAV | ||||

|---|---|---|---|---|---|---|---|

| HL | ML | LL | DARK | NL | |||

| (Z)-3-Hexen-1-ol | Green, leafy, grassy | 70 | 1.23 ± 0.05 a | 0.45 ± 0.01 d | 0.87 ± 0.01 b | 1.26 ± 0.02 a | 0.66 ± 0.02 c |

| 5-ethyldihydro-2(3H)-Furanone | Caramel, nutty, roasted, sweet, creamy | 9.7 | 1.56 ± 0.16 b | 2.97 ± 0.11 a | N.D | 1.69 ± 0.04 b | N.D |

| 1-Pentanol | Fruity | 5 | 6.6 ± 0.23 c | 9.39 ± 0.11 a | 5.74 ± 0.33 d | 7.74 ± 0.04 b | 5.12 ± 0.01 e |

| Methyl salicylate | Minty, wintergreen-like | 40 | 3.11 ± 0.07 b | 3.57 ± 0.09 a | 2.23 ± 0.07 c | 2.9 ± 0.1 b | 2.39 ± 0.05 c |

| 1-Hexanol | Green, grassy | 5.6 | 4.62 ± 0.17 a | N.D | 2.07 ± 0.1 c | 3.77 ± 0.06 b | 1.52 ± 0.04 d |

| 3-Methyl-butanal | Apple-like and chocolate-like flavors under high dilution | 0.2 | 228.81 ± 13.23 b | 257.14 ± 4.57 a | 189.91 ± 4.27 c | 138.98 ± 1.16 d | 151.57 ± 4.2 d |

| trans-Linalool oxide (furanoid) | Sweet, floral, creamy | 190 | 1.72 ± 0.05 c | 2.38 ± 0.02 a | 2.17 ± 0.01 b | 2.23 ± 0.01 b | 1.65 ± 0.02 c |

| Nerol | Fresh, citrus, floral, green, sweet, lemon-like | 49 | 1.22 ± 0.02 b | 1.52 ± 0.02 a | N.D | 0.1 ± 0 d | 0.51 ± 0 c |

| β-Cyclocitral | Herbal, clean, rose-like, fruity | 3 | 7.02 ± 0.1 b | 9.3 ± 0.32 a | 5.98 ± 0.41 c | 3.63 ± 0.01 d | 3.19 ± 0.05 d |

| trans-β-Ionone | Violet, raspberry, floral | 0.007 | 64,204.26 ± 1270.98 a | 56,976.93 ± 916.74 b | 47,613 ± 360.76 c | 33,787.68 ± 418.39 d | 32,198.97 ± 686.29 d |

| 1-Octen-3-ol | Earthy, green, oily, vegetable-like, fungal | 1 | 344.92 ± 12.82 b | 73.29 ± 3.9 e | 164.47 ± 2.73 d | 254.03 ± 3.24 c | 393.34 ± 2.37 a |

| Phenylethyl alcohol | Floral, rose-like | 390 | 1.77 ± 0.01 a | 1.76 ± 0.02 a | 1.52 ± 0.01 b | 1.29 ± 0.01 c | 1.19 ± 0.01 d |

| Linalool | Floral, sweet, grape-like, woody | 0.22 | 798.65 ± 15.82 c | 1624.81 ± 5.67 a | 1401.15 ± 20.29 b | 1384.34 ± 14.01 b | 796.2 ± 19.8 c |

| Safranal | Woody, spicy, medicinal, powdery, herbal | 3 | 4.06 ± 0.36 c | 4.95 ± 0.48 bc | 6.04 ± 0.4 a | 5.5 ± 0.13 ab | 4.87 ± 0.02 bc |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Y.; Liu, S.; Kang, Y.; Periakaruppan, R.; Zhuang, J.; Wang, Y.; Chen, X.; Liu, X.; Li, X. The Light-Intensity-Affected Aroma Components of Green Tea during Leaf Spreading. Foods 2024, 13, 2349. https://doi.org/10.3390/foods13152349

He Y, Liu S, Kang Y, Periakaruppan R, Zhuang J, Wang Y, Chen X, Liu X, Li X. The Light-Intensity-Affected Aroma Components of Green Tea during Leaf Spreading. Foods. 2024; 13(15):2349. https://doi.org/10.3390/foods13152349

Chicago/Turabian StyleHe, Youyue, Shujing Liu, Yuzhong Kang, Rajiv Periakaruppan, Jing Zhuang, Yuhua Wang, Xuan Chen, Xinqiu Liu, and Xinghui Li. 2024. "The Light-Intensity-Affected Aroma Components of Green Tea during Leaf Spreading" Foods 13, no. 15: 2349. https://doi.org/10.3390/foods13152349