Effects of Wickerhamomyces anomalus Co-Fermented with Saccharomyces cerevisiae on Volatile Flavor Profiles during Steamed Bread Making Using Electronic Nose and HS-SPME-GC-MS

Abstract

1. Introduction

2. Materials and Methods

2.1. Yeast Strains and Culture Conditions

2.2. Dough and Steamed Bread Making

2.3. E-Nose Analysis

2.4. HS-SPME-GC-MS

2.5. ROAV

2.6. Statistical Analysis

3. Results

3.1. Dynamic Changes of Volatile Compounds during the Making of Steamed Bread Using the E-Nose

3.2. Dynamic Changes of Volatile Compounds during the Making of Steamed Bread Using HS-SPME-GC-MS

3.3. Effect of Different Yeast Strains on the Formation of Volatile Compounds in the Fermentation of Dough

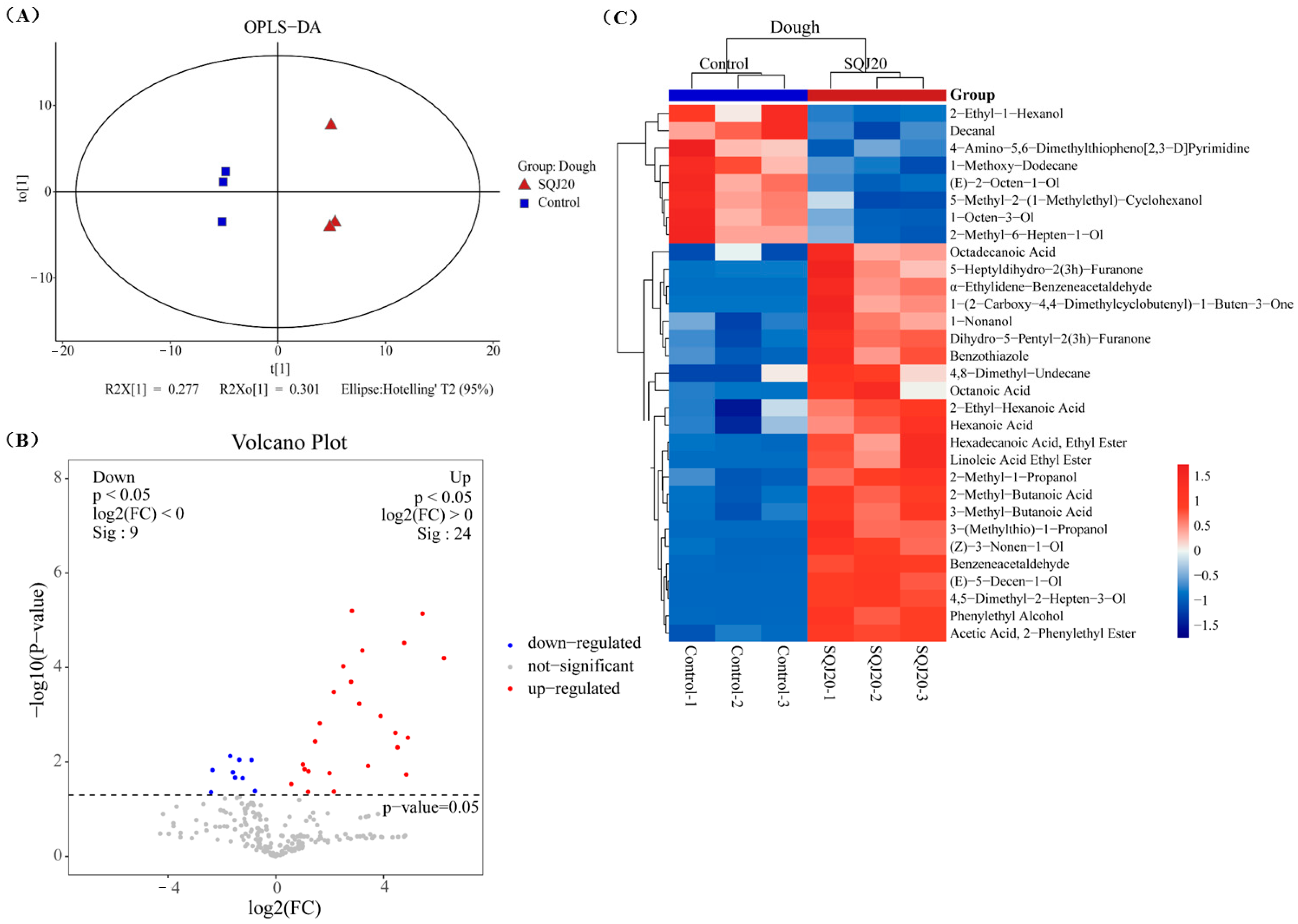

3.3.1. Fermentation Using S. cerevisiae SQJ20

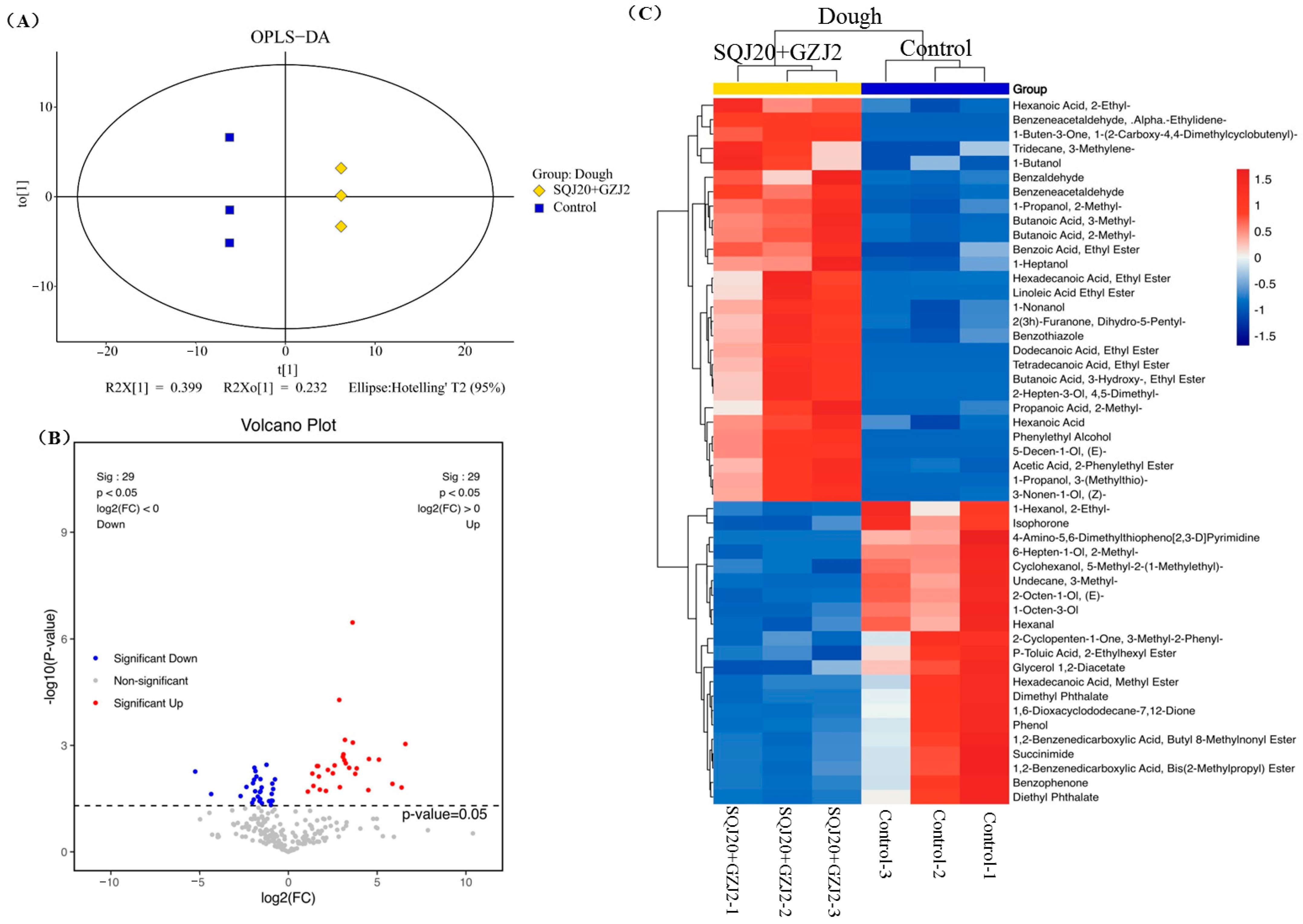

3.3.2. Mixed Fermentation by S. cerevisiae SQJ20 and W. anomalus GZJ2

3.3.3. Effects of W. anomalus GZJ2 on the Formation of Volatile Compounds

3.3.4. Key Metabolic Pathways during Dough Fermentation

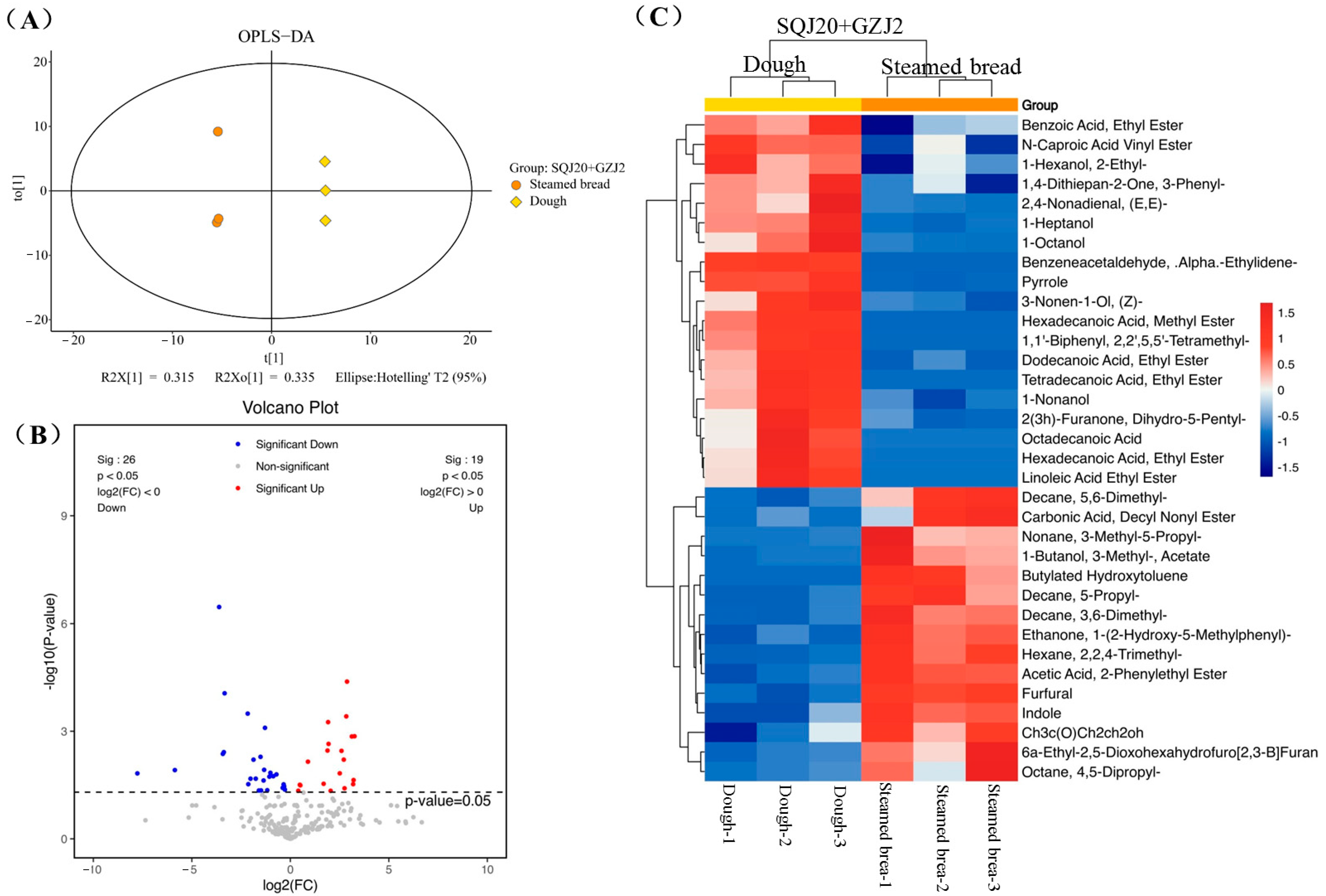

3.4. Changes in the Volatile Compounds of Co-Fermented Steamed Bread during the Steaming Process

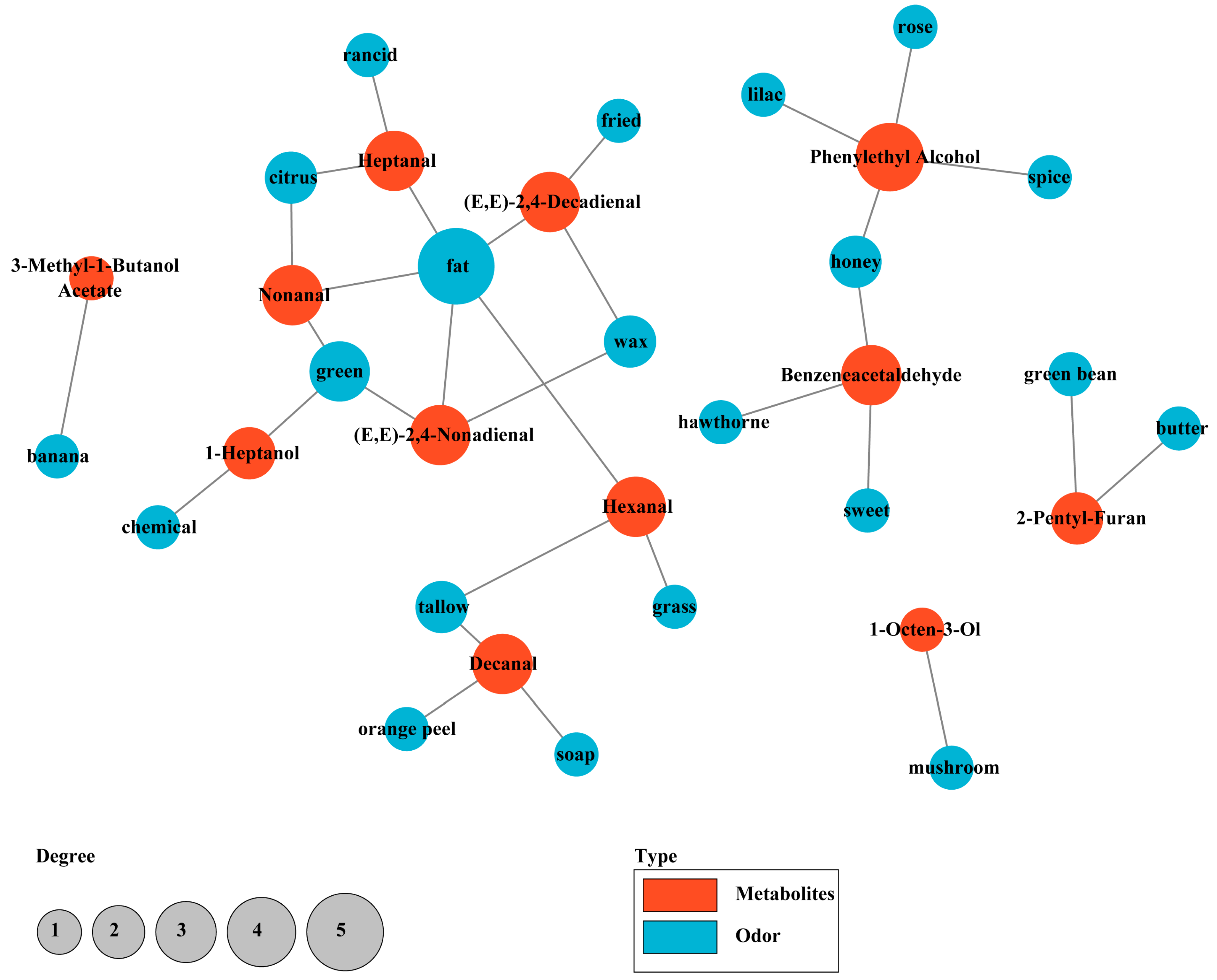

3.5. Effect of S. cerevisiae and W. anomalus on the Formation of Volatile Aroma Compounds in Steamed Bread

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, Y.; Huang, W.; Zhu, H.; Rayas-Duarte, P. Spontaneous sourdough processing of Chinese Northern-style steamed breads and their volatile compounds. Food Chem. 2009, 114, 685–692. [Google Scholar] [CrossRef]

- Karrar, E.; Musa, A.; Sheth, S.; Huang, W.; Sarpong, F.; Wang, X. Effect of sorghum sourdough and nabag (zizyphus spina-christi) pulp powder on dough fermentation and quality characteristics of bread. J. Food Meas. Charact. 2019, 14, 455–464. [Google Scholar] [CrossRef]

- Arora, K.; Ameur, H.; Polo, A.; Di Cagno, R.; Rizzello, C.G.; Gobbetti, M. Thirty years of knowledge on sourdough fermentation: A systematic review. Trends Food Sci. Technol. 2021, 108, 71–83. [Google Scholar] [CrossRef]

- Li, Z.J.; Li, H.F.; Deng, C.; Liu, C.H. Effect of Mixed Strain Starter Culture on Rheological Properties of Wheat Dough and Quality of Steamed Bread. J. Texture Stud. 2014, 45, 180–186. [Google Scholar] [CrossRef]

- Cakir, E.; Arici, M.; Durak, M.Z. Effect of starter culture sourdough prepared with Lactobacilli and Saccharomyces cerevisiae on the quality of hull-less barley-wheat bread. LWT 2021, 152, 112230. [Google Scholar] [CrossRef]

- Li, Z.; Song, K.; Li, H.; Ma, R.; Cui, M. Effect of mixed Saccharomyces cerevisiae Y10 and Torulaspora delbrueckii Y22 on dough fermentation for steamed bread making. Int. J. Food Microbiol. 2019, 303, 58–64. [Google Scholar] [CrossRef]

- Sha, H.Y.; Wang, Q.Q.; Li, Z.J. Comparison of the effect of exopolysaccharide-producing lactic acid bacteria from sourdough on dough characteristics and steamed bread quality. Int. J. Food Sci. Technol. 2023, 58, 378–386. [Google Scholar] [CrossRef]

- Shen, J.; Shi, K.; Dong, H.; Yang, K.; Lu, Z.; Lu, F.; Wang, P. Screening of Sourdough Starter Strains and Improvements in the Quality of Whole Wheat Steamed Bread. Molecules 2022, 27, 3510. [Google Scholar] [CrossRef]

- Yue, M.; Gu, H.; Ding, X.; Liu, Y.; Wang, L.; Sun, L. Mixed fermentation of Wickerhamomyces anomalus and Saccharomyces cerevisiae to improve the quality of steamed bread. Food Sci. 2024, 45, 125–137. [Google Scholar] [CrossRef]

- Li, Y.; Ma, Y.; Xu, M.; Yaqoob, S.; Aregbe, A.Y.; Xiong, Y. Impact of fermentation through Wickerhamomyces anomalus and Saccharomyces cerevisiae on aroma and quality of mulberry wine. Int. J. Food Sci. Technol. 2023, 59, 971–984. [Google Scholar] [CrossRef]

- Cai, W.; Li, B.; Chen, Y.; Fu, G.; Fan, H.; Deng, M.; Wan, Y.; Liu, N.; Li, M. Increase the Content of Ester Compounds in Blueberry Wine Fermentation with the Ester-Producing Yeast: Candida glabrata, Pichia anomala, and Wickerhamomyces anomalus. Foods 2022, 11, 3655. [Google Scholar] [CrossRef] [PubMed]

- Fan, H.; Zheng, X.; Ai, Z.; Liu, C.; Li, R.; Bian, K. Analysis of volatile aroma components from Mantou fermented by different starters. J. Food Process. Preserv. 2018, 42, e13627. [Google Scholar] [CrossRef]

- Wu, C.; Liu, R.; Huang, W.; Rayas-Duarte, P.; Wang, F.; Yao, Y. Effect of sourdough fermentation on the quality of Chinese Northern-style steamed breads(Article). J. Cereal Sci. 2012, 56, 127–133. [Google Scholar] [CrossRef]

- Zhang, G.-H.; Wu, T.; Sadiq, F.A.; Yang, H.-Y.; Liu, T.-J.; Ruan, H.; He, G.-Q. A study revealing the key aroma compounds of steamed bread made by Chinese traditional sourdough. J. Zhejiang Univ. Sci. B 2016, 17, 787–797. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, J.; Xu, F.; Wu, X.; Hu, W.; Chang, Y.; Zhang, L.; Chen, J.; Liu, C. GC-MS, GC-O and OAV analyses of key aroma compounds in Jiaozi Steamed Bread. Grain Oil Sci. Technol. 2020, 3, 9–17. [Google Scholar] [CrossRef]

- Chang, X.; Huang, X.; Xu, W.; Tian, X.; Wang, C.; Wang, L.; Yu, S. Monitoring of dough fermentation during Chinese steamed bread processing by near-infrared spectroscopy combined with spectra selection and supervised learning algorithm. J. Food Process. Eng. 2021, 44, e13783. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, G.; Yao, Y.; Zhu, W.; Xu, S.; Li, H. Research on the aroma properties and microbial succession patterns in the processing of Chinese yellow sticky rice jiuqu steamed bread. LWT 2023, 180, 114704. [Google Scholar] [CrossRef]

- Chang, X.; Huang, X.; Tian, X.; Wang, C.; Aheto, J.H.; Ernest, B.; Yi, R. Dynamic characteristics of dough during the fermentation process of Chinese steamed bread. Food Chem. 2020, 312, 126050. [Google Scholar] [CrossRef]

- Mei, S.; Ding, J.; Chen, X. Identification of differential volatile and non-volatile compounds in coffee leaves prepared from different tea processing steps using HS-SPME/GC-MS and HPLC-Orbitrap-MS/MS and investigation of the binding mechanism of key phytochemicals with olfactory and taste receptors using molecular docking. Food Res. Int. 2023, 168, 112760. [Google Scholar]

- Yan, B.W.; Sadiq, F.A.; Cai, Y.J.; Fan, D.M.; Zhang, H.; Zhao, J.X.; Chen, W. Identification of Key Aroma Compounds in Type I Sourdough-Based Chinese Steamed Bread: Application of Untargeted Metabolomics Analysisp. Int. J. Mol. Sci. 2019, 20, 818. [Google Scholar] [CrossRef]

- Wang, Y.; He, Y.; Liu, Y.; Wang, D. Analyzing Volatile Compounds of Young and Mature Docynia delavayi Fruit by HS-SPME-GC-MS and rOAV. Foods 2022, 12, 59. [Google Scholar] [CrossRef] [PubMed]

- Vararu, F.; Moreno-García, J.; Zamfir, C.-I.; Cotea, V.V.; Moreno, J. Selection of aroma compounds for the differentiation of wines obtained by fermenting musts with starter cultures of commercial yeast strains. Food Chem. 2016, 197, 373–381. [Google Scholar] [CrossRef]

- Cai, J.; Zhu, B.-Q.; Wang, Y.-H.; Lu, L.; Lan, Y.-B.; Reeves, M.J.; Duan, C.-Q. Influence of pre-fermentation cold maceration treatment on aroma compounds of Cabernet Sauvignon wines fermented in different industrial scale fermenters. Food Chem. 2014, 154, 217–229. [Google Scholar] [CrossRef]

- Pico, J.; Bernal, J.; Gómez, M. Wheat bread aroma compounds in crumb and crust: A review. Food Res. Int. 2015, 75, 200–215. [Google Scholar] [CrossRef] [PubMed]

- Maggi, F.; Papa, F.; Cristalli, G.; Sagratini, G.; Vittori, S. Characterisation of the mushroom-like flavour of Melittis melissophyllum L. subsp. melissophyllum by headspace solid-phase microextraction (HS-SPME) coupled with gas chromatography (GC–FID) and gas chromatography–mass spectrometry (GC–MS). Food Chem. 2010, 123, 983–992. [Google Scholar] [CrossRef]

- Li, Y.; Leng, W.; Xue, J.; Yuan, L.; Liu, H.; Gao, R. A multi-omics-based investigation into the flavor formation mechanisms during the fermentation of traditional Chinese shrimp paste. Food Res. Int. 2023, 166, 112585. [Google Scholar] [CrossRef]

- Zhang, L.; Cao, Q.-Q.; Granato, D.; Xu, Y.-Q.; Ho, C.-T. Association between chemistry and taste of tea: A review. Trends Food Sci. Technol. 2020, 101, 139–149. [Google Scholar] [CrossRef]

- Pico, J.; Martínez, M.M.; Bernal, J.; Gómez, M. Evolution of volatile compounds in gluten-free bread: From dough to crumb. Food Chem. 2017, 227, 179–186. [Google Scholar] [CrossRef] [PubMed]

- Birch, A.N.; Petersen, M.A.; Hansen, Å.S. Aroma of Wheat Bread Crumb. Cereal Chem. 2015, 3015, 7–17. [Google Scholar] [CrossRef]

- Liu, D.; Zhou, G.; Xu, X. “ROAV” method: A new method for determining key odor compounds of Rugao ham. Shipin Kexue 2010, 29, 370–374. [Google Scholar]

- Su, D.; He, J.; Zhou, Y.; Li, Y.; Zhou, H. Aroma effects of key volatile compounds in Keemun black tea at different grades: HS-SPME-GC-MS, sensory evaluation, and chemometrics. Food Chem. 2022, 373, 131587. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Chen, J.; Chen, X.; Chen, D.; Deng, S. Use of relative odor activity value (ROAV) to link aroma profiles to volatile compounds: Application to fresh and dried eel (Muraenesox cinereus). Int. J. Food Prop. 2020, 23, 2257–2270. [Google Scholar] [CrossRef]

- Hazelwood, L.A.; Daran, J.M.; van Maris, A.J.A.; Pronk, J.T.; Dickinson, J.R. The ehrlich pathway for fusel alcohol production: A century of research on Saccharomyces cerevisiae metabolism. Appl. Environ. Microbiol. 2008, 74, 2259–2266. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.J.; Li, Y.; Sadiq, F.A.; Yang, H.Y.; Gu, J.S.; Yuan, L.; Lee, Y.K.; He, G.Q. Predominant yeasts in Chinese traditional sourdough and their influence on aroma formation in Chinese steamed bread. Food Chem. 2018, 242, 404–411. [Google Scholar] [CrossRef] [PubMed]

- Jiang, H.; Deng, J.H.; Chen, Q.S. Monitoring of simultaneous saccharification and fermentation of ethanol by multi-source data deep fusion strategy based on near-infrared spectra and electronic nose signals. Eng. Appl. Artif. Intel. 2024, 127, 107299. [Google Scholar] [CrossRef]

- Bonah, E.; Huang, X.; Aheto, J.H.; Osae, R. Application of electronic nose as a non-invasive technique for odor fingerprinting and detection of bacterial foodborne pathogens: A review. J. Food Sci. Technol. 2020, 57, 1977–1990. [Google Scholar] [CrossRef] [PubMed]

- Api, A.M.; Belmonte, F.; Belsito, D.; Biserta, S.; Botelho, D.; Bruze, M.; Burton, G.A.; Buschmann, J.; Cancellieri, M.A.; Dagli, M.L.; et al. RIFM fragrance ingredient safety assessment, ethyl 3-hydroxybutyrate, CAS Registry Number 5405-41-4. Food Chem. Toxicol. 2020, 138, 111264. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Zhou, Q.; Peck, J.; Soles, R.; Qian, M.C. The effect of wine closures on volatile sulfur and other compounds during post-bottle ageing. Flavour Fragr. J. 2013, 28, 118–128. [Google Scholar] [CrossRef]

- Yan, B.W.; Sadiq, F.A.; Cai, Y.J.; Fan, D.M.; Chen, W.; Zhang, H.; Zhao, J.X. Microbial diversity in traditional type I sourdough and jiaozi and its influence on volatiles in Chinese steamed bread. LWT-Food Sci. Technol. 2019, 101, 764–773. [Google Scholar] [CrossRef]

- Yu, S.; Huang, X.; Wang, L.; Ren, Y.; Zhang, X.; Wang, Y. Characterization of selected Chinese soybean paste based on flavor profiles using HS-SPME-GC/MS, E-nose and E-tongue combined with chemometrics. Food Chem. 2022, 375, 131840. [Google Scholar] [CrossRef]

| Sensor Name | Characteristic Substance Species | Example |

|---|---|---|

| W1C | aromatic | aromatic compounds, benzene |

| W5S | broadrange | nitrogen oxides |

| W3C | aromatic | aroma, ammonia |

| W6S | hydrogen | hydrides |

| W5C | arom-aliph | olefins, aromatics, polar molecules |

| W1S | broad-methane | short chain alkanes |

| W1W | sulphur-organic | sulfides, terpene compounds |

| W2S | broad-alcohol | alcohols, aldehydes, ketones, aromatic compounds |

| W2W | sulph-chlor | organic sulfides, aromatic compounds |

| W3S | methane-aliph | long-chain alkane aliphatic groups |

| Metabolites | Sub Class | FC (SQJ20/Control) | FC (SQJ20 + GZJ2/Control) |

|---|---|---|---|

| Phenylethyl Alcohol | Alcohols | 75.69 | 96.40 |

| Hexadecanoic Acid, Ethyl Ester | Esters | 29.93 | 83.09 |

| Linoleic Acid Ethyl Ester | Esters | 21.70 | 58.16 |

| 3-(Methylthio)-1-Propanol | Alcohols | 14.85 | 34.28 |

| 2-Methyl-Propanoic Acid | Acid | / | 22.69 |

| Dodecanoic Acid, Ethyl Ester | Esters | / | 23.22 |

| 2-Phenylethyl-Acetic Acid, Ester | Esters | 9.25 | 14.39 |

| 3-Hydroxy-Butanoic Acid, Ethyl Ester | Esters | / | 13.61 |

| α-Ethylidene-Benzeneacetaldehyde | Aldehydes | 22.92 | 12.25 |

| (E)-5-Decen-1-Ol | Alcohols | 27.17 | 12.39 |

| Tetradecanoic Acid, Ethyl Ester | Esters | / | 10.74 |

| 3-Methyl-Butanoic Acid | Acid | 4.45 | 9.39 |

| Phenylacetaldehyde | Aldehydes | 43.59 | 9.10 |

| 5-Heptyldihydro-2(3h)-Furanone | Heterocycle | 28.71 | / |

| 4,8-Dimethyl-Undecane | Hydrocarbons | 4.46 | / |

| Octanoic Acid | Acid | 3.98 | / |

| Octadecanoic Acid | Acid | 2.29 | / |

| 2-Methyl-1-Propanol | Alcohols | 8.56 | 8.58 |

| (Z)-3-Nonen-1-Ol | Alcohols | 6.93 | 8.90 |

| 2-Methyl-Butanoic Acid | Acid | 5.67 | 8.39 |

| 1-(2-Carboxy-4,4-Dimethylcyclobutenyl)-1-Buten-3-One | Ketones | 10.75 | 7.28 |

| Benzaldehyde | Aldehydes | / | 7.47 |

| 2-Ethyl-Hexanoic Acid | Acid | 2.32 | 6.08 |

| 4,5-Dimethyl-2-Hepten-3-Ol | Alcohols | 7.10 | 5.68 |

| Benzoic Acid, Ethyl Ester | Esters | / | 4.67 |

| 3-Methylene-Tridecane | Hydrocarbons | / | 4.33 |

| 1-Butanol | Alcohols | / | 3.41 |

| Dihydro-5-Pentyl-2(3h)-Furanone | Heterocycle | 3.10 | 3.29 |

| Hexanoic Acid | Acid | 2.01 | 3.19 |

| 1-Nonanol | Alcohols | 2.09 | 3.06 |

| 1-Heptanol | Alcohols | / | 2.66 |

| Benzothiazole | Heterocycle | 2.75 | 2.55 |

| CAS | Metabolites | Sub Class | FC(SB/D) |

|---|---|---|---|

| 104-61-0 | Dihydro-5-Pentyl-2(3h)-Furanone | Heterocycle | 0.48 |

| 93-89-0 | Benzoic Acid, Ethyl Ester | Esters | 0.44 |

| 3075-84-1 | 2,2′,5,5′-Tetramethyl-1,1′-Biphenyl | Hydrocarbons | 0.41 |

| 10340-23-5 | (Z)-3-Nonen-1-Ol | Alcohols | 0.40 |

| 111-87-5 | 1-Octanol | Alcohols | 0.39 |

| 104-76-7 | 2-Ethyl-1-Hexanol | Alcohols | 0.36 |

| 143-08-8 | 1-Nonanol | Alcohols | 0.35 |

| 3-Phenyl-1,4-Dithiepan-2-One | Ketones | 0.33 | |

| 57-11-4 | Octadecanoic Acid | Acid | 0.30 |

| 111-70-6 | 1-Heptanol | Alcohols | 0.27 |

| 3050-69-9 | N-Caproic Acid Vinyl Ester | Esters | 0.25 |

| 5910-87-2 | (E,E)-2,4-Nonadienal | Aldehydes | 0.23 |

| 112-39-0 | Hexadecanoic Acid, Methyl Ester | Esters | 0.22 |

| 109-97-7 | Pyrrole | Heterocycle | 0.10 |

| 106-33-2 | Dodecanoic Acid, Ethyl Ester | Esters | 0.10 |

| 124-06-1 | Tetradecanoic Acid, Ethyl Ester | Esters | 0.09 |

| 4411-89-6 | α-Ethylidene-Benzeneacetaldehyde | Aldehydes | 0.08 |

| 544-35-4 | Linoleic Acid Ethyl Ester | Esters | 0.02 |

| 628-97-7 | Hexadecanoic Acid, Ethyl Ester | Esters | 0.00 |

| 1450-72-2 | 1-(2-Hydroxy-5-Methylphenyl)-Ethanone | Ketones | 9.56 |

| 6a-Ethyl-2,5-Dioxohexahydrofuro[2,3-B]Furan | Heterocycle | 9.25 | |

| 31081-18-2 | 3-Methyl-5-Propyl-Nonane | Hydrocarbons | 9.12 |

| 128-37-0 | Butylated Hydroxytoluene | Other | 8.70 |

| 98-01-1 | Furfural | Aldehydes | 7.35 |

| 16747-26-5 | 2,2,4-Trimethyl-Hexane | Hydrocarbons | 7.16 |

| Carbonic Acid, Decyl Nonyl Ester | Esters | 6.74 | |

| 1636-43-7 | 5,6-Dimethyl-Decane, | Hydrocarbons | 6.56 |

| 17312-53-7 | 3,6-Dimethyl-Decane, | Hydrocarbons | 6.05 |

| 123-92-2 | 3-Methyl-1-Butanol Acetate | Esters | 5.69 |

| 20905-05-9 | 4,5-Dipropyl-Octane | Hydrocarbons | 4.13 |

| 17312-62-8 | 5-Propyl-Decane | Hydrocarbons | 3.84 |

| 103-45-7 | Acetic Acid, 2-Phenylethyl Ester | Esters | 3.78 |

| 120-72-9 | Indole | Heterocycle | 3.70 |

| 590-90-9 | Ch3c(O)Ch2ch2oh | Other | 3.23 |

| No. | CAS | Categories | Metabolites | OT (μg/L) | ROAV | Odor Description | |

|---|---|---|---|---|---|---|---|

| SQJ20 | SQJ20 + GZJ2 | ||||||

| 1 | 60-12-8 | Alcohols | Phenylethyl Alcohol | 750.00 | 3.58 | 4.84 | honey, spice, rose, lilac |

| 2 | 3391-86-4 | Alcohols | 1-Octen-3-Ol | 1.00 | 49.31 | 50.07 | mushroom |

| 3 | 111-70-6 | Alcohols | 1-Heptanol | 3.00 | 3.58 | 3.11 | chemical, green |

| 4 | 123-92-2 | Esters | 3-Methyl-1-Butanol Acetate | 2.00 | 13.44 | 16.72 | banana |

| 5 | 122-78-1 | Aldehydes | Phenylacetaldehyde | 4.00 | 7.99 | 5.30 | hawthorne, honey, sweet |

| 6 | 66-25-1 | Aldehydes | Hexanal | 4.50 | 6.78 | 6.73 | grass, tallow, fat |

| 7 | 111-71-7 | Aldehydes | Heptanal | 3.00 | 1.28 | 1.07 | fat, citrus, rancid |

| 8 | 124-19-6 | Aldehydes | Nonanal | 1.00 | 5.11 | 12.16 | fat, citrus, green |

| 9 | 112-31-2 | Aldehydes | Decanal | 0.10 | 52.17 | 23.27 | soap, orange peel, tallow |

| 10 | 5910-87-2 | Aaldehydes | (E,E)-2,4-Nonadienal | 0.09 | 18.11 | 22.85 | fat, wax, green |

| 11 | 25152-84-5 | Aldehydes | (E,E)-2,4-Decadienal | 0.07 | 100.00 | 100.00 | fried, wax, fat |

| 12 | 3777-69-3 | Furan | 2-Pentyl-Furan | 6.00 | 0.33 | 6.99 | green bean, butter |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, X.; Yue, M.; Gu, H.; Li, S.; Chen, S.; Wang, L.; Sun, L. Effects of Wickerhamomyces anomalus Co-Fermented with Saccharomyces cerevisiae on Volatile Flavor Profiles during Steamed Bread Making Using Electronic Nose and HS-SPME-GC-MS. Foods 2024, 13, 2490. https://doi.org/10.3390/foods13162490

Ding X, Yue M, Gu H, Li S, Chen S, Wang L, Sun L. Effects of Wickerhamomyces anomalus Co-Fermented with Saccharomyces cerevisiae on Volatile Flavor Profiles during Steamed Bread Making Using Electronic Nose and HS-SPME-GC-MS. Foods. 2024; 13(16):2490. https://doi.org/10.3390/foods13162490

Chicago/Turabian StyleDing, Xialiang, Meixiang Yue, Henghao Gu, Suyang Li, Shiyi Chen, Liang Wang, and Ling Sun. 2024. "Effects of Wickerhamomyces anomalus Co-Fermented with Saccharomyces cerevisiae on Volatile Flavor Profiles during Steamed Bread Making Using Electronic Nose and HS-SPME-GC-MS" Foods 13, no. 16: 2490. https://doi.org/10.3390/foods13162490

APA StyleDing, X., Yue, M., Gu, H., Li, S., Chen, S., Wang, L., & Sun, L. (2024). Effects of Wickerhamomyces anomalus Co-Fermented with Saccharomyces cerevisiae on Volatile Flavor Profiles during Steamed Bread Making Using Electronic Nose and HS-SPME-GC-MS. Foods, 13(16), 2490. https://doi.org/10.3390/foods13162490