Chocolate Ganaches: Formulation, Processing and Stability in View of the New Production Trends

Abstract

1. Introduction

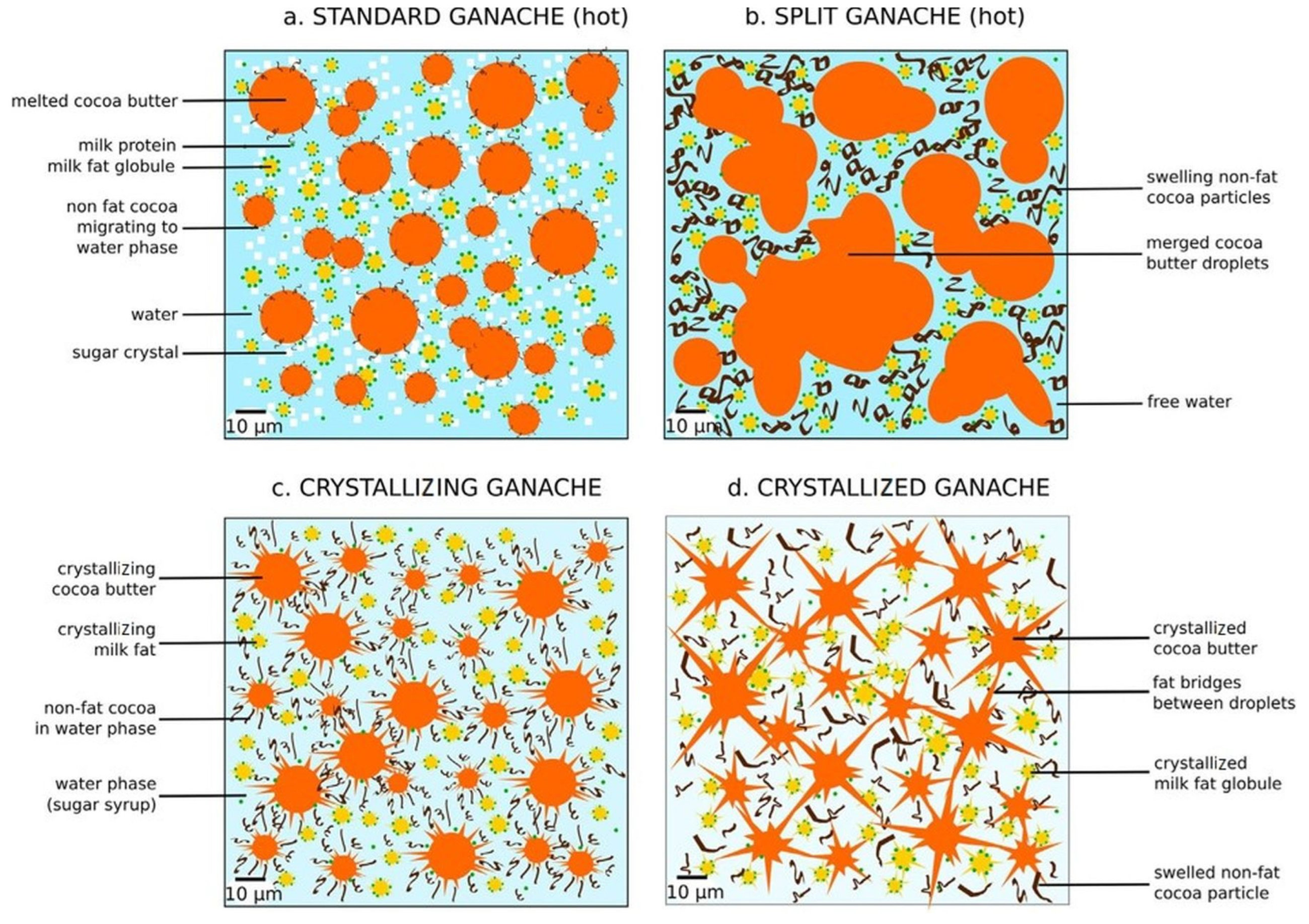

2. Ganache Nature

3. Research Progress and Development of Ganache Formulation and Processing

3.1. Ganache Formulation

3.2. Future Trends in Ganache Formulation

3.2.1. Ganache with Vegetable Cream and Coconut Milk

3.2.2. Ganache with Fruit Addition

3.2.3. Ganache with Application of Hydrocolloids

3.2.4. Ganache with Chilli Flavor

3.2.5. Ganache with Sacha Inchi Seeds

3.2.6. Ganache with Cannabis (Hemp) Ingredients

3.2.7. Ganache with Oleogels

3.3. Ganache Processing by Altered Emulsification Time and Low-Pressure Conditions

3.4. High-Pressure Processing of Ganache

4. Effects of Recipe and Processing on Ganache Quality and Stability

4.1. Processing Imperfections of Ganache

4.1.1. Crack Formation in Ganache-Filled Products

4.1.2. Fat Bloom Development in Ganache-Filled Products

4.2. Shelf-Life Stability of Ganache Products

4.2.1. Impact of Recipe Ingredients on Ganache Shelf-Life Stability

4.2.2. Effect of Preservation Techniques on Ganache Shelf-Life Stability

4.2.3. Impact of High-Pressure Processing on Ganache Shelf-Life Stability

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Izzreen, I.; Fisal, A.; Siti Norizah, M.N. Effect of Hydrocolloids at Different Concentrations on the Physicochemical Properties and Particle Size Distribution of White Chocolate Ganache. Malays. Cocoa J. 2022, 14, 173–183. [Google Scholar]

- McGill, J.; Hartel, R.W. Investigation into the Microstructure, Texture and Rheological Properties of Chocolate Ganache. J. Food Sci. 2018, 83, 689–699. [Google Scholar] [CrossRef]

- Hermé, P. Macarons, 2nd ed.; Martiniere, B.L., Ed.; Coderbugle, CAR: Manila, Philippines, 2018; pp. 1–264. [Google Scholar]

- Palczak, J.; Giboreau, A.; Rogeaux, M.; Delarue, J. How do Pastry and Culinary Chefs Design Sensory Complexity? Int. J. Gastron. Food Sci. 2020, 19, 100182. [Google Scholar] [CrossRef]

- Rigg, A. Macarons: Chic and Delicious French Treats, 2nd ed.; Ryland Peters & Small: London, UK, 2014; pp. 1–64. [Google Scholar]

- McGill, J.; Hartel, R.; Hofberger, R. The Art and Science of Ganache. Manuf. Confect. 2018, 138, 11–21. [Google Scholar]

- Neuwirth, V.; Lapčíková, B.; Lapčík, L.; Valenta, T.; Míšková, Z. Effect of Technological Processing and Recipe Formulation on the Physico-Chemical Properties of Ganaches and Chocolate Pralines. J. Food Eng. 2024, 378, 112124. [Google Scholar] [CrossRef]

- Merachli, F.; Devienne, J.; Delmas, R.; Plawinski, L.; Leal-Calderon, F.; Delample, M. Impact of Cocoa Fibers on the Stability and Rheological Properties of Chocolate Ganaches. LWT 2021, 139, 110505. [Google Scholar] [CrossRef]

- Goralchuk, A.; Gubsky, S.; Omel’chenko, S.; Riabets, O.; Grinchenko, O.; Fedak, N.; Kotlyar, O.; Cheremska, T.; Skrynnik, V. Impact of Added Food Ingredients on Foaming and Texture of the Whipped Toppings: A Chemometric Analysis. Eur. Food Res. Technol. 2020, 246, 1955–1970. [Google Scholar] [CrossRef]

- Park, M.A.; Lee, K.J.; Kim, S.J.; Kim, M.R. Quality Characteristics and Antioxidant Activities of Ganache Added with Porphyra Tenera Powder. Korean J. Food Preserv. 2020, 27, 333–345. [Google Scholar] [CrossRef]

- Cubides, Y.T.P. Developing Milk Protein Based Structure for New Dairy Products, 1st ed.; North Carolina State University: Raleigh, NC, USA, 2014; pp. 1–169. [Google Scholar]

- Yilmaz, İ.; Doğan, G. Product Development and Sensory Evaluation of Dark Chocolate Filled with Chestnut Honey. Black Sea J. Agric. 2023, 6, 452–458. [Google Scholar] [CrossRef]

- Popov-Raljić, J.V.; Laličić-Petronijević, J.G.; Georgijev, A.S.; Popov, V.S.; Mladenović, M.A. Sensory Evaluation of Pralines Containing Different Honey Products. Sensors 2010, 10, 7913–7933. [Google Scholar] [CrossRef]

- Clark, C. Chocolate. In Superfoods. Cultural and Scientific Perspectives; Miller, J.P., Van Buiten, C., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 37–50. [Google Scholar] [CrossRef]

- Norton, J.E.; Fryer, P.J. Investigation of Changes in Formulation and Processing Parameters on the Physical Properties of Cocoa Butter Emulsions. J. Food Eng. 2012, 113, 329–336. [Google Scholar] [CrossRef]

- Norton, J.E.; Fryer, P.J.; Parkinson, J.; Cox, P.W. Development and Characterisation of Tempered Cocoa Butter Emulsions Containing Up to 60% Water. J. Food Eng. 2009, 95, 172–178. [Google Scholar] [CrossRef]

- Greweling, P.P. Chocolates and Confections: Formula, Theory, and Technique for the Artisan Confectioner, 2nd ed.; Wiley, The Culinary Institute of America (CIA): Hyde Park, NY, USA, 2012; pp. 1–544. [Google Scholar]

- Saglio, A.; Bourgeay, J.; Socrate, R.; Canette, A.; Cuvelier, G. Understanding the Structure of Ganache: Link between Composition and Texture. Int. J. Gastron. Food Sci. 2018, 13, 29–37. [Google Scholar] [CrossRef]

- Kim, S.M.; Woo, J.H.; Kim, H.W.; Park, H.J. Formulation and Evaluation of Cold-Extruded Chocolate Ganache for Three-Dimensional Food Printing. J. Food Eng. 2022, 314, 110785. [Google Scholar] [CrossRef]

- Herrero, D.; Etienne, G. Pâtisserie, Les Clés De La Réussite—Coffret En 2 Volumes, 1st ed.; Délicéo: Bordeaux, France, 2009; pp. 1–1052. [Google Scholar]

- Leal-Calderon, F.; Thivilliers, F.; Schmitt, V. Structured Emulsions. Curr. Opin. Colloid Interface Sci. 2007, 12, 206–212. [Google Scholar] [CrossRef]

- Wybauw, J. Fine Chocolates, Great Experience 3: Extending Shelf Life, 3rd ed.; Lannoo Publishers: Bucharest, Romania, 2010. [Google Scholar]

- Greweling, P. The Crystallization of Ganache. Manuf. Confect. 2007, 87, 53–56. [Google Scholar]

- Peyronel, F.; Pink, D.A. Using USAXS to Predict the Under-Tempered Chocolate Microstructure. Food Res. Int. 2021, 143, 110224. [Google Scholar] [CrossRef]

- Dias, J.; Alvarenga, N.; Sousa, I. Effect of Hydrocolloids on Low-Fat Chocolate Fillings. J. Food Sci. Technol. 2015, 52, 7209–7217. [Google Scholar] [CrossRef]

- Dias, J.; Alvarenga, N.; Sousa, I. Shelf-Life of Reduced-Fat White Chocolate Fillings using Iota-Carrageenan. Emir. J. Food Agric. 2017, 29, 893–898. [Google Scholar] [CrossRef]

- Indiarto, R.; Situmorang, A.K.N.; Harunaningtyas, A.; Arifin, H.R.; Subroto, E.; Herawati, E.R.N.; Djali, M.; Mahani; Muhammad, D.R.A. Reformulation of White Chocolate with Soy- and Coconut-Based Vegetable Ingredients Incorporating Encapsulated Cinnamon Extract: Investigation of Physicochemical, Antioxidant, and Sensory Properties. Int. J. Food Prop. 2024, 27, 704–728. [Google Scholar] [CrossRef]

- Kim, Y.J.; Kang, S.; Kim, D.H.; Kim, Y.J.; Kim, W.R.; Kim, Y.M.; Park, S. Calorie Reduction of Chocolate Ganache through Substitution of Whipped Cream. J. Ethn. Foods 2017, 4, 51–57. [Google Scholar] [CrossRef]

- Gonçalves, E.V.; Caetano Da, S.; Lannes, S. Chocolate Rheology. Ciênc. Tecnol. Aliment. 2010, 30, 845–851. [Google Scholar] [CrossRef]

- Glicerina, V.; Balestra, F.; Rosa, M.D.; Romani, S. Microstructural and Rheological Properties of White Chocolate during Processing. Food Bioprocess Technol. 2014, 8, 770. [Google Scholar] [CrossRef]

- Kumbár, V.; Kouřilová, V.; Dufková, R.; Votava, J.; Hřivna, L. Rheological and Pipe Flow Properties of Chocolate Masses at Different Temperatures. Foods 2021, 10, 2519. [Google Scholar] [CrossRef] [PubMed]

- Cavella, S.; Miele, N.A.; Fidaleo, M.; Borriello, A.; Masi, P. Evolution of Particle Size Distribution, Flow Behaviour and Stability during Mill Ball Refining of a White Chocolate Flavouring Paste. LWT 2020, 132, 109910. [Google Scholar] [CrossRef]

- Neuwirth, V. Effect of the Processing and Composition of Chocolate Pralines’ Fillings on their Final Quality. Master’s Thesis, Tomas Bata University in Zlin, Zlin, Czech Republic, 2023. [Google Scholar]

- Costa, C.; Medronho, B.; Filipe, A.; Mira, I.; Lindman, B.; Edlund, H.; Norgren, M. Emulsion Formation and Stabilization by Biomolecules: The Leading Role of Cellulose. Polymers 2019, 11, 1570. [Google Scholar] [CrossRef] [PubMed]

- Galanakis, C.M. Food Structure and Functionality, 1st ed.; Academic Press: Cambridge, MA, USA, 2021. [Google Scholar] [CrossRef]

- Bai, L.; Liu, F.; Xu, X.; Huan, S.; Gu, J.; McClements, D.J. Impact of Polysaccharide Molecular Characteristics on Viscosity Enhancement and Depletion Flocculation. J. Food Eng. 2017, 207, 35–45. [Google Scholar] [CrossRef]

- Dias, J.; Coelho, P.; Alvarenga, N.B.; Duarte, R.V.; Saraiva, J.A. Evaluation of the Impact of High Pressure on the Storage of Filled Traditional Chocolates. Innov. Food Sci. Emerg. Technol. 2018, 45, 36–41. [Google Scholar] [CrossRef]

- Seçuk, B.; Seçím, Y. Development of Chili Pepper Ganache Filled Chocolate in Artisan Chocolate Production, Determination of Sensory and Physicochemical Characteristics. Food Sci. Technol. 2022, 42, e01721. [Google Scholar] [CrossRef]

- Izzreen, I.; Ly, S.K.; Khaironi, J.; Fisal, A.; Seng, N.S.S.; Ghani, M.A. Physicochemical, Total Phenolic Content, Antioxidant Activity, and Sensory Acceptability of Milk and Dark Chocolates Filled with Sacha Inchi Ganache. Malays. Cocoa J. 2023, 15, 36. [Google Scholar]

- Beal, K. Considerations in the Addition of Cannabis to Chocolate. Curr. Opin. Food Sci. 2019, 28, 14–17. [Google Scholar] [CrossRef]

- Rupasinghe, H.P.V.; Davis, A.; Kumar, S.K.; Murray, B.; Zheljazkov, V.D. Industrial Hemp (Cannabis sativa Subsp. Sativa) as an Emerging Source for Value-Added Functional Food Ingredients and Nutraceuticals. Molecules 2020, 25, 4078. [Google Scholar] [CrossRef]

- Steinbach, W. Hemp. Pralines. Patent No. DE19746830, 12 August 1999. [Google Scholar]

- Bartončíková, M.; Lapčíková, B.; Lapčík, L.; Valenta, T. Hemp-Derived CBD used in Food and Food Supplements. Molecules 2023, 28, 8047. [Google Scholar] [CrossRef]

- Scharfe, M.; Flöter, E. Oleogelation: From Scientific Feasibility to Applicability in Food Products. Eur. J. Lipid Sci. Technol. 2020, 122, 2000213. [Google Scholar] [CrossRef]

- Bot, A.; Flöter, E. Chapter 2—Edible Oil Oleogels Based on Self-assembled β-Sitosterol+γ-Oryzanol Tubules. In Edible Oleogels, 2nd ed.; Marangoni, A.G., Garti, N., Eds.; AOCS Press: Champaign, IL, USA, 2018; pp. 31–63. [Google Scholar] [CrossRef]

- Sun, P.; Xia, B.; Ni, Z.; Wang, Y.; Elam, E.; Thakur, K.; Ma, Y.; Wei, Z. Characterization of Functional Chocolate Formulated using Oleogels Derived from Β-Sitosterol with Γ-Oryzanol/Lecithin/Stearic Acid. Food Chem. 2021, 360, 130017. [Google Scholar] [CrossRef]

- Matheson, A.B.; Koutsos, V.; Dalkas, G.; Euston, S.; Clegg, P. Microstructure of Β-Sitosterol:Γ-Oryzanol Edible Organogels. Langmuir 2017, 33, 4537–4542. [Google Scholar] [CrossRef]

- Pinto, T.C.; Martins, A.J.; Pastrana, L.; Pereira, M.C.; Cerqueira, M.A. Water-in-Oleogel Emulsion Based on Γ-Oryzanol and Phytosterol Mixtures: Challenges and its Potential use for the Delivery of Bioactives. J. Am. Oil Chem. Soc. 2022, 99, 1045–1053. [Google Scholar] [CrossRef]

- Wendt, A.; Abraham, K.; Wernecke, C.; Pfeiffer, J.; Flöter, E. Application of Β-Sitosterol + Γ-Oryzanol-Structured Organogel as Migration Barrier in Filled Chocolate Products. J. Am. Oil Chem. Soc. 2017, 94, 1131–1140. [Google Scholar] [CrossRef]

- Fernandes Almeida, R.; Aguiar Borges, L.; Torres da Silva, T.; Serafim Timóteo dos Santos, N.; Gianasi, F.; Augusto Caldas Batista, E.; Efraim, P. Chocolates, Compounds and Spreads: A Review on the use of Oleogels, Hydrogels and Hybrid Gels to Reduce Saturated Fat Content. Food Res. Int. 2024, 178, 113986. [Google Scholar] [CrossRef] [PubMed]

- Balasubramaniam, V.M.; Farkas, D.; Turek, E.J. Preserving Foods through High-Pressure Processing. Food Technol. Mag. 2008, 62, 33–38. [Google Scholar]

- Panda, A.; Coelho, P.; Alvarenga, N.B.; Silva, J.L.; Lampreia, C.; Santos, M.T.; Pinto, C.A.; Amaral, R.A.; Saraiva, J.A.; Dias, J. Effect of High Pressure on the Properties of Chocolate Fillings during Long-Term Storage. Foods 2022, 11, 970. [Google Scholar] [CrossRef] [PubMed]

- Nopens, I.; Foubert, I.; De Graef, V.; Van Laere, D.; Dewettinck, K.; Vanrolleghem, P. Automated Image Analysis Tool for Migration Fat Bloom Evaluation of Chocolate Coated Food Products. LWT 2008, 41, 1884–1891. [Google Scholar] [CrossRef]

- Briones, V.; Aguilera, J.M.; Brown, C. Effect of Surface Topography on Color and Gloss of Chocolate Samples. J. Food Eng. 2006, 77, 776–783. [Google Scholar] [CrossRef]

- Subramaniam, P.J. Shelf-life prediction and testing. In Science and Technology of Enrobed and Filled Chocolate, Confectionery and Bakery Products; Talbot, G., Ed.; Woodhead Publishing Ltd.: Cambridge, UK, 2009; pp. 233–254. [Google Scholar]

- Tan, T.Y.C.; Lim, X.Y.; Yeo, J.H.H.; Lee, S.W.H.; Lai, N.M. The Health Effects of Chocolate and Cocoa: A Systematic Review. Nutrients 2021, 13, 2909. [Google Scholar] [CrossRef]

- Dahlenborg, H.; Millqvist-Fureby, A.; Bergenståhl, B. Effect of Shell Microstructure on Oil Migration and Fat Bloom Development in Model Pralines. Food Struct. 2015, 5, 51–65. [Google Scholar] [CrossRef]

- Svanberg, L.; Ahrné, L.; Lorén, N.; Windhab, E. Effect of Pre-Crystallization Process and Solid Particle Addition on Cocoa Butter Crystallization and Resulting Microstructure in Chocolate Model Systems. Procedia Food Sci. 2011, 1, 1910–1917. [Google Scholar] [CrossRef]

- Yu, D.; Xue, Z.; Mu, T. Eutectics: Formation, Properties, and Applications. Chem. Soc. Rev. 2021, 50, 8596–8638. [Google Scholar] [CrossRef] [PubMed]

- Svanberg, L.; Lorén, N.; Ahrné, L. Chocolate Swelling during Storage Caused by Fat or Moisture Migration. J. Food Sci. 2012, 77, E328–E334. [Google Scholar] [CrossRef] [PubMed]

- Popov-Raljić, J.V.; Laličić-Petronijević, J.G. Sensory Properties and Color Measurements of Dietary Chocolates with Different Compositions during Storage for Up to 360 Days. Sensors 2009, 9, 1996–2016. [Google Scholar] [CrossRef]

- Marvig, C.L.; Kristiansen, R.M.; Madsen, M.G.; Nielsen, D.S. Identification and Characterisation of Organisms Associated with Chocolate Pralines and Sugar Syrups used for their Production. Int. J. Food Microbiol. 2014, 185, 167–176. [Google Scholar] [CrossRef] [PubMed]

- Slettengren, K. Crack Formation in Chocolate Pralines. Master’s Thesis, Chalmers University of Technology, Göteborg, Sweden, 2010. [Google Scholar]

- Smith, K.W.; Cain, F.W.; Talbot, G. Effect of Nut Oil Migration on Polymorphic Transformation in a Model System. Food Chem. 2007, 102, 656–663. [Google Scholar] [CrossRef]

- Clercq, N.D.; Depypere, F.; Delbaere, C.; Nopens, I.; Bernaert, H.; Dewettinck, K. Influence of Cocoa Butter Diacylglycerols on Migration Induced Fat Bloom in Filled Chocolates. Eur. J. Lipid Sci. Technol. 2014, 116, 1388–1399. [Google Scholar] [CrossRef]

- Kinta, Y.; Hatta, T. Composition and Structure of Fat Bloom in Untempered Chocolate. J. Food Sci. 2005, 70, 450–452. [Google Scholar] [CrossRef]

- Kinta, Y.; Hatta, T. Composition, Structure, and Color of Fat Bloom due to the Partial Liquefaction of Fat in Dark Chocolate. J. Am. Oil Chem. Soc. 2007, 84, 107–115. [Google Scholar] [CrossRef]

- Timms, R.E. Oil and Fat Interactions. Manuf. Confect. 2002, 82, 50–64. [Google Scholar]

- Ziegler, G.R.; Shetty, A.; Anantheswaran, R.C. Nut Oil Migration through Chocolate. Manuf. Confect. 2004, 84, 118–126. [Google Scholar]

- Depypere, F.; De Clercq, N.; Segers, M.; Lewille, B.; Dewettinck, K. Triacylglycerol Migration and Bloom in Filled Chocolates: Effects of Low-Temperature Storage. Eur. J. Lipid Sci. Technol. 2009, 111, 280–289. [Google Scholar] [CrossRef]

- Tietz, R.A.; Hartel, R.W. Effects of Minor Lipids on Crystallization of Milk Fat-Cocoa Butter Blends and Bloom Formation in Chocolate. J. Am. Oil Chem. Soc. 2000, 77, 763–771. [Google Scholar] [CrossRef]

- Palomino Camargo, C.E. Chapter II. Microbiological and Physicochemical Factors that Affect the Safety and Quality of Chocolate. In Chocolate: Cocoa Byproducts Technology, Rheology, Styling, and Nutrition, 1st ed.; Sira, E.E.P., Ed.; Nova Science Publishers: Hauppauge, NY, USA, 2015; pp. 49–75. [Google Scholar]

- De Clercq, N.; Van Coillie, E.; Van Pamel, E.; De Meulenaer, B.; Devlieghere, F.; Vlaemynck, G. Detection and Identification of Xerophilic Fungi in Belgian Chocolate Confectionery Factories. Food Microbiol. 2015, 46, 322–328. [Google Scholar] [CrossRef] [PubMed]

- do Nascimento, M.d.S.; Brum, D.M.; Pena, P.O.; Berto, M.I.; Efraim, P. Inactivation of Salmonella during Cocoa Roasting and Chocolate Conching. Int. J. Food Microbiol. 2012, 159, 225–229. [Google Scholar] [CrossRef]

- Miquelim, J.N.; Alcântara, M.R.; Lannes, S.C.d.S. Stability of Fruit Bases and Chocolate Fillings. Food Sci. Technol. 2011, 31, 270–276. [Google Scholar] [CrossRef]

- Van der Veken, E. Balancing Technological Sugars in Ganaches: Introduction to the Use of Technological Sugars in Ganaches; Arcane Chocolates: Dublin, Ireland, 2019. [Google Scholar]

- Milk Chocolate Ganache for Moulded Pralines. Callebaut Chocolate Academy: Wieze, Belgium, 2024. Available online: https://www.callebaut.com/en/chocolate-recipe/1421/milk-chocolate-ganache-moulded-pralines (accessed on 18 July 2024).

- Alessandro Del Nobile, M.; Conte, A. Secondary Shelf Life of Foods: State of the Art and Future Perspective. Food Eng. Rev. 2023, 15, 748–762. [Google Scholar] [CrossRef]

- Is Ganache Shelf Stable? The Importance of Chocolate Shelf Life; Hill Country Chocolate: Fredericksburg, TX, USA, 2024.

- Nabi, B.G.; Mukhtar, K.; Arshad, R.N.; Radicetti, E.; Tedeschi, P.; Shahbaz, M.U.; Walayat, N.; Nawaz, A.; Inam-Ur-Raheem, M.; Aadil, R.M. High-Pressure Processing for Sustainable Food Supply. Sustainability 2021, 13, 13908. [Google Scholar] [CrossRef]

- Sehrawat, R.; Kaur, B.P.; Nema, P.K.; Tewari, S.; Kumar, L. Microbial Inactivation by High Pressure Processing: Principle, Mechanism and Factors Responsible. Food Sci. Biotechnol. 2021, 30, 19–35. [Google Scholar] [CrossRef]

| Chocolate Ganache Variants | Energy (kcal) | Carbohydrate Content (wt.%) | Fat Content (wt.%) | Protein Content (wt.%) |

|---|---|---|---|---|

| Whipped cream ganache | 436 | 25.5 | 35.5 | 4.0 |

| Milk ganache | 296 | 26.5 | 19.0 | 4.5 |

| Vegetable cream ganache | 386 | 25.5 | 30.0 | 4.1 |

| Coconut milk ganache | 359 | 25.4 | 26.7 | 4.0 |

| Ingredients | Content (wt.%) | Nutrients | Content (wt.%) |

|---|---|---|---|

| Raspberry puree | 32.23 | Total saccharides | 36.70 |

| Crystal sugar | 4.87 | Mono- and disaccharides | 32.84 |

| D-(+)-glucose | 2.47 | Total fats | 22.48 |

| D-(-)-fructose | 2.47 | Cocoa butter | 18.56 |

| Sorbitol | 2.47 | Milk fat | 3.92 |

| Chocolate | 50.70 | Saturated fatty acids | 13.59 |

| Butter | 4.78 | Total proteins | 2.97 |

| Milk proteins | 0.03 | ||

| Other proteins | 2.94 |

| Carrageenan/Pectin/Xanthan Gum Content (wt.%) [1] | Iota-Carrageenan Content (wt.%) [26] | |||||||

|---|---|---|---|---|---|---|---|---|

| Ingredients | Control | 0.1 | 0.3 | 0.5 | Ingredients | Control | 0.5 | 1.0 |

| White chocolate | 49.0 | 49.0 | 49.0 | 49.0 | White chocolate | 22.0 | 22.0 | 22.0 |

| Whipping cream | 35.0 | 34.9 | 34.7 | 34.5 | Skimmed milk | 45.0 | 44.5 | 44.0 |

| Unsalted cow butter | 9.0 | 9.0 | 9.0 | 9.0 | Sugar | 22.0 | 22.0 | 22.0 |

| Invert sugar | 7.0 | 7.0 | 7.0 | 7.0 | Invert sugar | 11.0 | 11.0 | 11.0 |

| Control Group Ganache (CG) | Powdered Chilli Pepper Ganache (PCP) | Chilli Pepper Seed Oil Ganache (CPS) | |||

|---|---|---|---|---|---|

| Ingredients | Content (wt.%) | Ingredients | Content (wt.%) | Ingredients | Content (wt.%) |

| Cream | 31.60 | Cream | 30.50 | Cream | 31.00 |

| White chocolate | 59.60 | White chocolate | 57.60 | White chocolate | 58.60 |

| Butter | 8.80 | Butter | 8.50 | Butter | 8.60 |

| Powder chilli pepper | 3.40 | Chilli pepper seed oil | 1.70 | ||

| Ingredients | Content (wt.%) | |

|---|---|---|

| Ganache with Sacha Inchi | Ganache without Sacha Inchi (Control Sample) | |

| White chocolate | 48.0 | 48.0 |

| Whipping cream | 24.8 | 34.8 |

| Cocoa butter | 10.0 | 10.0 |

| Invert sugar | 7.0 | 7.0 |

| Sacha inchi | 10.0 | - |

| Carrageenan | 0.2 | 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lapčíková, B.; Lapčík, L.; Valenta, T.; Neuwirth, V. Chocolate Ganaches: Formulation, Processing and Stability in View of the New Production Trends. Foods 2024, 13, 2543. https://doi.org/10.3390/foods13162543

Lapčíková B, Lapčík L, Valenta T, Neuwirth V. Chocolate Ganaches: Formulation, Processing and Stability in View of the New Production Trends. Foods. 2024; 13(16):2543. https://doi.org/10.3390/foods13162543

Chicago/Turabian StyleLapčíková, Barbora, Lubomír Lapčík, Tomáš Valenta, and Vojtěch Neuwirth. 2024. "Chocolate Ganaches: Formulation, Processing and Stability in View of the New Production Trends" Foods 13, no. 16: 2543. https://doi.org/10.3390/foods13162543

APA StyleLapčíková, B., Lapčík, L., Valenta, T., & Neuwirth, V. (2024). Chocolate Ganaches: Formulation, Processing and Stability in View of the New Production Trends. Foods, 13(16), 2543. https://doi.org/10.3390/foods13162543