Advances in Biodegradable Food Packaging Using Wheat-Based Materials: Fabrications and Innovations, Applications, Potentials, and Challenges

Abstract

1. Introduction

2. Wheat Properties

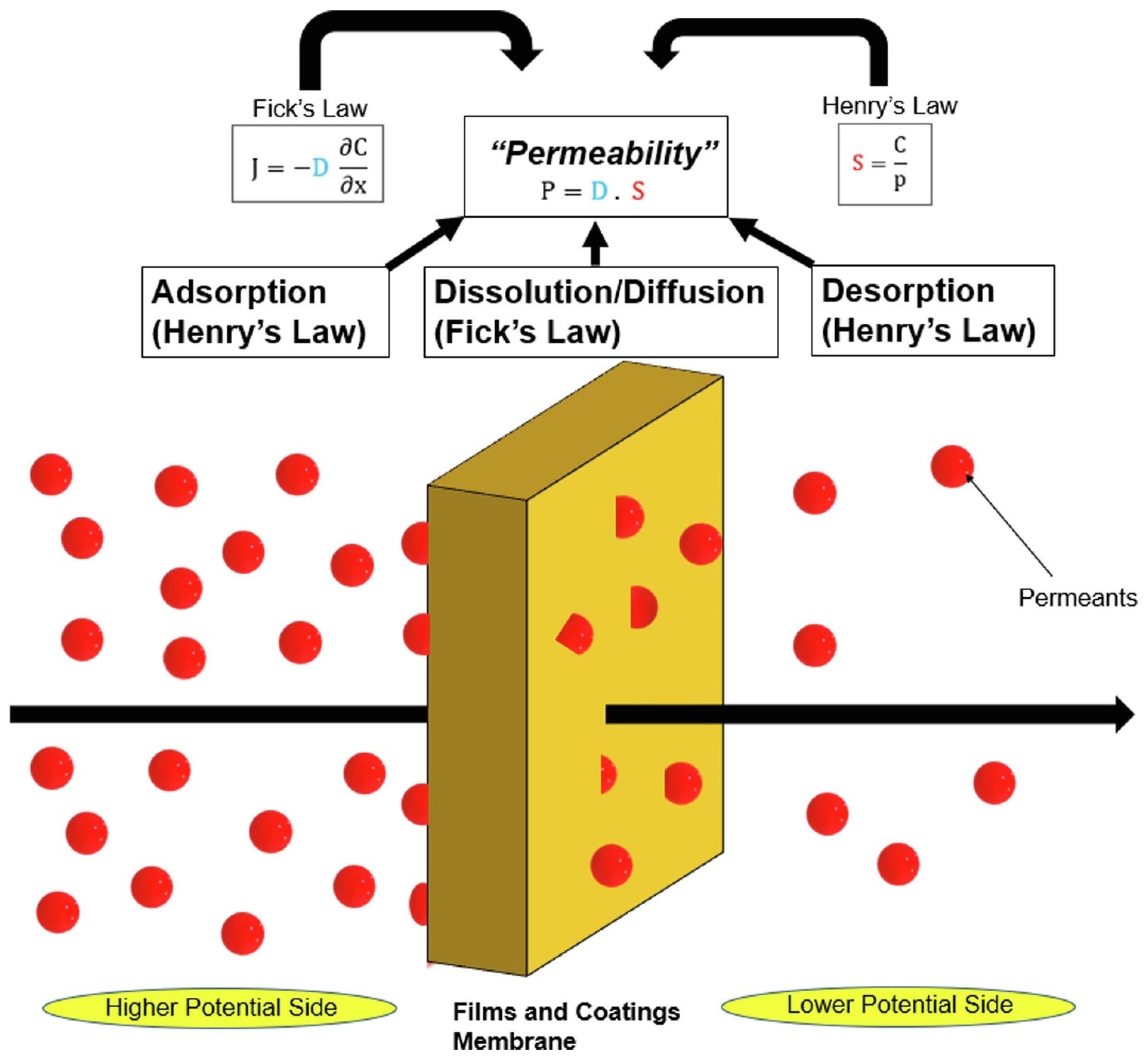

3. Fundamental Mechanisms of Biodegradable Food Packaging

4. Fabrication of Wheat Starch-Based, Gluten-Based, and Fiber-Based Coatings or Films

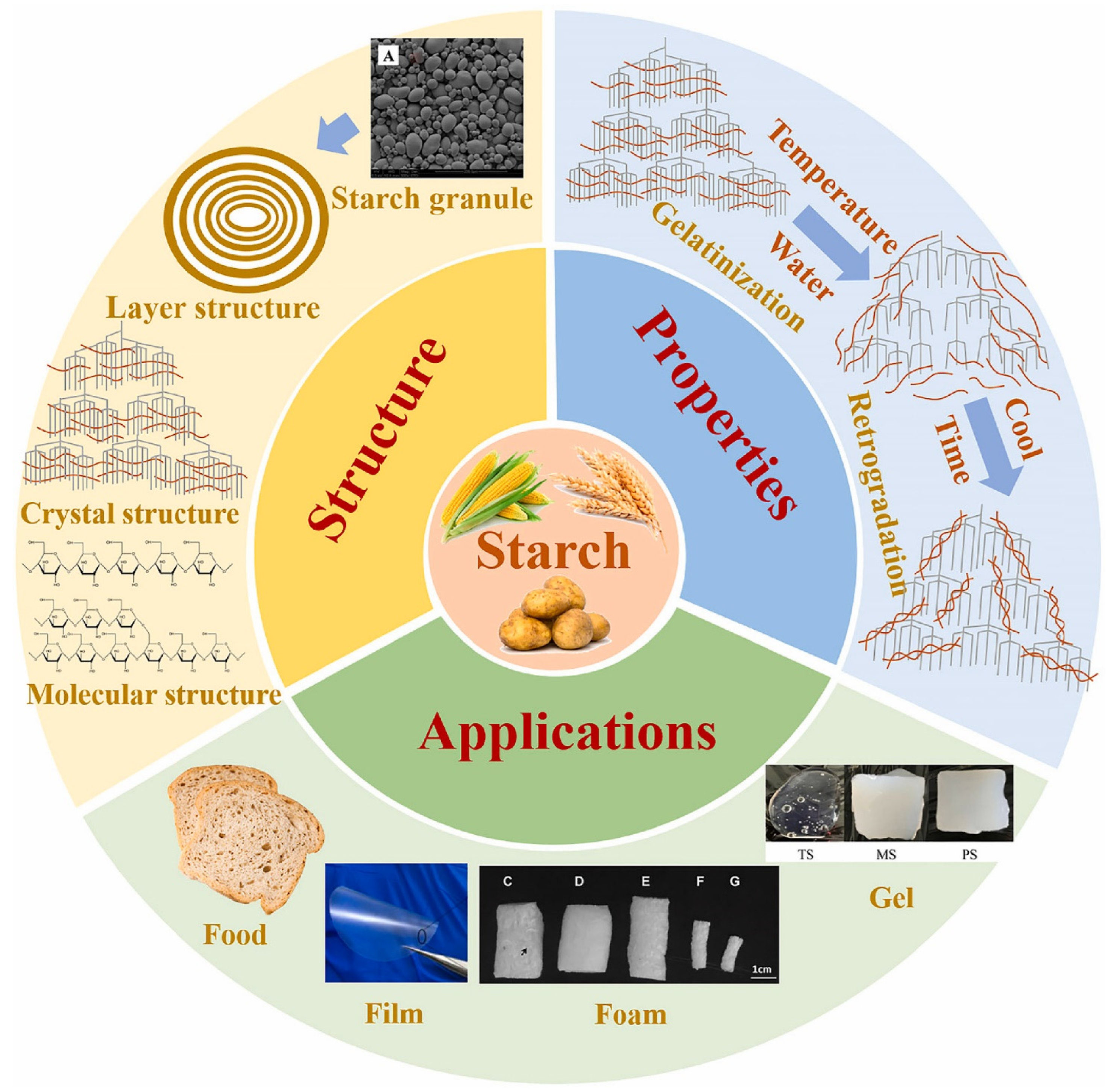

4.1. Wheat Starch-Based Coatings or Films

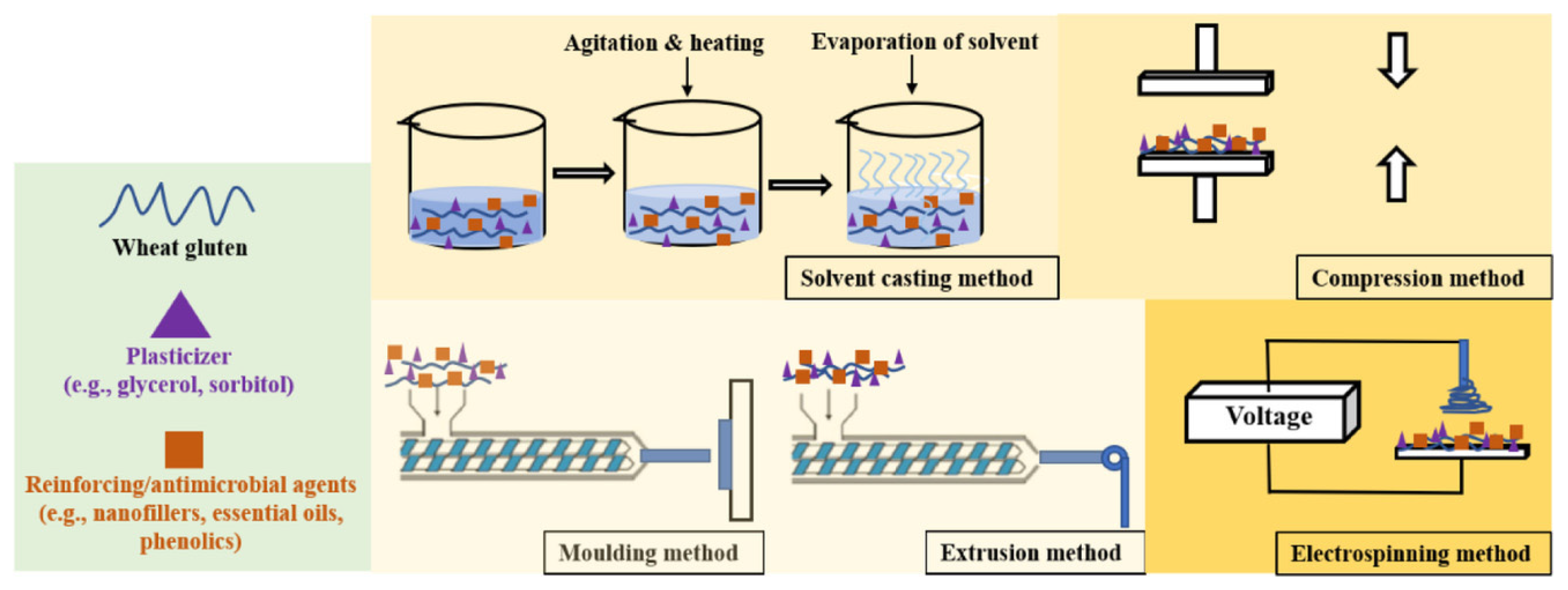

4.2. Wheat Gluten-Based Coatings and Films

4.3. Wheat Fiber as Base/Additives for Coatings and Films

5. Applications and Innovation of Wheat-Based Materials for Food Packaging

6. Potential and Future Trends

7. Challenges of Utilizing Wheat-Based Materials for Food Packaging

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mendes, A.C.; Pedersen, G.A. Perspectives on sustainable food packaging—Is bio-based plastics a solution? Trends Food Sci. Technol. 2021, 112, 839–846. [Google Scholar] [CrossRef]

- Dey, A.; Dhumal, C.V.; Sengupta, P.; Kumar, A.; Pramanik, N.K.; Alam, T. Challenges and possible solutions to mitigate the problems of single-use plastics used for packaging food items: A review. J. Food Sci. Technol. 2021, 58, 3251–3269. [Google Scholar] [CrossRef] [PubMed]

- Hahladakis, J.N. Delineating the global plastic marine litter challenge: Clarifying the misconceptions. Environ. Monit. Assess. 2020, 192, 267. [Google Scholar] [CrossRef]

- Jiang, L.; Jia, F.; Han, Y.; Meng, X.; Xiao, Y.; Bai, S. Development and characterization of zein edible films incorporated with catechin/β-cyclodextrin inclusion complex nanoparticles. Carbohydr. Polym. 2021, 261, 117877. [Google Scholar] [CrossRef]

- Barbosa, C.H.; Andrade, M.A.; Vilarinho, F.; Fernando, A.L.; Silva, A.S. Active Edible Packaging. Encyclopedia 2021, 1, 360–370. [Google Scholar] [CrossRef]

- Ribeiro, A.M.; Estevinho, B.N.; Rocha, F. Preparation and Incorporation of Functional Ingredients in Edible Films and Coatings. Food Bioprocess Technol. 2021, 14, 209–231. [Google Scholar] [CrossRef]

- Mohammed, A.A.B.A.; Borhana Omran, A.A.; Hasan, Z.; Ilyas, R.A.; Sapuan, S.M. Wheat Biocomposite Extraction, Structure, Properties and Characterization: A Review. Polymers 2021, 13, 3624. [Google Scholar] [CrossRef]

- Saratale, G.D.; Saratale, R.G.; Varjani, S.; Cho, S.K.; Ghodake, G.S.; Kadam, A.; Mulla, S.I.; Bharagava, R.N.; Kim, D.S.; Shin, H.S. Development of ultrasound aided chemical pretreatment methods to enrich saccharification of wheat waste biomass for polyhydroxybutyrate production and its characterization. Ind. Crops Prod. 2020, 150, 112425. [Google Scholar] [CrossRef]

- FAO. Available online: https://www.fao.org/faostat/en/#data/QCL/visualize (accessed on 4 August 2024).

- Khosroshahi, E.D.; Razavi, S.H. Wheat germ valorization by fermentation: A novel insight into the stabilization, nutritional/functional values and therapeutic potentials with emphasis on anti-cancer effects. Trends Food Sci. Technol. 2023, 131, 175–189. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, S.; Sun, B.; Wang, F.; Huang, J.; Wang, X.; Bao, Q. Effects of thermal properties and behavior of wheat starch and gluten on their interaction: A review. Int. J. Biol. Macromol. 2021, 177, 474–484. [Google Scholar] [CrossRef]

- Gao, X.; Tong, J.; Guo, L.; Yu, L.; Li, S.; Yang, B.; Wang, L.; Liu, Y.; Li, F.; Guo, J.; et al. Influence of gluten and starch granules interactions on dough mixing properties in wheat (Triticum aestivum L.). Food Hydrocoll. 2020, 106, 105885. [Google Scholar] [CrossRef]

- Shevkani, K.; Singh, N.; Bajaj, R.; Kaur, A. Wheat starch production, structure, functionality and applications—A review. Int. J. Food Sci. Technol. 2017, 52, 38–58. [Google Scholar] [CrossRef]

- USDA. FoodData Central. Available online: https://fdc.nal.usda.gov/fdc-app.html#/food-search?query=&type=Foundation (accessed on 4 August 2024).

- Majzoobi, M.; Ghiasi, F.; Eskandari, M.H.; Farahnaky, A. Roasted Wheat Germ: A Natural Plant Product in Development of Nutritious Milk Pudding; Physicochemical and Nutritional Properties. Foods 2022, 11, 1815. [Google Scholar] [CrossRef] [PubMed]

- Tian, S.; Yu, B.; Du, K.; Li, Y. Purification of wheat germ albumin hydrolysates by membrane separation and gel chromatography and evaluating their antioxidant activities. LWT 2022, 161, 113365. [Google Scholar] [CrossRef]

- Didar, Z.; Hesarinejad, M.A. Active packaging based on wheat germ protein isolate–Malva sylvestris leaf mucilage embedded with D-limonene nanoliposome: Preparation and characterization. Chem. Biol. Technol. Agric. 2023, 10, 67. [Google Scholar] [CrossRef]

- Liao, M.; Damayanti, W.; Zhao, Y.; Xu, X.; Zheng, Y.; Wu, J.; Jiao, S. Hot Air-Assisted Radio Frequency Stabilizing Treatment Effects on Physicochemical Properties, Enzyme Activities and Nutritional Quality of Wheat Germ. Food Bioprocess Technol. 2020, 13, 901–910. [Google Scholar] [CrossRef]

- Alzuwaid, N.T.; Pleming, D.; Fellows, C.M.; Sissons, M. Fortification of durum wheat spaghetti and common wheat bread with wheat bran protein concentrate-impacts on nutrition and technological properties. Food Chem. 2021, 334, 127497. [Google Scholar] [CrossRef]

- Anderson, C.; Simsek, S. Mechanical profiles and topographical properties of films made from alkaline extracted arabinoxylans from wheat bran, maize bran, or dried distillers grain. Food Hydrocoll. 2019, 86, 78–86. [Google Scholar] [CrossRef]

- Yilmaz-Turan, S.; Jiménez-Quero, A.; Menzel, C.; de Carvalho, D.M.; Lindström, M.E.; Sevastyanova, O.; Moriana, R.; Vilaplana, F. Bio-based films from wheat bran feruloylated arabinoxylan: Effect of extraction technique, acetylation and feruloylation. Carbohydr. Polym. 2020, 250, 116916. [Google Scholar] [CrossRef]

- Laddomada, B.; Caretto, S.; Mita, G. Wheat Bran Phenolic Acids: Bioavailability and Stability in Whole Wheat-Based Foods. Molecules 2015, 20, 15666–15685. [Google Scholar] [CrossRef]

- Souza Filho, P.F.; Zamani, A.; Ferreira, J.A. Valorization of Wheat Byproducts for the Co-Production of Packaging Material and Enzymes. Energies 2020, 13, 1300. [Google Scholar] [CrossRef]

- Fu, Z.Q.; Wu, H.J.; Wu, M.; Huang, Z.G.; Zhang, M. Effect of Wheat Bran Fiber on the Behaviors of Maize Starch Based Films. Starch 2020, 72, 1900319. [Google Scholar] [CrossRef]

- Iqbal, M.J.; Shams, N.; Fatima, K.; Iqbal, M.J.; Shams, N.; Fatima, K. Nutritional Quality of Wheat. In Wheat; Intech Open: London, UK, 2022. [Google Scholar] [CrossRef]

- Awol, S.M.; Kuyu, C.G.; Bereka, T.Y.; Abamecha, N. Physicochemical stability, microbial growth and sensory quality of refined wheat flour as affected by packaging materials during storage. J. Stored Prod. Res. 2024, 105, 102217. [Google Scholar] [CrossRef]

- Sahin, A.W.; Wiertz, J.; Arendt, E.K. Evaluation of a new method to determine the water addition level in gluten-free bread systems. J. Cereal Sci. 2020, 93, 102971. [Google Scholar] [CrossRef]

- Guo, W.; Spotti, M.J.; Portillo-Perez, G.; Bonilla, J.C.; Bai, W.; Martinez, M.M. Molecular changes and interactions of wheat flour biopolymers during bread-making: Implications to upcycle bread waste into bioplastics. Carbohydr. Polym. 2024, 342, 122414. [Google Scholar] [CrossRef]

- Admasu, F.; Fentie, E.G.; Admassu, H.; Shin, J.H. Functionalization of wheat bread with prebiotic dietary insoluble fiber from orange-fleshed sweet potato peel and haricot bean flours. LWT 2024, 200, 116182. [Google Scholar] [CrossRef]

- Shaikh, S.; Yaqoob, M.; Aggarwal, P. An overview of biodegradable packaging in food industry. Curr. Res. Food Sci. 2021, 4, 503–520. [Google Scholar] [CrossRef]

- Motelica, L.; Ficai, D.; Ficai, A.; Oprea, O.C.; Kaya, D.A.; Andronescu, E. Biodegradable Antimicrobial Food Packaging: Trends and Perspectives. Foods 2020, 9, 1438. [Google Scholar] [CrossRef]

- Shao, P.; Liu, L.; Yu, J.; Lin, Y.; Gao, H.; Chen, H.; Sun, P. An overview of intelligent freshness indicator packaging for food quality and safety monitoring. Trends Food Sci. Technol. 2021, 118, 285–296. [Google Scholar] [CrossRef]

- Du, H.; Sun, X.; Chong, X.; Yang, M.; Zhu, Z.; Wen, Y. A review on smart active packaging systems for food preservation: Applications and future trends. Trends Food Sci. Technol. 2023, 141, 104200. [Google Scholar] [CrossRef]

- Rozman, A.S.; Hashim, N.; Maringgal, B.; Abdan, K.; Sabarudin, A. Recent advances in active agent-filled wrapping film for preserving and enhancing the quality of fresh produce. Food Control 2023, 144, 109400. [Google Scholar] [CrossRef]

- Gil-Pérez, I.; Rebollar, R.; Lidón, I. Without words: The effects of packaging imagery on consumer perception and response. Curr. Opin. Food Sci. 2020, 33, 69–77. [Google Scholar] [CrossRef]

- Rambabu, K.; Bharath, G.; Banat, F.; Show, P.L.; Cocoletzi, H.H. Mango leaf extract incorporated chitosan antioxidant film for active food packaging. Int. J. Biol. Macromol. 2019, 126, 1234–1243. [Google Scholar] [CrossRef]

- Ezati, P.; Riahi, Z.; Rhim, J.W. CMC-based functional film incorporated with copper-doped TiO2 to prevent banana browning. Food Hydrocoll. 2022, 122, 107104. [Google Scholar] [CrossRef]

- Kumar, R.; Ghoshal, G.; Goyal, M. Moth bean starch (Vigna aconitifolia): Isolation, characterization, and development of edible/biodegradable films. J. Food Sci. Technol. 2019, 56, 4891–4900. [Google Scholar] [CrossRef] [PubMed]

- Romani, V.P.; Martins, V.G.; da Silva, A.S.; Martins, P.C.; Nogueira, D.; Carbonera, N. Amazon-sustainable-flour from açaí seeds added to starch films to develop biopolymers for active food packaging. J. Appl. Polym. Sci. 2022, 139, 51579. [Google Scholar] [CrossRef]

- Chowdhury, S.; Teoh, Y.L.; Ong, K.M.; Rafflisman Zaidi, N.S.; Mah, S.K. Poly(vinyl) alcohol crosslinked composite packaging film containing gold nanoparticles on shelf life extension of banana. Food Packag. Shelf Life 2020, 24, 100463. [Google Scholar] [CrossRef]

- Wang, H.; Ding, F.; Ma, L.; Zhang, Y. Edible films from chitosan-gelatin: Physical properties and food packaging application. Food Biosci. 2021, 40, 100871. [Google Scholar] [CrossRef]

- Marano, S.; Laudadio, E.; Minnelli, C. Tailoring the Barrier Properties of PLA: A State-of-the-Art Review for Food Packaging Applications. Polymers 2022, 14, 1626. [Google Scholar] [CrossRef]

- Trinh, B.M.; Chang, B.P.; Mekonnen, T.H. The barrier properties of sustainable multiphase and multicomponent packaging materials: A review. Prog. Mater. Sci. 2023, 133, 101071. [Google Scholar] [CrossRef]

- Suhag, R.; Kumar, N.; Trajkovska, A.; Upadhyay, A. Film formation and deposition methods of edible coating on food products: A review. Food Res. Int. 2020, 136, 109582. [Google Scholar] [CrossRef] [PubMed]

- Kamarudin, S.H.; Rayung, M.; Abu, F.; Ahmad, S.; Fadil, F.; Salahuddin, M.; Basri, M.; Samsudin, H.; Abdullah, L.C. A Review on Antimicrobial Packaging from Biodegradable. Polymers 2022, 14, 174. [Google Scholar] [CrossRef]

- Flórez, M.; Guerra-Rodríguez, E.; Cazón, P.; Vázquez, M. Chitosan for food packaging: Recent advances in active and intelligent films. Food Hydrocoll. 2022, 124, 107328. [Google Scholar] [CrossRef]

- Salem, A.; Jridi, M.; Abdelhedi, O.; Fakhfakh, N.; Nasri, M.; Debeaufort, F.; Zouari, N. Development and characterization of fish gelatin-based biodegradable film enriched with Lepidium sativum extract as active packaging for cheese preservation. Heliyon 2021, 7, e08099. [Google Scholar] [CrossRef] [PubMed]

- Priyadarshi, R.; Roy, S.; Ghosh, T.; Biswas, D.; Rhim, J.W. Antimicrobial nanofillers reinforced biopolymer composite films for active food packaging applications—A review. Sustain. Mater. Technol. 2022, 32, e00353. [Google Scholar] [CrossRef]

- Bahrami, A.; Delshadi, R.; Assadpour, E.; Jafari, S.M.; Williams, L. Antimicrobial-loaded nanocarriers for food packaging applications. Adv. Colloid Interface Sci. 2020, 278, 102140. [Google Scholar] [CrossRef]

- Chawla, R.; Sivakumar, S.; Kaur, H. Antimicrobial edible films in food packaging: Current scenario and recent nanotechnological advancements—A review. Carbohydr. Polym. Technol. Appl. 2021, 2, 100024. [Google Scholar] [CrossRef]

- Jayakumar, A.; Radoor, S.; Kim, J.T.; Rhim, J.W.; Nandi, D.; Parameswaranpillai, J.; Siengchin, S. Recent innovations in bionanocomposites-based food packaging films—A comprehensive review. Food Packag. Shelf Life 2022, 33, 100877. [Google Scholar] [CrossRef]

- Almasi, H.; Jahanbakhsh Oskouie, M.; Saleh, A. A review on techniques utilized for design of controlled release food active packaging. Crit. Rev. Food Sci. Nutr. 2021, 61, 2601–2621. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, W.; Zhu, W.; McClements, D.J.; Liu, X.; Liu, F. A review of multilayer and composite films and coatings for active biodegradable packaging. npj Sci. Food 2022, 6, 18. [Google Scholar] [CrossRef]

- Cheng, H.; Chen, L.; McClements, D.J.; Yang, T.; Zhang, Z.; Ren, F.; Miao, M.; Tian, Y.; Jin, Z. Starch-based biodegradable packaging materials: A review of their preparation, characterization and diverse applications in the food industry. Trends Food Sci. Technol. 2021, 114, 70–82. [Google Scholar] [CrossRef]

- Rovera, C.; Türe, H.; Hedenqvist, M.S.; Farris, S. Water vapor barrier properties of wheat gluten/silica hybrid coatings on paperboard for food packaging applications. Food Packag. Shelf Life 2020, 26, 100561. [Google Scholar] [CrossRef]

- Bangar, S.P.; Kajla, P.; Ghosh, T. Valorization of wheat straw in food packaging: A source of cellulose. Int. J. Biol. Macromol. 2023, 227, 762–776. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Zhang, H.; McClements, D.J.; Zhang, Z.; Zhang, R.; Jin, Z.; Tian, Y. Effect of dietary fibers on the structure and digestibility of fried potato starch: A comparison of pullulan and pectin. Carbohydr. Polym. 2019, 215, 47–57. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Chao, C.; Yu, J.; Wang, S.; Wang, S.; Copeland, L. New insights into starch gelatinization by high pressure: Comparison with heat-gelatinization. Food Chem. 2020, 318, 126493. [Google Scholar] [CrossRef]

- Donmez, D.; Pinho, L.; Patel, B.; Desam, P.; Campanella, O.H. Characterization of starch–water interactions and their effects on two key functional properties: Starch gelatinization and retrogradation. Curr. Opin. Food Sci. 2021, 39, 103–109. [Google Scholar] [CrossRef]

- do Val Siqueira, L.; Arias, C.I.L.F.; Maniglia, B.C.; Tadini, C.C. Starch-based biodegradable plastics: Methods of production, challenges and future perspectives. Curr. Opin. Food Sci. 2021, 38, 122–130. [Google Scholar] [CrossRef]

- Xu, J.; Li, Y. Wheat gluten–based coatings and films: Preparation, properties, and applications. J. Food Sci. 2023, 88, 582–594. [Google Scholar] [CrossRef]

- Cook, W.H.; Rose, R.C. Solubility of Gluten. Nature 1934, 134, 380–381. [Google Scholar] [CrossRef]

- Wu, Q.; Rabu, J.; Goulin, K.; Sainlaud, C.; Chen, F.; Johansson, E.; Olsson, R.T.; Hedenqvist, M.S. Flexible strength-improved and crack-resistant biocomposites based on plasticised wheat gluten reinforced with a flax-fibre-weave. Compos. Part A Appl. Sci. Manuf. 2017, 94, 61–69. [Google Scholar] [CrossRef]

- Angellier-Coussy, H.; Gastaldi, E.; Gontard, N.; Guillard, V. Influence of processing temperature on the water vapour transport properties of wheat gluten based agromaterials. Ind. Crops Prod. 2011, 33, 457–461. [Google Scholar] [CrossRef]

- Zubeldía, F.; Ansorena, M.R.; Marcovich, N.E. Wheat gluten films obtained by compression molding. Polym. Test. 2015, 43, 68–77. [Google Scholar] [CrossRef]

- Asgher, M.; Qamar, S.A.; Bilal, M.; Iqbal, H.M.N. Bio-based active food packaging materials: Sustainable alternative to conventional petrochemical-based packaging materials. Food Res. Int. 2020, 137, 109625. [Google Scholar] [CrossRef] [PubMed]

- Senthil Muthu Kumar, T.; Senthil Kumar, K.; Rajini, N.; Siengchin, S.; Ayrilmis, N.; Varada Rajulu, A. A comprehensive review of electrospun nanofibers: Food and packaging perspective. Compos. Part B Eng. 2019, 175, 107074. [Google Scholar] [CrossRef]

- Zhang, Y.; Deng, L.; Zhong, H.; Pan, J.; Li, Y.; Zhang, H. Superior water stability and antimicrobial activity of electrospun gluten nanofibrous films incorporated with glycerol monolaurate. Food Hydrocoll. 2020, 109, 106116. [Google Scholar] [CrossRef]

- Rahman, A.; Fehrenbach, J.; Ulven, C.; Simsek, S.; Hossain, K. Utilization of wheat-bran cellulosic fibers as reinforcement in bio-based polypropylene composite. Ind. Crops Prod. 2021, 172, 114028. [Google Scholar] [CrossRef]

- Ahmed, S.; Janaswamy, S.; Yadav, M.P. Biodegradable films from the lignocellulosic fibers of wheat straw biomass and the effect of calcium ions. Int. J. Biol. Macromol. 2024, 264, 130601. [Google Scholar] [CrossRef]

- Gumber, S.; Kanwar, S.; Mazumder, K. Properties and antimicrobial activity of wheat-straw nanocellulose-arabinoxylan acetate composite films incorporated with silver nanoparticles. Int. J. Biol. Macromol. 2023, 246, 125480. [Google Scholar] [CrossRef]

- Yang, S.; Bai, S.; Wang, Q. Sustainable packaging biocomposites from polylactic acid and wheat straw: Enhanced physical performance by solid state shear milling process. Compos. Sci. Technol. 2018, 158, 34–42. [Google Scholar] [CrossRef]

- Martino, L.; Berthet, M.A.; Angellier-Coussy, H.; Gontard, N. Understanding external plasticization of melt extruded PHBV-wheat straw fibers biodegradable composites for food packaging. J. Appl. Polym. Sci. 2015, 132, 1–11. [Google Scholar] [CrossRef]

- Tian, S.Q.; Zhao, R.Y.; Chen, Z.C. Review of the pretreatment and bioconversion of lignocellulosic biomass from wheat straw materials. Renew. Sustain. Energy Rev. 2018, 91, 483–489. [Google Scholar] [CrossRef]

- Ciaramitaro, V.; Piacenza, E.; Meo, P.L.; Librici, C.; Calvino, M.M.; Conte, P.; Lazzara, G.; Chillura Martino, D.F. From micro to macro: Physical-chemical characterization of wheat starch-based films modified with PEG200, sodium citrate, or citric acid. Int. J. Biol. Macromol. 2023, 253, 127225. [Google Scholar] [CrossRef] [PubMed]

- Yousefi, A.R.; Savadkoohi, B.; Zahedi, Y.; Hatami, M.; Ako, K. Fabrication and characterization of hybrid sodium montmorillonite/TiO2 reinforced cross-linked wheat starch-based nanocomposites. Int. J. Biol. Macromol. 2019, 131, 253–263. [Google Scholar] [CrossRef] [PubMed]

- Punia, S.; Sandhu, K.S.; Dhull, S.B.; Kaur, M. Dynamic, shear and pasting behaviour of native and octenyl succinic anhydride (OSA) modified wheat starch and their utilization in preparation of edible films. Int. J. Biol. Macromol. 2019, 133, 110–116. [Google Scholar] [CrossRef]

- Bonilla, J.; Atarés, L.; Vargas, M.; Chiralt, A. Properties of wheat starch film-forming dispersions and films as affected by chitosan addition. J. Food Eng. 2013, 114, 303–312. [Google Scholar] [CrossRef]

- Leiva, R.; Hernández-Fernández, A.F.; Ortega, J.; Surmenev, A.; Felipe, A.; Hernández-Fernández, J.; Toro, R.O. Active Films Based on Starch and Wheat Gluten (Triticum vulgare) for Shelf-Life Extension of Carrots. Polymers 2022, 14, 5077. [Google Scholar] [CrossRef]

- Sharma, T.; Kaur, G.; Singh, A.; Kumar, V.; Dar, B.N. Enhancing litchi shelf life with gluten-based nanocomposite films: A comparative study of montmorillonite and starch nanocrystals reinforced with chitosan. Sci. Hortic. 2024, 332, 113239. [Google Scholar] [CrossRef]

- Nataraj, D.; Sakkara, S.; HN, M.; Reddy, N. Properties and applications of citric acid crosslinked banana fibre-wheat gluten films. Ind. Crops Prod. 2018, 124, 265–272. [Google Scholar] [CrossRef]

- Fabra, M.J.; Lopez-Rubio, A.; Lagaron, J.M. Effect of the film-processing conditions, relative humidity and ageing on wheat gluten films coated with electrospun polyhydryalkanoate. Food Hydrocoll. 2015, 44, 292–299. [Google Scholar] [CrossRef]

- Wu, H.; Xu, C.; Li, J.; Guan, Y.; Mao, J.; Kong, F.; Peng, F.; Gao, H. Development and properties of wheat straw nano-holocellulose and reduced graphene oxide composite films for active packaging materials. Ind. Crops Prod. 2022, 189, 115816. [Google Scholar] [CrossRef]

| Nutrition | Wheat Germ | Wheat Bran | Whole Wheat Flour | White Flour (Plain) | White Flour (Self-Raising) | White Flour (Bread Making) |

|---|---|---|---|---|---|---|

| Protein (g) | 23.2 | 15.6 | 15.1 | 10.3 | 9.89 | 12 |

| Fat (g) | 9.72 | 4.25 | 2.73 | 0.98 | 0.97 | 1.66 |

| Carbohydrates (g) | 51.8 | 64.5 | 71.2 | 76.3 | 74.2 | 72.5 |

| Total sugars (g) | n.d. | 0.41 | n.d. | 0.27 | 0.22 | 0.31 |

| Fiber (g) | 13.2 | 42.8 | n.d. | 2.7 | 2.7 | 2.4 |

| Minerals (mg) | 2147.3 | 1803.9 | 622.2 | 290.59 | 2306.80 | 281.42 |

| Vitamin E (mg) | n.d. | 1.49 | n.d. | 0.06 | 0.05 | 0.4 |

| Vitamin B (mg) | n.d. | n.d. | 0.268 | n.d. | n.d. | n.d. |

| Wheat Material | Food Application | Packaging Type | Key Findings | Reference |

|---|---|---|---|---|

| Starch | n.d. | Starch film |

| [75] |

| Starch | n.d. | Starch film |

| [76] |

| Starch | Grapes | Edible films |

| [77] |

| Starch | n.d. | Starch-chitosan film |

| [78] |

| Gluten and Starch | Carrot | Gluten and starch film |

| [79] |

| Gluten | Litchis | Films |

| [80] |

| Gluten | n.d. | Coatings |

| [55] |

| Gluten | n.d. | Film |

| [81] |

| Gluten | n.d. | Gluten film |

| [82] |

| Fiber | n.d. | AXAc film |

| [71] |

| Fiber | n.d. | Nanoholocellulose film |

| [83] |

| Fiber | n.d. | Cellulose film |

| [70] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alibekov, R.S.; Urazbayeva, K.U.; Azimov, A.M.; Rozman, A.S.; Hashim, N.; Maringgal, B. Advances in Biodegradable Food Packaging Using Wheat-Based Materials: Fabrications and Innovations, Applications, Potentials, and Challenges. Foods 2024, 13, 2964. https://doi.org/10.3390/foods13182964

Alibekov RS, Urazbayeva KU, Azimov AM, Rozman AS, Hashim N, Maringgal B. Advances in Biodegradable Food Packaging Using Wheat-Based Materials: Fabrications and Innovations, Applications, Potentials, and Challenges. Foods. 2024; 13(18):2964. https://doi.org/10.3390/foods13182964

Chicago/Turabian StyleAlibekov, Ravshanbek S., Klara U. Urazbayeva, Abdugani M. Azimov, Azri Shahir Rozman, Norhashila Hashim, and Bernard Maringgal. 2024. "Advances in Biodegradable Food Packaging Using Wheat-Based Materials: Fabrications and Innovations, Applications, Potentials, and Challenges" Foods 13, no. 18: 2964. https://doi.org/10.3390/foods13182964

APA StyleAlibekov, R. S., Urazbayeva, K. U., Azimov, A. M., Rozman, A. S., Hashim, N., & Maringgal, B. (2024). Advances in Biodegradable Food Packaging Using Wheat-Based Materials: Fabrications and Innovations, Applications, Potentials, and Challenges. Foods, 13(18), 2964. https://doi.org/10.3390/foods13182964