Rheological Properties and Sensory Profile of Yoghurt Produced with Novel Combination of Probiotic Cultures

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Chemical Composition

2.3. Colour Measurement

2.4. Texture Analysis

2.5. Rheological Analysis

2.5.1. Flow Curve Measurements

2.5.2. Yield Stress Determination

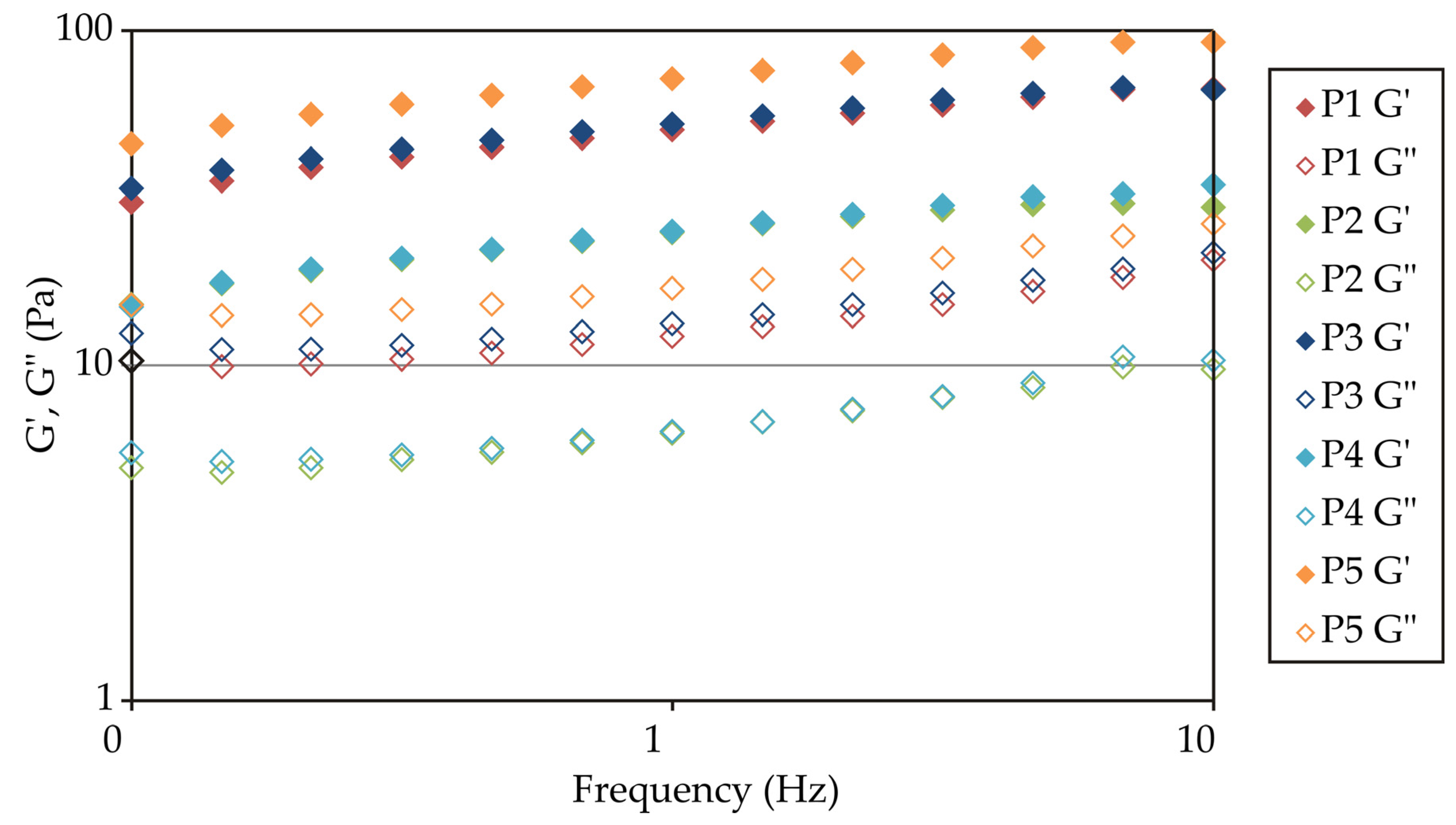

2.5.3. Dynamic Oscillatory Measurements

2.6. Sensory Evaluation

2.7. Statistical Analysis

3. Results and Discussion

3.1. Physicochemical Properties

3.2. Rheological Properties

3.3. Sensory Properties

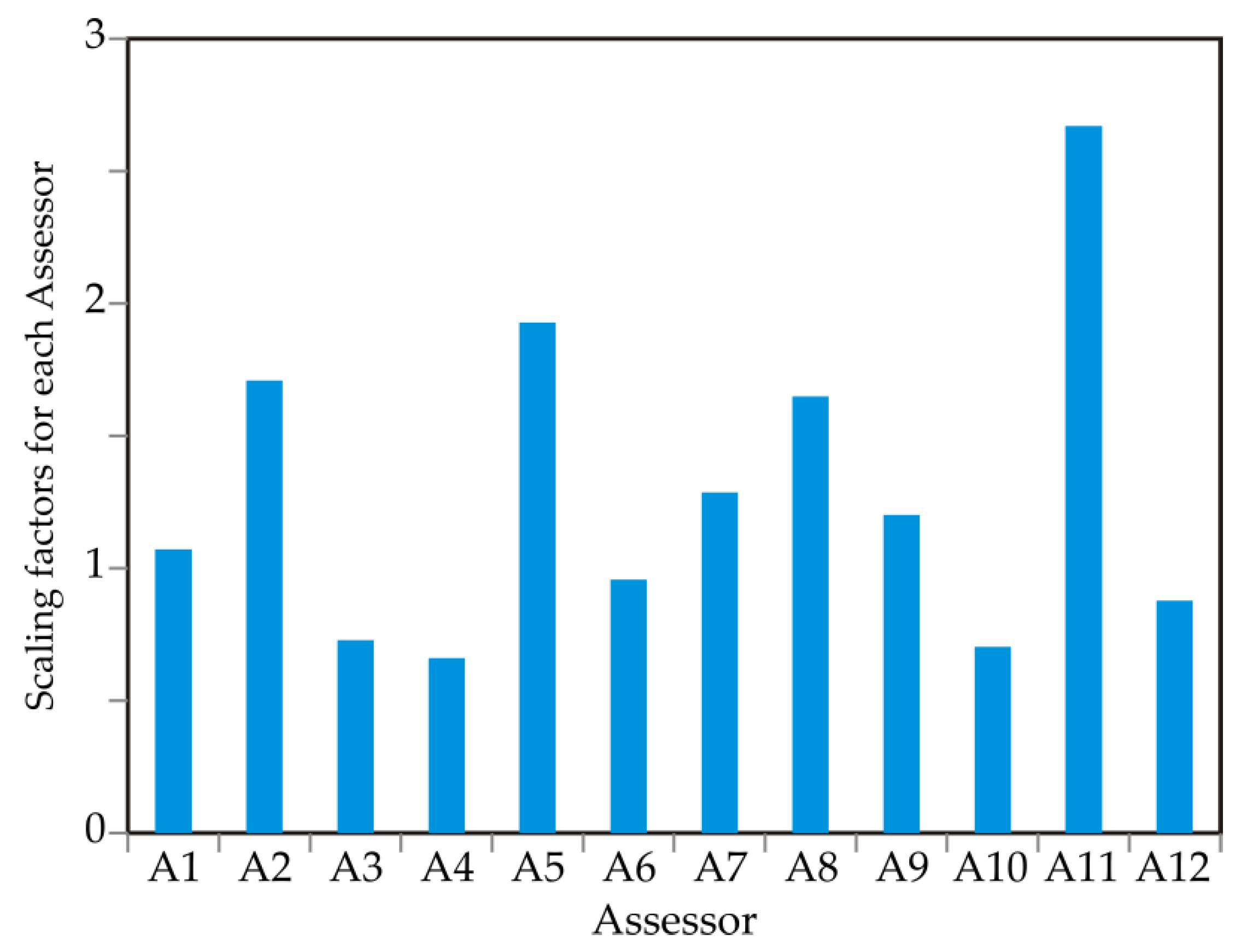

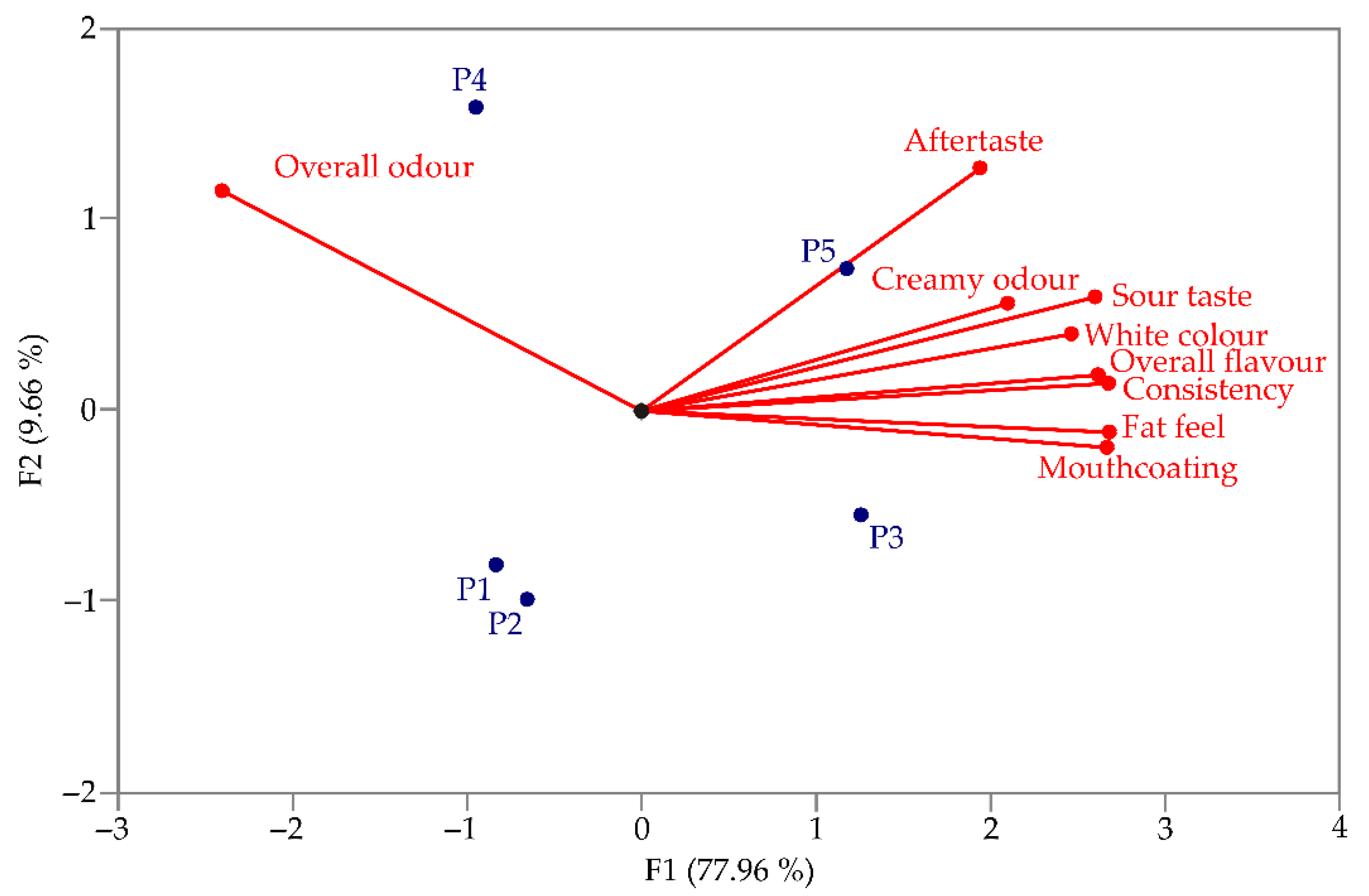

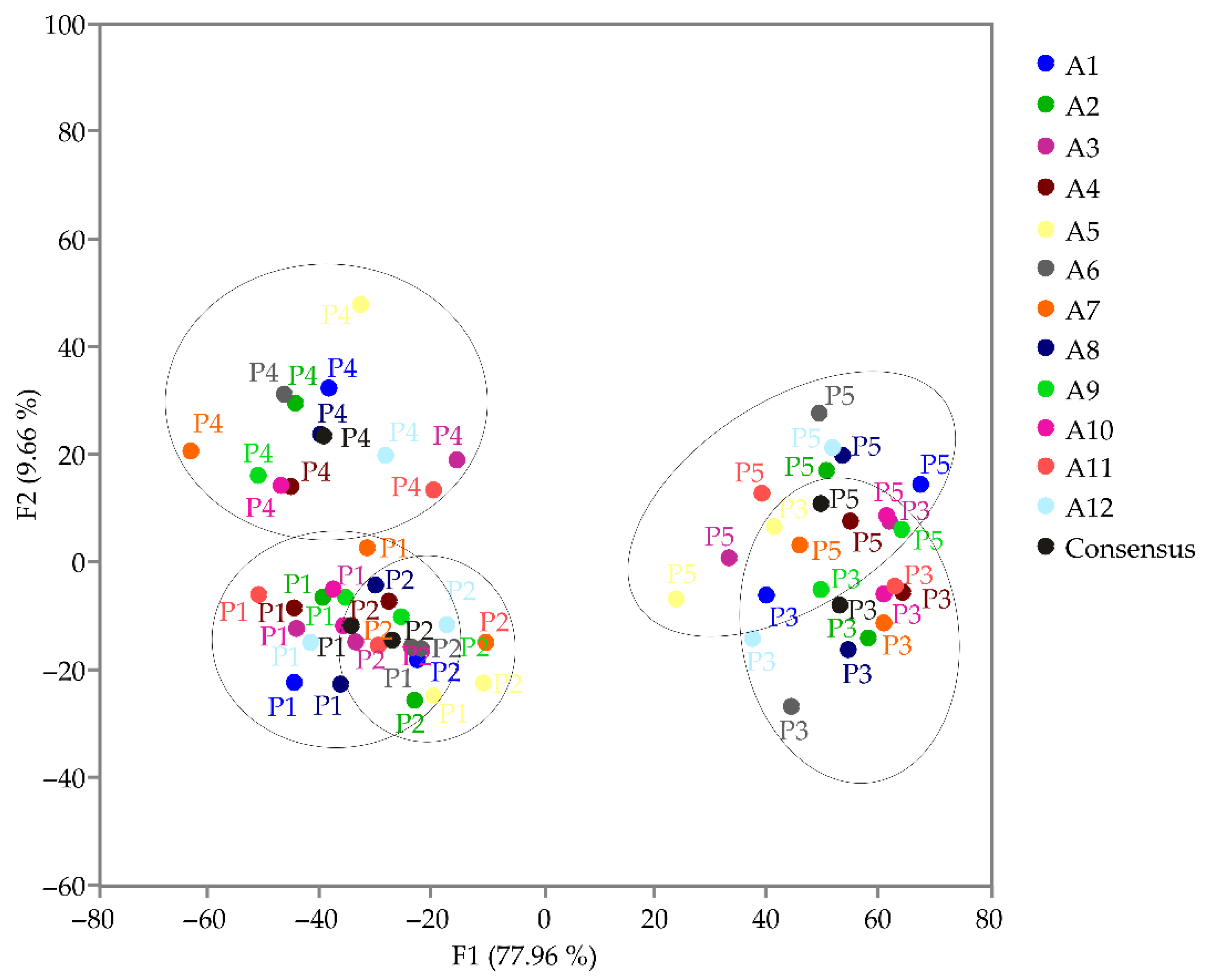

Generalized Procrustes Analysis (GPA) and Principal Component Analysis (PCA)

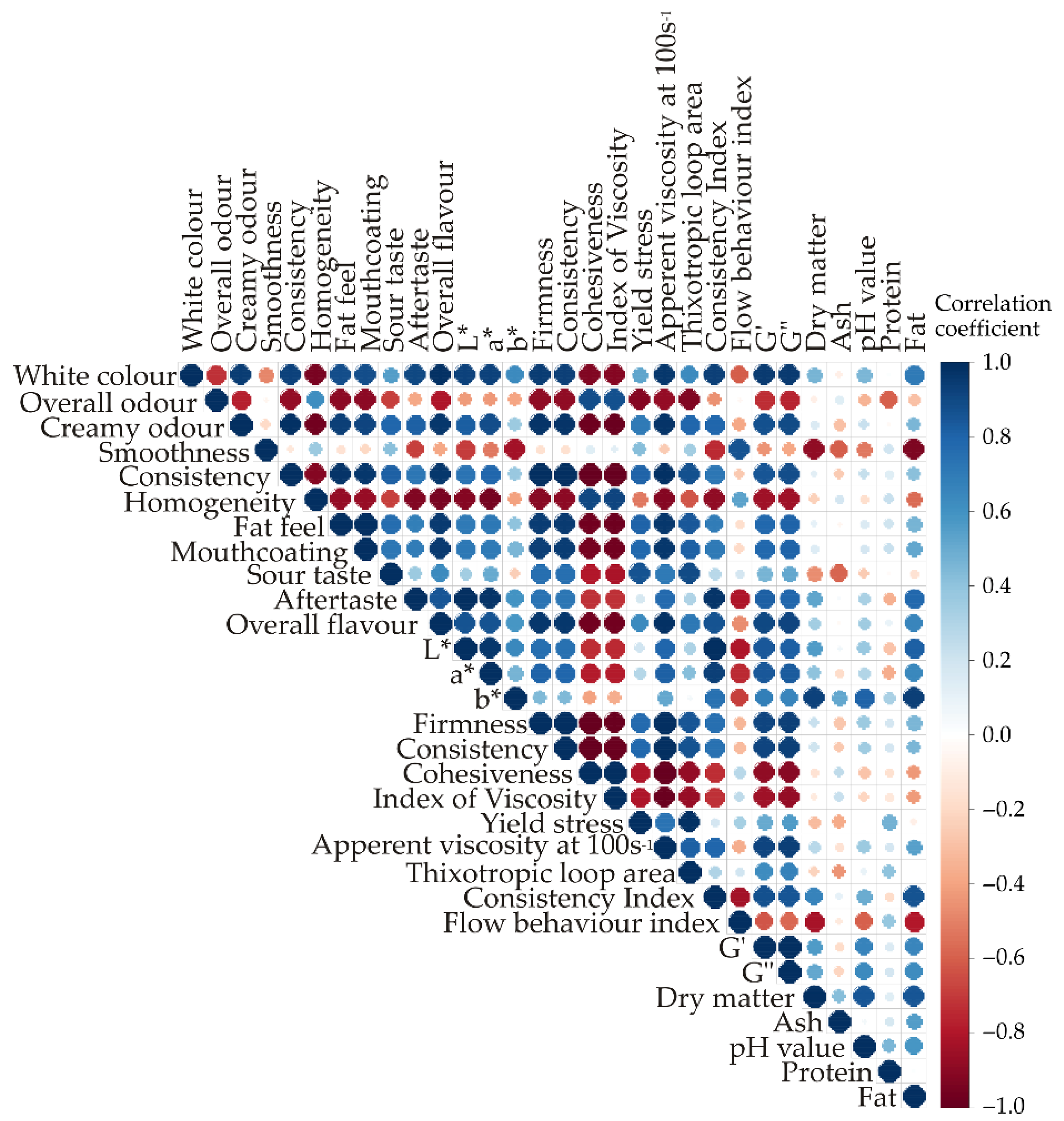

3.4. Correlation Analysis and Principal Component Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Saleh, A.; Mohamed, A.A.; Alamri, M.S.; Hussain, S.; Qasem, A.A.; Ibraheem, M.A. Effect of different starches on the rheological, sensory and storage attributes of non-fat set yogurt. Foods 2020, 9, 61. [Google Scholar] [CrossRef] [PubMed]

- Bai, M.; Huang, T.; Guo, S.; Wang, Y.; Wang, J.; Kwok, L.Y.; Dan, T.; Zhang, H.; Bilige, M. Probiotic Lactobacillus casei Zhang improved the properties of stirred yogurt. Food Biosci. 2020, 37, 100718. [Google Scholar] [CrossRef]

- Gilbert, A.; Turgeon, S.L. Studying stirred yogurt microstructure and its correlation to physical properties: A review. Food Hydrocoll. 2021, 121, 106970. [Google Scholar] [CrossRef]

- Aktar, T. Physicochemical and sensory characterisation of different yoghurt production methods. Int. Dairy J. 2022, 125, 105245. [Google Scholar] [CrossRef]

- Cruz, A.G.D.; Cavalcanti, R.N.; Guerreiro, L.M.R.; Sant’Ana, A.D.S.; Nogueira, L.C.; Oliveira, C.A.F.D.; Deliza, R.; Cunha, R.L.; Faria, J.A.F.; Bolini, H.M.A. Developing a prebiotic yogurt: Rheological, physico-chemical and microbiological aspects and adequacy of survival analysis methodology. J. Food Eng. 2013, 114, 323–330. [Google Scholar] [CrossRef]

- Sah, B.N.P.; Vasiljevic, T.; McKechnie, S.; Donkor, O.N. Physicochemical, textural and rheological properties of probiotic yogurt fortified with fibre-rich pineapple peel powder during refrigerated storage. LWT-Food Sci.Technol. 2016, 65, 978–986. [Google Scholar] [CrossRef]

- Tiwari, S.; Kavitake, D.; Devi, P.B.; Shetty, P.H. Bacterial exopolysaccharides for improvement of technological, functional and rheological properties of yoghurt. Int. J. Biol. Macromol. 2021, 183, 1585–1595. [Google Scholar] [CrossRef]

- Brüls, M.; Foroutanparsa, S.; Maljaars, C.E.P.; Olsthoorn, M.; Tas, R.P.; Voets, I.K. Investigating the impact of exopolysaccharides on yogurt network mechanics and syneresis through quantitative microstructural analysis. Food Hydrocoll. 2024, 150, 109629. [Google Scholar] [CrossRef]

- Folkenberg, D.M.; Dejmek, P.; Skriver, A.; Guldager, H.S.; Ipsen, R. Sensory and rheological screening of exopolysaccharide producing strains of bacterial yoghurt cultures. Int. Dairy J. 2006, 16, 111–118. [Google Scholar] [CrossRef]

- Mende, S.; Rohm, H.; Jaros, D. Influence of exopolysaccharides on the structure, texture, stability and sensory properties of yoghurt and related products. Int. Dairy J. 2016, 52, 57–71. [Google Scholar] [CrossRef]

- Culpepper, T.; Rowe, C.C.; Rusch, C.T.; Burns, A.M.; Federico, A.P.; Girard, S.A.; Tompkins, T.A.; Nieves, C.; Dennis-Wall, J.C.; Christman, M.C.; et al. Three probiotic strains exert different effects on plasma bile acid profiles in healthy obese adults: Randomised, double-blind placebo-controlled crossover study. Benefic. Microbes 2019, 10, 497–509. [Google Scholar] [CrossRef]

- Ford, A.L.; Nagulesapillai, V.; Piano, A.; Auger, J.; Girard, S.A.; Christman, M.; Tompkins, T.A.; Dahl, W.J. Microbiota stability and gastrointestinal tolerance in response to a high-protein diet with and without a prebiotic, probiotic, and synbiotic: A randomized, double-blind, placebo-controlled trial in older women. J. Acad. Nutr. Diet. 2020, 120, 500–516. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, J.; Yao, Z.; Ni, L.; Zhao, Y.; Wei, S.; Chen, Z. Effect and mechanism of Bifidobacterium animalis B94 in the prevention and treatment of liver injury in rats. Front. Cell. Infect. Microbiol. 2022, 12, 914684. [Google Scholar] [CrossRef] [PubMed]

- Islek, A.; Sayar, E.; Yilmaz, A.; Baysan, B.O.; Mutlu, D.; Artan, R. The role of Bifidobacterium lactis B94 plus inulin in the treatment of acute infectious diarrhea in children. Turk. J. Gastroenterol. 2014, 25, 628–633. [Google Scholar] [CrossRef] [PubMed]

- Alyousif, Z.; Miller, J.L.; Auger, J.; Sandoval, M.; Piano, A.; Tompkins, T.A.; Dahl, W.J. Microbiota profile and efficacy of probiotic supplementation on laxation in adults affected by Prader-Willi Syndrome: A randomized, double-blind, crossover trial. Mol. Genet. Genomic Med. 2020, 8, e1535. [Google Scholar] [CrossRef] [PubMed]

- Ustundag, G.H.; Altuntas, H.; Soysal, Y.D.; Kokturk, F. The effects of synbiotic “Bifidobacterium lactis B94 plus inulin” addition on standard triple therapy of Helicobacter pylori eradication in children. Can. J. Gastroenterol. Hepatol. 2017, 130596. [Google Scholar]

- Donkor, O.N.; Henriksson, A.; Vasiljevic, T.; Shah, N.P. Effect of acidification on the activity of probiotics in yoghurt during cold storage. Int. Dairy J. 2006, 16, 1181–1189. [Google Scholar] [CrossRef]

- Benković, M.; Kos, B.; Tonković, K.; Leboš, A.; Šušković, J.; Gregurek, L. Utjecaj probiotičkog soja Bifidobacterium animalis subsp. lactis LAFTI® B94, inulina i transglutaminaze na svojstva čvrstog jogurta. Mljekarstvo 2008, 58, 95–115. (In Croatian) [Google Scholar]

- Soni, R.; Jain, N.K.; Shah, V.; Soni, J.; Suthar, D.; Gohel, P. Development of probiotic yogurt: Effect of strain combination on nutritional, rheological, organoleptic and probiotic properties. J. Food Sci. Technol. 2020, 57, 2038–2050. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 21st ed.; AOAC International: Rockville, MD, USA, 2019. [Google Scholar]

- ISO 19662:2018; Milk–Determination of Fat Content–Acido-Butyrometric (Gerber Method). ISO: Geneva, Switzerland, 2018.

- ISO 8586:2023; Sensory Analysis–Selection and Training of Sensory Assessors. ISO: Geneva, Switzerland, 2023.

- ISO 8589:2007/Amd 1:2014; Sensory Analysis–General Guidance for the Design of Test Rooms. ISO: Geneva, Switzerland, 2015.

- Meilgaard, M.C.; Carr, B.T.; Civille, G.V. Sensory Evaluation Techniques, 3rd ed.; CRC Press: Boca Raton, FL, USA, 1999. [Google Scholar]

- McEwan, J.A. Preference mapping for product optimization. In Multivariate Analysis of Data in Sensory Science, 1st ed.; Naes, T., Risvik, E., Eds.; Elsevier Science B.V: Amsterdam, The Netherlands, 1996; Volume 16, pp. 71–102. [Google Scholar]

- Belović, M.; Mastilović, J.; Kevrešan, Ž. Change of surface colour parameters during storage of paprika (Capsicum annuum L.). Food Feed Res. 2014, 41, 85–92. [Google Scholar] [CrossRef]

- González-Martınez, C.; Becerra, M.; Cháfer, M.; Albors, A.; Carot, J.M.; Chiralt, A. Influence of substituting milk powder for whey powder on yoghurt quality. Trends Food Sci. Technol. 2002, 13, 334–340. [Google Scholar] [CrossRef]

- Jakubowska, M.; Karamucki, T. The effect of storage time and temperature on the quality of natural yoghurt. Acta Sci. Pol. Zootech. 2020, 18, 29–38. [Google Scholar] [CrossRef]

- Delikanli, B.; Ozcan, T. Improving the textural properties of yogurt fortified with milk proteins. J. Food Process. Preserv. 2017, 41, e13101. [Google Scholar] [CrossRef]

- Ozturkoglu-Budak, S.; Akal, H.C.; Buran, İ.; Yetişemiyen, A. Effect of inulin polymerization degree on various properties of synbiotic fermented milk including Lactobacillus acidophilus La-5 and Bifidobacterium animalis Bb-12. J. Dairy Sci. 2019, 102, 6901–6913. [Google Scholar] [CrossRef]

- Laiho, S.; Williams, R.P.; Poelman, A.; Appelqvist, I.; Logan, A. Effect of whey protein phase volume on the tribology, rheology and sensory properties of fat-free stirred yoghurts. Food Hydrocoll. 2017, 67, 166–177. [Google Scholar] [CrossRef]

- Javanmard, M.; Wong, E.; Howes, T.; Stokes, J.R. Application of the thixotropic elasto-viscoplastic model as a structure probing technique for acid milk gel suspensions. J. Food Eng. 2018, 222, 250–257. [Google Scholar] [CrossRef]

- Buldo, P.; Benfeldt, C.; Folkenberg, D.M.; Jensen, H.B.; Amigo, J.M.; Sieuwerts, S.; Thygesen, K.; van den Berg, F.; Ipsen, R. The role of exopolysaccharide-producing cultures and whey protein ingredients in yoghurt. LWT-Food Sci. Technol. 2016, 72, 189–198. [Google Scholar] [CrossRef]

- Erturk, M.Y.; Bonilla, J.C.; Kokini, J. Relationship of non-linear rheological properties and quantitative network analysis parameters as a function of increasingly large amplitude deformations in non-fat, low-fat and high-fat yogurt products. Food Hydrocoll. 2021, 111, 106194. [Google Scholar] [CrossRef]

- Meyer, D.; Bayari, S.; Tárrega, A.; Costell, E. Inulin as texture modifier in dairy products. Food Hydrocoll. 2011, 25, 1881–1890. [Google Scholar] [CrossRef]

- Kip, P.; Meyer, D.; Jellema, R.H. Inulins improve sensoric and textural properties of low-fat yoghurts. Int. Dairy J. 2006, 16, 1098–1103. [Google Scholar] [CrossRef]

- Frøst, M.B.; Janhøj, T. Understanding creaminess. Int. Dairy J. 2007, 17, 1298–1311. [Google Scholar] [CrossRef]

- Otto, M. Chemometrics Statistics and Computer Application in Analytical Chemistry; Wiley-VCH: Weinheim, Germany, 1999. [Google Scholar]

- Kaiser, H.F.; Rice, J. Little Jiffy, mark IV. Educ. Psychol. Meas. 1974, 34, 111–117. [Google Scholar] [CrossRef]

| Attribute | Descriptor | Definition | Technique |

|---|---|---|---|

| Appearance | White colour intensity | Intensity of white colour | Visually |

| Odour | Overall odour intensity | Overall odour intensity of the sample | Olfactory |

| Creamy odour intensity | Intensity of cream-like product odour | Olfactory | |

| Texture | Smoothness | The degree to which the sample feels smooth and free of lumps | Orally |

| Consistency | The degree of compactness of the sample when pressed between the tongue and palate | Orally | |

| Homogeneity | The degree of uniformity of the particles | Orally | |

| Fat feel | It refers to the intensity of the greasy feeling in the mouth during the manipulation of the sample between the tongue and the palate; the content of fatty components is observed | Orally | |

| Mouthcoating | Sensation of having a smooth/greasy coating on the tongue and other parts of the oral cavity | Orally | |

| Taste | Sour | Basic taste produced by acid substances such as citric, acetic and lactic acid | Orally |

| Aftertaste | Aftertaste intensity, 1 min after the sample is swallowed | Orally |

| Parameter | P1 | P2 | P3 | P4 | P5 |

|---|---|---|---|---|---|

| Dry matter (%) | 11.45 ± 0.24 b | 10.68 ± 0.24 c | 9.72 ± 0.11 d | 9.73 ± 0.11 d | 12.00 ± 0.13 a |

| Ash (%) | 0.69 ± 0.02 bc | 0.78 ± 0.02 a | 0.67 ± 0.02 c | 0.68 ± 0.01 c | 0.73 ± 0.02 ab |

| pH value | 4.39 ± 0.12 a | 4.24 ± 0.06 ab | 4.25 ± 0.08 ab | 4.17 ± 0.06 b | 4.35 ± 0.07 ab |

| Protein (%) | 3.32 ± 0.14 a | 3.29 ± 0.20 a | 3.33 ± 0.18 a | 2.80 ± 0.22 a | 3.03 ± 0.15 a |

| Fat (%) | 1.73 ± 0.07 bc | 1.98 ± 0.14 b | 1.44 ± 0.09 cd | 1.22 ± 0.07 d | 2.99 ± 0.18 a |

| L* | 84.23 ± 0.09 c | 83.92 ± 0.01 d | 83.81 ± 0.09 e | 84.61 ± 0.01 a | 84.40 ± 0.01 b |

| a* | −3.31 ± 0.02 c | −3.31 ± 0.01 c | −3.25 ± 0.04 b | −3.07 ± 0.01 a | −3.33 ± 0.01 c |

| b* | 7.33 ± 0.04 a | 6.77 ± 0.02 d | 6.83 ± 0.02 c | 6.53 ± 0.02 e | 6.98 ± 0.01 b |

| Firmness (g) | 26.18 ± 1.85 b | 24.78 ± 1.12 bc | 40.10 ± 1.92 a | 21.99 ± 0.68 c | 26.35 ± 2.03 b |

| Consistency (gs) | 684.0 ± 21.56 b | 669.4 ± 25.69 bc | 1117 ± 65.83 a | 594.5 ± 22.49 c | 691.4 ± 31.09 b |

| Cohesiveness (g) | −18.53 ± 0.78 b | −19.68 ± 0.80 b | −66.14 ± 6.89 a | −17.19 ± 0.54 b | −19.48 ± 0.45 b |

| Index of viscosity (gs) | −23.10 ± 4.66 b | −25.10 ± 5.59 b | −157.5 ± 14.25a | −9.70 ± 4.57 b | −25.44 ± 4.15 b |

| Descriptor | P1 | P2 | P3 | P4 | P5 |

|---|---|---|---|---|---|

| White colour intensity | 55.5 ± 17.3 a | 53.2 ± 18.1 a | 61.4 ± 16.1 a | 53.2 ± 18.5 a | 67.2 ± 16.8 a |

| Overall odour intensity | 44.2 ± 23.9 ab | 44.8 ± 22.7 ab | 31.0 ± 16.1 b | 52.5 ± 23.7 a | 38.1 ± 17.7 ab |

| Creamy odour intensity | 30.4 ± 18.8 a | 26.9 ± 19.2 a | 49.2 ± 19.0 a | 31.8 ± 21.4 a | 51.8 ± 17.3 a |

| Smoothness | 77.2 ± 23.4 a | 76.8 ± 21.3 a | 79.3 ± 17.8 a | 78.2 ± 22.7 a | 74.3 ± 17.6 a |

| Consistency | 37.9 ± 10.1 b | 34.8 ± 16.2 b | 71.8 ± 16.8 a | 35.6 ± 15.1 b | 69.6 ± 14.4 a |

| Homogeneity | 80.6 ± 16.4 a | 80.8 ± 14.6 a | 76.4 ± 21.0 a | 79.1 ± 18.9 a | 74.0 ± 23.4 a |

| Fat feel | 31.0 ± 11.8 a | 38.6 ± 11.9 a | 64.9 ± 14.5 a | 30.6 ± 14.8 a | 62.7 ± 16.4 a |

| Mouthcoating | 33.2 ± 15.1 a | 42.7 ± 13.2 a | 68.6 ± 14.4 a | 31.2 ± 14.9 a | 68.1 ± 14.4 a |

| Sour taste | 34.7 ± 20.0 a | 34.0 ± 21.7 a | 56.3 ± 23.2 a | 42.5 ± 18.7 a | 44.2 ± 25.3 a |

| Aftertaste | 29.6 ± 28.5 a | 28.8 ± 23.5 a | 33.1 ± 27.6 a | 31.7 ± 29.6 a | 44.3 ± 34.1 a |

| Overall flavour intensity | 48.5 ± 17.2 a | 48.8 ± 22.5 a | 63.4 ± 15.8 a | 45.9 ± 18.8 a | 69.8 ± 10.6 a |

| Factors | |||||

|---|---|---|---|---|---|

| No | Descriptors | Products | Assessors | ||

| F | p | F | p | ||

| 1 | White colour | 6.825 | 0.000 | 18.988 | <0.0001 |

| 2 | Overall odour | 3.364 | 0.017 | 5.585 | <0.0001 |

| 3 | Creamy odour | 7.061 | 0.000 | 4.047 | 0.000 |

| 4 | Smoothness | 0.227 | 0.922 | 7.510 | <0.0001 |

| 5 | Consistency | 28.506 | <0.0001 | 3.078 | 0.004 |

| 6 | Homogeneity | 0.566 | 0.688 | 6.006 | <0.0001 |

| 7 | Fat feel | 22.538 | <0.0001 | 2.371 | 0.021 |

| 8 | Mouthcoating | 21.505 | <0.0001 | 1.510 | 0.162 |

| 9 | Sour taste | 2.533 | 0.054 | 2.206 | 0.032 |

| 10 | Aftertaste | 2.227 | 0.081 | 15.684 | <0.0001 |

| 11 | Overall flavour | 5.646 | 0.001 | 2.311 | 0.024 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ilić, N.; Belović, M.; Memiši, N.; Pestorić, M.; Škrobot, D.; Pezo, L.; Jevtić-Mučibabić, R.; Sanz, Y.; Brouzes, J. Rheological Properties and Sensory Profile of Yoghurt Produced with Novel Combination of Probiotic Cultures. Foods 2024, 13, 3021. https://doi.org/10.3390/foods13193021

Ilić N, Belović M, Memiši N, Pestorić M, Škrobot D, Pezo L, Jevtić-Mučibabić R, Sanz Y, Brouzes J. Rheological Properties and Sensory Profile of Yoghurt Produced with Novel Combination of Probiotic Cultures. Foods. 2024; 13(19):3021. https://doi.org/10.3390/foods13193021

Chicago/Turabian StyleIlić, Nebojša, Miona Belović, Nurgin Memiši, Mladenka Pestorić, Dubravka Škrobot, Lato Pezo, Rada Jevtić-Mučibabić, Yolanda Sanz, and Jerome Brouzes. 2024. "Rheological Properties and Sensory Profile of Yoghurt Produced with Novel Combination of Probiotic Cultures" Foods 13, no. 19: 3021. https://doi.org/10.3390/foods13193021

APA StyleIlić, N., Belović, M., Memiši, N., Pestorić, M., Škrobot, D., Pezo, L., Jevtić-Mučibabić, R., Sanz, Y., & Brouzes, J. (2024). Rheological Properties and Sensory Profile of Yoghurt Produced with Novel Combination of Probiotic Cultures. Foods, 13(19), 3021. https://doi.org/10.3390/foods13193021