Physicochemical and Morphological Changes in Long-Grain Brown Rice Milling: A Study Using Image Visualization Technologies

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Degree of Milling (DOM)

2.3. Ratio of Broken Kernels, Rice Color, and Appearance Image Acquisition

2.4. DF and Vitamin B1 Contents

2.5. Microstructure Analysis

2.6. X-ray Micro-CT Analysis

2.7. Water Distribution and Mobility in the Samples

2.8. Volatile Analysis

2.9. Statistical Analysis

3. Results and Discussion

3.1. DOM, Broken Rice, Color, Content of DF, and Vitamin B1 Changes in Rice during the Milling Process

3.2. Rice Appearance Image Analysis

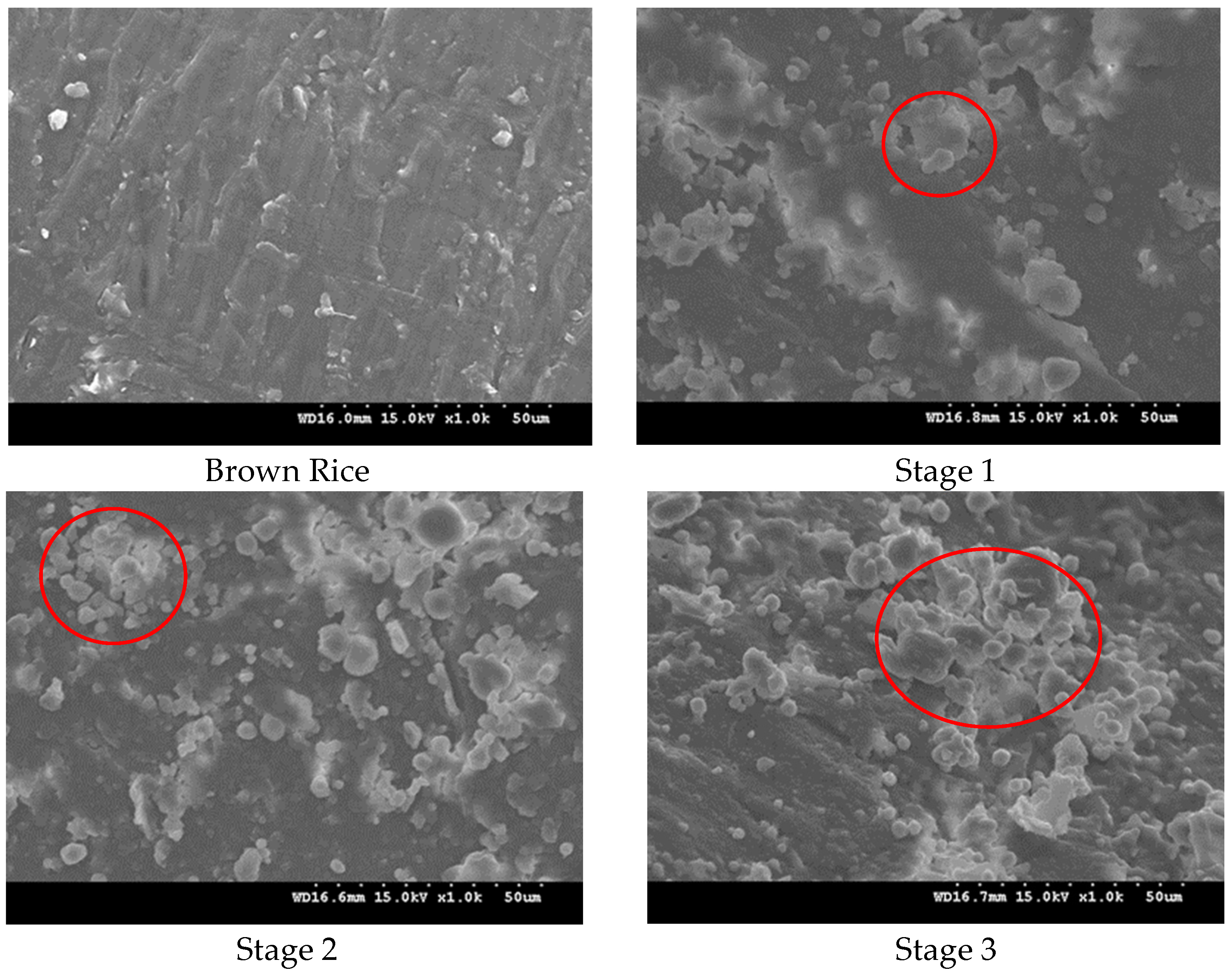

3.3. Microstructure Properties

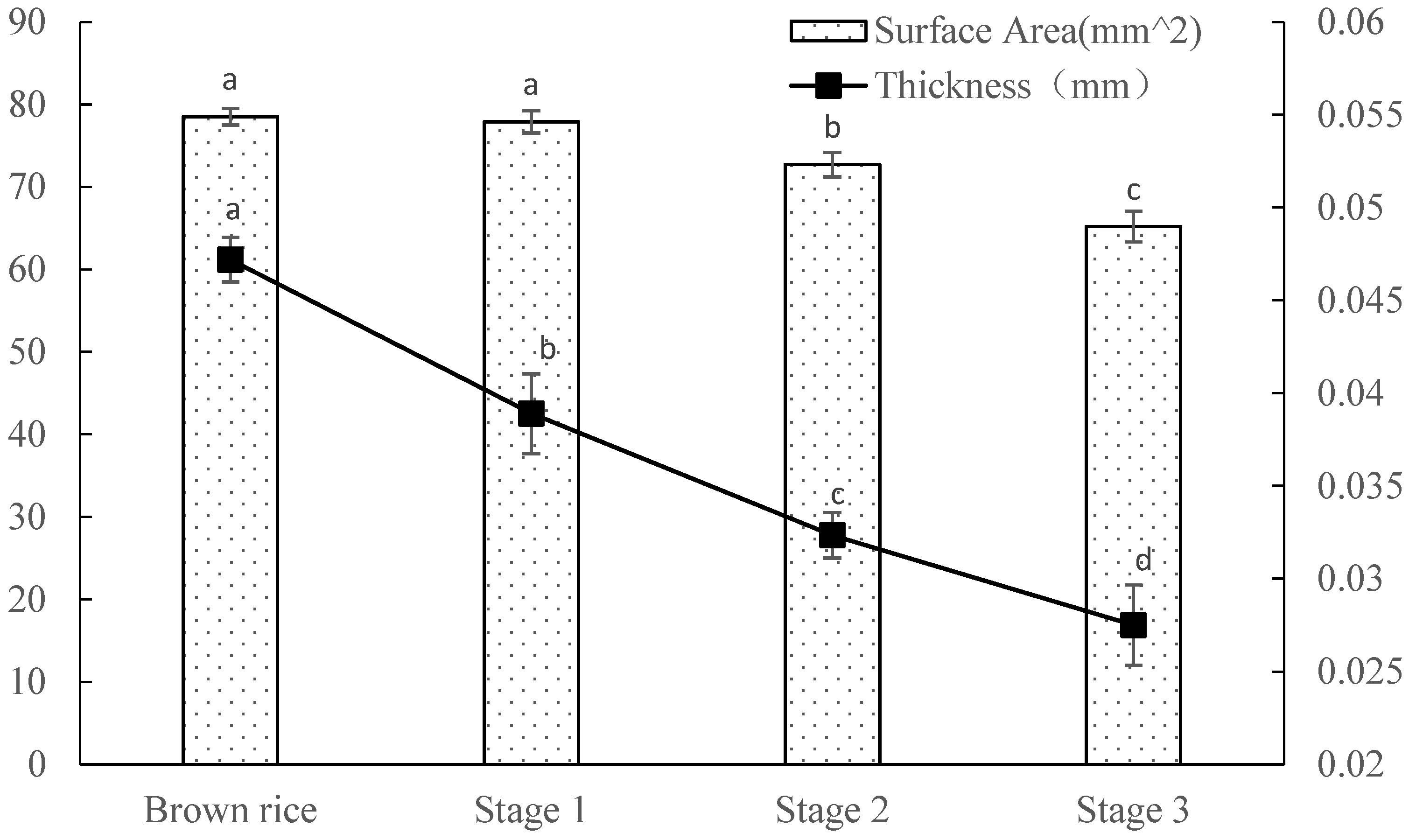

3.4. Micro-CT Analysis

3.5. Molecular Mobility (1H NMR) Analysis

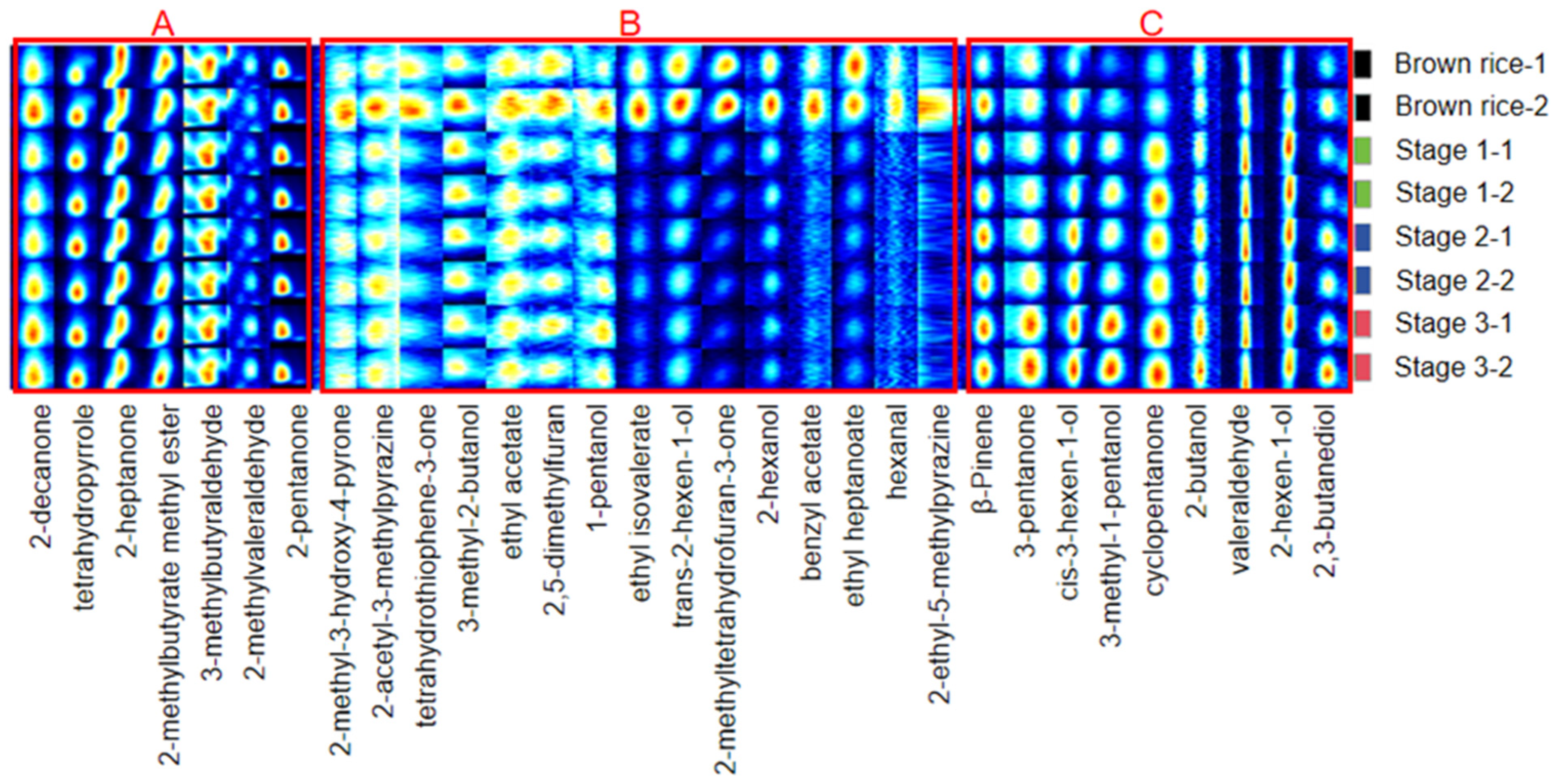

3.6. Volatile Component Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sen, S.; Chakraborty, R.; Kalita, P. Rice—Not just a staple food: A comprehensive review on its phytochemicals and therapeutic potential. Trends Food Sci. Technol. 2020, 97, 265–285. [Google Scholar] [CrossRef]

- Summpunn, P.; Deh-Ae, N.; Panpipat, W.; Manurakchinakorn, S.; Bhoopong, P.; Donlao, N.; Rawdkuen, S.; Shetty, K.; Chaijan, M. Nutritional Profiles of yoom noon rice from royal initiative of Southern Thailand: A comparison of white rice, brown rice, and germinated brown rice. Foods 2023, 12, 2952. [Google Scholar] [CrossRef] [PubMed]

- Sandhu, R.S.; Singh, N.; Kaler, R.S.S.; Kaur, A.; Shevkani, K. Effect of degree of milling on physicochemical, structural, pasting and cooking properties of short and long grain indica rice cultivars. Food Chem. 2018, 260, 231–238. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Li, F.; Huang, K.; Li, S.; Cao, H.; Xie, J.; Guan, X. Structural changes of starch under different milling degrees affect the cooking and textural properties of rice. Food Chem. X 2023, 17, 100627. [Google Scholar] [CrossRef] [PubMed]

- Longvah, T.; Boiroju, N.K.; Prasad, V.S.S.; Kumar, K.O.; Mangthya, K.; Sharma, P.; Ananthan, R.; Babu, V.R. Nutrient diversity in 251 Indian rice germplasms and dietary nutrient supply through rice in rice based diets. LWT 2021, 148, 111721. [Google Scholar] [CrossRef]

- Huang, W.D.; Miao, X.X.; Liu, Z.M.; Zhou, K.; Yang, B.R.; Li, C.G. Effect of rice milling technology on milled rice yield of long-grain high quality indica rice. Hunan Agric. Sci. 2021, 11, 71–74. [Google Scholar] [CrossRef]

- Kim, S.Y.; Lee, H. Effects of quality characteristics on milled rice produced under different milling conditions. J. Korean Soc. Appl. Biol. Chem. 2012, 55, 643–649. [Google Scholar] [CrossRef]

- Zhao, S.; Shi, J.; Cai, S.; Xiong, T.; Cai, F.; Li, S.; Chen, X.; Fan, C.; Mei, X.; Sui, Y. Effects of milling degree on nutritional, sensory, gelatinization and taste quality of different rice varieties. LWT 2023, 186, 115244. [Google Scholar] [CrossRef]

- Ren, H.; Qi, S.; Zhang, L.; Wang, L.; Huang, J.; Yang, H.; Ren, C.; Zhou, W. Variations in the appearance quality of brown rice during the four stages of milling. J. Cereal Sci. 2021, 102, 103344. [Google Scholar] [CrossRef]

- Liu, J.; Tang, Z.; Zhang, J.; Chen, Q.; Xu, P.; Liu, W. Visual perception-based statistical modeling of complex grain image for product quality monitoring and supervision on assembly production line. PLoS ONE 2016, 11, e0146484. [Google Scholar] [CrossRef]

- Roy, P.; Ijiri, T.; Okadome, H.; Nei, D.; Orikasa, T.; Nakamura, N.; Shiina, T. Effect of processing conditions on overall energy consumption and quality of rice (Oryza sativa L.). J. Food Eng. 2008, 89, 343–348. [Google Scholar] [CrossRef]

- Zareiforoush, H.; Minaei, S.; Alizadeh, M.R.; Banakar, A. Potential applications of computer vision in quality inspection of rice: A review. Food Eng. Rev. 2015, 7, 321–345. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, M.; Liu, G.; Deng, Y.; Zhang, Y.; Tang, X.; Li, P.; Wei, Z. Effect of the degree of milling on the physicochemical properties, pasting properties and in vitro digestibility of simiao rice. Grain Oil Sci. Technol. 2021, 4, 45–53. [Google Scholar] [CrossRef]

- Chen, W.; Li, W.; Wang, Y. Evaluation of rice degree of milling based on Bayesian optimization and multi-scale residual model. Foods 2022, 11, 3720. [Google Scholar] [CrossRef] [PubMed]

- Tuncel, N.B.; Yılmaz, N.; Kocabıyık, H.; Uygur, A. The effect of infrared stabilized rice bran substitution on physicochemical and sensory properties of pan breads: Part I. J. Cereal Sci. 2014, 59, 155–161. [Google Scholar] [CrossRef]

- Akhter, K.T.; Shozib, H.B.; Islam, M.H.; Sarwar, S.; Islam, M.M.; Akanda, M.R.; Siddiquee, M.A.; Mohiduzzaman, M.D.; Rahim, A.T.; Shaheen, N. Variations in the major nutrient composition of dominant high-yield varieties (hyvs) in parboiled and polished rice of Bangladesh. Foods 2023, 12, 3997. [Google Scholar] [CrossRef]

- Vicent, V.; Ndoye, F.-T.; Verboven, P.; Nicolaï, B.; Alvarez, G. Effect of dynamic storage temperatures on the microstructure of frozen carrot imaged using x-ray micro-ct. J. Food Eng. 2019, 246, 232–241. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.; Wang, A.; Dai, Z.; Wang, R.; Sun, H.; Strappe, P.; Zhou, Z. Characteristics of moisture migration and volatile compounds of rice stored under various storage conditions. J. Cereal Sci. 2021, 102, 103323. [Google Scholar] [CrossRef]

- Fan, X.; Jiao, X.; Liu, J.; Jia, M.; Blanchard, C.; Zhou, Z. Characterizing the volatile compounds of different sorghum cultivars by both GC-MS and HS-GC-IMS. Food Res. Int. 2021, 140, 109975. [Google Scholar] [CrossRef]

- Fei, J.; Feng, W.; Jia, F.; Han, Y.; Chen, P.; Li, A.; Wang, Y.; Zhang, J.; Shen, S.; Hao, X. The mechanism of bran layer removal in friction rice mills. Biosyst. Eng. 2023, 229, 85–95. [Google Scholar] [CrossRef]

- Ping, J.; Ren, L.; Xiao, H.T.; Yan, X.L.; Du, Q.Z. Effect of milling on proximate composition, γ-oryzanol, vitamin B1, polyphenolic, and bioaccessibility of phenolic of brown rice. J. Food Process. Preserv. 2022, 46, e17215. [Google Scholar] [CrossRef]

- Lamberts, L.; Delcour, J.A. Carotenoids in raw and parboiled brown and milled rice. J. Agric. Food Chem. 2008, 56, 11914–11919. [Google Scholar] [CrossRef] [PubMed]

- Lamberts, L.; Bie, E.D.; Vandeputte, G.E.; Veraverbeke, W.S.; Derycke, V.; Man, W.D.; Delcour, J.A. Effect of milling on colour and nutritional properties of rice. Food Chem. 2007, 100, 1496–1503. [Google Scholar] [CrossRef]

- Olatunde, G.A.; Atungulu, G.G. Milling behavior and microstructure of rice dried using microwave set at 915 MHz frequency. J. Cereal Sci. 2018, 80, 167–173. [Google Scholar] [CrossRef]

- Contardo, I.; Bouchon, P. Enhancing micro-ct Methods to quantify oil content and porosity in starch-gluten matrices. J. Food Eng. 2018, 237, 154–161. [Google Scholar] [CrossRef]

- Wang, L.; Duan, W.; Qian, H.; Zhang, H.; Qi, X. Research status and development trend of brown rice food. Food Ferment. Ind. 2016, 42, 236–243. [Google Scholar] [CrossRef]

- Pan, Q.; Zhou, J.; Shen, W.; Wang, Z.; Cai, H.; Jia, X. Effect of extruded wheat bran on volatile and physicochemical properties of bread during its shelf life. J. Cereal Sci. 2022, 107, 103525. [Google Scholar] [CrossRef]

- Qiao, C.-C.; Tian, X.-H.; Wang, L.-X.; Jiang, P.; Zhai, X.-T.; Wu, N.-N.; Tan, B. Quality characteristics, texture properties and moisture migration of fresh brown rice noodles under different storage and temperatures conditions. J. Cereal Sci. 2022, 104, 103434. [Google Scholar] [CrossRef]

- Cheng, S.; Zhang, T.; Yao, L.; Wang, X.; Song, Y.; Wang, H.; Wang, H.; Tan, M. Use of low-field-nmr and MRI to characterize water mobility and distribution in pacific oyster (Crassostrea gigas) during drying process. Dry. Technol. 2018, 36, 630–636. [Google Scholar] [CrossRef]

- Wood, D.F.; Siebenmorgen, T.J.; Williams, T.G.; Orts, W.J.; Glenn, G.M. Use of microscopy to assess bran removal patterns in milled rice. J. Agric. Food Chem. 2012, 60, 6960–6965. [Google Scholar] [CrossRef]

- Pan, Z.; Khir, R.; Thompson, J.F. Effect of milling temperature and post milling cooling procedures on rice milling quality appraisals. Cereal Chem. 2013, 90, 107–113. [Google Scholar] [CrossRef]

- Li, Z.; Sun, X.; Xu, T.; Dai, W.; Yan, Q.; Li, P.; Fang, Y.; Ding, J. Insight into the dynamic variation and retention of major aroma volatile compounds during the milling of Suxiang Japonica rice. Food Chem. 2023, 405, 134468. [Google Scholar] [CrossRef]

- Din, Y.L.; Wang, H.D.; Tang, G.W.; Tian, X. HS-GC-IMS and fingerprint of volatile organic compounds of chrysanthemum for 5 medicinal and dietary uses. Food Mach. 2022, 38, 52–58. [Google Scholar] [CrossRef]

- de Melo Pereira, G.V.; de Carvalho Neto, D.P.; Júnior, A.I.; Vásquez, Z.S.; Medeiros, A.B.P.; Vandenberghe, L. Exploring the impacts of postharvest processing on the aroma formation of coffee beans—A review. Food Chem. 2019, 272, 441–452. [Google Scholar] [CrossRef] [PubMed]

- Gao, C.; Li, Y.; Pan, Q.; Fan, M.; Wang, L.; Qian, H. Analysis of the key aroma volatile compounds in rice bran during storage and processing via HS-SPME GC/MS. J. Cereal Sci. 2021, 99, 103178. [Google Scholar] [CrossRef]

- Xian, Q.H.; Lin, L.; Zhen, L.G.; Zhi, W.Z. Volatile compounds, affecting factors and evaluation methods for rice aroma: A review. Trends Food Sci. Technol. 2020, 97, 136–146. [Google Scholar] [CrossRef]

| DOM (%) | Broken Rice Rate (%) | Whiteness | Dietary Fiber/(g/100 g) | VB1/(mg/100 g) | |

|---|---|---|---|---|---|

| Brown rice | 0 | 0.00 | 18.60 ± 0.17 a | 1.36 ± 0.11 a | 0.18 ± 0.01 a |

| Stage 1 | 1.26 ± 0.05 a | 11.27 ± 1.12 a | 30.90 ± 0.36 b | 0.94 ± 0.04 b | 0.10 ± 0.03 b |

| Stage 2 | 5.34 ± 0.34 b | 15.77 ± 1.36 b | 35.87 ± 0.75 c | 0.65 ± 0.01 c | 0.08 ± 0.02 b |

| Stage 3 | 8.53 ± 1.02 c | 17.00 ± 1.05 c | 37.43 + 0.21 d | 0.62 ± 0.03 c | 0.06 ± 0.01 b |

| T21 (ms) | T22 (ms) | T23 (ms) | A21 | A22 | A23 | |

|---|---|---|---|---|---|---|

| Brown rice | 0.66 ± 0.00 | 14.73 ± 4.01 a | 70.72 ± 4.93 a | 86.64 ± 0.05 a | 1.61 ± 0.20 a | 11.75 ± 0.15 a |

| Stage 1 | 0.66 ± 0.00 | 61.51 ± 4.28 b | 328.25 ± 22.87 b | 91.86 ± 0.05 b | 6.62 ± 0.18 b | 1.52 ± 0.13 b |

| Stage 2 | 0.66 ± 0.00 | 75.65 ± 0.00 c | 253.15 ± 52.23 c | 95.82 ± 0.14 c | 3.70 ± 0.11 c | 1.16 ± 0.22 c |

| Stage 3 | 0.66 ± 0.00 | 37.89 ± 2.82 d | 232.53 ± 17.30 c | 96.39 ± 0.01 c | 2.44 ± 0.21 d | 0.49 ± 0.04 d |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, X.; Dong, R.; Chen, X.; Wang, Z.; Zhang, H.; Shen, W. Physicochemical and Morphological Changes in Long-Grain Brown Rice Milling: A Study Using Image Visualization Technologies. Foods 2024, 13, 3033. https://doi.org/10.3390/foods13193033

Jia X, Dong R, Chen X, Wang Z, Zhang H, Shen W. Physicochemical and Morphological Changes in Long-Grain Brown Rice Milling: A Study Using Image Visualization Technologies. Foods. 2024; 13(19):3033. https://doi.org/10.3390/foods13193033

Chicago/Turabian StyleJia, Xiwu, Rong Dong, Xuan Chen, Zhan Wang, Hongjian Zhang, and Wangyang Shen. 2024. "Physicochemical and Morphological Changes in Long-Grain Brown Rice Milling: A Study Using Image Visualization Technologies" Foods 13, no. 19: 3033. https://doi.org/10.3390/foods13193033

APA StyleJia, X., Dong, R., Chen, X., Wang, Z., Zhang, H., & Shen, W. (2024). Physicochemical and Morphological Changes in Long-Grain Brown Rice Milling: A Study Using Image Visualization Technologies. Foods, 13(19), 3033. https://doi.org/10.3390/foods13193033