The Effects of Adding Extruded Highland Barley Flour on the Thermomechanical Properties of Wheat Flour Dough and the Overall Quality of Fresh Wet Noodles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation and Chemical Analysis of Flour

2.3. Pasting Properties

2.4. Mixolab Measurements

2.5. Preparation of Fresh Wet Noodles

2.6. Scanning Electron Microscopy (SEM)

2.7. Color Measurements

2.8. Cooking Characteristics

2.9. In Vitro Starch Digestibility

2.10. Textural Analysis

2.11. Sensory Evaluation

2.12. Statistical Analysis

3. Results and Discussion

3.1. Effects of HBF and EHBF Addition on the Pasting Properties of Wheat Flour

3.2. Effects of HBF and EHBF Addition on the Mixolab Parameters of Wheat Flour Dough

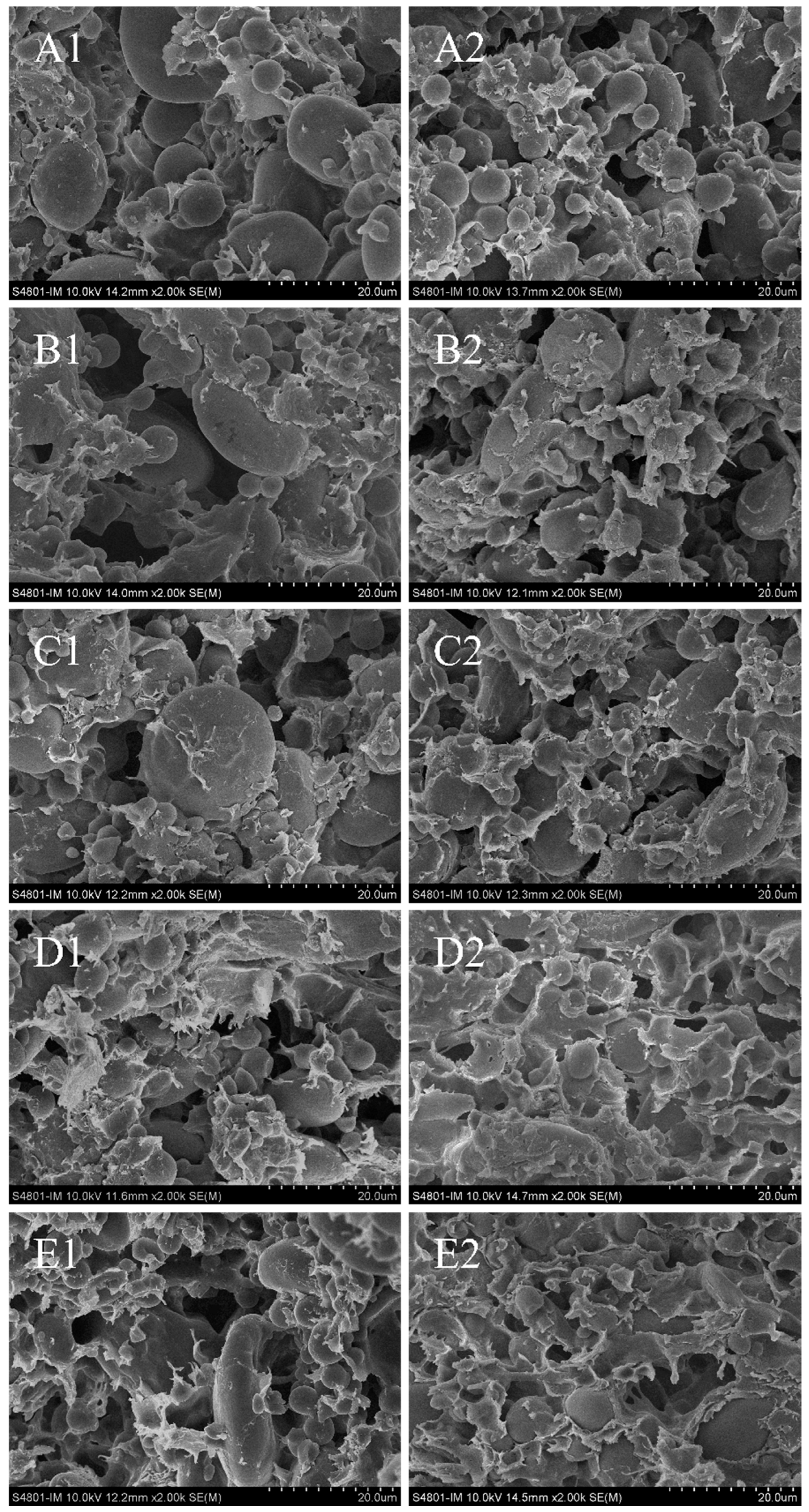

3.3. Effects of HBF and EHBF Addition on the Microstructure of Fresh Wet Noodles

3.4. Effects of HBF and EHBF Addition on the Color Characteristics of Fresh Wet Noodles

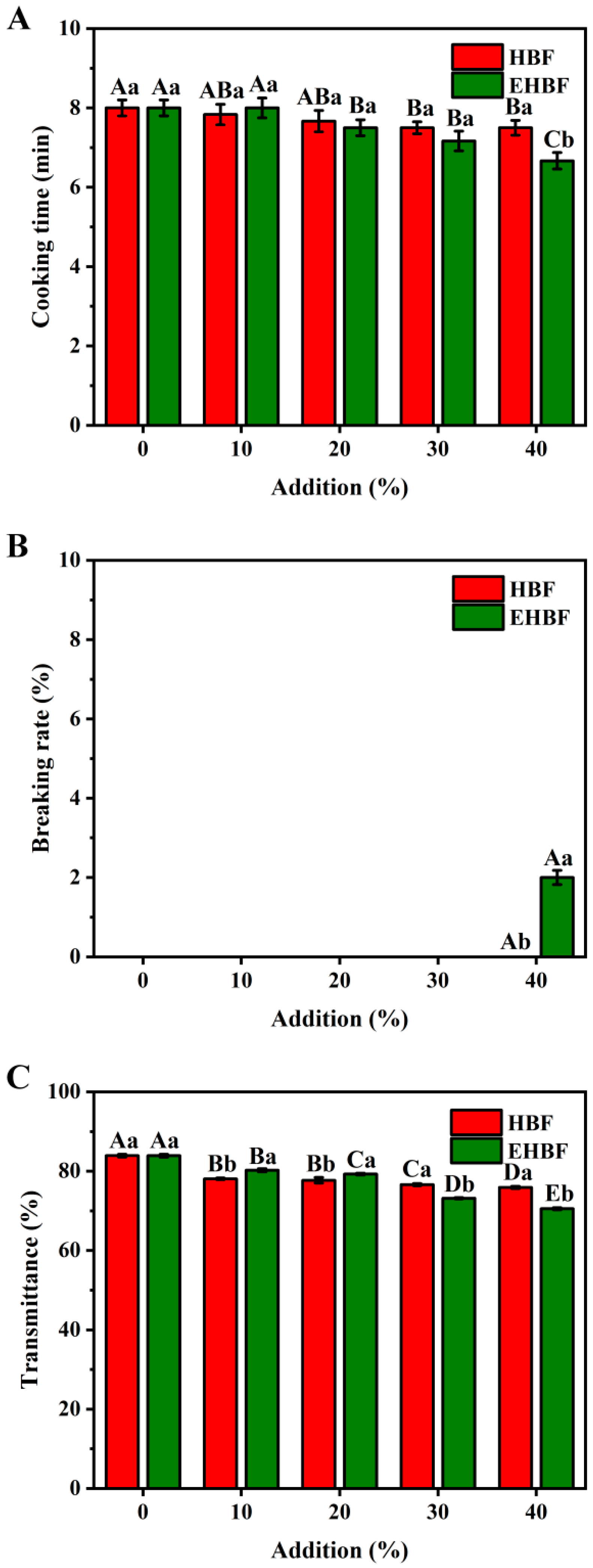

3.5. Effects of HBF and EHBF Addition on the Cooking Quality of Fresh Wet Noodles

3.6. Effects of Adding HBF and EHBF on the Starch Digestibility of Fresh Wet Noodles

3.7. Effects of HBF and EHBF Addition on the Texture Properties of Fresh Wet Noodles

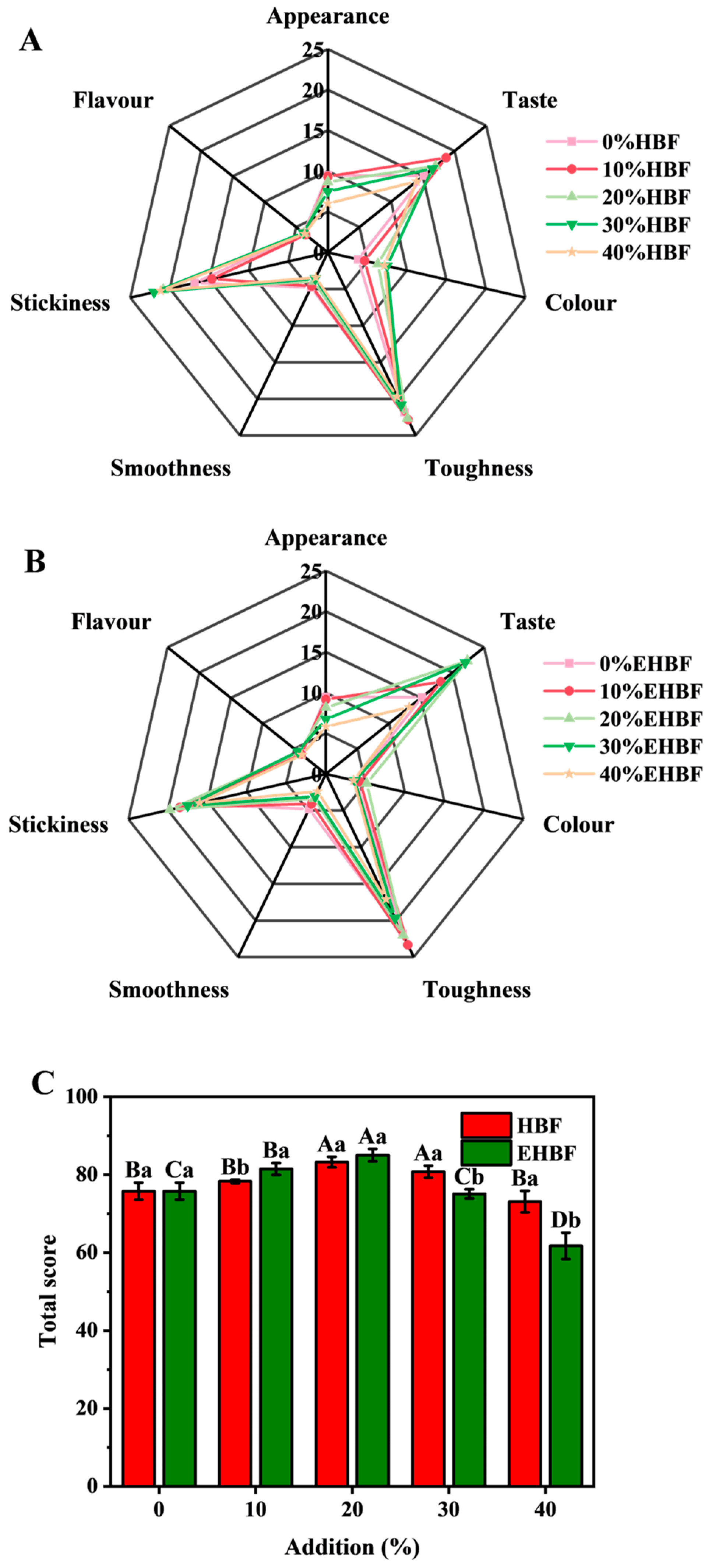

3.8. Effects of Adding HBF and EHBF on the Sensory Evaluation of Fresh Wet Noodles

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fu, M.; Sun, X.; Wu, D.; Meng, L.; Feng, X.; Cheng, W.; Gao, C.; Yang, Y.; Shen, X.; Tang, X. Effect of partial substitution of buckwheat on cooking characteristics, nutritional composition, and in vitro starch digestibility of extruded gluten-free rice noodles. LWT 2020, 126, 109332. [Google Scholar] [CrossRef]

- Chen, M.; Wang, L.; Qian, H.; Zhang, H.; Li, Y.; Wu, G.; Qi, X. The effects of phosphate salts on the pasting, mixing and noodle-making performance of wheat flour. Food Chem. 2019, 283, 353–358. [Google Scholar] [CrossRef] [PubMed]

- Xing, J.-J.; Jiang, D.-H.; Guo, X.-N.; Yang, Z.; Zhu, K.-X. Effect of dough mixing with slightly acidic electrolyzed water on the shelf-life and quality characteristics of fresh wet noodles. Food Control 2021, 124, 107891. [Google Scholar] [CrossRef]

- Tuersuntuoheti, T.; Wang, Z.; Zheng, Y.; Wang, S.; Wang, Z.; Wu, Y.; Liang, S.; Li, X.; Zhang, M. Study on the shelf life and quality characteristics of highland barley fresh noodles as affected by microwave treatment and food preservatives. Food Sci. Nutr. 2019, 7, 2958–2967. [Google Scholar] [CrossRef]

- Tuersuntuoheti, T.; Wang, Z.; Wang, Z.; Duan, M.; Zheng, Y.; Wu, Y.; Liang, S.; Li, X.; Zhang, M. Microbes, bioactive compounds, quality characteristics, and structural changes during the storage of Qingke barley fresh noodles. J. Food Process. Preserv. 2019, 43, e14275. [Google Scholar] [CrossRef]

- Li, L.; Zhou, W.; Wu, A.; Qian, X.; Xie, L.; Zhou, X.; Zhang, L. Effect of ginkgo biloba powder on the physicochemical properties and quality characteristics of wheat dough and fresh wet noodles. Foods 2022, 11, 698. [Google Scholar] [CrossRef]

- Zhao, B.; Shang, J.; Liu, L.; Tong, L.; Zhou, X.; Wang, S.; Zhang, Y.; Wang, L.; Zhou, S. Effect of roasting process on enzymes inactivation and starch properties of highland barley. Int. J. Biol. Macromol. 2020, 165, 675–682. [Google Scholar] [CrossRef]

- Huang, L.; Dong, J.-L.; Zhang, K.-Y.; Zhu, Y.-y.; Shen, R.-L.; Qu, L.-B. Thermal processing influences the physicochemical properties, in vitro digestibility and prebiotics potential of germinated highland barley. LWT 2021, 140, 110814. [Google Scholar] [CrossRef]

- Ge, X.; Jing, L.; Zhao, K.; Su, C.; Zhang, B.; Zhang, Q.; Han, L.; Yu, X.; Li, W. The phenolic compounds profile, quantitative analysis and antioxidant activity of four naked barley grains with different color. Food Chem. 2021, 335, 127655. [Google Scholar] [CrossRef]

- Montalbano, A.; Tesoriere, L.; Diana, P.; Barraja, P.; Carbone, A.; Spanò, V.; Parrino, B.; Attanzio, A.; Livrea, M.A.; Cascioferro, S. Quality characteristics and in vitro digestibility study of barley flour enriched ditalini pasta. LWT 2016, 72, 223–228. [Google Scholar] [CrossRef]

- Zhao, B.; Shang, J.; Wang, L.; Liu, L.; Tong, L.; Zhou, X.; Wang, S.; Zhang, Y.; Zhou, S. Evaluation of ingredient mixing procedure on quality characteristics of noodles enriched with half hulless barley flour. Int. J. Food Sci. Technol. 2020, 55, 3350–3360. [Google Scholar] [CrossRef]

- Fuse, Y.; Higa, M.; Miyashita, N.; Fujitani, A.; Yamashita, K.; Ichijo, T.; Aoe, S.; Hirose, T. Effect of high β-glucan barley on postprandial blood glucose and insulin levels in type 2 diabetic patients. Clin. Nutr. Res. 2020, 9, 43–51. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Wang, M.; Li, C.; Meng, Q.; Meng, Y.; Ying, J.; Bai, S.; Shen, Q.; Xue, Y. Beneficial effects of partly milled highland barley on the prevention of high-fat diet-induced glycometabolic disorder and the modulation of gut microbiota in mice. Nutrients 2022, 14, 762. [Google Scholar] [CrossRef] [PubMed]

- Obadi, M.; Qi, Y.; Xu, B. Highland barley starch (Qingke): Structures, properties, modifications, and applications. Int. J. Biol. Macromol. 2021, 185, 725–738. [Google Scholar] [CrossRef] [PubMed]

- Chang, Y.; Cui, S.; Roberts, K.; Ng, P.; Wang, Q. Evaluation of extrusion-modified fenugreek gum. Food Hydrocoll. 2011, 25, 1296–1301. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, J.; Luo, S.; Li, C.; Ye, J.; Liu, C.; Gilbert, R.G. Physicochemical and structural properties of pregelatinized starch prepared by improved extrusion cooking technology. Carbohyd. Polym. 2017, 175, 265–272. [Google Scholar] [CrossRef] [PubMed]

- Gao, L.; Cheng, W.; Fu, M.; Wu, D.; Tang, X. Effect of improved extrusion cooking technology modified buckwheat flour on whole buckwheat dough and noodle quality. Food Struct. 2022, 31, 100248. [Google Scholar] [CrossRef]

- Seetapan, N.; Limparyoon, N.; Yooberg, R.; Leelawat, B.; Charunuch, C. Influence of addition of extruded rice flour on preparation and quality of fresh gluten-free yellow alkaline noodles. J. Cereal Sci. 2019, 90, 102828. [Google Scholar] [CrossRef]

- Zhang, H.; Meng, Y.; Liu, X.; Guan, X.; Huang, K.; Li, S. Effect of extruded mung bean flour on dough rheology and quality of Chinese noodles. Cereal Chem. 2019, 96, 836–846. [Google Scholar] [CrossRef]

- Hou, D.; Duan, W.; Xue, Y.; Yousaf, L.; Hu, J.; Shen, Q. Effects of superfine grinding and extrusion on dough mixing properties and noodle quality of black soybean flour. J. Food Meas. Charact. 2020, 14, 125–134. [Google Scholar] [CrossRef]

- American Association of Cereal Chemists. Approved Methods of the American Association of Cereal Chemists; Amer Assn of Cereal Chemists: St. Paul, MN, USA, 2000. [Google Scholar]

- Zhang, F.; Laraib, Y.; Chai, X.; Shen, Y.; Wang, X.; Li, S.; Guo, E.; Diao, X.; Shen, Q. The effect of reducing agent DTT on pasting, hydration and microstructure properties of foxtail millet. J. Cereal Sci. 2020, 95, 103044. [Google Scholar] [CrossRef]

- Sun, X.; Pei, F.; Fang, Y. The effects of hydrocolloids on the thermomechanical, viscoelastic and microstructural properties of whole wheat flour dough. Food Chem. 2022, 370, 130976. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Xu, M.; Wu, H.; Jing, L.; Gong, B.; Gou, M.; Zhao, K.; Li, W. The compositional, physicochemical and functional properties of germinated mung bean flour and its addition on quality of wheat flour noodle. J. Food Sci. Technol. 2018, 55, 5142–5152. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Ma, Y.; Zhao, Y.; Pan, Y.; Tian, R.; Yao, X.; Yao, Y.; Cao, X.; Geng, L.; Wang, Z. Effect of Hulless Barley Flours on Dough Rheological Properties, Baking Quality, and Starch Digestibility of Wheat Bread. Front. Nutr. 2021, 8, 785847. [Google Scholar] [CrossRef]

- Pu, H.; Yue, M.; Guo, S.; Li, Y.; Yang, Y.; Kuang, J.; Huang, J. Influence of wheat flour substitution with potato pulp on dough rheology, microstructure and noodle quality. Int. J. Food Sci. Technol. 2021, 56, 2895–2903. [Google Scholar] [CrossRef]

- Li, W.; Bai, Y.; Zhang, Q.; Hu, X.; Shen, Q. Effects of potassium alum addition on physicochemical, pasting, thermal and gel texture properties of potato starch. Int. J. Food Sci. Technol. 2011, 46, 1621–1627. [Google Scholar] [CrossRef]

- Sun, H.; Ju, Q.; Ma, J.; Chen, J.; Li, Y.; Yuan, Y.; Hu, Y.; Fujita, K.; Luan, G. The effects of extruded corn flour on rheological properties of wheat-based composite dough and the bread quality. Food Sci. Nutr. 2019, 7, 2977–2985. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Jiao, A.; Xu, E.; Chen, Y.; Jin, Z. Effects of extrusion technology combined with enzymatic hydrolysis on the structural and physicochemical properties of porous corn starch. Food Bioprocess Technol. 2020, 13, 442–451. [Google Scholar] [CrossRef]

- Han, L.; Zhou, Y.; Tatsumi, E.; Shen, Q.; Cheng, Y.; Li, L. Thermomechanical properties of dough and quality of noodles made from wheat flour supplemented with different grades of tartary buckwheat (Fagopyrum tataricum Gaertn.) flour. Food Bioprocess Technol. 2013, 6, 1953–1962. [Google Scholar] [CrossRef]

- Ma, J.; Kaori, F.; Ma, L.; Gao, M.; Dong, C.; Wang, J.; Luan, G. The effects of extruded black rice flour on rheological and structural properties of wheat-based dough and bread quality. Int. J. Food Sci. Technol. 2019, 54, 1729–1740. [Google Scholar] [CrossRef]

- Pu, H.; Wei, J.; Wang, L.; Huang, J.; Chen, X.; Luo, C.; Liu, S.; Zhang, H. Effects of potato/wheat flours ratio on mixing properties of dough and quality of noodles. J. Cereal Sci. 2017, 76, 236–242. [Google Scholar] [CrossRef]

- Shao, L.-F.; Guo, X.-N.; Li, M.; Zhu, K.-X. Effect of different mixing and kneading process on the quality characteristics of frozen cooked noodle. LWT 2019, 101, 583–589. [Google Scholar] [CrossRef]

- Niu, M.; Hou, G.G.; Kindelspire, J.; Krishnan, P.; Zhao, S. Microstructural, textural, and sensory properties of whole-wheat noodle modified by enzymes and emulsifiers. Food Chem. 2017, 223, 16–24. [Google Scholar] [CrossRef]

- Sudha, M.; Vetrimani, R.; Leelavathi, K. Influence of fibre from different cereals on the rheological characteristics of wheat flour dough and on biscuit quality. Food Chem. 2007, 100, 1365–1370. [Google Scholar] [CrossRef]

| Sample | Peak Viscosity (mPa·s) | Trough Viscosity (mPa·s) | Breakdown (mPa·s) | Final Viscosity (mPa·s) | Setback (mPa·s) | Pasting Temperature (°C) |

|---|---|---|---|---|---|---|

| Control | 1653.67 ± 19.86 a | 1249.00 ± 20.88 a | 404.67 ± 40.43 c | 2369.67 ± 20.31 a | 1120.67 ± 33.50 a | 86.68 ± 0.78 c |

| 10% HBF | 1434.33 ± 24.17 c | 947.67 ± 5.77 c | 486.67 ± 19.86 b | 1865.33 ± 22.72 c | 917.67 ± 17.50 b | 86.08 ± 0.45 c |

| 20% HBF | 1280.00 ± 44.40 d | 759.67 ± 40.10 e | 520.33 ± 15.31 b | 1588.00 ± 60.65 e | 828.33 ± 29.02 c | 84.97 ± 0.03 c |

| 30% HBF | 1110.67 ± 43.00 f | 594.67 ± 23.86 g | 516.00 ± 31.24 b | 1361.33 ± 46.09 fg | 766.67 ± 35.02 d | 84.45 ± 0.91 c |

| 40% HBF | 1093.00 ± 27.62 f | 533.00 ± 29.05 h | 560.00 ± 4.58 a | 1302.00 ± 29.55 g | 769.00 ± 6.08 d | 84.20 ± 0.83 c |

| 10% EHBF | 1524.67 ± 23.54 b | 1121.67 ± 33.56 b | 403.00 ± 22.52 c | 2079.33 ± 34.30 b | 957.67 ± 38.37 b | 87.47 ± 0.83 b |

| 20% EHBF | 1320.67 ± 26.08 d | 934.00 ± 14.80 c | 386.67 ± 12.01 c | 1767.00 ± 34.77 d | 833.00 ± 19.97 c | 88.02 ± 0.49 ab |

| 30% EHBF | 1201.00 ± 11.79 e | 828.67 ± 6.11 d | 372.33 ± 5.69 c | 1599.67 ± 13.65 e | 771.00 ± 7.55 d | 88.30 ± 0.10 a |

| 40% EHBF | 1018.67 ± 46.48 g | 692.00 ± 34.66 f | 326.67 ± 11.85 d | 1378.00 ± 55.43 f | 686.00 ± 20.88 e | 88.25 ± 0.85 a |

| Sample | Water Absorption (%) | Protein Weakening (C2, Nm) | Starch Gelatinization (C3, Nm) | Starch Retrogradation (C5, Nm) | Dough Development (min) | Dough Stability (min) |

|---|---|---|---|---|---|---|

| Control | 64.05 ± 1.34 de | 0.54 ± 0.01 a | 1.91 ± 0.01 a | 3.52 ± 0.01 a | 4.14 ± 0.16 a | 5.75 ± 0.33 a |

| 10% HBF | 60.72 ± 1.49 e | 0.47 ± 0.00 b | 1.88 ± 0.02 a | 2.81 ± 0.24 b | 3.43 ± 0.11 ab | 4.09 ± 0.30 c |

| 20% HBF | 60.92 ± 1.52 e | 0.46 ± 0.01 b | 1.88 ± 0.04 a | 2.56 ± 0.07 c | 3.35 ± 0.11 ab | 4.14 ± 0.44 c |

| 30% HBF | 61.24 ± 1.41 e | 0.45 ± 0.02 b | 1.86 ± 0.06 a | 2.32 ± 0.06 d | 3.08 ± 1.20 bc | 5.19 ± 0.05 b |

| 40% HBF | 61.71 ± 1.12 e | 0.45 ± 0.00 b | 1.84 ± 0.00 a | 2.21 ± 0.01 de | 1.54 ± 0.02 e | 5.73 ± 0.08 ab |

| 10% EHBF | 67.35 ± 1.35 d | 0.40 ± 0.01 c | 1.65 ± 0.02 b | 2.72 ± 0.01 bc | 2.74 ± 0.27 cd | 3.19 ± 0.37 d |

| 20% EHBF | 75.08 ± 1.56 c | 0.38 ± 0.00 cd | 1.49 ± 0.02 c | 2.05 ± 0.09 e | 2.14 ± 0.05 cd | 2.62 ± 0.16 e |

| 30% EHBF | 82.35 ± 1.23 b | 0.37 ± 0.00 d | 1.28 ± 0.00 d | 1.63 ± 0.04 f | 2.02 ± 0.19 de | 2.39 ± 0.05 e |

| 40% EHBF | 88.52 ± 1.38 a | 0.37 ± 0.02 d | 1.09 ± 0.04 e | 1.29 ± 0.03 g | 1.82 ± 0.07 de | 2.40 ± 0.03 e |

| Sample | RDS (%) | SDS (%) | RS (%) | HI (%) | eGI |

|---|---|---|---|---|---|

| Control | 61.74 ± 1.23 a | 28.92 ± 0.82 g | 9.33 ± 0.41 e | 82.14 ± 2.55 a | 84.80 ± 1.21 a |

| 10% HBF | 55.09 ± 1.15 de | 32.41 ± 0.61 d | 12.20 ± 0.41 b | 70.03 ± 1.82 c | 78.16 ± 1.48 d |

| 20% HBF | 53.61 ± 0.64 e | 33.79 ± 0.31 c | 12.59 ± 0.31 b | 70.34 ± 1.99 c | 78.33 ± 1.46 d |

| 30% HBF | 50.63 ± 1.21 f | 36.77 ± 0.82 b | 12.59 ± 0.46 b | 64.69 ± 2.25 d | 75.22 ± 1.74 e |

| 40% HBF | 48.13 ± 1.39 g | 38.34 ± 0.21 a | 13.52 ± 0.23 a | 59.65 ±1.45 e | 72.46 ± 1.43 f |

| 10% EHBF | 59.38 ± 0.53 b | 30.22 ± 0.37 f | 10.40 ± 0.32 d | 78.03 ± 1.42 ab | 82.54 ± 1.65 b |

| 20% EHBF | 57.87 ± 0.95 bc | 30.66 ± 0.93 ef | 11.46 ± 0.45 c | 76.19 ± 2.23 b | 81.54 ± 1.42 b |

| 30% EHBF | 55.89 ± 0.86 d | 31.66 ± 0.51 de | 12.45 ± 0.26 b | 74.53 ± 1.93 b | 80.63 ± 1.15 bc |

| 40% EHBF | 56.17 ± 0.97 cd | 31.46 ± 0.79 de | 12.37 ± 0.15 b | 72.38 ± 2.75 c | 79.45 ± 1.39 cd |

| Sample | Hardness (N) | Adhesiveness (N·s) | Springiness | Cohesiveness | Chewiness (N) | Resilience |

|---|---|---|---|---|---|---|

| Control | 2187.94 ± 55.19 a | −107.35 ± 30.82 bc | 0.84 ± 0.04 b | 0.58 ± 0.02 cd | 1069.32 ± 96.64 a | 0.24 ± 0.01 c |

| 10% HBF | 1772.18 ± 20.89 b | −69.77 ± 33.32 ab | 0.92 ± 0.02 a | 0.60 ± 0.02 bc | 973.35 ± 37.32 b | 0.23 ± 0.02 cd |

| 20% HBF | 1621.81 ± 10.44 c | −59.41 ± 12.54 ab | 0.90 ± 0.03 ab | 0.60 ± 0.02 bc | 880.95 ± 68.61 b | 0.21 ± 0.01 de |

| 30% HBF | 1565.83 ± 36.29 c | −48.49 ± 27.84 a | 0.75 ± 0.05 c | 0.50 ± 0.02 e | 580.62 ± 63.50 d | 0.20 ± 0.02 ef |

| 40% HBF | 1465.00 ± 10.80 d | −55.00 ± 22.35 a | 0.75 ± 0.02 c | 0.50 ± 0.02 e | 545.11 ± 30.84 d | 0.18 ± 0.01 f |

| 10% EHBF | 1620.22 ± 52.17 c | −145.02 ± 59.51 c | 0.90 ± 0.02 ab | 0.63 ± 0.01 a | 928.58 ± 54.05 b | 0.28 ± 0.01 ab |

| 20% EHBF | 1401.81 ± 6.32 e | −92.13 ± 13.16 ab | 0.89 ± 0.02 ab | 0.62 ± 0.01 ab | 775.99 ± 14.83 c | 0.27 ± 0.01 b |

| 30% EHBF | 1365.96 ± 35.05 e | −79.14 ± 17.19 ab | 0.88 ± 0.05 ab | 0.61 ± 0.01 ab | 727.03 ± 37.03 c | 0.31 ± 0.01 a |

| 40% EHBF | 1247.03 ± 43.79 f | −91.68 ± 0.67 ab | 0.85 ± 0.05 b | 0.57 ± 0.01 d | 605.92 ± 16.34 d | 0.24 ± 0.02 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Wang, X.; Zhang, X.; Du, Y.; Liang, F.; Zhang, F.; Wu, C.; Zhao, Q.; Shen, Q. The Effects of Adding Extruded Highland Barley Flour on the Thermomechanical Properties of Wheat Flour Dough and the Overall Quality of Fresh Wet Noodles. Foods 2024, 13, 3105. https://doi.org/10.3390/foods13193105

Zhu Y, Wang X, Zhang X, Du Y, Liang F, Zhang F, Wu C, Zhao Q, Shen Q. The Effects of Adding Extruded Highland Barley Flour on the Thermomechanical Properties of Wheat Flour Dough and the Overall Quality of Fresh Wet Noodles. Foods. 2024; 13(19):3105. https://doi.org/10.3390/foods13193105

Chicago/Turabian StyleZhu, Yiqing, Xuecong Wang, Xinyu Zhang, Yan Du, Feng Liang, Fan Zhang, Chongyi Wu, Qingyu Zhao, and Qun Shen. 2024. "The Effects of Adding Extruded Highland Barley Flour on the Thermomechanical Properties of Wheat Flour Dough and the Overall Quality of Fresh Wet Noodles" Foods 13, no. 19: 3105. https://doi.org/10.3390/foods13193105