Improvement in Taste Quality of Rice Porridge Using Konjac Glucomannan

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Rice Porridge

2.3. Boiling Properties of Rice Grain

2.4. Pasting Properties of Rice Flour

2.5. Color of Rice Porridge

2.6. Water Mobility and Distribution of Rice Porridge

2.7. Texture Properties of Rice Porridge

2.8. Flavor Profiles of Rice Porridge

2.8.1. Electronic Nose (E-Nose)

2.8.2. Gas Chromatograph-Mass Spectrometer (GC-MS)

2.9. Sensory Evaluation of Rice Porridge

2.10. Statistical Analysis

3. Results and Discussion

3.1. Boiling Properties Analysis

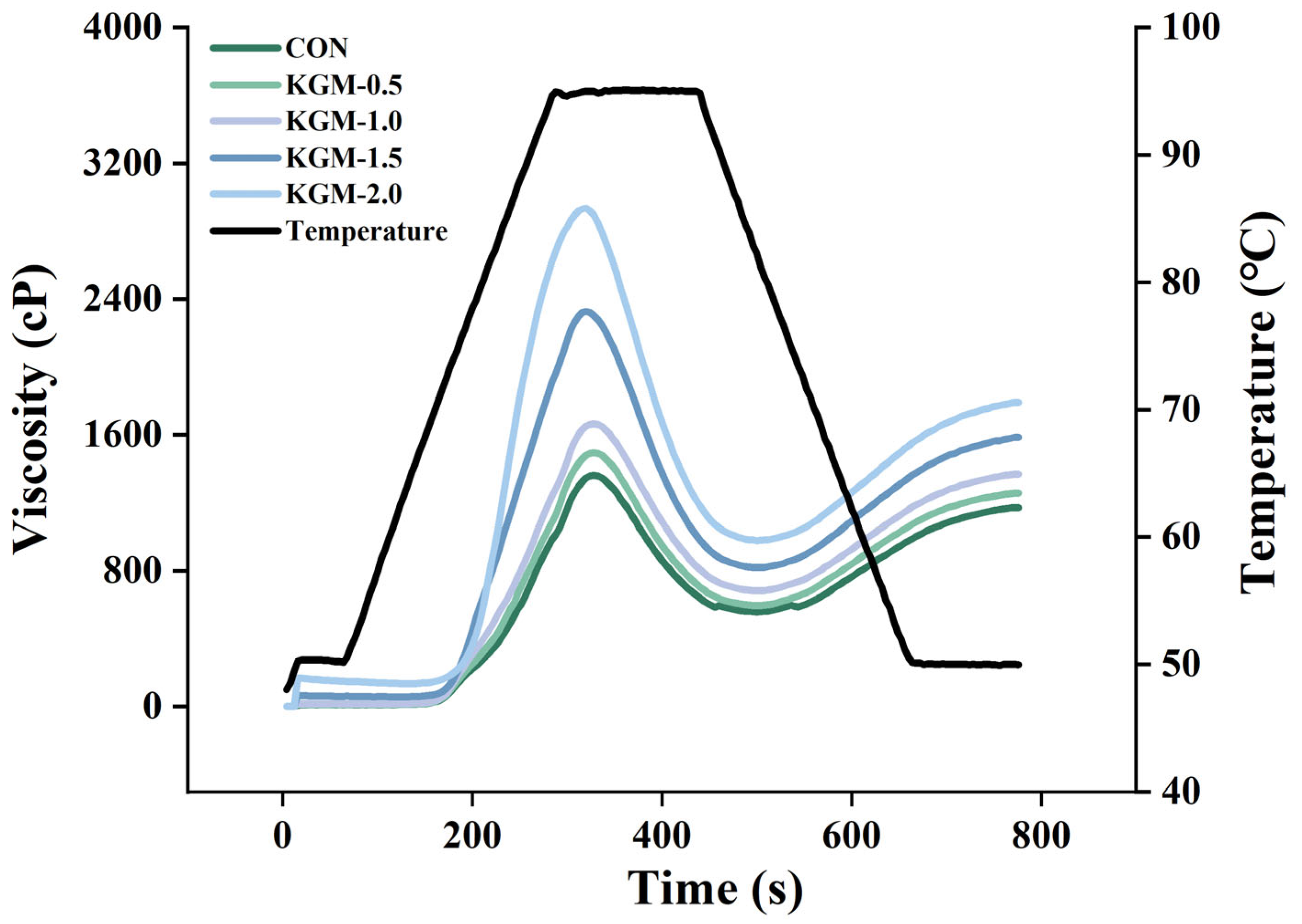

3.2. Pasting Properties Analysis

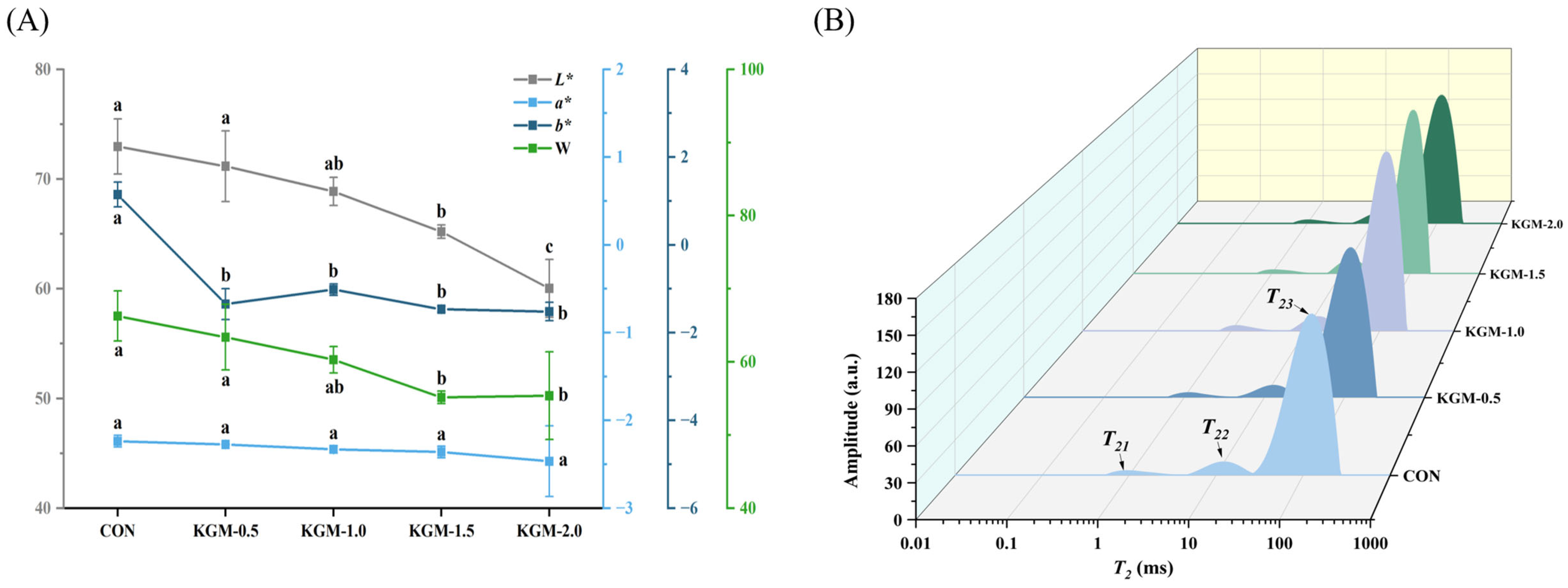

3.3. Color Analysis

3.4. Water Distribution Analysis

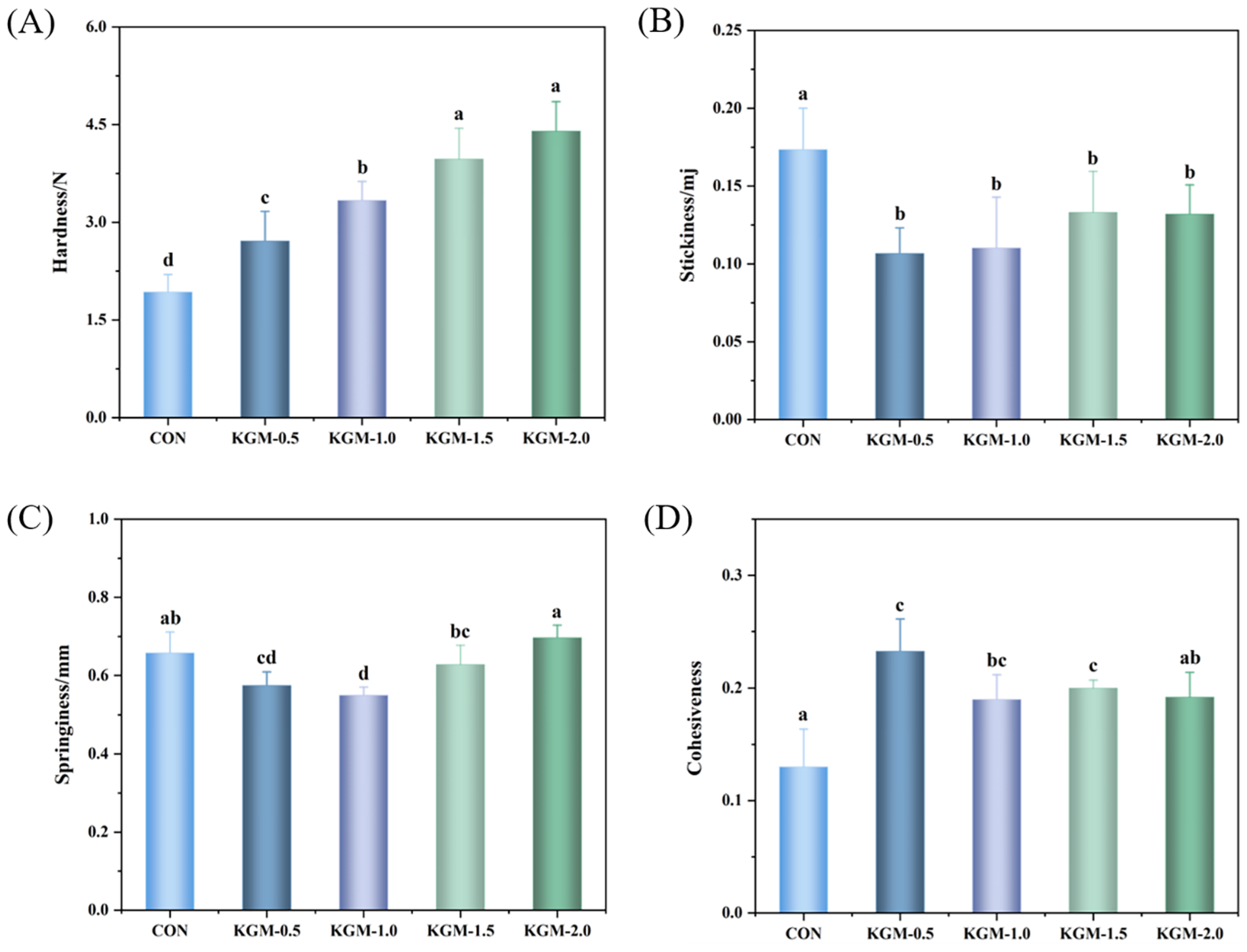

3.5. Texture Analysis

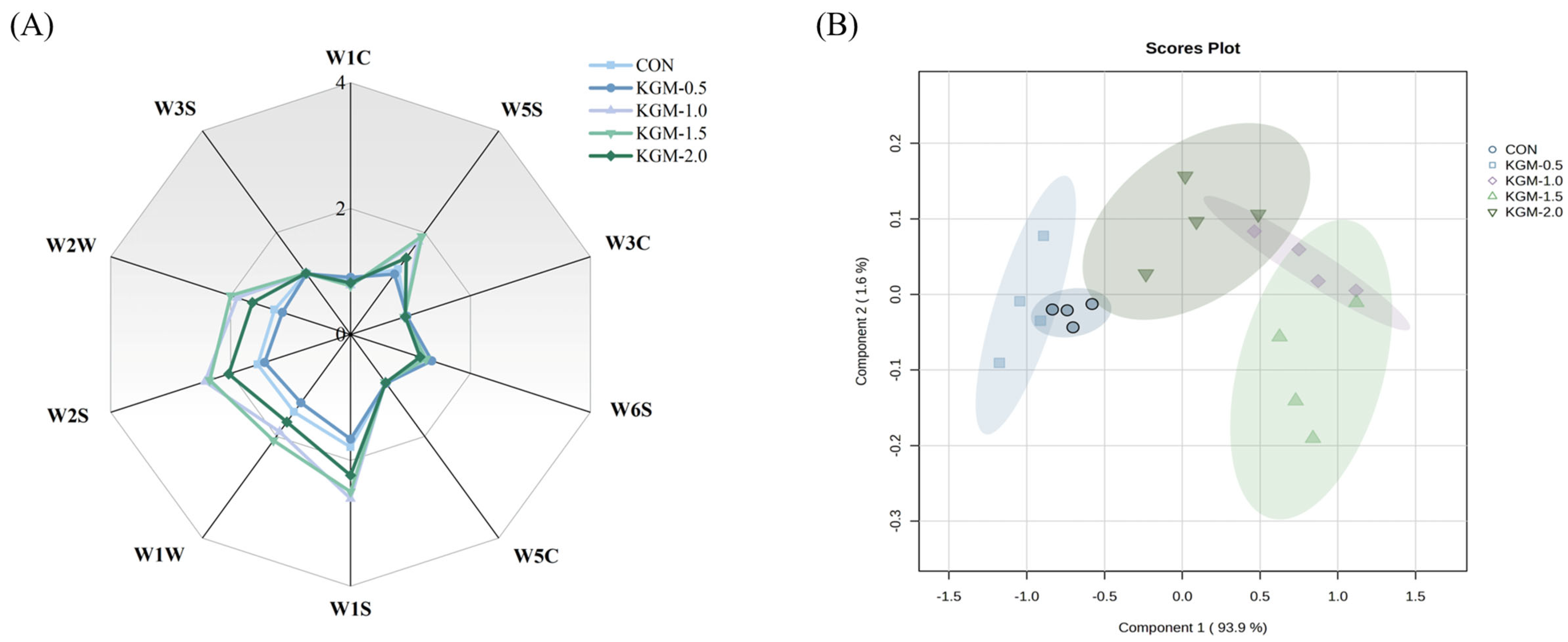

3.6. E-Nose Analysis

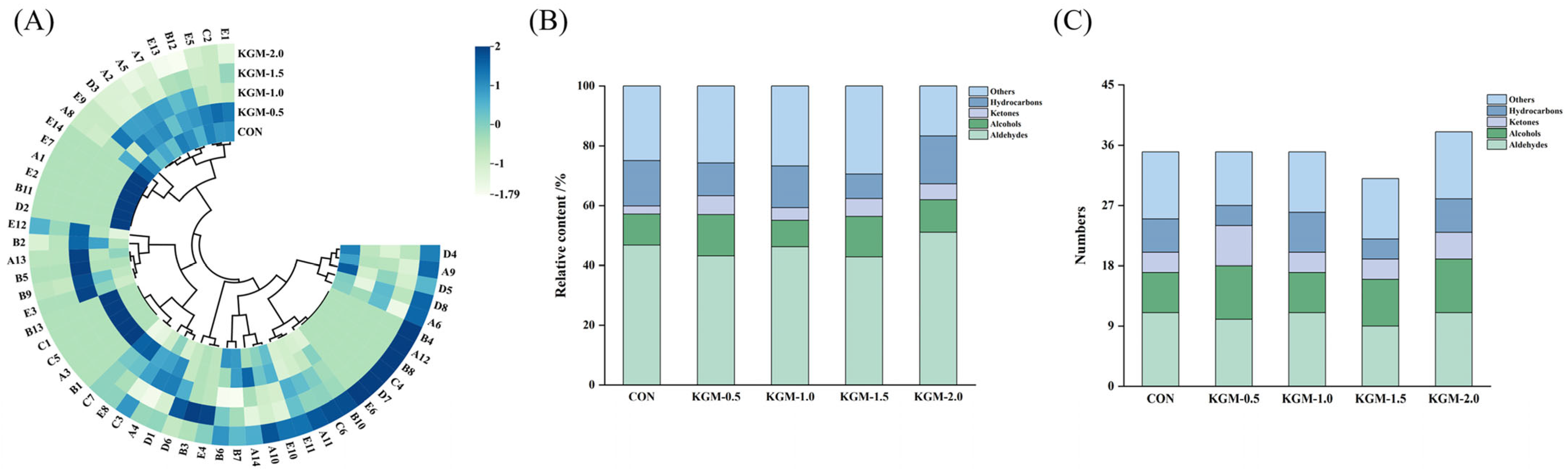

3.7. GC-MS Analysis

3.8. Sensory Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Asimi, S.; Ren, X.; Zhang, M.; Li, S.; Guan, L.; Wang, Z.; Liang, S.; Wang, Z. Fingerprinting of volatile organic compounds for the geographical discrimination of rice samples from Northeast China. Foods 2022, 11, 1695. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Tian, A.; Zhao, K.; Zhang, R.; Lei, Z.; Qin, X.; Wu, X.; Liu, Y.; Liu, P.; Yang, S.; et al. Effect of cooking methods on volatile compounds and texture properties in rice porridge. LWT-Food Sci. Technol. 2023, 184, 115111. [Google Scholar] [CrossRef]

- Mayachiew, P.; Charunuch, C.; Devahastin, S. Physicochemical and thermal properties of extruded instant functional rice porridge powder as affected by the addition of soybean or mung bean. J. Food Sci. 2015, 80, E2782–E2791. [Google Scholar] [CrossRef] [PubMed]

- Mi, Y.; Wang, Z.; Guan, L.; Zhang, M.; Li, S.; Ye, G.; Ren, X.; Liang, S. Analysis of volatile compounds in rice porridge of different japonica rice varieties in Northeast China. J. Cereal Sci. 2023, 113, 103749. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, N.; Fray, R.G.; Fisk, I.; Liu, C.; Li, H.; Han, Y. Characterization of volatile aroma compounds after in-vial cooking of foxtail millet porridge with gas chromatography-mass spectrometry. J. Cereal Sci. 2018, 82, 8–15. [Google Scholar] [CrossRef]

- Ma, S.; Zhu, P.; Wang, M. Effects of konjac glucomannan on pasting and rheological properties of corn starch. Food Hydrocoll. 2019, 89, 234–240. [Google Scholar] [CrossRef]

- Ren, B.; Xie, H.; Guo, L.; Zhong, K.; Gao, H. Effect of konjac glucomannan on sensory, physical and thermal properties of mochi. Int. J. Food Eng. 2020, 16, 20190227. [Google Scholar] [CrossRef]

- Lu, P.; Guo, J.; Fan, J.; Wang, P.; Yan, X. Combined effect of konjac glucomannan addition and ultrasound treatment on the physical and physicochemical properties of frozen dough. Food Chem. 2023, 411, 135516. [Google Scholar] [CrossRef]

- Nagasawa, T.; Kimura, T.; Yoshida, A.; Tsunekawa, K.; Araki, O.; Ushiki, K.; Ishigaki, H.; Shoho, Y.; Suda, I.; Hiramoto, S.; et al. Konjac glucomannan attenuated triglyceride metabolism during rice gruel tolerance test. Nutrients 2021, 13, 2191. [Google Scholar] [CrossRef]

- Jowee, N.; Brownlee, I.A. The effect of high β-glucan flour incorporation into instant rice porridge on satiety and energy intake. Bioact. Carbohydr. Diet. Fibre 2017, 11, 60–66. [Google Scholar]

- Wang, G.; Yan, X.; Wang, B.; Hu, X.; Chen, X.; Ding, W. Effects of milling methods on the properties of rice flour and steamed rice cakes. LWT-Food Sci. Technol. 2022, 167, 113848. [Google Scholar] [CrossRef]

- Jia, Z.; Luo, Y.; Barba, F.J.; Wu, Y.; Ding, W.; Xiao, S.; Lyu, Q.; Wang, X.; Fu, Y. Effect of β-cyclodextrins on the physical properties and anti-staling mechanisms of corn starch gels during storage. Carbohydr. Polym. 2022, 284, 119187. [Google Scholar] [CrossRef] [PubMed]

- Shen, M.; Huang, K.; Guan, X.; Xia, J.; Sun, Z.; Yu, Z.; Fang, Y. Effects of milling on texture and in vitro starch digestibility of oat rice. Food Chem. X 2023, 19, 100783. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Zhang, M.; Ren, X.; Guan, L.; Ye, G.; Li, Y. Improvement in storage stability of fresh instant rice using non-starch polysaccharides. Int. J. Food Sci. Tech. 2024, 59, 2961–2970. [Google Scholar] [CrossRef]

- Zhong, Y.; He, F.; Wang, M.; Zhang, Y.; Lan, H.; Chen, L.; Zeng, Z. Effects of stabilization combined with fermentation treatments on the volatile composition and flavor profile of cooked black rice. Food Biosci. 2023, 56, 103377. [Google Scholar] [CrossRef]

- Nguyen, T.T.L.; Flanagan, B.M.; Tao, K.Y.; Ni, D.D.; Gidley, M.J.; Fox, G.P.; Gilbert, R.G. Effect of processing on the solubility and molecular size of oat β-glucan and consequences for starch digestibility of oat-fortified noodles. Food Chem. 2021, 372, 131291. [Google Scholar] [CrossRef]

- Li, K.; Bao, J.; Corke, H.; Sun, M. Genotypic diversity and environmental stability of starch physicochemical properties in the USDA rice mini-core collection. Food Chem. 2017, 221, 1186–1196. [Google Scholar] [CrossRef]

- Chen, H.; Chen, D.; He, L.; Wang, T.; Ren, W. Correlation of taste values with chemical compositions and Rapid Visco Analyser profiles of 36 indica rice (Oryza sativa L.) varieties. Food Chem. 2021, 349, 129176. [Google Scholar] [CrossRef] [PubMed]

- Su, H.; Tu, J.; Zheng, M.; Deng, K.; Lu, X. Effects of oligosaccharides on particle structure, pasting and thermal properties of wheat starch granules under different freezing temperatures. Food Chem. 2020, 315, 126209. [Google Scholar] [CrossRef]

- Hao, M.; Zhu, X.; Ji, X.; Shi, M.; Yan, Y. Effect of konjac glucomannan on structure, physicochemical properties, and in vitro digestibility of yam starch during Extrusion. Foods 2024, 13, 463. [Google Scholar] [CrossRef]

- Li, J.; Zhu, M.; Gu, L.; Su, Y.; Yang, Y.; Chang, C.; Han, Q. Freeze-thaw stability of konjac glucomannan hydrogels supplemented with natural tapioca/corn starch. LWT-Food Sci. Technol. 2023, 182, 114841. [Google Scholar] [CrossRef]

- Zhou, Y.; Charles, G.; Yun, W.; Liang, J.; Foster, T.J.; Cheng, Y. Effect of a small amount of sodium carbonate on konjac glucomannan-induced changes in thermal behavior of wheat starch. Carbohydr. Polym. 2014, 114, 357–364. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Kong, Q.; Li, X.; Lin, J.; Chen, H.; Bao, Q.; Yuan, Y. Effect of mild-parboiling treatment on the structure, colour, pasting properties and rheology properties of germinated brown rice. LWT-Food Sci. Technol. 2020, 130, 109623. [Google Scholar] [CrossRef]

- Chen, R.; Williams, P.A.; Shu, J.; Luo, S.; Chen, J.; Liu, C. Pectin adsorption onto and penetration into starch granules and the effect on the gelatinization process and rheological properties. Food Hydrocoll. 2022, 129, 107618. [Google Scholar] [CrossRef]

- Fu, Y.; Liu, X.; Xie, Q.; Chen, L.; Wang, X. Effects of Laminaria japonica polysaccharides on the texture, retrogradation, and structure performances in frozen dough bread. LWT- Food Sci. Technol. 2021, 151, 112239. [Google Scholar] [CrossRef]

- Huang, M.; Kennedy, J.F.; Li, B.; Xu, X.; Xie, B.J. Characters of rice starch gel modifed by gellan, carrageenan, and glucomannan: A texture profile analysis study. Carbohydr. Polym. 2007, 25, 411–418. [Google Scholar] [CrossRef]

- Zheng, J.; Wang, N.; Yang, J.; You, Y.; Zhang, F.; Kan, J.; Wu, L. New insights into the interaction between bamboo shoot polysaccharides and lotus root starch during gelatinization, retrogradation, and digestion of starch. Int. J. Biol. Macromol. 2024, 254, 127877. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, F.; Huang, K.; Li, S.; Cao, H.; Xie, J.; Guan, X. Structural changes of starch under different milling degrees affect the cooking and textural properties of rice. Food Chem. X. 2023, 17, 100627. [Google Scholar] [CrossRef]

- Ma, R.; Jin, Z.; Wang, F.; Tian, Y. Contribution of starch to the flavor of rice-based instant foods. Crit. Rev. Food Sci. Nutr. 2021, 62, 8577–8588. [Google Scholar] [CrossRef]

- Ma, R.; Tian, Y.; Chen, L.; Jin, Z. Impact of cooling rates on the flavor of cooked rice during storage. Food Biosci. 2020, 35, 100563. [Google Scholar] [CrossRef]

- Choi, S.; Seo, H.; Lee, K.; Lee, S.; Lee, J.; Lee, J. Effect of milling and long-term storage on volatiles of black rice (Oryza sativa L.) determined by headspace solid-phase microextraction with gas chromatography-mass spectrometry. Food Chem. 2019, 276, 572–582. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Liu, K.; Zhang, C. Electronic nose for volatile organic compounds analysis in rice aging. Trends Food Sci. Technol. 2021, 109, 83–93. [Google Scholar] [CrossRef]

- Ding, C.; Khir, R.; Pan, Z.; Wood, D.F.; Tu, K.; El-Mashad, H.; Berrios, J. Improvement in storage stability of infrared-dried rough rice. Food Bioprocess Technol. 2016, 9, 1010–1020. [Google Scholar] [CrossRef]

| Water Absorption/% | Swelling Power % | Dry Matter/% | Iodine Blue Value | |

|---|---|---|---|---|

| CON | 317.23 ± 34.30 a | 455.30 ± 63.21 a | 2.86 ± 0.18 a | 1.10 ± 0.09 a |

| KGM-0.5 | 310.59 ± 35.71 a | 452.93 ± 14.58 ab | 2.69 ± 0.25 a | 0.85 ± 0.06 b |

| KGM-1.0 | 289.77 ± 9.40 ab | 409.07 ± 6.76 ab | 2.55 ± 0.39 a | 0.59 ± 0.01 c |

| KGM-1.5 | 266.53 ± 6.75 ab | 395.08 ± 18.00 ab | 2.57 ± 0.47 a | 0.53 ± 0.01 d |

| KGM-2.0 | 235.63 ± 9.31 b | 366.55 ± 25.55 b | 2.45 ± 0.15 a | 0.50 ± 0.01 d |

| Odor Scores | Appearance Scores | Palatability Scores | Taste Scores | Total Scores | |

|---|---|---|---|---|---|

| CON | 16.36 ± 2.41 ab | 18.43 ± 2.87 a | 22.79 ± 3.17 a | 20.93 ± 1.90 a | 78.50 ± 7.08 ab |

| KGM-0.5 | 17.14 ± 1.79 a | 19.29 ± 2.89 a | 22.50 ± 1.87 a | 22.36 ± 1.60 a | 81.29 ± 5.04 ab |

| KGM-1.0 | 17.29 ± 1.82 a | 20.50 ± 2.93 a | 23.93 ± 2.27 a | 21.93 ± 2.09 a | 83.64 ± 7.66 a |

| KGM-1.5 | 15.71 ± 2.13 ab | 19.36 ± 2.79 a | 22.50 ± 2.85 a | 21.43 ± 2.28 a | 79.00 ± 7.24 ab |

| KGM-2.0 | 15.00 ± 3.59 b | 18.79 ± 3.40 a | 22.36 ± 3.56 a | 20.57 ± 3.41 a | 76.71 ± 10.67 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Zhang, W.; Zhang, M.; Guan, L.; Ye, G. Improvement in Taste Quality of Rice Porridge Using Konjac Glucomannan. Foods 2024, 13, 3146. https://doi.org/10.3390/foods13193146

Li S, Zhang W, Zhang M, Guan L, Ye G. Improvement in Taste Quality of Rice Porridge Using Konjac Glucomannan. Foods. 2024; 13(19):3146. https://doi.org/10.3390/foods13193146

Chicago/Turabian StyleLi, Sixuan, Wenhui Zhang, Min Zhang, Lina Guan, and Guodong Ye. 2024. "Improvement in Taste Quality of Rice Porridge Using Konjac Glucomannan" Foods 13, no. 19: 3146. https://doi.org/10.3390/foods13193146

APA StyleLi, S., Zhang, W., Zhang, M., Guan, L., & Ye, G. (2024). Improvement in Taste Quality of Rice Porridge Using Konjac Glucomannan. Foods, 13(19), 3146. https://doi.org/10.3390/foods13193146