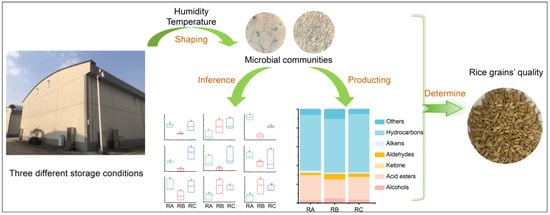

Deciphering the Microbiological Mechanisms Underlying the Impact of Different Storage Conditions on Rice Grain Quality

Abstract

Share and Cite

Qiu, Z.; Wu, F.; Hu, H.; Guo, J.; Wu, C.; Wang, P.; Ling, J.; Cui, Y.; Ye, J.; Fang, G.; et al. Deciphering the Microbiological Mechanisms Underlying the Impact of Different Storage Conditions on Rice Grain Quality. Foods 2024, 13, 266. https://doi.org/10.3390/foods13020266

Qiu Z, Wu F, Hu H, Guo J, Wu C, Wang P, Ling J, Cui Y, Ye J, Fang G, et al. Deciphering the Microbiological Mechanisms Underlying the Impact of Different Storage Conditions on Rice Grain Quality. Foods. 2024; 13(2):266. https://doi.org/10.3390/foods13020266

Chicago/Turabian StyleQiu, Zhuzhu, Fenghua Wu, Hao Hu, Jian Guo, Changling Wu, Peng Wang, Jiangang Ling, Yan Cui, Jing Ye, Guanyu Fang, and et al. 2024. "Deciphering the Microbiological Mechanisms Underlying the Impact of Different Storage Conditions on Rice Grain Quality" Foods 13, no. 2: 266. https://doi.org/10.3390/foods13020266

APA StyleQiu, Z., Wu, F., Hu, H., Guo, J., Wu, C., Wang, P., Ling, J., Cui, Y., Ye, J., Fang, G., & Liu, X. (2024). Deciphering the Microbiological Mechanisms Underlying the Impact of Different Storage Conditions on Rice Grain Quality. Foods, 13(2), 266. https://doi.org/10.3390/foods13020266