Quality Evaluation and Browning Control in the Multi-Stage Processing of Mume Fructus (Wumei)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

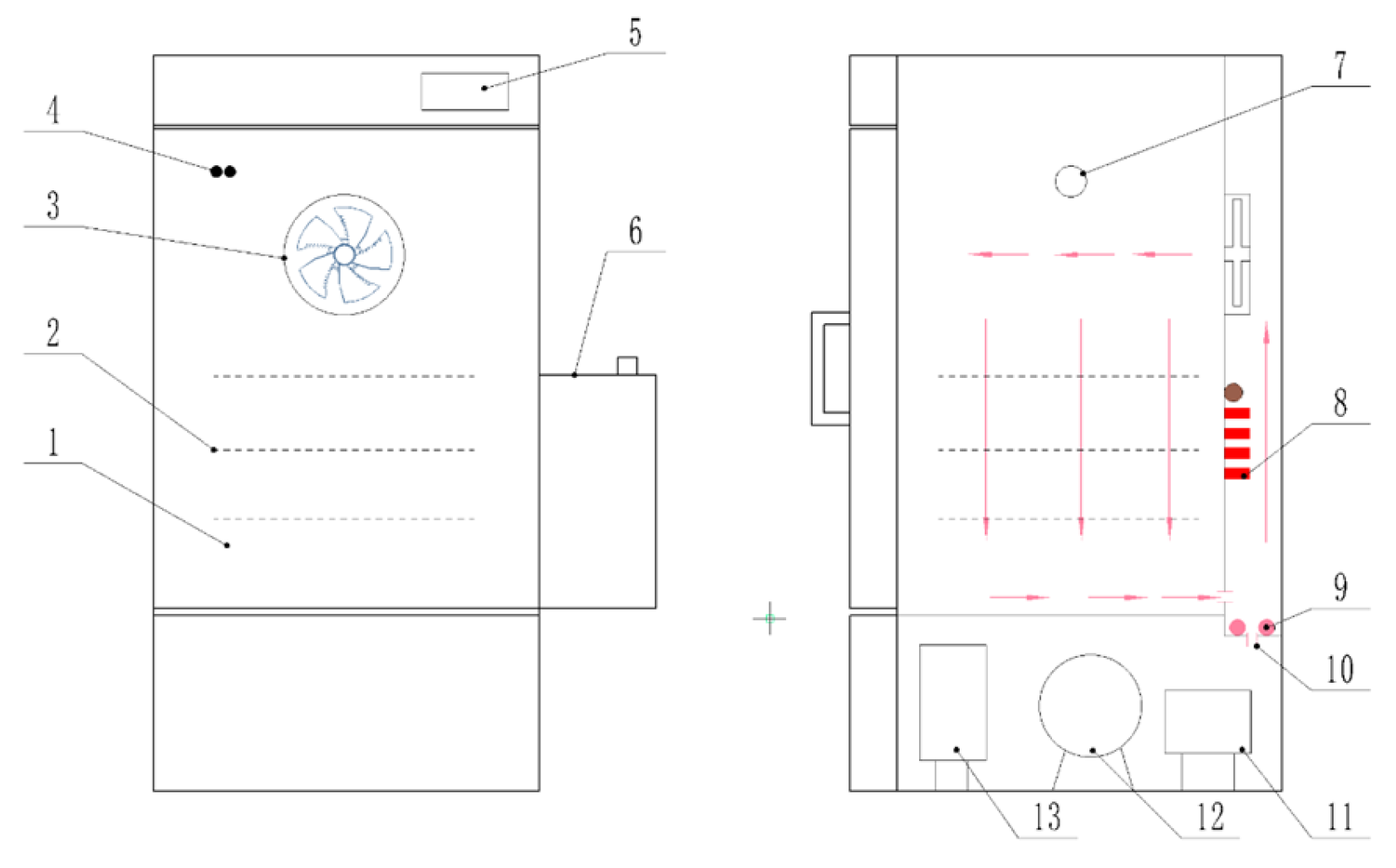

2.2. Processing Equipment

2.3. Determination of Optimal Moisture Transition Point for THPC-HAD

2.4. Multi-Stage Successive Combined Drying Strategy for Mume Fructus

2.5. Moisture Ratio (MR)

2.6. Image and Color Measurement

2.7. Texture Measurement (TM)

2.8. Intrinsic Quality Indicators

2.8.1. Determination of Total Ash (TA) Content

2.8.2. Determination of Extract Content

2.8.3. Determination of Citric Acid (CA) Content

2.8.4. Determination of Total Phenolic (TP) Content

2.8.5. Determination of Total Flavonoid (TF) Content

2.9. Total Antioxidant Capacity (TAC)

2.10. Statistical Analyses

3. Results and Discussion

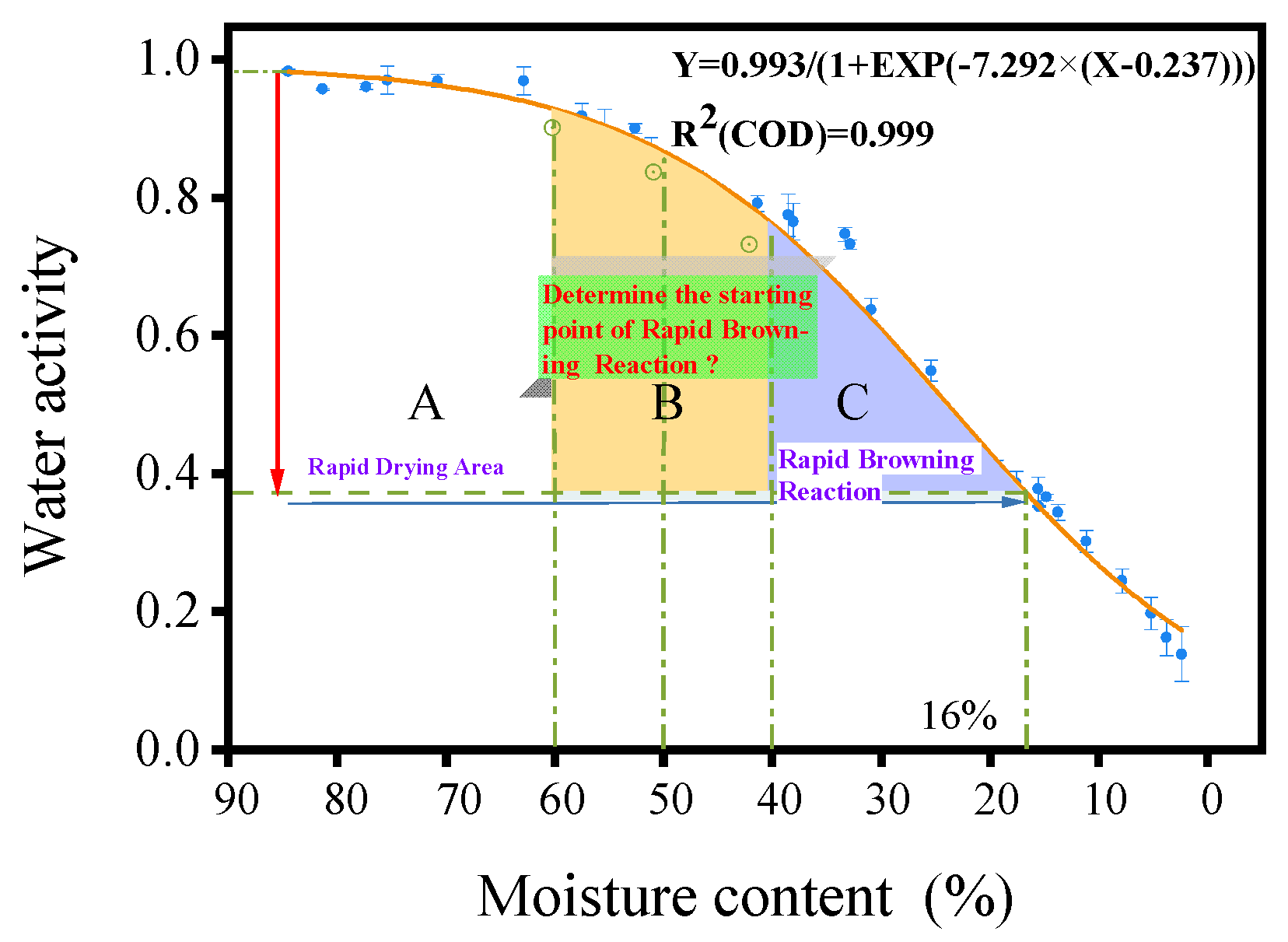

3.1. Relationship between Moisture Content (MC) and Water Activity (AW)

3.2. Suitable Moisture Transition Point for THPC-HAD Processing of MF

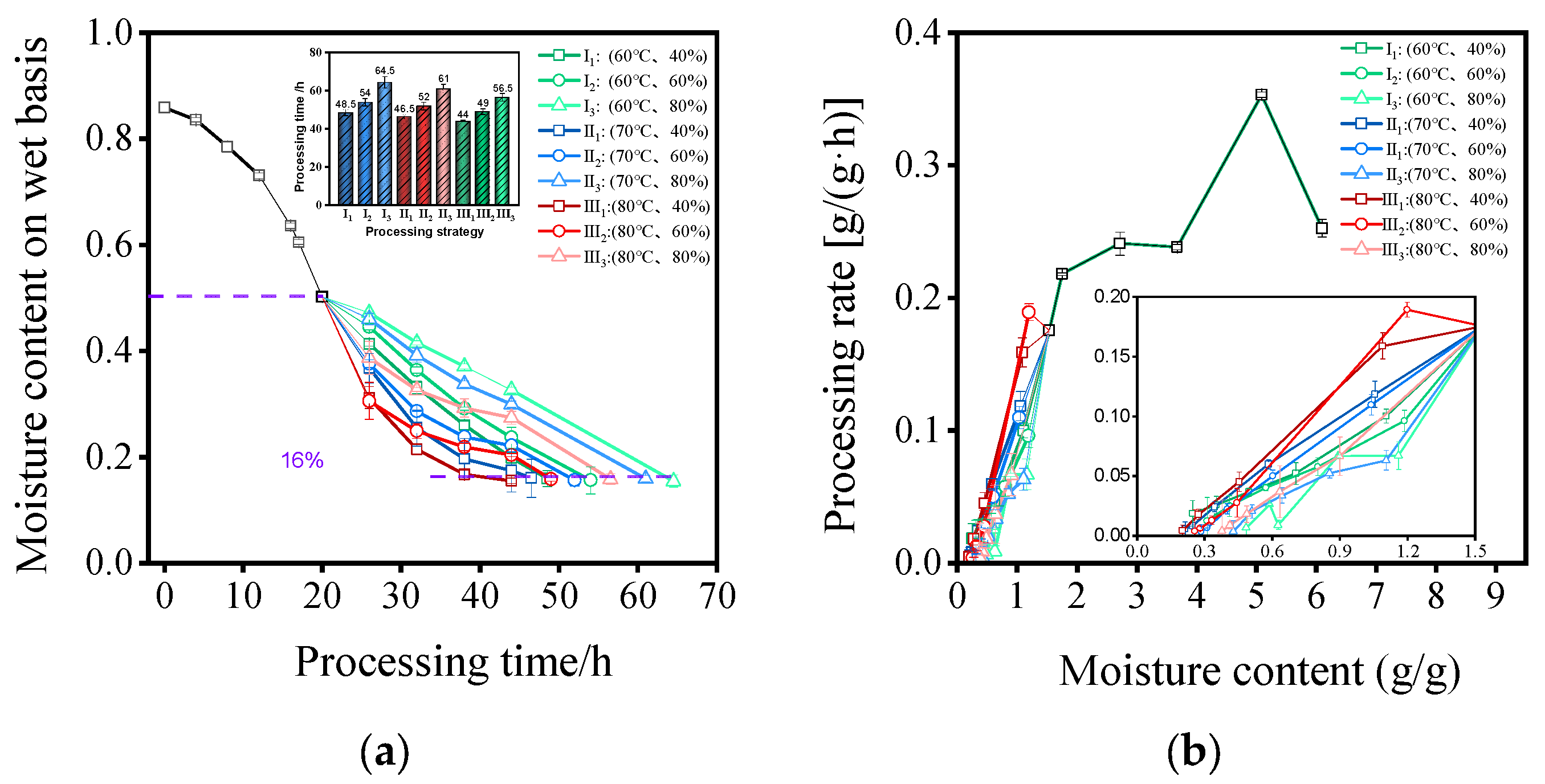

3.3. Effect of Temperature and Humidity Conditions on Drying Characteristics of MF

3.4. Effect of Temperature and Humidity Conditions on BPC and TPA of MF

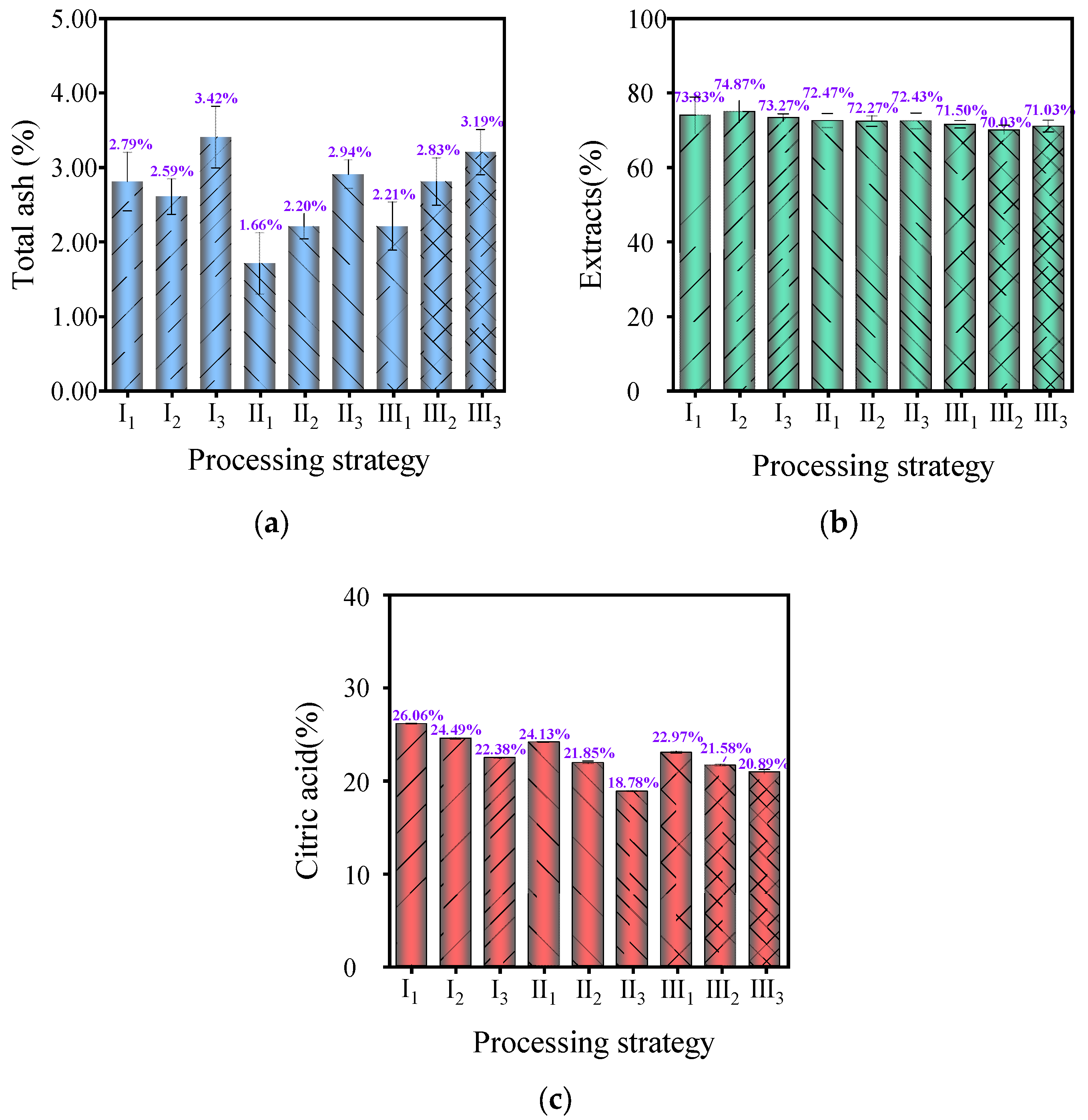

3.5. Effect of Temperature and Humidity Conditions on TA, Extracts, and CA in MF

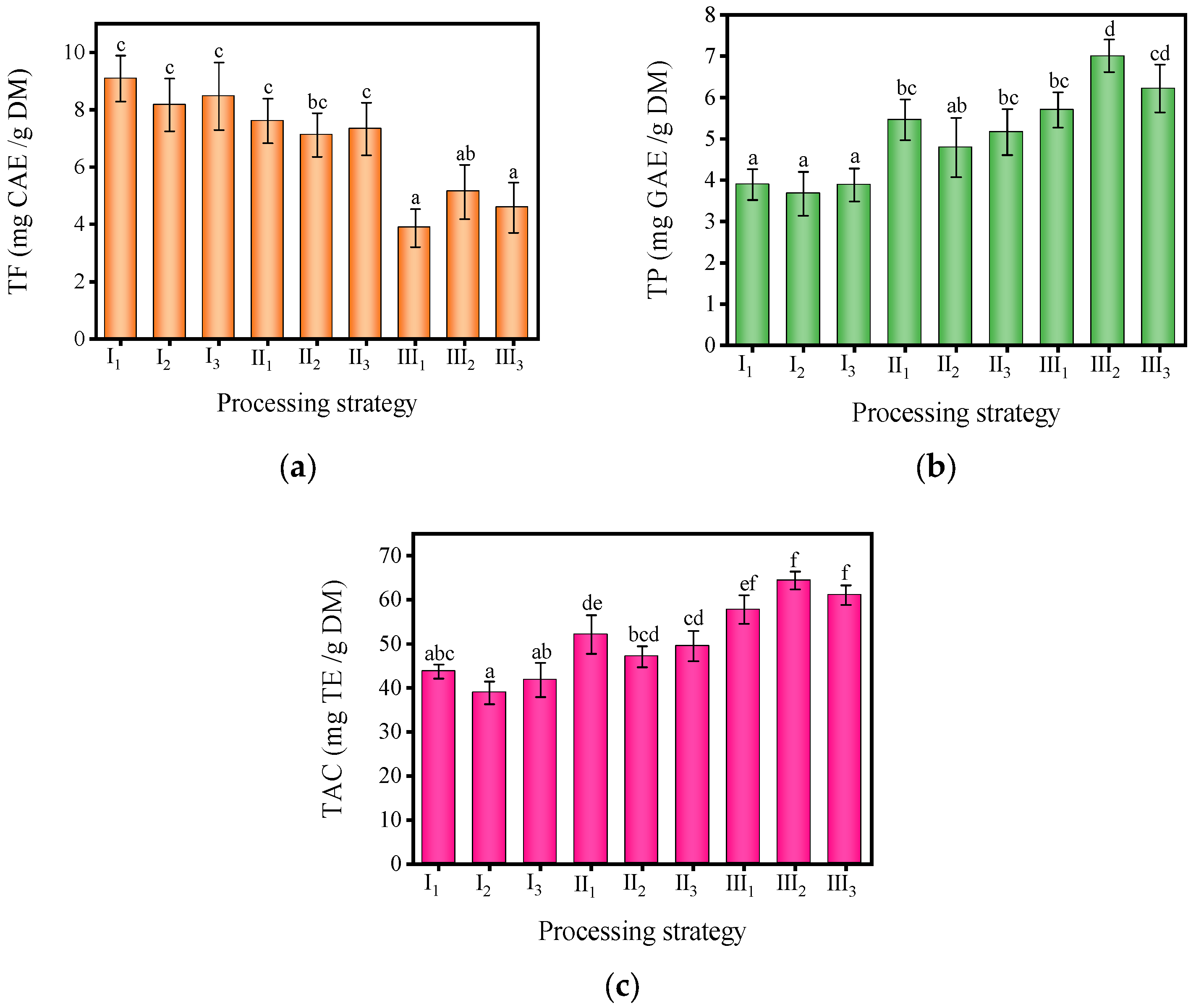

3.6. Effect of Temperature and Humidity Conditions on TP, TF, and TAC in MF

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- State Pharmacopoeia Commission. Pharmacopoeia of People’s Republic of China; China Medical Science and Technology Press: Beijing, China, 2020. [Google Scholar]

- Gong, X.-P.; Tang, Y.; Song, Y.-Y.; Du, G.; Li, J. Comprehensive review of phytochemical constituents, pharmacological properties, and clinical applications of Prunus mume. Front. Pharmacol. 2021, 12, 679378. [Google Scholar] [CrossRef]

- Gao, Z.; Shao, J.; Sun, H.; Zhong, W.; Zhuang, W.; Zhang, Z. Evaluation of different kinds of organic acids and their anti-bacterial activity in Japanese Apricot fruits. Afr. J. Agric. Res. 2012, 7, 4911–4918. [Google Scholar] [CrossRef]

- Bobrich, A.; Fanning, K.J.; Rychlik, M.; Russell, D.; Topp, B.; Netzel, M. Phytochemicals in Japanese plums: Impact of maturity and bioaccessibility. Food Res. Int. 2014, 65, 20–26. [Google Scholar] [CrossRef]

- Wang, S.; Wei, S.; Zhu, Y.; Zhang, M.; Cao, X.; Chang, Y.; Ouyang, H.; He, J. Comparative Investigation of the Differences in Chemical Compounds between Raw and Processed Mume Fructus Using Plant Metabolomics Combined with Chemometrics Methods. Molecules 2022, 27, 6344. [Google Scholar] [CrossRef]

- Ou, J.; Wang, R.; Li, X.; Huang, L.; Yuan, Q.; Fang, C.; Wu, D. Comparative Analysis of Free Amino Acids and Nucleosides in Different Varieties of Mume Fructus Based on Simultaneous Determination and Multivariate Statistical Analyses. Int. J. Anal. Chem. 2020, 2020, 4767605. [Google Scholar] [CrossRef] [PubMed]

- Park, J.C.; Ma, J.H.; Jeon, W.K.; Han, J.S. Fructus mume extracts alleviate cognitive impairments in 5XFAD transgenic mice. BMC Complement. Altern. Med. 2016, 16, 426. [Google Scholar] [CrossRef]

- Zhu, Y.; Ju, R.; Ma, F.; Qian, J.; Yan, J.; Li, S.; Li, Z. Moisture variation analysis of the green plum during the drying process based on low-field nuclear magnetic resonance. J. Food Sci. 2021, 86, 5137–5147. [Google Scholar] [CrossRef]

- Luo, M.; Zhang, G.R.; Luo, Y.J.; Yin, X.C.; Ma, Y.; Yuan, Y.P.; Li, J. Effects of different drying methods on the quality of plum. Food Ferment. Ind. 2018, 44, 152–159. [Google Scholar]

- Ding, C.; Li, B.S. Changes of Colors in Prunus mume during Smoking Processing. Mod. Food Sci. Technol. 2012, 28, 23–26. [Google Scholar]

- Li, J.H. Research of Quality Assessment and Processing Temperature for Dark Plum (Wumei). Master’s Thesis, Chengdu University of Traditional Chinese Medicine, Chengdu, China, 2019. [Google Scholar]

- Gong, R.Z.; Huo, X.H.; Zhang, L.; Liu, C.; Li, S.S.; Sun, Y.S. Advances in effects and regulation of Maillard reaction on quality of Chinese materia medica. Chin. Tradit. Herbal. Drugs 2019, 50, 243–251. [Google Scholar]

- Chen, P.; Zhang, J.B.; Gong, J.Y.; Xu, G.F.; Fan, Y.; Ni, G.H. Research Progress on the Mechanism and Brown Change Prevention of Fresh Chinese Herbal Medicine. Mod. Tradit. Chin. Med. 2016, 36, 102–107. [Google Scholar]

- Sherwin, C.; Labuza, T. Role of Moisture in Maillard Browning Reaction Rate in Intermediate Moisture Foods: Comparing Solvent Phase and Matrix Properties. J. Food Sci. 2003, 68, 588–593. [Google Scholar] [CrossRef]

- Fox, M.; Loncin, M.; Weiss, M. Investigations into the Influence of Water Activity, Ph and Heat Treatment on the Velocity of the Maillard Reaction in Foods. J. Food Qual. 1983, 6, 103–118. [Google Scholar] [CrossRef]

- Liu, S.; Sun, H.; Ma, G.; Zhang, T.; Wang, L.; Pei, H.; Li, X.; Gao, L. Insights into flavor and key influencing factors of Maillard reaction products: A recent update. Front. Nutr. 2022, 9, 973677. [Google Scholar] [CrossRef] [PubMed]

- Ai, Z.; Lin, Y.; Xie, Y.; Mowafy, S.; Zhang, Y.; Li, M.; Liu, Y. Effect of high-humidity hot air impingement steaming on Cistanche deserticola slices: Drying characteristics, weight loss, microstructure, color, and active components. Front. Nutr. 2022, 9, 824822. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.-E.; Wang, W. Changes in nutritional and bio-functional compounds and antioxidant capacity during black garlic processing. J. Food Sci. Technol. 2018, 55, 479–488. [Google Scholar] [CrossRef] [PubMed]

- Cheng, X.; Ji, H.; Cheng, C.; Sun, Y.; Cheng, H.; Wang, D.; Pan, Y.; Liu, X. Comprehensive determination of the processing level of rhizome of Polygonatum sibiricum by macroscopic, micromorphological, and microscopic characterizations. Microsc. Res. Tech. 2022, 85, 2669–2678. [Google Scholar] [CrossRef] [PubMed]

- Kroh, L.W.; Schulz, A. News on the Maillard reaction of oligomeric carbohydrates: A survey. Nahrung 2001, 45, 160–163. [Google Scholar] [CrossRef]

- Association of Official Analytical Chemists. Official Methods of Analysis, 15th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 1990. [Google Scholar]

- Wang, H.; Liu, Z.-L.; Vidyarthi, S.K.; Wang, Q.-H.; Gao, L.; Li, B.-R.; Wei, Q.; Liu, Y.-H.; Xiao, H.-W. Effects of different drying methods on drying kinetics, physicochemical properties, microstructure, and energy consumption of potato (Solanum tuberosum L.) cubes. Dry. Technol. 2021, 39, 418–431. [Google Scholar] [CrossRef]

- Abramovič, H.; Jamnik, M.; Burkan, L.; Kač, M. Water activity and water content in Slovenian honeys. Food Control. 2008, 19, 1086–1090. [Google Scholar] [CrossRef]

- Li, X.; Wang, R.; Li, X.L.; Zhang, W.; Ou, J.M.; Wu, D.L. Study on UPLC Fingerprints and Pattern Recognition of Mume Fructus with Different Processing Methods. Chin. J. Inf. Tradit. Chin. Med. 2020, 27, 76–81. [Google Scholar]

- Aversa, M.; Curcio, S.; Calabrò, V.; Iorio, G. Experimental Evaluation of Quality Parameters during Drying of Carrot Samples. Food Bioprocess. Technol. 2012, 5, 118–129. [Google Scholar] [CrossRef]

- Bai, J.-W.; Sun, D.-W.; Xiao, H.-W.; Mujumdar, A.; Gao, Z.-J. Novel high-humidity hot air impingement blanching (HHAIB) pretreatment enhances drying kinetics and color attributes of seedless grapes. Innov. Food Sci. Emerg. Technol. 2013, 20, 230–237. [Google Scholar] [CrossRef]

- Pathare, P.B.; Opara, U.L.; Al-Said, F.A.-J. Colour Measurement and Analysis in Fresh and Processed Foods: A Review. Food Bioprocess. Technol. 2013, 6, 36–60. [Google Scholar] [CrossRef]

- Li, X.; Liu, Y.; Gao, Z.; Xie, Y.; Wang, H. Computer vision online measurement of shiitake mushroom (Lentinus edodes) surface wrinkling and shrinkage during hot air drying with humidity control. J. Food Eng. 2021, 292, 110253. [Google Scholar] [CrossRef]

- Missang, C.E.; Maingonnat, J.F.; Renard, C.M.; Audergon, J.-M. Apricot cell wall composition: Relation with the intra-fruit texture heterogeneity and impact of cooking. Food Chem. 2012, 133, 45–54. [Google Scholar] [CrossRef]

- Gao, Q.H.; Wu, C.S.; Wang, M.; Xu, B.N.; Du, L.J. Effect of drying of jujubes (Ziziphus jujuba Mill.) on the contents of sugars organic acids alpha-tocopherol betacarotene and phenolic compounds. J. Agric. Food Chem. 2012, 60, 9642–9648. [Google Scholar] [CrossRef] [PubMed]

- Benzie, I.F.F.; Strain, J.J. The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: The FRAP assay. Anal. Biochem. 1996, 239, 70–76. [Google Scholar] [CrossRef]

- Kumar, M.; Rekha; Gehlot, R.; Mahato, D.K.; Arora, S. Effect of hybrid drying on the quality attributes of formulated instant banana-milk powders and shakes during storage. J. Food Sci. Technol. 2022, 59, 2318–2327. [Google Scholar] [CrossRef]

- Sagar, V.R.; Kumar, R. Effect of drying treatments and storage stability on quality characteristics of bael powder. J. Food Sci. Technol. 2014, 51, 2162–2168. [Google Scholar] [CrossRef] [PubMed]

- Barooah, N.; Das, P.; Barooah, M.S.; Seth, D.K.; Dutta, P. Storage Studies on Spray Dried Ripe Banana Powder Produced by Response Surface Methodology. Int. J. Curr. Microbiol. Appl. Sci. 2018, 7, 1922–1933. [Google Scholar] [CrossRef]

- Ju, H.Y.; Zou, Y.Z.; Xiao, H.W.; Zhang, W.P.; Yu, X.L.; Gao, Z.J. Effects of relative humidity on water diffusion and evaporation during hot air drying of carrot. Trans. Chin. Soc. Agric. Eng. 2023, 39, 232–240. [Google Scholar]

- Geng, Z.H.; Li, M.Q.; Zhu, L.C.; Yu, X.L.; Hu, B.; Zhang, Q.; Wang, J.Y.; Yang, X.H. Research on drying uniformity and technology of sea buckthorn with infrared combined hot air based on temperature and humidity control. Trans. Chin. Soc. Agric. Eng. 2023, 30, 264–270. [Google Scholar]

- Sarpong, F.; Yu, X.; Zhou, C.; Oteng-Darko, P.; Amenorfe, L.P.; Wu, B.; Bai, J.; Ma, H. Drying characteristic, enzyme inactivation and browning pigmentation kinetics of controlled humidity-convective drying of banana slices. Heat Mass. Transf. 2018, 54, 3117–3130. [Google Scholar] [CrossRef]

- Yu, X.-L.; Zielinska, M.; Ju, H.-Y.; Mujumdar, A.S.; Duan, X.; Gao, Z.-J.; Xiao, H.-W. Multistage relative humidity control strategy enhances energy and exergy efficiency of convective drying of carrot cubes. Int. J. Heat Mass. Transf. 2020, 149, 119231. [Google Scholar] [CrossRef]

- Corrêa, J.L.G.; Braga, A.M.P.; Hochheim, M.; Silva, M.A. The Influence of Ethanol on the Convective Drying of Unripe, Ripe, and Overripe Bananas. Dry. Technol. 2012, 30, 817–826. [Google Scholar] [CrossRef]

- Wang, J.; Mu, W.-S.; Fang, X.-M.; Mujumdar, A.; Yang, X.-H.; Xue, L.-Y.; Xie, L.; Xiao, H.-W.; Gao, Z.-J.; Zhang, Q. Pulsed vacuum drying of Thompson seedless grape: Effects of berry ripeness on physicochemical properties and drying characteristic. Food Bioprod. Process. 2017, 106, 117–126. [Google Scholar] [CrossRef]

- Chong, C.H.; Law, C.L.; Cloke, M.; Hii, C.L.; Abdullah, L.C.; Daud, W.R.W. Drying kinetics and product quality of dried Chempedak. J. Food Eng. 2008, 88, 522–527. [Google Scholar] [CrossRef]

- Askari, G.R.; Emam-Djomeh, Z.; Mousavi, S.M. Effects of Combined Coating and Microwave Assisted Hot-air Drying on the Texture, Microstructure and Rehydration Characteristics of Apple Slices. Food Sci. Technol. Int. 2006, 12, 39–46. [Google Scholar] [CrossRef]

- Long, T.; Tian, K.; Wei, C.; Liu, M.; Wu, M.; Li, Z.; Uchimiya, M. Temperature and moisture mediated changes in chemical and microbial properties of biochars in an Anthrosol. Sci. Total Environ. 2022, 845, 157219. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Lin, Y.; Tai, Y.N.; Liu, Z.Y.; Xu, W.; Wu, S.S. Effects of Baking Temperature on the Properties, Extracts and Components Contents of Alismatis Rhizoma During Processing. J. Chin. Med. Mater. 2022, 45, 2850–2855. [Google Scholar]

- Behera, B.C.; Mishra, R.; Mohapatra, S. Microbial citric acid: Production, properties, application, and future perspectives. Food Front. 2021, 2, 62–76. [Google Scholar] [CrossRef]

- Cavallo, E.; Charreau, H.; Cerrutti, P.; Foresti, M.L. Yarrowia lipolytica: A model yeast for citric acid production. FEMS Yeast Res. 2017, 17, fox084. [Google Scholar] [CrossRef]

- Karaman, S.; Toker, O.S.; Çam, M.; Hayta, M.; Doğan, M.; Kayacier, A. Bioactive and physicochemical properties of persimmon as affected by drying methods. Dry. Technol. 2014, 32, 258–267. [Google Scholar] [CrossRef]

- Lang, G.H.; Lindemann, I.d.S.; Ferreira, C.D.; Hoffmann, J.F.; Vanier, N.L.; de Oliveira, M. Effects of drying temperature and long-term storage conditions on black rice phenolic compounds. Food Chem. 2019, 287, 197–204. [Google Scholar] [CrossRef]

- Matys, A.; Witrowa-Rajchert, D.; Parniakov, O.; Wiktor, A. Assessment of the effect of air humidity and temperature on con-vective drying of apple with pulsed electric field pretreatment. LWT-Food Sci. 2023, 188, 115455. [Google Scholar] [CrossRef]

- Zannou, O.; Pashazadeh, H.; Ghellam, M.; Hassan, A.M.A.; Koca, I. Optimization of drying temperature for the assessment of functional and physical characteristics of autumn olive berries. J. Food Process. Preserv. 2021, 45, e15658. [Google Scholar] [CrossRef]

- Sarpong, F.; Yu, X.; Zhou, C.; Amenorfe, L.P.; Bai, J.; Wu, B.; Ma, H. The kinetics and thermodynamics study of bioactive compounds and antioxidant degradation of dried banana (Musa ssp.) slices using controlled humidity convective air drying. J. Food Meas. Charact. 2018, 12, 1935–1946. [Google Scholar] [CrossRef]

- Garau, M.C.; Simal, S.; Rosselló, C.; Femenia, A. Effect of air-drying temperature on physicochemical properties of dietary fibre and antioxidant capacity of orange (Citrus aurantium v. Canoneta) by-products. Food Chem. 2007, 104, 1014–1024. [Google Scholar] [CrossRef]

- Wojdyło, A.; Figiel, A.; Lech, K.; Nowicka, P.; Oszmiański, J. Effect of Convective and Vacuum–Microwave Drying on the Bioactive Compounds, Color, and Antioxidant Capacity of Sour Cherries. Food Bioprocess. Technol. 2014, 7, 829–841. [Google Scholar]

- Manzocco, L.; Calligaris, S.; Mastrocola, D.; Nicoli, M.C.; Lerici, C.R. Review of non-enzymatic browning and antioxidant capacity in processed foods. Trends Food Sci. Technol. 2000, 11, 340–346. [Google Scholar] [CrossRef]

| Processing Time/h | 0 | 14 | 17 | 23 |

|---|---|---|---|---|

| Image |  |  |  |  |

| MC | 85.89 ± 0.8% | 60% | 50% | 40% |

| L* | 54.41 ± 1.59 a | 38.89 ± 0.96 bc | 36.83 ± 0.61 c | 28.58 ± 0.81 d |

| a* | −7.57 ± 0.79 a | 6.81 ± 0.59 b | 7.21 ± 0.62 b | 6.64 ± 0.34 b |

| b* | 37.20 ± 1.34 a | 20.79 ± 1.05 bc | 19.47 ± 0.93 c | 10.86 ± 1.00 d |

| ΔE | - | 26.79 ± 0.92 a | 29.03 ± 0.56 b | 39.54 ± 1.11 c |

| C0 | 37.97 ± 1.27 a | 21.88 ± 1.18 bc | 20.76 ± 1.07 c | 12.73 ± 1.00 d |

| BI | 92.73 ± 1.39 a | 86.60 ± 1.08 b | 83.72 ± 0.89 c | 63.99 ± 1.39 d |

| Average Processing Time at 60 °C/h | 55.89 | 45.83 | 38.67 | 29.17 |

| Average Processing Time at 70 °C/h | 53.28 | 42.17 | 36.17 | 27.50 |

| Average Processing Time at 80 °C/h | 50.22 | 37.83 | 32.83 | 26.00 |

| Average | 53.13 | 41.94 | 35.89 | 27.56 |

| Processing Condition | BI | TPA | |||||

|---|---|---|---|---|---|---|---|

| Hardness (N) | Springiness (mm) | Cohesiveness | Gumminess (N) | Chewiness (mJ) | Resilience | ||

| I1 | 44.83 ± 1.52 f | 68.03 ± 3.97 c | 0.60 ± 0.04 a | 0.69 ± 0.05 cd | 46.81 ± 0.11 c | 28.18 ± 1.71 bc | 0.27 ± 0.03 ab |

| I2 | 41.26 ± 1.50 ef | 44.70 ± 3.81 b | 0.76 ± 0.04 cd | 0.62 ± 0.05 abc | 27.51 ± 0.66 b | 20.97 ± 1.46 b | 0.26 ± 0.03 ab |

| I3 | 38.40 ± 1.79 de | 27.80 ± 2.96 a | 0.76 ± 0.04 cd | 0.56 ± 0.04 a | 15.56 ± 0.87 a | 11.82 ± 1.16 a | 0.23 ± 0.04 a |

| II1 | 34.29 ± 1.27 cd | 150.68 ± 8.65 e | 0.78 ± 0.04 cde | 0.66 ± 0.04 cd | 99.99 ± 11.83 d | 78.00 ± 12.55 e | 0.30 ± 0.02 bc |

| II2 | 31.03 ± 1.38 c | 70.12 ± 3.87 c | 0.71 ± 0.05 bc | 0.65 ± 0.03 bcd | 45.50 ± 3.80 c | 32.04 ± 3.54 c | 0.27 ± 0.03 ab |

| II3 | 34.75 ± 2.51 cd | 42.08 ± 4.72 b | 0.84 ± 0.04 e | 0.65 ± 0.04 bcd | 27.16 ± 2.43 b | 22.81 ± 3.10 bc | 0.26 ± 0.02 ab |

| III1 | 38.64 ± 4.09 de | 189.45 ± 9.60 f | 0.67 ± 0.04 ab | 0.69 ± 0.04 cd | 129.78 ± 3.48 e | 86.45 ± 6.04 e | 0.31 ± 0.02 bc |

| III2 | 23.65 ± 2.12 b | 93.99 ± 6.50 d | 0.82 ± 0.04 de | 0.55 ± 0.05 a | 51.26 ± 2.92 c | 42.07 ± 3.81 d | 0.35 ± 0.03 c |

| III3 | 12.72 ± 2.71 a | 50.54 ± 5.42 b | 0.75 ± 0.04 cd | 0.57 ± 0.05 ab | 28.81 ± 1.01 b | 21.38 ± 1.07 b | 0.27 ± 0.03 ab |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, L.; Zhang, H.; Wang, H.; Li, A.-C.; Wu, M.; Wang, Q.-Z.; Zheng, Z.-A. Quality Evaluation and Browning Control in the Multi-Stage Processing of Mume Fructus (Wumei). Foods 2024, 13, 272. https://doi.org/10.3390/foods13020272

Gao L, Zhang H, Wang H, Li A-C, Wu M, Wang Q-Z, Zheng Z-A. Quality Evaluation and Browning Control in the Multi-Stage Processing of Mume Fructus (Wumei). Foods. 2024; 13(2):272. https://doi.org/10.3390/foods13020272

Chicago/Turabian StyleGao, Lei, Hui Zhang, Hui Wang, Ai-Chao Li, Min Wu, Qing-Zhu Wang, and Zhi-An Zheng. 2024. "Quality Evaluation and Browning Control in the Multi-Stage Processing of Mume Fructus (Wumei)" Foods 13, no. 2: 272. https://doi.org/10.3390/foods13020272

APA StyleGao, L., Zhang, H., Wang, H., Li, A.-C., Wu, M., Wang, Q.-Z., & Zheng, Z.-A. (2024). Quality Evaluation and Browning Control in the Multi-Stage Processing of Mume Fructus (Wumei). Foods, 13(2), 272. https://doi.org/10.3390/foods13020272