Systematic Literature Review of Barriers and Enablers to Implementing Food Informatics Technologies: Unlocking Agri-Food Chain Innovation

Abstract

:1. Introduction

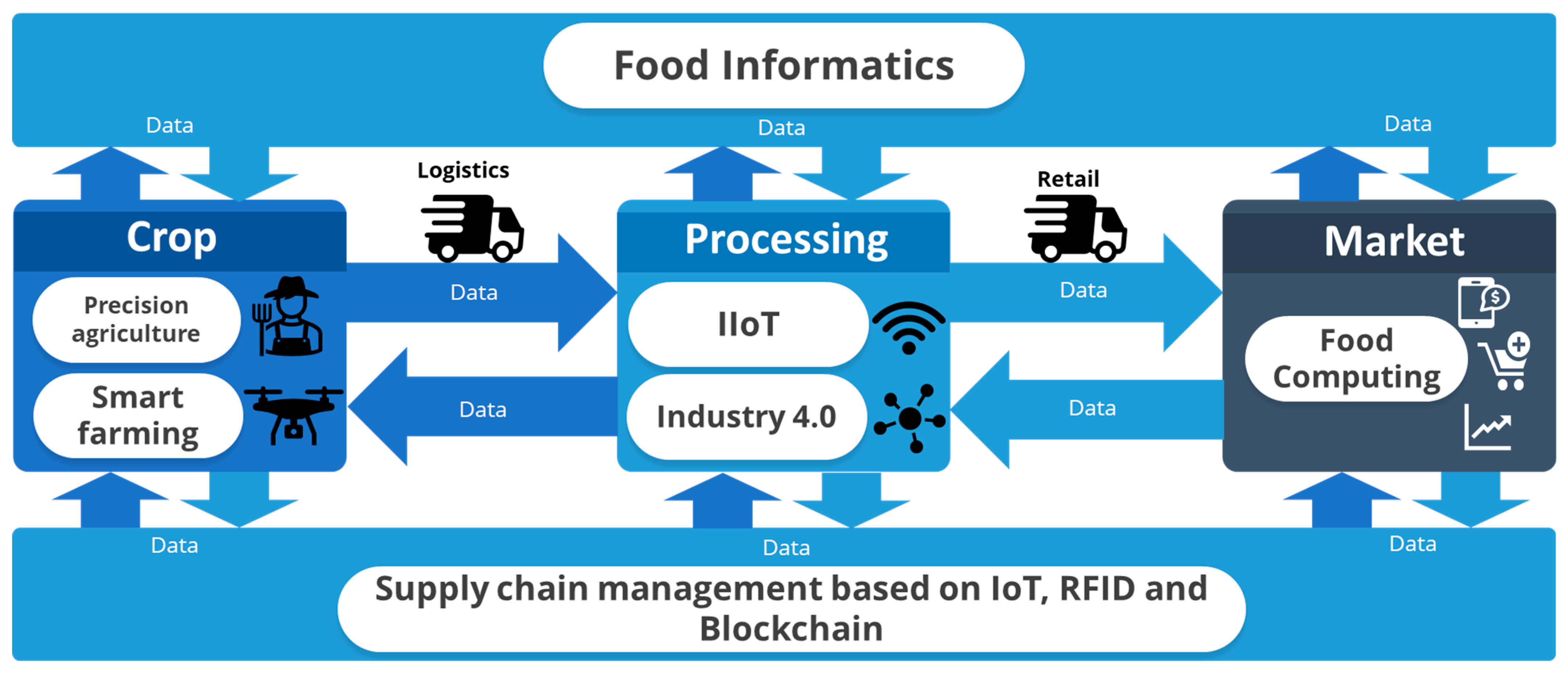

2. Theoretical Background

| Link | Technology | Description/Application | Support References |

|---|---|---|---|

| Production—Processing and Marketing | Artificial Intelligence (AI) | It simulates human intelligence, allowing information to be processed and learned, and problems to be solved optimally. AI components are embedded in applications for climate management, waste control, nutrition management, disease detection and treatment, demand projection, quality management, inventory control, consumer analysis, and food fraud detection. | [41,42,43,44,45,46] |

| Production | Drones | Uncrewed aerial vehicles. These can be adapted with different technologies to monitor activities, product application, inspection, topography, and cartography. These data are reported and stored for decision-making. | [42] |

| Production—Processing and Marketing | IoT | These are systems of interconnected sensors that communicate and interact with each other, allowing for the capture of information from actuators. These have the potential to be applied in different links of the agri-food chains due to their impact on sustainability, energy consumption, manufacturing costs, security, supply chain tracking, marketing, and consumer experience. | [47,48] |

| Processing | IIoT | These are sensors, devices, and industrial machines interconnected to capture information and share it in real-time. Their applications are primarily found in the processing link because they allow for the optimization of production processes based on the real-time monitoring of process variables, quality control, traceability, logistics, and inventory management. This technology facilitates the implementation of smart factories. | [49,50] |

| Production—Processing and Marketing | Blockchain | Blockchain can be defined as “a decentralized and distributed data recording system in which transactions are recorded and added in chronological order to create permanent and tamper-proof records.” This technology is applicable throughout the agri-food chain, facilitating the traceability, quality verification, and certification of origin processes. It also increases food safety, brand reputation, and end-consumer satisfaction. | [51,52,53] |

| Production—Processing and Marketing | Cloud Computing | Virtual storage systems accessed through the Internet; these are only accessed via an Internet connection and avoid the use of local applications such as physical servers and computers. This service model can be implemented to apply technologies such as IoT, Blockchain, and AI, among others. | [54,55,56,57] |

| Production—Processing and Marketing | Edge Computing | These are data processing models that allow for increased response times because they act as a cloud closer to local devices and end users. This technology is applied in the production, processing, and marketing links since it supports others, such as machine learning, IoT, and Blockchain. | [58,59,60] |

| Production—Processing and Marketing | RFID | This is a radio-frequency identification system that allows for the tracking of products in real-time, inventory management, quality control, and maintenance processes, increasing transparency. | [61,62] |

| Production—Processing and Marketing | Robotics–Cobots | This is the application of robots designed to interact directly with humans in shared spaces, allowing for the more efficient development of tasks, reduction of risks, and improvement of process automation. These robots are mainly used in the production and processing links; however, their use extends to the marketing link. | [63,64,65] |

| Production—Processing and Marketing | Digital Twins | These are virtual representations of physical entities that are permanently updated through data to generate dynamics that allow decisions to be made in the real world. Their applications range from cultivation and processing to logistics and food packaging. | [48,66,67] |

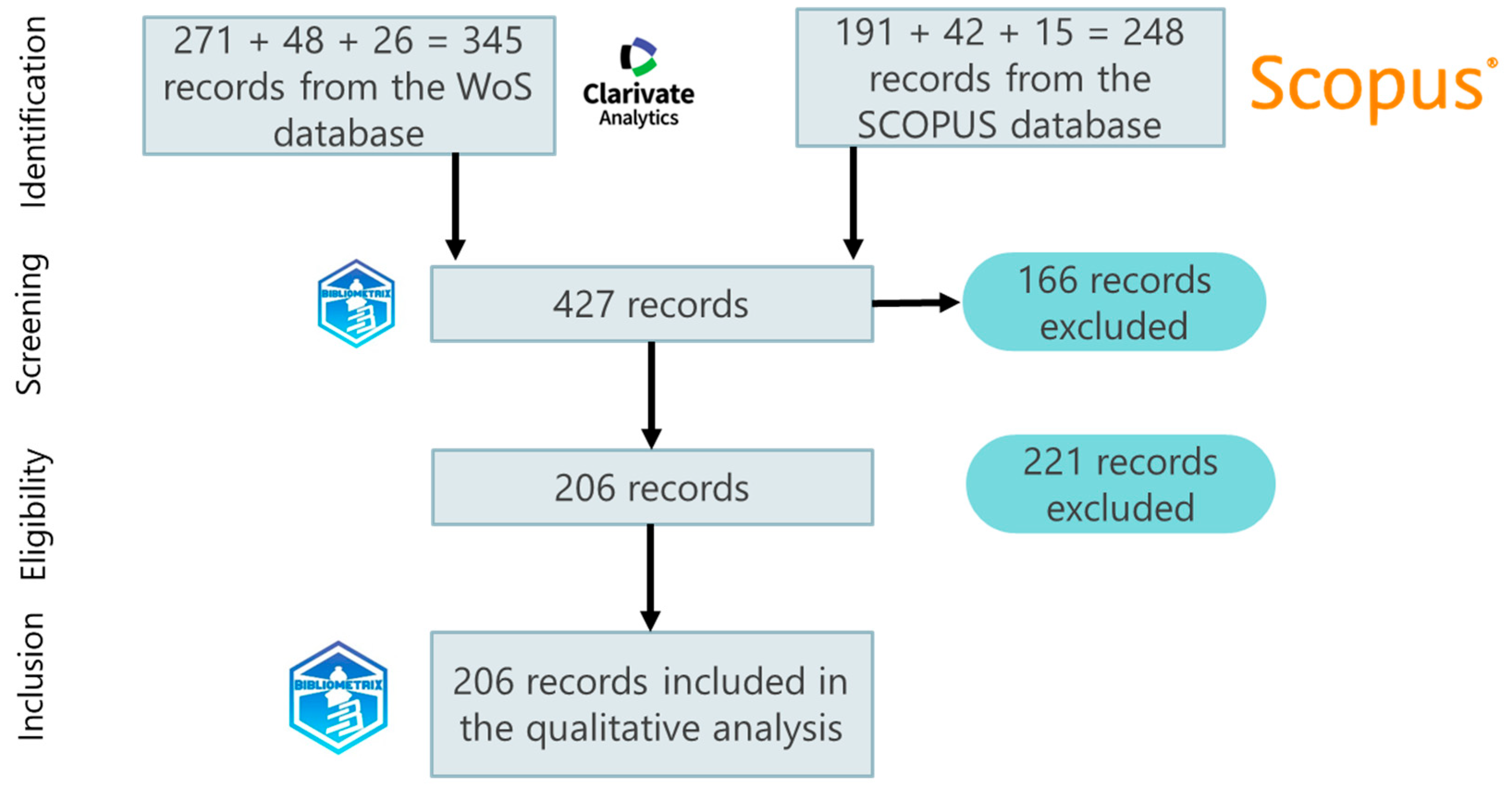

3. Materials and Methods

4. Results

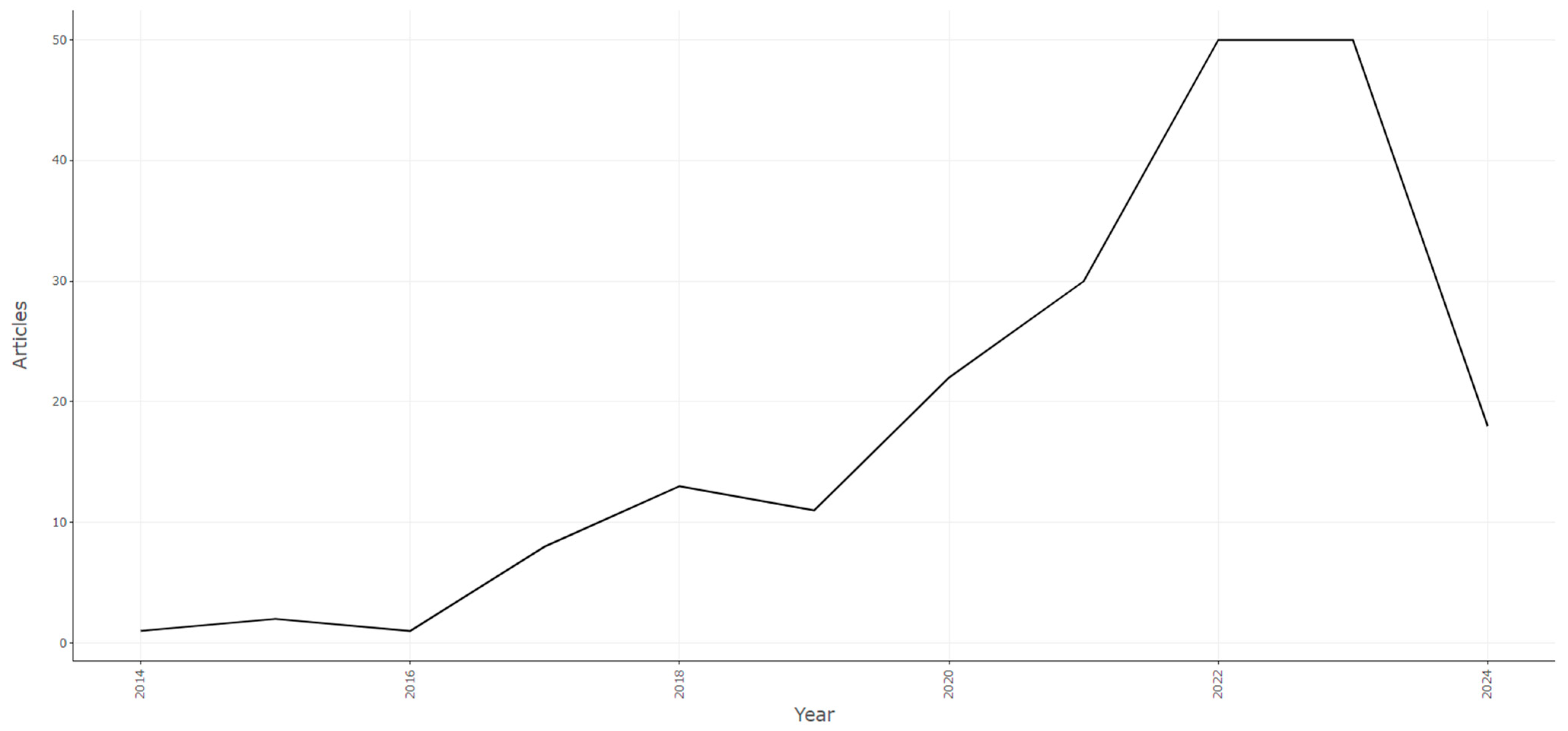

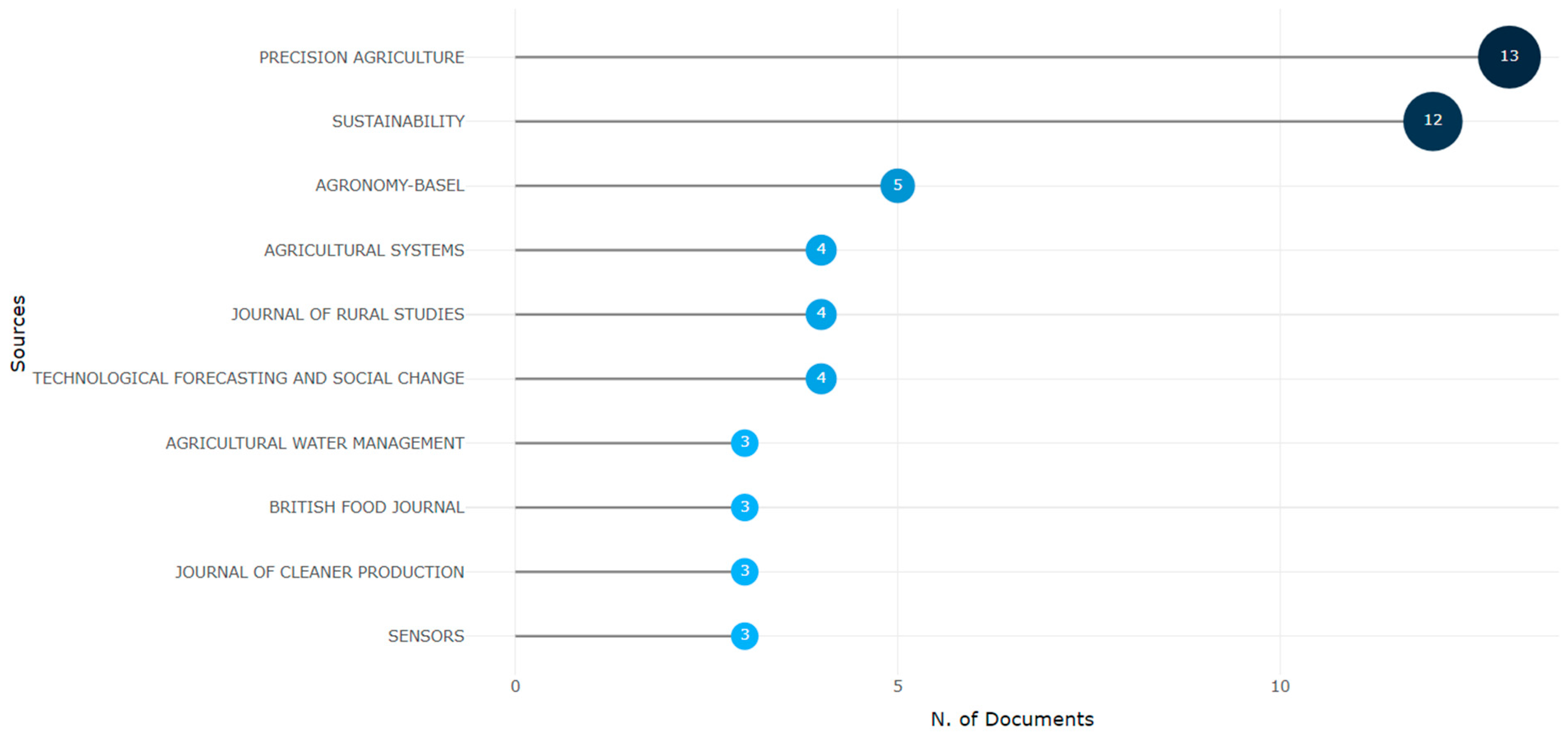

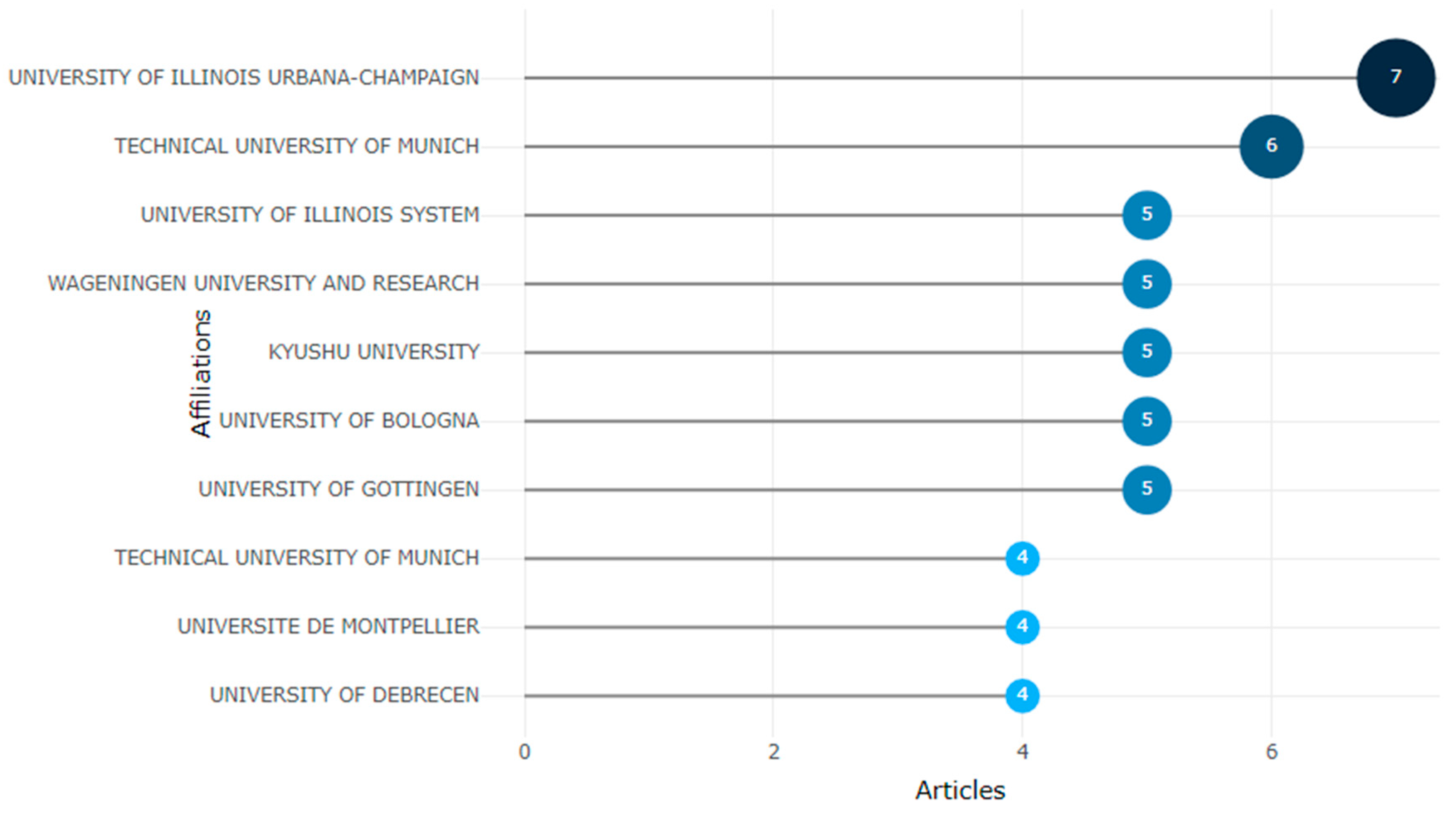

4.1. Level of Metrics

- Question 1: What factors influence supply chain actors to adopt Blockchain technology, and how can these factors streamline information systems architecture?

- Question 2: How can information systems architecture make the supply chain inclusive and increase support for value creation for actors?

- Question 3: How can information systems architecture ensure food quality and safety and impact sustainable supply chain practices?

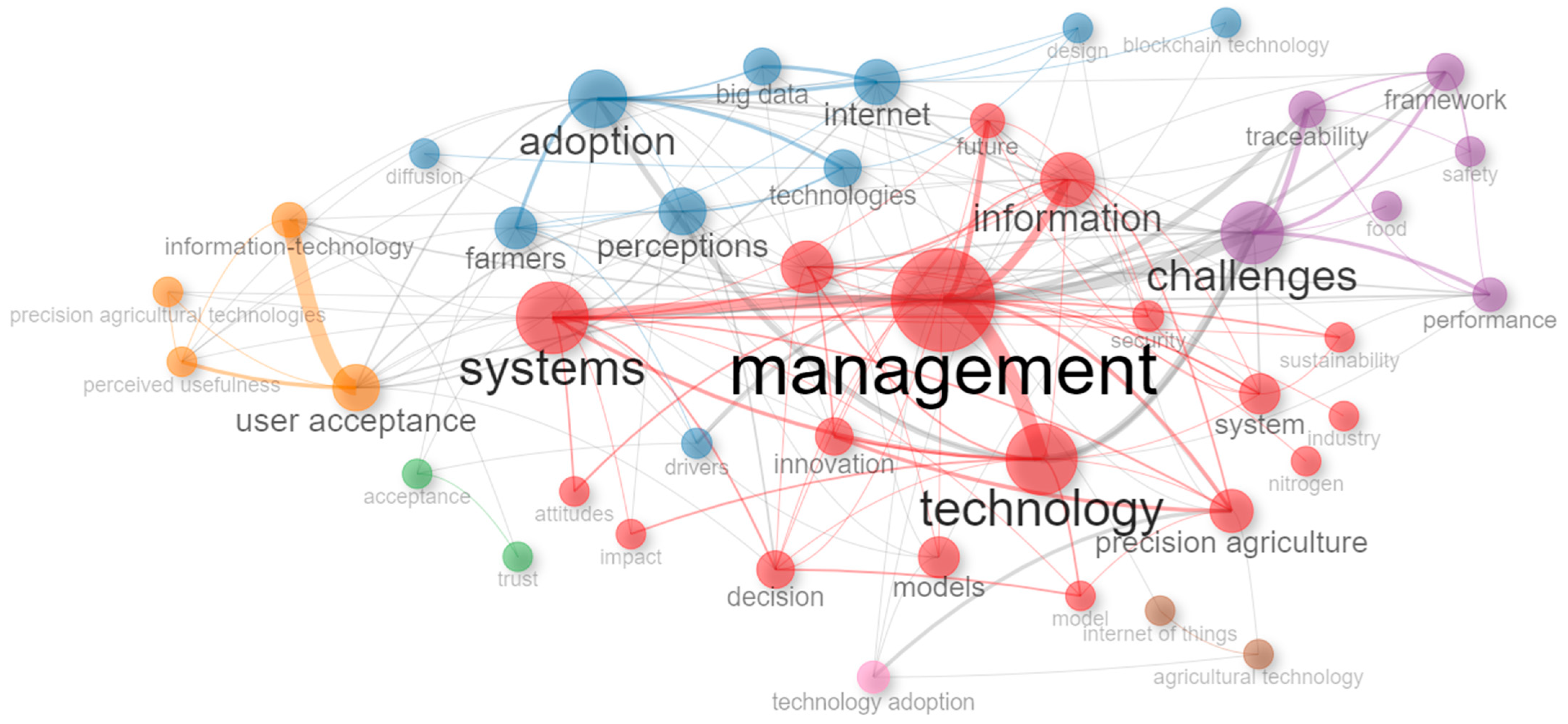

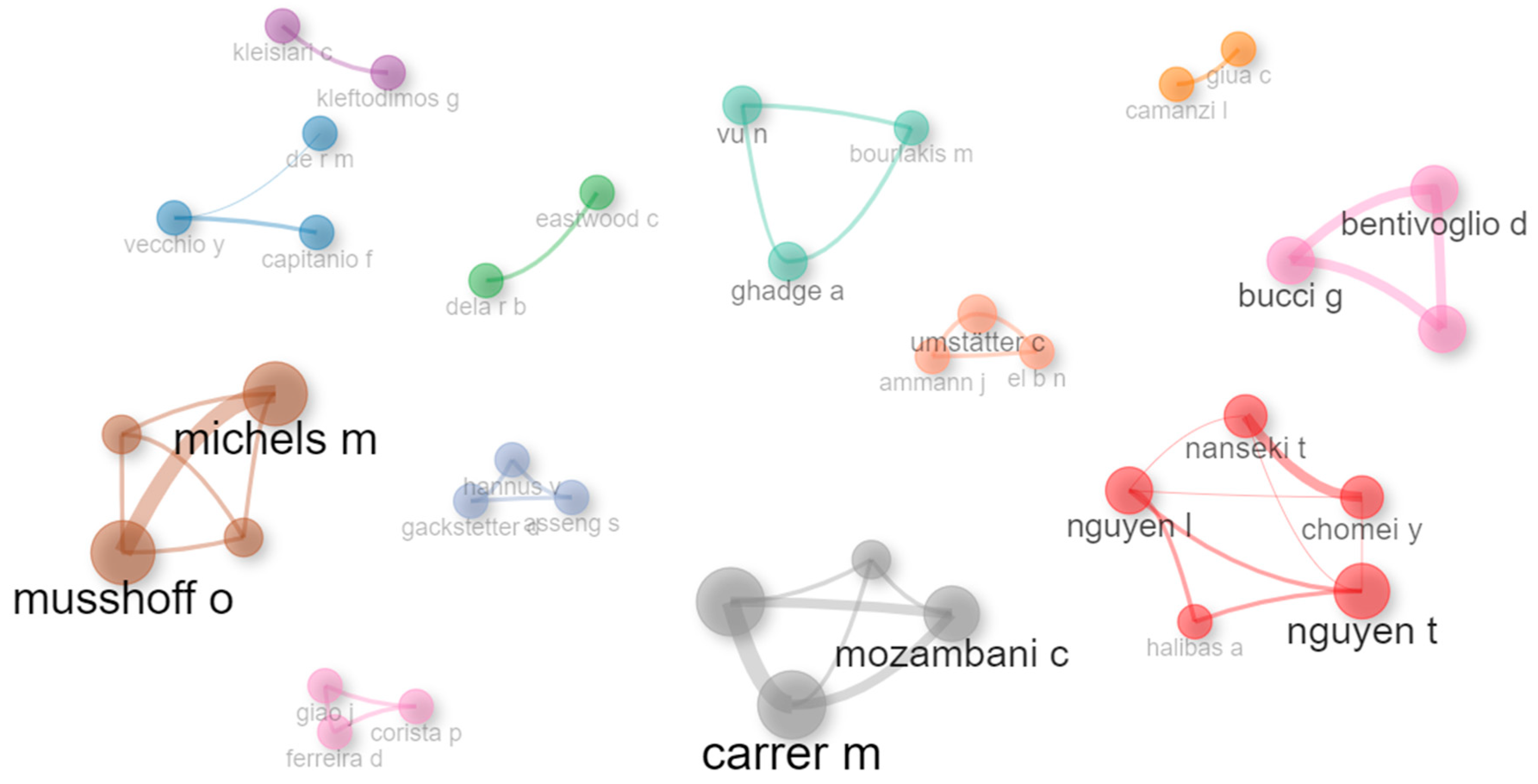

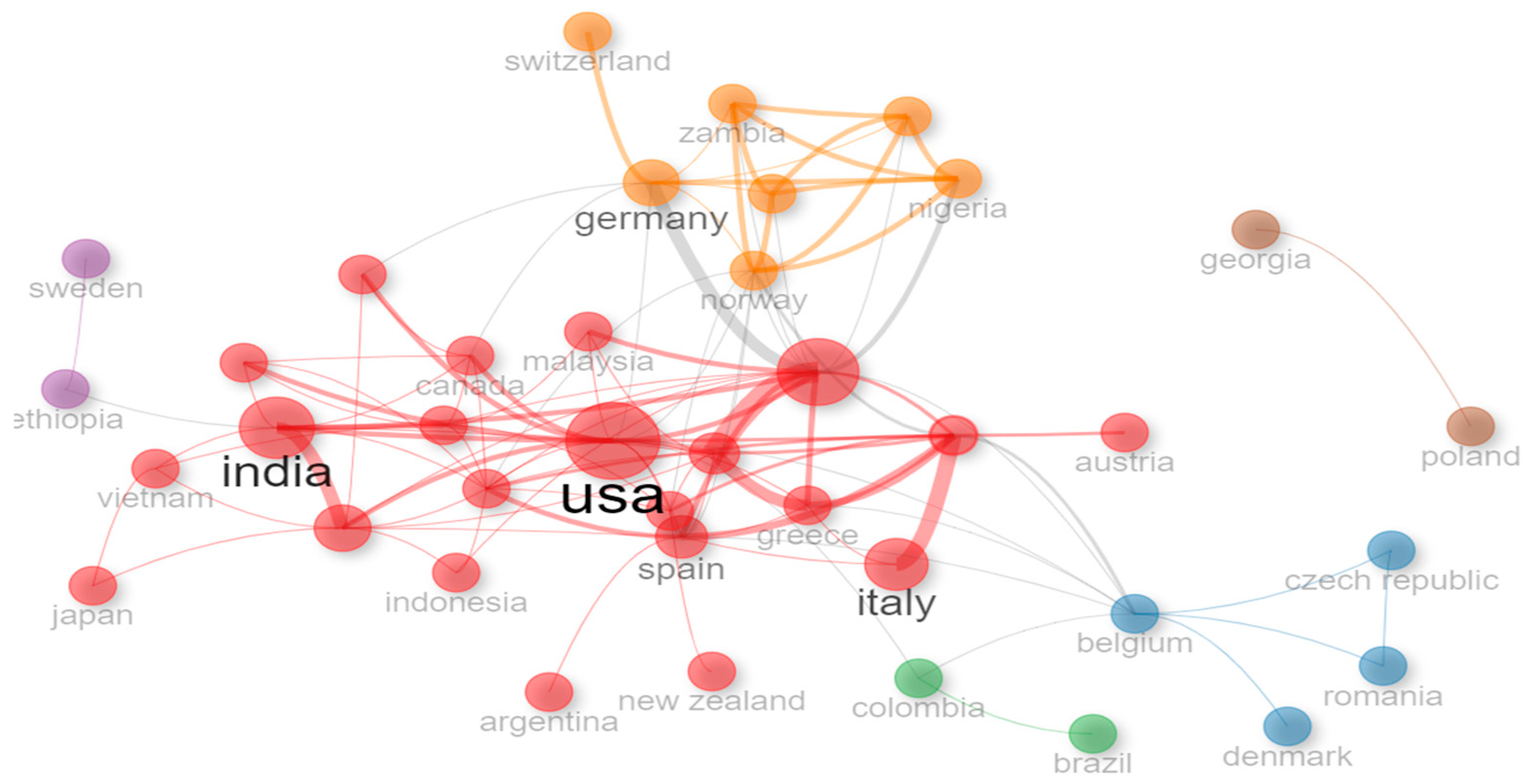

4.2. Level of Knowledge Structures

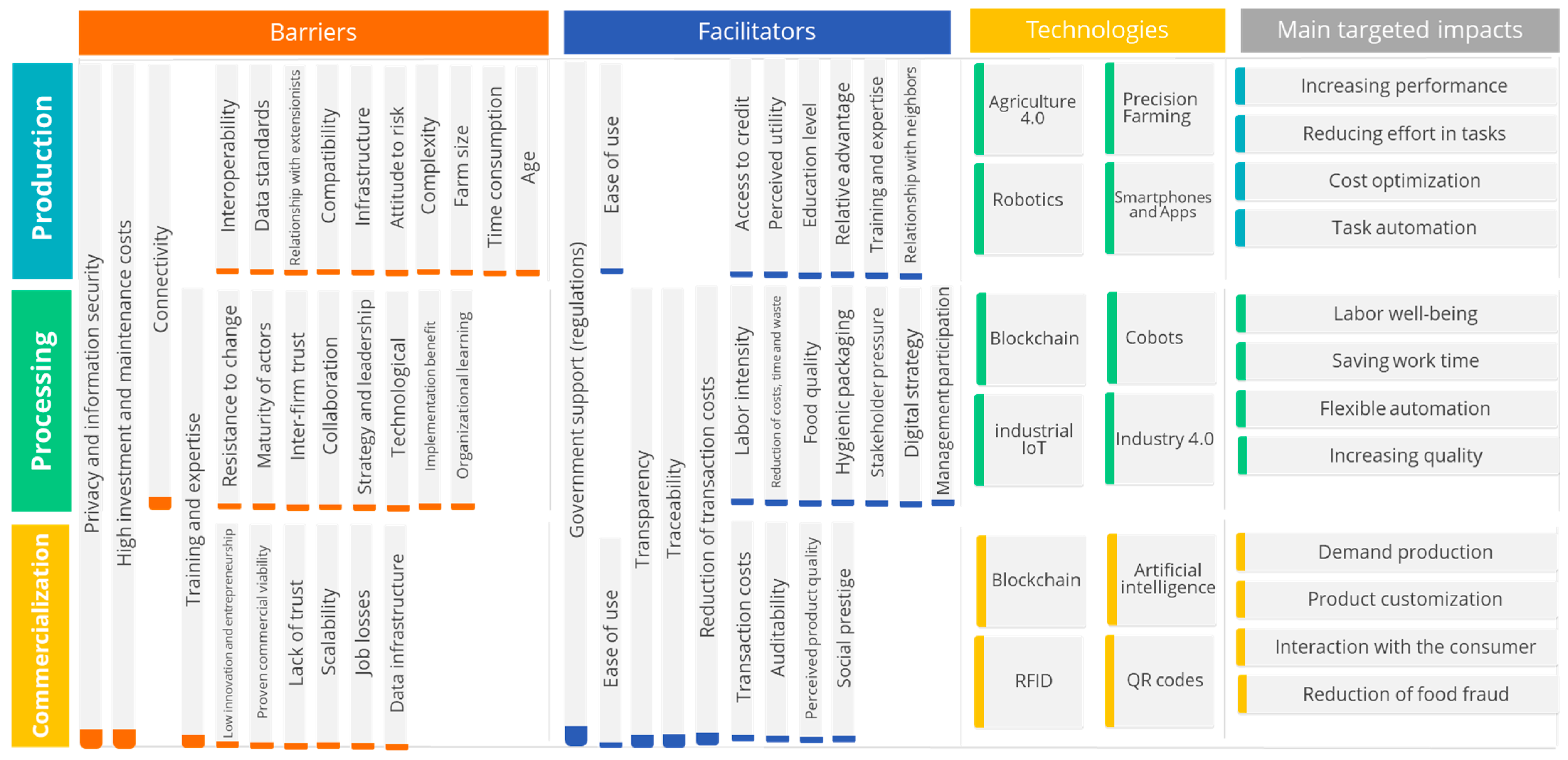

4.3. Barriers and Enablers Identified for the Production Link

| Barrier | Description | Chain | Technology | Reference |

|---|---|---|---|---|

| Interoperability | This allows technologies to exchange data in a fluid manner. | Banana | Agriculture 4.0 | [10,78] |

| Age | The chronological age of potential users influences their risk perception and usefulness levels, which is why many studies have focused on evaluating how young people or adults exhibit different patterns of technology adoption. | Coffee Pisciculture | Agriculture 4.0 Precision farming Smartphone Smart weeding Wireless sensor networks | [10,13,14,15,79,80,81,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98] |

| Cost | The costs associated with the purchase, rental, and maintenance of technologies reduce or motivate their adoption. | Not mentioned | Agriculture 4.0 Smartphone | [10,12,13,79,90,93,94,96,99,100,101,102,103] |

| Complexity | It is related to the difficulty in understanding, controlling, and managing the technologies to be adopted. | Not mentioned | Agriculture 4.0 | [4,10,13,77,104,105] |

| Privacy and information security | The privacy and security of information poses a risk for the parties involved, which is why it becomes a risk that farmers prefer not to take. | Not mentioned | Agriculture 4.0 Robotic Smart weeding | [10,11,12,13,14,15] |

| Data standards | How the organization is structured is a barrier, given that low data quality and interoperability become barriers to its reuse and comparability. | Not mentioned | Agriculture 4.0 | [10,13] |

| Time consumption | The time commitment required for implementing and using technologies can limit their adoption. | Not mentioned | Agriculture 4.0 | [10,13,80,98] |

| Compatibility | The adoption of technologies also depends on the ease with which they can be coupled with other technologies already implemented. | Not mentioned | Agriculture 4.0 | [8,13,79,93,94,104,105,106] |

| Infrastructure | The physical infrastructure required for the implementation of technologies, both internal and external, limits their adoption and use. | Not mentioned | Agriculture 4.0 Precision agriculture | [12,101,104] |

| Attitude towards risk | The perception of risk, especially in terms of return on investment, limits the adoption of technologies. | Banana | Precision farming IoT | [4,8,13,78,80,93,94,103,104,107,108,109] |

| Relationship with extension agents | Technologies promoted by external agents require assertive communication and relationships between the parties to achieve their proper implementation. | Sugarcane Maize | Precision farming | [8,13,79,81,94,96,99,108,110,111] |

| Farm size | The size of the farm has been analyzed as a limitation in the adoption of technologies; farms of smaller size are especially less likely to adopt. | Grapes Coffee Maize | Satellite maps Smartphone Smart weeding | [4,13,14,80,81,82,83,84,90,92,94,95,96,103,108,111,112] |

| Connectivity | Technologies associated with Food Informatics require an Internet connection, so infrastructure is necessary in production areas. | Not mentioned | Information management system Agriculture 4.0 Smartphone | [10,90,100,104,113] |

| Job losses | Farmers associate the adoption of technologies with the loss of jobs, so they prefer to abstain from using them. | Not mentioned | Precision agriculture | [12] |

| Enabler | Description | Chain | Technology | Reference |

|---|---|---|---|---|

| Access to credit | Acquiring technologies through credit facilitates access to technology, since it allows current access with the commitment to pay for it in a certain period. | Sugarcane | Precision farming | [13,79,110] |

| Ease of use | Ease of use is an enabler studied through different technology acceptance models and is directly associated with the simplicity and intuition with which a user can use the technology. Complex technologies are less adoptable. | Not mentioned | Agriculture 4.0 Precision agriculture | [10,13,79,89,93,98] |

| Perceived usefulness | Ease of use is an enabler studied through different technology acceptance models and is associated with the degree to which a user believes that the technology will improve their performance or solve the identified problem. | Sugarcane | Artificial intelligence | [13,81,89,93,98,110] |

| Level of education | The educational level has been analyzed as an important variable in the adoption processes, considering that it can range from secondary to postgraduate levels. | Sugarcane Pisciculture Maize | Agriculture 4.0 Smartphone Smart weeding | [15,78,82,86,88,90,91,111,123,124] |

| Relative advantage | The level of efficiency or competitiveness that adopting a technology can provide is also a key element for technological adoption. | Not mentioned | Agriculture 4.0 IoT Precision agriculture | [4,8,10,13,15,93,97,103,105,106,107,125] |

| User training, skills, and experience | The skills and experience of the user facilitate the process of importing and using the technology. | Sugarcane | Agriculture 4.0 Smartphone | [10,12,81,82,89,94,96,100,108,110,125,126] |

| Relationship with neighbors | The possibility of sharing experiences and learning through associative networks or even neighbors generates confidence about using or not certain technologies. | Not mentioned | Fertilization technologies Wireless sensor networks | [4,15,89,95,127] |

| Government support | Policies associated with promoting and using technologies through programs or subsidies can facilitate the adoption process because they reduce acquisition, operation, maintenance, and training costs. | Not mentioned | Precision agriculture | [15,107,120,121,122] |

4.4. Barriers and Enablers Identified for the Processing Link

4.5. Barriers and Enablers Identified for the Marketing Link

| Barrier | Description | Technology | Authors |

|---|---|---|---|

| Data privacy and security | The privacy and security of information captured through various means of consumer preference or consumption patterns or preferences has an impact. | Blockchain | [6,155,156] |

| Data infrastructure and storage costs | The costs associated with deploying the infrastructure and its operation limit the adoption processes when these are high, and there are no subsidies or benefits. | Blockchain | [155,157] |

| Data infrastructure | The costs of servers and energy consumption to carry out the processes of capturing, storing, and processing information have an impact. | Blockchain | [155,157] |

| Lack of expertise | Technologies 4.0 require expertise not only to create them, but also to operate them. The above generates discomfort among operators. | Blockchain | [150,155] |

| Low innovation and entrepreneurship | The willingness to adopt technology and innovate also depends on the ability to recognize the value of information in the environment to apply it to their benefit. | Blockchain | [155] |

| Proven commercial viability | Technologies that have been validated under the normal conditions of use and operation and through pilots are more likely to be adopted because users can check the experiences of third parties. | Blockchain | [155] |

| Lack of trust between stakeholders | The lack of trust between participants in delivering information and maintaining its custody and integrity limits the exchange of data and the adoption of technologies. | Blockchain | [53] |

| Scalability | If the number of information capture nodes is low, the speed and number of transactions are limited. | Blockchain | [157] |

| Job losses | Using technologies that incorporate AI is considered a threat to job loss. | Artificial intelligence | [41] |

5. Discussion

Research Implications

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gharehgozli, A.; Iakovou, E.; Chang, Y.; Swaney, R. Trends in Global E-Food Supply Chain and Implications for Transport: Literature Review and Research Directions. Res. Transp. Bus. Manag. 2017, 25, 2–14. [Google Scholar] [CrossRef]

- Godfray, H.C.J.; Beddington, J.R.; Crute, I.R.; Haddad, L.; Lawrence, D.; Muir, J.F.; Pretty, J.; Robinson, S.; Thomas, S.M.; Toulmin, C. Food Security: The Challenge of Feeding 9 Billion People. Science 2010, 327, 812–818. [Google Scholar] [CrossRef] [PubMed]

- Ronaghi, M.H.; Forouharfar, A. A Contextualized Study of the Usage of the Internet of Things (IoTs) in Smart Farming in a Typical Middle Eastern Country within the Context of Unified Theory of Acceptance and Use of Technology Model (UTAUT). Technol. Soc. 2020, 63, 101415. [Google Scholar] [CrossRef]

- Nguyen, L.L.H.; Halibas, A.; Nguyen, T.Q. Determinants of Precision Agriculture Technology Adoption in Developing Countries: A Review. J. Crop Improv. 2023, 37, 1–24. [Google Scholar] [CrossRef]

- Verma, A.; Bhattacharya, P.; Madhani, N.; Trivedi, C.; Bhushan, B.; Tanwar, S.; Sharma, G.; Bokoro, P.N.; Sharma, R. Blockchain for Industry 5.0: Vision, Opportunities, Key Enablers, and Future Directions. IEEE Access 2022, 10, 69160–69199. [Google Scholar] [CrossRef]

- Saha, A.; Raut, R.D.; Kumar, M. Leveraging Blockchain Technology to Combat Food Fraud in the Agri-food Supply Chain. Int. J. Food Sci. Technol. 2024, 59, 3469–3477. [Google Scholar] [CrossRef]

- Bader, F.; Rahimifard, S. Challenges for Industrial Robot Applications in Food Manufacturing. In Proceedings of the 2nd International Symposium on Computer Science and Intelligent Control, New York, NY, USA, 21 September 2018; pp. 1–8. [Google Scholar]

- Pathak, H.S.; Brown, P.; Best, T. A Systematic Literature Review of the Factors Affecting the Precision Agriculture Adoption Process. Precis. Agric. 2019, 20, 1292–1316. [Google Scholar] [CrossRef]

- Vu, N.; Ghadge, A.; Bourlakis, M. Blockchain Adoption in Food Supply Chains: A Review and Implementation Framework. Prod. Plan. Control 2023, 34, 506–523. [Google Scholar] [CrossRef]

- Giua, C.; Materia, V.C.; Camanzi, L. Management Information System Adoption at the Farm Level: Evidence from the Literature. Br. Food J. 2021, 123, 884–909. [Google Scholar] [CrossRef]

- Basu, S.; Omotubora, A.; Beeson, M.; Fox, C. Legal Framework for Small Autonomous Agricultural Robots. AI Soc. 2020, 35, 113–134. [Google Scholar] [CrossRef]

- Ofori, M.; El-Gayar, O. Drivers and Challenges of Precision Agriculture: A Social Media Perspective. Precis. Agric. 2021, 22, 1019–1044. [Google Scholar] [CrossRef]

- Osrof, H.Y.; Tan, C.L.; Angappa, G.; Yeo, S.F.; Tan, K.H. Adoption of Smart Farming Technologies in Field Operations: A Systematic Review and Future Research Agenda. Technol. Soc. 2023, 75, 102400. [Google Scholar] [CrossRef]

- Feisthauer, P.; Hartmann, M.; Börner, J. Adoption Intentions of Smart Weeding Technologies—A Lab-in-the-Field Experiment with German Crop Farmers. Q Open 2024, 4, qoae002. [Google Scholar] [CrossRef]

- Phuensane, P.; Jaroenwanit, P.; Hongthong, P. Influence of Demographic Characteristics and Extrinsic Motivations on Farmers’ Smart Farming Adoption in Northeastern Thailand. GMSARN Int. J. 2022, 16, 359–365. [Google Scholar]

- Poppe, K.; Vrolijk, H.; van Dijk, R. Design of a System for Information Transfer to Reduce Administrative Burdens in the Agrifood Sector. Int. J. Food Syst. Dyn. 2021, 12, 301–313. [Google Scholar] [CrossRef]

- Sittón-Candanedo, I.; Alonso, R.S.; Corchado, J.M.; Rodríguez-González, S.; Casado-Vara, R. A Review of Edge Computing Reference Architectures and a New Global Edge Proposal. Futur. Gener. Comput. Syst. 2019, 99, 278–294. [Google Scholar] [CrossRef]

- Roussaki, I.; Doolin, K.; Skarmeta, A.; Routis, G.; Lopez-Morales, J.A.; Claffey, E.; Mora, M.; Martinez, J.A. Building an Interoperable Space for Smart Agriculture. Digit. Commun. Netw. 2023, 9, 183–193. [Google Scholar] [CrossRef]

- Orjuela-Garzón, W.A.; Quintero-ramírez, S. Behavioral Patterns of Agents in the Transfer Processes of (Internet of Things) IoT Technologies in Agricultural Production Chains. J. Eng. Appl. Sci. 2020, 15, 1728–1736. [Google Scholar] [CrossRef]

- Tsolakis, N.K.; Keramydas, C.A.; Toka, A.K.; Aidonis, D.A.; Iakovou, E.T. Agrifood Supply Chain Management: A Comprehensive Hierarchical Decision-Making Framework and a Critical Taxonomy. Biosyst. Eng. 2014, 120, 47–64. [Google Scholar] [CrossRef]

- Fróna, D.; Szenderák, J.; Harangi-Rákos, M. The Challenge of Feeding the World. Sustainability 2019, 11, 5816. [Google Scholar] [CrossRef]

- Kamilaris, A.; Cole, I.R.; Prenafeta-Boldú, F.X. Blockchain in Agriculture. In Food Technology Disruptions; Elsevier: Amsterdam, The Netherlands, 2021; pp. 247–284. [Google Scholar]

- Gebbers, R.; Adamchuk, V.I. Precision Agriculture and Food Security. Science 2010, 327, 828–831. [Google Scholar] [CrossRef]

- Wolfert, S.; Ge, L.; Verdouw, C.; Bogaardt, M.J. Big Data in Smart Farming? A Review. Agric. Syst. 2017, 153, 69–80. [Google Scholar] [CrossRef]

- Krupitzer, C.; Stein, A. Food Informatics—Review of the Current State-of-the-Art, Revised Definition, and Classification into the Research Landscape. Foods 2021, 10, 2889. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.D.; He, W.; Li, S. Internet of Things in Industries: A Survey. IEEE Trans. Ind. Inform. 2014, 10, 2233–2243. [Google Scholar] [CrossRef]

- Luque, A.; Peralta, M.E.; de las Heras, A.; Córdoba, A. State of the Industry 4.0 in the Andalusian Food Sector. Procedia Manuf. 2017, 13, 1199–1205. [Google Scholar] [CrossRef]

- Min, W.; Jiang, S.; Liu, L.; Rui, Y.; Jain, R. A Survey on Food Computing. ACM Comput. Surv. 2020, 52, 1–36. [Google Scholar] [CrossRef]

- Abad, E.; Palacio, F.; Nuin, M.; de Zárate, A.G.; Juarros, A.; Gómez, J.M.; Marco, S. RFID Smart Tag for Traceability and Cold Chain Monitoring of Foods: Demonstration in an Intercontinental Fresh Fish Logistic Chain. J. Food Eng. 2009, 93, 394–399. [Google Scholar] [CrossRef]

- Mondal, S.; Wijewardena, K.P.; Karuppuswami, S.; Kriti, N.; Kumar, D.; Chahal, P. Blockchain Inspired RFID-Based Information Architecture for Food Supply Chain. IEEE Internet Things J. 2019, 6, 5803–5813. [Google Scholar] [CrossRef]

- van Deursen, A.J.A.M.; Mossberger, K. Any Thing for Anyone? A New Digital Divide in Internet-of-Things Skills. Policy Internet 2018, 10, 122–140. [Google Scholar] [CrossRef]

- Carlsson, B. Technological Systems and Economic Growth: Comparing Finland, Sweden, Japan, and the United States. In Explaining Technical Change in a Small Country; Vuori, S., Vuorinen, P., Eds.; Physica-Verlag HD: Heidelberg, Germany, 1994; pp. 159–183. ISBN 3790807605. [Google Scholar]

- Chen, Y. Teaching Material in Technology Transfer; Yuan Ze University Press: Taoyuan City, Taiwan, 1995. [Google Scholar]

- Lipinski, J.; Minutolo, M.C.; Crothers, L.M. The Complex Relationship Driving Technology Transfer: The Potential Opportunities Missed by Universites. J. Behav. Appl. Manag. 2008, 9, 112–133. [Google Scholar] [CrossRef]

- Verma, P.; Sinha, N. Integrating Perceived Economic Wellbeing to Technology Acceptance Model: The Case of Mobile Based Agricultural Extension Service. Technol. Forecast. Soc. Chang. 2018, 126, 207–216. [Google Scholar] [CrossRef]

- Mahdad, M.; Hasanov, M.; Isakhanyan, G.; Dolfsma, W. A Smart Web of Firms, Farms and Internet of Things (IOT): Enabling Collaboration-Based Business Models in the Agri-Food Industry. Br. Food J. 2022, 124, 1857–1874. [Google Scholar] [CrossRef]

- Centerholt, V.; Kjidderö, F.; Saarikko, T.; Grahn, S. Value Chains vs. Ecosystems: Current Perspectives Among Swedish SMEs Entering the Interconnected World of IoT. Adv. Transdiscipl. Eng. 2020, 13, 489–500. [Google Scholar] [CrossRef]

- Konur, S.; Lan, Y.; Thakker, D.; Morkyani, G.; Polovina, N.; Sharp, J. Towards Design and Implementation of Industry 4.0 for Food Manufacturing. Neural Comput. Appl. 2023, 35, 23753–23765. [Google Scholar] [CrossRef]

- Rogers, E.M. Diffusion of Innovations, 3rd ed.; Macmillan Publishing: New York, NY, USA, 1962; ISBN 0028740742 (CLOTH) 0029266718 (PAPER). [Google Scholar]

- Tohidyan, S.; Rezaei-Moghaddam, K. Determinants of Iranian Agricultural Consultants’ Intentions toward Precision Agriculture: Integrating Innovativeness to the Technology Acceptance Model. J. Saudi Soc. Agric. Sci. 2017, 16, 280–286. [Google Scholar] [CrossRef]

- Bačiulienė, V.; Bilan, Y.; Navickas, V.; Civín, L. The Aspects of Artificial Intelligence in Different Phases of the Food Value and Supply Chain. Foods 2023, 12, 1654. [Google Scholar] [CrossRef]

- Spanaki, K.; Karafili, E.; Sivarajah, U.; Despoudi, S.; Irani, Z. Artificial Intelligence and Food Security: Swarm Intelligence of AgriTech Drones for Smart AgriFood Operations. Prod. Plan. Control 2022, 33, 1498–1516. [Google Scholar] [CrossRef]

- Talaviya, T.; Shah, D.; Patel, N.; Yagnik, H.; Shah, M. Implementation of Artificial Intelligence in Agriculture for Optimisation of Irrigation and Application of Pesticides and Herbicides. Artif. Intell. Agric. 2020, 4, 58–73. [Google Scholar] [CrossRef]

- Misra, N.N.; Dixit, Y.; Al-Mallahi, A.; Bhullar, M.S.; Upadhyay, R.; Martynenko, A. IoT, Big Data, and Artificial Intelligence in Agriculture and Food Industry. IEEE Internet Things J. 2022, 9, 6305–6324. [Google Scholar] [CrossRef]

- Al-Sarayreh, M.; Gomes Reis, M.; Carr, A.; Reis, M.M. dos Inverse Design and AI/Deep Generative Networks in Food Design: A Comprehensive Review. Trends Food Sci. Technol. 2023, 138, 215–228. [Google Scholar] [CrossRef]

- Buyuktepe, O.; Catal, C.; Kar, G.; Bouzembrak, Y.; Marvin, H.; Gavai, A. Food Fraud Detection Using Explainable Artificial Intelligence. Expert Syst. 2023, e13387. [Google Scholar] [CrossRef]

- Dadhaneeya, H.; Nema, P.K.; Arora, V.K. Internet of Things in Food Processing and Its Potential in Industry 4.0 Era: A Review. Trends Food Sci. Technol. 2023, 139, 104109. [Google Scholar] [CrossRef]

- Wu, B.; Gao, B.; Xu, W.; Wang, H.; Yi, Y.; Premalatha, R. Sustainable Food Smart Manufacturing Technology. Inf. Process. Manag. 2022, 59, 102754. [Google Scholar] [CrossRef]

- Grover, J. Industrial IoT and Its Applications. In IoT for Sustainable Smart Cities and Society; Springer International Publishing: Cham, Switzerland, 2022; pp. 107–124. [Google Scholar]

- Redchuk, A.; Walas Mateo, F.; Pascal, G.; Tornillo, J.E. Adoption Case of IIoT and Machine Learning to Improve Energy Consumption at a Process Manufacturing Firm, under Industry 5.0 Model. Big Data Cogn. Comput. 2023, 7, 42. [Google Scholar] [CrossRef]

- Treiblmaier, H. The Impact of the Blockchain on the Supply Chain: A Theory-Based Research Framework and a Call for Action. Supply Chain Manag. Int. J. 2018, 23, 545–559. [Google Scholar] [CrossRef]

- Treiblmaier, H.; Garaus, M. Using Blockchain to Signal Quality in the Food Supply Chain: The Impact on Consumer Purchase Intentions and the Moderating Effect of Brand Familiarity. Int. J. Inf. Manag. 2023, 68, 102514. [Google Scholar] [CrossRef]

- Mohammed, A.; Potdar, V.; Quaddus, M.; Hui, W. Blockchain Adoption in Food Supply Chains: A Systematic Literature Review on Enablers, Benefits, and Barriers. IEEE Access 2023, 11, 14236–14255. [Google Scholar] [CrossRef]

- Rajak, A.R.A. Emerging Technological Methods for Effective Farming by Cloud Computing and IoT. Emerg. Sci. J. 2022, 6, 1017–1031. [Google Scholar] [CrossRef]

- Duan, P.; Wang, W.; Zhang, W.; Gong, F.; Zhang, P.; Rao, Y. Food Image Recognition Using Pervasive Cloud Computing. In Proceedings of the 2013 IEEE International Conference on Green Computing and Communications and IEEE Internet of Things and IEEE Cyber, Physical and Social Computing, Beijing, China, 20–23 August 2013; pp. 1631–1637. [Google Scholar]

- Guo, Y.; Chen, Y.; Wei, W.; Li, H. Research on Food Recommendation Method Based on Knowledge Graph. In International Conference on Computer Science and Education; Springer Nature Singapore: Singapore, 2022; pp. 521–533. [Google Scholar]

- Gilal, N.U.; Al-Thelaya, K.; Al-Saeed, J.K.; Abdallah, M.; Schneider, J.; She, J.; Awan, J.H.; Agus, M. Evaluating Machine Learning Technologies for Food Computing from a Data Set Perspective. Multimed. Tools Appl. 2023, 83, 32041–32068. [Google Scholar] [CrossRef]

- Liu, C.; Cao, Y.; Luo, Y.; Chen, G.; Vokkarane, V.; Yunsheng, M.; Chen, S.; Hou, P. A New Deep Learning-Based Food Recognition System for Dietary Assessment on An Edge Computing Service Infrastructure. IEEE Trans. Serv. Comput. 2018, 11, 249–261. [Google Scholar] [CrossRef]

- Akhtar, M.N.; Shaikh, A.J.; Khan, A.; Awais, H.; Bakar, E.A.; Othman, A.R. Smart Sensing with Edge Computing in Precision Agriculture for Soil Assessment and Heavy Metal Monitoring: A Review. Agriculture 2021, 11, 475. [Google Scholar] [CrossRef]

- Gai, K.; Fang, Z.; Wang, R.; Zhu, L.; Jiang, P.; Choo, K.-K.R. Edge Computing and Lightning Network Empowered Secure Food Supply Management. IEEE Internet Things J. 2022, 9, 14247–14259. [Google Scholar] [CrossRef]

- Soltani Firouz, M.; Mohi-Alden, K.; Omid, M. A Critical Review on Intelligent and Active Packaging in the Food Industry: Research and Development. Food Res. Int. 2021, 141, 110113. [Google Scholar] [CrossRef] [PubMed]

- Ghaani, M.; Cozzolino, C.A.; Castelli, G.; Farris, S. An Overview of the Intelligent Packaging Technologies in the Food Sector. Trends Food Sci. Technol. 2016, 51, 1–11. [Google Scholar] [CrossRef]

- Carolan, M. Automated Agrifood Futures: Robotics, Labor and the Distributive Politics of Digital Agriculture. J. Peasant Stud. 2020, 47, 184–207. [Google Scholar] [CrossRef]

- Iqbal, J.; Khan, Z.H.; Khalid, A. Prospects of Robotics in Food Industry. Food Sci. Technol. 2017, 37, 159–165. [Google Scholar] [CrossRef]

- Duong, L.N.K.; Al-Fadhli, M.; Jagtap, S.; Bader, F.; Martindale, W.; Swainson, M.; Paoli, A. A Review of Robotics and Autonomous Systems in the Food Industry: From the Supply Chains Perspective. Trends Food Sci. Technol. 2020, 106, 355–364. [Google Scholar] [CrossRef]

- Hassoun, A.; Aït-Kaddour, A.; Abu-Mahfouz, A.M.; Rathod, N.B.; Bader, F.; Barba, F.J.; Biancolillo, A.; Cropotova, J.; Galanakis, C.M.; Jambrak, A.R.; et al. The Fourth Industrial Revolution in the Food Industry—Part I: Industry 4.0 Technologies. Crit. Rev. Food Sci. Nutr. 2023, 63, 6547–6563. [Google Scholar] [CrossRef]

- Li, Y.; Su, D.A.; Mardani, A. Digital Twins and Blockchain Technology in the Industrial Internet of Things (IIoT) Using an Extended Decision Support System Model: Industry 4.0 Barriers Perspective. Technol. Forecast. Soc. Chang. 2023, 195, 122794. [Google Scholar] [CrossRef]

- Vu, N.; Ghadge, A.; Bourlakis, M. Evidence-Driven Model for Implementing Blockchain in Food Supply Chains. Int. J. Logist. Res. Appl. 2023, 26, 568–588. [Google Scholar] [CrossRef]

- Orjuela-Garzón, W.A.; Rincón-Moreno, J.A.; Méndez-Arteaga, J.J. Trends in the Use and Recovery of Electronic Waste As Aggregates in Eco-Friendly Concrete. J. Solid Waste Technol. Manag. 2021, 47, 513–528. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef] [PubMed]

- Andrade Navia, M.; Ramirez Plazas, E.; Orjuela-Garzon, W.A. Vigilancia Tecnológica Aplicada a La Cadena Productiva de Cacao. Espacios 2018, 39, 1–11. [Google Scholar]

- Caputo, A.; Kargina, M. A User-Friendly Method to Merge Scopus and Web of Science Data during Bibliometric Analysis. J. Mark. Anal. 2022, 10, 82–88. [Google Scholar] [CrossRef]

- Aria, M.; Cuccurullo, C. Bibliometrix: An R-Tool for Comprehensive Science Mapping Analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- Venkatesh, V.; Morris, M.G.; Davis, G.B. User Acceptance of Information Technology: Toward a Unified View. MIS Q. 2003, 27, 425–478. [Google Scholar] [CrossRef]

- Davis, F.D. Perceived Usefulness, Perceived Ease of Use, and User Acceptance of Information Technology. Manag. Inf. Syst. Res. Cent. 1989, 13, 319–340. [Google Scholar] [CrossRef]

- Fishbein, M.; Ajzen, I. Belief, Attitude, Intention and Behaviour: An Introduction to Theory and Research. Philos. Rhetor. 1977, 10, 130–132. [Google Scholar]

- Vecchio, Y.; De Rosa, M.; Pauselli, G.; Masi, M.; Adinolfi, F. The Leading Role of Perception: The FACOPA Model to Comprehend Innovation Adoption. Agric. Food Econ. 2022, 10, 5. [Google Scholar] [CrossRef]

- Franco, D.; Singh, D.R.; Praveen, K.V. Evaluation of Adoption of Precision Farming and Its Profitability in Banana Crop. Indian J. Econ. Dev. 2018, 14, 225. [Google Scholar] [CrossRef]

- Yatribi, T. Factors Affecting Precision Agriculture Adoption: A Systematic Litterature Review. Economics 2020, 8, 103–121. [Google Scholar] [CrossRef]

- Michels, M.; von Hobe, C.F.; Musshoff, O. A Trans-Theoretical Model for the Adoption of Drones by Large-Scale German Farmers. J. Rural Stud. 2020, 75, 80–88. [Google Scholar] [CrossRef]

- John, D.; Hussin, N.; Shahibi, M.S.; Ahmad, M.; Hashim, H.; Ametefe, D.S. A Systematic Review on the Factors Governing Precision Agriculture Adoption among Small-Scale Farmers. Outlook Agric. 2023, 52, 469–485. [Google Scholar] [CrossRef]

- Michels, M.; Fecke, W.; Feil, J.H.; Musshoff, O.; Pigisch, J.; Krone, S. Smartphone Adoption and Use in Agriculture: Empirical Evidence from Germany. Precis. Agric. 2020, 21, 403–425. [Google Scholar] [CrossRef]

- Luther, Z.R.; Swinton, S.M.; van Deynze, B. What Drives Voluntary Adoption of Farming Practices That Can Abate Nutrient Pollution? J. Soil Water Conserv. 2020, 75, 640–650. [Google Scholar] [CrossRef]

- Bahri, T.S.; Manyamsari, I.; Putri, R.J.; Iskandar, E. Technology Needs Assessment for the Development of Smart Coffee Production in Aceh, Indonesia. IOP Conf. Ser. Earth Environ. Sci. 2024, 1290, 012053. [Google Scholar] [CrossRef]

- Weir, M.J.; Sproul, T.W. Identifying Drivers of Genetically Modified Seafood Demand: Evidence from a Choice Experiment. Sustainability 2019, 11, 3934. [Google Scholar] [CrossRef]

- Amoussouhoui, R.; Arouna, A.; Ruzzante, S.; Banout, J. Adoption of ICT4D and Its Determinants: A Systematic Review and Meta-Analysis. Heliyon 2024, 10, e30210. [Google Scholar] [CrossRef]

- Vecchio, Y.; Agnusdei, G.P.; Miglietta, P.P.; Capitanio, F. Adoption of Precision Farming Tools: The Case of Italian Farmers. Int. J. Environ. Res. Public Health 2020, 17, 869. [Google Scholar] [CrossRef]

- Kasinath, B.L.; Lal, S.V.; Kumar, S.; Kapoor, P.; Basantia, D.; Meena, B.L.; Kumar, M.; Paul, T.; Ahmed, S.K.Z.; Kundu, A. Knowledge Level of North Andaman Farmers towards Scientific Vegetable Cultivation Practices-a Case Study. Plant Arch. 2018, 18, 2443–2447. [Google Scholar]

- Taheri, F.; D’Haese, M.; Fiems, D.; Azadi, H. The Intentions of Agricultural Professionals towards Diffusing Wireless Sensor Networks: Application of Technology Acceptance Model in Southwest Iran. Technol. Forecast. Soc. Chang. 2022, 185, 122075. [Google Scholar] [CrossRef]

- Marescotti, M.E.; Demartini, E.; Filippini, R.; Gaviglio, A. Smart Farming in Mountain Areas: Investigating Livestock Farmers’ Technophobia and Technophilia and Their Perception of Innovation. J. Rural Stud. 2021, 86, 463–472. [Google Scholar] [CrossRef]

- Molina-Maturano, J.; Verhulst, N.; Tur-Cardona, J.; Güereña, D.T.; Gardeazábal-Monsalve, A.; Govaerts, B.; Speelman, S. Understanding Smallholder Farmers’ Intention to Adopt Agricultural Apps: The Role of Mastery Approach and Innovation Hubs in Mexico. Agronomy 2021, 11, 194. [Google Scholar] [CrossRef]

- Blasch, J.; Vuolo, F.; Essl, L.; van der Kroon, B. Drivers and Barriers Influencing the Willingness to Adopt Technologies for Variable Rate Application of Fertiliser in Lower Austria. Agronomy 2021, 11, 1965. [Google Scholar] [CrossRef]

- Sood, A.; Bhardwaj, A.K.; Sharma, R.K. Towards Sustainable Agriculture: Key Determinants of Adopting Artificial Intelligence in Agriculture. J. Decis. Syst. 2022, 1–45. [Google Scholar] [CrossRef]

- Kendall, H.; Clark, B.; Li, W.; Jin, S.; Jones, G.D.; Chen, J.; Taylor, J.; Li, Z.; Frewer, L.J. Precision Agriculture Technology Adoption: A Qualitative Study of Small-Scale Commercial “Family Farms” Located in the North China Plain. Precis. Agric. 2022, 23, 1–33. [Google Scholar] [CrossRef]

- Konrad, M.T.; Nielsen, H.Ø.; Pedersen, A.B.; Elofsson, K. Drivers of Farmers’ Investments in Nutrient Abatement Technologies in Five Baltic Sea Countries. Ecol. Econ. 2019, 159, 91–100. [Google Scholar] [CrossRef]

- Pérez-Ortega, D.J.; Bolaños-Alomia, F.A.; da Silva, A.M. Variables That Influence the Application of Precision Agriculture in Colombia: Review of Studies. Cienc. Tecnol. Agropecu. 2022, 23, e2298. [Google Scholar] [CrossRef]

- Kolady, D.E.; Van der Sluis, E.; Uddin, M.M.; Deutz, A.P. Determinants of Adoption and Adoption Intensity of Precision Agriculture Technologies: Evidence from South Dakota. Precis. Agric. 2021, 22, 689–710. [Google Scholar] [CrossRef]

- Hrynevych, O.; Canto, M.B.; García, M.J. Tendencies of Precision Agriculture in Ukraine: Disruptive Smart Farming Tools as Cooperation Drivers. Agriculture 2022, 12, 698. [Google Scholar] [CrossRef]

- Balogh, P.; Bujdos, Á.; Czibere, I. Main Motivational Factors of Farmers Adopting Precision Farming in Hungary. Agronomy 2020, 10, 610. [Google Scholar] [CrossRef]

- Kenny, U.; Regan, Á. Co-Designing a Smartphone App for and with Farmers: Empathising with End-Users’ Values and Needs. J. Rural Stud. 2021, 82, 148–160. [Google Scholar] [CrossRef]

- Gusev, A.S.; Betin, O.I.; Skvortsov, E.A.; Ziablitckaia, N.V.; Vashukevich, N.V.; Malkova, Y.V. The Analysis of Factors and Motivative Aspects Promoting and Hindering the Implementation of Precision Farming Technologies. WSEAS Trans. Environ. Dev. 2020, 16, 820–830. [Google Scholar] [CrossRef]

- Blasch, J.; Van Der Kroon, B.; Van Beukering, P.; Munster, R.; Fabiani, S.; Nino, P.; Vanino, S. Farmer Preferences for Adopting Precision Farming Technologies: A Case Study from Italy. Eur. Rev. Agric. Econ. 2022, 49, 33–81. [Google Scholar] [CrossRef]

- Khanna, M.; Atallah, S.S.; Kar, S.; Sharma, B.; Wu, L.; Yu, C.; Chowdhary, G.; Soman, C.; Guan, K. Digital Transformation for a Sustainable Agriculture in the United States: Opportunities and Challenges. Agric. Econ. 2022, 53, 924–937. [Google Scholar] [CrossRef]

- Fragomeli, R.; Annunziata, A.; Punzo, G. Promoting the Transition towards Agriculture 4.0: A Systematic Literature Review on Drivers and Barriers. Sustainability 2024, 16, 2425. [Google Scholar] [CrossRef]

- Tama, R.A.Z.; Hoque, M.M.; Liu, Y.; Alam, M.J.; Yu, M. An Application of Partial Least Squares Structural Equation Modeling (PLS-SEM) to Examining Farmers’ Behavioral Attitude and Intention towards Conservation Agriculture in Bangladesh. Agriculture 2023, 13, 503. [Google Scholar] [CrossRef]

- Lee, C.L.; Strong, R.; Dooley, K.E. Analyzing Precision Agriculture Adoption across the Globe: A Systematic Review of Scholarship from 1999–2020. Sustainability 2021, 13, 295. [Google Scholar] [CrossRef]

- Harisudin, M.; Kusnandar; Riptanti, E.W.; Setyowati, N.; Khomah, I. Determinants of the Internet of Things Adoption by Millennial Farmers. AIMS Agric. Food 2023, 8, 329–342. [Google Scholar] [CrossRef]

- Carrer, M.J.; de Filho, H.M.S.; de Vinholis, M.M.B.; Mozambani, C.I. Precision Agriculture Adoption and Technical Efficiency: An Analysis of Sugarcane Farms in Brazil. Technol. Forecast. Soc. Chang. 2022, 177, 121510. [Google Scholar] [CrossRef]

- Pantazi, X.E.; Moshou, D.; Alexandridis, T.; Whetton, R.L.; Mouazen, A.M. Wheat Yield Prediction Using Machine Learning and Advanced Sensing Techniques. Comput. Electron. Agric. 2016, 121, 57–65. [Google Scholar] [CrossRef]

- Mozambani, C.I.; de Souza Filho, H.M.; de Vinholis, M.M.B.; Carrer, M.J. Adoption of Precision Agriculture Technologies by Sugarcane Farmers in the State of São Paulo, Brazil. Precis. Agric. 2023, 24, 1813–1835. [Google Scholar] [CrossRef]

- Amengor, N.E.; Awunyo-Vitor, D.; Owusu Asante, B.; Wongnaa, C.A. Awareness and Adoption of Drought Tolerant Maize in Guinea Savanna and Forest-Savanna Transition Zone in Ghana. Cogent Food Agric. 2022, 8, 2147476. [Google Scholar] [CrossRef]

- Groher, T.; Heitkämper, K.; Walter, A.; Liebisch, F.; Umstätter, C. Status Quo of Adoption of Precision Agriculture Enabling Technologies in Swiss Plant Production. Precis. Agric. 2020, 21, 1327–1350. [Google Scholar] [CrossRef]

- Benyam, A.; Soma, T.; Fraser, E. Digital Agricultural Technologies for Food Loss and Waste Prevention and Reduction: Global Trends, Adoption Opportunities and Barriers. J. Clean. Prod. 2021, 323, 129099. [Google Scholar] [CrossRef]

- Zheng, S.; Wang, Z.; Wachenheim, C.J. Technology Adoption among Farmers in Jilin Province, China. China Agric. Econ. Rev. 2019, 11, 206–216. [Google Scholar] [CrossRef]

- Watcharaanantapong, P.; Roberts, R.K.; Lambert, D.M.; Larson, J.A.; Velandia, M.; English, B.C.; Rejesus, R.M.; Wang, C. Timing of Precision Agriculture Technology Adoption in US Cotton Production. Precis. Agric. 2014, 15, 427–446. [Google Scholar] [CrossRef]

- Orjuela-Garzon, W.; Quintero, S.; Giraldo, D.P.; Lotero, L.; Nieto-Londoño, C. A Theoretical Framework for Analysing Technology Transfer Processes Using Agent-Based Modelling: A Case Study on Massive Technology Adoption (AMTEC) Program on Rice Production. Sustainability 2021, 13, 11143. [Google Scholar] [CrossRef]

- Higgins, V.; Bryant, M.; Howell, A.; Battersby, J. Ordering Adoption: Materiality, Knowledge and Farmer Engagement with Precision Agriculture Technologies. J. Rural Stud. 2017, 55, 193–202. [Google Scholar] [CrossRef]

- Michels, M.; Fecke, W.; Feil, J.H.; Musshoff, O.; Lülfs-Baden, F.; Krone, S. “Anytime, Anyplace, Anywhere”—A Sample Selection Model of Mobile Internet Adoption in German Agriculture. Agribusiness 2020, 36, 192–207. [Google Scholar] [CrossRef]

- Barnes, A.P.; Soto, I.; Eory, V.; Beck, B.; Balafoutis, A.; Sánchez, B.; Vangeyte, J.; Fountas, S.; van der Wal, T.; Gómez-Barbero, M. Exploring the Adoption of Precision Agricultural Technologies: A Cross Regional Study of EU Farmers. Land Use Policy 2019, 80, 163–174. [Google Scholar] [CrossRef]

- Cerro-Giner, J.D.; Sanz-Muñoz, D.; Valente, J.; Rossi, C.; Cancar, L.; Barrientos Cruz, A. Flota de Vehículos Aéreos Para Fotografía de Alta Resolución En Aplicaciones de Agricultura de Precisión. Proyecto RHEA. Actas Las XXXV Jorn. Automática 2014, 1, 1–7. [Google Scholar]

- Miao, R.; Khanna, M. Harnessing Advances in Agricultural Technologies to Optimize Resource Utilization in the Food-Energy-Water Nexus. Annu. Rev. Resour. Econ. 2020, 12, 65–85. [Google Scholar] [CrossRef]

- Khanna, M. Digital Transformation of the Agricultural Sector: Pathways, Drivers and Policy Implications. Appl. Econ. Perspect. Policy 2021, 43, 1221–1242. [Google Scholar] [CrossRef]

- Nguyen, L.L.H.; Khuu, D.T.; Halibas, A.; Nguyen, T.Q. Factors That Influence the Intention of Smallholder Rice Farmers to Adopt Cleaner Production Practices: An Empirical Study of Precision Agriculture Adoption. Eval. Rev. 2024, 48, 692–735. [Google Scholar] [CrossRef]

- Masi, M.; Di Pasquale, J.; Vecchio, Y.; Capitanio, F. Precision Farming: Barriers of Variable Rate Technology Adoption in Italy. Land 2023, 12, 1084. [Google Scholar] [CrossRef]

- Partalidou, M.; Paltaki, A.; Lazaridou, D.; Vieri, M.; Lombardo, S.; Michailidis, A. Business Model Canvas Analysis on Greek Farms Implementing Precision Agriculture. Agric. Econ. Rev. 2018, 19, A43–A58. [Google Scholar] [CrossRef]

- Cardenas Tamayo, R.A.; Lugo Ibarra, M.G.; Garcia Macias, J.A. Better Crop Management with Decision Support Systems Based on Wireless Sensor Networks. In Proceedings of the 7th International Conference on Electrical Engineering Computing Science and Automatic Control, Tuxtla Gutierrez, Mexico, 8–10 September 2010; pp. 412–417. [Google Scholar] [CrossRef]

- Bentivoglio, D.; Bucci, G.; Belletti, M.; Finco, A. A Theoretical Framework on Network’s Dynamics for Precision Agriculture Technologies Adoption. Rev. Econ. E Sociol. Rural 2022, 60, e245721. [Google Scholar] [CrossRef]

- Walton, J.C.; Larson, J.A.; Roberts, R.K.; Lambert, D.M.; English, B.C.; Larkin, S.L.; Marra, M.C.; Martin, S.W.; Paxton, K.W.; Reeves, J.M. Factors Influencing Farmer Adoption of Portable Computers for Site-Specific Management: A Case Study for Cotton Production. J. Agric. Appl. Econ. 2010, 42, 193–209. [Google Scholar] [CrossRef]

- Lewis, D.J.; Barham, B.L.; Robinson, B. Are There Spatial Spillovers in the Adoption of Clean Technology? The Case of Organic Dairy Farming. Land Econ. 2011, 87, 250–267. [Google Scholar] [CrossRef]

- Caffaro, F.; Micheletti Cremasco, M.; Roccato, M.; Cavallo, E. Drivers of Farmers’ Intention to Adopt Technological Innovations in Italy: The Role of Information Sources, Perceived Usefulness, and Perceived Ease of Use. J. Rural Stud. 2020, 76, 264–271. [Google Scholar] [CrossRef]

- Corista, P.; Ferreira, D.; Giao, J.; Sarraipa, J.; Goncalves, R.J. An IoT Agriculture System Using FIWARE. In Proceedings of the 2018 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), IEEE, Stuttgart, Germany, 17–20 June 2018; pp. 1–6. [Google Scholar]

- Fortineau, V.; Paviot, T.; Lamouri, S. Improving the Interoperability of Industrial Information Systems with Description Logic-Based Models—The State of the Art. Comput. Ind. 2013, 64, 363–375. [Google Scholar] [CrossRef]

- Malisic, B.; Misic, N.; Krco, S.; Martinovic, A.; Tinaj, S.; Popovic, T. Blockchain Adoption in the Wine Supply Chain: A Systematic Literature Review. Sustainability 2023, 15, 14408. [Google Scholar] [CrossRef]

- Jahanbin, P.; Wingreen, S.C.; Sharma, R.; Ijadi, B.; Reis, M.M. Enabling Affordances of Blockchain in Agri-Food Supply Chains: A Value-Driver Framework Using Q-Methodology. Int. J. Innov. Stud. 2023, 7, 307–325. [Google Scholar] [CrossRef]

- Yap, T.L.; Nayak, R.; Vu, N.T.H.; Bui, D.T.; Pham, T.T.T.; Allen, D.W.E. Adopting Blockchain-Based Traceability in the Fruit Supply Chain in a Developing Economy: Facilitators and Barriers. Inf. Technol. People 2023. [Google Scholar] [CrossRef]

- Cuel, R.; Cangelosi, G.M. In Vino Veritas? Blockchain Preliminary Effects on Italian Wine SMEs. In Digital Business Transformation: Organizing, Managing and Controlling in the Information Age; Springer: Berlin/Heidelberg, Germany, 2020; pp. 301–314. [Google Scholar]

- Romanello, R.; Veglio, V. Industry 4.0 in Food Processing: Drivers, Challenges and Outcomes. Br. Food J. 2022, 124, 375–390. [Google Scholar] [CrossRef]

- Hassoun, A.; Marvin, H.J.P.; Bouzembrak, Y.; Barba, F.J.; Castagnini, J.M.; Pallarés, N.; Rabail, R.; Aadil, R.M.; Bangar, S.P.; Bhat, R.; et al. Digital Transformation in the Agri-Food Industry: Recent Applications and the Role of the COVID-19 Pandemic. Front. Sustain. Food Syst. 2023, 7, 1217813. [Google Scholar] [CrossRef]

- Da Silva, F.T.; Baierle, I.C.; de Correa, R.G.F.; Sellitto, M.A.; Peres, F.A.P.; Kipper, L.M. Open Innovation in Agribusiness: Barriers and Challenges in the Transition to Agriculture 4.0. Sustainability 2023, 15, 8562. [Google Scholar] [CrossRef]

- Ali, I.; Aboelmaged, M.G.S. Implementation of Supply Chain 4.0 in the Food and Beverage Industry: Perceived Drivers and Barriers. Int. J. Product. Perform. Manag. 2022, 71, 1426–1443. [Google Scholar] [CrossRef]

- Pham, C.M.; Lokuge, S.; Nguyen, T.-T.; Adamopoulos, A. Exploring Knowledge Management Enablers for Blockchain-Enabled Food Supply Chain Implementations. J. Knowl. Manag. 2024, 28, 210–231. [Google Scholar] [CrossRef]

- Despoudi, S.; Sivarajah, U.; Spanaki, K.; Charles, V.; Durai, V.K. Industry 4.0 and Circular Economy for Emerging Markets: Evidence from Small and Medium-Sized Enterprises (SMEs) in the Indian Food Sector. Ann. Oper. Res. 2023. [Google Scholar] [CrossRef]

- Saurabh, S.; Dey, K. Blockchain Technology Adoption, Architecture, and Sustainable Agri-Food Supply Chains. J. Clean. Prod. 2021, 284, 124731. [Google Scholar] [CrossRef]

- Toader, D.-C.; Rădulescu, C.M.; Toader, C. Investigating the Adoption of Blockchain Technology in Agri-Food Supply Chains: Analysis of an Extended UTAUT Model. Agriculture 2024, 14, 614. [Google Scholar] [CrossRef]

- Sharma, A.; Sharma, A.; Singh, R.K.; Bhatia, T. Blockchain Adoption in Agri-Food Supply Chain Management: An Empirical Study of the Main Drivers Using Extended UTAUT. Bus. Process Manag. J. 2023, 29, 737–756. [Google Scholar] [CrossRef]

- Yadav, S.; Luthra, S.; Garg, D. Modelling Internet of Things (IoT)-Driven Global Sustainability in Multi-Tier Agri-Food Supply Chain under Natural Epidemic Outbreaks. Environ. Sci. Pollut. Res. 2021, 28, 16633–16654. [Google Scholar] [CrossRef]

- Zhao, G.; Jones, P.; Liu, S.; Lopez, C.; Dennehy, D.; Chen, X. Analysis of the Drivers of Industry 4.0 Technology Deployment to Achieve Agri-Food Supply Chain Sustainability: A Hybrid Approach. In Proceedings of the 2023 IEEE International Symposium on Technology and Society (ISTAS), Swansea, Wales, 13–15 September 2023; IEEE: New York, NY, USA; pp. 1–8. [Google Scholar]

- Kumar, M.; Choubey, V.K.; Raut, R.D.; Jagtap, S. Enablers to Achieve Zero Hunger through IoT and Blockchain Technology and Transform the Green Food Supply Chain Systems. J. Clean. Prod. 2023, 405, 136894. [Google Scholar] [CrossRef]

- Yi, Y.; Bremer, P.; Mather, D.; Mirosa, M. Factors Affecting the Diffusion of Traceability Practices in an Imported Fresh Produce Supply Chain in China. Br. Food J. 2022, 124, 1350–1364. [Google Scholar] [CrossRef]

- Mishra, H.; Maheshwari, P. Blockchain in Indian Public Distribution System: A Conceptual Framework to Prevent Leakage of the Supplies and Its Enablers and Disablers. J. Glob. Oper. Strateg. Sourc. 2021, 14, 312–335. [Google Scholar] [CrossRef]

- Liu, S.; Hua, G.; Kang, Y.; Edwin Cheng, T.C.; Xu, Y. What Value Does Blockchain Bring to the Imported Fresh Food Supply Chain? Transp. Res. Part E Logist. Transp. Rev. 2022, 165, 102859. [Google Scholar] [CrossRef]

- Huang, W.; Yin, M.; Xia, J.; Zhang, X. A Review of Cross-Scale and Cross-Modal Intelligent Sensing and Detection Technology for Food Quality: Mechanism Analysis, Decoupling Strategy and Integrated Applications. Trends Food Sci. Technol. 2024, 151, 104646. [Google Scholar] [CrossRef]

- Huang, W.; Wang, X.; Xia, J.; Li, Y.; Zhang, L.; Feng, H.; Zhang, X. Flexible Sensing Enabled Agri-Food Cold Chain Quality Control: A Review of Mechanism Analysis, Emerging Applications, and System Integration. Trends Food Sci. Technol. 2023, 133, 189–204. [Google Scholar] [CrossRef]

- Mastorakis, G.; Kopanakis, I.; Makridis, J.; Chroni, C.; Synani, K.; Lasaridi, K.; Abeliotis, K.; Louloudakis, I.; Daliakopoulos, I.N.; Manios, T. Managing Household Food Waste with the FoodSaveShare Mobile Application. Sustainability 2024, 16, 2800. [Google Scholar] [CrossRef]

- Okorie, O.; Russell, J.; Jin, Y.; Turner, C.; Wang, Y.; Charnley, F. Removing Barriers to Blockchain Use in Circular Food Supply Chains: Practitioner Views on Achieving Operational Effectiveness. Clean. Logist. Supply Chain 2022, 5, 100087. [Google Scholar] [CrossRef]

- Tayal, A.; Solanki, A.; Kondal, R.; Nayyar, A.; Tanwar, S.; Kumar, N. Blockchain-based Efficient Communication for Food Supply Chain Industry: Transparency and Traceability Analysis for Sustainable Business. Int. J. Commun. Syst. 2021, 34, e4696. [Google Scholar] [CrossRef]

- Tanwar, S.; Parmar, A.; Kumari, A.; Jadav, N.K.; Hong, W.C.; Sharma, R. Blockchain Adoption to Secure the Food Industry: Opportunities and Challenges. Sustainability 2022, 14, 7036. [Google Scholar] [CrossRef]

- Kumar, N.; Upreti, K.; Mohan, D. Blockchain Adoption for Provenance and Traceability in the Retail Food Supply Chain: A Consumer Perspective. Int. J. E-Bus. Res. 2022, 18, 1–17. [Google Scholar] [CrossRef]

- Rogers, E.M. The Nature of Technology Transfer. Sci. Commun. 2002, 23, 323–341. [Google Scholar] [CrossRef]

- Boev, V.U.; Ermolenko, O.D.; Bogdanova, R.M.; Mironova, O.A.; Yaroshenko, S.G. Digitalization of Agro-Industrial Complex as a Basis for Building Organizational-Economic Mechanism of Sustainable Development: Foreign Experience and Perspectives in Russia. In Digital Economy: Complexity and Variety vs. Rationality; Springer: Berlin/Heidelberg, Germany, 2020; pp. 960–968. [Google Scholar]

- Köhler, S.; Bager, S.; Pizzol, M. Sustainability Standards and Blockchain in Agro-Food Supply Chains: Synergies and Conflicts. Technol. Forecast. Soc. Chang. 2022, 185, 122094. [Google Scholar] [CrossRef]

- Ahmed, W.A.H.; MacCarthy, B.L.; Treiblmaier, H. Why, Where and How Are Organizations Using Blockchain in Their Supply Chains? Motivations, Application Areas and Contingency Factors. Int. J. Oper. Prod. Manag. 2022, 42, 1995–2028. [Google Scholar] [CrossRef]

| Keywords Associated with the Use of Technologies in Cultivation | Keywords Associated with the Cultivation Link in Agri-Food Chains | Keywords Associated with Adoption and Use | Keywords Associated with Decision Factors |

|---|---|---|---|

| Smart farming Smart monitoring Precision farming Agriculture 4.0 Digital* agriculture* Precision Agriculture | Crop Farm Agriculture Cultivation | Adoption Appropriation Transfer Acquisition Implementation Use Application | determinant* inhibitor* driver* enabler* barrier* “Influential Elements” motiva* |

| Keywords Associated with the Use of Technologies in Processing (Transformation) | Keywords Associated with the Processing Link in Agri-Food Chains | Keywords Associated with Adoption and Use | Keywords Associated with Decision Factors |

|---|---|---|---|

| IiOt Industry 4.0 “Industrial IoT” Smart Factory Smart Manufacturing Industrial robot Blockchain Industrial Internet of Things | “Food manufacturing” “Food processing” “Food industr*” Food science Food Supply Chain | Adoption Appropriation Transfer Acquisition Implementation Use | determinant* inhibitor* driver* enabler* barrier* “Influential Elements” motiva* |

| Keywords Associated with the Use of Technologies in Marketing | Keywords Associated with the Marketing Link in Agri-Food Chains | Keywords Associated with Adoption and Use | Keywords Associated with Decision Factors |

|---|---|---|---|

| Food computing Internet of food Food Informatics Augmented Reality Blockchain Computer Vision Machine Learning Deep Learning Sensor Technology Mobile Applications | Food Quality Food Storage Food Packaging Food Products “Food branding” “Food advertising” “Food promotion” Food Preference Food Labeling Food Consumption Food recommendation Food design | Adoption Appropriation Transfer Acquisition Implementation Use application | determinant* inhibitor* driver* enabler* barrier* “Influential Elements” motiva* |

| Query Algorithm | # of Results |

|---|---|

| Scopus (((TITLE-ABS-KEY (“crop”)) OR (TITLE-ABS-KEY (“farm*”)) OR (TITLE-ABS-KEY (“agriculture”)) OR (TITLE-ABS-KEY (“cultivation”))) AND (TITLE-ABS-KEY (“smart monitoring”) OR TITLE-ABS-KEY (“Smart Farming”) OR TITLE-ABS-KEY (“Precision Agriculture”) OR TITLE-ABS-KEY (“Precision farm*”) OR TITLE-ABS-KEY (“Agriculture 4.0”) OR TITLE-ABS-KEY (“Digital* agriculture*”) OR TITLE-ABS-KEY (“Precision Agriculture”)) AND ((TITLE-ABS-KEY (adoption)) OR (TITLE-ABS-KEY (appropriation)) OR (TITLE-ABS-KEY (transfer)) OR (TITLE-ABS-KEY (acquisition)) OR (TITLE-ABS-KEY (implementation)) OR (TITLE-ABS-KEY (use)) OR (TITLE-ABS-KEY (Application))) AND (TITLE-ABS-KEY (determinant*) OR TITLE-ABS-KEY (inhibitor*) OR TITLE-ABS-KEY (driver*) OR TITLE-ABS-KEY (enabler*) OR TITLE-ABS-KEY (motiva*) OR TITLE-ABS-KEY (barrier*) OR TITLE-ABS-KEY (“Influential Elements”))) PUBYEAR > 2013 | 191 |

| WoS (((TI = crop OR AB = crop OR AK = crop) OR (TI = farm* OR AB = farm* OR AK = farm*) OR (TI = agriculture OR AB = agriculture OR AK = agriculture) OR (TI = cultivation OR AB = cultivation OR AK = cultivation)) AND ((TI = “Smart farming” OR AB = “Smart farming” OR AK = “Smart farming”) OR (TI = “smart monitoring” OR AB = “smart monitoring” OR AK = “smart monitoring”) OR (TI = “Precision farming” OR AB = “Precision farming” OR AK = “Precision farming”) OR (TI = “Agriculture 4.0” OR AB = “Agriculture 4.0” OR AK = “Agriculture 4.0”) OR (TI = “Digital* agriculture*” OR AB = “Digital* agriculture*” OR AK = “Digital* agriculture*”) OR (TI = “Precision Agriculture” OR AB = “Precision Agriculture” OR AK = “Precision Agriculture”)) AND ((TI = Adoption OR AB = Adoption OR AK = Adoption) OR (TI = Appropriation OR AB = Appropriation OR AK = Appropriation) OR (TI = Transfer OR AB = Transfer OR AK = Transfer) OR (TI = Acquisition OR AB = Acquisition OR AK = Acquisition) OR (TI = Implementation OR AB = Implementation OR AK = Implementation) OR (TI = Use OR AB = Use OR AK = Use) OR (TI = Application OR AB = Application OR AK = Application)) AND ((TI = determinant* OR AB = determinant* OR AK = determinant*) OR (TI = inhibitor* OR AB = inhibitor* OR AK = inhibitor*) OR (TI = driver* OR AB = driver* OR AK = driver*) OR (TI = enabler* OR AB = enabler* OR AK = enabler*) OR (TI = barrier* OR AB = barrier* OR AK = barrier*) OR (TI = “Influential Elements” OR AB = “Influential Elements” OR AK = “Influential Elements”) OR (TI = motiva* OR AB = motiva* OR AK = motiva*))) AND PY = (2014–2024) | 271 |

| Query Algorithm | # of Results |

|---|---|

| Scopus ((TITLE-ABS-KEY (“food manufactu*”) OR TITLE-ABS-KEY (“food proces*”) OR TITLE-ABS-KEY (“food industr*”) OR TITLE-ABS-KEY (“food science”) OR TITLE-ABS-KEY (“food supply chain”))) AND ((TITLE-ABS-KEY (“iiot”) OR TITLE-ABS-KEY (“industry 4.0”) OR TITLE-ABS-KEY (“industrial iot”) OR TITLE-ABS-KEY (“smart factory”) OR TITLE-ABS-KEY (“smart manufact*”) OR TITLE-ABS-KEY (“industrial robot”) OR TITLE-ABS-KEY (blockchain) OR TITLE-ABS-KEY (“industrial internet of thing*”))) AND ((TITLE-ABS-KEY (adoption) OR TITLE-ABS-KEY (appropriation) OR TITLE-ABS-KEY (transfer) OR TITLE-ABS-KEY (acquisition) OR TITLE-ABS-KEY (implementation) OR TITLE-ABS-KEY (use))) AND ((TITLE-ABS-KEY (determinant*) OR TITLE-ABS-KEY (inhibitor*) OR TITLE-ABS-KEY (driver*) OR TITLE-ABS-KEY (enabler*) OR TITLE-ABS-KEY (motiva*) OR TITLE-ABS-KEY (barrier*) OR TITLE-ABS-KEY (“influential element*”))) PUBYEAR > 2013 | 42 |

| WoS ((TI = IiOt OR AB = IiOt OR AK = IiOt) OR (TI = “Industry 4.0” OR AB = “Industry 4.0” OR AK = “Industry 4.0”) OR (TI = “Smart Factory” OR AB = “Smart Factory” OR AK = “Smart Factory”) OR (TI = “Smart Manufacturing” OR AB = “Smart Manufacturing” OR AK = “Smart Manufacturing”) OR (TI = “industrial robot” OR AB = “industrial robot” OR AK = “industrial robot”) OR (TI = Blockchain OR AB = Blockchain OR AK = Blockchain) OR (TI = “Industrial Internet of Things” OR AB = “Industrial Internet of Things” OR AK = “Industrial Internet of Things”)) AND ((TI = “Food manufacturing” OR AB = “Food manufacturing” OR AK = “Food manufacturing”) OR (TI = “food processing” OR AB = “food processing” OR AK = “food processing”) OR (TI = “Food industr*” OR AB = “Food industr*” OR AK = “Food industr*”) OR (TI = “Food science” OR AB = “Food science” OR AK = “Food science”) OR (TI = “Food Supply Chain” OR AB = “Food Supply Chain” OR AK = “Food Supply Chain”)) AND ((TI = Adoption OR AB = Adoption OR AK = Adoption) OR (TI = Appropriation OR AB = Appropriation OR AK = Appropriation) OR (TI = Transfer OR AB = Transfer OR AK = Transfer) OR (TI = Acquisition OR AB = Acquisition OR AK = Acquisition) OR (TI = Implementation OR AB = Implementation OR AK = Implementation) OR (TI = Use OR AB = Use OR AK = Use) OR (TI = Application OR AB = Application OR AK = Application)) AND ((TI = determinant* OR AB = determinant* OR AK = determinant*) OR (TI = inhibitor* OR AB = inhibitor* OR AK = inhibitor*) OR (TI = driver* OR AB = driver* OR AK = driver*) OR (TI = enabler* OR AB = enabler* OR AK = enabler*) OR (TI = barrier* OR AB = barrier* OR AK = barrier*) OR (TI = “Influential Elements” OR AB = “Influential Elements” OR AK = “Influential Elements”) OR (TI = motiva* OR AB = motiva* OR AK = motiva*)) AND PY = (2014–2024) | 48 |

| Query Algorithm | # of Results |

|---|---|

| Scopus ((TITLE-ABS-KEY (“Food branding”) OR TITLE-ABS-KEY (“Food advertising”) OR TITLE-ABS-KEY (“Food promotion”) OR TITLE-ABS-KEY (“food marketing”) OR TITLE-ABS-KEY (“Food Preference”) OR TITLE-ABS-KEY (“Food Labeling”) OR TITLE-ABS-KEY (“Food Consumption”) OR TITLE-ABS-KEY (“Food recommendation”) OR TITLE-ABS-KEY (“Food Quality”) OR TITLE-ABS-KEY (“Food Storage”) OR TITLE-ABS-KEY (“Food Packaging”) OR TITLE-ABS-KEY (“Food Products”) OR TITLE-ABS-KEY (“food design”))) AND ((TITLE-ABS-KEY (“Food computing”) OR TITLE-ABS-KEY (“Internet of food”) OR TITLE-ABS-KEY (“Food informatic*”) OR TITLE-ABS-KEY (“Augmented Reality”) OR TITLE-ABS-KEY (blockchain) OR TITLE-ABS-KEY (“Computer Vision”) OR TITLE-ABS-KEY (“Machine Learning”) OR TITLE-ABS-KEY (“Deep Learning”) OR TITLE-ABS-KEY (“Sensor Technology”) OR TITLE-ABS-KEY (“Mobile Application*”))) AND ((TITLE-ABS-KEY (adoption) OR TITLE-ABS-KEY (appropriation) OR TITLE-ABS-KEY (transfer) OR TITLE-ABS-KEY (acquisition) OR TITLE-ABS-KEY (implementation) OR TITLE-ABS-KEY (use) OR TITLE-ABS-KEY (application))) AND ((TITLE-ABS-KEY (determinant*) OR TITLE-ABS-KEY (inhibitor*) OR TITLE-ABS-KEY (driver*) OR TITLE-ABS-KEY (enabler*) OR TITLE-ABS-KEY (motiva*) OR TITLE-ABS-KEY (barrier*) OR TITLE-ABS-KEY (“influential element*”))) PUBYEAR > 2013 | 15 |

| WoS (((TI = “Food computing” OR AB = “Food computing” OR AK = “Food computing”) OR (TI = “Internet of food” OR AB = “Internet of food” OR AK = “Internet of food”) OR (TI = “Food informatics” OR AB = “Food informatics” OR AK = “Food informatics”) OR (TI = “Augmented Reality” OR AB = “Augmented Reality” OR AK = “Augmented Reality”) OR (TI = Blockchain OR AB = Blockchain OR AK = Blockchain) OR (TI = “Computer Vision” OR AB = “Computer Vision” OR AK = “Computer Vision”) OR (TI = “Machine Learning” OR AB = “Machine Learning” OR AK = “Machine Learning”) OR (TI = “Deep Learning” OR AB = “Deep Learning” OR AK = “Deep Learning”) OR (TI = “Sensor Technology” OR AB = “Sensor Technology” OR AK = “Sensor Technology”) OR (TI = “Mobile Application*” OR AB = “Mobile Application*” OR AK = “Mobile Application*”)) AND ((TI = “Food Products” OR AB = “Food Products” OR AK = “Food Products”) OR (TI = “Food branding” OR AB = “Food branding” OR AK = “Food branding”) OR (TI = “Food advertising” OR AB = “Food advertising” OR AK = “Food advertising”) OR (TI = “Food promotion” OR AB = “Food promotion” OR AK = “Food promotion”) OR (TI = “Food Preference” OR AB = “Food Preference” OR AK = “Food Preference”) OR (TI = “Food Labeling” OR AB = “Food Labeling” OR AK = “Food Labeling”) OR (TI = “Food Consumption” OR AB = “Food Consumption” OR AK = “Food Consumption”) OR (TI = “Food recommendation” OR AB = “Food recommendation” OR AK = “Food recommendation”) OR (TI = “food design” OR AB = “food design” OR AK = “food design”)) AND ((TI = Adoption OR AB = Adoption OR AK = Adoption) OR (TI = Appropriation OR AB = Appropriation OR AK = Appropriation) OR (TI = Transfer OR AB = Transfer OR AK = Transfer) OR (TI = Acquisition OR AB = Acquisition OR AK = Acquisition) OR (TI = Implementation OR AB = Implementation OR AK = Implementation) OR (TI = Use OR AB = Use OR AK = Use) OR (TI = Application OR AB = Application OR AK = Application)) AND ((TI = determinant* OR AB = determinant* OR AK = determinant*) OR (TI = inhibitor* OR AB = inhibitor* OR AK = inhibitor*) OR (TI = driver* OR AB = driver* OR AK = driver*) OR (TI = enabler* OR AB = enabler* OR AK = enabler*) OR (TI = barrier* OR AB = barrier* OR AK = barrier*) OR (TI = “Influential Elements” OR AB = “Influential Elements” OR AK = “Influential Elements”) OR (TI = motiva* OR AB = motiva* OR AK = motiva*))) AND PY = (2014–2024) | 26 |

| Barrier | Description | Chain | Technology | Reference |

|---|---|---|---|---|

| Connectivity | Access to energy and Internet infrastructure is key to deploying technologies associated with real-time data capture. | Wine | Blockchain | [133] |

| Governance, privacy, and information security | Data privacy related to the different links presents a risk for the associated parties. | Fruits | Blockchain | [133,134,135] |

| Training and expertise of collaborators | Digital skills are necessary for the implementation of technologies. | Wine Processing of fruits and vegetables | Blockchain Robotization | [9,133,136,137,138,139] |

| Collaboration | The joint development of actions for the implementation of technologies improves the performance of the process. | Wine Cotton Food and beverage industry | Blockchain Industry 4.0 | [136,138,140] |

| Technological | Industrial equipment does not guarantee the standardization of products and, if necessary, is obsolete. | Bakery | Industry 4.0 | [38] |

| Organizational learning | Employee skills, educational level, and absorption capacity have an impact. | Not mentioned | Blockchain | [141] |

| Strategy and leadership | Integrated knowledge management strategies, clear purposes, strategic planning, and relationships have an impact. | Not mentioned | Blockchain | [141] |

| High investment and maintenance costs | Initial investments are required to implement Food Informatics solutions, and their implementation does not guarantee immediate return. | Wine Processing of fruits and vegetables Cotton | Blockchain Industry 4.0 | [9,133,135,137,138,142,143] |

| Level of preparation or maturity of the actors in the chain | The level of preparation of the partners is derived from the social influence raised by the UTAUT model. | Not mentioned | Blockchain | [144] |

| Lack of knowledge of the exact benefits of implementation | The lack of knowledge of the cost–benefit relationship of implementing new technologies results in uncertainty that is difficult to assume. | Food and beverage industry | Industry 4.0 | [140] |

| Resistance to change | Resistance on the part of organizations and employees during the adoption process has an impact. | Fruits | Blockchain | [135] |

| Inter-firm trust | It is an essential factor when several organizations are present in the same value chain. | Non mentioned | Blockchain | [145] |

| Enabler | Description | Chain | Technology | Reference |

|---|---|---|---|---|

| Transparency | It ensures quality and information, precision, and credibility towards the market. | Not mentioned | Blockchain | [9,134,145] |

| Traceability | It facilitates the real-time tracking of products (quantities, origins, and destination dates). | Wine | Blockchain | [9,134,143] |

| Management involvement | It guarantees funds and resources to participate in the adoption processes. | Not mentioned | Not mentioned | [146] |

| Digital strategy | Agri-businesses should have a clear digital processing (transformation) strategy to promote the use and implementation of technology. | Fruits processing | Robotization | [137] |

| Policies and regulations | Clear regulations and policies are required at the national level to adopt technologies. | Cotton | Industry 4.0 | [138] |

| Reduction of labor intensity | When the perception of the benefit of technology is in reducing the workload, it can drive the adoption of technology. | Not mentioned | Industry 4.0 | [147] |

| Reduction of transaction costs | The elimination of intermediaries reduces transaction costs. | Wine | Blockchain | [143] |

| Reduction of costs, time, and waste | The implementation of technologies eliminates the costs associated with employee training, reduces production times by increasing productivity, and also increases the efficient use of materials. | Poultry Bovine | Robotization Blockchain and IoT | [7,69,148] |

| Food quality and safety | Quality and safety are vital parameters for the final consumer, so their assurance will reduce fraud and the lack of standardization. | Not mentioned | Blockchain and IoT | [148] |

| Hygienic packaging | The increase in control points directly impacts traceability in the hygiene of handling processes. | Not mentioned | Blockchain and IoT | [148] |

| Pressure from buyers/suppliers, competitors, and consumers | The links in logistics, marketing, and consumption indirectly pressure the implementation of technologies to link them to their own systems. | Not mentioned | Blockchain | [9] |

| Enabler | Description | Chain | Technology | Authors |

|---|---|---|---|---|

| Social prestige | Depending on the positioning of the brand or product, customers may be more willing to participate in the adoption and use of technology processes. | Fresh products | Blockchain–RFID | [149] |

| Transparency | Transparency is associated with the ability to track the journey of a product from the production link to the consumer, generating trust. | Not mentioned | Blockchain–RFID | [150] |

| Traceability | Traceability allows for the tracking of products throughout the value chain through shared and immutable records. | Not mentioned | Blockchain–RFID | [150] |

| Auditability | Linking stakeholders in the model allows for the auditability of the parties. | Not mentioned | Blockchain–RFID | [150] |

| Reduction of transaction costs | Technologies 4.0 help reduce logistics costs and related taxes. | Not mentioned | Blockchain–RFID | [150,156] |

| Ease of use | If the system is easy to implement and use, it allows marketers to implement them in their businesses. | Not mentioned | Blockchain | [158] |

| Perceived quality of the product | The information available through Food Informatics technologies affects the purchase intention. | Not mentioned | Blockchain | [52] |

| Government support (regulations) | Local and national policies based on solving real bottlenecks, compared to others that encourage the adoption of specific technologies, can be effective. | Not mentioned | Blockchain | [53,156] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Orjuela-Garzon, W.A.; Sandoval-Aldana, A.; Mendez-Arteaga, J.J. Systematic Literature Review of Barriers and Enablers to Implementing Food Informatics Technologies: Unlocking Agri-Food Chain Innovation. Foods 2024, 13, 3349. https://doi.org/10.3390/foods13213349

Orjuela-Garzon WA, Sandoval-Aldana A, Mendez-Arteaga JJ. Systematic Literature Review of Barriers and Enablers to Implementing Food Informatics Technologies: Unlocking Agri-Food Chain Innovation. Foods. 2024; 13(21):3349. https://doi.org/10.3390/foods13213349

Chicago/Turabian StyleOrjuela-Garzon, William Alejandro, Angélica Sandoval-Aldana, and Jonh Jairo Mendez-Arteaga. 2024. "Systematic Literature Review of Barriers and Enablers to Implementing Food Informatics Technologies: Unlocking Agri-Food Chain Innovation" Foods 13, no. 21: 3349. https://doi.org/10.3390/foods13213349

APA StyleOrjuela-Garzon, W. A., Sandoval-Aldana, A., & Mendez-Arteaga, J. J. (2024). Systematic Literature Review of Barriers and Enablers to Implementing Food Informatics Technologies: Unlocking Agri-Food Chain Innovation. Foods, 13(21), 3349. https://doi.org/10.3390/foods13213349