Simulation Analysis of 3-D Airflow and Temperature Uniformity of Paddy in a Laboratory Drying Oven

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

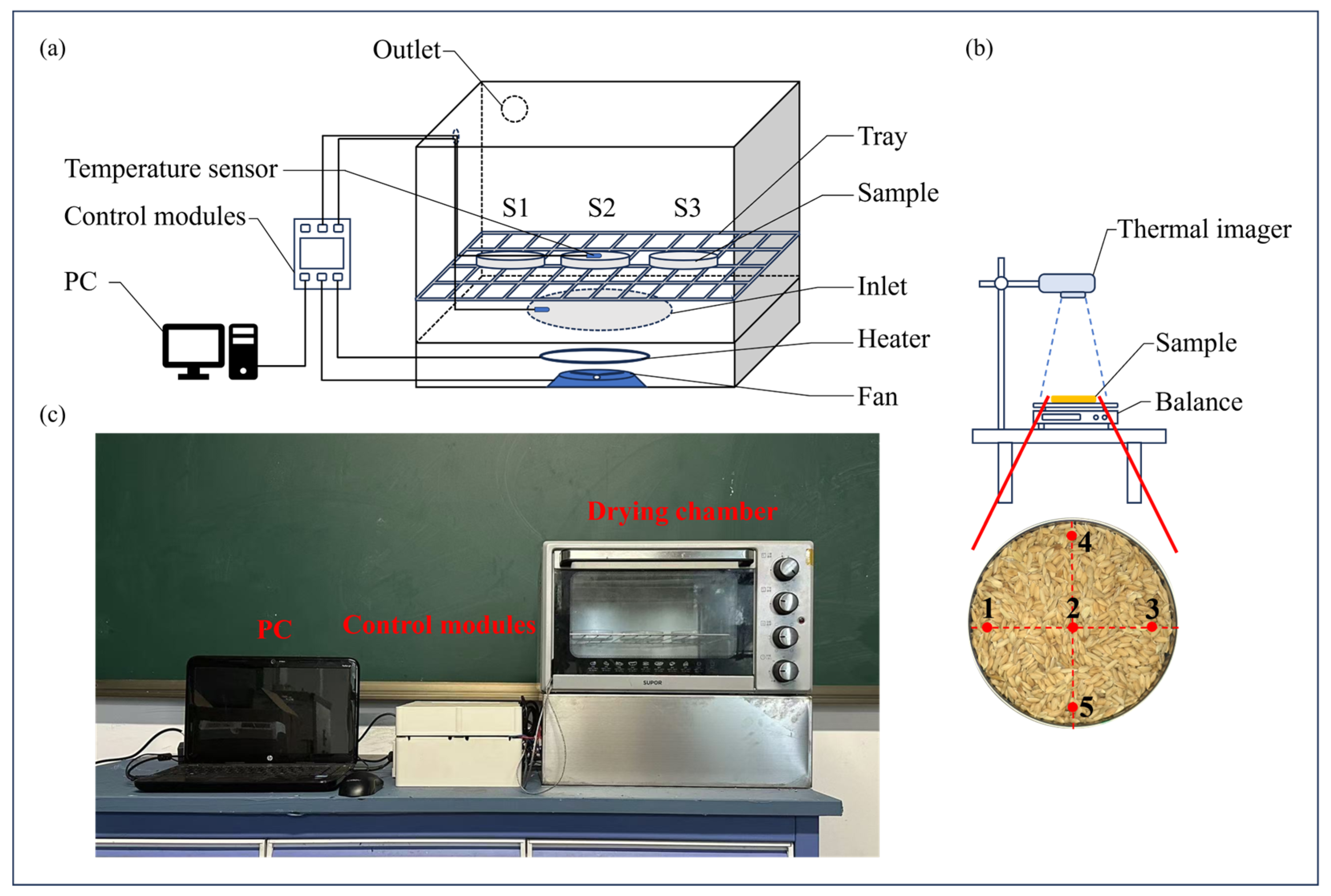

2.2. Drying Equipment and Experimental Design

2.3. Evaluation of Drying Uniformity and Model Validation

3. Mathematical Model Development

3.1. Problem Description and Assumptions

3.2. Physical Model

3.3. Governing Equations

3.3.1. Heat and Mass Transfer Equations

3.3.2. Initial and Boundary Conditions

3.3.3. Heat and Mass Transfer Coefficient Calculation

| Parameters | Value or Expression | Unit | Reference |

|---|---|---|---|

| The initial temperature of paddy, T0 | 20 | °C | This work |

| Drying air temperature, Tair | 60 | °C | This work |

| The initial temperature of air, Ta0 | 25 | °C | This work |

| Molecular weight of vapor, | 0.01802 | kg/mol | [34] |

| Activation energy, Ea | 29.85017 | kJ/mol | [27] |

| The initial moisture content of paddy, Mwb | 0.245 | kg/kg, (w.b.) | This work |

| Density of paddy, ρm | 1716 | kg/m3 | This work |

| Diffusion coefficient of paddy, D | m2/s | [27] | |

| Specific heat capacity of paddy, Cpm | kJ·kg−1K−1 | [35] | |

| Thermal conductivity of paddy, km | W·m−1K−1 | [35] | |

| Density of air, ρair | kg/m3 | [27] | |

| Thermal conductivity of air, kair | W·m−1K−1 | [27] | |

| Specific heat capacity of air, Cpair | kJ·kg−1K−1 | [27] | |

| Dynamic viscosity of air, μair | Pa·s | [27] | |

| Diffusivity of water in air, Dair | m2/s | [27] |

3.4. Airflow Modeling

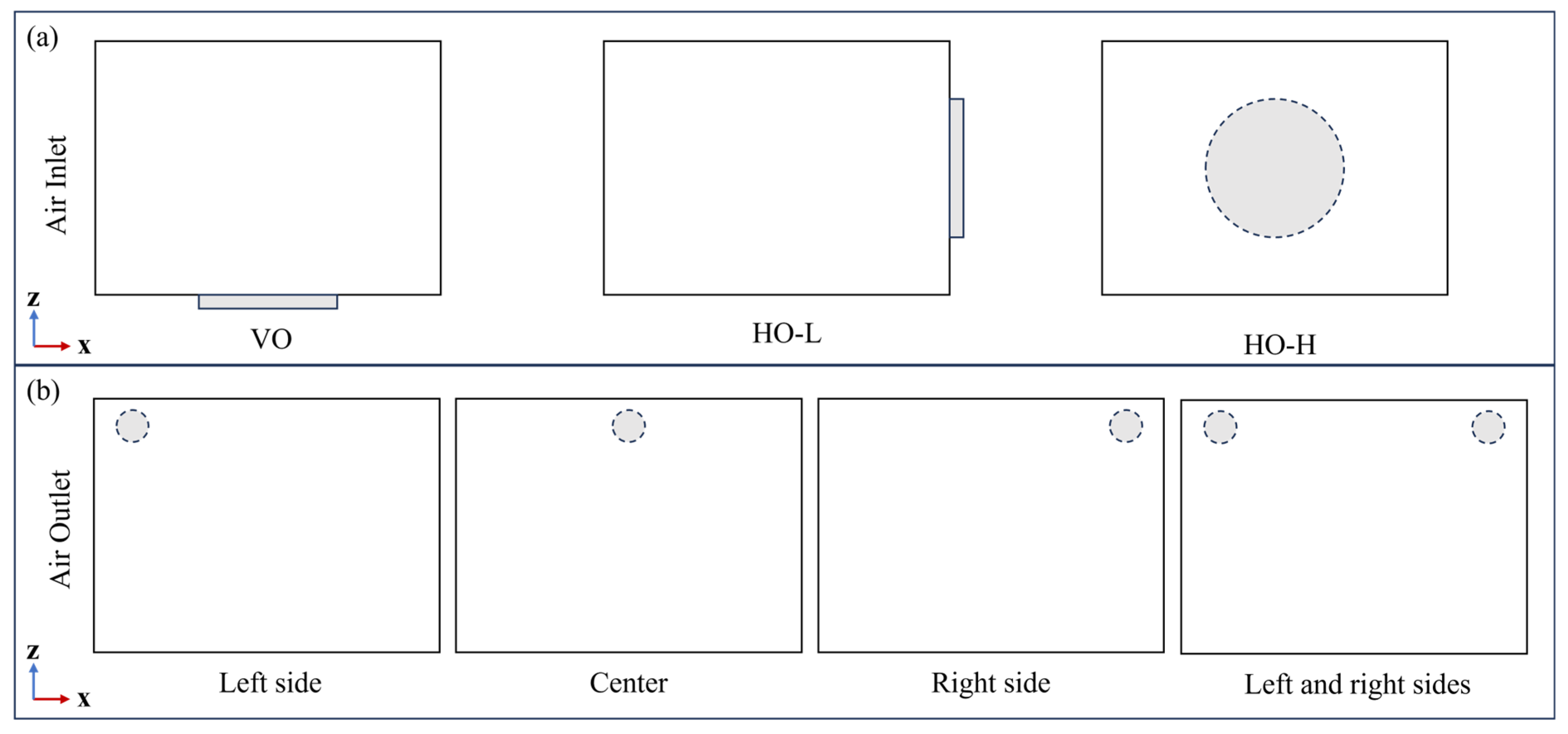

3.5. Factors Affecting Drying Uniformity

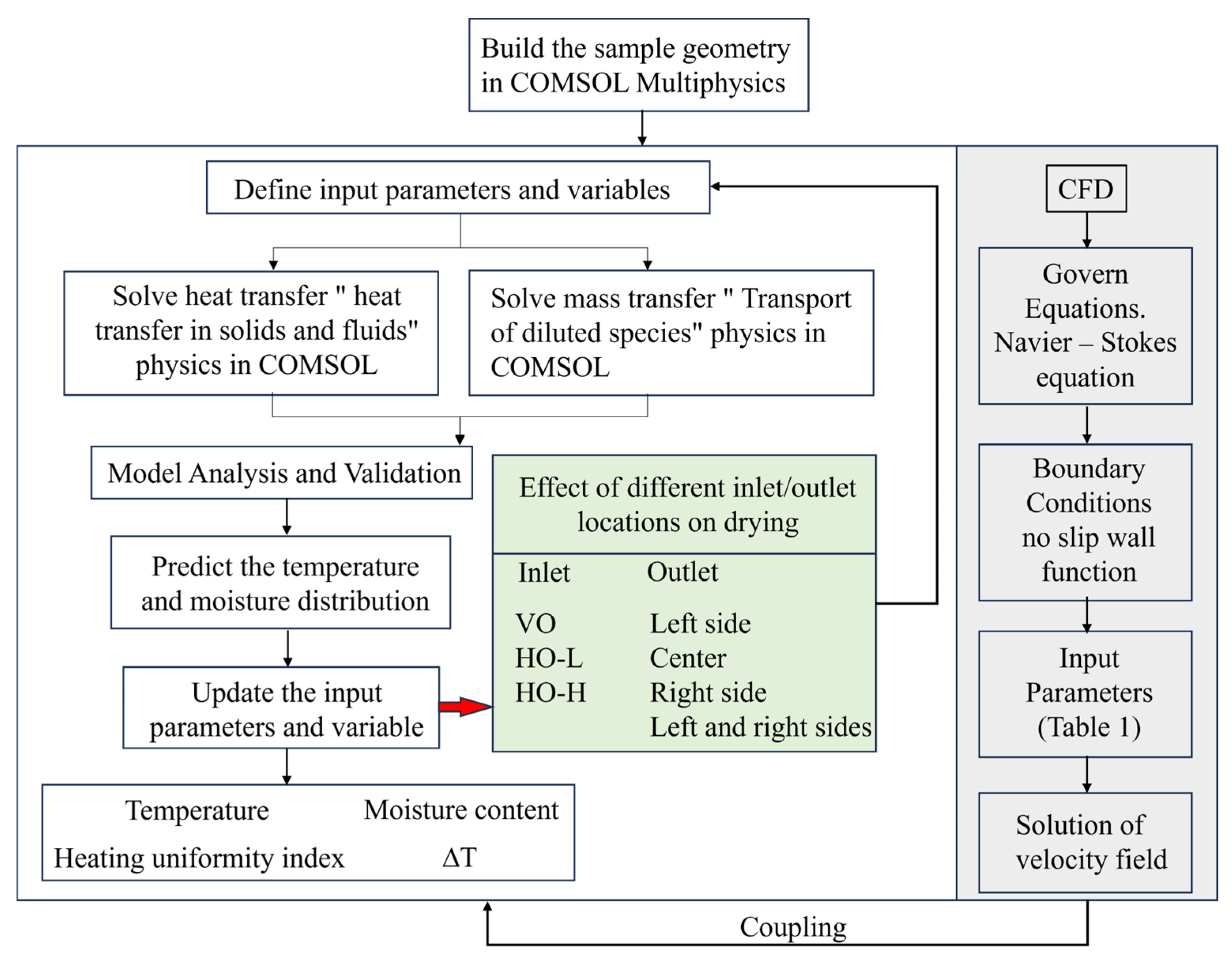

3.6. Simulation Procedure

3.7. Model Validation and Analysis

4. Discussion

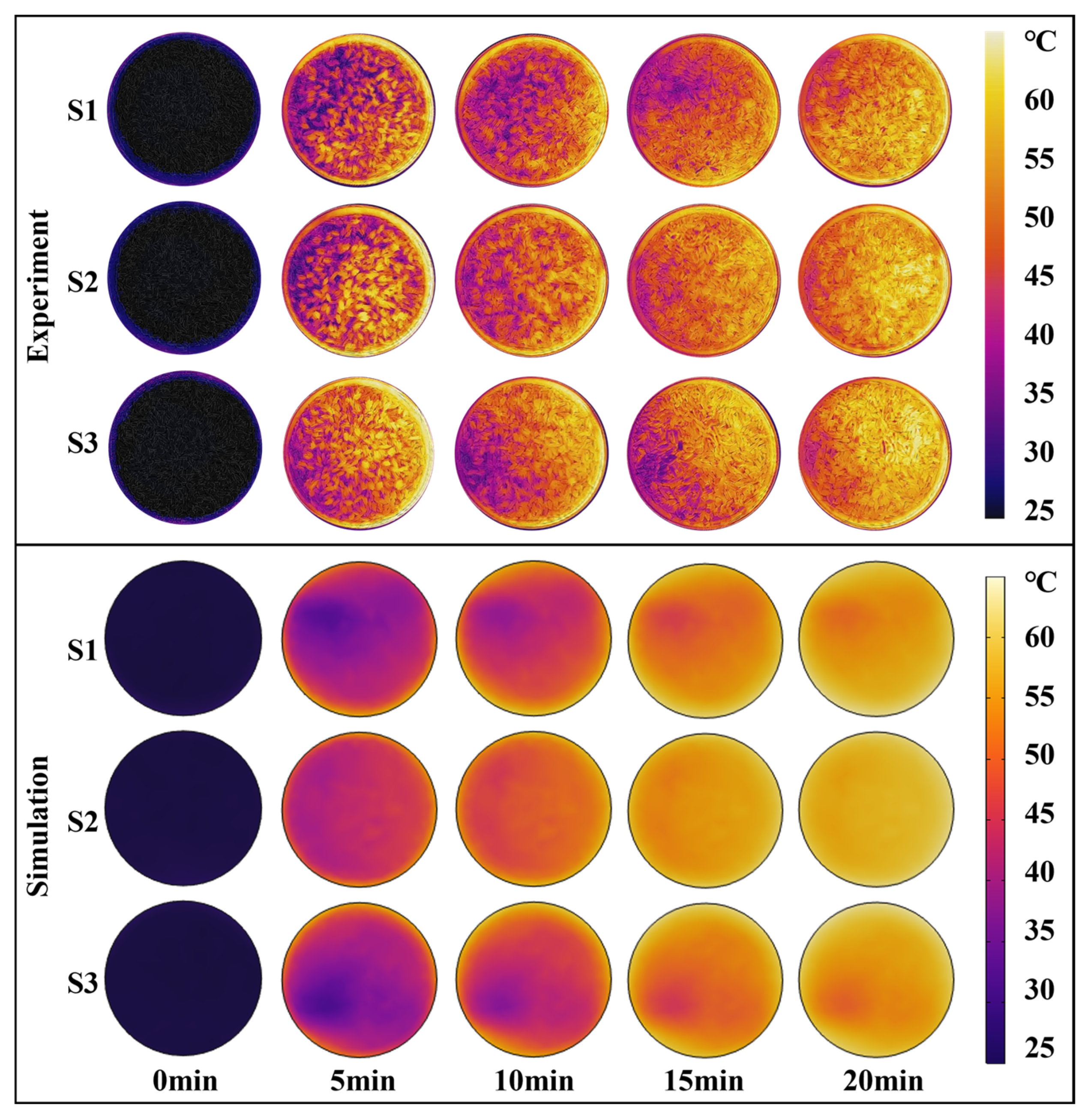

4.1. Model Validation

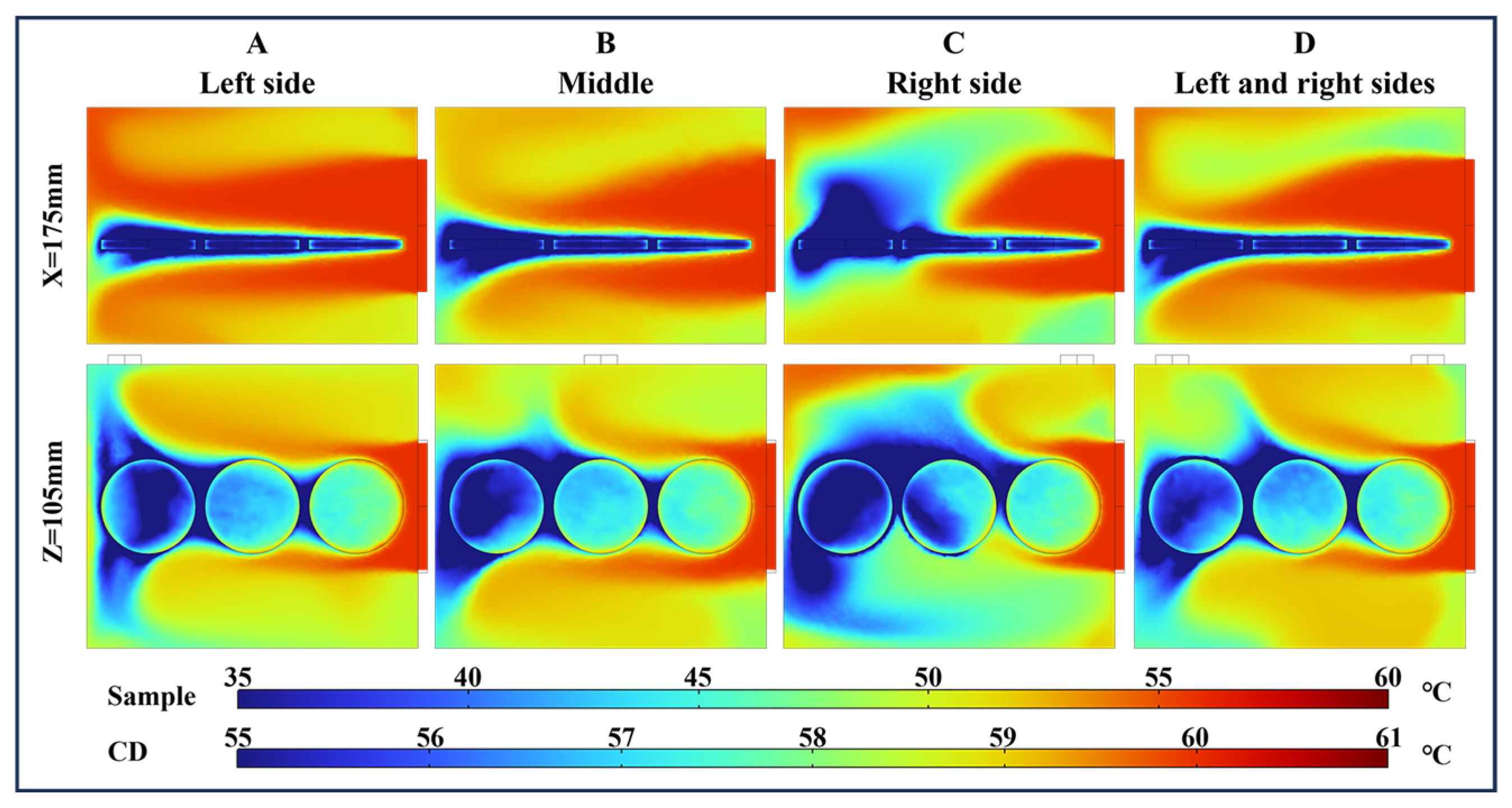

4.2. Flow Field Distribution for Different Airflow Directions

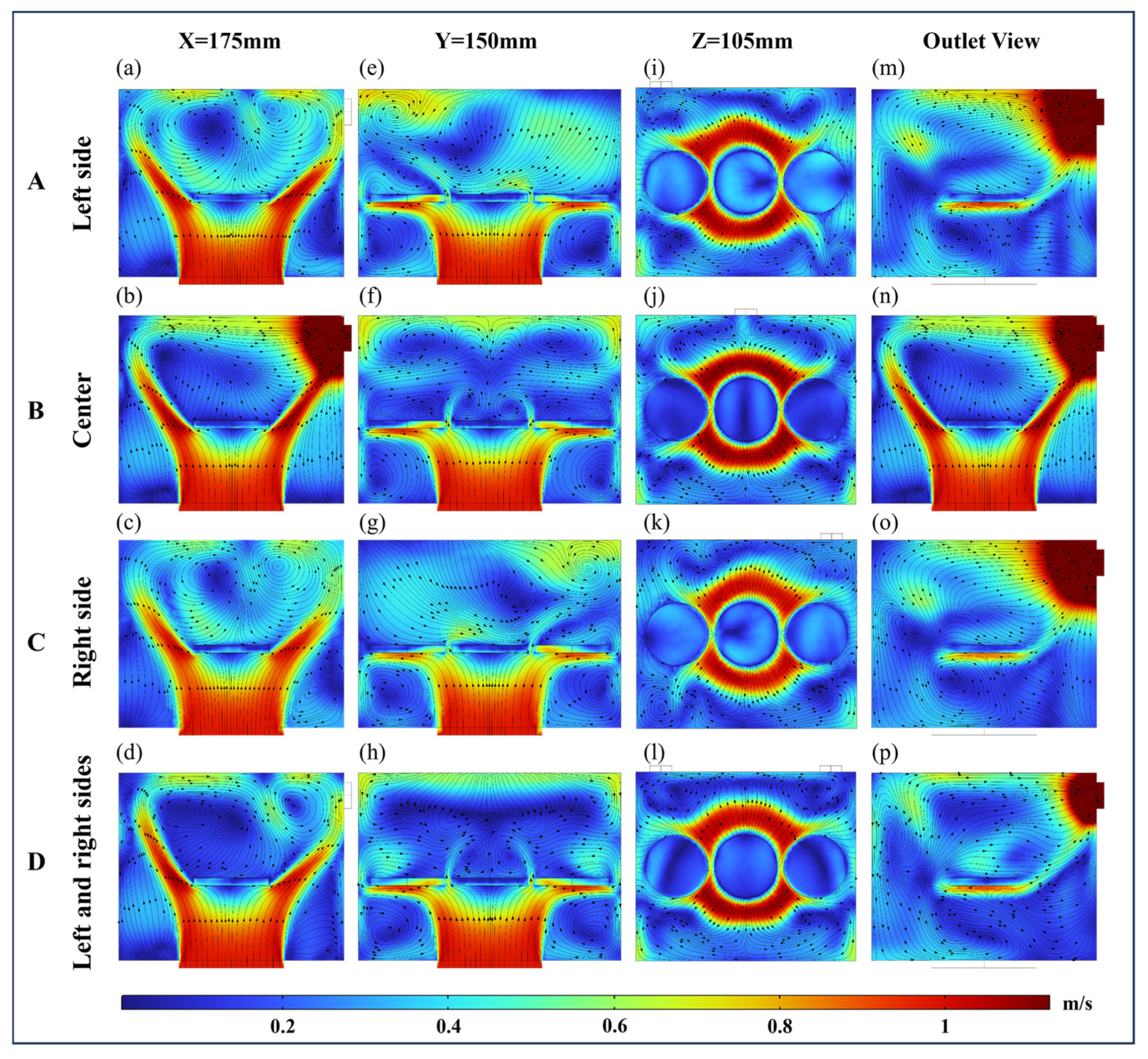

4.2.1. Flow Field Distribution Analysis of VO

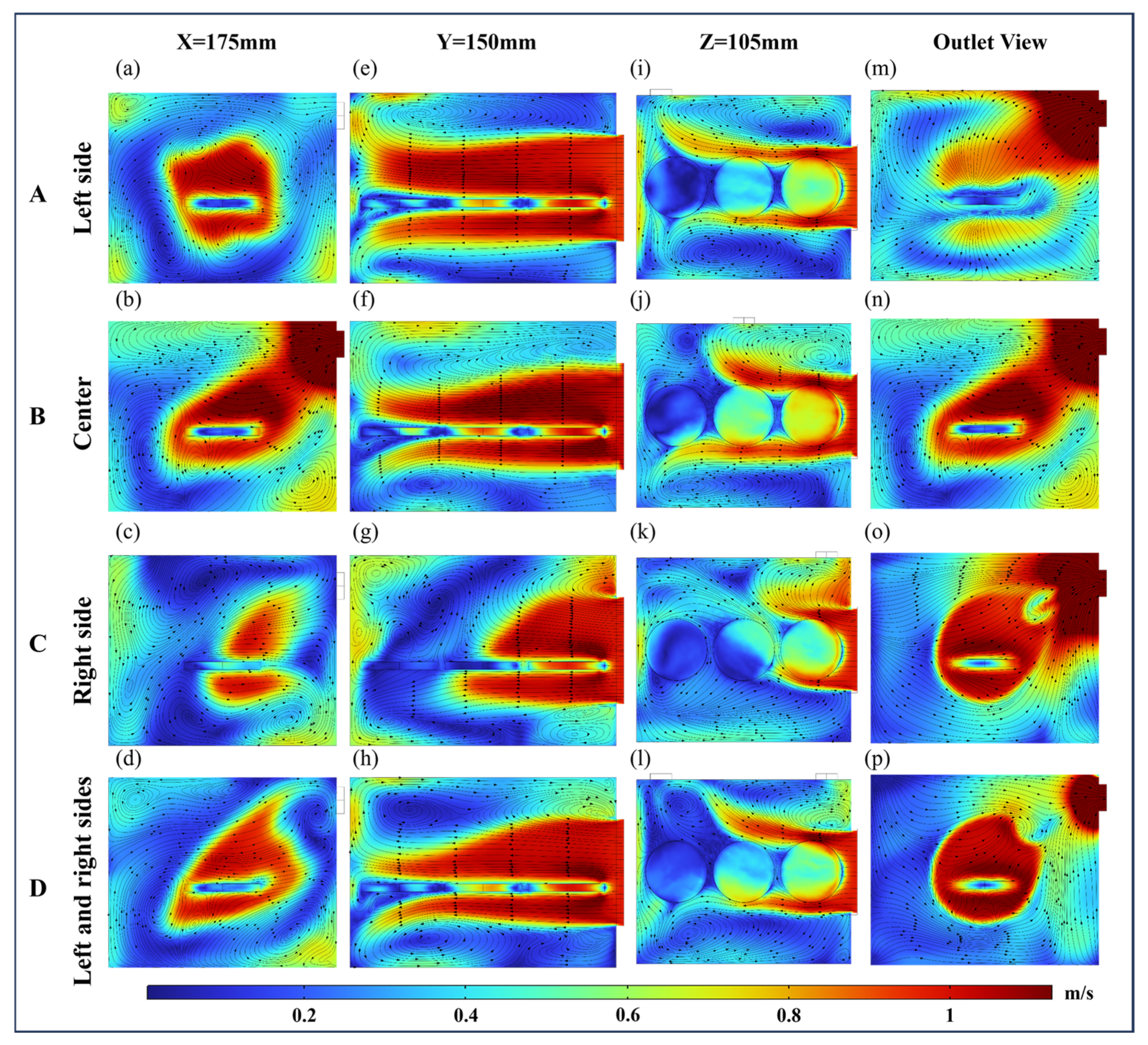

4.2.2. Flow Field Distribution Analysis of HO-L

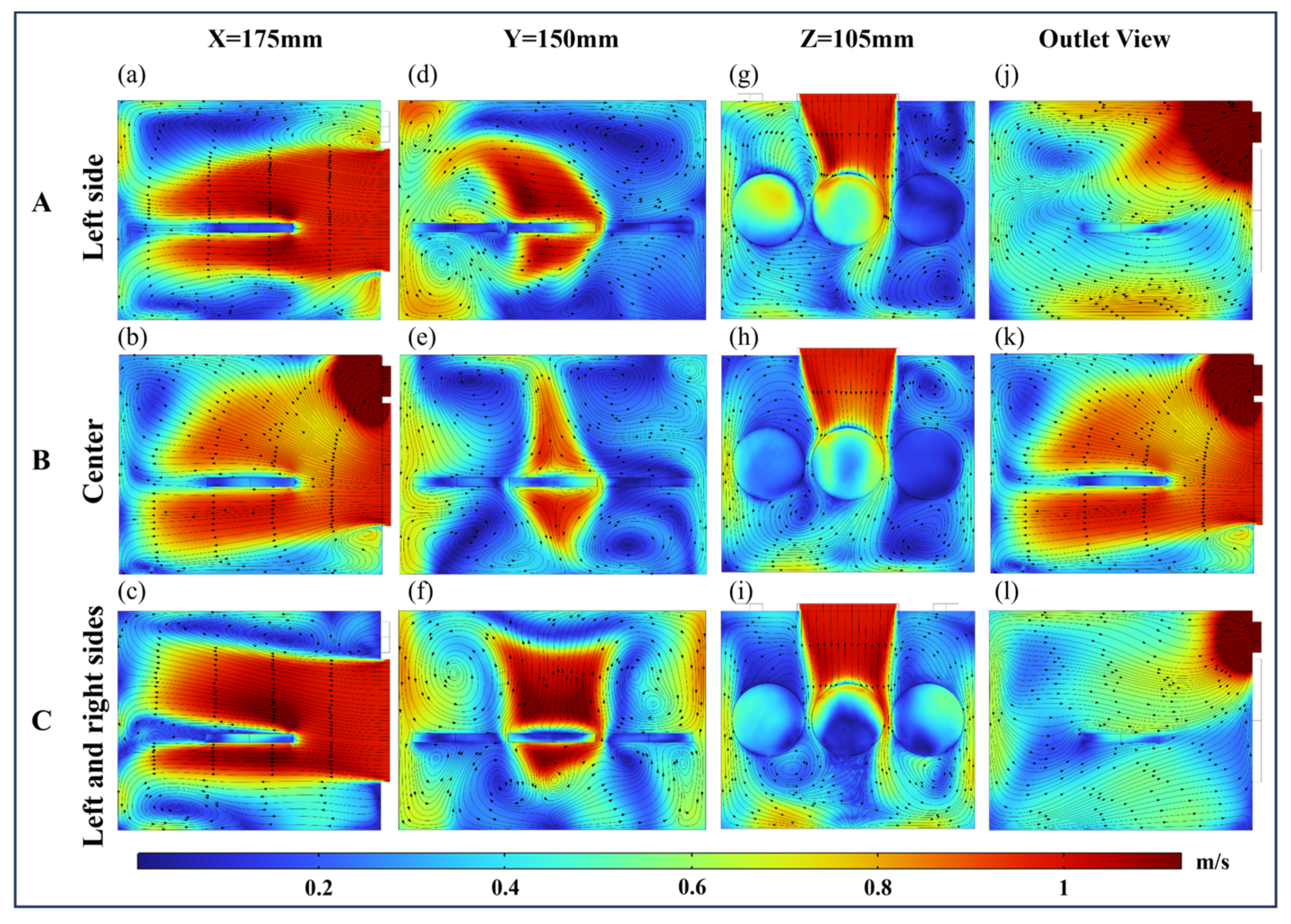

4.2.3. Flow Field Distribution Analysis of HO-H

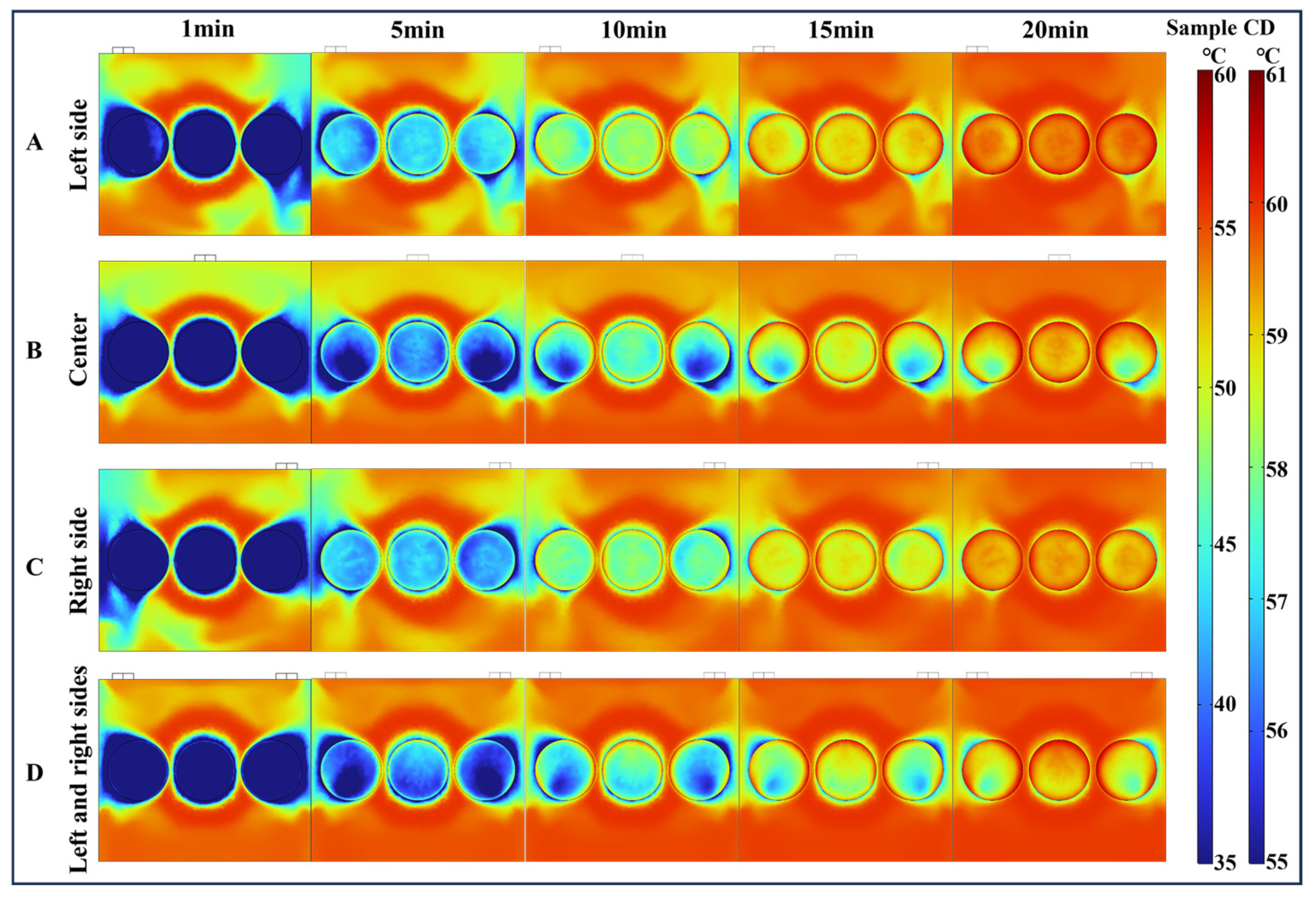

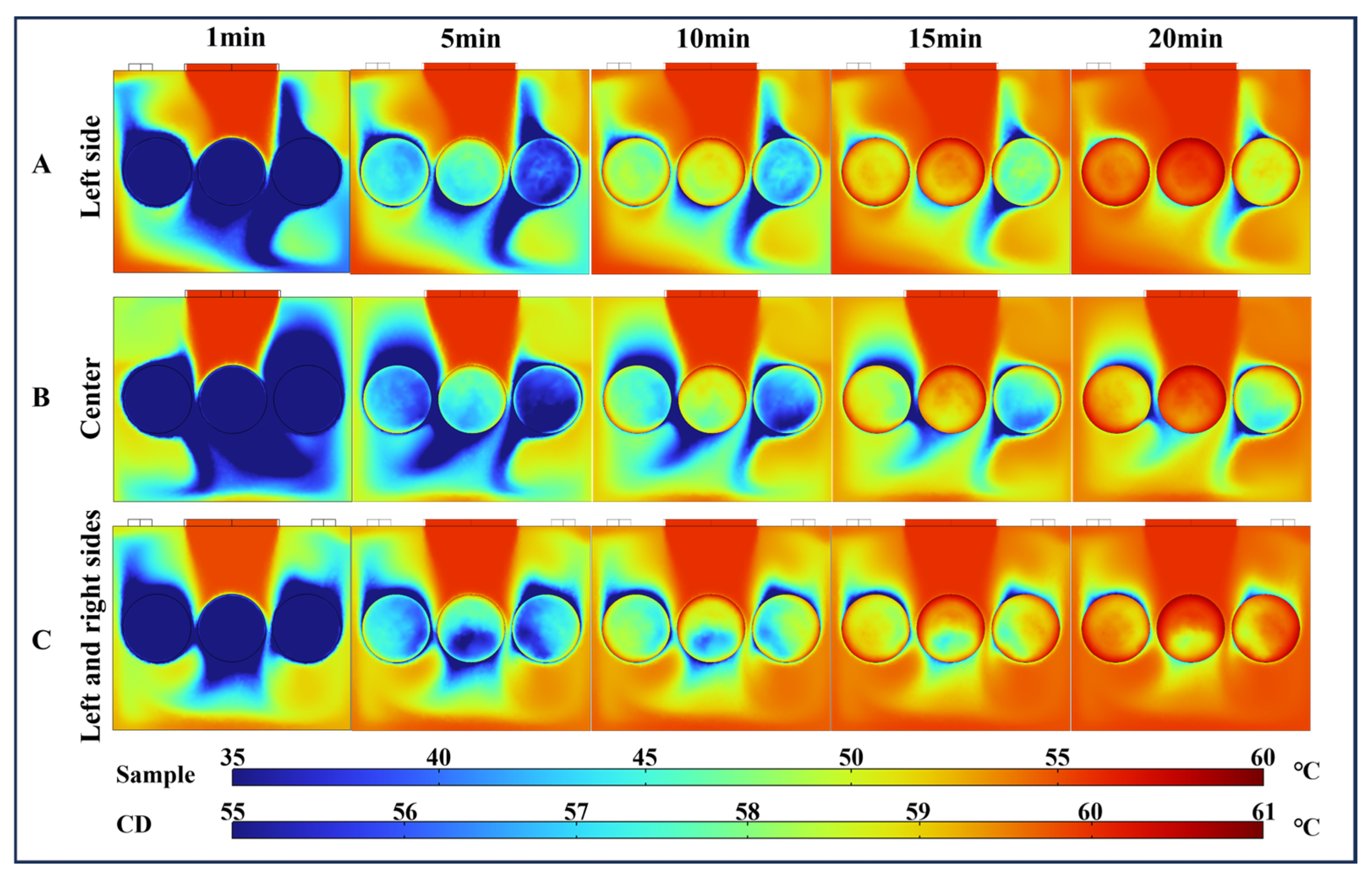

4.3. Temperature Distribution Under Different Airflow Directions

4.3.1. Temperature Distribution Analysis of VO

4.3.2. Temperature Distribution Analysis of HO-L

4.3.3. Temperature Distribution Analysis of Airflow of HO-H

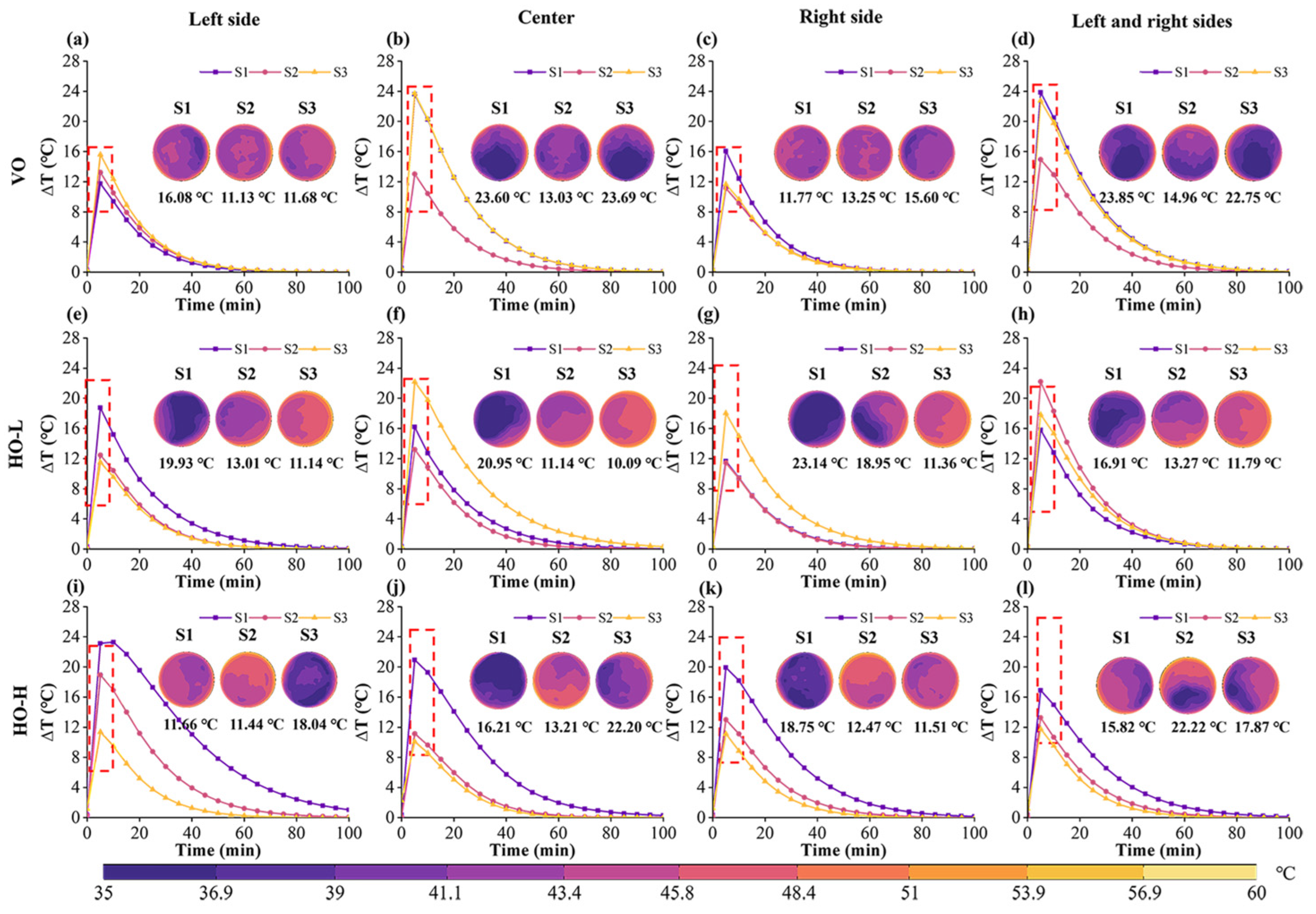

4.4. Effect of Different Parameters on Drying Uniformity of Paddy

4.5. Effect of Different Air Flow Directions on the Temperature Difference of Paddy

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Nomenclature | |||

| c | moisture concentration (mol/m3) | R2 | coefficient of determination |

| c0 | initial moisture concentration (mol/m3) | Re | Reynolds number |

| ce | equilibrium moisture concentration (mol/m3) | Req | distance or equivalent radius (m) |

| C1, C2 | empirical constants | RMSE | root mean square error |

| Cpair | specific heat capacity of air (J·kg−1K−1) | S1, S2, S3 | Sample1, Sample2, Sample3 |

| Cpm | specific heat capacity of paddy (J·kg−1K−1) | Sc | Schmidt number |

| CD | convection drying | Sh | Sherwood number |

| CFD | computational fluid dynamics | t | time (min) |

| COU | coefficient of uniformity | T | temperature (°C) |

| D | diffusion coefficients (m2/s) | T0 | initial temperature of paddy (°C) |

| D0 | Arrhenius factor (m2/s) | Tair | drying air temperature (°C) |

| Dair | diffusivity of water in air (m2/s) | Tmax | maximum temperature (°C) |

| Deff | effective moisture diffusivity (m2/s) | Tmin | minimum temperature (°C) |

| Ea | activation energy (J/mol) | u | air velocity vector (m/s) |

| Gk | production of turbulent kinetic energy | VO | vertical orientation |

| hm | mass transfer coefficient (m/s) | ∆T | difference in temperature (°C) |

| ht | heat transfer coefficient (W·m−2s−1) | Greek symbols | |

| HO-L | horizontal orientation with longitudinal arrangement of materials | μair | viscosity of air (kg/m3) |

| HO-H | horizontal orientation with horizontal arrangement of materials | μt | turbulent viscosity (kg/m3) |

| Hvap | enthalpy of water evaporation (J/kg) | κ | kinetic energy |

| kg | thermal conductivity of paddy (W·m−1K−1) | ε | dissipation rate |

| kair | thermal conductivity of air (W·m−1K−1) | σ | Prandtl number |

| MC | moisture content (kg/kg, w.b.) | ρair | density of air (kg/m3) |

| M0 | initial moisture content (kg/kg, w.b.) | ρm | density of paddy (kg/m3) |

| Me | equilibrium moisture content (d.b.) | Subscripts | |

| MH2O | molecular mass of water (kg/mol) | air | air |

| Mwb | wet-basis moisture content (kg/kg, w.b.) | d.b. | dry basis |

| n | number of data | e | equilibrium |

| Nu | Nusselt number | exp | experiment |

| Pr | Prandtl number | sim | simulation |

| R | universal gas constant (J·mol−1K−1) | w.b. | wet basis |

References

- Tong, C.; Gao, H.; Luo, S.; Liu, L.; Bao, J. Impact of postharvest operations on rice grain quality: A review. Compr. Rev. Food Sci. Food Saf. 2019, 18, 626–640. [Google Scholar] [CrossRef] [PubMed]

- Müller, A.; Nunes, M.T.; Maldaner, V.; Coradi, P.C.; Moraes, R.S.D.; Martens, S.; Leal, A.F.; Pereira, V.F.; Marin, C.K. Rice drying, storage and processing: Effects of post-harvest operations on grain quality. Rice Sci. 2022, 29, 16–30. [Google Scholar] [CrossRef]

- Matias, G.S.; Lermen, F.H.; Matos, C.; Nicolin, D.J.; Fischer, C.; Rossoni, D.F.; Jorge, L.M.M. A model of distributed parameters for non-Fickian diffusion in grain drying based on the fractional calculus approach. Biosyst. Eng. 2023, 226, 16–26. [Google Scholar] [CrossRef]

- Nirmaan, A.M.C.; Rohitha Prasantha, B.D.; Peiris, B.L. Comparison of microwave drying and oven-drying techniques for moisture determination of three paddy (Oryza sativa L.) varieties. Chem. Biol. Technol. Agric. 2020, 7, 1. [Google Scholar] [CrossRef]

- Li, B.; Feng, S.; He, Q.; Zhu, Y.; Hu, Z.; Jiang, Y.; Su, L. Numerical simulation of rice drying process in a deep bed under an angular air duct. J. Food Process Eng. 2023, 46, e14438. [Google Scholar] [CrossRef]

- Defraeye, T. Advanced computational modelling for drying processes—A review. Appl. Energy 2014, 131, 323–344. [Google Scholar] [CrossRef]

- Zhao, A.; Rui, X.; Rong, B.; Wang, G. Conjugate modeling of flow and simultaneous heat and mass transfer in convective drying of porous substances. Appl. Therm. Eng. 2021, 199, 117571. [Google Scholar] [CrossRef]

- Chasiotis, V.; Tzempelikos, D.; Mitrakos, D.; Filios, A. Numerical and experimental analysis of heat and moisture transfer of lavandula x allardii leaves during non-isothermal convective drying. J. Food Eng. 2021, 311, 110708. [Google Scholar] [CrossRef]

- Wang, J.; Wang, D.; Zhan, T.; Qiu, S.; Tao, D.; Ji, D.; Cheng, E. Effect of tempering drying on the physicochemical properties of paddy rice. J. Food Process. Preserv. 2022, 46, e16374. [Google Scholar] [CrossRef]

- Onwude, D.I.; Hashim, N.; Abdan, K.; Janius, R.; Chen, G.; Kumar, C. Modelling of coupled heat and mass transfer for combined infrared and hot-air drying of sweet potato. J. Food Eng. 2018, 228, 12–24. [Google Scholar] [CrossRef]

- Pei, Y.; Li, Z.; Song, C.; Li, J.; Xu, W.; Zhu, G. Analysis and modelling of temperature and moisture gradient for ginger slices in hot air drying. J. Food Eng. 2022, 323, 111009. [Google Scholar] [CrossRef]

- Zhao, L.; Yang, J.; Du, T.; Wu, Z. A 3-Dimensional Body Fitted Simulation of Heat and Mass Transfer in Rice Kernel during Hot Air Drying Process. Int. J. Food Eng. 2019, 15, 20180382. [Google Scholar] [CrossRef]

- Wei, S.; Wang, Z.; Xie, W.; Wang, F.; Chen, P.; Yang, D. A heat and mass transfer model based on multi-component heterogeneity for corn kernel tempering drying: Development and application. Comput. Electron. Agric. 2020, 171, 105335. [Google Scholar] [CrossRef]

- Chen, P.; Chen, N.; Zhu, W.; Wang, D.; Jiang, M.; Qu, C.; Li, Y.; Zou, Z. A Heat and Mass Transfer Model of Peanut Convective Drying Based on a Two-Component Structure. Foods 2023, 12, 1823. [Google Scholar] [CrossRef]

- Selimefendigil, F.; Coban, S.O.; Öztop, H.F. Numerical analysis of heat and mass transfer of a moving porous moist object in a two dimensional channel. Int. Commun. Heat Mass Transf. 2021, 121, 105093. [Google Scholar] [CrossRef]

- Huo, P.; Wang, Y. Numerical Simulation and Optimization of Airflow Distribution in Ceramic Drying Room. Heat Transf. Eng. 2024, 1–15. [Google Scholar] [CrossRef]

- Wang, P.; Liu, G.; Ao, S.; Sun, D.; Yu, B.; Wu, X. Numerical investigation of airflow and heat transfer characteristics and optimal design of the American ginseng drying room. Appl. Therm. Eng. 2021, 183, 115885. [Google Scholar] [CrossRef]

- Chen, F.; Warning, A.D.; Datta, A.K.; Chen, X. Susceptors in microwave cavity heating: Modeling and experimentation with a frozen pie. J. Food Eng. 2017, 195, 191–205. [Google Scholar] [CrossRef]

- Su, T.; Zhang, W.; Zhang, Z.; Wang, X.; Zhang, S. Energy utilization and heating uniformity of multiple specimens heated in a domestic microwave oven. Food Bioprod. Process. 2022, 132, 35–51. [Google Scholar] [CrossRef]

- Wu, S.; Song, Y.; Wang, X.; Xu, J.; Xiao, B.; Qiao, K. Simulation and optimization of heating rate and thermal uniformity of microwave reactor for biomass pyrolysis. Chem. Eng. Sci. 2022, 250, 117386. [Google Scholar] [CrossRef]

- Basak, T. Theoretical analysis on the role of annular metallic shapes for microwave processing of food dielectric cylinders with various irradiations. Int. J. Heat Mass Transf. 2011, 54, 242–259. [Google Scholar] [CrossRef]

- Basak, T.; Bhattacharya, M.; Panda, S. A generalized approach on microwave processing for the lateral and radial irradiations of various Groups of food materials. Food Sci. Emerg. Technol. 2016, 33, 333–347. [Google Scholar] [CrossRef]

- Bezerra, C.V.; Meller Da Silva, L.H.; Corrêa, D.F.; Rodrigues, A.M.C. A modeling study for moisture diffusivities and moisture transfer coefficients in drying of passion fruit peel. Int. J. Heat Mass Transf. 2015, 85, 750–755. [Google Scholar] [CrossRef]

- Castro, A.M.; Mayorga, E.Y.; Moreno, F.L. Mathematical Mathematical modelling of convective drying of fruits: A review. J. Food Eng. 2018, 223, 152–167. [Google Scholar] [CrossRef]

- Aprajeeta, J.; Gopirajah, R.; Anandharamakrishnan, C. Shrinkage and porosity effects on heat and mass transfer during potato drying. J. Food Eng. 2015, 144, 119–128. [Google Scholar] [CrossRef]

- Law, M.C.; Liew, E.L.; Chang, S.L.; Chan, Y.S.; Leo, C.P. Modelling microwave heating of discrete samples of oil palm kernels. Appl. Therm. Eng. 2016, 98, 702–726. [Google Scholar] [CrossRef]

- Shen, L.; Zhu, Y.; Liu, C.; Wang, L.; Liu, H.; Kamruzzaman, M.; Liu, C.; Zhang, Y.; Zheng, X. Modelling of moving drying process and analysis of drying characteristics for germinated brown rice under continuous microwave drying. Biosyst. Eng. 2020, 195, 64–88. [Google Scholar] [CrossRef]

- Ranjbaran, M.; Emadi, B.; Zare, D. CFD Simulation of Deep-Bed Paddy Drying Process and Performance. Dry. Technol. 2014, 32, 919–934. [Google Scholar] [CrossRef]

- Defraeye, T.; Radu, A. Insights in convective drying of fruit by coupled modeling of fruit drying, deformation, quality evolution and convective exchange with the airflow. Appl. Therm. Eng. 2018, 129, 1026–1038. [Google Scholar] [CrossRef]

- Yu, X.-L.; Zielinska, M.; Ju, H.-Y.; Mujumdar, A.S.; Duan, X.; Gao, Z.-J.; Xiao, H.-W. Multistage relative humidity control strategy enhances energy and exergy efficiency of convective drying of carrot cubes. Int. J. Heat Mass Transf. 2020, 149, 119231. [Google Scholar] [CrossRef]

- Perussello, C.A.; Kumar, C.; De Castilhos, F.; Karim, M.A. Heat and mass transfer modeling of the osmo-convective drying of yacon roots (Smallanthus sonchifolius). Appl. Therm. Eng. 2014, 63, 23–32. [Google Scholar] [CrossRef]

- Zhao, L.; Yang, J.; Wang, S.; Wu, Z. Investigation of glass transition behavior in a rice kernel drying process by mathematical modeling. Dry. Technol. 2020, 38, 1092–1105. [Google Scholar] [CrossRef]

- Hii, C.L.; Law, C.L.; Law, M.C. Simulation of heat and mass transfer of cocoa beans under stepwise drying conditions in a heat pump dryer. Appl. Therm. Eng. 2013, 54, 264–271. [Google Scholar] [CrossRef]

- Law, M.C.; Chang, J.S.L.; Chan, Y.S.; Pui, D.Y.; You, K.Y. Experimental characterization and modeling of microwave heating of oil palm kernels, mesocarps, and empty fruit bunches. Dry. Technol. 2019, 37, 69–91. [Google Scholar] [CrossRef]

- Lague, C.; Jenkins, B.M. Modeling pre-harvest stress-cracking of rice kernels Part II implementation and use of the model. Trans. ASAE 1991, 34, 1812–1823. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, G.; Choi, C.Y. Effect of airflow speed and direction on convective heat transfer of standing and reclining cows. Biosyst. Eng. 2018, 167, 87–98. [Google Scholar] [CrossRef]

- Lemus-Mondaca, R.; Zambra, C.; Rosales, C. Computational modelling and energy consumption of turbulent 3D drying process of olive-waste cake. J. Food Eng. 2019, 263, 102–113. [Google Scholar] [CrossRef]

- Zhao, H.-B.; Wu, K.; Zhang, J.-F. Simulation study on active air flow distribution characteristics of closed heat pump drying system with waste heat recovery. Energies 2021, 14, 6358. [Google Scholar] [CrossRef]

- Woo Park, H.; Byong Yoon, W. Effects of air movement in a hot air dryer on the drying characteristics of colored potato (Solanum tuberosum L.) using computational fluid dynamic. Int. J. Agric. Biol. Eng. 2018, 11, 232–240. [Google Scholar] [CrossRef]

- Caccavale, P.; De Bonis, M.V.; Ruocco, G. Conjugate heat and mass transfer in drying: A modeling review. J. Food Eng. 2016, 176, 28–35. [Google Scholar] [CrossRef]

- Chen, J.; Lau, S.K.; Chen, L.; Wang, S.; Subbiah, J. Modeling radio frequency heating of food moving on a conveyor belt. Food Bioprod. Process. 2017, 102, 307–319. [Google Scholar] [CrossRef]

- Kaveh, M.; Amiri Chayjan, R. Modeling thin-layer drying of turnip slices under semi-industrial continuous band dryer. J. Food Process. Preserv. 2017, 41, e12778. [Google Scholar] [CrossRef]

- Yang, X.-H.; Deng, L.-Z.; Mujumdar, A.S.; Xiao, H.-W.; Zhang, Q.; Kan, Z. Evolution and modeling of colour changes of red pepper (Capsicum annuum L.) during hot air drying. J. Food Eng. 2018, 231, 101–108. [Google Scholar] [CrossRef]

- Wei, S.; Xie, W.; Zheng, Z.; Ren, L.; Yang, D. Numerical study on drying uniformity of bulk corn kernels during radio frequency-assisted hot air drying. Biosyst. Eng. 2023, 227, 117–129. [Google Scholar] [CrossRef]

- Perez, J.H.; Tanaka, F.; Tanaka, F.; Hamanaka, D.; Uchino, T. Three-dimensional numerical modeling of convective heat transfer during shallow-depth forced-air drying of brown rice grains. Dry. Technol. 2015, 33, 1350–1359. [Google Scholar] [CrossRef]

- Shen, L.; Wang, L.; Zheng, C.; Liu, C.; Zhu, Y.; Liu, H.; Liu, C.; Shi, Y.; Zheng, X.; Xu, H. Continuous microwave drying of germinated brown rice: Effects of drying conditions on fissure and color, and modeling of moisture content and stress inside kernel. Dry. Technol. 2021, 39, 669–697. [Google Scholar] [CrossRef]

- Yang, Z. Flow around three circular cylinders in equilateral-triangular arrangement. Ocean Eng. 2020, 263, 102–113. [Google Scholar] [CrossRef]

- Sabarez, H.T. Computational modelling of the transport phenomena occurring during convective drying of prunes. J. Food Eng. 2012, 111, 279–288. [Google Scholar] [CrossRef]

- Chen, P.; Fan, M.; Zhu, W.; Liu, Y.; Jiang, M.; Wang, Y.; Wang, X. Numerical simulation of hot air drying of wheat grain piles based on CFD-DEM and experimental research. Dry. Technol. 2024, 42, 199–211. [Google Scholar] [CrossRef]

- El-Mesery, H.S. Convective hot air drying of grapes: Drying kinetics, mathematical modeling, energy, thermal analysis. J. Therm. Anal. Calorim. 2023, 148, 6893–6908. [Google Scholar] [CrossRef]

- Chaudhari, V.D.; Kulkarni, G.N.; Sewatkar, C.M. Mathematical modeling and computational fluid dynamics simulation of cabinet type solar dryer: Optimal temperature control. J. Food Process Eng. 2021, 44, e13643. [Google Scholar] [CrossRef]

- Mishra, R.K.; Chandramohan, V.P.; Talukdar, P. Numerical modeling of convective drying of food with spatially dependent transfer coefficient in a turbulent flow field. Int. J. Therm. Sci. 2014, 78, 145–157. [Google Scholar] [CrossRef]

- Meng, Y. Relationship between heat/mass transfer and color change during drying process. J. Food Meas. Charact. 2022, 16, 4151–4160. [Google Scholar] [CrossRef]

| Samples | Temperature (°C) | Moisture Content (w.b.) | ||

|---|---|---|---|---|

| RMSE | R2 | RMSE | R2 | |

| S1 | 2.285 | 0.964 | 0.241 | 0.995 |

| S2 | 2.270 | 0.963 | 0.298 | 0.992 |

| S3 | 2.279 | 0.963 | 0.256 | 0.994 |

| Save | 2.155 | 0.967 | 0.252 | 0.995 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Pei, Y.; Mu, Z.; Fan, L.; Kong, J.; Tian, G.; Miao, S.; Meng, X.; Qiu, H. Simulation Analysis of 3-D Airflow and Temperature Uniformity of Paddy in a Laboratory Drying Oven. Foods 2024, 13, 3466. https://doi.org/10.3390/foods13213466

Wang C, Pei Y, Mu Z, Fan L, Kong J, Tian G, Miao S, Meng X, Qiu H. Simulation Analysis of 3-D Airflow and Temperature Uniformity of Paddy in a Laboratory Drying Oven. Foods. 2024; 13(21):3466. https://doi.org/10.3390/foods13213466

Chicago/Turabian StyleWang, Changzhi, Yongsheng Pei, Zhongqiu Mu, Lin Fan, Jian Kong, Guizhong Tian, Shiyuan Miao, Xiangyi Meng, and Hai Qiu. 2024. "Simulation Analysis of 3-D Airflow and Temperature Uniformity of Paddy in a Laboratory Drying Oven" Foods 13, no. 21: 3466. https://doi.org/10.3390/foods13213466

APA StyleWang, C., Pei, Y., Mu, Z., Fan, L., Kong, J., Tian, G., Miao, S., Meng, X., & Qiu, H. (2024). Simulation Analysis of 3-D Airflow and Temperature Uniformity of Paddy in a Laboratory Drying Oven. Foods, 13(21), 3466. https://doi.org/10.3390/foods13213466