Exploring the Potential of Duck Egg White Jelly: Enhancing Texture, Reducing Phosphate, and Innovating Emulsified Meat Snacks

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Duck Egg White Jelly

2.3. Preparation of Emulsified Meat Snacks

2.4. Measurement of pH and Viscosity of Raw Emulsified Meat Pastes

2.5. Texture Profile Analysis

2.6. Cooking Loss

2.7. Purge Loss

2.8. Color Measurement

2.9. Sensory Evaluation

2.10. Statistical Analysis

3. Results and Discussion

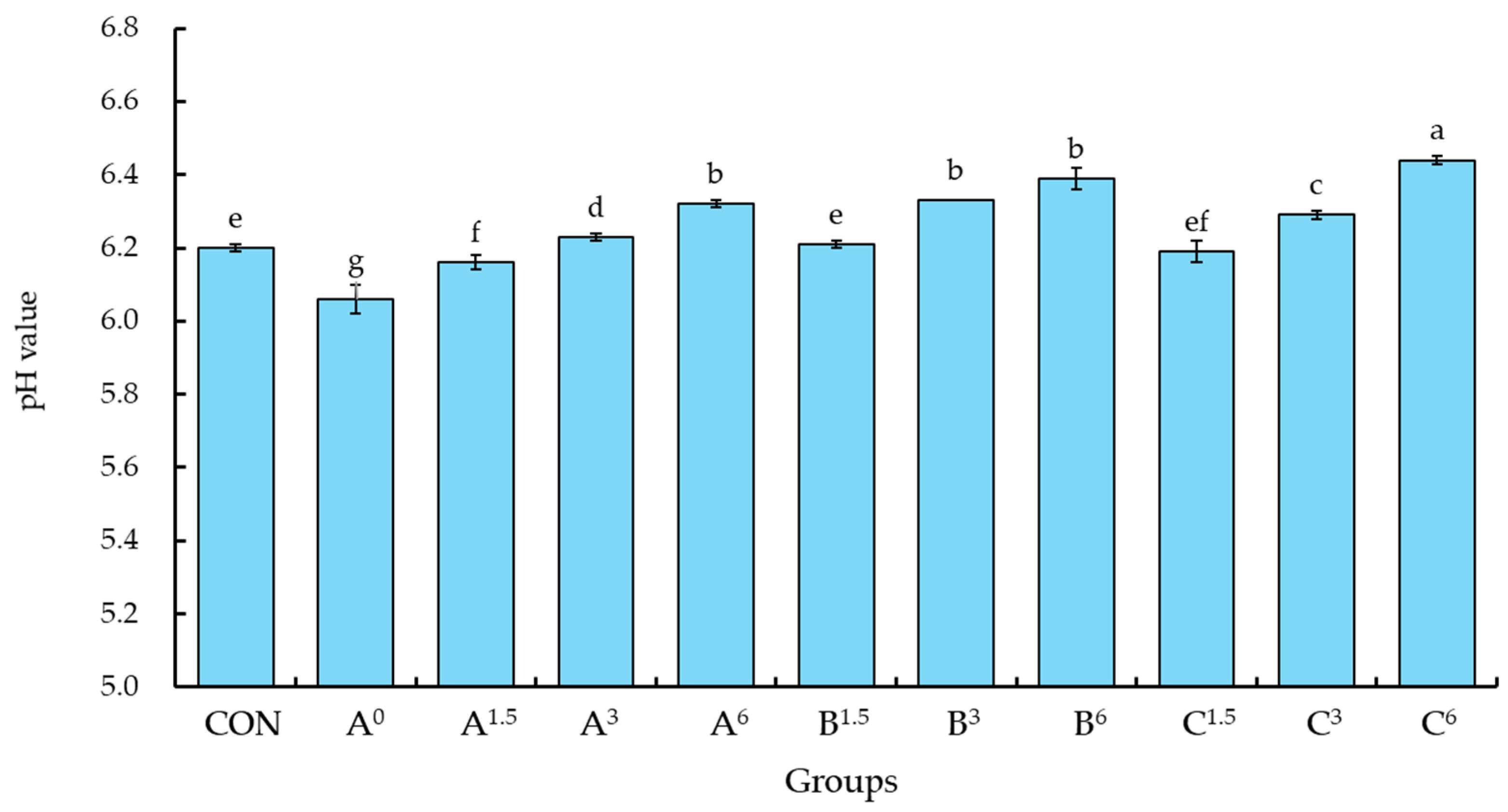

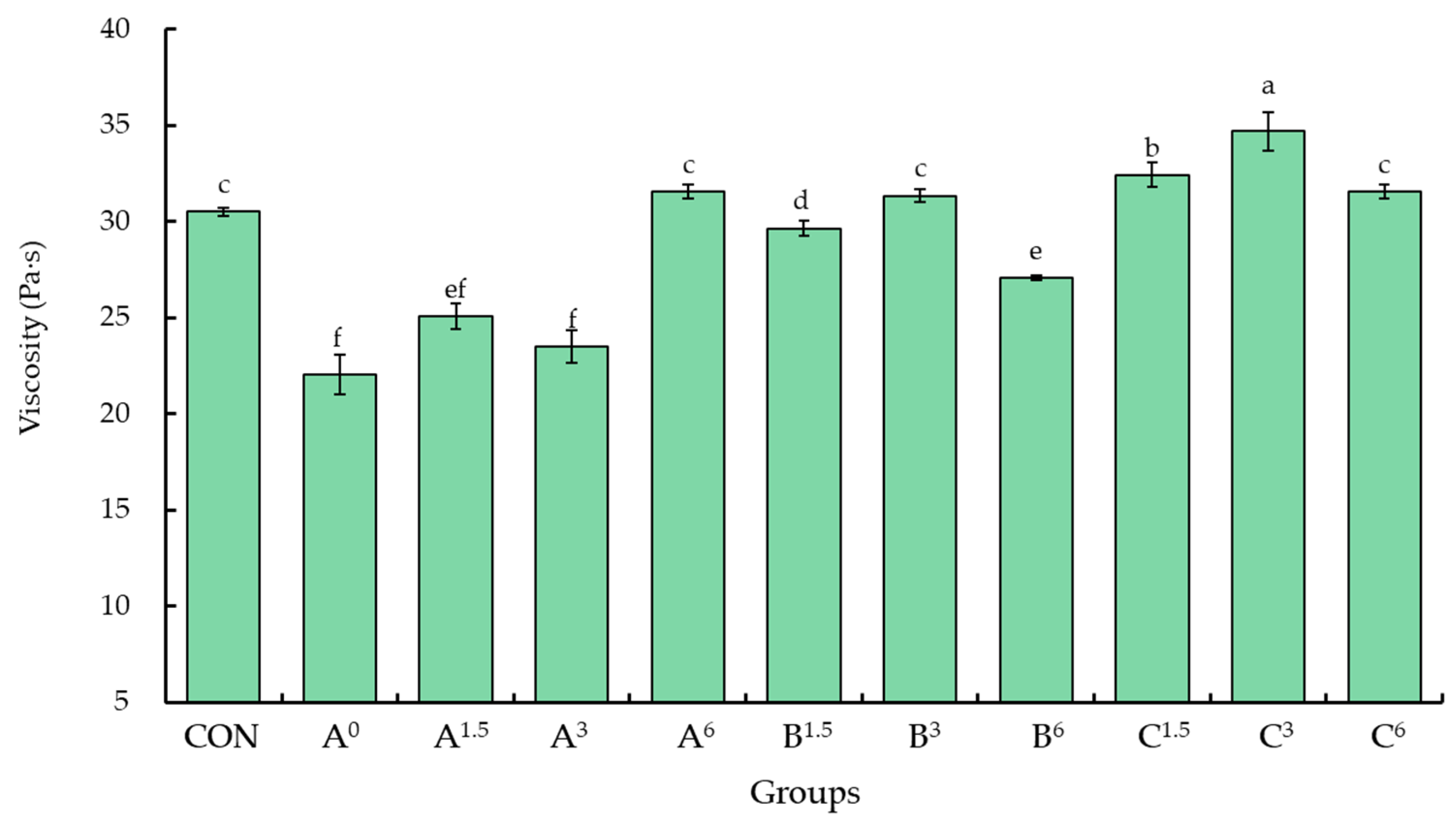

3.1. Effects of Alkaline Duck Egg White Jelly on the pH and Viscosity of Raw Meat Pastes

3.2. Effects of Alkaline Duck Egg White Jelly on the Texture Profile and Water-Holding Capacity of Emulsified Meat Snacks

3.3. Effects of Alkaline Duck Egg White Jelly on the Color and Sensory Properties of Emulsified Meatballs

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hsu, S.Y.; Chung, H.Y. Effects of processing factors on qualities of emulsified meatball. J. Food Eng. 1998, 36, 337–347. [Google Scholar] [CrossRef]

- Barbut, S. Importance of fat emulsification and protein matrix characteristics in meat batter stability. J. Muscle Foods 1995, 6, 161–177. [Google Scholar] [CrossRef]

- Shao, J.H.; Zou, Y.F.; Xu, X.L.; Wu, J.Q.; Zhou, G.H. Evaluation of structural changes in raw and heated meat batters prepared with different lipids using Raman spectroscopy. Food Res. Int. 2011, 44, 2955–2961. [Google Scholar] [CrossRef]

- Purnomo, H.; Rahardiyan, D. Indonesian traditional meatball. Int. Food Res. J. 2008, 15, 101–108. [Google Scholar]

- Balestra, F.; Petracci, M. Technofunctional Ingredients for Meat Products: Current Challenges. In Sustainable Meat Production and Processing; Elsevier: Amsterdam, The Netherlands, 2019; pp. 45–62. [Google Scholar]

- Eilert, S.J.; Mandigo, R.W. Use of phosphates and salt to improve lean meat water retention in high-moisture preblends. J. Muscle Foods 1996, 7, 1–16. [Google Scholar] [CrossRef]

- Long, N.H.B.S.; Gál, R.; Buňka, F. Use of phosphates in meat products. Afr. J. Biotechnol. 2011, 10, 19874–19882. [Google Scholar] [CrossRef]

- Kristinsson, H.; Hultin, H. Role of pH and ionic strength on water relationships in washed minced chicken-breast muscle gels. J. Food Sci. 2003, 68, 917–922. [Google Scholar] [CrossRef]

- Shults, G.; Wierbicki, E. Effects of sodium chloride and condensed phosphates on the water-holding capacity, pH, and swelling of chicken muscle. J. Food Sci. 1973, 38, 991–994. [Google Scholar] [CrossRef]

- Glorieux, S.; Goemaere, O.; Steen, L.; Fraeye, I. Phosphate reduction in emulsified meat products: Impact of phosphate type and dosage on quality characteristics. Food Technol. Biotechnol. 2017, 55, 390–397. [Google Scholar] [CrossRef]

- Delgado-Pando, G.; Ekonomou, S.I.; Stratakos, A.C.; Pintado, T. Clean label alternatives in meat products. Foods 2021, 10, 1615. [Google Scholar] [CrossRef]

- European Food Safety Authority (EFSA). Re-evaluation of phosphoric acid–phosphates–di-, tri- and polyphosphates (E 338–341, E 343, E 450–452) as food additives and the safety of proposed extension of use. EFSA J. 2019, 17, 5674. [Google Scholar] [CrossRef]

- Cho, M.G.; Bae, S.M.; Jeong, J.Y. Egg shell and oyster shell powder as alternatives for synthetic phosphate: Effects on the quality of cooked ground pork products. Korean J. Food Sci. Anim. Resour. 2017, 37, 571–578. [Google Scholar] [CrossRef] [PubMed]

- Bae, S.M.; Cho, M.K.; Jeong, J.Y. Effects of various calcium powders as replacers for synthetic phosphate on the quality properties of ground pork meat products. Korean J. Food Sci. Anim. Resour. 2017, 37, 456–463. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, J.; Ma, Y.; Ma, Z.; Ma, Q.; Li, Z.; Wang, S. Effect of partial substitution of complex phosphates with sodium bicarbonate on aggregation, conformation and gel properties of beef-pork-chicken complex myofibrillar proteins. J. Sci. Food Agric. 2024, 104, 7386–7396. [Google Scholar] [CrossRef]

- Wang, Y.; Yuan, J.J.; Li, K.; Wang, J.L.; Li, J.G.; Chen, B.; Bai, Y.H. Effects of combined chickpea protein isolate and chitosan on the improvement of technological quality in phosphate-free pork meat emulsions: Its relation to modifications on protein thermal and structural properties. Meat Sci. 2023, 201, 109194. [Google Scholar] [CrossRef]

- Yuan, D.; Liang, X.; Kong, B.; Xia, X.; Cao, C.; Zhang, H.; Liu, Q.; Li, X. Influence of seaweed dietary fibre as a potential alternative to phosphates on the quality profiles and flavour attributes of frankfurters. Meat Sci. 2024, 213, 109511. [Google Scholar] [CrossRef]

- Kao, W.; Lin, K. Quality of reduced–fat frankfurter modified by konjac–starch mixed gels. J. Food Sci. 2006, 71, S326–S332. [Google Scholar] [CrossRef]

- Park, K.S.; Choi, Y.I.; Lee, S.H.; Kim, C.H.; Auh, J.H. Application of functional carbohydrates as a substitute for inorganic polyphosphate in pork meat processing. Korean J. Food Sci. Technol. 2008, 40, 118–121. [Google Scholar]

- Almeida, C.M.; Wagner, R.; Mascarin, L.G.; Zepka, L.Q.; Campagnol, P.V.B. Production of low-fat emulsified cooked sausages using amorphous cellulose gel. J. Food Qual. 2014, 37, 437–443. [Google Scholar] [CrossRef]

- Jung, D.Y.; Lee, H.J.; Shin, D.J.; Kim, C.H.; Jo, C. Mechanism of improving emulsion stability of emulsion-type sausage with oyster mushroom (Pleurotus ostreatus) powder as a phosphate replacement. Meat Sci. 2022, 194, 108993. [Google Scholar] [CrossRef]

- Jeong, J.Y. Determining the optimal level of natural calcium powders and whey protein concentrate blends as phosphate replacers in cooked ground pork products. Korean J. Food Sci. Anim. Resour. 2018, 38, 1246–1252. [Google Scholar] [CrossRef] [PubMed]

- He, W.; Xiao, N.; Zhao, Y.; Yao, Y.; Xu, M.; Du, H.; Wu, N.; Tu, Y. Effect of polysaccharides on the functional properties of egg white protein: A review. J. Food Sci. 2021, 86, 656–666. [Google Scholar] [CrossRef] [PubMed]

- Feiner, G. Additives: Proteins, carbohydrates, fillers and other additives. In Meat Products Handbook; Feiner, G., Ed.; Woodhead Publishing: Cambridge, UK, 2006; pp. 89–141. [Google Scholar]

- Goemaere, O.; Glorieux, S.; Govaert, M.; Steen, L.; Fraeye, I. Phosphate elimination in emulsified meat products: Impact of protein-based ingredients on quality characteristics. Foods 2021, 10, 882. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.H. Salting yolks directly using fresh duck egg yolks with salt and maltodextrin. J. Poult. Sci. 2017, 54, 97–102. [Google Scholar] [CrossRef]

- Zheng, N.Y.; Chen, Y.C.; Chen, Y.P.; Shiu, J.S.; Wang, S.Y. Development of a heatable duck egg white translucent jelly: An evaluation of its physicochemical properties and thermal stability. Poult. Sci. 2021, 100, 101373. [Google Scholar] [CrossRef]

- Ding, Y.; Wang, S.Y.; Yang, D.J.; Chang, M.H.; Chen, Y.C. Alleviative effects of litchi (Litchi chinensis Sonn.) flower on lipid peroxidation and protein degradation in emulsified pork meatballs. J. Food Drug Anal. 2015, 23, 501–508. [Google Scholar] [CrossRef]

- Wu, Y.H.S.; Lin, D.Q.; Wang, S.Y.; Lin, Y.L.; Chen, J.W.; Nakthong, S.; Chen, Y.C. Effects of wheat-fiber addition on emulsion and lipid/protein stabilities of an omega-3 fatty-acid fortified chicken-surimi product. Poult. Sci. 2021, 100, 1319–1327. [Google Scholar] [CrossRef]

- Thangavelu, K.P.; Kerry, J.P.; Tiwari, B.K.; McDonnell, C.K. Novel processing technologies and ingredient strategies for the reduction of phosphate additives in processed meat. Trends Food Sci. Technol. 2019, 94, 43–53. [Google Scholar] [CrossRef]

- Knipe, C.L.; Olson, D.G.; Rust, R.E. Effects of selected inorganic phosphates, phosphate levels, and reduced sodium chloride levels on protein solubility, stability, and pH of meat emulsions. J. Food Sci. 1985, 50, 1010. [Google Scholar] [CrossRef]

- Shand, P.J. Textural, water-holding, and sensory properties of low-fat pork bologna with normal or waxy starch hull-less barley. J. Food Sci. 2000, 65, 101–107. [Google Scholar] [CrossRef]

- Aktaş, N.; Gençcelep, H. Effect of starch type and its modifications on the physicochemical properties of bologna-type sausage produced with sheep tail fat. Meat Sci. 2006, 74, 404–408. [Google Scholar] [CrossRef] [PubMed]

- Totosaus, A.; Montejano, J.G.; Salazar, J.A.; Guerrero, I. A review of physical and chemical protein–gel induction. Int. J. Food Sci. Technol. 2002, 37, 589–601. [Google Scholar] [CrossRef]

- Yapar, A.; Atay, S.; Kayacier, A.; Yetim, H. Effects of different levels of salt and phosphate on some emulsion attributes of the common carp (Cyprinus carpio L., 1758). Food Hydrocoll. 2006, 20, 825–830. [Google Scholar] [CrossRef]

- Tamm, A.; Bolumar, T.; Bajovic, B.; Toepfl, S. Salt (NaCl) reduction in cooked ham by a combined approach of high-pressure treatment and the salt replacer KCl. Innov. Food Sci. Emerg. Technol. 2016, 36, 294–302. [Google Scholar] [CrossRef]

- Li, C.; Li, J.; Li, X.; Hviid, M.; Lundstrom, K. Effect of low–voltage electrical stimulation after dressing on color stability and water holding capacity of bovine longissimus muscle. Meat Sci. 2011, 88, 559–565. [Google Scholar] [CrossRef]

- Hong, G.P.; Lee, S.; Min, S.G. Effects of substituted level of added water for fat on the quality characteristics of spreadable liver sausage. Food Sci. Biotechnol. 2004, 13, 397–402. [Google Scholar]

- Yoo, S.S.; Kook, S.H.; Park, S.Y.; Shim, J.H.; Chin, K.B. Evaluation of curing and flavor ingredients, and different cooking methods on the product quality and flavor compounds of low-fat sausages. Food Sci. Biotechnol. 2005, 14, 634–638. [Google Scholar]

- Vasanthi, C.; Venkataramanujam, V.; Dushyanthan, K. Effect of cooking temperature and time on the physico-chemical, histological and sensory properties of female carabeef (buffalo) meat. Meat Sci. 2007, 76, 274–280. [Google Scholar] [CrossRef]

- Choi, J.H.; Jeong, J.Y.; Han, D.J.; Choi, Y.S.; Kim, H.Y.; Lee, M.A.; Lee, E.S.; Paik, H.D.; Kim, C.J. Effects of pork/beef levels and various casings on quality properties of semi-dried jerky. Meat Sci. 2008, 80, 278–286. [Google Scholar] [CrossRef]

- García-García, E.; Totosaus, A. Low-fat sodium-reduced sausages: Effect of the interaction between locust bean gum, potato starch, and κ-carrageenan by a mixture design approach. Meat Sci. 2008, 78, 406–413. [Google Scholar] [CrossRef]

- Buzała, M.; Słomka, A.; Janicki, B. Heme iron in meat as the main source of iron in the human diet. J. Elem. 2015, 21, 303–314. [Google Scholar] [CrossRef]

- Boles, J.A.; Pegg, R. Meat Color; Montana State University and Saskatchewan Food Product Innovation Program; University of Saskatchewan: Saskatoon, SK, Canada, 2010. [Google Scholar]

| Raw Meat Materials (100 kg) | Additives and Seasonings * | |||||||

|---|---|---|---|---|---|---|---|---|

| Group | Lean Pork Meat (kg) | Back Fat (kg) | Phosphate (%) | Duck Egg White Jelly (%) | Salt (%) | Sugar (%) | Garlic Powder (%) | White Pepper Powder (%) |

| CON | 75 | 25 | 0.2 | 0 | 1.3 | 2.0 | 0.2 | 0.2 |

| A0 | 75 | 25 | 0 | 0 | 1.3 | 2.0 | 0.2 | 0.2 |

| A1.5 | 75 | 25 | 0 | 1.5 | 1.3 | 2.0 | 0.2 | 0.2 |

| A3 | 75 | 25 | 0 | 3.0 | 1.3 | 2.0 | 0.2 | 0.2 |

| A6 | 75 | 25 | 0 | 6.0 | 1.3 | 2.0 | 0.2 | 0.2 |

| B1.5 | 75 | 25 | 0.1 | 1.5 | 1.3 | 2.0 | 0.2 | 0.2 |

| B3 | 75 | 25 | 0.1 | 3.0 | 1.3 | 2.0 | 0.2 | 0.2 |

| B6 | 75 | 25 | 0.1 | 6.0 | 1.3 | 2.0 | 0.2 | 0.2 |

| C1.5 | 75 | 25 | 0.2 | 1.5 | 1.3 | 2.0 | 0.2 | 0.2 |

| C3 | 75 | 25 | 0.2 | 3.0 | 1.3 | 2.0 | 0.2 | 0.2 |

| C6 | 75 | 25 | 0.2 | 6.0 | 1.3 | 2.0 | 0.2 | 0.2 |

| Groups | Hardness (N) | Springiness | Cohesiveness | Gumminess (N) | Chewiness (N·mm) | Resilience |

|---|---|---|---|---|---|---|

| CON | 99.04 ± 1.15 c | 0.78 ± 0.08 cd | 0.64 ± 0.01 e | 62.97 ± 1.32 b | 49.18 ± 5.68 c | 0.26 ± 0.00 d |

| A0 | 63.22 ± 0.65 g | 0.76 ± 0.01 d | 0.43 ± 0.01 g | 27.32 ± 0.89 e | 20.79 ± 0.89 de | 0.13 ± 0.01 g |

| A1.5 | 50.14 ± 0.63 i | 0.77 ± 0.01 cd | 0.48 ± 0.01 f | 24.12 ± 0.35 e | 18.57 ± 0.52 e | 0.16 ± 0.01 f |

| A3 | 56.23 ± 0.18 h | 0.79 ± 0.03 cd | 0.44 ± 0.03 g | 24.93 ± 1.51 e | 19.68 ± 0.87 de | 0.15 ± 0.02 fg |

| A6 | 64.50 ± 1.05 g | 0.78 ± 0.01 cd | 0.49 ± 0.01 f | 31.80 ± 0.94 d | 24.79 ± 0.96 d | 0.18 ± 0.01 e |

| B1.5 | 87.74 ± 0.51 e | 0.93 ± 0.01 a | 0.68 ± 0.01 cd | 58.06 ± 0.21 c | 53.92 ± 0.70 bc | 0.29 ± 0.00 bc |

| B3 | 78.96 ± 0.63 f | 0.91 ± 0.01 ab | 0.73 ± 0.01 a | 56.21 ± 0.61 c | 51.84 ± 0.16 bc | 0.33 ± 0.00 a |

| B6 | 104.12 ± 2.56 a | 0.85 ± 0.03 abcd | 0.72 ± 0.00 ab | 65.84 ± 2.81 b | 57.59 ± 1.34 ab | 0.31 ± 0.00 b |

| C1.5 | 91.79 ± 0.62 d | 0.84 ± 0.04 abcd | 0.69 ± 0.02 bc | 63.67 ± 1.58 b | 53.63 ± 3.14 bc | 0.30 ± 0.01 bc |

| C3 | 99.46 ± 1.69 bc | 0.86 ± 0.02 abc | 0.65 ± 0.01 de | 64.62 ± 0.90 b | 55.65 ± 0.95 ab | 0.29 ± 0.00 c |

| C6 | 102.80 ± 1.65 ab | 0.83 ± 0.01 bcd | 0.71 ± 0.00 abc | 73.16 ± 1.15 a | 60.52 ± 0.56 a | 0.34 ± 0.00 a |

| Purge Loss (%) | |||||

|---|---|---|---|---|---|

| Groups | 0 Day | 7 Day | 14 Day | 21 Day | 28 Day |

| CON | 1.09 ± 0.07 b | 1.24 ± 0.02 b | 1.29 ± 0.09 cd | 2.09 ± 0.09 c | 2.16 ± 0.14 cd |

| A0 | 1.81 ± 0.08 a | 2.23 ± 0.03 a | 3.11 ± 0.05 a | 3.82 ± 0.65 a | 3.94 ± 0.22 a |

| A1.5 | 1.71 ± 0.02 a | 2.19 ± 0.08 a | 2.28 ± 0.01 b | 2.38 ± 0.01 b | 2.40 ± 0.01 c |

| A3 | 1.81 ± 0.02 a | 2.16 ± 0.02 a | 2.23 ± 0.09 b | 2.34 ± 0.19 b | 2.35 ± 0.09 c |

| A6 | 1.89 ± 0.01 a | 2.17 ± 0.02 a | 2.35 ± 0.05 b | 2.48 ± 0.05 b | 2.82 ± 0.65 b |

| B1.5 | 1.18 ± 0.05 b | 1.23 ± 0.03 b | 1.35 ± 0.07 c | 1.89 ± 0.06 cd | 2.23 ± 0.28 cd |

| B3 | 0.85 ± 0.10 c | 0.94 ± 0.17 d | 1.07 ± 0.06 e | 1.57 ± 0.36 e | 1.97 ± 0.06 d |

| B6 | 1.24 ± 0.14 b | 1.27 ± 0.09 b | 1.44 ± 0.03 c | 1.84 ± 0.37 d | 2.34 ± 0.37 c |

| C1.5 | 1.06 ± 0.04 b | 1.11 ± 0.02 c | 1.20 ± 0.02 d | 1.80 ± 0.02 d | 1.90 ± 0.12 d |

| C3 | 1.14 ± 0.04 b | 1.17 ± 0.06 c | 1.24 ± 0.09 cd | 1.84 ± 0.09 d | 1.99 ± 0.09 d |

| C6 | 1.08 ± 0.09 b | 1.15 ± 0.03 c | 1.22 ± 0.01 cd | 1.82 ± 0.01 d | 1.92 ± 0.01 d |

| Groups | L* | a* | b* | Whiteness |

|---|---|---|---|---|

| CON | 75.34 ± 0.50 cd | 1.83 ± 0.25 abc | 14.86 ± 0.40 cde | 71.14 ± 0.42 cd |

| A0 | 76.94 ± 0.51 abc | 2.15 ± 0.16 a | 14.97 ± 0.29 cde | 72.42 ± 0.54 abc |

| A1.5 | 76.26 ± 1.42 bc | 1.41 ± 0.20 cde | 14.47 ± 0.18 e | 72.14 ± 1.15 bc |

| A3 | 76.34 ± 0.23 bc | 1.91 ± 0.06 ab | 14.94 ± 0.05 cde | 71.96 ± 0.22 bc |

| A6 | 78.25 ± 0.35 a | 1.24 ± 0.12 def | 14.77 ± 0.19 cde | 73.68 ± 0.40 a |

| B1.5 | 75.72 ± 0.51 bcd | 1.05 ± 0.04 ef | 14.92 ± 0.16 cde | 71.48 ± 0.13 bcd |

| B3 | 75.83 ± 0.21 bcd | 1.58 ± 0.03 bcd | 15.93 ± 0.19 a | 71.01 ± 0.23 cd |

| B6 | 76.20 ± 0.43 bc | 0.99 ± 0.02 f | 15.69 ± 0.15 ab | 71.48 ± 0.43 bcd |

| C1.5 | 77.35 ± 0.48 ab | 1.34 ± 0.22 def | 14.72 ± 0.24 de | 72.95 ± 0.52 ab |

| C3 | 74.36 ± 0.10 d | 1.93 ± 0.06 ab | 15.23 ± 0.13 bcd | 70.11 ± 0.13 d |

| C6 | 75.74 ± 0.11 bcd | 1.21 ± 0.13 def | 15.40 ± 0.36 abc | 71.24 ± 0.29 cd |

| Groups | Color | Texture | Flavor | Total Acceptability |

|---|---|---|---|---|

| CON | 5.22 ± 0.21 | 6.31 ± 0.19 b | 6.31 ± 0.22 ab | 6.33 ± 0.22 b |

| A0 | 5.14 ± 0.22 | 4.31 ± 0.29 d | 4.61 ± 0.35 d | 4.56 ± 0.32 d |

| A1.5 | 5.11 ± 0.22 | 4.75 ± 0.27 cd | 5.00 ± 0.36 cd | 5.00 ± 0.34 cd |

| A3 | 5.06 ± 0.24 | 5.28 ± 0.28 c | 5.81 ± 0.31 b | 5.36 ± 0.29 c |

| A6 | 5.08 ± 0.22 | 4.56 ± 0.31 cd | 5.17 ± 0.33 bc | 4.97 ± 0.30 cd |

| B1.5 | 5.24 ± 0.20 | 6.78 ± 0.17 a | 6.66 ± 0.24 a | 6.77 ± 0.25 ab |

| B3 | 5.36 ± 0.19 | 7.06 ± 0.20 a | 6.54 ± 0.23 a | 6.98 ± 0.27 a |

| B6 | 5.19 ± 0.26 | 6.83 ± 0.29 a | 6.55 ± 0.28 a | 6.56 ± 0.21 ab |

| C1.5 | 5.50 ± 0.25 | 6.81 ± 0.22 a | 6.67 ± 0.23 a | 6.83 ± 0.22 ab |

| C3 | 5.33 ± 0.22 | 6.81 ± 0.21 a | 6.53 ± 0.21 a | 6.67 ± 0.24 ab |

| C6 | 5.33 ± 0.24 | 6.61 ± 0.24 ab | 6.22 ± 0.28 ab | 6.39 ± 0.28 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, N.-Y.; Chen, Y.-P.; Liu, Y.-C.; Shiu, J.-S.; Chang, L.-B.; Wang, S.-Y. Exploring the Potential of Duck Egg White Jelly: Enhancing Texture, Reducing Phosphate, and Innovating Emulsified Meat Snacks. Foods 2024, 13, 3892. https://doi.org/10.3390/foods13233892

Zheng N-Y, Chen Y-P, Liu Y-C, Shiu J-S, Chang L-B, Wang S-Y. Exploring the Potential of Duck Egg White Jelly: Enhancing Texture, Reducing Phosphate, and Innovating Emulsified Meat Snacks. Foods. 2024; 13(23):3892. https://doi.org/10.3390/foods13233892

Chicago/Turabian StyleZheng, Nian-Yao, Yen-Po Chen, Yu-Cheng Liu, Jia-Shian Shiu, Lian-Ben Chang, and Sheng-Yao Wang. 2024. "Exploring the Potential of Duck Egg White Jelly: Enhancing Texture, Reducing Phosphate, and Innovating Emulsified Meat Snacks" Foods 13, no. 23: 3892. https://doi.org/10.3390/foods13233892

APA StyleZheng, N.-Y., Chen, Y.-P., Liu, Y.-C., Shiu, J.-S., Chang, L.-B., & Wang, S.-Y. (2024). Exploring the Potential of Duck Egg White Jelly: Enhancing Texture, Reducing Phosphate, and Innovating Emulsified Meat Snacks. Foods, 13(23), 3892. https://doi.org/10.3390/foods13233892