Investigation of Rheological and Flow Properties of Buckwheat Dough with and Without Xanthan and Guar Gums for Optimized 3D Food Printing Across Temperature Variations

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Dough Preparation

2.3. Rheological Measurements

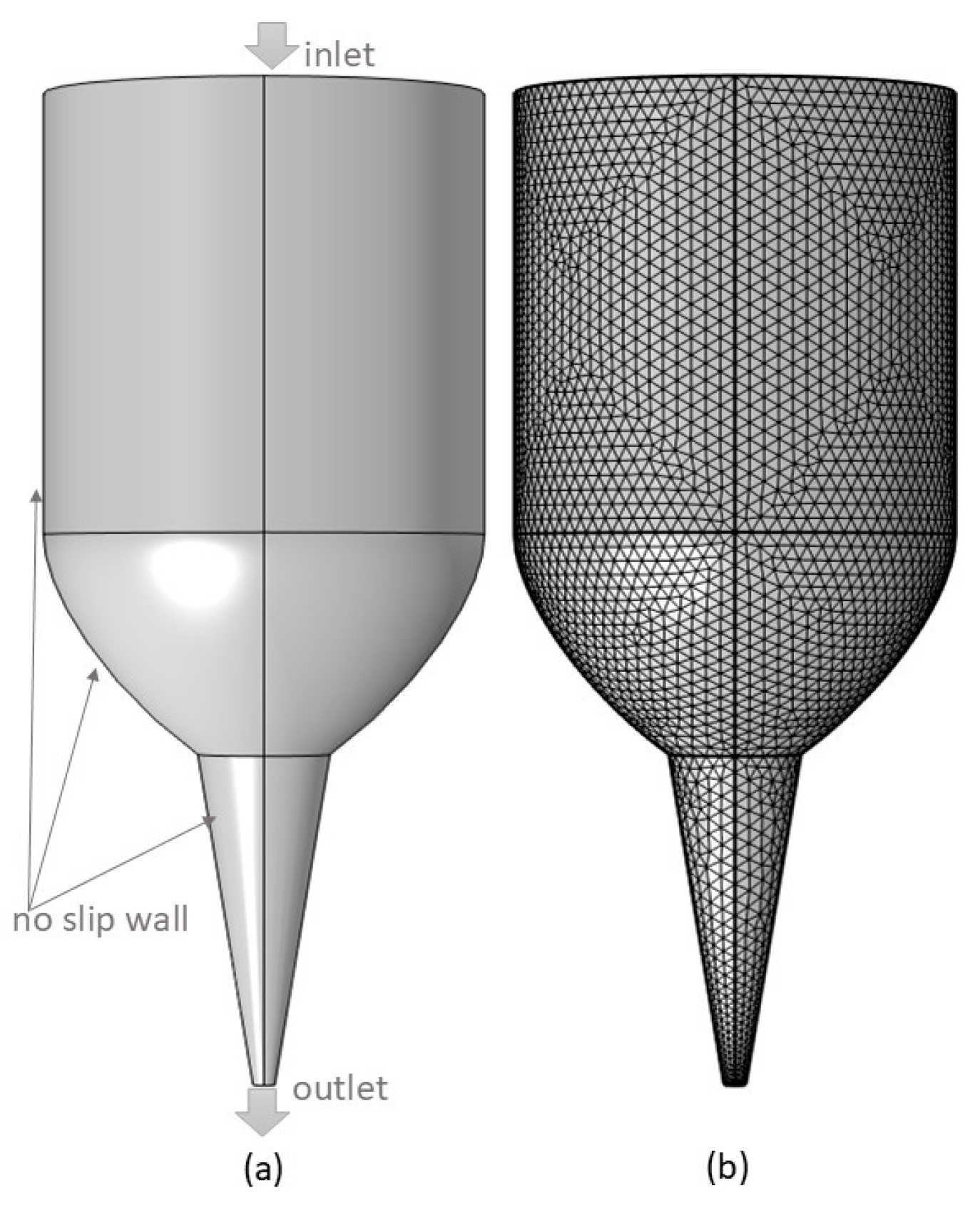

2.4. CFD Simulation of the Extrusion Process

3. Results and Discussion

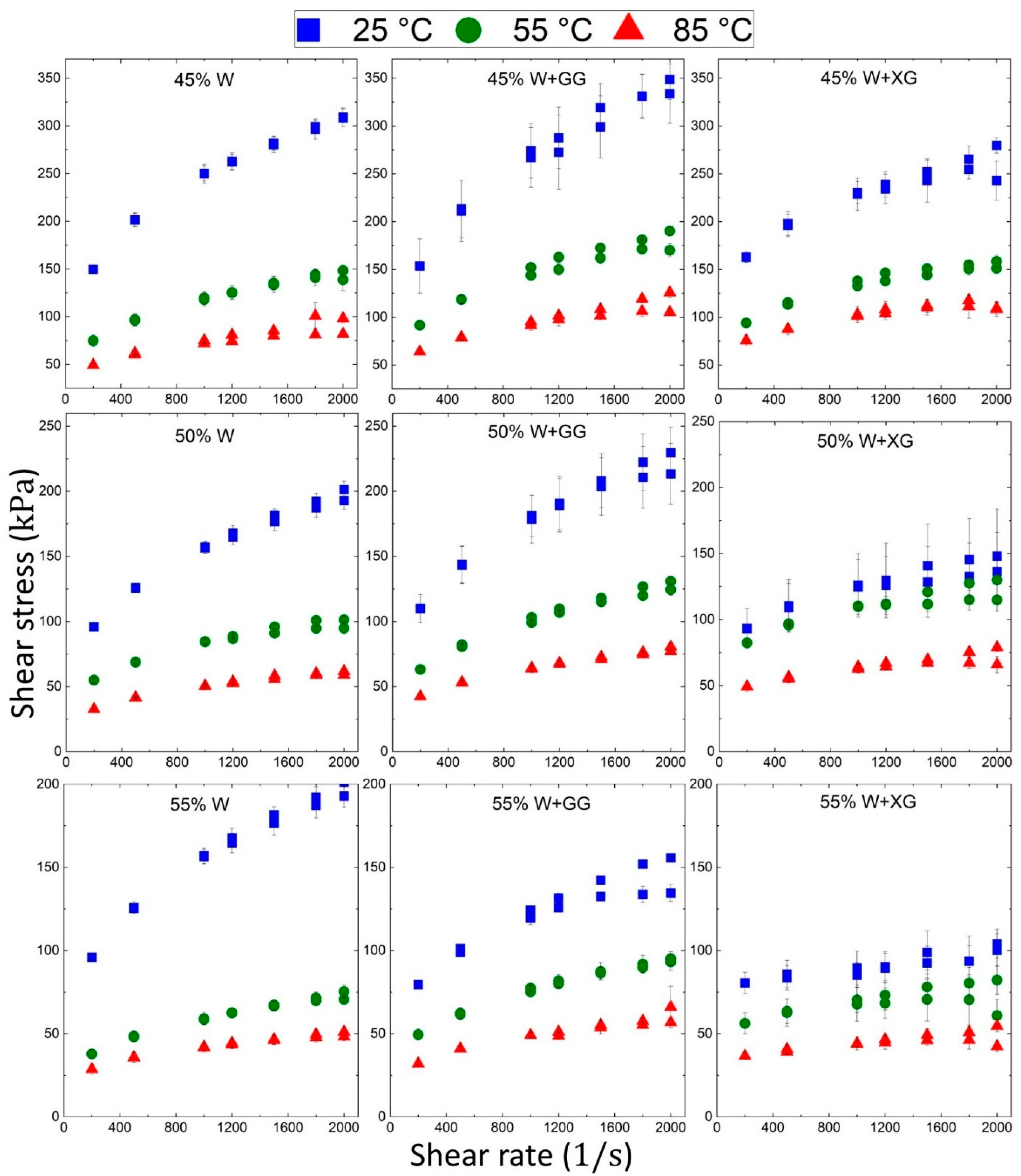

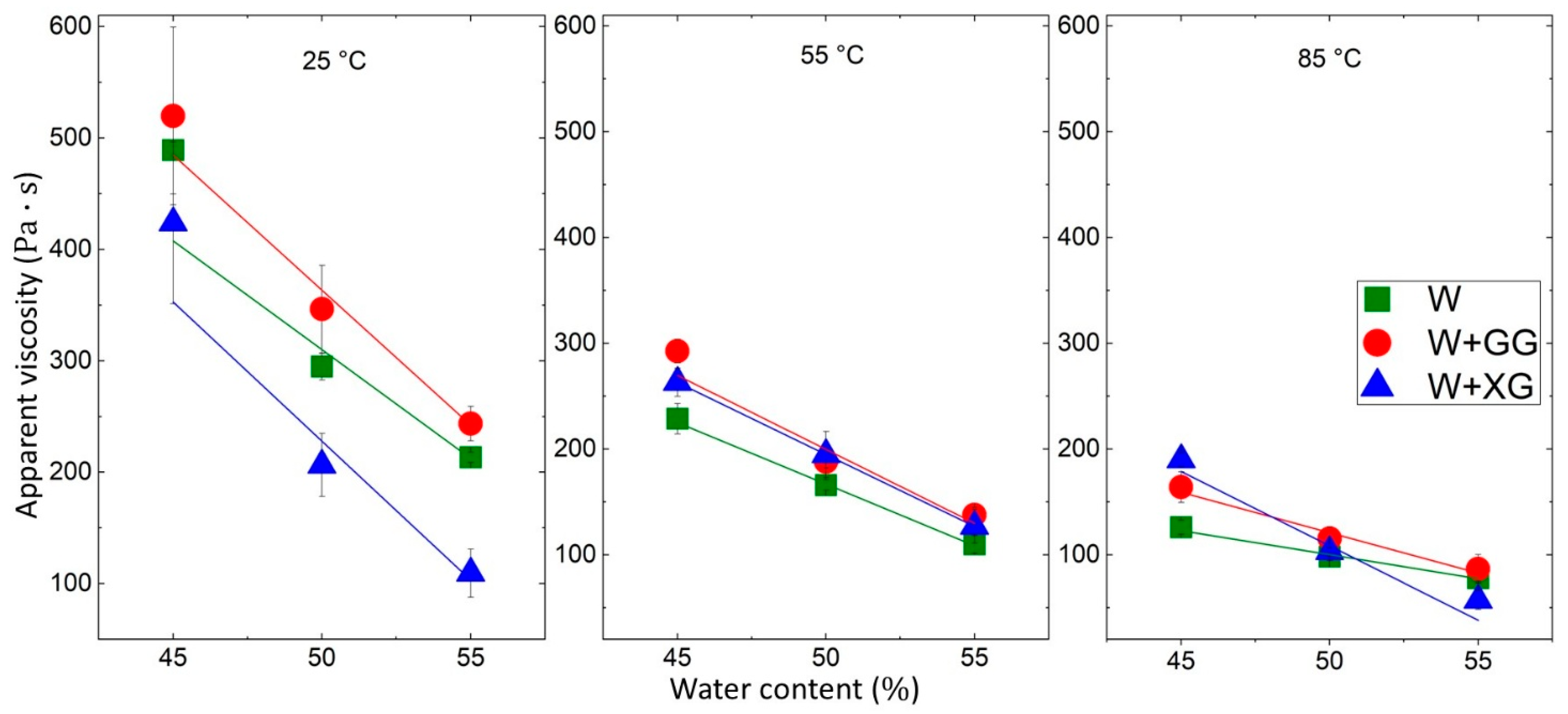

3.1. Apparent Viscosity and Effect of Water Content

3.2. Effect of Temperature on Buckwheat Dough Rheology

3.3. Effect of Guar Gum and Xanthan Gum on Buckwheat Dough Rheology

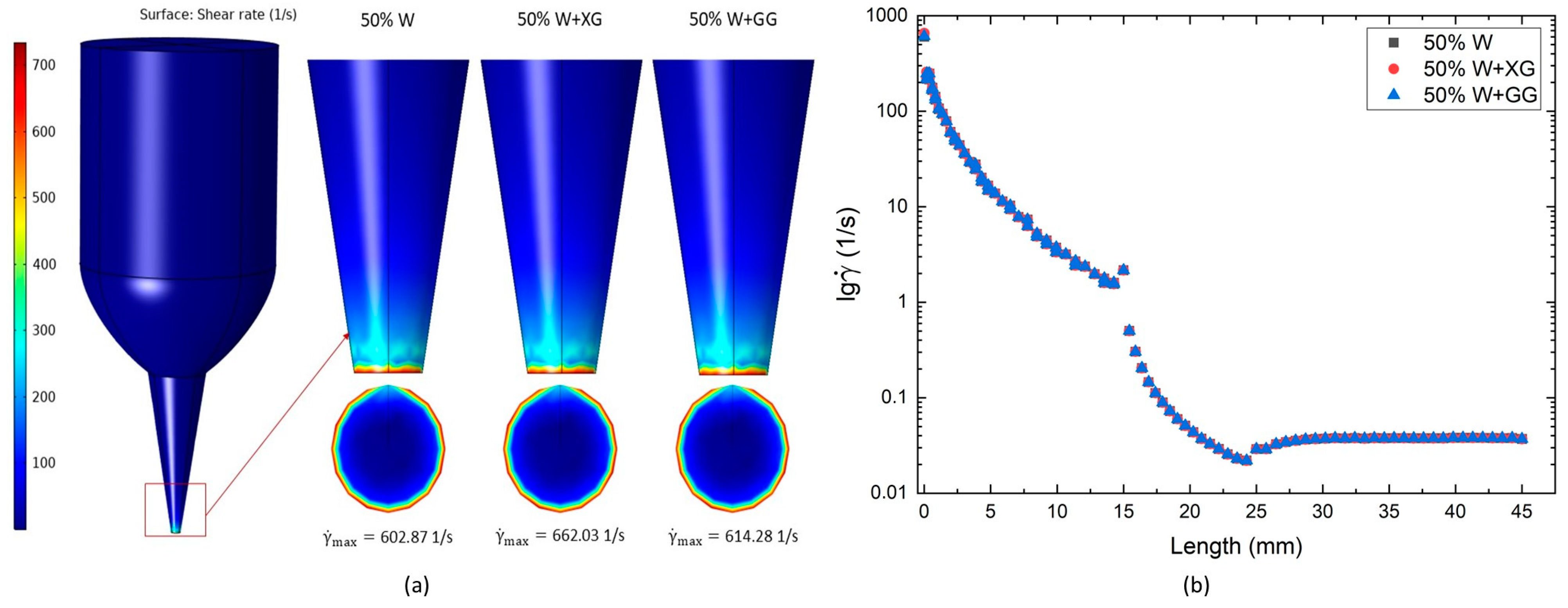

3.4. Shear Rate Distribution in CFD

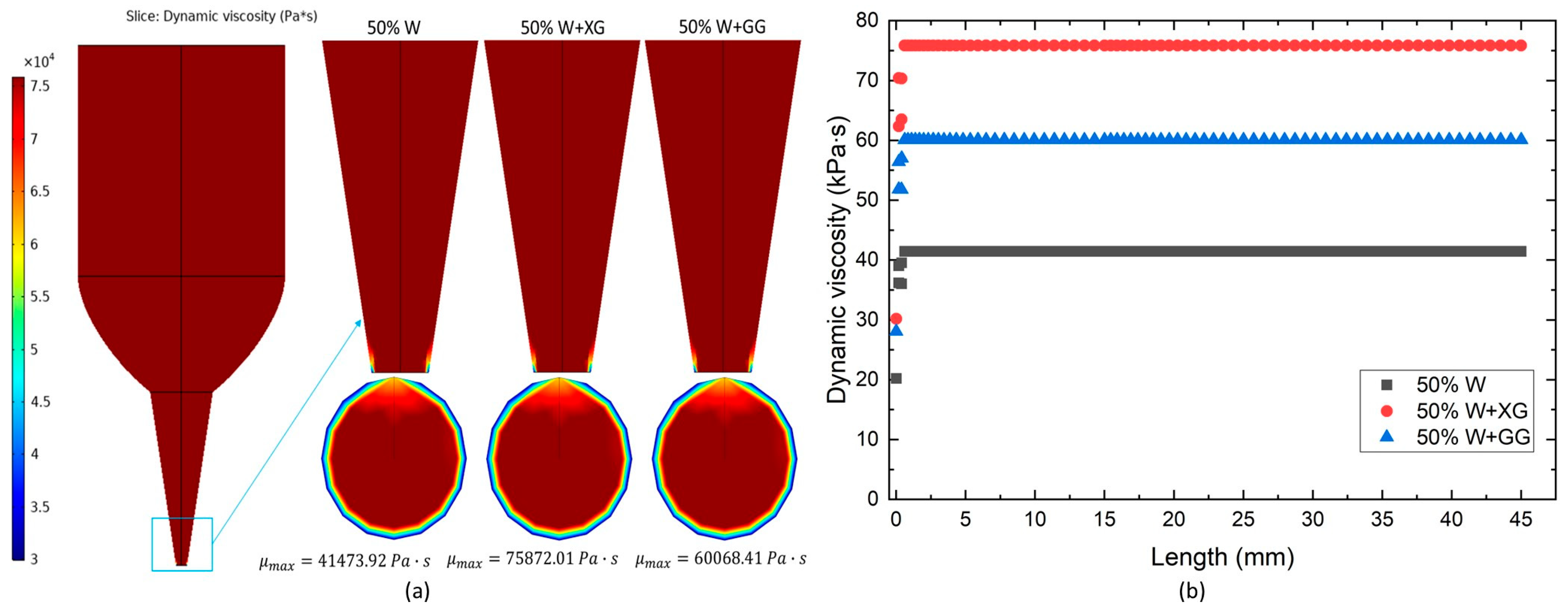

3.5. Viscosity Distribution in CFD

3.6. Pressure Distribution in CFD

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AM | Additive Manufacturing |

| BW | Buckwheat |

| CAD | Computer-Aided Design |

| CFD | Computational Fluid Dynamics |

| FEM | Finite Element Method |

| GG | Guar Gum |

| RPM | Revolutions per minute |

| XG | Xanthan Gum |

References

- Noreen, S.; Rizwan, B.; Khan, M.; Farooq, S. Health benefits of buckwheat (Fagopyrum esculentum), potential remedy for diseases, rare to cancer: A mini review. Infect. Disord. Drug Targets Disord. 2021, 21, 15–20. [Google Scholar] [CrossRef]

- Sofi, S.A.; Ahmed, N.; Farooq, A.; Rafiq, S.; Zargar, S.M.; Kamran, F.; Dar, T.A.; Mir, S.A.; Dar, B.; Mousavi Khaneghah, A. Nutritional and bioactive characteristics of buckwheat, and its potential for developing gluten-free products: An updated overview. Food Sci. Nutr. 2023, 11, 2256–2276. [Google Scholar] [CrossRef] [PubMed]

- Martinez-Villaluenga, C.; Penas, E.; Hernandez-Ledesma, B. Pseudocereal grains: Nutritional value, health benefits and current applications for the development of gluten-free foods. Food Chem. Toxicol. 2020, 137, 111178. [Google Scholar] [CrossRef] [PubMed]

- Rangappa, K.; Kumar, A.; Choudhury, B.U.; Moirangthem, P.; Layek, J.; Rajkhowa, D.; Sarma, A.K.; Chanu, N.K.; Debnath, S.; Ayam, G.; et al. Buckwheat: Potential stress-tolerant crop for mid-hills of Eastern Himalaya under changing climate. In PseudoCereals-Recent Advances and New Perspectives; IntechOpen: London, UK, 2023. [Google Scholar] [CrossRef]

- Zhou, M.; Tang, Y.; Deng, X.; Ruan, C.; Kreft, I.; Tang, Y.; Wu, Y. Chapter One—Overview of Buckwheat Resources in the World. In Buckwheat Germplasm in the World; Zhou, M., Kreft, I., Suvorova, G., Tang, Y., Woo, S.H., Eds.; Academic Press: Cambridge, MA, USA, 2018; pp. 1–7. [Google Scholar] [CrossRef]

- Van Vliet, S.; Kronberg, S.L.; Provenza, F.D. Plant-based meats, human health, and climate change. Front. Sustain. Food Syst. 2020, 4, 555088. [Google Scholar] [CrossRef]

- Toh, D.W.K.; Fu, A.S.; Mehta, K.A.; Lam, N.Y.L.; Haldar, S.; Henry, C.J. Plant-Based Meat Analogs and Their Effects on Cardiometabolic Health: An 8-Week Randomized Controlled Trial Comparing Plant-Based Meat Analogs with Their Corresponding Animal-Based Foods. Am. J. Clin. Nutr. 2024, 119, 1405–1416. [Google Scholar] [CrossRef] [PubMed]

- Auyeskhan, U.; Azhbagambetov, A.; Sadykov, T.; Dairabayeva, D.; Talamona, D.; Chan, M.Y. Reducing meat consumption in Central Asia through 3D printing of plant-based protein—Enhanced alternatives—A mini review. Front. Nutr. 2024, 10, 1308836. [Google Scholar] [CrossRef] [PubMed]

- Appiani, M.; Rabitti, N.S.; Proserpio, C.; Pagliarini, E.; Laureati, M. Tartary buckwheat: A new plant-based ingredient to enrich corn-based gluten-free formulations. Foods 2021, 10, 2613. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, L. Formulated food inks for extrusion-based 3D printing of personalized foods: A mini review. Curr. Opin. Food Sci. 2022, 44, 100803. [Google Scholar] [CrossRef]

- Guo, C.; Zhang, M.; Devahastin, S. Color/aroma changes of 3D-Printed buckwheat dough with yellow flesh peach as triggered by microwave heating of gelatin-gum Arabic complex coacervates. Food Hydrocoll. 2021, 112, 106358. [Google Scholar] [CrossRef]

- Varvara, R.A.; Szabo, K.; Vodnar, D.C. 3D food printing: Principles of obtaining digitally-designed nourishment. Nutrients 2021, 13, 3617. [Google Scholar] [CrossRef] [PubMed]

- Escalante-Aburto, A.; Trujillo-de Santiago, G.; Alvarez, M.M.; Chuck-Hernandez, C. Advances and prospective applications of 3D food printing for health improvement and personalized nutrition. Compr. Rev. Food Sci. Food Saf. 2021, 20, 5722–5741. [Google Scholar] [CrossRef]

- Pulatsu, E.; Su, J.W.; Lin, J.; Lin, M. Factors affecting 3D printing and post-processing capacity of cookie dough. Innov. Food Sci. Emerg. Technol. 2020, 61, 102316. [Google Scholar] [CrossRef]

- Schoenlechner, R.; Siebenhandl, S.; Berghofer, E. Pseudocereals. In Gluten-Free Cereal Products and Beverages; Arendt, E.K., Dal Bello, F., Eds.; Food Science and Technology; Academic Press: San Diego, CA, USA, 2008; pp. 149–190. [Google Scholar] [CrossRef]

- Zhong, Y.; Zeng, S.; Lv, Y.; Lv, W.; Xiao, H.; Sheng, S. Effect of guar gum on the rheological properties, microstructure and 3D printing performance of egg yolk powder-potato starch composite gel. Food Hydrocoll. 2024, 153, 110018. [Google Scholar] [CrossRef]

- Xu, J.; Fan, Y.; Liu, H.; Liu, Q.; Zhamsaranova, S.; Kong, B.; Chen, Q. Improvement of rheological properties and 3D printability of pork pastes by the addition of xanthan gum. LWT 2023, 173, 114325. [Google Scholar] [CrossRef]

- Peressini, D.; Pin, M.; Sensidoni, A. Rheology and breadmaking performance of rice-buckwheat batters supplemented with hydrocolloids. Food Hydrocoll. 2011, 25, 340–349. [Google Scholar] [CrossRef]

- Yıldız, E.; Sumnu, S.; Sahin, S. Effects of buckwheat flour, gums and proteins on rheological properties of gluten-free batters and structure of cakes. Qual. Assur. Saf. Crops Foods 2018, 10, 245–254. [Google Scholar] [CrossRef]

- Kaur, M.; Sandhu, K.S.; Arora, A.; Sharma, A. Gluten free biscuits prepared from buckwheat flour by incorporation of various gums: Physicochemical and sensory properties. LWT-Food Sci. Technol. 2015, 62, 628–632. [Google Scholar] [CrossRef]

- Oyinloye, T.M.; Yoon, W.B. Application of computational fluid dynamics (CFD) simulation for the effective design of food 3D printing (A review). Processes 2021, 9, 1867. [Google Scholar] [CrossRef]

- Singh, S.K.; Muthukumarappan, K. Rheological characterization and CFD simulation of soy white flakes based dough in a single screw extruder. J. Food Process Eng. 2017, 40, e12368. [Google Scholar] [CrossRef]

- Oyinloye, T.M.; Yoon, W.B. Application of computational fluid dynamics (CFD) in the deposition process and printability assessment of 3D printing using rice paste. Processes 2021, 10, 68. [Google Scholar] [CrossRef]

- Guo, C.F.; Zhang, M.; Bhandari, B. A comparative study between syringe-based and screw-based 3D food printers by computational simulation. Comput. Electron. Agric. 2019, 162, 397–404. [Google Scholar] [CrossRef]

- Cristiano, M.C.; Froiio, F.; Costanzo, N.; Poerio, A.; Lugli, M.; Fresta, M.; Britti, D.; Paolino, D. Effects of flour mean particle size, size distribution and water content on rheological properties of wheat flour doughs. Eur. Food Res. Technol. 2019, 245, 2053–2062. [Google Scholar] [CrossRef]

- Rosand RH7/RH10. Capillary Rheometer Backed with Rheological Experience. Available online: https://analyzing-testing.netzsch.com/_Resources/Persistent/f/8/7/a/f87a786a82673418f5b876c9e06da581beea4813/Rosand_RH7_RH10_en_web.pdf (accessed on 20 October 2024).

- Meng, L.; Wu, D.; Kelly, A.; Woodhead, M.; Liu, Y. Experimental investigation of the rheological behaviors of polypropylene in a capillary flow. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Shaw, M.T. Introduction to Polymer Rheology, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Bagley, E. End corrections in the capillary flow of polyethylene. J. Appl. Phys. 1957, 28, 624–627. [Google Scholar] [CrossRef]

- Smith, C.; Rosenau, J.; Peleg, M. Evaluation of the flowability of melted Mozzarella cheese by capillary rheometry. J. Food Sci. 1980, 45, 1142–1145. [Google Scholar] [CrossRef]

- Tan, C.; Toh, W.Y.; Wong, G.; Li, L. Extrusion-based 3D food printing–Materials and machines. Int. J. Bioprint. 2018, 4, 143. [Google Scholar] [CrossRef] [PubMed]

- Carnicer, V.; Alcazar, C.; Orts, M.; Sanchez, E.; Moreno, R. Microfluidic rheology: A new approach to measure viscosity of ceramic suspensions at extremely high shear rates. Open Ceram. 2021, 5, 100052. [Google Scholar] [CrossRef]

- Paradkar, A.; Kelly, A.; Coates, P.; York, P. Shear and extensional rheology of hydroxypropyl cellulose melt using capillary rheometry. J. Pharm. Biomed. Anal. 2009, 49, 304–310. [Google Scholar] [CrossRef]

- Akdogan, H.; Tomas, R.L.; Oliveira, J.C. Rheological properties of rice starch at high moisture contents during twin-screw extrusion. LWT-Food Sci. Technol. 1997, 30, 488–496. [Google Scholar] [CrossRef]

- Bird, R.B.; Armstrong, R.C.; Hassager, O. Dynamics of Polymeric Liquids. In Volume 1: Fluid Mechanics, 2 ed.; JohnWiley & Sons: New York, NY, USA, 1987. [Google Scholar]

- Garcia-Gutierrez, N.; Salvador, A.; Sanz, T.; Ferrando, M.; Guell, C.; Mendez, C.; de Lamo-Castellvi, S. Rheological and Textural Characterisation of Chickpea Dough and Baked 3D-Printed Snacks Enriched with Alphitobius diaperinus and Locusta migratoria Powders. In Food and Bioprocess Technology; Springer: Berlin/Heidelberg, Germany, 2024; pp. 1–9. [Google Scholar] [CrossRef]

- Yang, F.; Guo, C.; Zhang, M.; Bhandari, B.; Liu, Y. Improving 3D printing process of lemon juice gel based on fluid flow numerical simulation. Lwt 2019, 102, 89–99. [Google Scholar] [CrossRef]

- Natural Machines. Foodini: Users. Available online: https://www.naturalmachines.com/users (accessed on 21 October 2024).

- Stickel, J.J.; Powell, R.L. Fluid mechanics and rheology of dense suspensions. Annu. Rev. Fluid Mech. 2005, 37, 129–149. [Google Scholar] [CrossRef]

- Mitsoulis, E.; Hatzikiriakos, S. Annular extrudate swell of a fluoropolymer melt. Int. Polym. Process. 2012, 27, 535–546. [Google Scholar] [CrossRef]

- Pant, A.; Lee, A.Y.; Karyappa, R.; Lee, C.P.; An, J.; Hashimoto, M.; Tan, U.X.; Wong, G.; Chua, C.K.; Zhang, Y. 3D food printing of fresh vegetables using food hydrocolloids for dysphagic patients. Food Hydrocoll. 2021, 114, 106546. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Bhandari, B.; Yang, C. Impact of rheological properties of mashed potatoes on 3D printing. J. Food Eng. 2018, 220, 76–82. [Google Scholar] [CrossRef]

- Hardt, N.; Boom, R.; Van der Goot, A. Wheat dough rheology at low water contents and the influence of xylanases. Food Res. Int. 2014, 66, 478–484. [Google Scholar] [CrossRef]

- Mastromatteo, M.; Guida, M.; Danza, A.; Laverse, J.; Frisullo, P.; Lampignano, V.; Del Nobile, M.A. Rheological, microstructural and sensorial properties of durum wheat bread as affected by dough water content. Food Res. Int. 2013, 51, 458–466. [Google Scholar] [CrossRef]

- Radhakrishnan, R.; Divoux, T.; Manneville, S.; Fielding, S.M. Understanding rheological hysteresis in soft glassy materials. Soft Matter 2017, 13, 1834–1852. [Google Scholar] [CrossRef]

- Lokumcu Altay, F.; Ak, M.M. Effects of temperature, shear rate and constituents on rheological properties of tahin (sesame paste). J. Sci. Food Agric. 2005, 85, 105–111. [Google Scholar] [CrossRef]

- Migliori, M.; Gabriele, D.; Baldino, N.; Lupi, F.; De Cindio, B. Rheological properties of batter dough: Effect of egg level. J. Food Process Eng. 2011, 34, 1266–1281. [Google Scholar] [CrossRef]

- Marcotte, M.; Hoshahili, A.R.T.; Ramaswamy, H. Rheological properties of selected hydrocolloids as a function of concentration and temperature. Food Res. Int. 2001, 34, 695–703. [Google Scholar] [CrossRef]

- Casas, J.; Santos, V.; Garcıa-Ochoa, F. Xanthan gum production under several operational conditions: Molecular structure and rheological properties. Enzym. Microb. Technol. 2000, 26, 282–291. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Huang, X.; Guo, S.; Wang, Y.; Feng, D.; Dong, X.; Qi, H. Undaria pinnatifida gel inks for food 3D printing are developed based on the colloidal properties of Undaria pinnatifida slurry and protein/colloidal/starch substances. Int. J. Biol. Macromol. 2024, 261, 129788. [Google Scholar] [CrossRef] [PubMed]

- Mirsaeedghazi, H.; Emam-Djomeh, Z.; Mousavi, S.M.A. Rheometric measurement of dough rheological characteristics and factors affecting it. Int. J. Agric. Biol. 2008, 10, 112–119. [Google Scholar]

- Xue, D.; Sethi, R. Viscoelastic gels of guar and xanthan gum mixtures provide long-term stabilization of iron micro-and nanoparticles. J. Nanopart. Res. 2012, 14, 1239. [Google Scholar] [CrossRef]

- Tiwari, B.; Muthukumarappan, K.; O’donnell, C.; Cullen, P. Rheological properties of sonicated guar, xanthan and pectin dispersions. Int. J. Food Prop. 2010, 13, 223–233. [Google Scholar] [CrossRef]

- Razavi, S.M.; Alghooneh, A.; Behrouzian, F. Thermo-rheology and thermodynamic analysis of binary biopolymer blend: A case study on sage seed gum-xanthan gum blends. Food Hydrocoll. 2018, 77, 307–321. [Google Scholar] [CrossRef]

- Djeghim, F.; Bourekoua, H.; Rozyło, R.; Bienczak, A.; Tana’s, W.; Zidoune, M.N. Effect of by-products from selected fruits and vegetables on gluten-free dough rheology and bread properties. Appl. Sci. 2021, 11, 4605. [Google Scholar] [CrossRef]

- Nasrollahzadeh, M.; Nezafat, Z.; Shafiei, N.; Soleimani, F. Polysaccharides in food industry. In Biopolymer-Based Metal Nanoparticle Chemistry for Sustainable Applications; Elsevier: Amsterdam, The Netherlands, 2021; pp. 47–96. [Google Scholar]

- Tahmouzi, S.; Meftahizadeh, H.; Eyshi, S.; Mahmoudzadeh, A.; Alizadeh, B.; Mollakhalili-Meybodi, N.; Hatami, M. Application of guar (Cyamopsis tetragonoloba L.) gum in food technologies: A review of properties and mechanisms of action. Food Sci. Nutr. 2023, 11, 4869–4897. [Google Scholar] [CrossRef] [PubMed]

- Nsengiyumva, E.M.; Alexandridis, P. Xanthan gum in aqueous solutions: Fundamentals and applications. Int. J. Biol. Macromol. 2022, 216, 583–604. [Google Scholar] [CrossRef] [PubMed]

- Kumar, Y.; Roy, S.; Devra, A.; Dhiman, A.; Prabhakar, P.K. Ultrasonication of mayonnaise formulated with xanthan and guar gums: Rheological modeling, effects on optical properties and emulsion stability. LWT 2021, 149, 111632. [Google Scholar] [CrossRef]

- Guo, Z.; Fei, F.; Song, X.; Zhou, C. Analytical Study and Experimental Verification of Shear-Thinning Ink Flow in Direct InkWriting Process. J. Manuf. Sci. Eng. 2023, 145, 071001. [Google Scholar] [CrossRef]

- Guo, C.; Zhang, M.; Devahastin, S. 3D extrusion-based printability evaluation of selected cereal grains by computational fluid dynamic simulation. J. Food Eng. 2020, 286, 110113. [Google Scholar] [CrossRef]

- Fatimi, A.; Tassin, J.F.; Bosco, J.; Deterre, R.; Axelos, M.A.; Weiss, P. Injection of calcium phosphate pastes: Prediction of injection force and comparison with experiments. J. Mater. Sci. Mater. Med. 2012, 23, 1593–1603. [Google Scholar] [CrossRef] [PubMed]

| No | Sample Designation | Water Ratio (% w/w) | Gum Inclusion |

|---|---|---|---|

| 1 | 45% W | 45 | No gum |

| 2 | 50% W | 50 | No gum |

| 3 | 55% W | 55 | No gum |

| 4 | 45% W + XG | 45 | XG |

| 5 | 50% W + XG | 50 | XG |

| 6 | 55% W + XG | 55 | XG |

| 7 | 45% W + GG | 45 | GG |

| 8 | 50% W + GG | 50 | GG |

| 9 | 55% W + GG | 55 | GG |

| T, (°C) | Sample Name | |||

|---|---|---|---|---|

| 25 | 45% W | 20,239.4 | 0.298 | 0.99 |

| 50% W | 9263.5 | 0.349 | 0.99 | |

| 55% W | 7886.8 | 0.318 | 0.99 | |

| 45% W + GG | 16,782.6 | 0.344 | 0.99 | |

| 50% W + GG | 12,579.0 | 0.321 | 0.99 | |

| 55% W + GG | 14,569.9 | 0.228 | 0.99 | |

| 45% W + XG | 30,803.2 | 0.191 | 0.99 | |

| 50% W + XG | 12,678.9 | 0.223 | 0.99 | |

| 55% W + XG | 19,982.2 | 0.022 | 0.98 | |

| 55 | 45% W | 9416.7 | 0.298 | 0.99 |

| 50% W | 9599.4 | 0.234 | 0.99 | |

| 55% W | 3827.7 | 0.329 | 0.99 | |

| 45% W + GG | 13,255.4 | 0.280 | 0.99 | |

| 50% W + GG | 5569.8 | 0.360 | 0.99 | |

| 55% W + GG | 4326.6 | 0.349 | 0.99 | |

| 45% W + XG | 20,393.5 | 0.179 | 0.99 | |

| 50% W + XG | 20,298.3 | 0.123 | 0.99 | |

| 55% W + XG | 24,346.0 | 0.001 | 0.99 | |

| 85 | 45% W | 3497.7 | 0.372 | 0.99 |

| 50% W | 4693.5 | 0.270 | 0.99 | |

| 55% W | 4018.9 | 0.256 | 0.99 | |

| 45% W + GG | 5451.4 | 0.338 | 0.99 | |

| 50% W + GG | 4026.4 | 0.329 | 0.99 | |

| 55% W + GG | 3152.8 | 0.323 | 0.99 | |

| 45% W + XG | 18,074.4 | 0.139 | 0.99 | |

| 50% W + XG | 5730.1 | 0.239 | 0.99 | |

| 55% W + XG | 2890.7 | 0.259 | 0.99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baimaganbetova, S.; Omirbekov, S.; Wang, Y.; Chan, M.-Y.; Talamona, D. Investigation of Rheological and Flow Properties of Buckwheat Dough with and Without Xanthan and Guar Gums for Optimized 3D Food Printing Across Temperature Variations. Foods 2024, 13, 4054. https://doi.org/10.3390/foods13244054

Baimaganbetova S, Omirbekov S, Wang Y, Chan M-Y, Talamona D. Investigation of Rheological and Flow Properties of Buckwheat Dough with and Without Xanthan and Guar Gums for Optimized 3D Food Printing Across Temperature Variations. Foods. 2024; 13(24):4054. https://doi.org/10.3390/foods13244054

Chicago/Turabian StyleBaimaganbetova, Sholpan, Sagyn Omirbekov, Yanwei Wang, Mei-Yen Chan, and Didier Talamona. 2024. "Investigation of Rheological and Flow Properties of Buckwheat Dough with and Without Xanthan and Guar Gums for Optimized 3D Food Printing Across Temperature Variations" Foods 13, no. 24: 4054. https://doi.org/10.3390/foods13244054

APA StyleBaimaganbetova, S., Omirbekov, S., Wang, Y., Chan, M.-Y., & Talamona, D. (2024). Investigation of Rheological and Flow Properties of Buckwheat Dough with and Without Xanthan and Guar Gums for Optimized 3D Food Printing Across Temperature Variations. Foods, 13(24), 4054. https://doi.org/10.3390/foods13244054