Terahertz Spectroscopic Identification of Roast Degree and Variety of Coffee Beans

Abstract

:1. Introduction

2. Material and Methods

2.1. Experimental Materials and Procedures

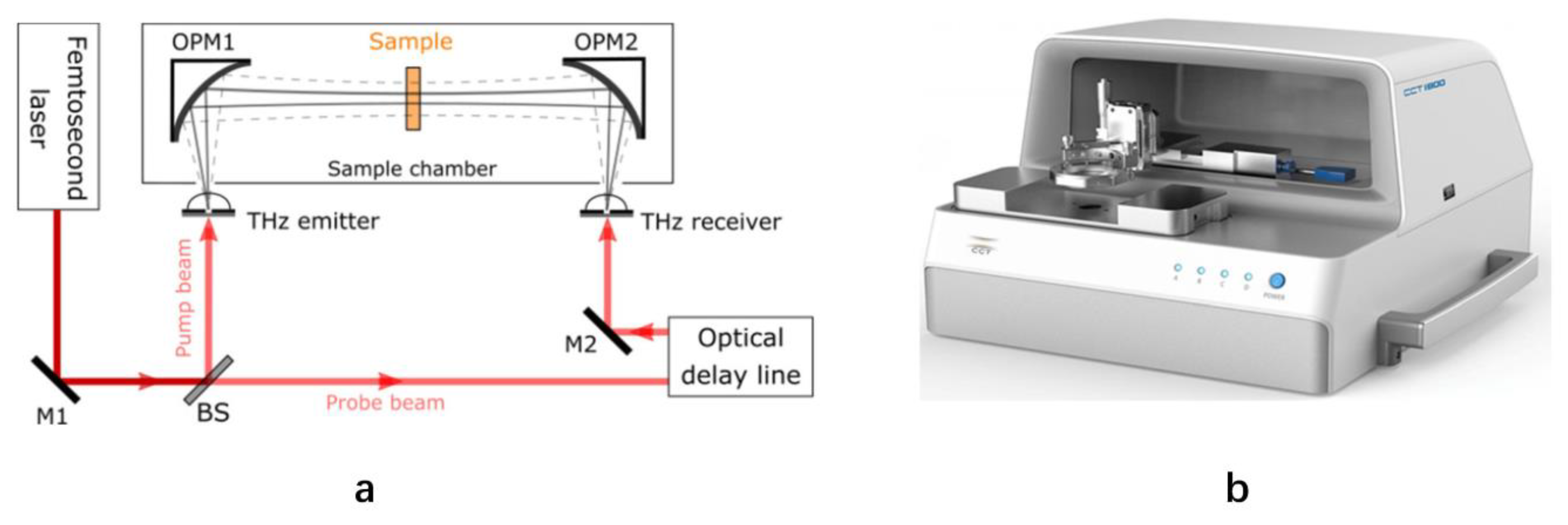

2.2. THz-TDS System Introduction

2.3. THz-TDS Detection

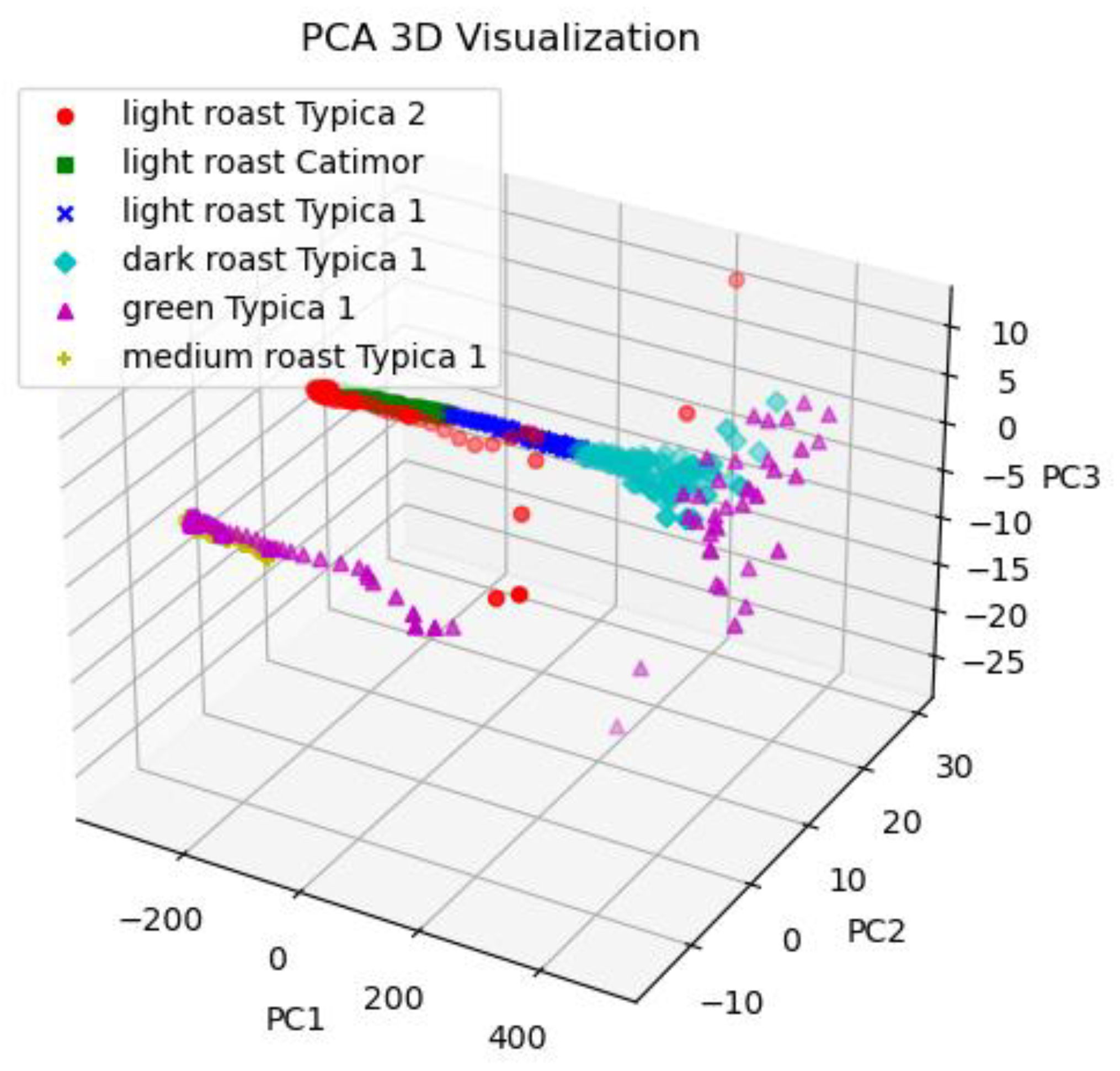

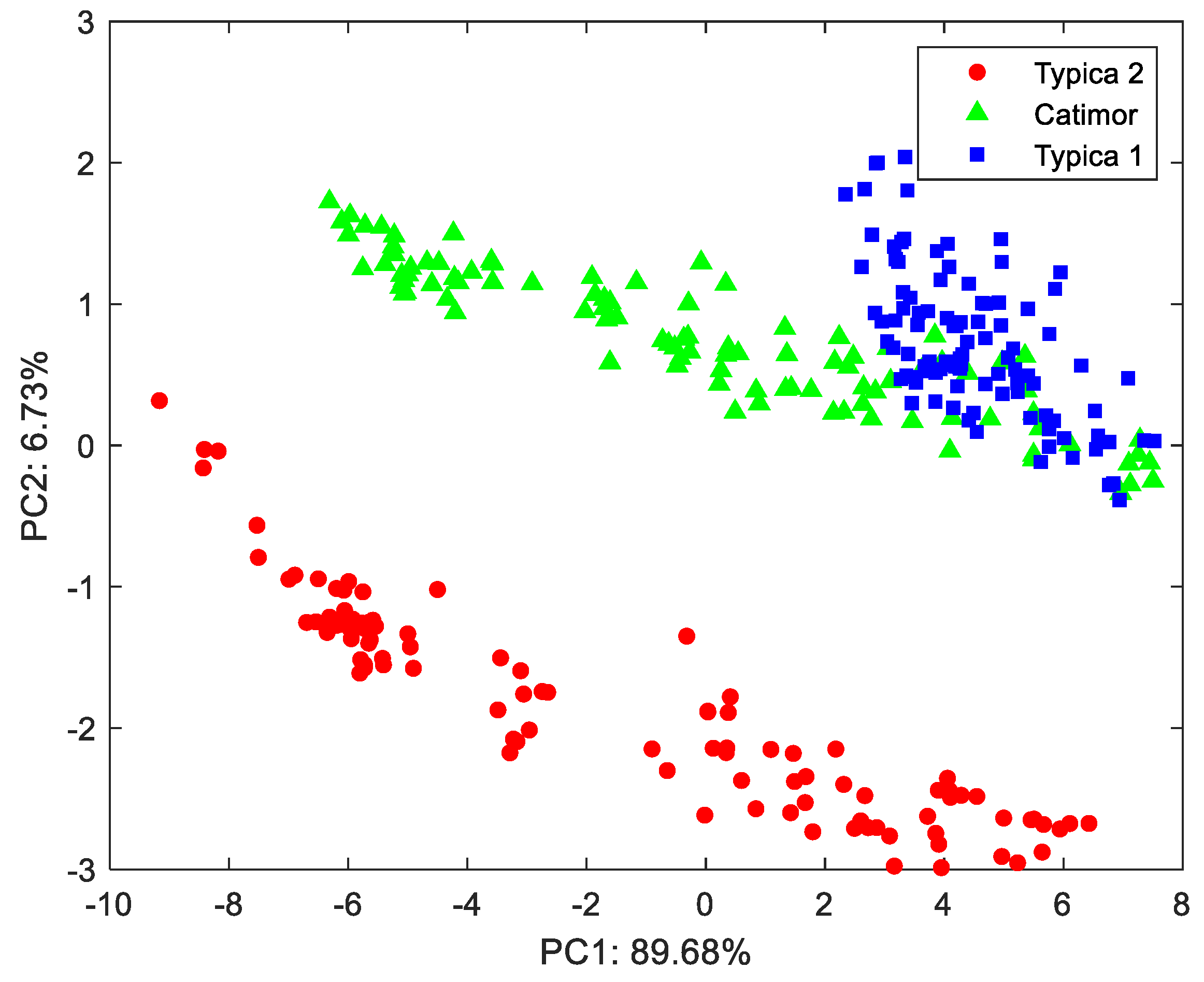

2.4. Dimension Reduction and Visualization

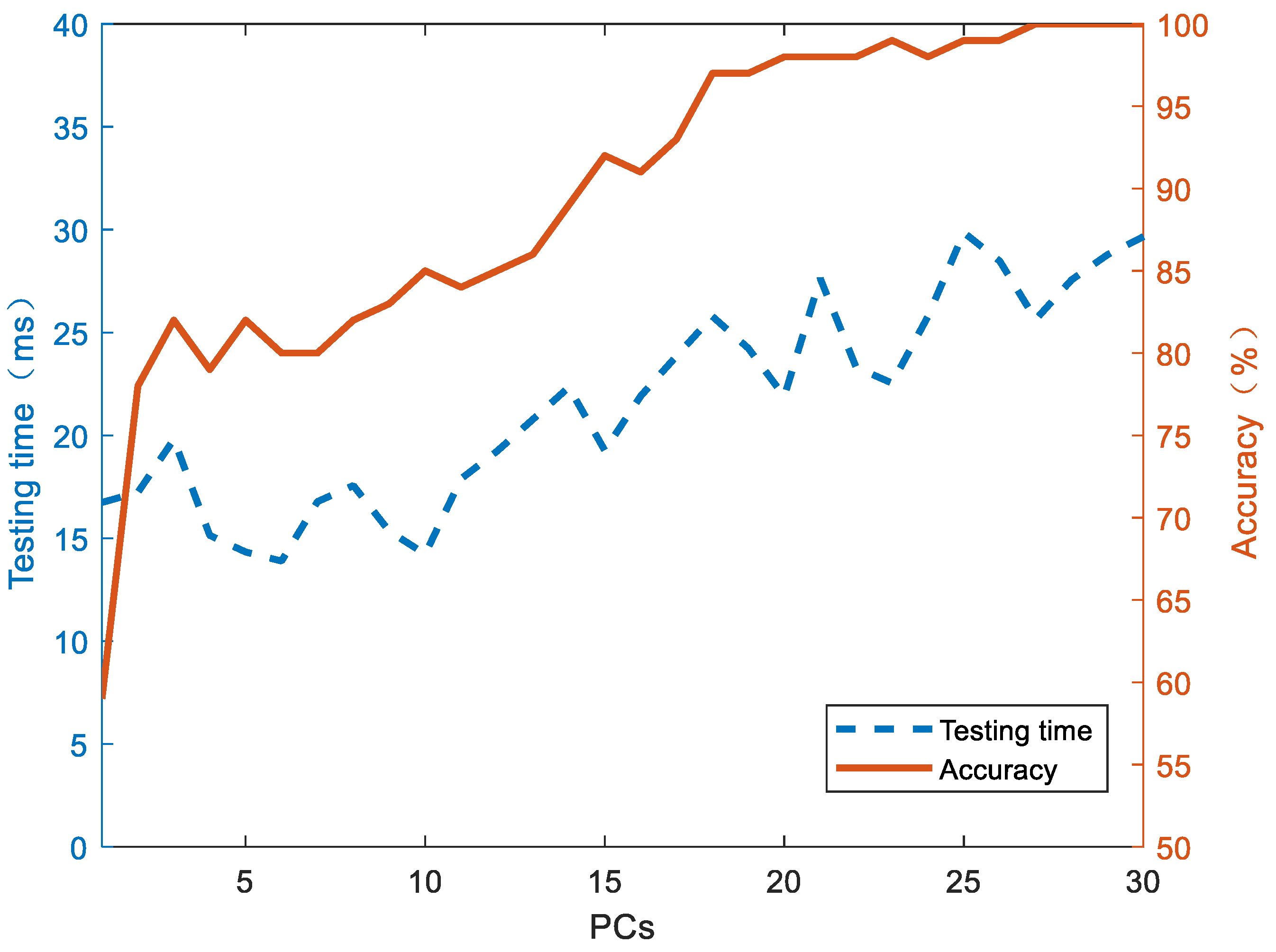

2.5. Modeling and Model Evaluation

2.6. Data Analysis

3. Results and Discussion

3.1. THz-TDS Spectral Analysis

3.2. Dimension Reduction and Visualization Using PCA

3.2.1. Coffee Bean Varieties

3.2.2. Coffee Bean Roasting Degrees

3.3. Results of Modeling and Analysis

3.3.1. Coffee Bean Varieties Prediction Result

3.3.2. Coffee Bean Roasting Degrees Prediction Result

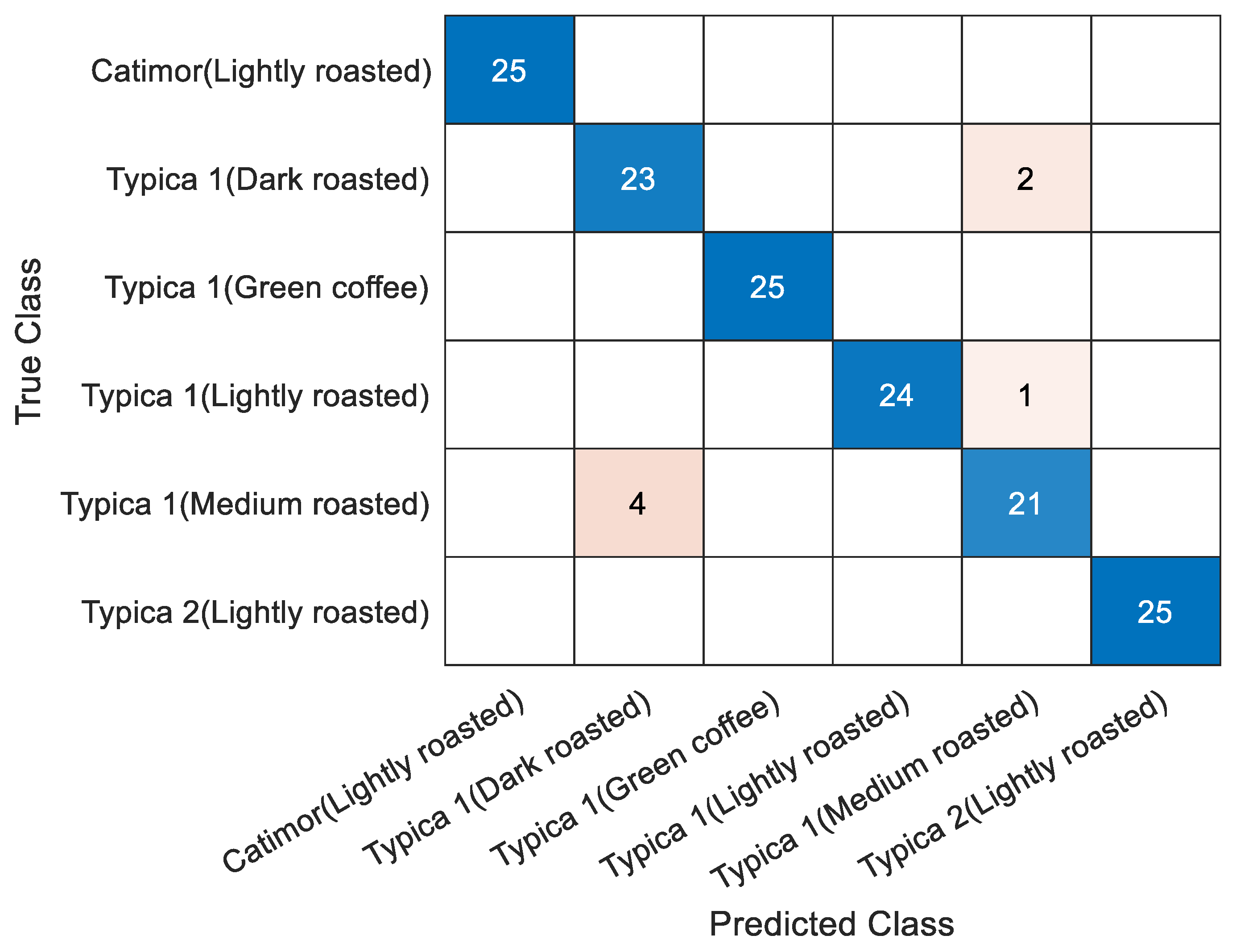

3.3.3. Comprehensive Detection of Coffee Beans

3.4. Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Van Dam, R.M.; Campion, E.W.; Hu, F.B. Coffee, Caffeine, and Health. N. Engl. J. Med. 2020, 383, 369–378. [Google Scholar] [CrossRef]

- Crozier, T.W.M.; Stalmach, A.; Lean, M.E.J.; Crozier, A. Espresso Coffees, Caffeine and Chlorogenic Acid Intake: Potential Health Implications. Food Funct. 2012, 3, 30–33. [Google Scholar] [CrossRef]

- Crozier, T.W.M.; Stalmach, A.; Lean, M.E.J.; Crozier, A. Exploring the Impacts of Postharvest Processing on the Microbiota and Metabolite Profiles During Green Coffee Bean Production. Appl. Environ. Microbiol. 2017, 83, e02398-16. [Google Scholar] [CrossRef]

- Pereira, L.L.; Guarçoni, R.C.; Pinheiro, P.F.; Osório, V.M.; Pinheiro, C.A.; Moreira, T.R.; Ten Caten, C.S. New Propositions About Coffee Wet Processing: Chemical and Sensory Perspectives. Food Chem. 2020, 310, 125943. [Google Scholar] [CrossRef] [PubMed]

- Duangjai, A.; Saokaew, S.; Goh, B.-H.; Phisalprapa, P. Shifting of Physicochemical and Biological Characteristics of Coffee Roasting under Ultrasound-Assisted Extraction. Front. Nutr. 2021, 8, 724591. [Google Scholar] [CrossRef]

- Putri, S.P.; Irifune, T.; Yusianto; Fukusaki, E. GC/MS Based Metabolite Profiling of Indonesian Specialty Coffee from Different Species and Geographical Origin. Metabolomics 2019, 15, 126. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Míguez, R.; Sánchez-López, E.; Plaza, M.; Marina, M.L.; Castro-Puyana, M. Capillary Electrophoresis-mass Spectrometry Metabolic Fingerprinting of Green and Roasted Coffee. J. Chromatogr. A 2019, 1605, 360353. [Google Scholar] [CrossRef] [PubMed]

- Mannino, G.; Kunz, R.; Maffei, M.E. Discrimination of Green Coffee (Coffea arabica and Coffea canephora) of Different Geographical Origin Based on Antioxidant Activity, High-Throughput Metabolomics, and DNA RFLP Fingerprinting. Antioxidants 2023, 12, 1135. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Liu, F.; He, Y. Identification of Coffee Bean Varieties Using Hyperspectral Imaging: Influence of Preprocessing Methods and Pixel-wise Spectra Analysis. Sci. Rep. 2018, 8, 2166. [Google Scholar] [CrossRef]

- Phuangsaijai, N.; Theanjumpol, P.; Kittiwachana, S. Performance Optimization of a Developed Near-Infrared Spectrometer Using Calibration Transfer with a Variety of Transfer Samples for Geographical Origin Identification of Coffee Beans. Molecules 2022, 27, 8202. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Y.; Zhou, Z.; Zhang, Y.; Wang, X. Detection Method for Tomato Leaf Mildew Based on Hyperspectral Fusion Terahertz Technology. Foods 2023, 12, 535. [Google Scholar] [CrossRef] [PubMed]

- Han, C.; Qu, F.; Wang, X.; Zhai, X.; Li, J.; Yu, K.; Zhao, Y. Terahertz Spectroscopy and Imaging Techniques for Herbal Medicinal Plants Detection: A Comprehensive Review. Crit. Rev. Anal. Chem. 2023, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Tang, M.; Zhang, M.; Fu, Y.; Chen, L.; Li, D.; Zhang, H.; Yang, Z.; Wang, C.; Xiu, P.; Wilksch, J.J.; et al. Terahertz Label-Free Detection of Nicotine-Induced Neural Cell Changes and the Underlying Mechanisms. Biosens. Bioelectron. 2023, 241, 115697. [Google Scholar] [CrossRef]

- Hoshina, H.; Iwasaki, Y.; Katahira, E.; Okamoto, M.; Otani, C. Structure and Dynamics of Bound Water in Poly (Ethylene-Vinylalcohol) Copolymers Studied by Terahertz Spectroscopy. Polymer 2018, 148, 49–60. [Google Scholar] [CrossRef]

- Li, Q.; Lei, T.; Sun, D.W. Analysis and Detection Using Novel Terahertz Spectroscopy Technique in Dietary Carbohydrate-Related Research: Principles and Application Advances. Crit. Rev. Food Sci. Nutr. 2023, 63, 1793–1805. [Google Scholar] [CrossRef]

- Huang, L.L.; Li, C.; Li, B.; Liu, M.L.; Lian, M.M.; Yang, S.Z. Studies on Qualitative and Quantitative Detection of Trehalose Purity by Terahertz Spectroscopy. Food Sci. Nutr. 2020, 8, 1828–1836. [Google Scholar] [CrossRef]

- Federici, J.F. Review of Moisture a5nd Liquid Detection and Mapping Using Terahertz Imaging. J. Infrared Millim. Terahertz Waves 2012, 33, 97–126. [Google Scholar] [CrossRef]

- Baek, S.H.; Lim, H.B.; Chun, H.S. Detection of Melamine in Foods Using Terahertz Time-Domain Spectroscopy. J. Agric. Food Chem. 2014, 62, 5403–5407. [Google Scholar] [CrossRef]

- Qu, F.F.; Pan, Y.; Lin, L.; Cai, C.Y.; Dong, T.; He, Y.; Nie, P.C. Experimental and Theoretical Study on Terahertz Absorption Characteristics and Spectral De-Noising of Three Plant Growth Regulators. J. Infrared Millim. Terahertz Waves 2018, 39, 1015–1027. [Google Scholar] [CrossRef]

- Nakajima, S.; Horiuchi, S.; Ikehata, A.; Ogawa, Y. Determination of Starch Crystallinity with the Fourier-Transform Terahertz Spectrometer. Carbohydr. Polym. 2021, 262, 117928. [Google Scholar] [CrossRef]

- Ge, H.Y.; Jiang, Y.Y.; Xu, Z.H.; Lian, F.Y.; Zhang, Y.; Xia, S.H. Identification of Wheat Quality Using Thz Spectrum. Opt. Express 2014, 22, 12533–12544. [Google Scholar] [CrossRef]

- Liu, H.S.; Zhang, Z.W.; Zhang, X.; Yang, Y.P.; Zhang, Z.Y.; Liu, X.Y.; Wang, F.; Han, Y.D.; Zhang, C.L. Dimensionality Reduction for Identification of Hepatic Tumor Samples Based on Terahertz Time-Domain Spectroscopy. IEEE Trans. Terahertz Sci. Technol. 2018, 8, 271–277. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, S.H.; Liao, Y.; Zhang, Z.Y. Simultaneous Determination of Amino Acid Mixtures in Cereal by Using Terahertz Time Domain Spectroscopy and Chemometrics. Chemom. Intell. Lab. Syst. 2017, 164, 8–15. [Google Scholar] [CrossRef]

- Yang, S.; Li, C.; Mei, Y.; Liu, W.; Liu, R.; Chen, W.; Han, D.; Xu, K. Determination of the Geographical Origin of Coffee Beans Using Terahertz Spectroscopy Combined with Machine Learning Methods. Front. Nutr. 2021, 8, 680627. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.C. Terahertz Pulsed Spectroscopy and Imaging for Pharmaceutical Applications: A Review. Int. J. Pharm. 2011, 417, 48–60. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.C.; Upadhya, P.C.; Linfield, E.H.; Davies, A.G. Vibrational Spectra of Nucleosides Studied Using Terahertz Time-Domain Spectroscopy. Vib. Spectrosc. 2004, 35, 111–114. [Google Scholar] [CrossRef]

- Zeitler, J.A.; Taday, P.F.; Newnham, D.A.; Pepper, M.; Gordon, K.C.; Rades, T. Terahertz Pulsed Spectroscopy and Imaging in the Pharmaceutical Setting—A Review. J. Pharm. Pharmacol. 2007, 59, 209–223. [Google Scholar] [CrossRef] [PubMed]

- Gowen, A.A.; O’Sullivan, C.; O’Donnell, C.P. Terahertz Time Domain Spectroscopy and Imaging: Emerging Techniques for Food Process Monitoring and Quality Control. Trends Food Sci. Technol. 2012, 25, 40–46. [Google Scholar] [CrossRef]

- Zheng, C.; Cai, S.; Li, Q.; Li, C.; Li, X. A Collaborative Classification Algorithm with Multi-View Terahertz Spectra. Results Phys. 2022, 42, 106023. [Google Scholar] [CrossRef]

- Walther, M.; Fischer, B.; Schall, M.; Helm, H.; Jepsen, P.U. Far-infrared vibrational spectra of all-trans, 9-cis and 13-cis retinal measured by THz time-domain spectroscopy. Chem. Phys. Lett. 2000, 332, 389–395. [Google Scholar] [CrossRef]

- Yamaguchi, S.; Fukushi, Y.; Kubota, O.; Itsuji, T.; Ouchi, T.; Yamamoto, S. Brain Tumor Imaging of Rat Fresh Tissue Using Terahertz Spectroscopy. Sci. Rep. 2016, 6, 30124. [Google Scholar] [CrossRef]

- Afsah-Hejri, L.; Akbari, E.; Toudeshki, A.; Homayouni, T.; Alizadeh, A.; Ehsani, R. Terahertz Spectroscopy and Imaging: A Review on Agricultural Applications. Comput. Electron. Agric. 2020, 177, 105628. [Google Scholar] [CrossRef]

- Tharwat, A.; Gaber, T.; Ibrahim, A.; Hassanien, A.E. Linear Discriminant Analysis: A Detailed Tutorial. AI Commun. 2017, 30, 169–190. [Google Scholar] [CrossRef]

- Li, Q.; Lei, T.; Cheng, Y.; Wei, X.; Sun, D.-W. Predicting Wheat Gluten Concentrations in Potato Starch Using Gpr and Svm Models Built by Terahertz Time-Domain Spectroscopy. Food Chem. 2024, 432, 137235. [Google Scholar] [CrossRef] [PubMed]

- Siuly; Yin, X.X.; Hadjiloucas, S.; Zhang, Y.C. Classification of Thz Pulse Signals Using Two-Dimensional Cross-Correlation Feature Extraction and Non-Linear Classifiers. Comput. Methods Programs Biomed. 2016, 127, 64–82. [Google Scholar] [CrossRef] [PubMed]

- Koch, I.; Naito, K.; Tanaka, H. Kernel Naive Bayes Discrimination for High-Dimensional Pattern Recognition. Aust. N. Z. J. Stat. 2019, 61, 401–428. [Google Scholar] [CrossRef]

- Li, B.; Zhang, D.P.; Shen, Y. Study on Terahertz Spectrum Analysis and Recognition Modeling of Common Agricultural Diseases. Spectrochim. Acta Part A-Mol. Biomol. Spectrosc. 2020, 243, 118820. [Google Scholar] [CrossRef]

- Liu, J.J.; Li, Z.; Hu, F.R.; Chen, T.; Zhu, A.J. A Thz Spectroscopy Nondestructive Identification Method for Transgenic Cotton Seed Based on Ga-Svm. Opt. Quantum Electron. 2015, 47, 313–322. [Google Scholar] [CrossRef]

- Bilge, G. Investigating the Effects of Geographical Origin, Roasting Degree, Particle Size and Brewing Method on the Physicochemical and Spectral Properties of Arabica Coffee by Pca Analysis. J. Food Sci. Technol.-Mysore 2020, 57, 3345–3354. [Google Scholar] [CrossRef]

| Roasting | Surface Color | Powder Color | First Burst Temperature (°C) | First Burst Time | End Temperature (°C) | End Time | Main Flavor Description | |

|---|---|---|---|---|---|---|---|---|

| Catimor | Light | 68.8 ± 1.6 c | 103.0 ± 0.3 a | 193 | 7′50″ | 200 | 8′23″ | Tropical fruit, fermented |

| Typica 1 | Green | -- | -- | -- | -- | -- | -- | -- |

| Typica 1 | Light | 84.4 ± 1.9 a | 101.8 ± 0.3 b | 190 | 7′40″ | 200 | 8′25″ | Dried fruit, slightly ripe fruit, woody |

| Typica 1 | Medium | 65.8 ± 1.5 c | 79.6 ± 0.2 d | 190 | 7′45″ | 210 | 9′34″ | Citric acid, grape, |

| Typica 1 | Dark | 47.5 ± 1.2 d | 57.0 ± 0.2 e | 190 | 7′38″ | 220 | 10′29″ | Roasted nuts, smoky |

| Typica 2 | Light | 77.9 ± 1.4 b | 92.4 ± 0.2 c | 184 | 7′50″ | 200 | 9′36″ | Barley tea, vegetative, peanut |

| Model | Cross-Validation | Prediction | ||

|---|---|---|---|---|

| Accuracy | Time (s) | Accuracy | Time (s) | |

| LD | 100% | 1.10 | 100% | 0.034 |

| SVM | 100% | 1.01 | 98.7% | 0.032 |

| NB | 99.7% | 20.77 | 100% | 0.402 |

| KNN | 100% | 0.73 | 94.7% | 0.029 |

| Model | Cross-Validation | Prediction | ||

|---|---|---|---|---|

| Accuracy | Time (s) | Accuracy | Time (s) | |

| LD | 100% | 4.31 | 100% | 0.054 |

| SVM | 99.0% | 3.09 | 96% | 0.052 |

| NB | 94.8% | 30.89 | 91% | 0.658 |

| KNN | 96.5% | 1.08 | 90% | 0.029 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, L.; Liu, M.; Li, B.; Chitrakar, B.; Duan, X. Terahertz Spectroscopic Identification of Roast Degree and Variety of Coffee Beans. Foods 2024, 13, 389. https://doi.org/10.3390/foods13030389

Huang L, Liu M, Li B, Chitrakar B, Duan X. Terahertz Spectroscopic Identification of Roast Degree and Variety of Coffee Beans. Foods. 2024; 13(3):389. https://doi.org/10.3390/foods13030389

Chicago/Turabian StyleHuang, Luelue, Miaoling Liu, Bin Li, Bimal Chitrakar, and Xu Duan. 2024. "Terahertz Spectroscopic Identification of Roast Degree and Variety of Coffee Beans" Foods 13, no. 3: 389. https://doi.org/10.3390/foods13030389