Enhancing Cookie Formulations with Combined Dehydrated Peach: A Machine Learning Approach for Technological Quality Assessment and Optimization

Abstract

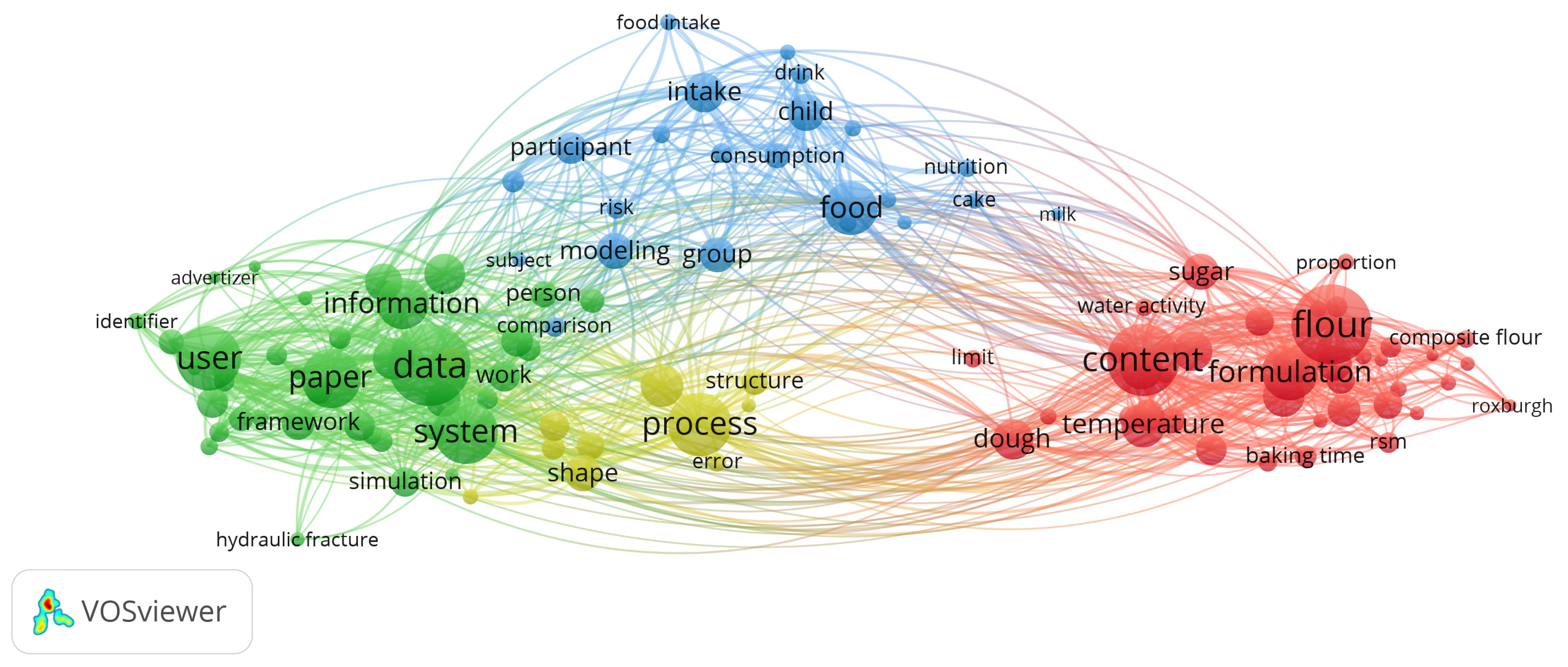

:1. Introduction

2. Materials and Methods

2.1. Experimental Data

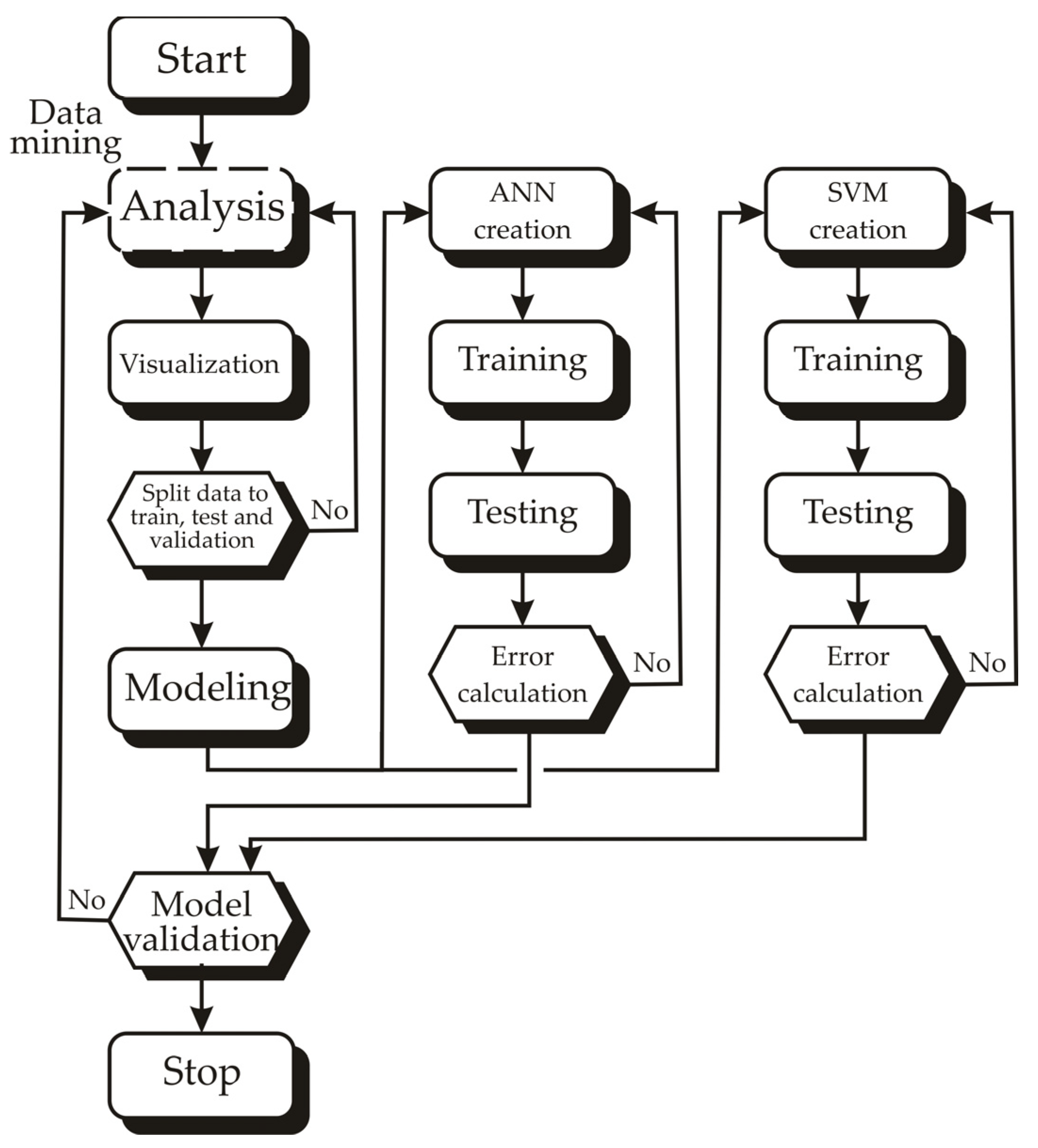

2.2. SVM Modeling

2.3. ANN Modeling

2.4. Global Sensitivity Analysis

2.5. The Accuracy of the Models

3. Results and Discussion

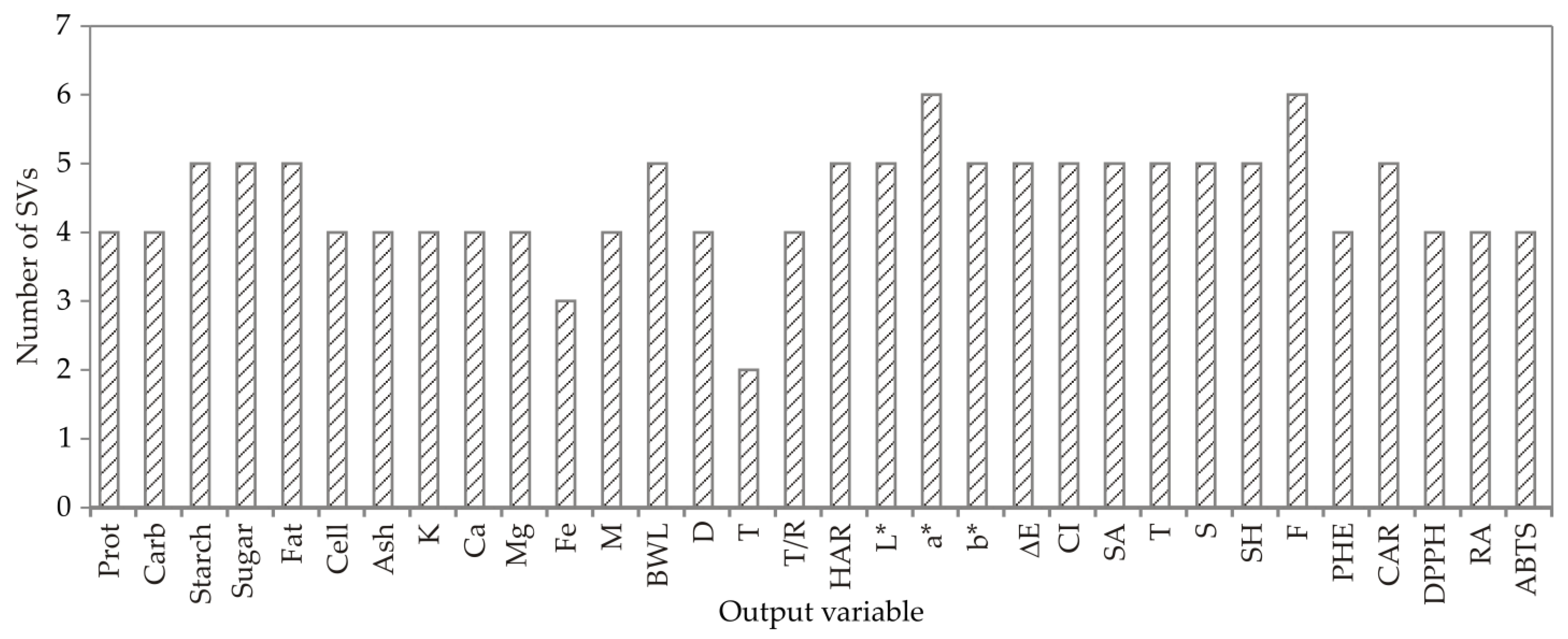

3.1. SVM Modeling

3.2. ANN Modeling

3.3. The Accuracy of the Models

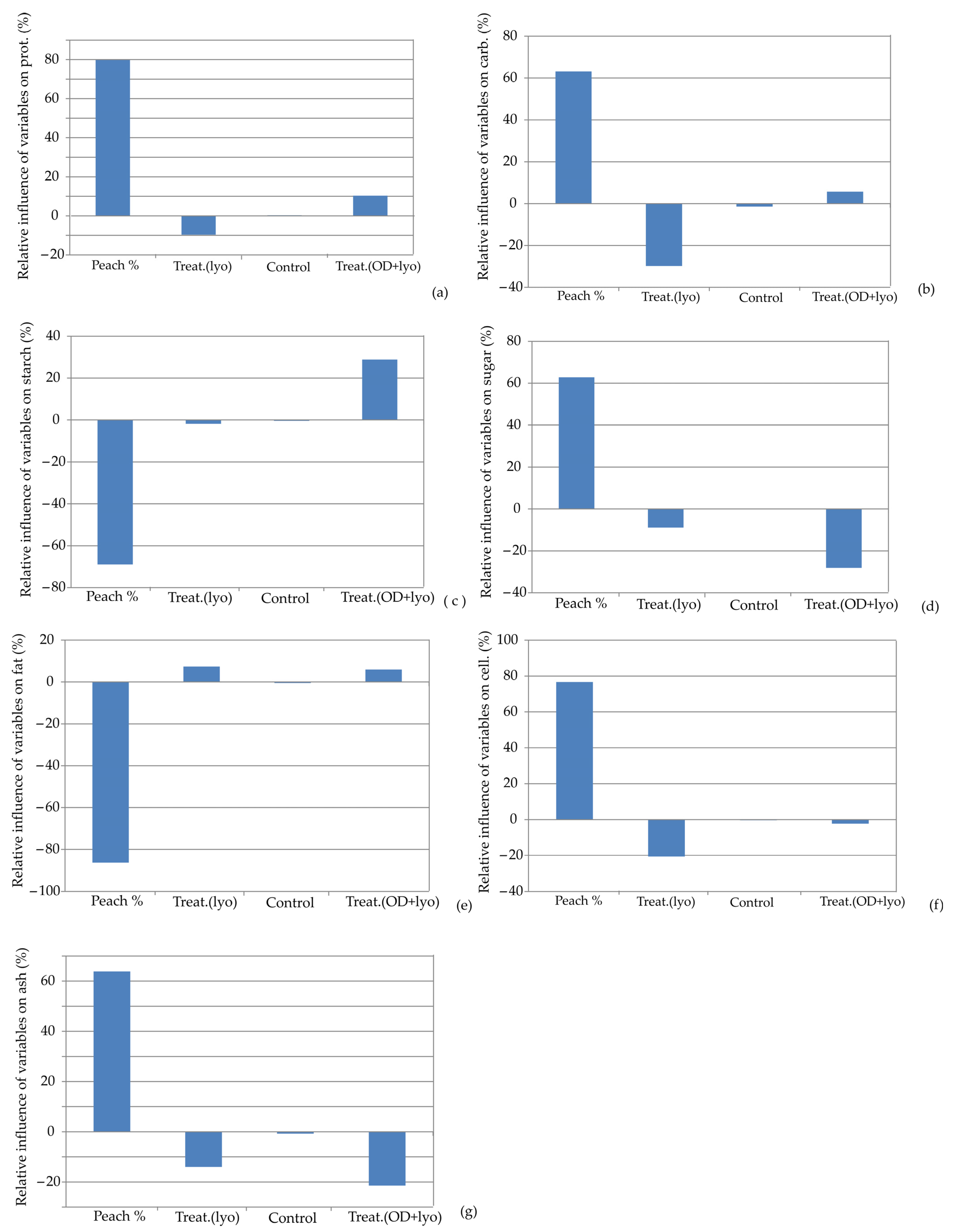

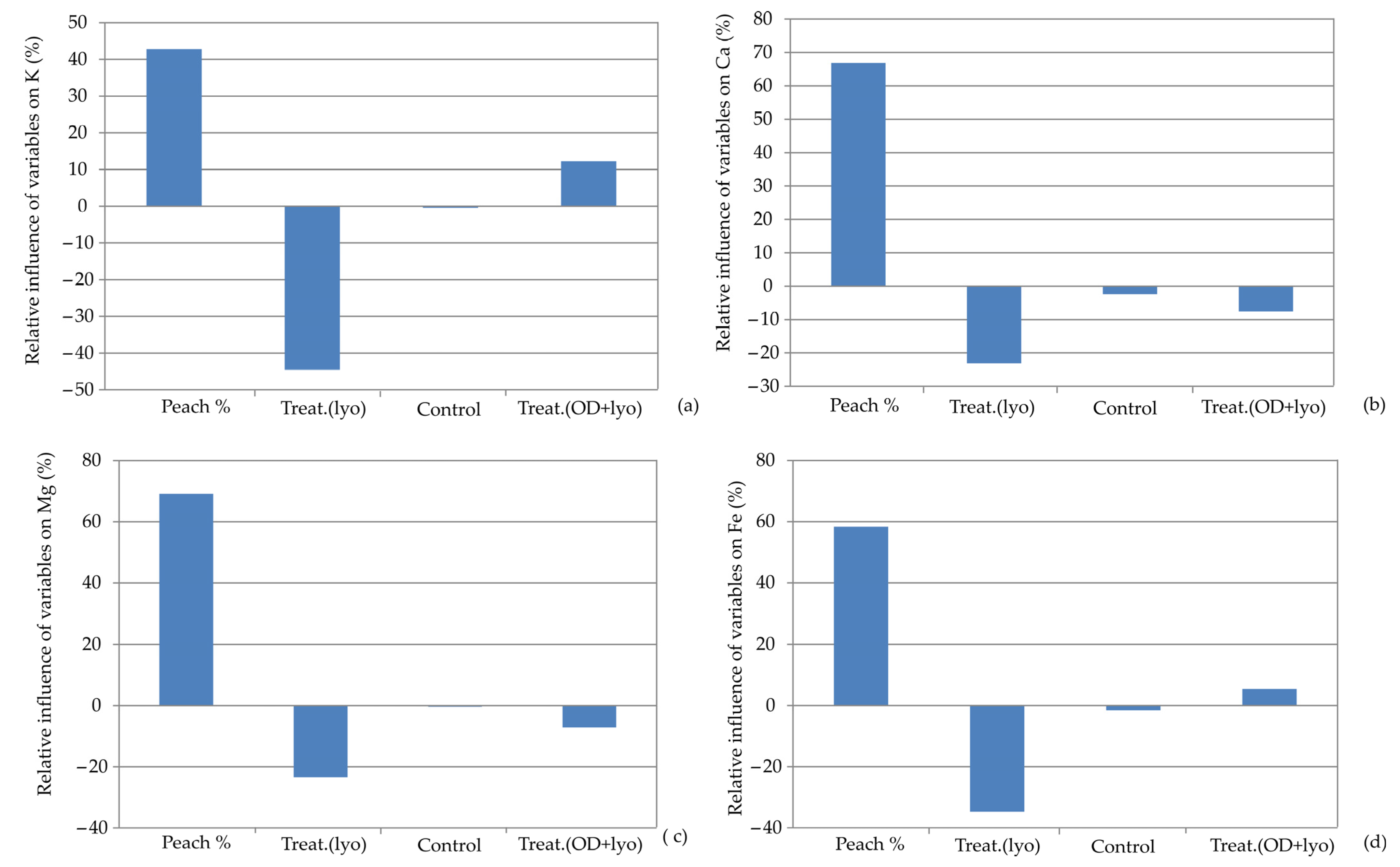

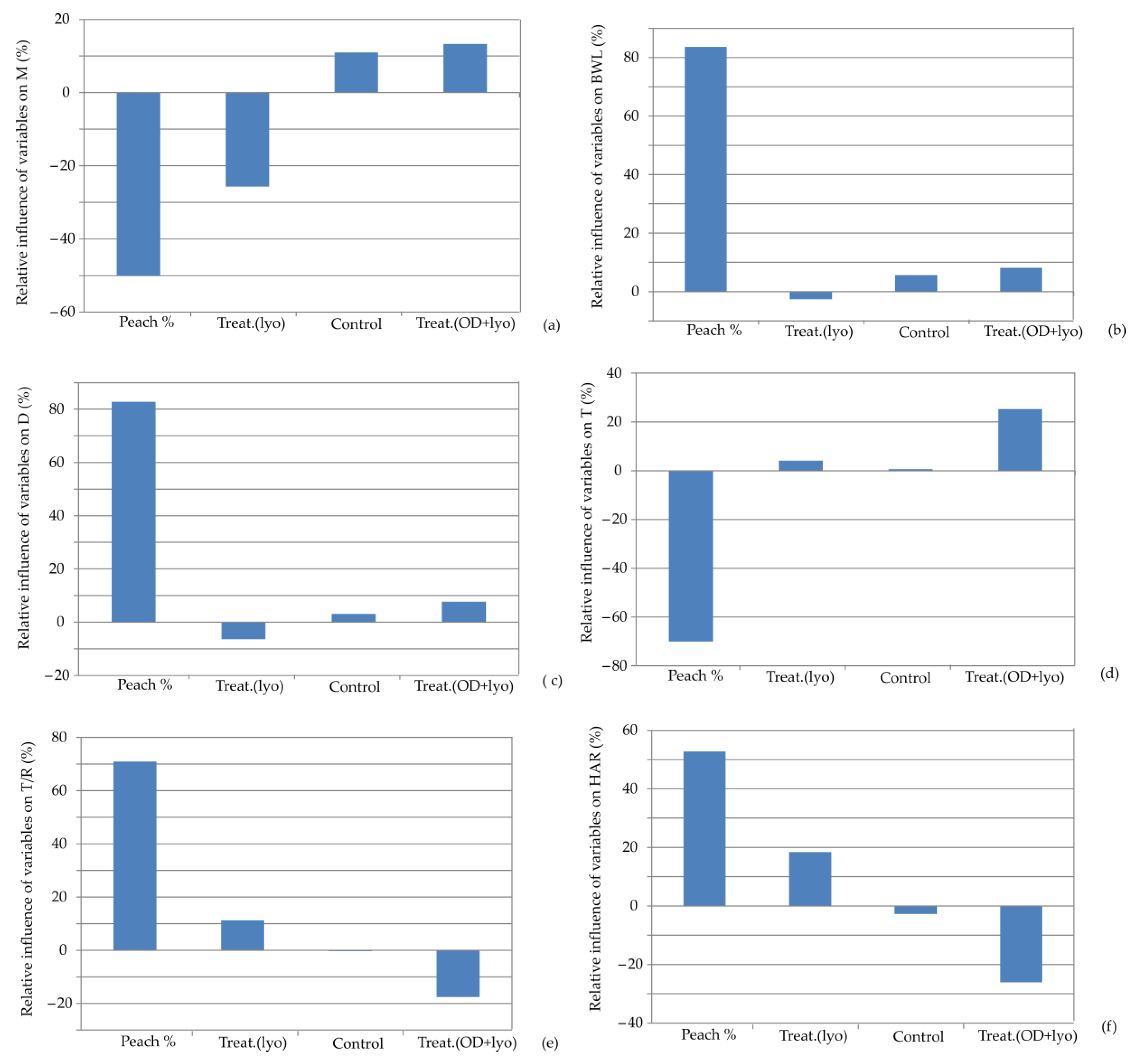

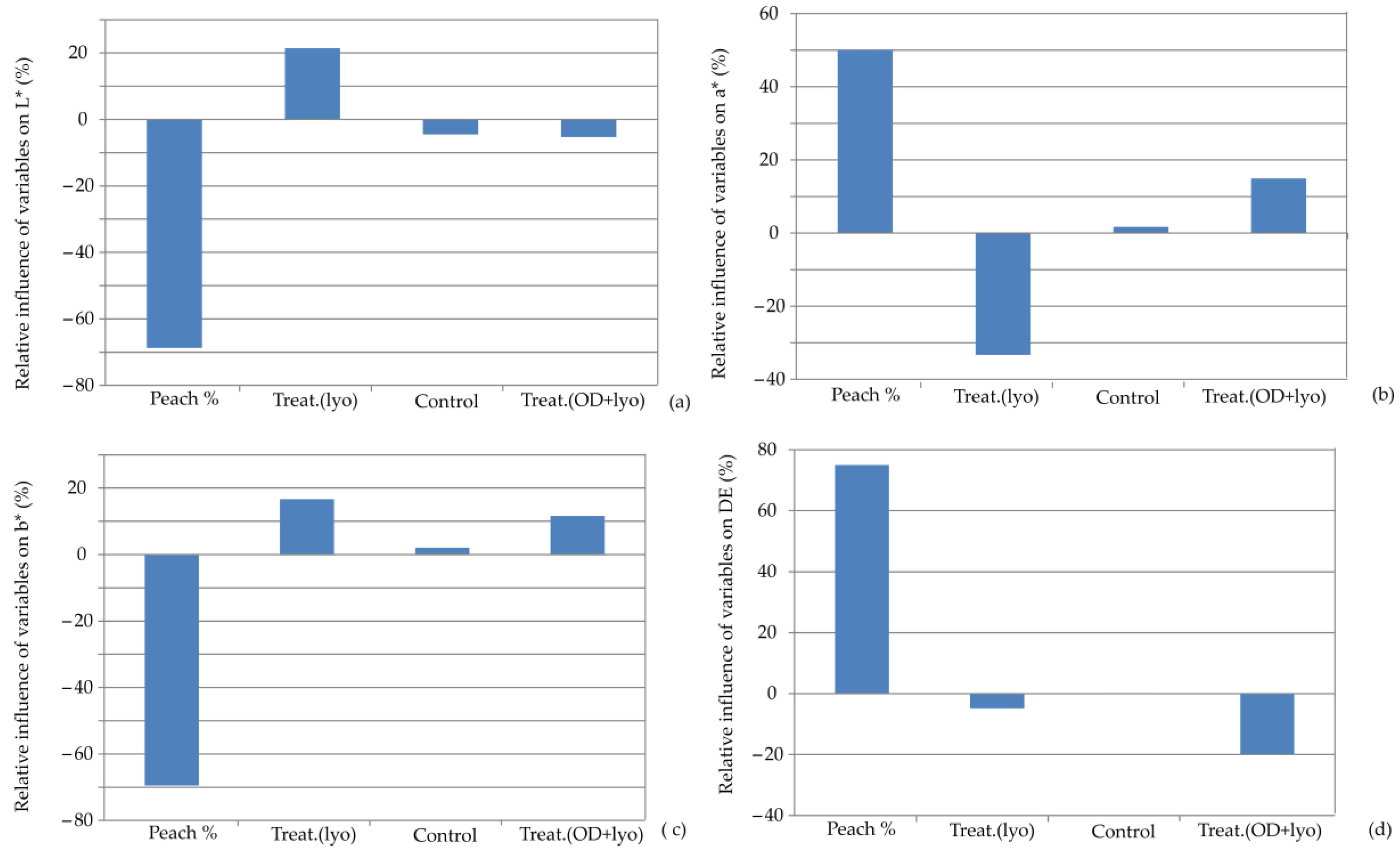

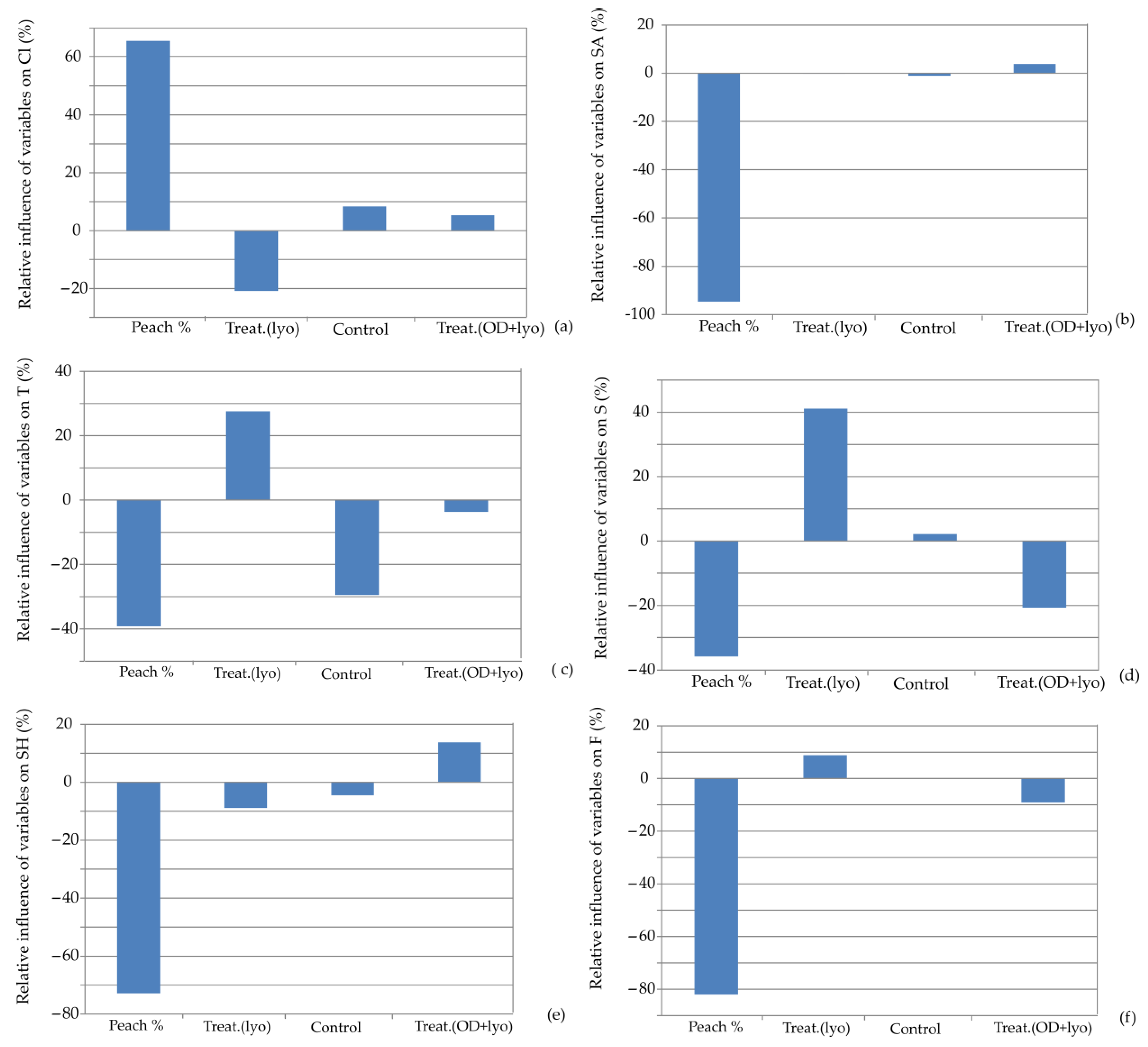

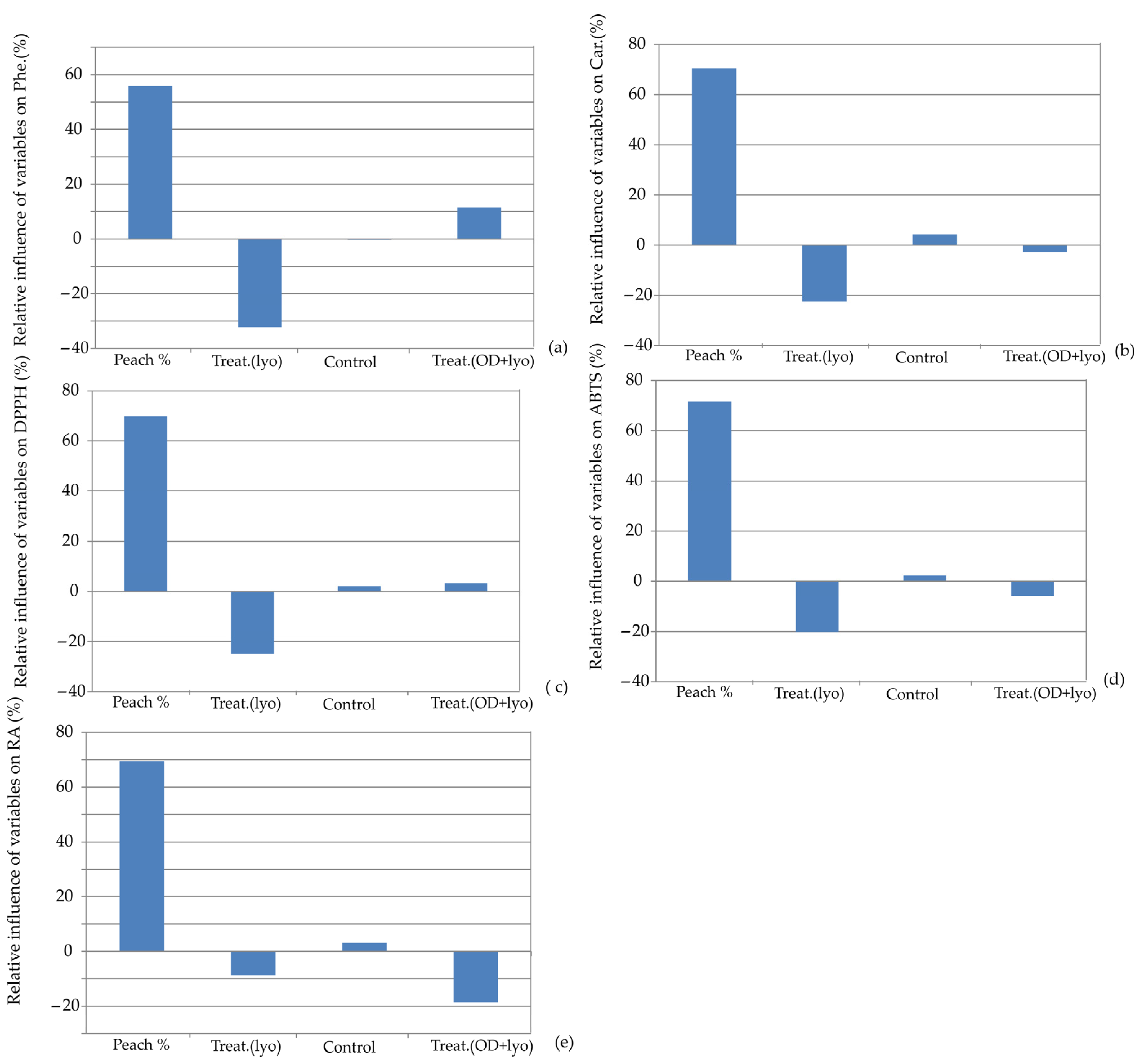

3.4. Global Sensitivity Analysis—Yoon’s Interpretation Method

3.5. Multi-Objective Optimization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Farris, S.; Piergiovanni, L. Optimization of manufacture of almond paste cookies using response surface methodology. J. Food Process Eng. 2009, 32, 64–87. [Google Scholar] [CrossRef]

- Mohd Basri, M.S.; Mohd Jais, N.; Sulaiman, A.; Mohd Nor, M.Z.; Abdul Karim Shah, N.N.; Ariffin, S.H. Optimizing the processing factor and formulation of oat-based cookie dough for enhancement in stickiness and moisture content using response surface methodology and superimposition. Processes 2020, 8, 797. [Google Scholar] [CrossRef]

- Grunert, K.G.; Wills, J.M. A review of European research on consumer response to nutrition information on food labels. J. Public Health 2007, 15, 385–399. [Google Scholar] [CrossRef]

- Fard, N.A.; Morales, G.D.F.; Mejova, Y.; Schifanella, R. On the interplay between educational attainment and nutrition: A spatially-aware perspective. EPJ Data Sci. 2021, 10, 18. [Google Scholar] [CrossRef]

- Krajewska, A.; Dziki, D. Enrichment of Cookies with Fruits and Their By-Products: Chemical Composition, Antioxidant Properties, and Sensory Changes. Molecules 2023, 28, 4005. [Google Scholar] [CrossRef] [PubMed]

- Chakraborty, N.; Chakraborty, R. Innovative Ingredients Fortified Nutrients Enriched Biscuits and Cookies: Quality and Sensory Analyses. Curr. Nutr. Food Sci. 2023, 19, 615–641. [Google Scholar] [CrossRef]

- Soni, M.; Yadav, A.; Maurya, A.; Das, S.; Dubey, N.K.; Dwivedy, A.K. Advances in Designing Essential Oil Nanoformulations: An Integrative Approach to Mathematical Modeling with Potential Application in Food Preservation. Foods 2023, 12, 4017. [Google Scholar] [CrossRef]

- Khan, M.I.H.; Sablani, S.S.; Nayak, R.; Gu, Y. Machine learning-based modeling in food processing applications: State of the art. Compr. Rev. Food Sci. Food Saf. 2022, 21, 1409–1438. [Google Scholar] [CrossRef]

- Paramesha, K.; Gururaj, H.L.; Jena, O.P. Applications of machine learning in biomedical text processing and food industry. In Machine Learning for Healthcare Applications; Elsevier: Amsterdam, The Netherlands, 2021; pp. 151–167. [Google Scholar]

- Martynenko, A.; Misra, N.N. Machine learning in drying. Dry. Technol. 2020, 38, 596–609. [Google Scholar] [CrossRef]

- Zhang, F.; O’Donnell, L.J. Support vector regression. In Machine Learning; Academic Press: Cambridge, MA, USA, 2020; pp. 123–140. [Google Scholar]

- Montesinos López, O.A.; Montesinos López, A.; Crossa, J. Support vector machines and support vector regression. In Multivariate Statistical Machine Learning Methods for Genomic Prediction; Springer International Publishing: Cham, Switzerland, 2022; pp. 337–378. [Google Scholar]

- Nirere, A.; Sun, J.; Atindana, V.A.; Hussain, A.; Zhou, X.; Yao, K. A comparative analysis of hybrid SVM and LS-SVM classification algorithms to identify dried wolfberry fruits quality based on hyperspectral imaging technology. J. Food Process. Preserv. 2022, 46, e16320. [Google Scholar] [CrossRef]

- Bhagya Raj, G.V.S.; Dash, K.K. Comprehensive study on applications of Artificial Neural Network in food process modeling. Crit. Rev. Food Sci. Nutr. 2022, 62, 2756–2783. [Google Scholar] [CrossRef]

- Sandoval, L.E.; Rivera, A.P.; Florez, L.C.; Figueroa, A.G. Application of Artificial Neural Networks (ANN) for predicting the effect of processing on the digestibility of foods. In Food Structure Engineering and Design for Improved Nutrition, Health and Well-Being; Academic Press: Cambridge, MA, USA, 2023; pp. 333–361. [Google Scholar]

- Henderson, C.E.; Potter, W.D.; McClendon, R.W.; Hoogenboom, G. Predicting aflatoxin contamination in peanuts: A genetic algorithm/neural network approach. Appl. Intell. 2000, 12, 183–192. [Google Scholar] [CrossRef]

- Abdoli, B.; Zare, D.; Jafari, A.; Chen, G. Evaluation of the air-borne ultrasound on fluidized bed drying of shelled corn: Effectiveness, grain quality, and energy consumption. Dry. Technol. 2018, 36, 1749–1766. [Google Scholar] [CrossRef]

- Rocha, W.F.D.C.; Prado, C.B.D.; Blonder, N. Comparison of chemometric problems in food analysis using non-linear methods. Molecules 2020, 25, 3025. [Google Scholar] [CrossRef] [PubMed]

- Al-Shaebi, Z.; Akdeniz, M.; Ahmed, A.O.; Altunbek, M.; Aydin, O. Breakthrough Solution for Antimicrobial Resistance Detection: Surface-Enhanced Raman Spectroscopy-based on Artificial Intelligence. Adv. Mater. Interfaces 2023, 2300664. [Google Scholar] [CrossRef]

- Kumar, R.; Saxena, S.; Kumar, V.; Prabha, V.; Kumar, R.; Kukreti, A. Service innovation research: A bibliometric analysis using VOSviewer. Compet. Rev. Int. Bus. J. 2023. [Google Scholar] [CrossRef]

- Filipović, V.; Lončar, B.; Filipović, J.; Nićetin, M.; Knežević, V.; Šeregelj, V.; Košutić, M.; Bodroža Solarov, M. Addition of combinedly dehydrated peach to the cookies—Technological quality testing and optimization. Foods 2022, 11, 1258. [Google Scholar] [CrossRef] [PubMed]

- Padalko, H.; Chomko, V.; Yakovlev, S.; Chumachenko, D. Ensemble machine learning approaches for fake news classification. Radioelectron. Comput. Syst. 2023, 4, 5–19. [Google Scholar] [CrossRef]

- Brandić, I.; Pezo, L.; Bilandžija, N.; Peter, A.; Šurić, J.; Voća, N. Comparison of Different Machine Learning Models for Modelling the Higher Heating Value of Biomass. Mathematics 2023, 11, 2098. [Google Scholar] [CrossRef]

- Zhu, F.; Zhu, C.; Lu, W.; Fang, Z.; Li, Z.; Pan, J. Soil Classification Mapping Using a Combination of Semi-Supervised Classification and Stacking Learning (SSC-SL). Remote Sens. 2024, 16, 405. [Google Scholar] [CrossRef]

- Afzal, S.; Ziapour, B.M.; Shokri, A.; Shakibi, H.; Sobhani, B. Building energy consumption prediction using multilayer perceptron neural network-assisted models; comparison of different optimization algorithms. Energy 2023, 282, 128446. [Google Scholar] [CrossRef]

- Weerakody, P.B.; Wong, K.W.; Wang, G.; Ela, W. A review of irregular time series data handling with gated recurrent neural networks. Neurocomputing 2021, 441, 161–178. [Google Scholar] [CrossRef]

- Otchere, D.A.; Ganat, T.O.A.; Gholami, R.; Ridha, S. Application of supervised machine learning paradigms in the prediction of petroleum reservoir properties: Comparative analysis of ANN and SVM models. J. Pet. Sci. Eng. 2021, 200, 108182. [Google Scholar] [CrossRef]

- Wen, Y.; Rahman, M.F.; Xu, H.; Tseng, T.L.B. Recent advances and trends of predictive maintenance from data-driven machine prognostics perspective. Measurement 2022, 187, 110276. [Google Scholar] [CrossRef]

- Abdolrasol, M.G.; Hussain, S.S.; Ustun, T.S.; Sarker, M.R.; Hannan, M.A.; Mohamed, R.; Ali, J.A.; Mekhilef, S.; Milad, A. Artificial Neural Networks based optimization techniques: A review. Electronics 2021, 10, 2689. [Google Scholar] [CrossRef]

- Kufel, J.; Bargieł-Łączek, K.; Kocot, S.; Koźlik, M.; Bartnikowska, W.; Janik, M.; Czogalik, Ł.; Dudek, P.; Magiera, M.; Lis, A.; et al. What is machine learning, Artificial Neural Networks and deep learning?—Examples of practical applications in medicine. Diagnostics 2023, 13, 2582. [Google Scholar] [CrossRef] [PubMed]

- Puntarić, E.; Pezo, L.; Zgorelec, Ž.; Gunjača, J.; Kučić Grgić, D.; Voća, N. Prediction of the production of separated municipal solid waste by Artificial Neural Networks in Croatia and the European Union. Sustainability 2022, 14, 10133. [Google Scholar] [CrossRef]

- Štrbac, S.; Stojić, N.; Lončar, B.; Pezo, L.; Ćuričić, L.; Prokić, D.; Pucarević, M. Heavy metal concentrations in the soil near illegal landfills in the vicinity of agricultural areas—Artificial Neural Network approach. J. Soils Sediments 2023, 24, 373–389. [Google Scholar] [CrossRef]

- Šurić, J.; Voća, N.; Peter, A.; Bilandžija, N.; Brandić, I.; Pezo, L.; Leto, J. Use of Artificial Neural Networks to Model Biomass Properties of Miscanthus (Miscanthus × giganteus) and Virginia Mallow (Sida hermaphrodita L.) in View of Harvest Season. Energies 2023, 16, 4312. [Google Scholar] [CrossRef]

- Stajčić, S.; Lato, P.; Čanadanović-Brunet, J.; Ćetković, G.; Mandić, A.; Tumbas Šaponjac, V.; Vulić, J.; Šeregelj, V.; Petrović, J. Encapsulation of bioactive compounds extracted from Cucurbita moschata pumpkin waste: The multi-objective optimisation study. J. Microencapsul. 2022, 39, 380–393. [Google Scholar] [CrossRef]

- Pezo, L.; Lončar, B.; Šovljanski, O.; Tomić, A.; Travičić, V.; Pezo, M.; Aćimović, M. Agricultural parameters and essential oil content composition prediction of aniseed, based on growing year, locality and fertilization type—An Artificial Neural Network approach. Life 2022, 12, 1722. [Google Scholar] [CrossRef]

- Alqahtani, A.; Shah, M.I.; Aldrees, A.; Javed, M.F. Comparative assessment of individual and ensemble machine learning models for efficient analysis of river water quality. Sustainability 2022, 14, 1183. [Google Scholar] [CrossRef]

- Althoff, D.; Rodrigues, L.N. Goodness-of-fit criteria for hydrological models: Model calibration and performance assessment. J. Hydrol. 2021, 600, 126674. [Google Scholar] [CrossRef]

- Kumar, V.; Kedam, N.; Sharma, K.V.; Mehta, D.J.; Caloiero, T. Advanced machine learning techniques to improve hydrological prediction: A comparative analysis of streamflow prediction models. Water 2023, 15, 2572. [Google Scholar] [CrossRef]

- Mrkonjić, Ž.; Pezo, L.; Brdar, M.; Rakić, D.; Mrkonjić, I.L.; Teslić, N.; Zeković, Z.; Pavlić, B. Valorization of wild thyme (Thymus serpyllum L.) herbal dust by supercritical fluid extraction–Experiments and modeling. J. Appl. Res. Med. Aromat. Plants 2024, 100529. [Google Scholar] [CrossRef]

- Voća, N.; Pezo, L.; Jukić, Ž.; Lončar, B.; Šuput, D.; Krička, T. Estimation of the storage properties of rapeseeds using an Artificial Neural Network. Ind. Crops Prod. 2022, 187, 115358. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, Z.; Yu, F.; Tao, Z. Ultrasound-assisted heat pump intermittent drying of adzuki bean seeds: Drying characteristics and parameter optimization. J. Food Process Eng. 2020, 43, e13501. [Google Scholar] [CrossRef]

- Lončar, B.; Pezo, L.; Filipović, V.; Nićetin, M.; Filipović, J.; Pezo, M.; Šuput, D.; Aćimović, M. Physico-chemical, textural and sensory evaluation of spelt muffins supplemented with apple powder enriched with sugar beet molasses. Foods 2022, 11, 1750. [Google Scholar] [CrossRef]

- Knežević, V.; Pezo, L.; Lončar, B.; Nićetin, M.; Filipović, V.; Šuput, D. Mineral content after osmotic treatment of nettle leaves (Urtica Dioica L.). J. Hyg. Eng. Des. 2022, 38, 238–242. [Google Scholar]

- Grigelmo-Miguel, N.; Carreras-Boladeras, E.; Martin-Belloso, O. Influence of the addition of peach dietary fiber in composition, physical properties and acceptability of reduced-fat muffins. Food Sci. Technol. Int. 2001, 7, 425–431. [Google Scholar] [CrossRef]

- Salehi, F.; Aghajanzadeh, S. Effect of dried fruits and vegetables powder on cakes quality: A review. Trends Food Sci. Technol. 2020, 95, 162–172. [Google Scholar] [CrossRef]

- Lin, S. Dietary fiber in bakery products: Source, processing, and function. Advances in food and nutrition research 2022, 99, 37–100. [Google Scholar]

- Mihaylova, D.; Popova, A.; Goranova, Z.; Doykina, P.; Goranov, B. Characterization of Muffins Reformulated with Chia and Lyophilized Peach Powder in Terms of Some Technological and Sensory Aspects. Food Technol. Biotechnol. 2023, 61, 273–282. [Google Scholar] [CrossRef]

- Abrahão, F.R.; Corrêa, J.L.G. Osmotic dehydration: More than water loss and solid gain. Crit. Rev. Food Sci. Nutr. 2023, 63, 2970–2989. [Google Scholar] [CrossRef]

- Šarić, L.; Filipčev, B.; Šimurina, O.; Plavšić, D.; Šarić, B.; Lazarević, J.; Milovanović, I. Sugar beet molasses: Properties and applications in osmotic dehydration of fruits and vegetables. Food Feed. Res. 2016, 43, 135–144. [Google Scholar] [CrossRef]

- Canalis, M.B.; Baroni, M.V.; León, A.E.; Ribotta, P.D. Effect of peach puree incorportion on cookie quality and on simulated digestion of polyphenols and antioxidant properties. Food Chem. 2020, 333, 127464. [Google Scholar] [CrossRef]

- Marcillo-Parra, V.; Tupuna-Yerovi, D.S.; González, Z.; Ruales, J. Encapsulation of bioactive compounds from fruit and vegetable by-products for food application–A review. Trends Food Sci. 2021, 116, 11–23. [Google Scholar] [CrossRef]

- Petchrompo, S.; Coit, D.W.; Brintrup, A.; Wannakrairot, A.; Parlikad, A.K. A review of Pareto pruning methods for multi-objective optimization. Comput. Ind. Eng. 2022, 167, 108022. [Google Scholar] [CrossRef]

- Shukla, A.K.; Tripathi, D.; Reddy, B.R.; Chandramohan, D. A study on metaheuristics approaches for gene selection in microarray data: Algorithms, applications and open challenges. Evol. Intell. 2020, 13, 309–329. [Google Scholar] [CrossRef]

- Rangaiah, G.P.; Feng, Z.; Hoadley, A.F. Multi-objective optimization applications in chemical process engineering: Tutorial and review. Processes 2020, 8, 508. [Google Scholar] [CrossRef]

- Martínez, S.; Eguía, P.; Granada, E.; Moazami, A.; Hamdy, M. A performance comparison of multi-objective optimization-based approaches for calibrating white-box building energy models. Energy Build. 2020, 216, 109942. [Google Scholar] [CrossRef]

| Output Variable | Net. Name | Performance | Error | Training Algorithm | Error Function | Activation | |||

|---|---|---|---|---|---|---|---|---|---|

| Train. | Test. | Train. | Test. | Hidden | Output | ||||

| Protein | MLP 4-9-1 | 0.997 | 1.000 | 0.0007 | 0.00009 | BFGS 5 | SOS | Identity | Tanh |

| Carbohydrate | MLP 4-4-1 | 0.992 | 1.000 | 0.0004 | 0.009 | BFGS 13 | SOS | Tanh | Exponential |

| Starch | MLP 4-7-1 | 0.998 | 1.000 | 0.0021 | 0.0226 | BFGS 54 | SOS | Exponential | Tanh |

| Sugar | MLP 4-7-1 | 0.999 | 1.000 | 0.0031 | 0.0527 | BFGS 32 | SOS | Tanh | Logistic |

| Fat | MLP 4-7-1 | 0.999 | 1.000 | 0.0002 | 0.0001 | BFGS 51 | SOS | Exponential | Exponential |

| Cellulose | MLP 4-6-1 | 0.997 | 1.000 | 0.0005 | 0.011 | BFGS 33 | SOS | Logistic | Exponential |

| Ash | MLP 4-3-1 | 0.999 | 1.000 | 0.00002 | 0.0001 | BFGS 24 | SOS | Logistic | Tanh |

| Output Variable | Net. Name | Performance | Error | Training Algorithm | Error Function | Activation | |||

|---|---|---|---|---|---|---|---|---|---|

| Train. | Test. | Train. | Test. | Hidden | Output | ||||

| K | MLP 4-6-1 | 0.999 | 1.000 | 0.1000 | 0.0007 | BFGS 32 | SOS | Tanh | Exponential |

| Ca | MLP 4-4-1 | 0.997 | 1.000 | 0.0573 | 0.0000 | BFGS 9 | SOS | Logistic | Identity |

| Mg | MLP 4-3-1 | 0.991 | 1.000 | 0.292 | 0.101 | BFGS 11 | SOS | Logistic | Tanh |

| Fe | MLP 4-7-1 | 0.993 | 1.000 | 0.00004 | 0.0001 | BFGS 15 | SOS | Logistic | Logistic |

| Output Variable | Net. Name | Performance | Error | Training Algorithm | Error Function | Activation | |||

|---|---|---|---|---|---|---|---|---|---|

| Train. | Test. | Train. | Test. | Hidden | Output | ||||

| M | MLP 4-9-1 | 0.962 | 1.000 | 0.243 | 2.543 | BFGS 5 | SOS | Identity | Identity |

| BWL | MLP 4-7-1 | 0.995 | 1.000 | 0.0298 | 0.0820 | BFGS 17 | SOS | Exponential | Tanh |

| D | MLP 4-6-1 | 0.977 | 1.000 | 0.091 | 0.016 | BFGS 28 | SOS | Exponential | Exponential |

| T | MLP 4-8-1 | 0.992 | 1.000 | 0.018 | 0.881 | BFGS 16 | SOS | Tanh | Tanh |

| T/R | MLP 4-8-1 | 0.996 | 1.000 | 0.007 | 0.112 | BFGS 21 | SOS | Logistic | Logistic |

| HAR | MLP 4-7-1 | 0.967 | 1.000 | 3.282. | 2.701 | BFGS 10 | SOS | Identity | Identity |

| Output Variable | Net. Name | Performance | Error | Training Algorithm | Error Function | Activation | |||

|---|---|---|---|---|---|---|---|---|---|

| Train. | Test. | Train. | Test. | Hidden | Output | ||||

| L* | MLP 4-6-1 | 0.980 | 1.000 | 0.1533 | 3.676 | BFGS 5 | SOS | Exponential | Exponential |

| a* | MLP 4-7-1 | 0.962 | 1.000 | 0.0778 | 1.3278 | BFGS 6 | SOS | Identity | Logistic |

| b* | MLP 4-6-1 | 0.999 | 1.000 | 0.0084 | 0.571 | BFGS 35 | SOS | Logistic | Logistic |

| ΔE | MLP 4-6-1 | 0.997 | 1.000 | 0.169 | 2.240 | BFGS 23 | SOS | Tanh | Logistic |

| Output Variable | Net. Name | Performance | Error | Training Algorithm | Error Function | Activation | |||

|---|---|---|---|---|---|---|---|---|---|

| Train. | Test. | Train. | Test. | Hidden | Output | ||||

| CI | MLP 4-3-1 | 0.973 | 1.000 | 0.0231 | 0.1886 | BFGS 10 | SOS | Identity | Identity |

| SA | MLP 4-5-1 | 0.990 | 1.000 | 0.0289 | 0.0262 | BFGS 14 | SOS | Exponential | Tanh |

| T | MLP 4-3-1 | 0.927 | 1.000 | 0.756 | 0.134 | BFGS 1 | SOS | Identity | Tanh |

| S | MLP 4-4-1 | 0.936 | 1.000 | 0.072 | 0.0349 | BFGS 4 | SOS | Identity | Logistic |

| SH | MLP 4-8-1 | 0.967 | 1.000 | 0.118 | 0.0400 | BFGS 3 | SOS | Exponential | Identity |

| B | MLP 4-6-1 | 0.828 | 1.000 | 0.219 | 0.0333 | BFGS 3 | SOS | Exponential | Identity |

| Output Variable | Net. Name | Performance | Error | Training Algorithm | Error Function | Activation | |||

|---|---|---|---|---|---|---|---|---|---|

| Train. | Test. | Train. | Test. | Hidden | Output | ||||

| PHE | MLP 4-4-1 | 0.996 | 1.000 | 0.0001 | 0.0000 | BFGS 5 | SOS | Logistic | Exponential |

| CAR | MLP 4-8-1 | 0.994 | 1.000 | 0.9142 | 7.7654 | BFGS 13 | SOS | Exponential | Identity |

| DPPH | MLP 4-7-1 | 0.995 | 1.000 | 0.004 | 0.0089 | BFGS 10 | SOS | Exponential | Identity |

| ABTS | MLP 4-8-1 | 0.953 | 1.000 | 9.090 | 4.446 | BFGS 5 | SOS | Identity | Tanh |

| RP | MLP 4-5-1 | 0.967 | 1.000 | 3.084 | 4.854 | BFGS 36 | SOS | Tanh | Identity |

| χ2 | RMSE | MBE | MPE | SSE | AARD | r2 | ||

|---|---|---|---|---|---|---|---|---|

| SVM | Prot | 0.001 | 0.027 | 0.007 | 0.324 | 0.006 | 0.163 | 0.968 |

| Carb | 0.001 | 0.035 | 0.001 | 0.041 | 0.011 | 0.259 | 0.981 | |

| Starch | 0.122 | 0.330 | −0.128 | 0.657 | 0.831 | 1.783 | 0.956 | |

| Sugar | 0.110 | 0.313 | 0.112 | 0.493 | 0.770 | 1.757 | 0.973 | |

| Fat | 0.007 | 0.081 | −0.026 | 0.509 | 0.053 | 0.470 | 0.979 | |

| Cell | 0.013 | 0.108 | 0.040 | 0.852 | 0.091 | 0.649 | 0.981 | |

| Ash | 0.002 | 0.044 | 0.016 | 4.563 | 0.015 | 0.248 | 0.958 | |

| K | 103.246 | 9.580 | 3.222 | 3.004 | 732.514 | 50.264 | 0.969 | |

| Ca | 2.158 | 1.385 | 0.561 | 3.112 | 14.432 | 7.143 | 0.951 | |

| Mg | 2.125 | 1.374 | 0.522 | 2.441 | 14.551 | 7.363 | 0.967 | |

| Fe | 0.001 | 0.035 | 0.017 | 1.693 | 0.008 | 0.215 | 0.895 | |

| M | 0.801 | 0.844 | −0.433 | 16.067 | 4.720 | 6.259 | 0.950 | |

| BWL | 0.670 | 0.772 | 0.280 | 5.296 | 4.659 | 6.142 | 0.966 | |

| D | 2.921 | 1.611 | 0.696 | 1.185 | 19.004 | 8.179 | 0.610 | |

| T | 1.774 | 1.256 | −0.264 | 9.509 | 13.560 | 8.669 | 0.452 | |

| T/R | 1.027 | 0.955 | 0.040 | 11.038 | 8.198 | 7.064 | 0.327 | |

| HAR | 8.246 | 2.707 | 0.717 | 10.559 | 61.342 | 21.775 | 0.972 | |

| L* | 8.554 | 2.757 | −0.994 | 5.070 | 59.531 | 15.842 | 0.927 | |

| a* | 0.610 | 0.736 | 0.362 | 3.954 | 3.703 | 4.571 | 0.909 | |

| b* | 1.937 | 1.312 | −0.529 | 5.414 | 12.976 | 7.042 | 0.888 | |

| ΔE | 10.786 | 3.096 | 1.155 | 8.773 | 74.285 | 17.660 | 0.923 | |

| CI | 0.192 | 0.413 | 0.194 | 4.495 | 1.195 | 2.390 | 0.891 | |

| SA | 0.396 | 0.593 | −0.223 | 16.690 | 2.718 | 4.703 | 0.961 | |

| T | 0.536 | 0.690 | −0.353 | 20.248 | 3.167 | 4.785 | 0.876 | |

| S | 0.022 | 0.139 | −0.028 | 3.347 | 0.167 | 1.053 | 0.981 | |

| SH | 0.098 | 0.295 | −0.136 | 7.770 | 0.616 | 1.774 | 0.914 | |

| B | 0.247 | 0.469 | −0.086 | 10.795 | 1.911 | 3.121 | 0.867 | |

| PHE | 0.013 | 0.106 | 0.045 | 19.904 | 0.083 | 0.434 | 0.744 | |

| CAR | 37.421 | 5.767 | 2.233 | 13.086 | 254.473 | 29.361 | 0.902 | |

| DPPH | 0.053 | 0.218 | 0.018 | 66.574 | 0.424 | 1.643 | 0.865 | |

| RA | 916.533 | 28.543 | 3.624 | 41.219 | 7214.037 | 201.384 | 0.830 | |

| ABTS | 822.893 | 27.046 | 10.830 | 30.537 | 5527.627 | 117.238 | 0.825 |

| χ2 | RMSE | MBE | MPE | SSE | AARD | r2 | ||

|---|---|---|---|---|---|---|---|---|

| ANN | Prot | 0.001 | 0.033 | 0.030 | 0.541 | 0.002 | 0.269 | 0.982 |

| Carb | 0.005 | 0.068 | −0.017 | 0.054 | 0.038 | 0.341 | 0.909 | |

| Starch | 0.015 | 0.115 | 0.034 | 0.238 | 0.110 | 0.679 | 0.989 | |

| Sugar | 0.032 | 0.168 | −0.050 | 0.284 | 0.232 | 0.975 | 0.988 | |

| Fat | 0.000 | 0.018 | 0.001 | 0.142 | 0.003 | 0.131 | 0.997 | |

| Cell | 0.006 | 0.075 | −0.025 | 0.523 | 0.045 | 0.364 | 0.973 | |

| Ash | 0.000 | 0.009 | 0.000 | 1.488 | 0.001 | 0.060 | 0.996 | |

| K | 0.177 | 0.396 | 0.117 | 0.179 | 1.291 | 2.664 | 1.000 | |

| Ca | 0.100 | 0.299 | 0.005 | 1.133 | 0.803 | 2.200 | 0.994 | |

| Mg | 0.562 | 0.707 | 0.155 | 1.914 | 4.281 | 5.071 | 0.980 | |

| Fe | 0.000 | 0.011 | 0.005 | 0.719 | 0.001 | 0.088 | 0.983 | |

| M | 1.689 | 1.225 | 0.498 | 12.668 | 11.276 | 7.363 | 0.870 | |

| BWL | 0.093 | 0.288 | −0.056 | 2.316 | 0.718 | 2.025 | 0.995 | |

| D | 0.168 | 0.386 | −0.091 | 0.462 | 1.267 | 3.106 | 0.951 | |

| T | 0.472 | 0.648 | 0.103 | 2.462 | 3.679 | 2.900 | 0.839 | |

| T/R | 0.069 | 0.248 | −0.017 | 2.380 | 0.549 | 1.257 | 0.955 | |

| HAR | 106.101 | 9.711 | −2.571 | 64.001 | 789.330 | 49.474 | 0.571 | |

| L* | 18.522 | 4.058 | 0.338 | 4.778 | 147.144 | 20.395 | 0.732 | |

| a* | 0.800 | 0.843 | −0.141 | 5.163 | 6.219 | 4.635 | 0.768 | |

| b* | 0.218 | 0.441 | −0.071 | 1.983 | 1.703 | 2.817 | 0.977 | |

| ΔE | 11.916 | 3.255 | −1.184 | 3.377 | 82.712 | 13.700 | 0.897 | |

| CI | 0.135 | 0.346 | −0.084 | 5.366 | 1.015 | 2.254 | 0.880 | |

| SA | 0.064 | 0.238 | 0.044 | 4.701 | 0.494 | 1.751 | 0.984 | |

| T | 1.372 | 1.104 | 0.108 | 30.445 | 10.873 | 8.272 | 0.729 | |

| S | 0.144 | 0.357 | −0.142 | 10.489 | 0.967 | 2.979 | 0.865 | |

| SH | 0.041 | 0.190 | 0.030 | 4.623 | 0.318 | 1.335 | 0.902 | |

| F | 0.402 | 0.598 | 0.053 | 15.452 | 3.189 | 4.665 | 0.660 | |

| PHE | 0.000 | 0.013 | −0.006 | 9.086 | 0.001 | 0.065 | 0.991 | |

| CAR | 5.483 | 2.208 | −0.715 | 13.945 | 39.256 | 13.930 | 0.969 | |

| DPPH | 0.005 | 0.068 | −0.030 | 26.712 | 0.034 | 0.420 | 0.960 | |

| RA | 28.326 | 5.018 | −1.850 | 8.088 | 195.822 | 32.000 | 0.987 | |

| ABTS | 334.897 | 17.254 | 10.065 | 83.982 | 1767.459 | 114.503 | 0.896 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lončar, B.; Pezo, L.; Knežević, V.; Nićetin, M.; Filipović, J.; Petković, M.; Filipović, V. Enhancing Cookie Formulations with Combined Dehydrated Peach: A Machine Learning Approach for Technological Quality Assessment and Optimization. Foods 2024, 13, 782. https://doi.org/10.3390/foods13050782

Lončar B, Pezo L, Knežević V, Nićetin M, Filipović J, Petković M, Filipović V. Enhancing Cookie Formulations with Combined Dehydrated Peach: A Machine Learning Approach for Technological Quality Assessment and Optimization. Foods. 2024; 13(5):782. https://doi.org/10.3390/foods13050782

Chicago/Turabian StyleLončar, Biljana, Lato Pezo, Violeta Knežević, Milica Nićetin, Jelena Filipović, Marko Petković, and Vladimir Filipović. 2024. "Enhancing Cookie Formulations with Combined Dehydrated Peach: A Machine Learning Approach for Technological Quality Assessment and Optimization" Foods 13, no. 5: 782. https://doi.org/10.3390/foods13050782

APA StyleLončar, B., Pezo, L., Knežević, V., Nićetin, M., Filipović, J., Petković, M., & Filipović, V. (2024). Enhancing Cookie Formulations with Combined Dehydrated Peach: A Machine Learning Approach for Technological Quality Assessment and Optimization. Foods, 13(5), 782. https://doi.org/10.3390/foods13050782