The Use of Waste Products from the Food Industry to Obtain High Value-Added Products

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leonard, M.M.; Sapone, A.; Catassi, C.; Fasano, A. Celiac Disease and Nonceliac Gluten Sensitivity. A Review. JAMA 2017, 318, 647–656. [Google Scholar] [CrossRef] [PubMed]

- Kruczek, B.; Gumul, D.; Olech, E.; Gambuś, H. Diet and the Context of Fruit Industry. Econ. Environ. Stud. 2017, 17, 389–398. [Google Scholar] [CrossRef]

- Gómez, M.; Martinez, M.M. Fruit and vegetable by-products as novel ingredients to improve the nutritional quality of baked goods. Crit. Rev. Food Sci. Nutr. 2018, 58, 2119–2135. [Google Scholar] [CrossRef] [PubMed]

- Padayachee, A.; Day, L.; Howell, K.; Gidley, M.J. Complexity and health functionality of plant cell wall fibers from fruits and vegetables. Crit. Rev. Food Sci. Nutr. 2017, 57, 59–81. [Google Scholar] [CrossRef] [PubMed]

- Makovicky, P.; Makovicky, P.; Caja, F.; Rimarova, K.; Samasca, G.; Vannucci, L. Celiac disease and gluten-free diet: Past, present and future. Gastroenterol. Hepatol. Bed Bench 2020, 13, 1–7. [Google Scholar] [PubMed]

- FAO. The State of Food and Agriculture 2019. Moving Forward on Food Loss and Waste Reduction; FAO: Rome, Italy, 2019. [Google Scholar]

- Srivastava, N.; Srivastava, M.; Alhazmi, A.; Kausar, T.; Haque, S.; Singh, R.; Ramteke, P.W.; Mishra, P.K.; Tuohy, M.; Leitgeb, M.; et al. Technological advances for improving fungal cellulase production from fruit wastes for bioenergy application: A review. Environ. Pollut. 2021, 287, 117370. [Google Scholar] [CrossRef] [PubMed]

- Kawecka, L.; Galus, S. Wytłoki owocowe—Charakterystyka i możliwości zagospodarowania [Fruit pomace—Characteristics and possibilities of recycling]. Postępy Tech. Przetwórstwa Spożywczego 2021, 1, 156–167. (In Polish) [Google Scholar]

- Sadh, P.K.; Duhan, S.; Duhan, J.S. Agro-industrial Wastes and Their Utilization Using Solid State Fermentation: A Review. Bioresour. Bioproc. 2018, 5, 1. [Google Scholar] [CrossRef]

- Reguengo, L.M.; Salgaço, M.K.; Sivieri, K.; Maróstica, M.R.J. Agro-industrial by-products: Valuable sources of bioactive compounds. Food Res. Int. 2022, 152, 110871. [Google Scholar] [CrossRef] [PubMed]

- Lemes, A.C.; Egea, M.B.; Oliveira Filho, J.G.; Gautério, G.V.; Ribeiro, B.D.; Coelho, M.A.Z. Biological Approaches for Extraction of Bioactive Compounds from Agroindustrial By-products: A Review. Front. Bioeng. Biotechnol. 2022, 9, 802543. [Google Scholar] [CrossRef] [PubMed]

- Santos, D.; da Silva, J.A.L.; Pintado, M. Fruit and Vegetable By-Products’ Flours as Ingredients: A Review on Production Process, Health Benefits and Technological Functionalities. LWT 2022, 154, 112707. [Google Scholar] [CrossRef]

- Parveen, H.; Bajpai, A.; Bhatia, S.; Singh, S. Analysis of biscuits enriched with fibre by incorporating carrot and beetroot pomace powder. Indian. J. Nutr. Diet. 2017, 54, 403. [Google Scholar] [CrossRef]

- Kultys, E.; Moczkowska-Wyrwisz, M. Effect of using carrot pomace and beetroot-apple pomace on physicochemical and sensory properties of pasta. LWT 2022, 168, 113858. [Google Scholar] [CrossRef]

- Gumul, D.; Ziobro, R.; Korus, J.; Kruczek, M. Apple pomace as a source of bioactive polyphenol compounds in gluten-free breads. Antioxidants 2021, 10, 80. [Google Scholar] [CrossRef] [PubMed]

- Maner, S.; Sharma, A.K.; Banerjee, K. Wheat flour replacement by wine grape pomace powder positively affects physical, functional and sensory properties of cookies. Proc. Natl. Acad. Sci. India Sect. B Biol. Sci. 2015, 87, 109–113. [Google Scholar] [CrossRef]

- Padalino, L.; Conte, A.; Lecce, L.; Likyova, D.; Sicari, V.; Pellicanò, T.M.; Poiana, M.; Del Nobile, M.A. Functional Pasta with Tomato By-Product as a Source of Antioxidant Compounds and Dietary Fibre. Czech J. Food Sci. 2017, 35, 48–56. [Google Scholar] [CrossRef]

- Xu, J.; Bock, J.E.; Stone, D. Quality and Textural Analysis of Noodles Enriched with Apple Pomace. J. Food Process. Preserv. 2020, 44, e14579. [Google Scholar] [CrossRef]

- Tolve, R.; Pasini, G.; Vignale, F.; Favati, F.; Simonato, B. Effect of Grape Pomace Addition on the Technological, Sensory, and Nutritional Properties of Durum Wheat Pasta. Foods 2020, 9, 354. [Google Scholar] [CrossRef] [PubMed]

- Sagar, N.A.; Pareek, S.; Sharma, S.; Yahia, E.M.; Lobo, M.G. Fruit and vegetable waste: Bioactive compounds, their extraction, and possible utilization. Compr. Rev. Food Sci. Food Saf. 2018, 17, 512–531. [Google Scholar] [CrossRef] [PubMed]

- United Nations. Resolution Adopted by the General Assembly on 25 September 2015, 526 A/RES/70/1, Transforming our World: The 2030 Agenda for Sustainable Development, 527, United Nations. 2015. Available online: https://undocs.org/en/A/RES/70/1 (accessed on 5 March 2023).

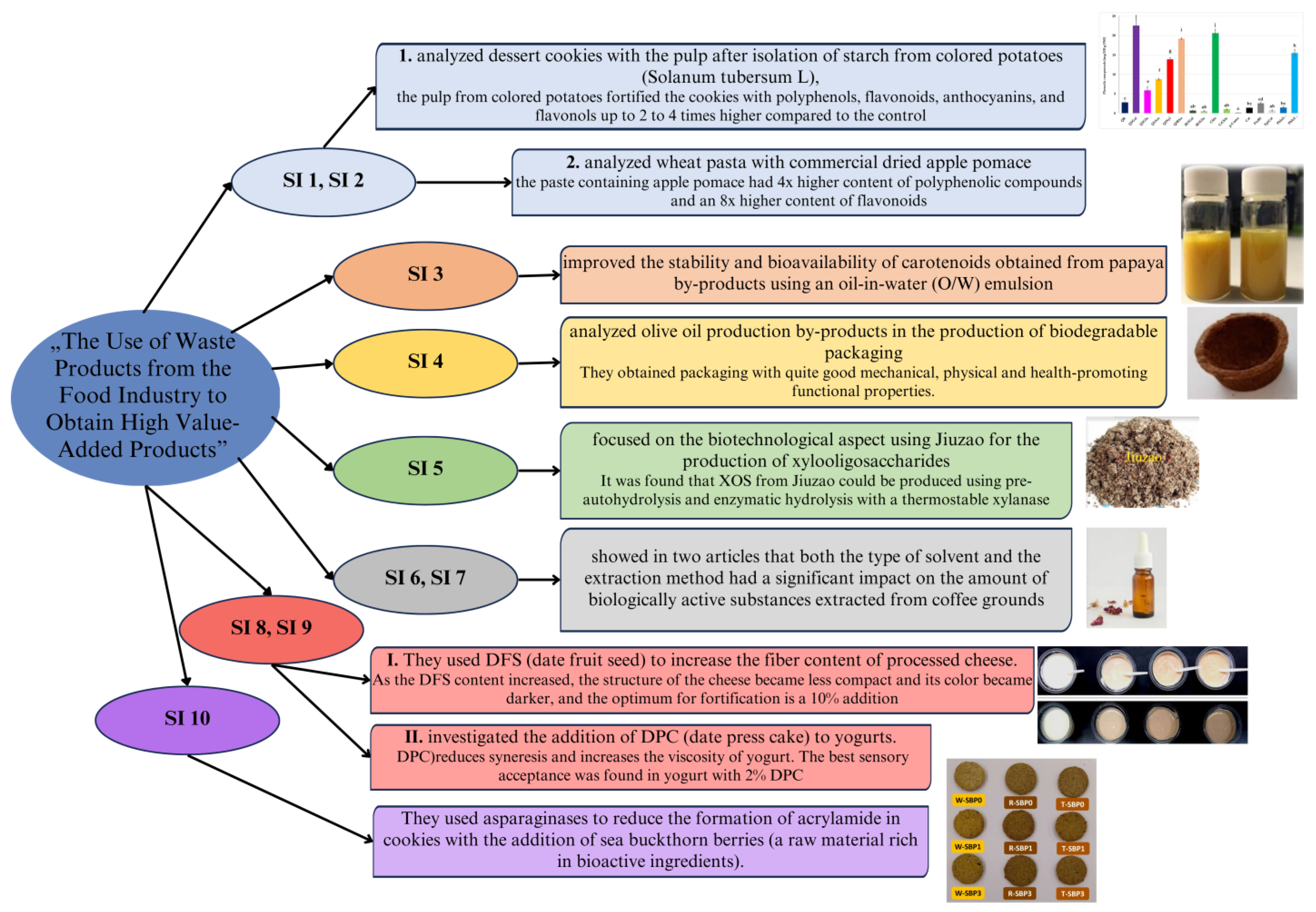

| Article Symbol | Bibliography | By-Product Used |

|---|---|---|

| SI 1 | Gumul, D.; Ziobro, R.; Korus, J.; Surma, M. Pulp from Colored Potatoes (Solanum tuberosum L.) as an Ingredient Enriching Dessert Cookies. Foods 2023, 12, 3735. | Potato pulp |

| SI 2 | Gumul, D.; Kruczek, M.; Ivanišová, E.; Słupski, J.; Kowalski, S. Apple Pomace as an Ingredient Enriching Wheat Pasta with Health-Promoting Compounds. Foods 2023, 12, 804. | Apple pomace |

| SI 3 | Lara-Abia, S.; Lobo, G.; Pérez-Pascual, N.; Welti-Chanes, J.; Cano, M.P. Improvement in the Stability and Bioaccessibility of Carotenoid and Carotenoid Esters from a Papaya By-Product Using O/W Emulsions. Foods 2023, 12, 2654 | Papaya pomace |

| SI 4 | Grzelczyk, J.; Oracz, J.; Gałąazka-Czarnecka, I. Quality Assessment of Waste from Olive Oil Production and Design of Biodegradable Packaging. Foods 2022, 11, 3776. | Olive oil pomace |

| SI 5 | Qin, L.; Ma, J.; Tian, H.; Ma, Y.; Wu, Q.; Cheng, S.; Fan, G. Production of Xylooligosaccharides from Jiuzao by Autohydrolysis Coupled with Enzymatic Hydrolysis Using a Thermostable Xylanase. Foods 2022, 11, 2663. | Jiuzao (a mixture of grain and rice hull residues after solid-state fermentation) |

| SI 6 | Bouhzam, I.; Cantero, R.; Margallo, M.; Aldaco, R.; Bala, A.; Fullana-i-Palmer, P.; Puig, R. Extraction of Bioactive Compounds from Spent Coffee Grounds Using Ethanol and Acetone Aqueous Solutions. Foods 2023, 12, 4400. | Spent coffee Grounds |

| SI 7 | Bouhzam, I.; Cantero, R.; Balcells, M.; Margallo, M.; Aldaco, R.; Bala, A.; Fullana-i-Palmer, P.; Puig, R. Environmental and Yield Comparison of Quick Extraction Methods for Caffeine and Chlorogenic Acid from Spent Coffee Grounds. Foods 2023, 12, 779. | Spent coffee Grounds |

| SI 8 | Alqahtani, N.K.; Alnemr, T.M.; Alqattan, A.M.; Aleid, S.M.; Habib, H.M. Physicochemical and Sensory Properties and Shelf Life of Block-Type Processed Cheeses Fortified with Date Seeds (Phoenix dactylifera L.) as a Functional Food. Foods 2023, 12, 679. | Date fruit seeds |

| SI 9 | Alqahtani, N.K.; Alnemr, T.M.; Alsalem, A.K.; Alotaibi, M.M.; Mohammed, M. Experimental Investigation and Modeling for the Influence of Adding Date Press Cake on Drinkable Yogurt Quality. Foods 2023, 12, 1219. | Date press cake |

| SI 10 | Ciesarová, Z.; Kukurová, K.; Jelemenská, V.; Horváthová, J.; Kubincová, J.; Belović, M.; Torbica, A. Asparaginase Treatment of Sea Buckthorn Berries as an Effective Tool for Acrylamide Reduction in Nutritionally Enriched Wholegrain Wheat, Rye and Triticale Biscuits. Foods 2023, 12, 3170. | Sea buckthorn berry pomace |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kowalski, S.; Gumul, D. The Use of Waste Products from the Food Industry to Obtain High Value-Added Products. Foods 2024, 13, 847. https://doi.org/10.3390/foods13060847

Kowalski S, Gumul D. The Use of Waste Products from the Food Industry to Obtain High Value-Added Products. Foods. 2024; 13(6):847. https://doi.org/10.3390/foods13060847

Chicago/Turabian StyleKowalski, Stanisław, and Dorota Gumul. 2024. "The Use of Waste Products from the Food Industry to Obtain High Value-Added Products" Foods 13, no. 6: 847. https://doi.org/10.3390/foods13060847

APA StyleKowalski, S., & Gumul, D. (2024). The Use of Waste Products from the Food Industry to Obtain High Value-Added Products. Foods, 13(6), 847. https://doi.org/10.3390/foods13060847