1. Introduction

Colors are one of the most important sensory attributes in foods. They directly affect final product consumption since they serve as key criteria for judging the quality and even taste of foods by consumers [

1]. Given the importance of colors in influencing eating behaviors, the industry uses artificial colorings (e.g., tartrazine, erythrosine, brilliant blue, and others) to intensify or preserve the initial colors of food during processing and storage stages [

2,

3]. This guarantee of product color quality control is carried out through color models, such as CIELab and RGB. The latter, for example, is capable of measuring the color of any object based on the sum of the variations in intensity between red, green, and blue [

4]. The main advantages of using artificial dyes are their good stability to temperature, light, pH, and storage time, as well as their good coloring properties and low-cost production [

2].

Regardless of the clear importance of artificial dyes, many have witnessed concerns about the potential adverse impacts of their production process on the environment and the possible risks to human health caused by their excessive intake [

5,

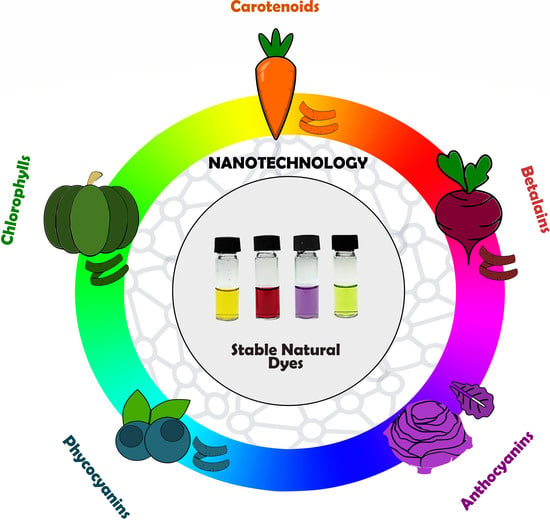

6]. On the other hand, there is a wide variety of natural pigments, such as anthocyanins, betanins, and carotenoids, which can replace artificial colorants. These biopigments are chemical compounds (metabolites) present in virtually all living organisms. Due to their rich structural diversity, they usually differ among themselves in terms of antioxidant, antineoplastic, anti-inflammatory, and antimicrobial properties [

7,

8,

9].

In this scenario, by-products from industrial processes, specifically vegetable residues, such as peels, pomace, and seeds, among others, have been considered promising sources for developing natural food colorants due to their low cost and abundance in industrial, commercial, and household sectors, as well as the presence of health-beneficial phytopigments [

10]. Furthermore, the reuse of food residues minimizes environmental pollution since their decomposition results in gas emissions that contribute to climate change [

11].

Despite the environmental benefits associated with the use of food residues, obtaining these natural colorants generally requires organic solvents. Due to this fact, there is an increasing interest in technology development aimed at using alternative and nontoxic (green) solvents due to global environmental and climate imbalances [

12]. That is why several studies have aimed at finding suitable sources for obtaining natural colorants from the use of sustainable technological innovations in correspondence with green chemistry principles [

13,

14].

Another challenge that needs to be overcome is the instability of natural compounds when subjected to environmental variations. In this sense, the use of nanotechnological strategies to minimize this degradation process appears as an emerging alternative, given that studies in the literature have already demonstrated the efficiency of nanosystems in protecting biopigments [

15]. Nanotechnology refers to a field of technology responsible for manipulating materials, devices, and systems on a nanometric scale (10

−9 m) [

16]. Currently, in the food industry, nanotechnology has been used in several ways, such as in the nanoencapsulation of functional substances, aiming to improve the nutritional quality of food, as well as in the application of nanoparticles in packaging to increase the shelf life of foods [

17,

18].

In this context, this study innovates by developing an eco-friendly method to extract natural pigments from food residues and produce lipid and polymeric nanosystems to enhance the stability of these compounds. This pioneering approach opens new avenues for the food, pharmaceutical, and cosmetic industries, enabling the development of sustainable products.

2. Materials and Methods

2.1. Materials

In total, eight food residues were chosen as raw materials for the extraction of natural dyes, such as (i) hybrid tetsukabuto pumpkin peels (Cucurbita maxima x Cucurbita moschata); (ii) moranga pumpkin (Cucurbita maxima) peels; (iii) sweet potato peels (Ipomoea potatoes); (iv) beetroot peels (Beta vulgaris L.); (v) carrot peels (Daucus carota subsp. sativus); (vi) chayote shells (Sechium edule Sw); (vii) cabbage stalks (Brassica oleracea L. var. acephala); and (viii) purple cabbage external leaves (Brassica oleracea L. var. capitata f. rubra). These food residues were obtained through a donation made by the SESI industrial kitchen in the Federal District (DF) and/or by the team members of the Laboratory of Nanobiotechnology (LNANO) at Embrapa Genetic Resources and Biotechnology. Sodium hypochlorite (NaClO) (Agistereli Ltda, Itapevi, SP, Brazil) and sodium bicarbonate (NaHCO3) (Kitano, São Bernardo do Campo, SP, Brazil) were purchased at a local supermarket. Ethanol (Itajá, Goianésia, GO, Brazil) and ultrapure water were used to prepare the extraction solutions. Nonionic surfactant Tween 80 (Sigma-Aldrich, St. Louis, MO, USA), soy lecithin (Saint Charbel, Viçosa, MG, Brazil), glacial acetic acid (Merck, Darmstadt, Germany), chitosan from shrimp shells, ≥75% deacetylated (Sigma-Aldrich, St. Louis, MO, USA), and sodium tripolyphosphate (Sigma-Aldrich, St. Louis, MO, USA) were used for the development of nanosystems containing natural pigments.

2.2. Sanitization Process

Firstly, all vegetables were subjected to pre-washing with running water, aiming to eliminate the surface dirt. Then, they went through a sanitization process with 2.5% NaClO, remaining submerged for 15 min. Subsequently, the residues were immersed in a NaHCO3 solution at a concentration of 10 mg/mL for 15 min. Finally, they were rinsed with distilled water for 2 min, dried with a paper towel, and stored at −20 °C in plastic packaging until the extraction assays.

2.3. Extraction of Natural Pigments

2.3.1. Solvent Screening

The extraction of natural pigments was carried out using ultrapure water and ethanol 25% and 96% as solvents. The food residues were individually weighed (0.5 g) and cut into small pieces to increase the contact surface and optimize the extraction process. The pigment extractions were conducted in a 1:10 solids-to-solvent ratio. The samples were sonicated for 30 min at 40 kHz in an ultrasound bath and then magnetic stirred for 30 min. Finally, the food residues were separated from the extraction solvent by centrifugation at 1500× g for 10 min. The supernatants (natural pigments) were collected and stored at 2–8 °C for colorimetric evaluation. From the RGB analyses, the best solvents and food residues were chosen. From there, extractions varying the residue mass concentrations were carried out.

2.3.2. Variation of Residue Mass Concentrations

The extraction of natural pigments was performed in triplicate using five different mass concentrations of food residues (3.3%, 5%, 10%, 20%, and 30%). The extractions were carried out in triplicate, following the same methodology described in

Section 2.3.1. The evaluation of RGB color profiles was carried out the day after the extraction and storage process.

2.4. Colorimetric Characterization

The colorimetric characterization of natural pigments was carried out in triplicate and determined by the RGB color space model. A volume of 200 μL of each pigment was added to a 96-well microplate. The microplate was placed on top of an acrylic box illuminated by a LightPad containing an LED light with a cool white color temperature of 6500 Kelvin (K). The images were acquired with an adapted iPod-based BiO Assay system using the Experimental Assistant app (n3D BioSciences Inc., Houston, TX, USA). The digital images were analyzed through the image processing software ImageJ (version 1.52a), which measured the light intensity in the RGB spectrums.

2.5. Color Profile Statistical Analysis

The mean and standard deviation data of R, G, and B color intensities were subjected to analysis of variance (ANOVA) at a significance level of 5% (p < 0.05) with the Paleontological Statistics software package—PAST (version 2.7c). The results are presented as the arithmetic mean ± standard deviation of the mean.

2.6. Development of Lipid and Polymeric Nanosystems

Using the best solvents and residue concentrations pre-established in previous trials, new extractions were conducted to obtain an adequate volume of natural pigment to produce micelles, liposomes, and polymeric chitosan nanoparticles. The nanostructured natural pigments were stored at 2–8 °C.

2.6.1. Micelles

Micelles were produced from natural pigment obtained from pumpkin peels (Cucurbita maxima). A total volume of 10 mL of pigment was added to 0.15 μL of the surfactant Tween 80. The sample was stirred until complete dissolution. Then, an aliquot was submitted as a rotary evaporator with an immersion bath at 50 °C. After the solvent evaporated, the sample was hydrated with ultrapure water. An empty control, without the presence of natural pigment, was also produced under the same conditions.

2.6.2. Liposomes

Liposomes were produced by the lipid film hydration method from natural pigment obtained from the peels of hybrid pumpkin (Cucurbita maxima x Cucurbita moschata) and red beet (Beta vulgaris L.). A total volume of 4 mL of pigments was added to 0.020 g of soy lecithin. The samples were stirred until complete dissolution. Then, an aliquot was submitted as a rotary evaporator with an immersion bath at 50 °C. After the solvent evaporation, the films were hydrated with ultrapure water. Empty controls, without the presence of natural pigments, were also produced under the same conditions.

2.6.3. Chitosan Polymeric Nanoparticles

Polymeric chitosan nanoparticles were produced from natural pigment obtained from the external leaves of purple cabbage (Brassica oleracea L. var. capitata f. rubra). A total volume of 2 mL of pigments was submitted as a rotary evaporator in 4 cycles (2 cycles of 1 h at 40 °C, followed by 2 cycles of 1 h at 50 °C). After the solvent evaporation, 2.0 mL of water acidified (0.1 mol/L) with glacial acetic acid was added. Subsequently, the solution was added to 0.004 g of medium molecular mass chitosan, remaining under stirring for 1 h. Then, a 1 mg/mL sodium tripolyphosphate solution was dripped gradually into the acidified solution. The formulation remained under constant stirring for 5 min after the end of dripping. Finally, it was subjected to the breaking of its particles using an ultraturrax at 21,500 rpm. An empty control, without the presence of natural pigment, was also produced under the same conditions.

2.7. Characterization of Nanostructured Pigments

The hydrodynamic diameter (HD) and the polydispersity index (PdI) of the nanosystems and their respective empty controls were evaluated using the dynamic light scattering (DLS) technique. The Zeta potential (ZP) was determined from its electrophoretic mobilities. The samples were diluted in a ratio of 1:10 in ultrapure water. The analyses were carried out on ZetaSizer Nano ZS equipment (Malvern Panalytical, Worcestershire, UK) by DLS and ZP. DLS analyses were performed at an angle of 173° using a He-Ne laser (4 mW) at a wavelength of 633 nm. Three measurements were taken of each sample at 25 °C in automatic run mode. The results are presented as the arithmetic mean ± standard deviation of the mean.

2.8. Evaluation of Colorimetric Stability

Colorimetric stability tests were carried out with natural pigments and their nanosystems stored at 2–8 °C protected from light for 26 days. Stability assessment occurred through RGB analysis carried out weekly, in triplicate, according to the methodology described in

Section 2.4. The results are presented as the arithmetic mean ± standard deviation of the mean.

4. Discussion

The food industry commonly uses artificial colorings in its products, seeking to ensure more attractive sensory characteristics. However, the demand for healthier alternatives is growing in the market, and an alternative to meet this demand is the use of natural dyes. The exploitation of food waste as a source of natural dyes opens doors for innovation in the food industry, promoting sustainability and the valorization of resources that would previously be discarded. However, to ensure the viability of using food waste as a source of natural dyes, it is necessary to consider the application of appropriate and eco-friendly extractive methods. In this study, the eco-friendly extraction method of natural pigments using green solvents was explored.

The ultrasonic bath treatment followed by magnetic stirring has proved to be a simple, fast, and efficient green technological method for extracting natural pigments. The ultrasound technique has been widely applied mainly for the extraction of bioactive compounds due to its several advantages, such as its short time of operation, accuracy, and non-destructive method [

24]. Higher extraction rates are commonly obtained using this technology due to the formation of acoustic cavitations in liquid media, thus generating greater penetration of the solvent into the plant matrix and release of intracellular content [

25]. In the study conducted by Sharma and Bhat [

26], ultrasound-assisted and microwave-assisted extractions were performed to obtain carotenoids. These extraction methods were compared with the conventional extraction method, and ultrasound-assisted extraction proved to be a more efficient technique due to its higher yields. The combination of the ultrasound technique with other extraction methods has recently become a focus in studies aimed at obtaining natural dyes due to the higher yields achieved [

27].

The color variations observed during the extraction of natural pigments can be explained by the chemical structure of the potential classes of pigments extracted: (i) anthocyanins, present in the external leaves of purple cabbage and sweet potato peels; (ii) betalains, present in beetroot peels; (iii) carotenoids, present in pumpkin and carrot peels; and (iv) chlorophylls, present in cabbage stalks, chayote peels, and tetsukabuto hybrid pumpkin. The polarity of these natural compounds and the interactions between these pigments with carbohydrates, proteins, and other components in foods can influence the extraction process [

28]. In addition, variations in the concentration of secondary metabolites affect the pigment hues. The content of secondary metabolites produced by a plant depends on several factors, such as temperature, humidity, light, altitude, macro- and micronutrients present in the soil, atmospheric composition, seasonality, plant genome, and mechanical stimuli, among others [

29]. A promising alternative to avoid this variability in the color profile is the use of screening tests and phytochemical analyses to identify the chemical constituents’ values of interest. Furthermore, dilution and/or concentration processes can be adopted to achieve greater similarity in color between natural pigments.

Regarding the use of green solvents for the extraction of natural dyes, ethanol has proved to be an effective solvent, as it is possible to obtain attractive natural colorants from different food residues. In this way, it is possible to replace organic solvents with green alternatives to obtain dyes from natural sources, as can also be seen in the study by Li et al. (2013) [

14].

The selection of the nanocarrier system for encapsulation was guided by the physicochemical properties of each dye. For instance, dyes extracted from moranga pumpkin peels are lipophilic and are thus frequently incorporated into micelles due to their affinity for hydrophobic environments. This affinity stems from the molecular structure of these compounds, which typically possess long non-polar hydrocarbon chains.

Micelles are aggregates of surfactant molecules that possess hydrophilic and hydrophobic moieties. The hydrophobic portions of the surfactant molecules cluster together at the core of the micelle, forming a hydrophobic environment [

30]. The micelles produced in this study exhibit structures with different dimensions compared to those reported in the literature. This variation is influenced by some factors, including the chemical structure and concentration of the surfactant; the presence of counterion; and temperature variations during micelle formation [

30].

The dye extracted from the external leaves of purple cabbage exhibits greater stability in an acidic environment. Therefore, chitosan polymeric nanoparticles emerge as a promising alternative to ensure this stability since chitosan, a natural biopolymer, is easily solubilized at acidic pH [

31]. Among the methods for developing chitosan nanoparticles, ionic gelation stands out. This technique relies on the electrostatic interaction between the positively charged amino groups of chitosan and the negatively charged groups of a polyanionic substance, such as sodium tripolyphosphate (TPP), under acidic pH [

31]. These nanoparticles can encapsulate and protect the dyes, reducing their degradation and increasing their resistance to photodegradation and other adverse conditions.

Dyes extracted from beetroot peels and tetsukabuto hybrid pumpkin peels are highly hydrophilic; therefore, a strategy for improving the stability of these compounds is their incorporation into liposomes. Liposomes are small, spherical vesicular structures formed by one or more phospholipid bilayers [

32]. These nanosystems are composed of a non-polar tail consisting of fatty acid chains (hydrophobic region) and a polar head (hydrophilic region) formed by a phosphate group and a base (choline, glycerol, etc.). In the presence of water, these structures align, originating one or more concentric lipid bilayers, which are separated by an aqueous compartment [

33]. Due to these characteristics, liposomes carry hydrophilic or lipophilic compounds.

Among the three nanotechnological strategies explored to enhance the stability of natural pigments, all nanosystems exhibited promising results. Compared to their unencapsulated counterparts, the pigments incorporated into these nanosystems displayed less color variation, indicating successful protection, particularly for pumpkin-derived pigments. The observed color changes in the LPCB and NPQPFR nanosystems can potentially be attributed to their high water content. Since these pigments are susceptible to nucleophilic attack by water molecules, the presence of water within the nanosystems could lead to alterations in color intensity [

34]. Therefore, the application of water removal strategies, such as freeze-drying and spray-drying, could be valuable tools to further improve colorimetric stability [

35].

5. Conclusions

Food residues (e.g., peels, stalks, and leaves) are promising sources to obtain natural pigments with varied color profiles. The extraction method is a simple and economical technique, proving to be a technological process with potential application on an industrial scale for obtaining natural pigments from different sources. In addition, the hydroethanolic extraction was very effective when performed with an ultrasound bath followed by magnetic stirring. This green solvent is an alternative to the use of organic solvents since there is a minimization of the negative impacts on both the environment and human health.

It is worth highlighting that studies of physicochemical characteristics and toxicity tests need to be explored to evaluate whether these natural colorants could be implemented in the food industrial sector at the stages of development, processing, and storage of foods, as well as in other industrial sectors, such as textiles, cosmetics, and inks, among others.

Furthermore, liposomes, micelles, and chitosan nanoparticles offer a compelling solution to overcome the challenge of rapid degradation observed with natural pigments during storage. Liposomes, formed by phospholipid bilayers, can encapsulate pigments, enhancing their stability and controlled release. Micelles also provide another encapsulation strategy, improving the water solubility and bioavailability of natural dyes. In addition, chitosan nanoparticles offer an attractive option to encapsulate stable dyes in an acidic environment. Their cationic nature allows for electrostatic interactions with the often negatively charged pigments, promoting efficient encapsulation and improved stability.

This research opens avenues for the further optimization of natural pigment extraction techniques, paving the way to explore new sources of natural dyes and aiming to meet the current market demand for more sustainable products.