The Effect of High-Pressure Processing of Caprine Milk on the Production and Properties of Yoghurt

Abstract

:1. Introduction

2. Materials and Methods

2.1. Milk Preparation and Yoghurt Production

2.2. Chemical Composition

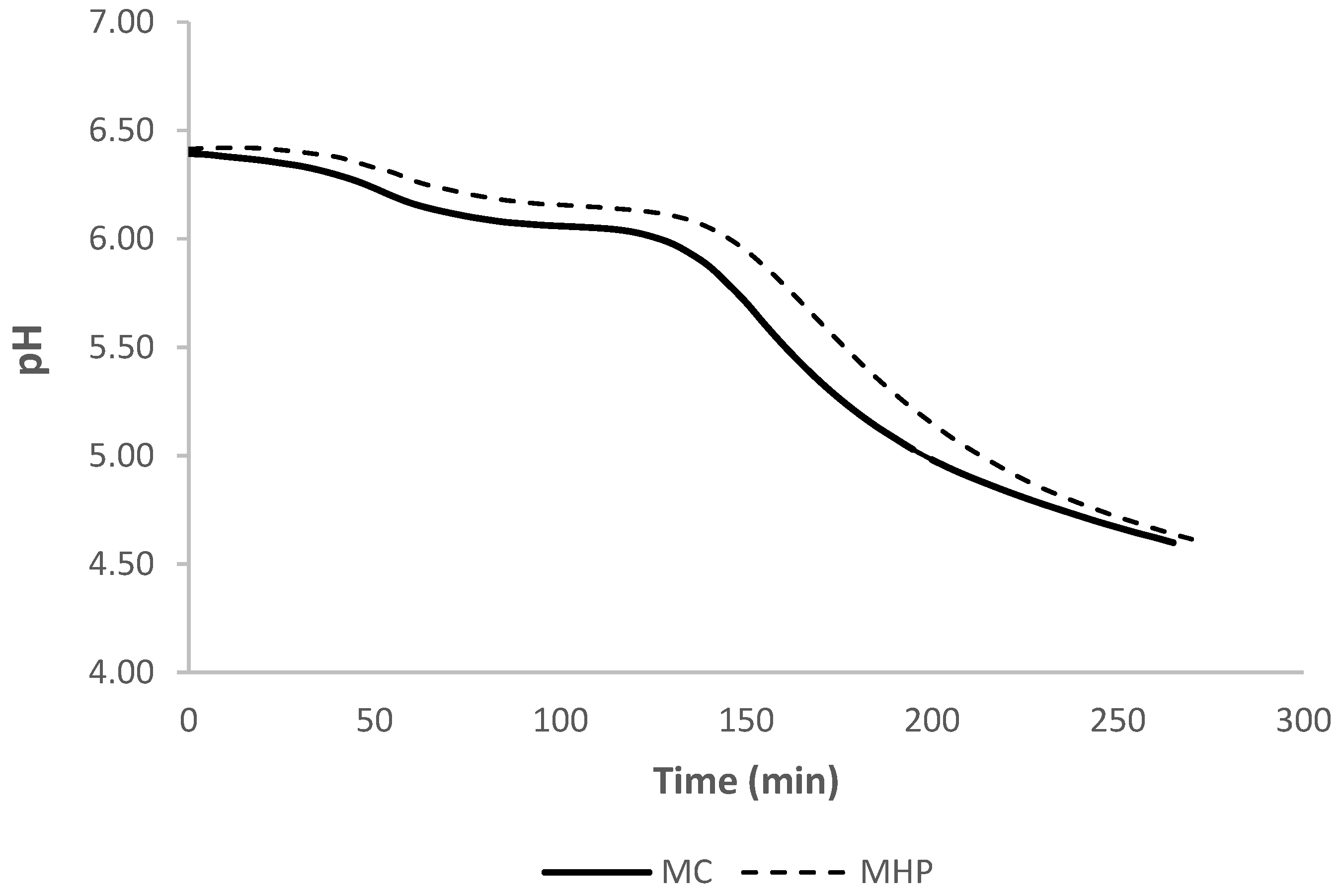

2.3. Kinetics of Milk Acidification

2.4. pH

2.5. Microbiological Analysis

2.6. Color Analysis

2.7. Analysis of Rheological Properties

Area of the Hysteresis Loop

- —area of the hysteresis loop calculated from the power model (Pa/s);

- —consistency index (Pa sn) from the Ostwald–de Waele model for an ascending shear rate sweep;

- flow index (-) from the Ostwald–de Waele model for an ascending shear rate sweep;

- consistency index (Pa sn) from the Ostwald-de Waele model for a descending shear rate sweep;

- flow index (-) from the Ostwald–de Waele model for a descending shear rate sweep;

- —shear rate (1/s).

2.8. Determination of WHC

2.9. Texture Analysis

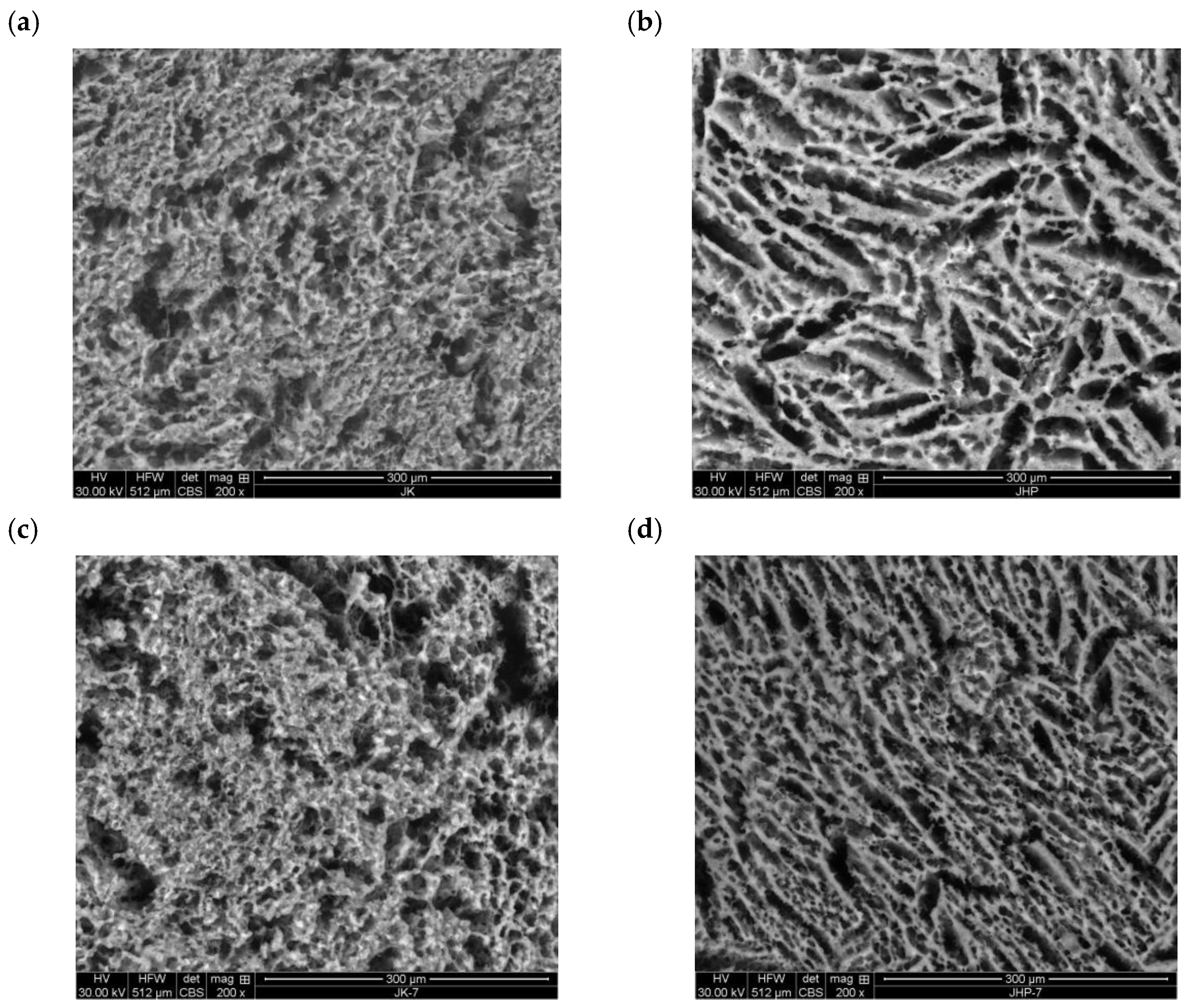

2.10. Scanning Electron Microscopy

2.11. Sensory Analysis

2.12. Statistical Analysis

3. Results and Discussion

3.1. Milk Characteristics and Acidification Profile

3.2. pH and Microbial Counts

3.3. Color

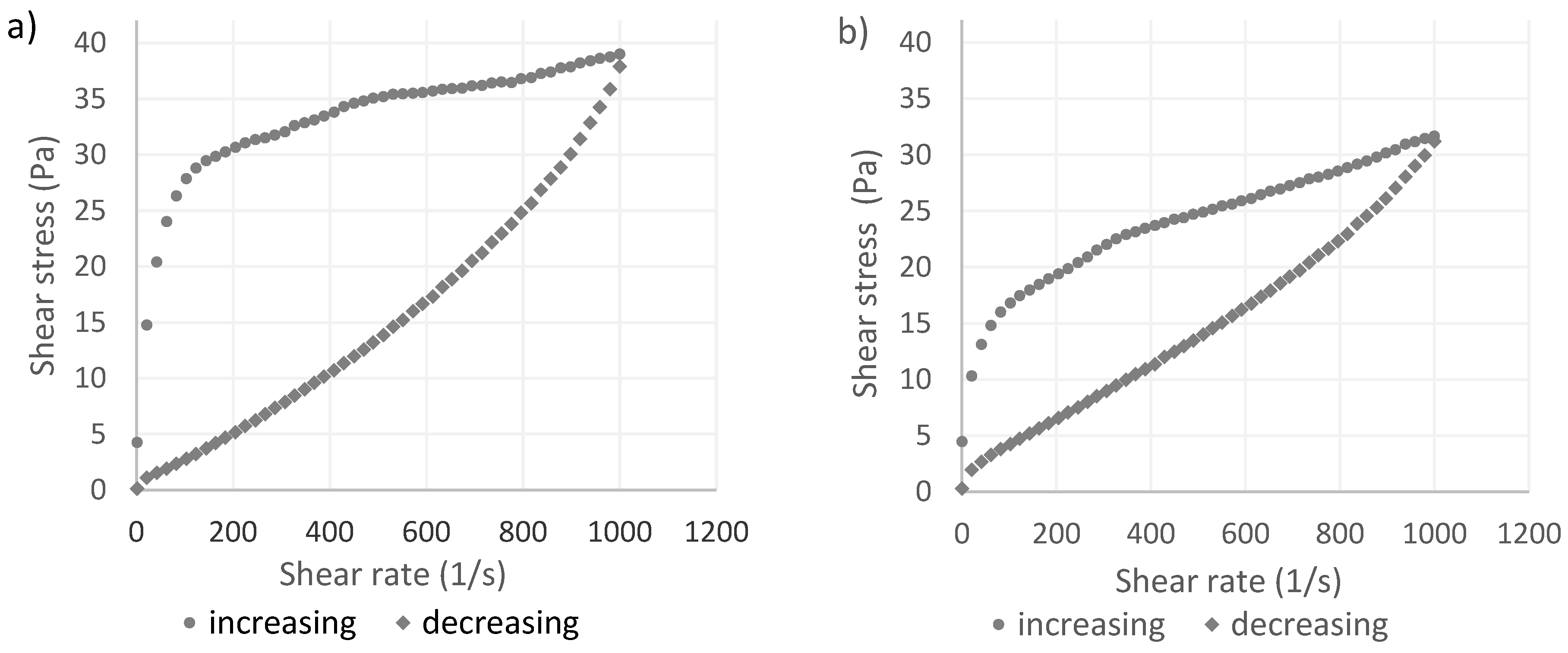

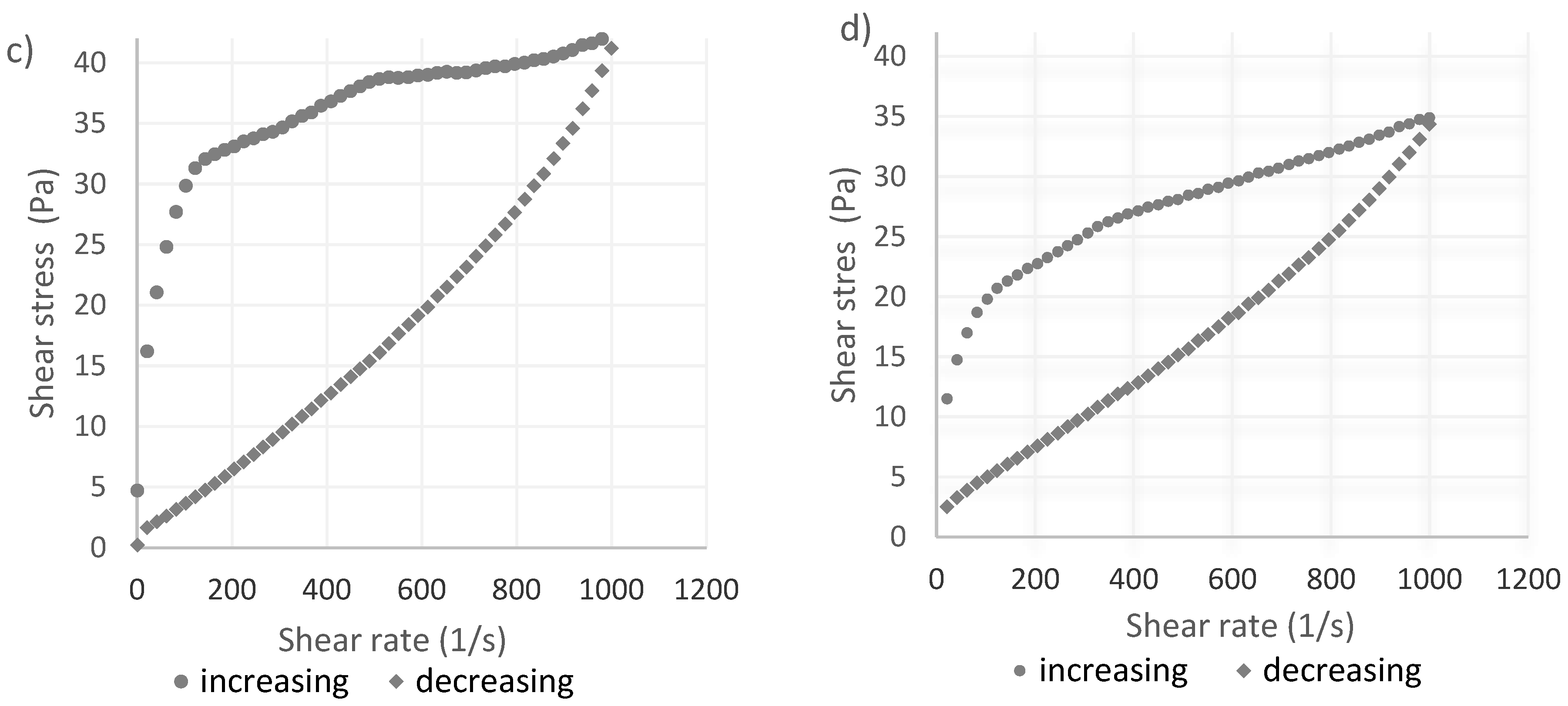

3.4. Rheological Properties

3.5. Textural Properties

3.6. Microstructure

3.7. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- FAO. FAOSTAT. Crops and Livestock Products. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 28 March 2024).

- Pulina, G.; Milán, M.J.; Lavín, M.P.; Theodoridis, A.; Morin, E.; Capote, J.; Thomas, D.L.; Francesconi, A.H.D.; Caja, G. Invited Review: Current Production Trends, Farm Structures, and Economics of the Dairy Sheep and Goat Sectors. J. Dairy Sci. 2018, 101, 6715–6729. [Google Scholar] [CrossRef] [PubMed]

- Joon, R.; Mishra, S.K.; Brar, G.S.; Singh, P.K.; Panwar, H. Instrumental Texture and Syneresis Analysis of Yoghurt Prepared from Goat and Cow Milk. Pharma Innov. J. 2017, 6, 971–974. Available online: https://www.thepharmajournal.com/archives/2017/vol6issue7/PartG/6-7-73-280.pdf (accessed on 28 March 2024).

- Park, Y.W.; Jeanjulien, C.; Siddique, A. Factors Affecting Sensory Quality of Goat Milk Cheeses: A Review. J. Adv. Dairy Res. 2017, 5, 185. [Google Scholar] [CrossRef]

- De Santis, D.; Giacinti, G.; Chemello, G.; Frangipane, M.T. Improvement of the Sensory Characteristics of Goat Milk Yogurt. J. Food Sci. 2019, 84, 2289–2296. [Google Scholar] [CrossRef] [PubMed]

- Naagar, S.; Kanawjia, S.K. Recent Advancements in the Functionality of the Components from Goat Milk and its Products. Indian J. Dairy Sci. 2019, 72, 453–461. [Google Scholar] [CrossRef]

- Razali, M.F.; Narayanan, S.; Hazmi, N.A.M.; Shah, N.N.A.K.; Kamal, S.M.M.; Fauzi, N.A.M.; Sulaiman, A. Minimal Processing for Goat Milk Preservation: Effect of High-Pressure Processing on its Quality. J. Food Process. Preserv. 2021, 45, e15590. [Google Scholar] [CrossRef]

- Paszczyk, B.; Czarnowska-Kujawska, M.; Klepacka, J.; Tońska, E. Health-Promoting Ingredients in Goat’s Milk and Fermented Goat’s Milk Drinks. Animals 2023, 13, 907. [Google Scholar] [CrossRef] [PubMed]

- Pal, M.; Dudhrejiya, T.P.; Pinto, S. Goat Milk Products and their Significance. Beverage Food World 2017, 44, 21–25. Available online: https://www.researchgate.net/profile/Mahendra-Pal-9/publication/318598392_Goat_Milk_Products_and_their_significance/links/5972366ba6fdcc83488162f0/Goat-Milk-Products-and-their-significance.pdf (accessed on 28 March 2024).

- Moatsou, G.; Park, Y.W. Goat Milk Products: Types of Products, Manufacturing Technology, Chemical Composition, and Marketing. In Handbook of Milk of Non-Bovine Mammals, 2nd ed.; Park, Y.W., Haenlein, G.F.W., Wendorff, W.L., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2017; pp. 84–150. [Google Scholar]

- Costa, M.P.; Rosario, A.I.L.S.; Silva, V.L.M.; Vieira, C.P.; Conte-Junior, C.A. Rheological, Physical and Sensory Evaluation of Low-Fat Cupuassu Goat Milk Yogurts Supplemented with Fat Replacer. Food Sci. Anim. Resour. 2022, 42, 210–224. [Google Scholar] [CrossRef]

- Delgado, K.; Vieira, C.; Dammak, I.; Frasão, B.; Brígida, A.; Costa, M.; Conte-Junior, C. Different Ultrasound Exposure Times Influence the Physicochemical and Microbial Quality Properties in Probiotic Goat Milk Yogurt. Molecules 2020, 25, 4638. [Google Scholar] [CrossRef]

- Huang, Z.; Huang, L.; Xing, G.; Xu, X.; Tu, C.; Dong, M. Effect of Co-Fermentation with Lactic Acid Bacteria and K. marxianus on Physicochemical and Sensory Properties of Goat Milk. Foods 2020, 9, 299. [Google Scholar] [CrossRef]

- Costa, M.P.; Frasao, B.S.; Silva, A.C.O.; Freitas, M.Q.; Franco, R.M.; Conte-Junior, C.A. Cupuassu (Theobroma grandiflorum) Pulp, Probiotic, and Prebiotic: Influence on Color, Apparent Viscosity, and Texture of Goat Milk Yogurts. J. Dairy Sci. 2015, 98, 5995–6003. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Zhang, R.; Zhang, F.; Wang, B.; Liu, Y. Storage Stability of Texture, Organoleptic, and Biological Properties of Goat Milk Yogurt Fermented with Probiotic Bacteria. Front. Nutr. 2023, 9, 1093654. [Google Scholar] [CrossRef] [PubMed]

- Jia, R.; Chen, H.; Chen, H.; Ding, W. Effects of Fermentation with Lactobacillus rhamnosus GG on Product Quality and Fatty Acids of Goat Milk Yogurt. J. Dairy Sci. 2016, 99, 221–227. [Google Scholar] [CrossRef] [PubMed]

- de Morais, J.L.; Garcia, E.F.; Viera, V.B.; Silva Pontes, E.D.; de Araújo, M.G.G.; de Figueirêdo, R.M.F.; Dos Santos Moreira, I.; do Egito, A.S.; Dos Santos, K.M.O.; Barbosa Soares, J.K.; et al. Autochthonous Adjunct Culture of Limosilactobacillus mucosae CNPC007 Improved the Techno-Functional, Physicochemical, and Sensory Properties of Goat Milk Greek-Style Yogurt. J. Dairy Sci. 2022, 105, 1889–1899. [Google Scholar] [CrossRef]

- da Silva Dantas, D.L.; Viera, V.B.; Barbosa Soares, J.K.; Dos Santos, K.M.O.; do Egito, A.S.; de Figueirêdo, R.M.F.; Dos Santos Lima, M.; Farias Machado, N.A.; de Souza, M.F.V.; da Conceiçao, M.L.; et al. Pilosocereus gounellei (Xique-Xique) Flour: Improving the Nutritional, Bioactive, and Technological Properties of Probiotic Goat-Milk Yogurt. LWT—Food Sci. Technol. 2022, 158, 113165. [Google Scholar] [CrossRef]

- Costa, M.P.; Monteiro, M.L.G.; Frasao, B.S.; Silva, V.L.M.; Rodrigues, B.L.; Chiappini, C.C.J.; Conte-Junior, C.A. Consumer Perception, Health Information, and Instrumental Parameters of Cupuassu (Theobroma grandiflorum) Goat Milk Yogurts. J. Dairy Sci. 2017, 100, 157–168. [Google Scholar] [CrossRef]

- Miocinovic, J.; Miloradovic, Z.; Josipovic, M.; Nedeljkovic, A.; Radovanovic, M.; Pudja, P. Rheological and Textural Properties of Goat and Cow Milk Set Type Yoghurts. Int. Dairy J. 2016, 58, 43–45. [Google Scholar] [CrossRef]

- Park, Y.W.; Oglesby, J.; Hayek, S.A.; Aljaloud, S.O.; Gyawali, R.; Ibrahim, S.A. Impact of Different Gums on Textural and Microbial Properties of Goat Milk Yogurts during Refrigerated Storage. Foods 2019, 8, 169. [Google Scholar] [CrossRef]

- Zhao, X.; Cheng, M.; Wang, C.; Jiang, H.; Zhang, X. Effects of Dairy Bioactive Peptides and Lotus Seeds/Lily Bulb Powder on Flavor and Quality Characteristics of Goat Milk Yogurt. Food Biosci. 2022, 47, 101510. [Google Scholar] [CrossRef]

- Ragab, E.S.; Yacoub, S.S.; Nassar, K.S.; Zhang, S.; Lv, J. Textural and Microstructural Properties of Set Yoghurt Produced from Goat Milk Treated by Homogenization and Thermosonication. Alex. Sci. Exch. J. 2021, 42, 985–995. [Google Scholar] [CrossRef]

- Ragab, E.S.; Zhang, S.; Korma, S.A.; Buniowska-Olejnik, M.; Nasser, S.A.A.; Esatbeyoglu, T.; Lv, J.; Nassar, K.S. Physicochemical and Rheological Properties of Stirred Yoghurt during Storage Induced from High-Intensity Thermosonicated Goat and Cow Milk. Fermentation 2023, 9, 42. [Google Scholar] [CrossRef]

- Ma, J.; Wang, Q.; Dou, N.; Li, Y.; Ma, Y.; Liu, Y.; Wu, M.; Wei, X.; Miao, Y.; Chen, L.; et al. Evaporative Concentration and High-Pressure Homogenization for Improving the Quality Attributes and Functionality of Goat Milk Yogurt. LWT—Food Sci. Technol. 2023, 184, 115016. [Google Scholar] [CrossRef]

- Needs, E.C.; Stenning, R.A.; Gill, A.L.; Ferragut, V.; Rich, G.T. High-Pressure Treatment of Milk: Effects on Casein Micelle Structure and on Enzymic Coagulation. J. Dairy Res. 2000, 67, 31–42. [Google Scholar] [CrossRef] [PubMed]

- Huppertz, T.; Fox, P.F.; de Kruif, K.G.; Kelly, A.L. High Pressure-Induced Changes in Bovine Milk Proteins: A Review. Biochim. Biophys. Acta 2006, 1764, 593–598. [Google Scholar] [CrossRef]

- Considine, T.; Patel, H.A.; Anema, S.G.; Singh, H.; Creamer, L.K. Interactions of Milk Proteins during Heat and High Hydrostatic Pressure Treatments—A Review. Innov. Food Sci. Emerg. Technol. 2007, 8, 1–23. [Google Scholar] [CrossRef]

- Kiełczewska, K.; Jankowska, A.; Dąbrowska, A.; Wachowska, M.; Ziajka, J. The Effect of High Pressure Treatment on the Dispersion of Fat Globules and the Fatty Acid Profile of Caprine Milk. Int. Dairy J. 2020, 102, 104607. [Google Scholar] [CrossRef]

- Kiełczewska, K.; Dąbrowska, A.; Jankowska, A.; Wachowska, M.; Kowalik, J. The Effect of High-Pressure Treatment and Skimming on Caprine Milk Proteins. Appl. Sci. 2021, 11, 5982. [Google Scholar] [CrossRef]

- ISO 7889 IDF 117; Yoghurt-Enumeration of Characteristic Microorganisms-Colony-Count Technique at 37 °C, 1st ed. International Organization for Standardization: Geneva, Switzerland, 2003.

- Bierzuńska, P.; Cais-Sokolińska, D.; Yiğit, A. Storage Stability of Texture and Sensory Properties of Yogurt with the Addition of Polymerized Whey Proteins. Foods 2019, 8, 548. [Google Scholar] [CrossRef]

- EN ISO 13299:2016-05E; Sensory analysis—Methodology—General Guidance for Establishing a Sensory Profile. International Standardization Organization: Geneva, Switzerland, 2016.

- EN ISO 8586:2014–03; Sensory Analysis. General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Expert Sensory Assessors. International Standardization Organization: Geneva, Switzerland, 2014.

- Huppertz, T.; Kelly, A.L.; Fox, P.F. Effects of High Pressure on Constituents and Properties of Milk. Int. Dairy J. 2002, 12, 561–572. [Google Scholar] [CrossRef]

- Chr. Hansen. YC-X16. Product Information; Version: 5 PI EU EN 11-11-2019; Chr. Hansen: Hørsholm, Denmark, 2019. [Google Scholar]

- Park, Y.W. Comparison of Buffering Components in Goat and Cow Milk. Small Rumin. Res. 1992, 8, 75–81. [Google Scholar] [CrossRef]

- Mituniewicz-Małek, A.; Ziarno, M.; Dmytrów, I.; Tuma, P.; Witczak, A.; Vovk, S. Properties of Drinking Yogurt obtained from Cow’s and Goat’s Organic Milk Fermented by Traditional Yogurt Cultures. Infrastruct. Ecol. Rural. Areas 2017, 14, 1755–1771. [Google Scholar] [CrossRef]

- Tamime, A.Y.; Robinson, R.K. Yoghurt—Science and Technology, 3rd ed.; Woodhead Publishing Limited: Abington, UK, 2007; pp. 450–480. Available online: https://www.sciencedirect.com/book/9781845692131/tamime-and-robinsons-yoghurt (accessed on 28 March 2024).

- Chr. Hansen. YoFlex® Product Range. Version 3. 2021. Available online: https://laboratoriolacteogallego.com/wp-content/uploads/2021/09/YoFlex_brochure_v3_WEB_EN.pdf (accessed on 28 March 2024).

- Deshwal, K.G.; Tiwari, S.; Kumar, A.; Raman, R.K.; Kadyan, S. Review on Factors Affecting and Control of Post-Acidification in Yoghurt and Related Products. Trends Food Sci. Technol. 2021, 109, 499–512. [Google Scholar] [CrossRef]

- Bylund, G. Dairy Processing Handbook; Tetra Pak Processing Systems AB: Lund, Sweden, 2015. [Google Scholar]

- Lanciotti, R.; Vannini, L.; Pittia, P.; Guerzoni, M.E. Suitability of High-Dynamic-Pressure-Treated Milk for the Production of Yoghurt. Food Microbiol. 2004, 21, 753–760. [Google Scholar] [CrossRef]

- WHO/FAO. Codex Standard for fermented milks (Codex Stan 243-2003). In Codex Alimentarius. Milk and Milk Products, 2nd ed.; Food and Agriculture Organization of the United Nations; World Health Organization: Rome, Italy, 2011; pp. 6–16. [Google Scholar]

- Gervilla, R.; Ferragut, V.; Guamis, B. High Hydrostatic Pressure Effects on Colour and Milk-Fat Globule of Ewe’s Milk. J. Food Sci. 2001, 66, 880–885. [Google Scholar] [CrossRef]

- Stratakos, A.C.; Inguglia, E.S.; Linton, M.; Tollerton, J.; Murphy, L.; Corcionivoschi, N.; Koidis, A.; Tiwari, B.K. Effect of High Pressure Processing on the Safety, Shelf Life and Quality of Raw Milk. Innov. Food Sci. Emer. Technol. 2019, 52, 325–333. [Google Scholar] [CrossRef]

- Knudsen, J.C.; Skibsted, L.H. High Pressure Effects on the Structure of Casein Micelles in Milk as Studied by Cryo-Transmission Electron Microscopy. Food Chem. 2010, 119, 202–208. [Google Scholar] [CrossRef]

- Walker, M.K.; Farkas, D.F.; Loveridge, V.; Meunier-Goddik, L. Fruit Yogurt Processed with High Pressure. Int. J. Food Sci. Tech. 2006, 41, 464–467. [Google Scholar] [CrossRef]

- Kalicka, D.; Znamirowska, A.; Buniowska, M.; Esteve Más, M.J.; Canoves, A.F. Effect of Stevia Addition on Selected Properties of Yoghurt during Refrigerated Storage. Pol. J. Nat. Sci. 2017, 32, 323–334. Available online: http://www.uwm.edu.pl/polish-journal/sites/default/files/issues/articles/kalicka_et_al._2017.pdf (accessed on 28 March 2024).

- Costa, R.G.; Beltrão Filho, E.M.; de Sousa, S.; Beltrão da Cruz, G.R.; do Egypto Queiroga, R.C.R.; da Cruz, E.N. Physicochemical and Sensory Characteristics of Yoghurts Made from Goat and Cow milk. Anim. Sci. J. 2016, 87, 703–709. [Google Scholar] [CrossRef] [PubMed]

- Harte, F.; Amonte, M.; Luedecke, L.; Swanson, B.G.; Barbosa-Cánovas, G.V. Yield Stress and Microstructure of Set Yogurt Made from High Hydrostatic Pressure-Treated Full Fat Milk. J. Food Sci. 2002, 67, 2245–2250. [Google Scholar] [CrossRef]

- Sert, D.; Mercan, E.; Tanrıkulu, M. Impact of High-Pressure Homogenisation of Milk on Physicochemical, Microbiological, and Textural Characteristics of Sheep Milk Yoghurt. Int. Dairy J. 2023, 144, 105704. [Google Scholar] [CrossRef]

- Serra, M.; Trujillo, A.J.; Quevedo, J.M.; Guamis, B.; Ferragut, V. Acid Coagulation Properties and Suitability for Yogurt Production of Cows’ Milk Treated by High-Pressure Homogenisation. Int. Dairy J. 2007, 17, 782–790. [Google Scholar] [CrossRef]

- Domagała, J. Instrumental Texture, Syneresis and Microstructure of Yoghurts Prepared from Goat, Cow and Sheep Milk. Int. J. Food Prop. 2009, 12, 605–615. [Google Scholar] [CrossRef]

- Gursel, A.; Gursoy, A.; Anli, E.A.K.; Budak, S.O.; Aydemir, S.; Durlu-Ozkaya, F. Role of Milk Protein-Based Products in Some Quality Attributes of Goat Milk Yogurt. J. Dairy Sci. 2016, 99, 2694–2703. [Google Scholar] [CrossRef] [PubMed]

- Stelios, K.; Emmanuel, A. Characteristics of Set Type Yoghurt Made from Caprine or Ovine Milk and Mixtures of the Two. Int. J. Food Sci. Tech. 2004, 39, 319–324. [Google Scholar] [CrossRef]

- Vargas, M.; Cháfer, M.; Albors, A.; Chiralt, A.; González-Martínez, C. Physicochemical and Sensory Characteristics of Yoghurt Produced from Mixtures of Cows’ and Goats’ Milk. Int. Dairy J. 2008, 18, 1146–1152. [Google Scholar] [CrossRef]

- Nguyen, H.T.H.; Afsar, S.; Day, L. Differences in the Microstructure and Rheological Properties of Low-Fat Yoghurts from Goat, Sheep and Cow Milk. Food Res. Int. 2018, 108, 423–429. [Google Scholar] [CrossRef]

- Tsevdou, M.; Theodorou, G.; Pantelaiou, S.; Chatzigeorgiou, A.; Politis, I.; Taoukis, P. Impact of Type and Enzymatic/High Pressure Treatment of Milk on the Quality and Bio-Functional Profile of Yoghurt. Foods 2020, 9, 49. [Google Scholar] [CrossRef]

- Al-Bedrani, D.I.J.; ALKaisy, Q.H.; Rahi, A.K.; Saadi, A.M. Evaluation of Milk Source on Physicochemical, Texture, Rheological and Sensory Properties of Yogurts. J. Appl. Nat. Sci. 2023, 15, 128–136. [Google Scholar] [CrossRef]

- Cruz, A.G.; Faria, J.A.F.; Saad, S.M.I.; Bolini, H.M.A.; Sant′Ana, A.S.; Cristianini, M. High Pressure Processing and Pulsed Electric Fields: Potential use in Probiotic Dairy Foods Processing. Trends Food Sci. Technol. 2010, 21, 483–493. [Google Scholar] [CrossRef]

| Parameter | Milk | |

|---|---|---|

| MC | MHP | |

| Total solids (%) | 15.10 ± 0.01 | 15.09 ± 0.00 |

| Fat (%) | 4.71 ± 0.01 | 4.69 ± 0.00 |

| Lactose (%) | 5.71 ± 0.01 | 5.73 ± 0.00 |

| Total protein (%) | 4.01 ± 0.01 | 4.03 ± 0.00 |

| Casein (%) | 3.88 ± 0.04 | 3.94 ± 0.00 |

| pH | 6.52 ± 0.03 | 6.56 ± 0.02 |

| Parameter | Yoghurt | |||

|---|---|---|---|---|

| YC | YHP | YC1 | YHP1 | |

| pH | 4.55 a ± 0.02 | 4.53 a ± 0.01 | 4.39 b ± 0.04 | 4.44 b ± 0.02 |

| Lactobacillus delbruecki ssp. bulgaricus (log cfu/mL) | 7.43 a ± 0.23 | 7.36 a ± 0.13 | 7.66 a ± 0.07 | 7.59 a ± 0.23 |

| Streptococcus thermophilus (log cfu/mL) | 7.73 a ± 0.14 | 8.13 b ± 0.10 | 8.08 b ± 0.18 | 8.27 b ± 0.11 |

| Color Parameter | Milk | Yoghurt | ||||

|---|---|---|---|---|---|---|

| MC | MHP | YC | YHP | YC1 | YHP1 | |

| L* | 84.88 b ± 0.01 | 83.64 a ± 0.21 | 86.27 ± 0.37 | 86.27 ± 0.38 | 86.15 ± 0.33 | 86.27 ± 0.40 |

| a* | −2.97 b ± 0.08 | −3.21 a ± 0.08 | −2.79 ± 0.01 | −2.81± 0.02 | −2.80 ± 0.08 | −2.81 ± 0.02 |

| b* | 4.93 a ± 0.13 | 5.14 b ± 0.01 | 5.67 ± 0.08 | 5.58 ± 0.04 | 5.78 ± 0.07 | 5.78 ± 0.02 |

| C* | 5.75 a ± 0.07 | 6.06 b ± 0.05 | 6.32 ± 0.07 | 6.32 ± 0.04 | 6.42 ± 0.10 | 6.42 ± 0.01 |

| WI | 6.94 a ± 0.06 | 7.29 b ± 0.06 | 7.32 ± 0.09 | 7.26 ± 0.01 | 7.42 ± 0.10 | 7.42 ± 0.02 |

| Rheological Properties | Yoghurt | ||||

|---|---|---|---|---|---|

| YC | YHP | YC1 | YHP1 | ||

| Ascending shear rate sweeps | Consistency index K (Pa sn) | 4.53 | 5.69 | 6.78 | 7.29 |

| Flow index n (-) | 0.27 | 0.25 | 0.26 | 0.27 | |

| Coefficient of determination R2 (-) | 0.99 | 0.99 | 0.99 | 0.99 | |

| Descending shear rate sweeps | Consistency index K (Pa sn) | 0.06 | 0.12 | 0.18 | 0.17 |

| Flow index n (-) | 0.81 | 0.80 | 0.71 | 0.74 | |

| Coefficient of determination R2 (-) | 0.99 | 0.99 | 0.99 | 0.99 | |

| Area of the hysteresis loop | ∆P (Pa/s) | 14,104.28 | 11,393.72 | 18,218.56 | 20,841.57 |

| Textural Properties | Yoghurt | |||

|---|---|---|---|---|

| YC | YHP | YC1 | YHP1 | |

| WHC (%) | 30.83 a ± 0.89 | 32.51 b ± 1.64 | 34.74 c ± 0.09 | 36.37 d ± 0.26 |

| Firmness (N) | 0.74 a ± 0.12 | 0.97 b ± 0.13 | 0.73 a ± 0.04 | 1.04 b ± 0.11 |

| Consistency (N s) | 18.53 a ± 1.83 | 24.94 b ± 2.74 | 17.54 a ± 0.23 | 26.86 b ± 2.04 |

| Cohesiveness (N) | −0.82 a ± 0.22 | −1.13 b ± 0.04 | −0.62 a ± 0.07 | −0.83 a ± 0.14 |

| Sensory Attributes | Yoghurt | p-Value | |||

|---|---|---|---|---|---|

| YC | YHP | YC1 | YHP1 | ||

| Appearance | |||||

| Color uniformity | 6.6 | 6.5 | 6.6 | 6.8 | >0.05 |

| Creamy color | 5.3 | 5.0 | 5.4 | 5.8 | >0.05 |

| Whey syneresis | 1.3 | 1.1 | 1.5 | 1.5 | >0.05 |

| Aroma | |||||

| Yoghurt-like | 5.0 b | 4.3 a | 5.5 b | 5.5 b | 0.025 |

| Sour | 2.8 a | 2.5 a | 3.3 b | 3.5 b | 0.048 |

| Goaty | 2.0 | 1.9 | 2.5 | 1.9 | >0.05 |

| Atypical | 1.0 | 1.0 | 1.0 | 1.0 | >0.05 |

| Consistency | |||||

| Uniform | 7.0 | 7.0 | 6.8 | 6.6 | >0.05 |

| Thick | 2.8 | 3.4 | 3.1 | 3.6 | >0.05 |

| Ropy | 3.9 d | 3.5 c | 2.6 b | 1.5 a | 0.000 |

| Gelatinous | 4.0 a | 5.6 b | 4.6 a | 5.8 b | 0.009 |

| Smooth mouthfeel | 6.9 | 6.9 | 6.9 | 6.8 | >0.05 |

| Taste | |||||

| Yoghurt-like | 4.6 a | 5.0 a | 5.3 ab | 5.6 b | 0.035 |

| Sour | 4.1 | 4.0 | 4.8 | 4.1 | >0.05 |

| Bitter | 1.0 | 1.0 | 1.0 | 1.0 | >0.05 |

| Sweet | 2.9 | 2.9 | 2.5 | 2.6 | >0.05 |

| Salty | 1.0 | 1.0 | 1.0 | 1.0 | >0.05 |

| Goaty | 3.1 | 3.1 | 3.5 | 3.0 | >0.05 |

| Foreign | 1.0 | 1.0 | 1.0 | 1.0 | >0.05 |

| Overall Acceptability | 5.1 ab | 5.6 b | 4.5 a | 5.8 b | 0.045 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jankowska, A.; Kiełczewska, K.; Wachowska, M.; Dąbrowska, A.; Siemianowski, K.; Haponiuk, E.; Stasiewicz, K. The Effect of High-Pressure Processing of Caprine Milk on the Production and Properties of Yoghurt. Foods 2024, 13, 1327. https://doi.org/10.3390/foods13091327

Jankowska A, Kiełczewska K, Wachowska M, Dąbrowska A, Siemianowski K, Haponiuk E, Stasiewicz K. The Effect of High-Pressure Processing of Caprine Milk on the Production and Properties of Yoghurt. Foods. 2024; 13(9):1327. https://doi.org/10.3390/foods13091327

Chicago/Turabian StyleJankowska, Agnieszka, Katarzyna Kiełczewska, Maria Wachowska, Aneta Dąbrowska, Krzysztof Siemianowski, Elżbieta Haponiuk, and Katarzyna Stasiewicz. 2024. "The Effect of High-Pressure Processing of Caprine Milk on the Production and Properties of Yoghurt" Foods 13, no. 9: 1327. https://doi.org/10.3390/foods13091327

APA StyleJankowska, A., Kiełczewska, K., Wachowska, M., Dąbrowska, A., Siemianowski, K., Haponiuk, E., & Stasiewicz, K. (2024). The Effect of High-Pressure Processing of Caprine Milk on the Production and Properties of Yoghurt. Foods, 13(9), 1327. https://doi.org/10.3390/foods13091327