Characterizing Edible Oils by Oblique-Incidence Reflectivity Difference Combined with Machine Learning Algorithms

Abstract

1. Introduction

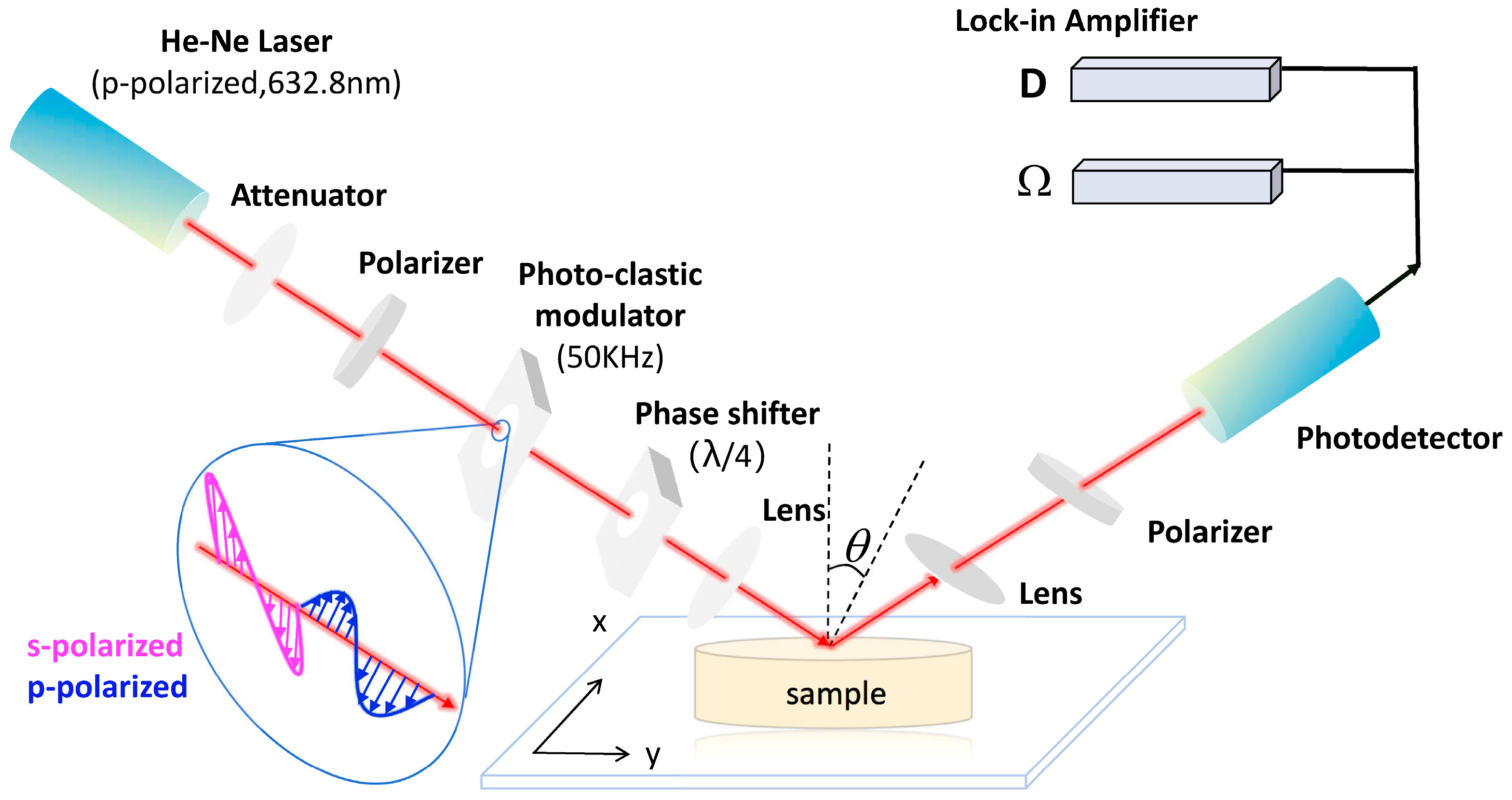

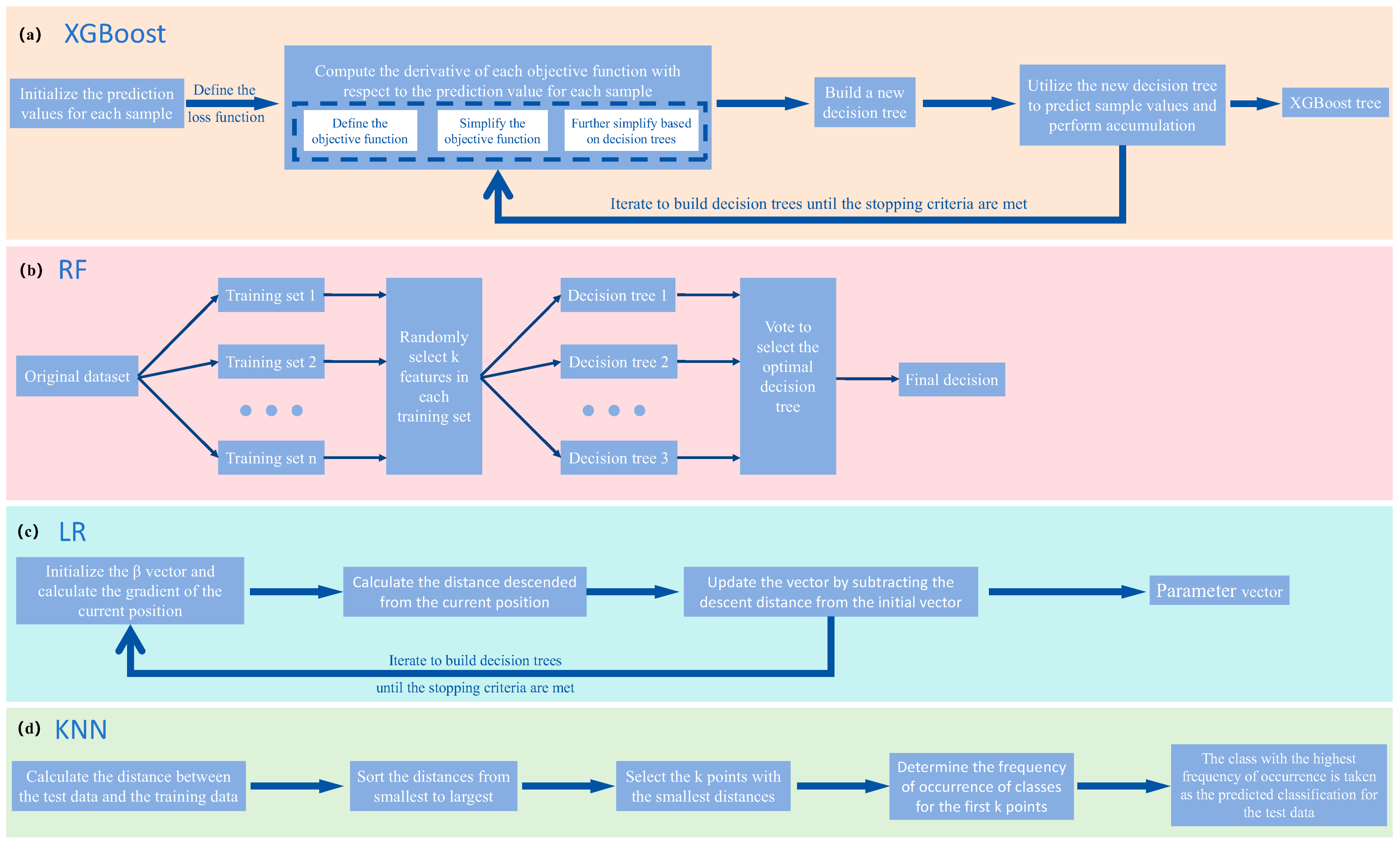

2. Materials and Methods

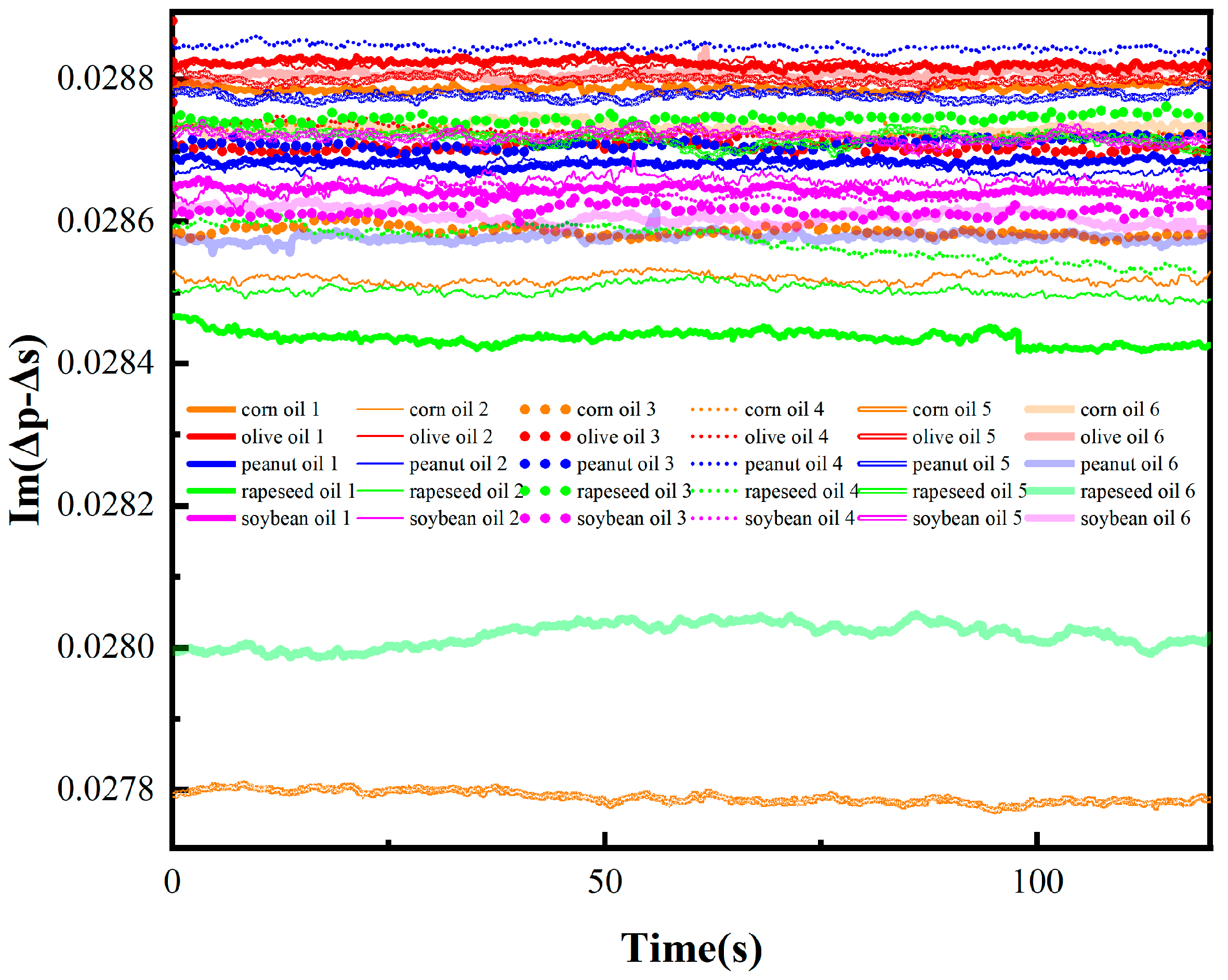

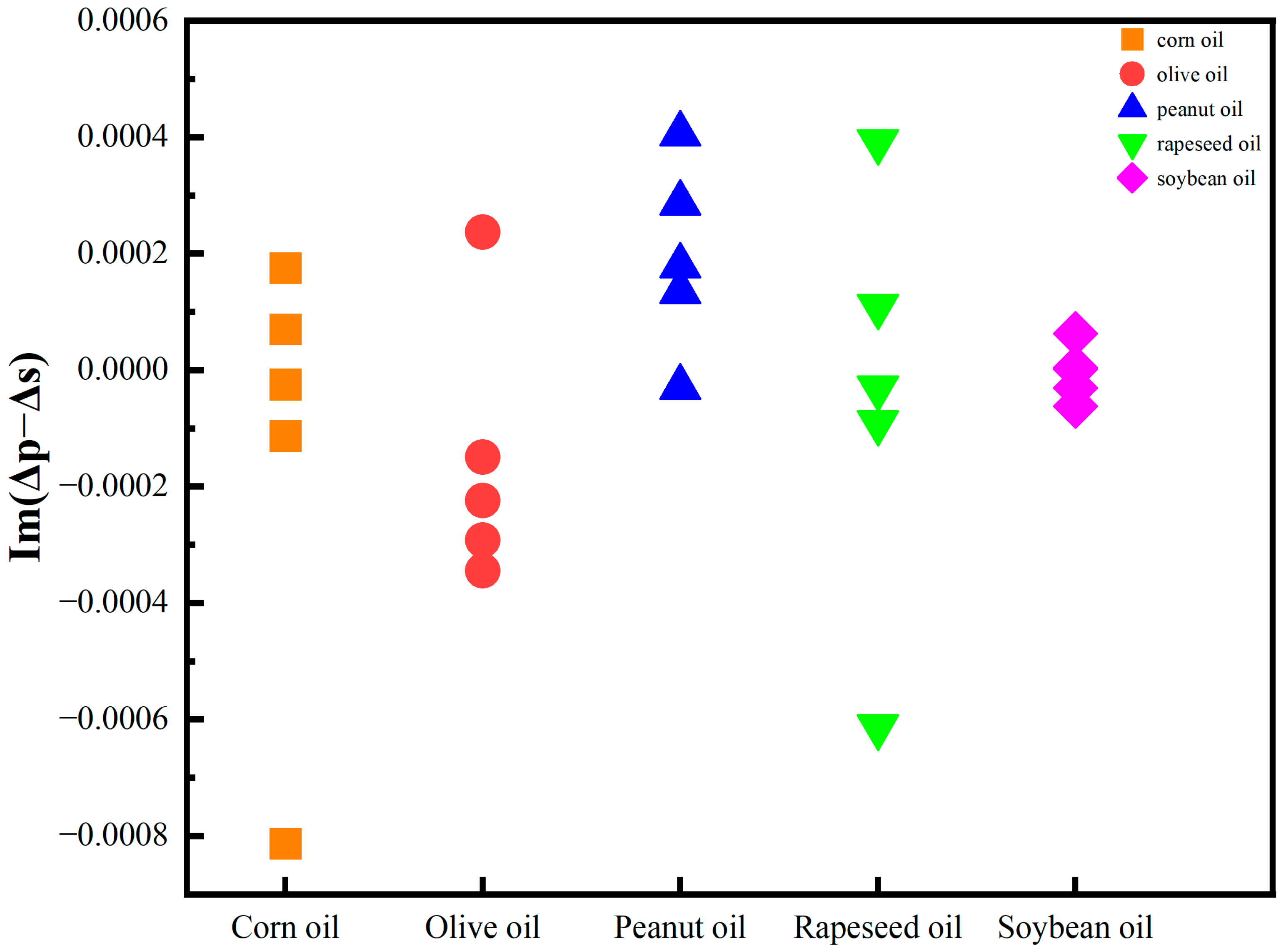

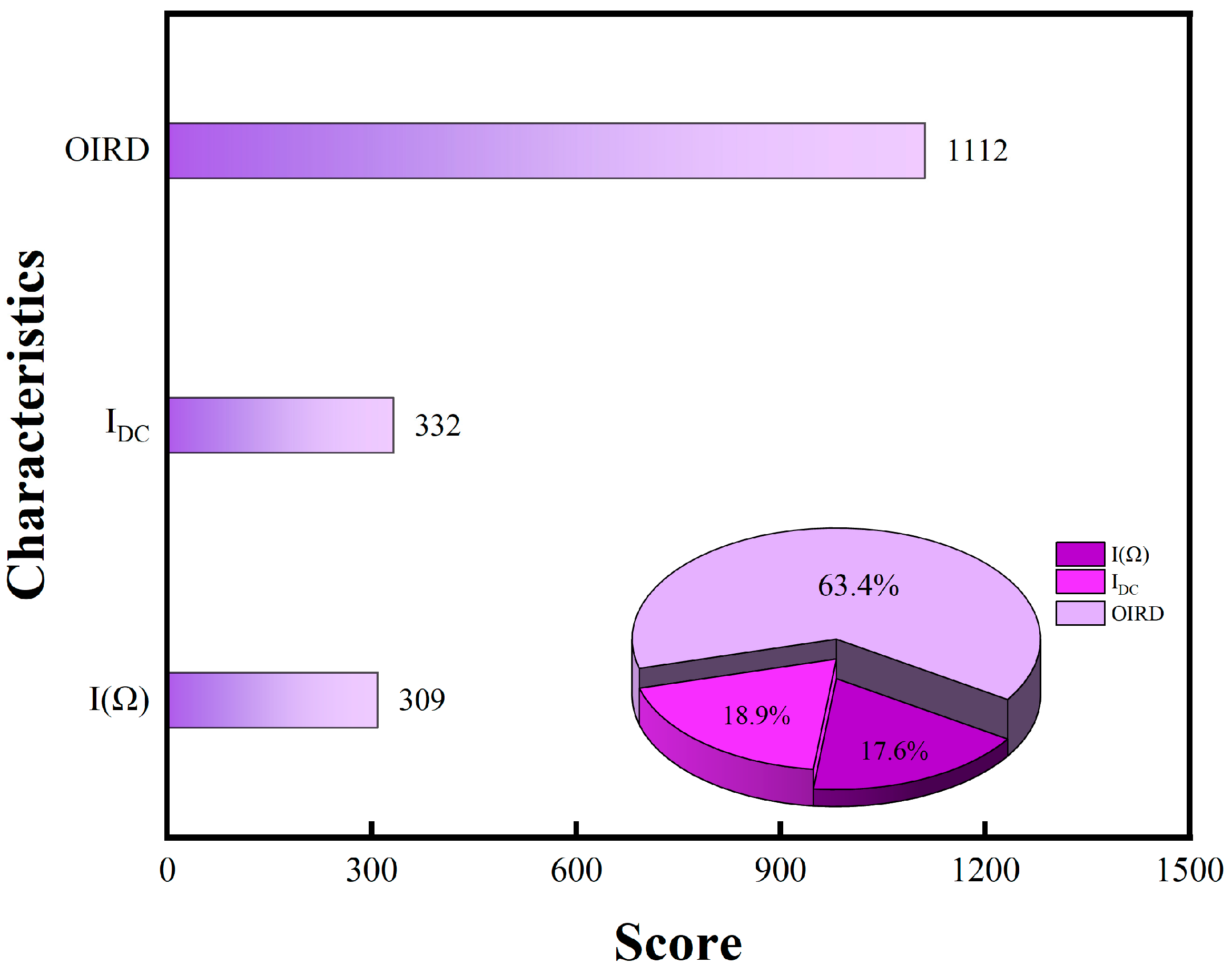

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chien, H.Y.; Shih, A.T.; Tseng, Y.M. Exploration of fast edible oil classification using infrared spectrum, machine learning, and chemometrics. In Proceedings of the 2019 IEEE 10th International Conference on Awareness Science and Technology (iCAST), Morioka, Japan, 23–25 October 2019; pp. 1–6. [Google Scholar]

- Tian, M.K.; Bai, Y.C.; Tian, H.Y.; Zhao, X.B. The chemical composition and health-promoting benefits of vegetable oils—A review. J. Mol. 2023, 28, 6393. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.X.; Lei, X.L.; Guo, L.L.; Xu, X.X.; Liu, L.Q.; Kuang, H.; Xu, C.; Yang, F.; Du, X. Current situation and prospect of rapid quantitative detection technology for edible oils safety hazard factors. J. China Oils Fats 2021, 8, 105–109. [Google Scholar]

- Yu, H.W.; Wang, Q.; Liu, L.; Shi, A.M.; Hu, H.; Liu, H.Z. Research process on hyperspectral imaging detection technology for the quality and safety of grain and oils. J. Spectrosc. 2016, 36, 3643–3650. [Google Scholar]

- Wu, X.J.; Gao, S.B.; Niu, Y.D.; Zhao, Z.L.; Xu, B.R.; Ma, R.Q.; Liu, H.L.; Zhang, Y.J. Identification of olive oil in vegetable blend oil by one-dimensional convolutional neural network combined with Raman spectroscopy. J. Food Compos. Anal. 2022, 108, 104396. [Google Scholar] [CrossRef]

- Jiang, L.L.; Hong, Z.; Hong, F.L. Application of UV spectrometry and chemometric models for detecting olive oil-vegetable oil blends adulteration. J. Food Sci. Technol. 2015, 52, 479–485. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, Y.Y.; Dai, Z.; Cui, L.H.; Lin, H.Z.; Li, Z.J.; Wu, K.H.; Liu, G.Y. Quantitative detection of extra virgin olive oil adulteration, as opposed to peanut and soybean oil, employing LED-induced fluorescence spectroscopy. J. Sens. 2022, 22, 1227. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, A.C.; Upadhyaya, K. Vegetable oil: Nutritional and industrial perspective. J. Curr. Genom. 2016, 17, 230–240. [Google Scholar] [CrossRef] [PubMed]

- Rajagukguk, Y.V.; Cevoli, C.; Grigoletto, I.; Tomaszewska-Gras, J. Rapid determination of the storage time of cold-pressed berry seed oils using flash gas chromatography E-Nose coupled with chemometrics. J. Food Eng. 2024, 364, 111795. [Google Scholar] [CrossRef]

- Roy, M.; Doddappa, M.; Yadav, B.K.; Jaganmohan, R.; Sinija, V.R.; Manickam, L.; Sarvanan, S. Detection of soybean oil adulteration in cow ghee (clarified milk fat): An ultrafast study using flash gas chromatography electronic nose coupled with multivariate chemometrics. J. Sci. Food Agric. 2022, 102, 4097–4108. [Google Scholar] [CrossRef]

- Kalo, P.; Kuuranne, T. Analysis of free and esterified sterols in fats and oils by flash chromatography, gas chromatography and electrospray tandem mass spectrometry. J. Chromatogr. A 2001, 935, 237–248. [Google Scholar] [CrossRef]

- Jing, Q.; Liu, S.; Song, Y.; Xu, T.; Ma, F.; Yu, L.; Hu, C.D.; Li, P.W.; Zhang, X.L. TaqMan real-time quantitative PCR for the detection of beef tallow to assess the authenticity of edible oils. Food Control 2024, 156, 110139. [Google Scholar] [CrossRef]

- Cui, F.; Liu, M.; Li, X.; Wang, D.; Ma, F.; Yu, L.; Hu, C.D.; Li, P.W.; Zhang, X.L. Gas chromatography ion mobility spectroscopy: A rapid and effective tool for monitoring oil oxidation. Food Res. Int. 2024, 176, 113842. [Google Scholar] [CrossRef] [PubMed]

- Geng, D.; Chen, X.; Lu, D.; Chen, B. Discrimination of different edible vegetable oils based on GC-IMS and SIMCA. Cyta-J. Food 2023, 21, 49–56. [Google Scholar] [CrossRef]

- de Magalhães, J.B.; Simon, K.F.; Veiga, E.A.; Galvão, A.C.; Robazza, W.D.S. Evaluating Adulteration of Commercial Extra Virgin Olive Oil with Canola and Sunflower Oils Through Electrochemical Impedance Spectroscopy. Food Bioprocess Technol. 2023, 1–13. [Google Scholar] [CrossRef]

- Jiménez, A.; Rufo, M.; Paniagua, J.M.; González-Mohino, A.; Olegario, L.S. Temperature dependence of acoustic parameters in pure and blended edible oils: Implications for characterization and authentication. Ultrasonics 2024, 138, 107216. [Google Scholar] [CrossRef] [PubMed]

- Irmak, Ş.; Dıraman, H. Chemometric characterization of raw olives from important Turkish table olive cultivars Cvs. using HPLC–DAD method based on their biophenolic profiles. J. Food Sci. Technol. 2022, 59, 1792–1800. [Google Scholar] [CrossRef] [PubMed]

- Rolandelli, G.; Buera, M.P.; Rodríguez, S.D. Monitoring thermal stability of pure and adulterated sesame oil using Fourier transform infrared spectroscopy and chemometric analysis. J. Food Compos. Anal. 2024, 125, 105806. [Google Scholar] [CrossRef]

- Nagpal, T.; Yadav, V.; Khare, S.K.; Siddhanta, S.; Sahu, J.K. Monitoring the lipid oxidation and fatty acid profile of oil using algorithm-assisted surface-enhanced Raman spectroscopy. Food Chem. 2023, 428, 136746. [Google Scholar] [CrossRef] [PubMed]

- Tang, C.; Qiao, J.; Wen, Y.; Zeng, Z.X.; Shao, S.J.; Dang, S.Q. Quality control of woody edible oil: The application of fluorescence spectroscopy and the influencing factors of fluorescence. Food Control 2022, 142, 109275. [Google Scholar] [CrossRef]

- Gu, H.; Sun, Y. A Rapid Method for Rapid Evaluation of Oil Quality Using Synchronous Fluorescence Spectroscopy. J. Nanoelectron. Optoelectron. 2018, 13, 743–748. [Google Scholar] [CrossRef]

- Poulli, K.I.; Mousdis, G.A.; Georgiou, C.A. Classification of edible and lampante virgin olive oil based on synchronous fluorescence and total luminescence spectroscopy. Anal. Chim. Acta 2005, 542, 151–156. [Google Scholar] [CrossRef]

- Songohoutou, E.E.; Daniel, L.; Nouga, A.B.; Palé, W.; Owono, L.C.; Kenfack, C.A. Monitoringthe Thermal Oxidation of Local Edible Oils by Fluorescence Spectroscopy Technique Coupled to Chemometric Methods. Food Anal. Method 2023, 16, 1422–1436. [Google Scholar] [CrossRef]

- Socaciu, C.; Fetea, F.; Ranga, F.; Bunea, A.; Dulf, F.; Socaci, S.; Pintea, A. Attenuated total reflectance-fourier transform infrared spectroscopy (ATR-FTIR) coupled with chemometrics, to control the botanical authenticity and quality of cold-pressed functional oils commercialized in Romania. Food Anal. Method. 2020, 10, 8695. [Google Scholar] [CrossRef]

- Su, N.; Pan, F.; Wang, L.; Weng, S.Z. Rapid detection of fatty acids in edible oils using vis-NIR reflectance spectroscopy with multivariate methods. Biosensors 2021, 11, 261. [Google Scholar] [CrossRef] [PubMed]

- Mahboubifar, M.; Hemmateenejad, B.; Javidnia, K.; Yousefinejad, S. Evaluation of long-heating kinetic process of edible oils using ATR–FTIR and chemometrics tools. J. Food Sci. Technol. 2017, 54, 659–668. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.W.; Luo, J.P.; Li, X.S.; Cheng, L.L. Edible oil terahertz spectral feature extraction method combining radial basis function and KPCA. Spectrosc. Spect. Anal. 2020, 40, 391–396. [Google Scholar]

- Nie, M.T.; Xu, D.G.; Wang, Y.Y.; Tang, L.H.; He, Y.X.; Liu, H.X.; Yao, J.Q. Investigation on characteristics of edible oil spectra with terahertz time-domain attenuated total reflection spectroscopy. Spectrosc. Spect. Anal. 2018, 38, 2016–2020. [Google Scholar]

- Liu, C.L.; Yang, Y.F.; Tian, F.; Wu, J.Z.; Sun, X.R. Study on Quantitative Analysis of Edible Oil Peroxide Value by Terahertz Time Domain Spectroscopy. Spectrosc. Spect. Anal. 2021, 41, 1387–1392. [Google Scholar]

- Yin, M.; Tang, S.; Tong, M. Identification of edible oils using terahertz spectroscopy combined with genetic algorithm and partial least squares discriminant analysis. Anal. Methods 2016, 8, 2794–2798. [Google Scholar] [CrossRef]

- Qin, F.K.; Meng, Z.H.; Li, A.Q.; Miao, X.Y.; Zhao, K.; Xiang, W.F. Optical Detection for the Adsorption Kinetics of Surfactant Solutions on the Surface/Interface: Oblique-Incidence Reflectivity Difference Investigation. IEEE Trans. Instrum. Meas. 2021, 71, 1501907. [Google Scholar] [CrossRef]

- Chen, R.; Ren, Z.Y.; Meng, Z.H.; Zhan, H.L.; Miao, X.Y.; Zhao, K.; Lu, H.B.; Jin, K.J.; Hao, S.J.; Yue, W.Z.; et al. Oblique-incidence reflectivity difference method combined with deep learning for predicting anisotropy of invisible-bedding shale. Energy Rep. 2020, 6, 795–801. [Google Scholar] [CrossRef]

- Fei, Y.; Sun, Y.S.; Li, Y.; Lau, K.; Yu, H.; Chokhawala, H.A.; Huang, S.; Landry, J.P.; Chen, X.; Zhu, X. Fluorescent labeling agents change binding profiles of glycan-binding proteins. J. Mol. Biosyst. 2011, 7, 3343–3352. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.S.; Landry, J.P.; Fei, Y.Y.; Zhu, X.D. An oblique-incidence reflectivity difference study of the dependence of probe-target reaction constants on surface target density using streptavidin-biotin reactions as a model. J. Instrum. Sci. Technol. 2013, 41, 535–544. [Google Scholar] [CrossRef]

- Feng, Z.; Ye, J.; Li, X.; Li, L.; Fang, C.; Wang, R.; Hu, W. Optical Approach for Mapping the Intercalation Capacity of Porous Electrodes. Anal. Chem. 2023, 96, 394–400. [Google Scholar] [CrossRef] [PubMed]

- Fang, C.X.; Li, J.Y.; Feng, Z.Z.H.; Li, L.; Fang, C.X.; Wang, R.F.; Hu, W.H. Spatiotemporal mapping of extracellular electron transfer flux in a microbial fuel cell using an oblique incident reflectivity difference technique. Anal. Chem. 2022, 94, 10841–10849. [Google Scholar] [CrossRef] [PubMed]

- Ning, H.; Wang, J.; Jiang, H.; Chen, Q. Quantitative detection of zearalenone in wheat grains based on near-infrared spectroscopy. Spectrochim. Acta A 2022, 280, 121545. [Google Scholar] [CrossRef] [PubMed]

- Fakhri, D.; Khodayari, A.; Mahmoodzadeh, A.; Hosseini, M.; Ibrahim, H.H.; Mohammed, A.H. Prediction of Mixed-mode I and II effective fracture toughness of several types of concrete using the extreme gradient boosting method and metaheuristic optimization algorithms. Eng. Fract. Mech. 2022, 276, 108916. [Google Scholar] [CrossRef]

- Xiong, X.; Guo, X.; Zeng, P.; Zou, R.; Wang, X. A short-term wind power forecast method via xgboost hyper-parameters optimization. Front. Energy Res. 2022, 10, 905155. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, F.; Sun, Y.; Yin, Y. Improved XGBoost model based on genetic algorithm. Int. J. Comput. Appl. Technol. 2020, 62, 240–245. [Google Scholar] [CrossRef]

- Dong, A.; Zhang, Y.; Guo, Z.; Luo, P.; Yao, Y.; He, J.; Zhu, Q.; Jiang, Y.; Xiong, K.; Guan, Q. Predicting the locations of missing persons in China by using NGO data and deep learning techniques. Int. J. Digit. Earth 2024, 17, 2304076. [Google Scholar] [CrossRef]

- Ishwaran, H.; Malley, J.D. Synthetic learning machines. Biodata Min. 2014, 7, 28. [Google Scholar] [CrossRef] [PubMed]

- Wichitaksorn, N.; Kang, Y.; Zhang, F. Random feature selection using random subspace logistic regression. Expert Syst. Appl. 2023, 217, 119535. [Google Scholar] [CrossRef]

- Barker, L.; Brown, C. Logistic regression when binary predictor variables are highly correlated. Stat. Med. 2001, 20, 1431–1442. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.Y.; Ma, Y.W.; Chen, J.L.; Lin, C.J.; Lee, W.L. Novel Dynamic KNN with Adaptive Weighting Mechanism for Beacon-based Indoor Positioning System. J. Internet Technol. 2019, 20, 1601–1610. [Google Scholar]

- Amat Sairin, M.; Abd Aziz, S.; Yoke Mun, C.; Khaled, A.Y.; Rokhani, F.Z. Analysis and prediction of the major fatty acids in vegetable oils using dielectric spectroscopy at 5–30 MHz. PLoS ONE 2022, 17, e0268827. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.D.; Lu, H.B.; Yang, G.Z.; Li, Z.Y.; Gou, B.Y.; Zhang, D.Z. Epitaxial growth of SrTiO3 on SrTiO3(001) using an oblique-incidence reflectance-difference technique. Phys. Rev. B 1998, 57, 2514–2519. [Google Scholar] [CrossRef]

- Zhong, C.; Li, L.; Chen, N.; Peng, Z.; Hu, W.H. Spatially resolved electrochemical reversibility of a conducting polymer thin film imaged by oblique-incidence reflectivity difference. Chem. Commun. 2020, 56, 1972–1975. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.; Lu, H.B.; Zhao, T.; Jin, K.J.; Chen, Z.H.; Yang, G.Z. Real-time optical monitoring of the heteroepitaxy of oxides by an oblique-incidence reflectance difference technique. Phys. Rev. B 2000, 61, 10404–10410. [Google Scholar] [CrossRef]

- Landry, J.P.; Zhu, X.D.; Gregg, J.P. Label-free detection of microarrays of biomolecules by oblique-incidence reflectivity difference microscopy. Opt. Lett. 2004, 29, 581–583. [Google Scholar] [CrossRef]

- Zhu, X.D.; James, P.L.; Sun, Y.S.; Gregg, J.P.; Lam, K.S.; Guo, X. Oblique-incidence reflectivity difference microscope for label-free high-throughput detection of biochemical reactions in a microarray format. Appl. Opt. 2007, 46, 1890–1895. [Google Scholar] [CrossRef]

- He, L.P.; Sun, Y.; Dai, J.; Wang, Y.; Lu, H.B.; Zhou, Y.L.; Yang, G.Z. Label-free and real-time detection of antigen-antibody interactions, by Oblique-incidence Reflectivity Difference (OIRD) method. Sci. China Phys. Mech. 2012, 55, 1585–1588. [Google Scholar] [CrossRef]

- Lu, H.; Wen, J.; Wang, X.; Yuan, K.; Li, W.; Lu, H.B.; Zhou, Y.L.; Jin, k.j.; Ruan, K.C.; Yang, G.Z. Detection of the specific binding on protein microarrays by oblique-incidence reflectivity difference method. J. Opt. 2010, 12, 095301. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, M.; Li, H.; Mai, X.H.; Sun, J.W.; Mi, L.; Ma, J.; Zhu, X.D.; Fei, Y.Y. Detection speed optimization of the OI-RD microscope for ultra-high throughput screening. Biomed. Opt. Express 2023, 14, 2386–2399. [Google Scholar] [CrossRef] [PubMed]

- Zhu, C.; Zhu, X.; Landry, J.P.; Cui, Z.; Li, Q.; Dang, Y.; Mi, L.; Zheng, F.; Fei, Y. Developing an efficient and general strategy for immobilization of small molecules onto microarrays using isocyanate chemistry. Sensors 2016, 16, 378. [Google Scholar] [CrossRef] [PubMed]

- Zhu, C.; Ge, B.; Chen, R.; Zhu, X.; Mi, L.; Ma, J.; Wang, X.; Zheng, F.; Fei, Y. Fast focal point correction in prism-coupled total internal reflection scanning imager using an electronically tunable lens. Sensors 2018, 18, 524. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.Y.; Wang, C.; Wang, Z.Y.; Zhu, C.G.; Li, J.; Sha, T.; Ma, L.X.; Gao, C.; Yang, Y.; Sun, Y.M.; et al. Allele-selective lowering of mutant HTT protein by HTT–LC3 linker compounds. Nature 2019, 575, 203–209. [Google Scholar] [CrossRef]

- Wang, J.Y.; Dai, J.; He, L.P.; Sun, Y.; Lu, H.B.; Wang, S.F.; Jin, K.J.; Zhou, Y.L.; Yang, G.Z. Label-free and real-time detections of the interactions of swine IgG with goat anti-swine IgG by oblique-incidence reflectivity difference technique. J. Appl. Phys. 2012, 112, 064702. [Google Scholar] [CrossRef]

- He, L.P.; Liu, S.; Dai, J.; Wu, L.; Liu, G.Z.; Wei, H.F.; Lu, H.B.; Jin, K.J.; Yang, G.Z. Label-free and real-time monitor of binding and dissociation processes between protein A and swine IgG by oblique-incidence reflectivity difference method. Chin. Phys. Lett. 2015, 32, 020703. [Google Scholar] [CrossRef]

- Sun, Y.S. Use of Microarrays as a high-throughput platform for label-free biosensing. J. Lab. Autom. 2015, 20, 334–353. [Google Scholar] [CrossRef]

- Sun, Y.S.; Zhu, X.D. Real-time, label-free detection of biomolecular interactions in sandwich assays by the oblique-incidence reflectivity difference technique. Sensors 2014, 14, 23307–23320. [Google Scholar] [CrossRef]

- Hu, S.; Wan, J.; Su, Y.; Song, Q.; Zeng, Y.; Nguyen, H.N.; Shin, J.; Cox, E.; Rho, H.S.; Woodard, C.; et al. DNA methylation presents distinct binding sites for human transcription factors. Elife 2013, 2, e00726. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Zhang, H.; Wu, X.; Ma, D.; Wu, J.; Wang, L.; Jiang, Y.; Fei, Y.; Zhu, C.; Tan, R.; et al. Nuclear cGAS suppresses DNA repair and promotes tumorigenesis. Nature 2018, 563, 131–136. [Google Scholar] [CrossRef] [PubMed]

- Qing, M.; Liu, J.; Huang, Q.; Qin, F.; Meng, Z.; Liang, H.; Gao, Z.; Zhan, H.; Miao, X.; Zhao, K. In situ probing of wax precipitation of waxy oil using oblique-incidence reflectivity difference at open bulk surface. Fuel 2022, 316, 123436. [Google Scholar] [CrossRef]

- Wang, J.; Zhan, H.L.; He, L.P.; Zhao, K.; He, L.P.; Jin, K.J.; Yang, G.Z. Evaluation of simulated reservoirs by using the oblique-incidence reflectivity difference technique. Sci. China Phys. Mech. 2016, 59, 114221. [Google Scholar] [CrossRef]

- Zhan, H.; Zhao, K.; Lu, H.B.; Jin, K.; Yang, G.; Chen, X. Oblique-incidence reflectivity difference application for morphology detection. Appl. Opt. 2017, 56, 8348–8352. [Google Scholar] [CrossRef] [PubMed]

- Zhan, H.; Zhao, K.; Lu, H.B.; Zhu, J.; Jin, K.; Yang, G.; Chen, X. In situ monitoring of water adsorption in active carbon using an oblique-incidence optical reflectance difference method. AIP Adv. 2017, 7, 095219. [Google Scholar] [CrossRef]

- Zhan, H.L.; Wang, J.; Zhao, K.; He, L.P.; Jin, K.J.; He, L.P.; Yang, G.Z.; Xiao, L.Z. Real-time detection of dielectric anisotropy or isotropy in unconventional oil-gas reservoir rocks supported by the oblique-incidence reflectivity difference technique. Sci. Rep. 2016, 6, 39306. [Google Scholar] [CrossRef] [PubMed]

- Meng, Z.; Qin, F.; Li, A.; Li, H.L.; Dong, S.J.; Song, C.; Miao, X.Y.; Yue, W.Z.; Zhao, K.; Zhan, H.L. Cluster structure of interfacial molecules studied by oblique incidence reflectance difference: Influences of salt ion on oil-water interfacial properties. J. Petrol. Sci. Eng. 2023, 220, 111147. [Google Scholar] [CrossRef]

- Feng, Z.; Li, X.; Fang, C.; Li, J.Y.; Wang, R.F.; Hu, W.H. Polystyrene microsphere monolayer assembled on glass slide for label-free OIRD immunoassay with enhanced sensitivit. J. Sens. Actuator B-Chem. Chem. 2023, 379, 133290. [Google Scholar] [CrossRef]

- Carmen, L.D.-T.-S.; Rodríguez, F.F.; Francisco, J.C.-M.; Victoria, R.A.; Miguel, A.A.; Julián, G.A.; Francisco, R.A. Recovery of phytochemical from three safflower (Carthamus tinctorius L.) by-products: Antioxidant properties, protective effect of human erythrocytes and profile by UPLC-DAD-MS. J. Food Process. Preserv. 2021, 45, e15765. [Google Scholar]

- Rodríguez-Félix, F.; López-Cota, A.G.; Moreno-Vásquez, M.J.; Graciano-Verdugo, A.Z.; Quintero-Reyes, I.E.; Del-Toro-Sánchez, C.L.; Tapia-Hernández, J.A. Sustainable-green synthesis of silver nanoparticles using safflower (Carthamus tinctorius L.) waste extract and its antibacterial activity. J. Heliyon 2021, 7, e06923. [Google Scholar] [CrossRef] [PubMed]

| Types of Edible Oils | Oil 1 | Oil 2 | Oil 3 | Oil 4 | Oil 5 |

|---|---|---|---|---|---|

| corn oil | corn oil 1 | corn oil 2 | corn oil 3 | corn oil 4 | corn oil 5 |

| olive oil | olive oil 1 | olive oil 2 | olive oil 3 | olive oil 4 | olive oil 5 |

| peanut oil | peanut oil 1 | peanut oil 2 | peanut oil 3 | peanut oil 4 | peanut oil 5 |

| rapeseed oil | rapeseed oil 1 | rapeseed oil 2 | rapeseed oil 3 | rapeseed oil 4 | rapeseed oil 5 |

| soybean oil | soybean oil 1 | soybean oil 2 | soybean oil 3 | soybean oil 4 | soybean oil 5 |

| Reference Table for the Fatty Acid Content in Edible Oils (%) | ||||

|---|---|---|---|---|

| Edible Oils | Saturated Fatty Acids | Monounsaturated Fatty Acids | Polyunsaturated Fatty Acids | |

| Oleic Acid (Ω-9) | Linoleic Acid (Ω-6) | Alpha-Linolenic Acid (Ω-3) | ||

| corn oil | 10–13 | 20–25 | 50–60 | 4–6 |

| olive oil | 9–11 | 67–75 | 10–15 | 0–3 |

| peanut oil | 17–18 | 30–40 | 30–40 | 0–3 |

| rapseed oil | 5–10 | 40–60 | 10–20 | 5–8 |

| soybean oil | 10–13 | 20–25 | 55–60 | 4–6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Hu, Y.; Liu, C.; Zhang, S.; Yan, S.; Liu, X.; Zhao, K. Characterizing Edible Oils by Oblique-Incidence Reflectivity Difference Combined with Machine Learning Algorithms. Foods 2024, 13, 1420. https://doi.org/10.3390/foods13091420

Sun X, Hu Y, Liu C, Zhang S, Yan S, Liu X, Zhao K. Characterizing Edible Oils by Oblique-Incidence Reflectivity Difference Combined with Machine Learning Algorithms. Foods. 2024; 13(9):1420. https://doi.org/10.3390/foods13091420

Chicago/Turabian StyleSun, Xiaorong, Yiran Hu, Cuiling Liu, Shanzhe Zhang, Sining Yan, Xuecong Liu, and Kun Zhao. 2024. "Characterizing Edible Oils by Oblique-Incidence Reflectivity Difference Combined with Machine Learning Algorithms" Foods 13, no. 9: 1420. https://doi.org/10.3390/foods13091420

APA StyleSun, X., Hu, Y., Liu, C., Zhang, S., Yan, S., Liu, X., & Zhao, K. (2024). Characterizing Edible Oils by Oblique-Incidence Reflectivity Difference Combined with Machine Learning Algorithms. Foods, 13(9), 1420. https://doi.org/10.3390/foods13091420