Mitigation of Mycotoxin Content by a Single-Screw Extruder in Triticale (x Triticosecale Wittmack)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Grinding and Mixing

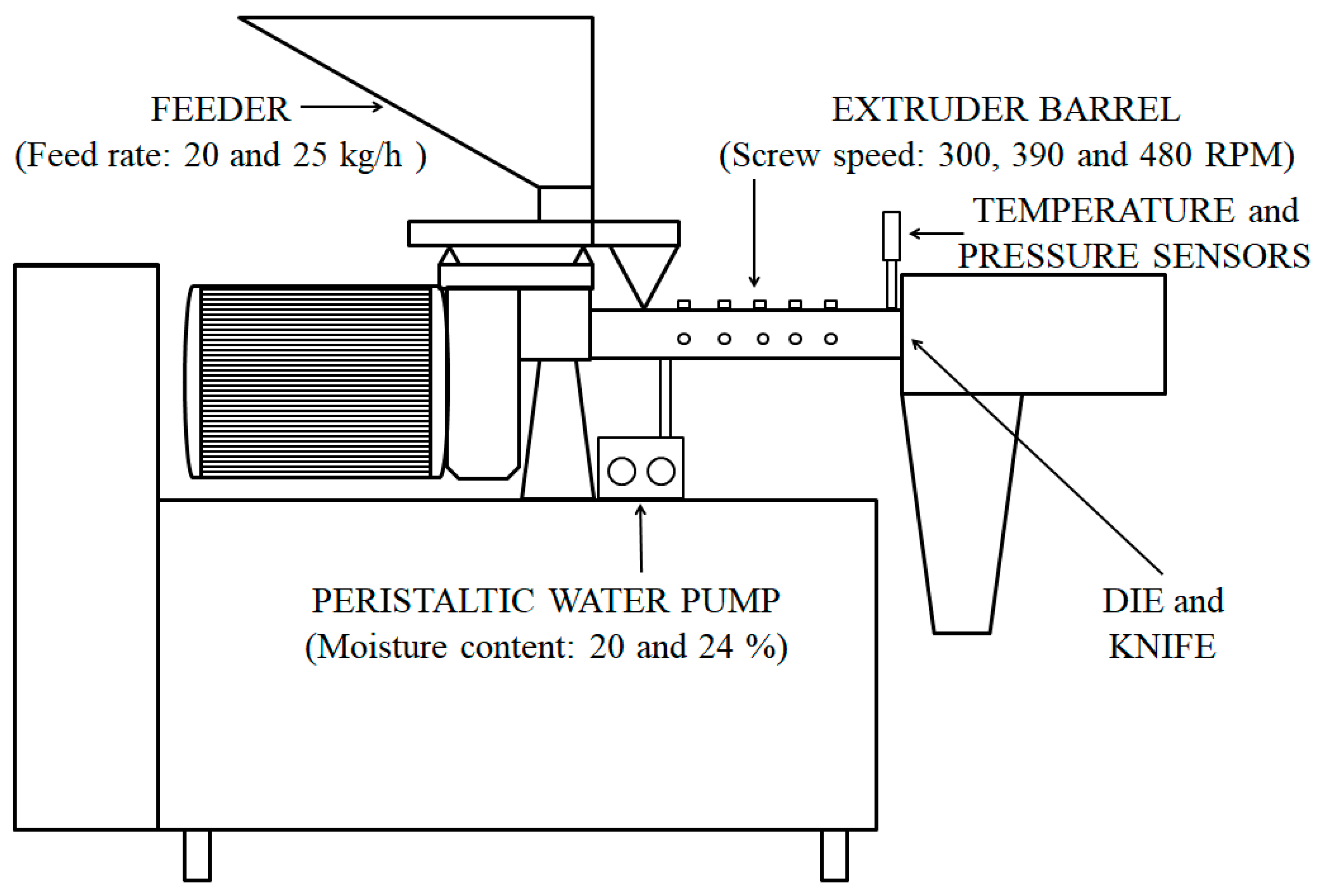

2.2. Extrusion Conditions

2.3. Physical and Chemical Analysis

2.4. Mycotoxin Determination by UPLC-MS/MS Analysis

2.5. Statistical Analysis

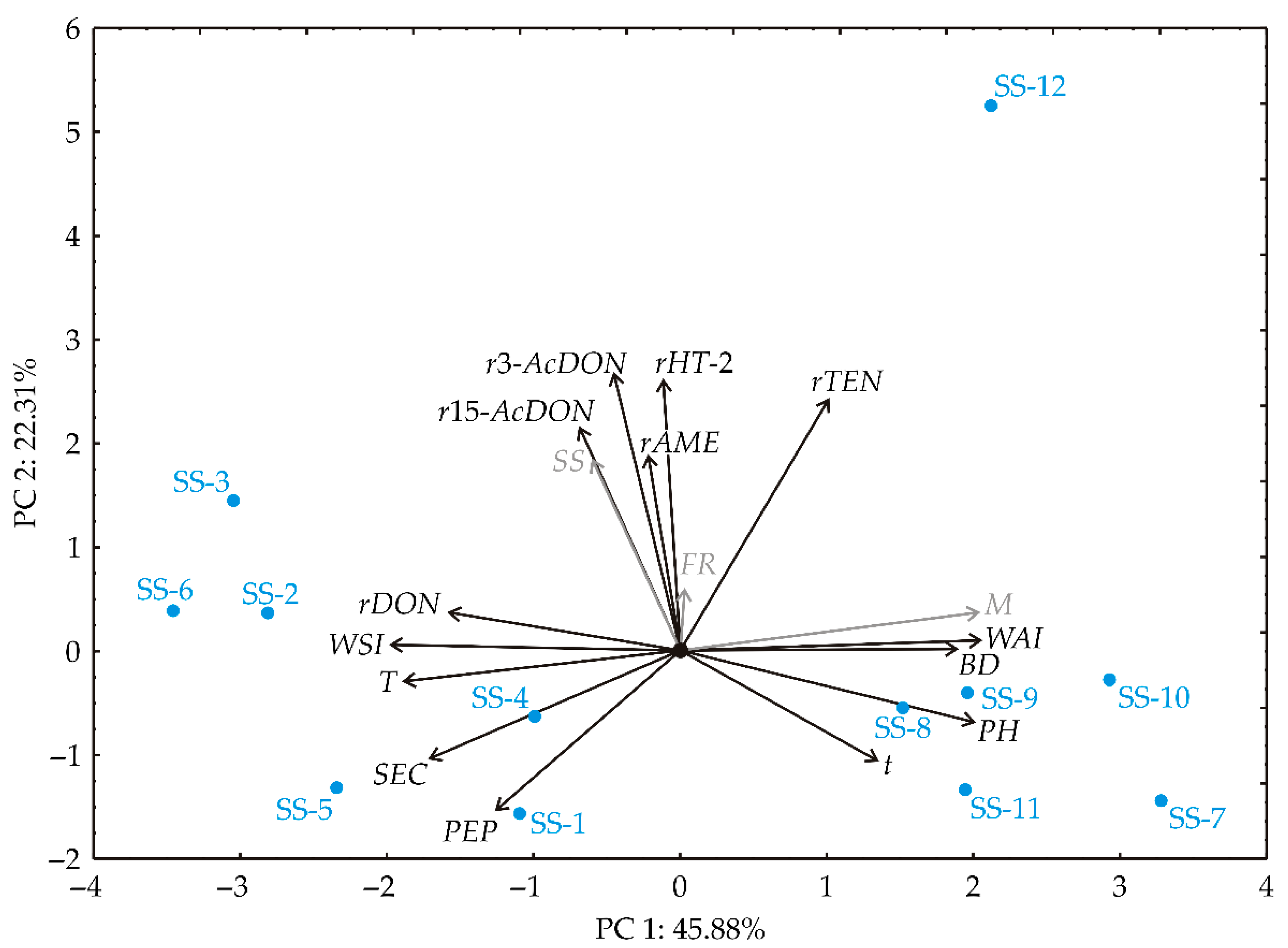

2.5.1. Principal Component Analysis

2.5.2. Response Surface Methodology

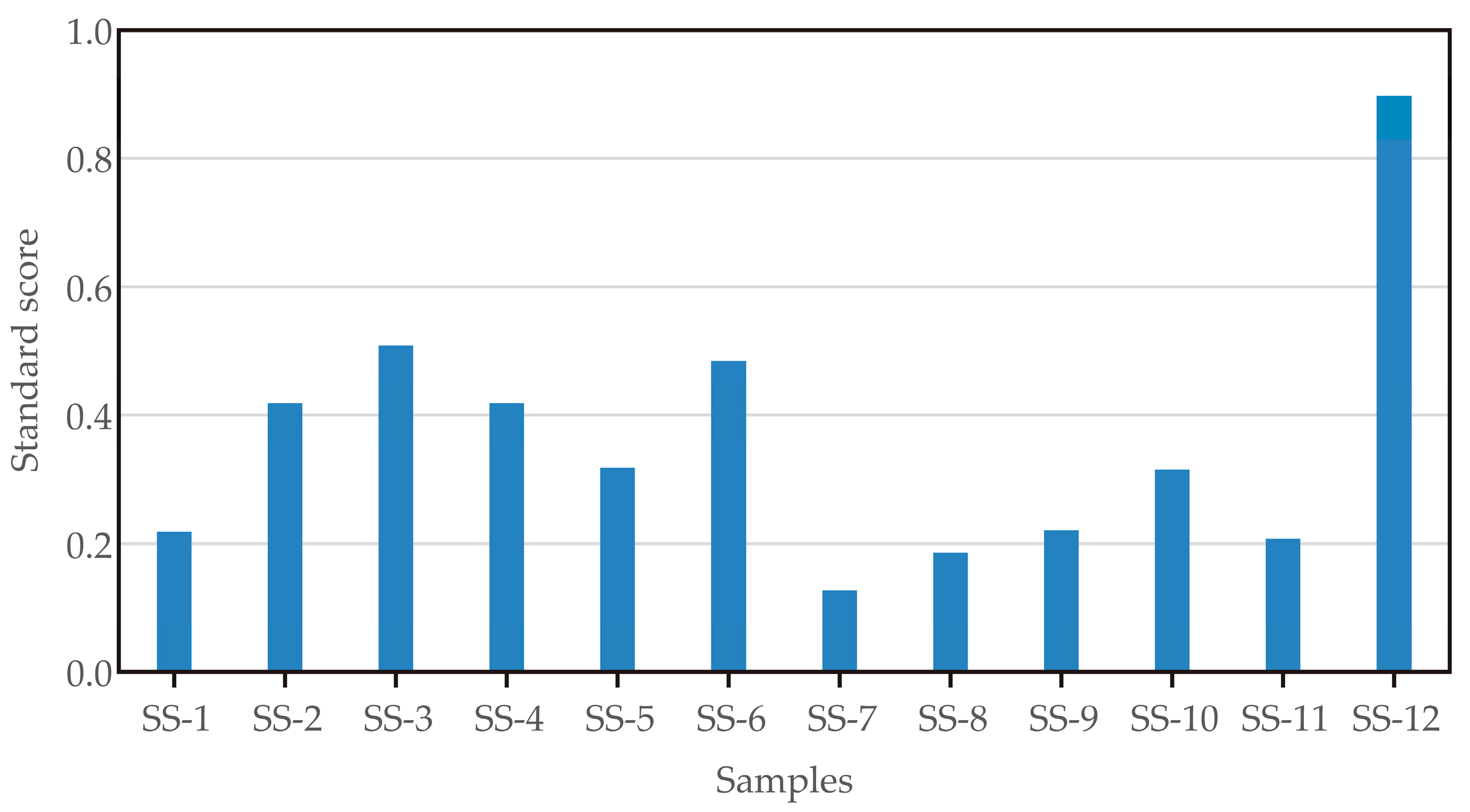

2.5.3. Standard Score

3. Results

3.1. Determination of Examined Mycotoxin Content

3.2. Reduction of Examined Mycotoxins via Single-Screw Extruder

3.3. Principal Component Analysis

3.4. Response Surface Method

4. Discussion

4.1. Mitigation of Mycotoxins During Extrusion Processing

4.2. Effects of Extrusion Condition on Quality Indicators of Triticale Pellets

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Marin, S.; Ramos, A.J.; Cano-Sancho, G.; Sanchis, V. Mycotoxins: Occurrence, toxicology, and exposure assessment. Food Chem. Toxicol. 2013, 60, 218–237. [Google Scholar] [CrossRef]

- Jimenez-Garcia, S.N.; Garcia-Mier, L.; Garcia-Trejo, J.F.; Ramirez-Gomez, X.S.; Guevara-Gonzalez, R.G.; Feregrino-Perez, A.A. Fusarium Mycotoxins and Metabolites that Modulate Their Production. In Fusarium—Plant Diseases, Pathogen Diversity, Genetic Diversity, Resistance and Molecular Markers; IntechOpen: London, UK, 2018. [Google Scholar] [CrossRef]

- Adebo, O.A.; Molelekoa, T.; Makhuvele, R.; Adebiyi, J.A.; Oyedeji, A.B.; Gbashi, S.; Adefisoye, M.A.; Ogundele, O.M.; Njobeh, P.B. A review on novel non-thermal food processing techniques for mycotoxin reduction. Int. J. Food Sci. Technol. 2021, 56, 13–27. [Google Scholar] [CrossRef]

- Agriopoulou, S.; Stamatelopoulou, E.; Varzakas, T. Advances in occurrence, importance, and mycotoxin control strategies: Prevention and detoxification in foods. Foods 2020, 9, 137. [Google Scholar] [CrossRef] [PubMed]

- Schaarschmidt, S.; Fauhl-Hassek, C. The Fate of Mycotoxins During the Processing of Wheat for Human Consumption. Compr. Rev. Food Sci. Food Saf. 2018, 17, 556–593. [Google Scholar] [CrossRef]

- Adeyeye, S.A.O. Fungal mycotoxins in foods: A review. Cogent. Food Agricul. 2016, 2, 1–11. [Google Scholar] [CrossRef]

- Bullerman, L.B.; Bianchini, A. Stability of mycotoxins during food processing. Int. J. Food Microbiol. 2007, 119, 140–146. [Google Scholar] [CrossRef]

- Ostry, V. Alternaria mycotoxins: An overview of chemical characterization, producers, toxicity, analysis and occurrence in foodstuffs. World Mycotoxin J. 2008, 1, 175–188. [Google Scholar] [CrossRef]

- Escriva, L.; Oueslati, S.; Font, G.; Manyes, L. Alternaria mycotoxins in food and feed: An overview. Hindawi J. Food Qual. 2017, 2017, 20. [Google Scholar]

- Pereira, V.L.; Fernandes, J.O.; Cunha, S.C. Mycotoxins in cereals and related foodstuffs: A review on occurrence and recent methods of analysis. Trends Food Sci. Technol. 2014, 36, 96–136. [Google Scholar] [CrossRef]

- Alshannaq, A.; Yu, J.-H. Occurrence, toxicity, and analysis of major mycotoxins in food. Int. J. Environ. Res. Public Health 2017, 14, 632. [Google Scholar] [CrossRef]

- Karlovsky, P.; Suman, M.; Berthiller, F.; De Meester, J.; Eisenbrand, G.; Perrin, I.; Oswald, P.I.; Speijers, G.; Chiodini, A.; Recker, T.; et al. Impact of food processing and detoxification treatments on mycotoxin contamination. Mycotoxin Res. 2016, 32, 179–205. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Hubert, J.; Yamdeu, G.; Gong, Y.Y.; Orfila, C. A review of postharvest approaches to reduce fungal and mycotoxin contamination of foods. Compr. Rev. Food Sci. Food Saf. 2020, 19, 1521–1560. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Wang, L.H.; Zeng, X.A.; Han, Z.; Brennan, C.S. Non-thermal technologies and its current and future application in the food industry: A review. Inter. J. Food Sci. Technol. 2019, 54, 1–13. [Google Scholar] [CrossRef]

- Wan, J.; Chen, B.; Rao, J. Occurrence and preventive strategies to control mycotoxins in cereal-based food. Compr. Rev. Food Sci. Food Saf. 2020, 19, 928–953. [Google Scholar] [CrossRef] [PubMed]

- Kabak, B. The fate of mycotoxins during thermal food processing. J. Sci. Food Agric. 2009, 89, 549–554. [Google Scholar] [CrossRef]

- Patriarca, A. Alternaria in food products. Curr. Opin. Food Sci. 2016, 11, 1–9. [Google Scholar] [CrossRef]

- Voss, K.A.; Bullerman, L.B.; Bianchini, A.; Hanna, M.A.; Ryu, D. Reduced toxicity of fumonisin B1 in corn grits by single-screw extrusion. J. Food Prot. 2008, 71, 2036–2041. [Google Scholar] [CrossRef]

- Massarolo, K.C.; Mendoza, J.R.; Verma, T.; Kupski, L.; Badiale-Furlong, E.; Bianchini, A. Fate of aflatoxins in cornmeal during single-screw extrusion: A bioaccessibility approach. LWT-Food Sci. Tech. 2021, 138, 110734. [Google Scholar] [CrossRef]

- Lee, H.J.; Kim, H.D.; Ryu, D. Practical Strategies to Reduce Ochratoxin A in Foods. Toxins 2024, 16, 58. [Google Scholar] [CrossRef]

- Janić Hajnal, E.; Čolović, R.; Pezo, L.; Orčić, D.; Vukmirović, Ð.; Mastilović, J. Possibility of Alternaria toxins reduction by extrusion processing of whole wheat flour. Food Chem. 2016, 213, 784–790. [Google Scholar] [CrossRef]

- Janić Hajnal, E.; Babic, J.; Pezo, L.; Banjac, V.; Čolović, R.; Kos, J.; Krulj, J.; Pavsic-Vrtač, K.; Jakovac-Strajn, B. Effects of extrusion process on Fusarium and Alternaria mycotoxins in whole grain triticale flour. LWT-Food Sci. Technol. 2022, 155, 112926. [Google Scholar] [CrossRef]

- Janić Hajnal, E.; Babič, J.; Pezo, L.; Banjac, V.; Filipčev, B.; Miljanić, J.; Kos, J.; Jakovac-Strajn, B. Reduction of Alternaria Toxins via the Extrusion Processing of Whole-Grain Red Sorghum Flour. Foods 2024, 13, 255. [Google Scholar] [CrossRef] [PubMed]

- Grasso, S. Extruded snacks from industrial by-products: A review. Trends Food Sci. Technol. 2020, 99, 284–294. [Google Scholar] [CrossRef]

- European Commission. Commission Regulation (EU) 2023/915 of 25 April 2023 on maximum levels for certain contaminants in food and repealing Regulation (EC) No 1881/2006. Off. J. Eur. Union 2023, 119, 103–157. [Google Scholar]

- European Commission. Commission Regulation (EU) 2024/1038 of 9 April 2024 Amending Regulation (EU) 2023/915 as Regards Maximum Levels of T-2 and HT-2 Toxins in Food. Off. J. Eur. Union 2024, 1038, 1–5. [Google Scholar]

- European Commission. Commission recommendation (EU) 2022/553 of 5 April 2022 on monitoring the presence of Alternaria toxins in food. Off. J. Eur. Communities 2022, 107, 90. [Google Scholar]

- Clark, P.M.; Behnke, K.C.; Poole, D.R. Effects of marker selection and mix time on the coefficient of variation (mix uniformity) of broiler feed. J. Appl. Poult. Res. 2007, 16, 464–470. [Google Scholar] [CrossRef]

- ISO 712/2009; Cereals and Cereal Products—Determination of Moisture Content—Reference Method. ISO: Geneva, Switzerland, 2009.

- Anderson, R.A.; Conway, H.F.; Peplinski, A.J. Gelatinization of corn grits by roll cooking, extrusion cooking and steaming. Starch-Stärke 1970, 22, 130–135. [Google Scholar] [CrossRef]

- Topi, D.; Tavčar-Kalcher, G.; Pavšič-Vrtač, K.; Babič, J.; Jakovac-Strajn, B. Alternaria Mycotoxins in Grains from Albania: Alternariol, Alternariol Monomethyl Ether, Tenuazonic Acid and Tentoxin. World Mycotoxin J. 2019, 12, 89–99. [Google Scholar] [CrossRef]

- Babič, J.; Tavčar-Kalcher, G.; Celar, F.A.; Kos, K.; Knific, T.; Jakovac-Strajn, B. Occurrence of Alternaria and other toxins in cereal grains intended for animal feeding collected in Slovenia: A three-year study. Toxins 2021, 13, 304. [Google Scholar] [CrossRef] [PubMed]

- STATISTICA (Data Analysis Software System); V14.0.0.15; TIBCO Stat-Soft Inc.: Tulsa, OK, USA, 2020.

- Zhang, X.; Fan, D. Can agricultural digital transformation help farmers increase income? An empirical study based on thousands of farmers in Hubei Province. Environ. Dev. Sustain. 2024, 26, 14405–14431. [Google Scholar] [CrossRef]

- Tobias, S.; Carlson, J.E. Brief report: Bartlett’s test of sphericity and chance findings in factor analysis. Multivar. Behav. Res. 1969, 4, 375–377. [Google Scholar] [CrossRef] [PubMed]

- Singha, P.; Muthukumarappan, K. Effects of processing conditions on the system parameters during single screw extrusion of blend containing apple pomace. J. Food Process Eng. 2017, 40, e12513. [Google Scholar] [CrossRef]

- Sadiq, F.A.; Yan, B.; Tian, F.; Zhao, J.; Zhang, H.; Chen, W. Lactic acid bacteria as antifungal and anti-mycotoxigenic agents: A comprehensive review. Compr. Rev. Food Sci. F. 2019, 18, 1403–1436. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Lohrey, L.; Cramer, B.; Yuan, Z.; Humpf, H.U. Impact of physicochemical parameters on the decomposition of deoxynivalenol during extrusion cooking of wheat grits. J. Agric. Food Chem. 2011, 59, 12480–12485. [Google Scholar] [CrossRef] [PubMed]

- Pleadin, J.; Kudumija, N.; Šubarić, D.; Lolić, M.; Škrivanko, M.; Tkalec, V.J.; Babić, J. The effect of thermal processing on the reduction of deoxynivalenol and zearalenone cereal content. Croat. J. Food Sci. Technol. 2019, 11, 44–51. [Google Scholar] [CrossRef]

- Srečec, S.; Štefanec, J.; Pleadin, J.; Bauman, I. Decreasing deoxynivalenol concentration in maize within the production chain of animal feed. Agro Food Ind. Hi Tech 2013, 24, 62–65. [Google Scholar]

- Cazzaniga, D.; Basilico, J.C.; Gonzalez, R.J.; Torres, R.L.; de Greef, D.M. Mycotoxins inactivation by extrusion cooking of corn flour. Lett. Appl. Microbiol. 2001, 33, 144–147. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Kuča, K.; Humpf, H.U.; Klímová, B.; Cramer, B. Fate of deoxynivalenol and deoxynivalenol-3-glucoside during cereal-based thermal food processing: A review study. Mycotoxin Res. 2017, 33, 79–91. [Google Scholar] [CrossRef]

- Pleadin, J.; Vulić, A.; Babić, J.; Šubarić, D. The incidence of T-2 and HT-2 toxins in cereals and methods of their reduction practice by the food industry. In Fusarium—Plant Diseases, Pathogen Diversity, Genetic Diversity, Resistance and Molecular Markers; Askun, T., Ed.; IntechOpen: London, UK, 2018; pp. 41–64. [Google Scholar]

- Schmidt, H.S.; Becker, S.; Cramer, B.; Humpf, H.U. Impact of mechanical and thermal energies on the degradation of T-2 and HT-2 toxins during extrusion cooking of oat flour. J. Agric. Food Chem. 2017, 65, 4177–4183. [Google Scholar] [CrossRef]

- Doğan, H.; Karwe, M.V. Physicochemical properties of quinoa extrudates. Food Sci. Technol. Int. 2003, 9, 101–114. [Google Scholar] [CrossRef]

- Charunuch, C.; Limsangouan, N.; Prasert, W.; Wongkrajang, K. Optimization of extrusion conditions for ready-to-eat breakfast cereal enhanced with defatted rice bran. Int. Food Res. J. 2014, 21, 713–722. [Google Scholar]

- Boakye, P.G.; Okyere, A.Y.; Kougblenou, I.; Kowalski, R.; Ismail, B.P.; Annor, G.A. Optimizing the extrusion conditions for the production of expanded intermediate wheatgrass (Thinopyrum intermedium) products. J. Food Sci. 2022, 87, 3496–3512. [Google Scholar] [CrossRef] [PubMed]

- Ding, Q.B.; Ainsworth, P.; Tucker, G.; Marson, H. The effect of extrusion conditions on the physicochemical properties and sensory characteristics of rice-based expanded snacks. J. Food Eng. 2005, 66, 283–289. [Google Scholar] [CrossRef]

- Ding, Q.B.; Ainsworth, P.; Plunkett, A.; Tucker, G.; Marson, H. The effect of extrusion conditions on the functional and physical properties of wheat-based expanded snacks. J. Food Eng. 2006, 73, 142–148. [Google Scholar] [CrossRef]

- Meng, X.; Threinen, D.; Hansen, M.; Driedger, D. Effects of extrusion conditions on system parameters and physical properties of a chickpea flour-based snack. Food Res. Int. 2010, 43, 650–658. [Google Scholar] [CrossRef]

- Alam, S.A.; Järvinen, J.; Kokkonen, H.; Jurvelin, J.; Poutanen, K.; Sozer, N. Factors affecting structural properties and in vitro starch digestibility of extruded starchy foams containing bran. J. Cereal Sci. 2016, 71, 190–197. [Google Scholar] [CrossRef]

- Ye, J.; Hu, X.; Luo, S.; Liu, W.; Chen, J.; Zeng, Z.; Liu, C. Properties of starch after extrusion: A review. Starch-Stärke 2018, 70, 1700110. [Google Scholar] [CrossRef]

- Hagenimana, A.; Ding, X.; Fang, T. Evaluation of rice flour modified by extrusion cooking. J. Cereal Sci. 2006, 43, 38–46. [Google Scholar] [CrossRef]

| Sample | M | FR | SS | T | PEP | SEC | t | BD | PH | WAI | WSI | rDON | r3-AcDON | r15-AcDON | rHT-2 | rTEN | rAME |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SS-1 | 20 | 20 | 300 | 128.5 | 0.42 | 140.8 | 25.0 | 0.240 | 11.1 | 6.66 | 21.5 | 3.28 | 12.1 | 27.1 | 19.7 | 3.06 | 25.5 |

| SS-2 | 20 | 20 | 390 | 141 | 0.31 | 134.2 | 22.0 | 0.207 | 9.56 | 5.50 | 35.5 | 3.85 | 14.2 | 66.7 | 47.9 | 1.77 | 27.0 |

| SS-3 | 20 | 20 | 480 | 134.6 | 0.55 | 143.0 | 16.0 | 0.186 | 9.08 | 4.66 | 35.4 | 4.49 | 18.0 | 56.3 | 54.1 | 6.28 | 43.3 |

| SS-4 | 20 | 25 | 300 | 130.4 | 0.26 | 133.8 | 31.0 | 0.231 | 13.2 | 6.44 | 23.9 | 6.38 | 8.9 | 36.3 | 17.3 | 3.96 | 54.4 |

| SS-5 | 20 | 25 | 390 | 132 | 0.41 | 186.6 | 23.0 | 0.234 | 11.4 | 6.50 | 24.9 | 6.41 | 17.8 | 26.2 | 38.2 | 4.96 | 13.1 |

| SS-6 | 20 | 25 | 480 | 141 | 0.28 | 186.1 | 20.0 | 0.183 | 9.13 | 5.56 | 33.2 | 7.27 | 27.2 | 19.6 | 57.8 | 15.9 | 26.8 |

| SS-7 | 24 | 20 | 300 | 103.8 | 0.20 | 116.6 | 35.0 | 0.396 | 17.7 | 8.66 | 16.2 | 0.72 | 1.9 | 17.9 | 31.0 | 15.3 | 13.2 |

| SS-8 | 24 | 20 | 390 | 134 | 0.11 | 128.7 | 26.0 | 0.401 | 14.5 | 7.84 | 19.7 | 1.20 | 0.3 | 22.8 | 52.4 | 13.2 | 11.7 |

| SS-9 | 24 | 20 | 480 | 113.6 | 0.21 | 117.7 | 18.0 | 0.418 | 18.4 | 7.72 | 19.0 | 1.99 | 4.5 | 24.8 | 45.0 | 18.4 | 10.6 |

| SS-10 | 24 | 25 | 300 | 97.6 | 0.10 | 110.9 | 34.0 | 0.298 | 16.9 | 8.96 | 12.6 | 3.22 | 1.0 | 34.0 | 26.6 | 18.1 | 35.6 |

| SS-11 | 24 | 25 | 390 | 100.1 | 0.23 | 113.5 | 30.0 | 0.301 | 16.8 | 8.98 | 20.5 | 3.69 | 2.2 | 7.13 | 35.5 | 2.06 | 32.9 |

| SS-12 | 24 | 25 | 480 | 103.5 | 0.10 | 91.5 | 24.0 | 0.352 | 13.7 | 8.96 | 14.9 | 3.80 | 60.7 | 61.5 | 86.5 | 47.7 | 55.9 |

| p-value | * | * | * | * | * | * | * | * | * | * | * | * | * | * |

| df | T | PEP | SEC | t | BD | PH | WAI | WSI | rDON | r3-AcDON | r15-AcDON | rHT-2 | rTEN | rAME | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M | 1 | 1999.501 *** | 6.453 * | 5023.339 ** | 75.000 ** | 0.065 *** | 99.175 *** | 20.784 *** | 423.888 *** | 24.253 *** | 62.921 | 339.658 | 145.416 | 517.010 * | 76.104 |

| FR | 1 | 215.901 | 0.003 | 142.554 | 33.333 ** | 0.005 ** | 0.054 | 1.592 *** | 24.981 | 19.350 *** | 370.997 | 79.103 | 11.532 | 100.412 | 638.615 |

| SS | 1 | 131.220 | 0.720 | 164.711 | 276.125 *** | 0.000 | 9.172 | 1.824 *** | 101.355 * | 1.942 *** | 935.810 * | 276.496 | 2768.497 ** | 287.800 | 7.805 |

| SS2 | 1 | 156.060 | 0.667 | 305.164 | 0.042 | 0.000 | 0.876 | 0.000 | 25.029 | 0.031 | 177.365 | 42.638 | 4.222 | 299.809 | 384.139 |

| M × FR | 1 | 204.188 | 0.213 | 1530.473 * | 0.333 | 0.006 *** | 4.199 | 0.081 | 1.044 | 0.224 * | 189.705 | 923.268 | 66.793 | 4.354 | 680.408 |

| M × SS | 1 | 0.125 | 0.845 | 662.844 | 6.125 | 0.004 ** | 1.594 | 0.473 | 40.761 | 0.008 | 180.485 | 60.149 | 0.122 | 38.625 | 93.503 |

| FR × SS | 1 | 0.045 | 0.980 | 110.261 | 3.125 | 0.000 | 4.489 | 0.538 ** | 3.279 | 0.130 | 603.180 | 80.702 | 337.581 | 155.592 | 63.264 |

| Error | 4 | 348.283 | 3.535 | 1020.300 | 16.583 | 0.001 | 9.729 | 0.269 | 52.598 | 0.136 | 626.060 | 2031.767 | 709.390 | 404.596 | 851.539 |

| R2 | 0.886 | 0.737 | 0.886 | 0.960 | 0.988 | 0.925 | 0.989 | 0.922 | 0.997 | 0.801 | 0.470 | 0.825 | 0.776 | 0.695 | |

| adjR2 | 0.687 | 0.275 | 0.687 | 0.889 | 0.967 | 0.793 | 0.971 | 0.785 | 0.992 | 0.453 | 0.000 | 0.518 | 0.385 | 0.162 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jakovac-Strajn, B.; Babič, J.; Pezo, L.; Banjac, V.; Čolović, R.; Kos, J.; Miljanić, J.; Janić Hajnal, E. Mitigation of Mycotoxin Content by a Single-Screw Extruder in Triticale (x Triticosecale Wittmack). Foods 2025, 14, 263. https://doi.org/10.3390/foods14020263

Jakovac-Strajn B, Babič J, Pezo L, Banjac V, Čolović R, Kos J, Miljanić J, Janić Hajnal E. Mitigation of Mycotoxin Content by a Single-Screw Extruder in Triticale (x Triticosecale Wittmack). Foods. 2025; 14(2):263. https://doi.org/10.3390/foods14020263

Chicago/Turabian StyleJakovac-Strajn, Breda, Janja Babič, Lato Pezo, Vojislav Banjac, Radmilo Čolović, Jovana Kos, Jelena Miljanić, and Elizabet Janić Hajnal. 2025. "Mitigation of Mycotoxin Content by a Single-Screw Extruder in Triticale (x Triticosecale Wittmack)" Foods 14, no. 2: 263. https://doi.org/10.3390/foods14020263

APA StyleJakovac-Strajn, B., Babič, J., Pezo, L., Banjac, V., Čolović, R., Kos, J., Miljanić, J., & Janić Hajnal, E. (2025). Mitigation of Mycotoxin Content by a Single-Screw Extruder in Triticale (x Triticosecale Wittmack). Foods, 14(2), 263. https://doi.org/10.3390/foods14020263