Application of Smart Packaging in Fruit and Vegetable Preservation: A Review

Abstract

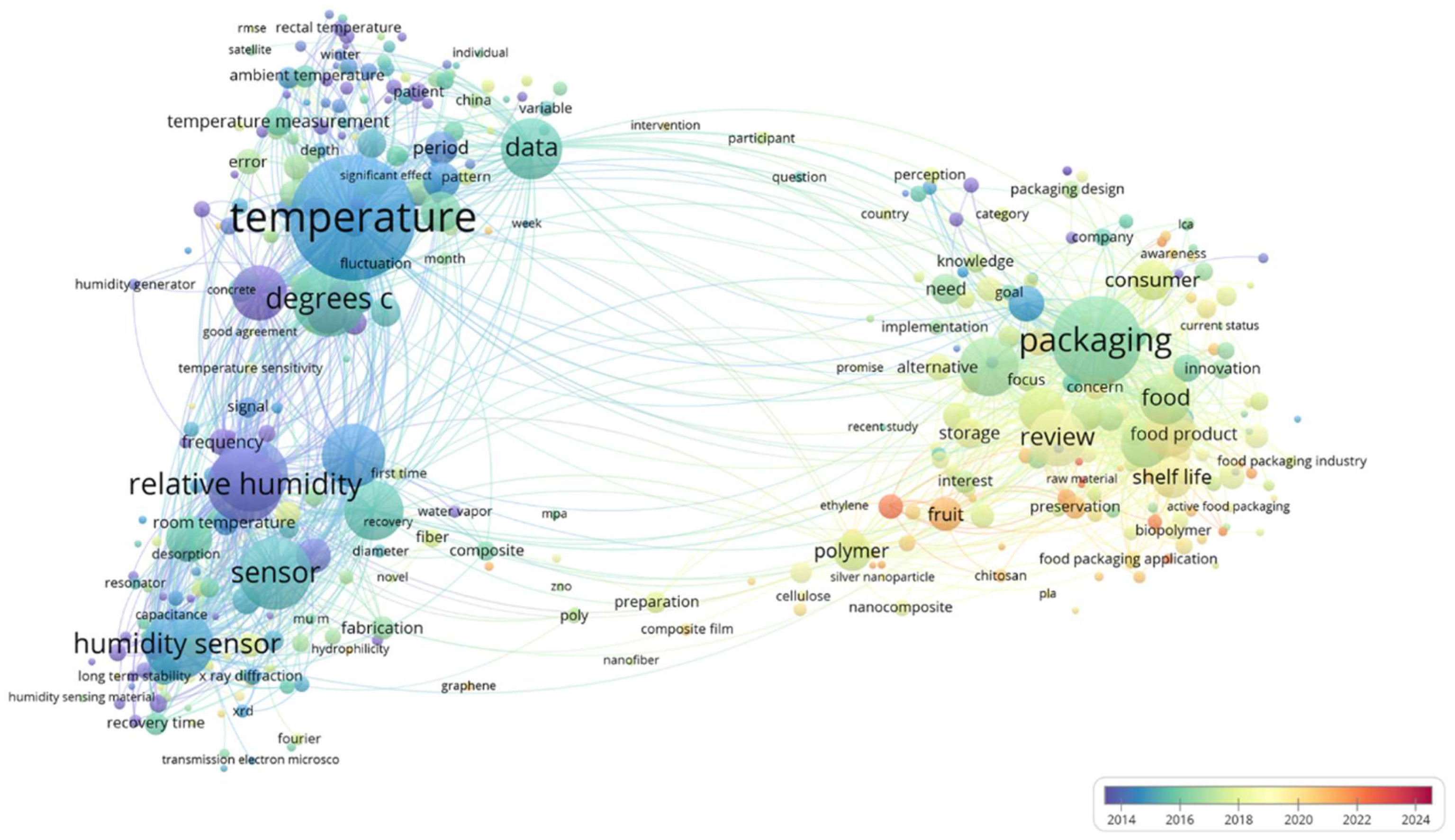

:1. Introduction

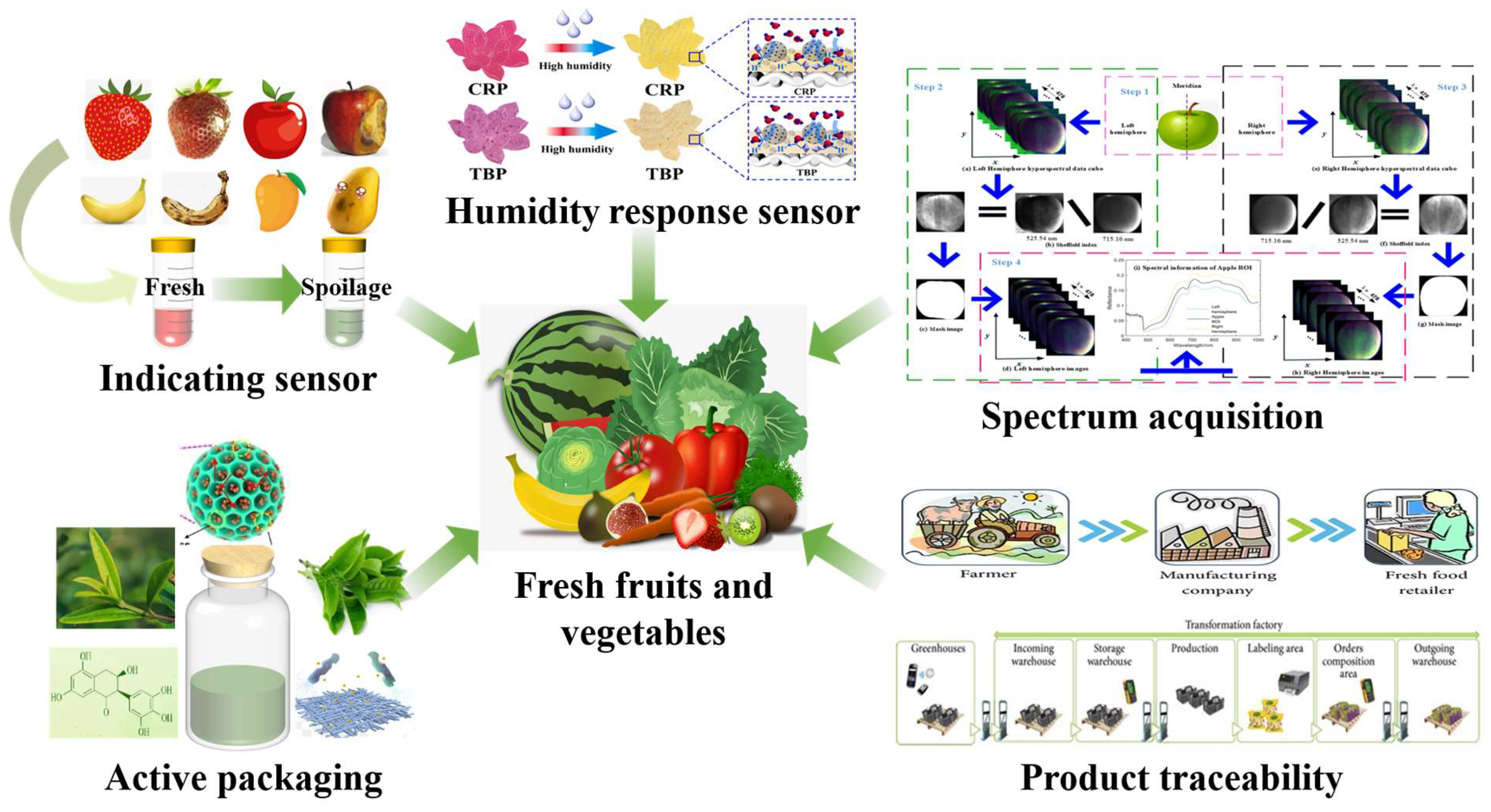

2. The Technical Principle of Smart Packaging

2.1. Smart Packaging Classification

2.1.1. Active Packaging

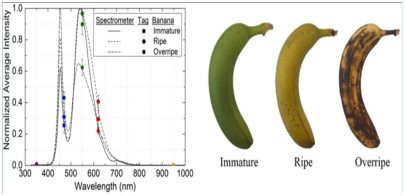

2.1.2. Indicative Intelligent Packaging

2.1.3. Sensing Intelligent Packaging

2.1.4. Data Carrier-Type Intelligent Packaging

2.2. Smart Packaging Materials

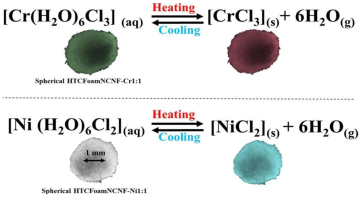

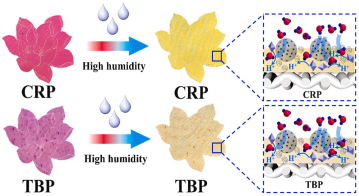

2.2.1. Temperature and Humidity-Sensitive Materials

2.2.2. Electronic Labels and Information Transfer Materials

2.2.3. Self-Healing Materials

2.2.4. Antibacterial Freshness-Keeping Materials

2.2.5. Biodegradable Materials

2.2.6. Nanotechnology Packaging Materials

3. Application of Smart Packaging in Fruit and Vegetable Preservation

3.1. Temperature and Humidity Intelligent Packaging

3.2. Antibacterial Freshness-Keeping Active Packaging

3.3. Biodegradable Active Packaging

3.4. Application of Nanotechnology in Fruit and Vegetable Preservation

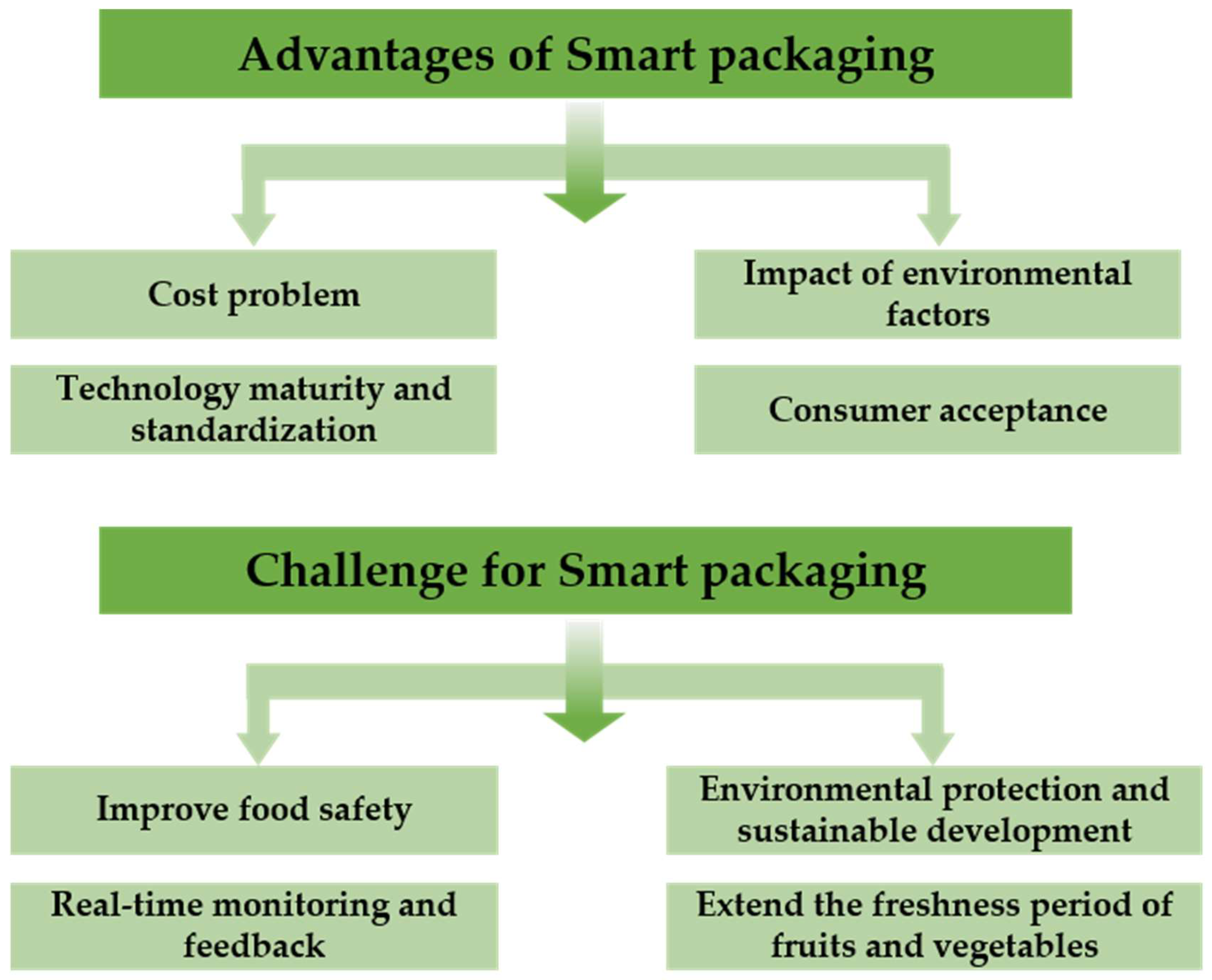

4. Advantages and Challenges of Smart Packaging in Fruit and Vegetable Preservation

4.1. Advantages of Smart Packaging in Fruit and Vegetable Preservation

4.1.1. Extend the Freshness Period of Fruits and Vegetables

4.1.2. Real-Time Monitoring and Feedback

4.1.3. Improve Food Safety

4.1.4. Environmental Protection and Sustainable Development

4.2. Challenges of Smart Packaging in Fruit and Vegetable Preservation

4.2.1. Cost Problem

4.2.2. Technology Maturity and Standardization

4.2.3. Consumer Acceptance

4.2.4. Impact of Environmental Factors

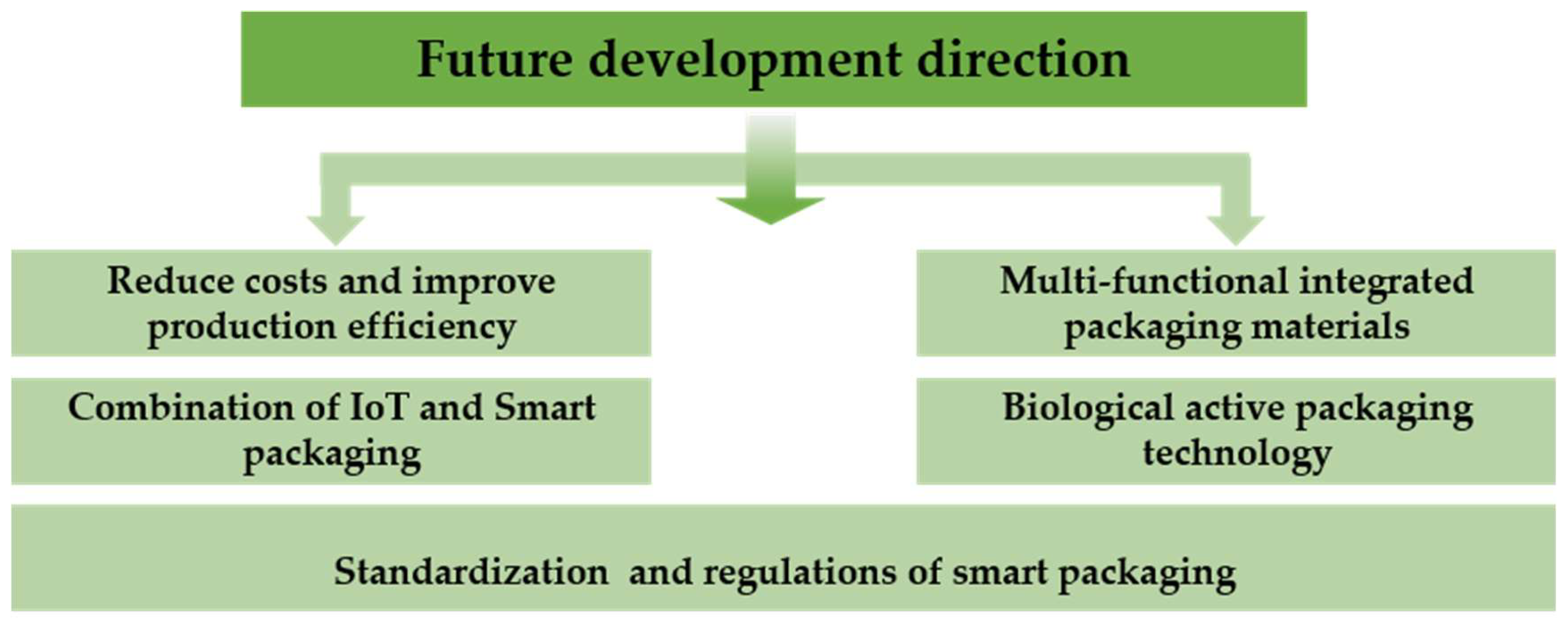

5. Future Development Direction

5.1. Reduce Costs and Improve Production Efficiency

5.2. Multifunctional Integrated Packaging Materials

5.3. Combination of IoT and Smart Packaging

5.4. Biological Smart Packaging Technology

5.5. Standardization and Regulations of Smart Packaging

6. Conclusions and Prospect

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

References

- Kadzińska, J.; Janowicz, M.; Kalisz, S.; Bryś, J.; Lenart, A. An overview of fruit and vegetable edible packaging materials. Packag. Technol. Sci. 2019, 32, 483–495. [Google Scholar] [CrossRef]

- Prokić, D.; Milošević, L.; Jasna, S.; Stojic, N.; Pucarević, M. The role of circular economy in food waste management in fulfilling the United Nations’ sustainable development goals. Acta Univ. Sapientiae Aliment. 2022, 15, 51–66. [Google Scholar] [CrossRef]

- Gasparrini, M.; Forbes-Hernandez, T.Y.; Cianciosi, D.; Quiles, J.L.; Mezzetti, B.; Xiao, J.; Giampieri, F.; Battino, M. The efficacy of berries against lipopolysaccharide-induced inflammation: A review. Trends Food Sci. Technol. 2021, 117, 74–91. [Google Scholar] [CrossRef]

- Li, W.; Lin, M.; Li, Y.; Yu, Q.; Liang, Y.; Zhang, Z. Advances in Metabolomics of Pear Fruit. Acta Hortic. Sin. 2024, 51, 1595–1609. [Google Scholar]

- Godana, E.A.; Yang, Q.; Zhang, X.; Zhao, L.; Wang, K.; Dhanasekaran, S.; Mehari, T.G.; Zhang, H. Biotechnological and Biocontrol Approaches for Mitigating Postharvest Diseases Caused by Fungal Pathogens and Their Mycotoxins in Fruits: A Review. J. Agric. Food Chem. 2023, 71, 17584–17596. [Google Scholar] [CrossRef]

- Wu, J.; Hong, X.; Wang, C.; Qi, S.; Ye, Q.; Qin, Z.; Zhou, H.; Li, C.; Wang, W.; Zhou, N. Joint associations of fresh fruit intake and physical activity with glycaemic control among adult patients with diabetes: A cross-sectional study. BMJ Open 2022, 12, e056776. [Google Scholar] [CrossRef]

- You, Y.; Zhou, Y.; Duan, X.; Mao, X.; Li, Y. Research progress on the application of different preservation methods for controlling fungi and toxins in fruit and vegetable. Crit. Rev. Food Sci. Nutr. 2023, 63, 12441–12452. [Google Scholar] [CrossRef]

- Guo, Z.M.; Wang, M.M.; Agyekum, A.A.; Wu, J.Z.; Chen, Q.S.; Zuo, M.; El-Seedi, H.R.; Tao, F.F.; Shi, J.Y.; Ouyang, Q.; et al. Quantitative detection of apple watercore and soluble solids content by near infrared transmittance spectroscopy. J. Food Eng. 2020, 279, 109955. [Google Scholar] [CrossRef]

- Guo, Z.M.; Guo, C.; Sun, L.; Zuo, M.; Chen, Q.S.; El-Seedi, H.R.; Zou, X.B. Identification of the apple spoilage causative fungi and prediction of the spoilage degree using electronic nose. J. Food Process Eng. 2021, 44, e13816. [Google Scholar] [CrossRef]

- Guo, Z.M.; Guo, C.; Chen, Q.S.; Ouyang, Q.; Shi, J.Y.; El-Seedi, H.R.; Zou, X.B. Classification for Penicillium expansum Spoilage and Defect in Apples by Electronic Nose Combined with Chemometrics. Sensors 2020, 20, 2130. [Google Scholar] [CrossRef]

- Maringgal, B.; Hashim, N.; Mohamed Amin Tawakkal, I.S.; Muda Mohamed, M.T. Recent advance in edible coating and its effect on fresh/fresh-cut fruits quality. Trends Food Sci. Technol. 2020, 96, 253–267. [Google Scholar] [CrossRef]

- Herman, R.A.; Ayepa, E.; Fometu, S.S.; Shittu, S.; Davids, J.S.; Wang, J. Mulberry fruit post-harvest management: Techniques, composition and influence on quality traits—A review. Food Control 2022, 140, 109126. [Google Scholar] [CrossRef]

- Zhou, Y.L.; Zhao, L.; Chen, Y.Q.; Dhanasekaran, S.; Chen, X.F.; Zhang, X.Y.; Yang, X.Z.; Wu, M.Y.; Song, Y.D.; Zhang, H.Y. Study on the control effect and physiological mechanism of Wickerhamomyces anomalus on primary postharvest diseases of peach fruit. Int. J. Food Microbiol. 2024, 413, 110575. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Yao, Y.Q.; Dhanasekaran, S.; Li, J.; Ngea, G.L.N.; Li, B.; Zhao, L.A.; Zhang, H.Y. Controlling black spot of postharvest broccoli by Meyerozyma guilliermondii and its regulation on ROS metabolism of broccoli. Biol. Control. 2022, 170, 104938. [Google Scholar] [CrossRef]

- Ribeiro, I.S.; Maciel, G.M.; Bortolini, D.G.; Fernandes, I.D.A.A.; Maroldi, W.V.; Pedro, A.C.; Rubio, F.T.V.; Haminiuk, C.W.I. Sustainable innovations in edible films and coatings: An overview. Trends Food Sci. Technol. 2024, 143, 104272. [Google Scholar] [CrossRef]

- Kang, L.X.; Liang, Q.F.; Liu, Y.X.; Rashid, A.; Qayum, A.; Zhou, C.W.; Han, X.; Ren, X.F.; Chi, Z.Z.; Chi, R.H.; et al. Preparation technology and preservation mechanism of novel Ag NPs-loaded ZIF-67 packaging film. Food Packag. Shelf Life 2024, 45, 101338. [Google Scholar] [CrossRef]

- Rashid, A.; Qayum, A.; Liang, Q.F.; Kang, L.X.; Raza, H.; Chi, Z.Z.; Chi, R.H.; Ren, X.F.; Ma, H.L. Preparation and characterization of ultrasound-assisted essential oil-loaded nanoemulsions stimulated pullulan-based bioactive film for strawberry fruit preservation. Food Chem. 2023, 422, 136254. [Google Scholar] [CrossRef]

- Tahir, H.E.; Hashim, S.B.H.; Arslan, M.; Mahunu, G.K.; Shishir, M.R.I.; Zhihua, L.; Khan, S.; Mariod, A.A.; Abaker, H.A.M.; Ibrahim, H.E.; et al. Characterization and identification of the key volatile and non-volatile substances of Vangueria madagascariensis J.F. Gmel fruits (Kirkir) and exploration of their binding interactions with olfactory and taste receptors using computational chemistry methodology. Food Chem. 2024, 460, 140631. [Google Scholar] [CrossRef]

- Kang, L.X.; Liang, Q.F.; Chen, H.X.; Zhou, Q.S.; Chi, Z.Z.; Rashid, A.; Ma, H.L.; Ren, X.F. Preparation technology and preservation mechanism of γ-CD-MOFs biaological packaging film loaded with curcumin. Food Chem. 2023, 420, 136142. [Google Scholar] [CrossRef]

- Wu, Y.Q.; Zhang, J.J.; Hu, X.T.; Huang, X.W.; Zhang, X.A.; Zou, X.B.; Shi, J.Y. Preparation of edible antibacterial films based on corn starch /carbon nanodots for bioactive food packaging. Food Chem. 2024, 444, 138467. [Google Scholar] [CrossRef]

- Zhang, J.J.; Zhang, J.N.; Huang, X.W.; Shi, J.Y.; Muhammad, A.; Zhai, X.D.; Xiao, J.B.; Li, Z.H.; Povey, M.; Zou, X.B. Study on cinnamon essential oil release performance based on pH-triggered dynamic mechanism of active packaging for meat preservation. Food Chem. 2023, 400, 134030. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.J.; Huang, X.W.; Zhang, J.N.; Liu, L.; Shi, J.Y.; Muhammad, A.; Zhai, X.D.; Zou, X.B.; Xiao, J.B.; Li, Z.H.; et al. Development of nanofiber indicator with high sensitivity for pork preservation and freshness monitoring. Food Chem. 2022, 381, 132224. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.K.; Li, M.R.; Li, Y.X.; Huang, X.W.; Li, Z.H.; Zhai, X.D.; Shi, J.Y.; Zou, X.B.; Xiao, J.B.; Sun, Y.; et al. Sodium alginate/guar gum based nanocomposite film incorporating β-Cyclodextrin/persimmon pectin-stabilized baobab seed oil Pickering emulsion for mushroom preservation. Food Chem. 2024, 437, 137891. [Google Scholar] [CrossRef]

- Kang, L.X.; Liang, Q.F.; Chen, H.X.; Zhou, Q.S.; Chi, Z.Z.; Rashid, A.; Ma, H.L.; Ren, X.F. Insights into ultrasonic treatment on the properties of pullulan/oat protein/nisin composite film:mechanical, structural and physicochemical properties. Food Chem. 2023, 402, 134237. [Google Scholar] [CrossRef]

- Rashid, A.; Qayum, A.; Bacha, S.A.; Liang, Q.F.; Liu, Y.X.; Kang, L.X.; Chi, Z.Z.; Chi, R.H.; Han, X.; Ekumah, J.N.; et al. Preparation and functional characterization of pullulan-sodium alginate composite film enhanced with ultrasound-assisted clove essential oil Nanoemulsions for effective preservation of cherries and mushrooms. Food Chem. 2024, 457, 140048. [Google Scholar] [CrossRef]

- Zhang, J.N.; Zhang, J.J.; Guan, Y.F.; Huang, X.W.; Arslan, M.; Shi, J.Y.; Li, Z.H.; Gong, Y.Y.; Holmes, M.; Zou, X.B. High- sensitivity bilayer nanofiber film based on polyvinyl alcohol/sodium alginate/polyvinylidene fluoride for pork spoilage visual monitoring and preservation. Food Chem. 2022, 394, 133439. [Google Scholar] [CrossRef]

- Huang, W.; Wang, X.; Zhang, J.; Xia, J.; Zhang, X. Improvement of blueberry freshness prediction based on machine learning and multi-source sensing in the cold chain logistics. Food Control 2023, 145, 109496. [Google Scholar] [CrossRef]

- Liang, N.; Sun, S.; Zhang, C.; He, Y.; Qiu, Z. Advances in infrared spectroscopy combined with artificial neural network for the authentication and traceability of food. Crit. Rev. Food Sci. Nutr. 2022, 62, 2963–2984. [Google Scholar] [CrossRef]

- Guo, C.; Zhu, C.; Liu, Y.; Huang, R.; Cao, B.; Zhu, Q.; Zhang, R.; Zhang, B. End-to-End lightweight Transformer-Based neural network for grasp detection towards fruit robotic handling. Comput. Electron. Agric. 2024, 221, 109014. [Google Scholar] [CrossRef]

- Chen, Z.; Sun, Y.; Zhang, X.; Shen, Y.; Khalifa, S.A.M.; Huang, X.; Shi, J.; Li, Z.; Zou, X. Green and sustainable self-cleaning flexible SERS base: Utilized for cyclic-detection of residues on apple surface. Food Chem. 2024, 441, 138345. [Google Scholar] [CrossRef]

- Dai, L.; Wang, X.; Mao, X.; He, L.; Li, C.; Zhang, J.; Chen, Y. Recent advances in starch-based coatings for the postharvest preservation of fruits and vegetables. Carbohydr. Polym. 2024, 328, 121736. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Liang, J.; Wu, Y.Q.; Li, W.L.; Huang, X.W.; Li, Z.H.; Zhang, X.N.; Zou, X.B.; Shi, J.Y. Fish freshness monitoring based on bilayer cellulose acetate/polyvinylidene fluoride membranes containing ZIF-8 loaded curcumin. Food Chem. 2024, 463, 141054. [Google Scholar] [CrossRef]

- Hashim SB, H.; Tahir, H.E.; Li, L.; Zhang, J.J.; Zhai, X.D.; Mahdi, A.A.; Awad, F.N.; Hassan, M.M.; Zou, X.B.; Shi, J.Y. Intelligent colorimetric pH sensoring packaging films based on sugarcane wax/agar integrated with butterfly pea flower extract for optical tracking of shrimp freshness. Food Chem. 2022, 373, 131514. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Zhang, J.J.; Zou, X.B.; Arslan, M.; Shi, J.Y.; Zhai, X.D.; Xiao, J.B.; Wang, X.; Huang, X.W.; Li, Z.H.; et al. A high-stable and sensitive colorimetric nanofiber sensor based on PCL incorporating anthocyanins for shrimp freshness. Food Chem. 2022, 377, 131909. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Chen, P.; Wang, M.; Zuo, M.; El-Seedi, H.R.; Chen, Q.; Shi, J.; Zou, X. Rapid enrichment detection of patulin and alternariol in apple using surface enhanced Raman spectroscopy with coffee-ring effect. Lwt-Food Sci. Technol. 2021, 152, 112333. [Google Scholar] [CrossRef]

- Ma, Y.; Yang, W.; Xia, Y.; Xue, W.; Wu, H.; Li, Z.; Zhang, F.; Qiu, B.; Fu, C. Properties and Applications of Intelligent Packaging Indicators for Food Spoilage. Membranes 2022, 12, 477. [Google Scholar] [CrossRef]

- Shuang, F.-F.; Zong, C.M.; Wang, C.C.; Hu, R.-Z.; Shen, Y.-S.; Ju, Y.-X.; Yao, X.-H.; Chen, T.; Zhao, W.-G.; Zhang, D.-Y. Chlorogenic acid and cellulose nanocrystal-assisted crosslinking preparation of a silk-based film to extend the shelf life of strawberries. Lwt-Food Sci. Technol. 2022, 172, 114218. [Google Scholar] [CrossRef]

- Xu, B.G.; Tiliwa, E.S.; Yan, W.Q.; Azam, S.M.R.; Wei, B.X.; Zhou, C.S.; Ma, H.L.; Bhandari, B. Recent development in high quality drying of fruits and vegetables assisted by ultrasound: A review. Food Res. Int. 2022, 152, 110744. [Google Scholar] [CrossRef]

- Wahia, H.; Mustapha, A.T.; Fakayode, O.A.; Zhang, L.; Zhou, C.S.; Dabbour, M. Inactivating Alicyclobacillus acidoterrestris spores with UVLED: Unraveling the role of turbidity, reactive oxygen species, and water dynamics. Food Control 2025, 168, 110941. [Google Scholar] [CrossRef]

- Wu, B.A.; Ma, Y.J.; Guo, Y.T.; Zielinska, M.; Gao, K.; Song, C.Y.; Bouhile, Y.; Qiu, C.C.; Pan, Z.L.; Ma, H.L. Research progress in the application of catalytic infrared technology in fruit and vegetable processing. Compr. Rev. Food Sci. Food Saf. 2024, 23, e13291. [Google Scholar] [CrossRef]

- Feng, Y.B.; Xu, B.G.; Yagoub, A.E.A.; Ma, H.L.; Sun, Y.H.; Xu, X.; Yu, X.J.; Zhou, C.S. Role of drying techniques on physical, rehydration, flavor, bioactive compounds and antioxidant characteristics of garlic. Food Chem. 2021, 343, 128404. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Yagoub, A.A.; Sun, Y.H.; Mujumdar, A.S.; Ma, H.L.; Wahia, H.; Zhou, C.S. Intensive pulsed light pretreatment combined with controlled temperature and humidity for convection drying to reduce browning and improve quality of dried shiitake mushrooms. J. Sci. Food Agric. 2021, 101, 5608–5617. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Yagoub, A.A.; Sun, Y.H.; Arun, M.S.; Ma, H.L.; Zhou, C.S. Role of thermal and non-thermal drying techniques on drying kinetics and the physicochemical properties of shiitake mushroom. J. Sci. Food Agric. 2022, 102, 214–222. [Google Scholar] [CrossRef] [PubMed]

- Zan, X.Y.; Shao, Z.Y.; Yang, Y.; Jia, W.; Sun, L.; Cui, F.J.; Li, W.; Zhu, H.A.; Sun, W.J.; Zhang, J.S. Improving overall postharvest quality of straw mushroom using an accessible and low-cost strategy. J. Food Compos. Anal. 2024, 128, 106036. [Google Scholar] [CrossRef]

- Zhang, J.J.; Huang, X.W.; Shi, J.Y.; Liu, L.; Zhang, X.A.; Zou, X.B.; Xiao, J.B.; Zhai, X.D.; Zhang, D.; Li, Y.X.; et al. A visual bi-layer indicator based on roselle anthocyanins with high hydrophobic property for monitoring griskin freshness. Food Chem. 2021, 355, 129573. [Google Scholar] [CrossRef]

- Yang, Z.K.; Zhai, X.D.; Zou, X.B.; Shi, J.Y.; Huang, X.W.; Li, Z.H.; Gong, Y.Y.; Holmes, M.; Povey, M.; Xiao, J.B. Bilayer pH-sensitive colorimetric films with light-blocking ability and electrochemical writing property: Application in monitoring crucian spoilage in smart packaging. Food Chem. 2021, 336, 127634. [Google Scholar] [CrossRef]

- Hashim SB, H.; Tahir, H.E.; Lui, L.; Zhang, J.J.; Zhai, X.D.; Mahdi, A.A.; Ibrahim, N.A.; Mahunu, G.K.; Hassan, M.M.; Xiaobo, Z.; et al. Smart films of carbohydrate-based/sunflower wax/purple Chinese cabbage anthocyanins: A biomarker of chicken freshness. Food Chem. 2023, 399, 133824. [Google Scholar] [CrossRef]

- Tahir, H.E.; Hashim SB, H.; Mahunu, G.K.; Arslan, M.; Shi, J.Y.; Mariod, A.A.; Zhang, J.J.; El-Seedi, H.R.; Zhai, X.D.; Musa, T.H.; et al. Smart films fabricated from natural pigments for measurement of total volatile basic nitrogen (TVB-N) content of meat for freshness evaluation: A systematic review. Food Chem. 2022, 396, 133674. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, X.Y.; Cui, X.H.; Cao, W.H.; Zhang, X.D.; Zhang, Y.K. Classification of Qianxi Tomatoes by Visible/Near Infrared Spectroscopy Combined With GMO-SVM. Spectrosc. Spectr. Anal. 2022, 42, 3291–3297. [Google Scholar] [CrossRef]

- Zhu, R.; Wu, X.H.; Wu, B.; Gao, J.X. High-accuracy classification and origin traceability of peanut kernels based on near-infrared (NIR) spectroscopy using Adaboost—Maximum uncertainty linear discriminant analysis. Curr. Res. Food Sci. 2024, 8, 100766. [Google Scholar] [CrossRef]

- Zhang, C.C.; Yang, Z.K.; Shi, J.Y.; Zou, X.B.; Zhai, X.D.; Huang, X.W.; Li, Z.H.; Holmes, M.; Daglia, M.; Xiao, J.B. Physical properties and bioactivities of chitosan/gelatin-based films loaded with tannic acid and its application on the preservation of fresh-cut apples. Lwt-Food Sci. Technol. 2021, 144, 111223. [Google Scholar] [CrossRef]

- Elalem, Y.K.; Maier, S.; Seifert, R.W. A machine learning-based framework for forecasting sales of new products with short life cycles using deep neural networks. Int. J. Forecast. 2023, 39, 1874–1894. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, M.; Wang, D.; Mujumdar, A.S.; Chen, Y. ANN-GA optimized composite color protectant combined with magnetic field assisted freezing: Effects on the quality of mushroom (Agaricus bisporus). Food Chem. 2024, 453, 139713. [Google Scholar] [CrossRef]

- Ashiagbor, K.; Jayan, H.; Yosri, N.; Amaglo, N.K.; Zou, X.B.; Guo, Z.M. Advancements in SERS based systematic evolution of ligands by exponential enrichment for detection of pesticide residues in fruits and vegetables. Food Chem. 2025, 463, 141394. [Google Scholar] [CrossRef]

- Bei, X.R.; Yu, X.J.; Li, D.Q.; Sun, Q.L.; Yu, Y.H.; Wang, Y.Q.; Okonkwo, C.E.; Zhou, C.S. Heat source replacement strategy using catalytic infrared: A future for energy saving drying of fruits and vegetables. J. Food Sci. 2023, 88, 4827–4839. [Google Scholar] [CrossRef]

- Wang, F.; Zhu, Y.; Qian, L.; Yin, Y.H.; Yuan, Z.Y.; Dai, Y.T.; Zhang, T.; Yang, D.Y.; Qiu, F.X. Lamellar Ti 3 C 2 MXene composite decorated with platinum-doped MoS 2 nanosheets as electrochemical sensing functional platform for highly sensitive analysis of organophosphorus pesticides. Food Chem. 2024, 459, 140379. [Google Scholar] [CrossRef]

- Ma, L.X.; Yang, X.A.; Yin, L.M.; Han, E.; Wang, C.; Zhou, R.Y.; Bai, J.W.; Wang, Y.S.; Guo, Z.M.; Cai, J.R. Rapid dual-modal detection of two types of pesticides in fruits using SERS-based immunoassay. J. Food Compos. Anal. 2024, 136, 106781. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, J.; Huang, X.; Zhai, X.; Li, Z.; Shi, J.; Sobhy, R.; Khalifa, I.; Zou, X. Lemon-derived carbon quantum dots incorporated guar gum/sodium alginate films with enhanced the preservability for blanched asparagus active packaging. Food Res. Int. 2025, 202, 115736. [Google Scholar] [CrossRef]

- Bian, H.; Luo, D.; Shi, J.; Zhou, X.; Xu, T.; Xiao, H.; Dai, H.; Li, T.; Huang, C.; Ragauskas, A.J. Cellulose nanofibrils-based packaging films synergistically reinforced by lignin and tea polyphenols for strawberry preservation. Chem. Eng. J. 2024, 502, 157843. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Y.; Wang, C.; Liu, X.; El-Seedi, H.R.; Gomez, P.L.; Alzamora, S.M.; Zou, X.; Guo, Z. Enhanced composite Co-MOF-derived sodium carboxymethyl cellulose visual films for real-time and in situ monitoring fresh-cut apple freshness. Food Hydrocoll. 2024, 157, 110475. [Google Scholar] [CrossRef]

- Zhan, S.; Yi, F.; Hou, F.; Song, L.; Chen, X.; Jiang, H.; Han, X.; Sun, X.; Liu, Z. Development of pH-freshness smart label based on gellan gum film incorporated with red cabbage anthocyanins extract and its application in postharvest mushroom. Colloids Surf. B Biointerfaces 2024, 236, 113830. [Google Scholar] [CrossRef] [PubMed]

- Maftoonazad, N.; Ramaswamy, H. Design and testing of an electrospun nanofiber mat as a pH biosensor and monitor the pH associated quality in fresh date fruit (Rutab). Polym. Test. 2019, 75, 76–84. [Google Scholar] [CrossRef]

- Zhang, W.; An, H.; Sun, X.; Du, H.; Li, Y.; Yang, M.; Zhu, Z.; Wen, Y. Dual-functional smart indicator for direct monitoring fruit freshness. Food Packag. Shelf Life 2023, 40, 101192. [Google Scholar] [CrossRef]

- Chen, H.-Z.; Zhang, M.; Bhandari, B.; Guo, Z. Applicability of a colorimetric indicator label for monitoring freshness of fresh-cut green bell pepper. Postharvest Biol. Technol. 2018, 140, 85–92. [Google Scholar] [CrossRef]

- Wang, D.Y.; Zhang, M.; Zhu, Q.B.; Adhikari, B. Intelligent vegetable freshness monitoring system developed by integrating eco-friendly fluorescent sensor arrays with deep convolutional neural networks. Chem. Eng. J. 2024, 488, 150739. [Google Scholar] [CrossRef]

- Mahata, B.; Acharyya, S.; Giri, S.; Mahata, T.; Banerji, P.; Guha, P.K. Fruit Freshness Monitoring Employing Chemiresistive Volatile Organic Compound Sensor and Machine Learning. Acs Appl. Nano Mater. 2023, 6, 22829–22836. [Google Scholar] [CrossRef]

- Fatchurrahman, D.; Castillejo, N.; Hilaili, M.; Nurwahyuningsih; Russo, L.; Kondo, N. Analysis of fluorescence changes in different sections of green bell pepper (Capsicum annuum L.) over storage periods. Postharvest Biol. Technol. 2024, 217, 113094. [Google Scholar] [CrossRef]

- Tao, B.R.; Bai, J.N.; Wu, H.; Miao, F.J. Design and research of multi-information fusion RFID sensor for fruit and vegetable quality detection. Microchim. Acta 2024, 191, 568. [Google Scholar] [CrossRef]

- Ben Hattab, C.; Naoui, S.; Latarch, L. Monitoring freshness of Tommy Mango Fruit with an RFID Tag. In Proceedings of the 21st Mediterranean Microwave Symposium (MMS), Pizzo Calabro, Italy, 9–13 May 2022; pp. 131–136. [Google Scholar]

- Karzarjeddi, M.; Ismail, M.Y.; Antti Sirviö, J.; Wang, S.; Mankinen, O.; Telkki, V.-V.; Patanen, M.; Laitinen, O.; Liimatainen, H. Adjustable hydro-thermochromic green nanofoams and films obtained from shapable hybrids of cellulose nanofibrils and ionic liquids for smart packaging. Chem. Eng. J. 2022, 443, 136369. [Google Scholar] [CrossRef]

- Zhang, J.; Tan, J.; Chen, X.; Yin, Y.; Wang, C. High humidity-sensitive discoloration materials fabricated with pH indicator ingredients. Dye Pigment. 2021, 195, 109740. [Google Scholar] [CrossRef]

- Saenjaiban, A.; Singtisan, T.; Suppakul, P.; Jantanasakulwong, K.; Punyodom, W.; Rachtanapun, P. Novel Color Change Film as a Time-Temperature Indicator Using Polydiacetylene/Silver Nanoparticles Embedded in Carboxymethyl Cellulose. Polymers 2020, 12, 2306. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Sun, J.; Zhou, X.; Wu, X.H.; Lu, B.; Dai, C.X. Research on apple origin classification based on variable iterative space shrinkage approach with stepwise regression-support vector machine algorithm and visible-near infrared hyperspectral imaging. J. Food Process Eng. 2020, 43, e13432. [Google Scholar] [CrossRef]

- Mainetti, L.; Mele, F.; Patrono, L.; Simone, F.; Stefanizzi, M.L.; Vergallo, R. An RFID-Based Tracing and Tracking System for the Fresh Vegetables Supply Chain. Int. J. Antennas Propag. 2013, 2013, 531364. [Google Scholar] [CrossRef]

- Cheng, R.; Niu, B.; Fang, X.; Chen, H.; Chen, H.; Wu, W.; Gao, H. Preparation and characterization of water vapor-responsive methylcellulose-polyethylene glycol-400 composite membranes and an indication of freshness of shiitake mushrooms. Int. J. Biol. Macromol. 2024, 270, 132189. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, Y.; Feng, T.; Luo, J.; Sameen, D.E.; Hossen, M.A.; Dai, J.; Li, S.; Qin, W. Development and characterization of aldehyde-sensitive cellulose/chitosan/beeswax colorimetric papers for monitoring kiwifruit maturity. Int. J. Biol. Macromol. 2021, 187, 566–574. [Google Scholar] [CrossRef]

- Yu, Y.; Li, H.; Song, Y.; Mao, B.; Huang, S.; Shao, Z.; Wang, D.; Yan, K.; Zhang, S. Preparation of Fresh-Keeping Paper Using Clove Essential Oil through Pickering Emulsion and Maintaining the Quality of Postharvest Cherry Tomatoes. Foods 2024, 13, 1331. [Google Scholar] [CrossRef]

- Yang, Z.; Li, C.; Wang, T.; Li, Z.; Zou, X.; Huang, X.; Zhai, X.; Shi, J.; Shen, T.; Gong, Y.; et al. Novel gellan gum-based probiotic film with enhanced biological activity and probiotic viability: Application for fresh-cut apples and potatoes. Int. J. Biol. Macromol. 2023, 239, 124128. [Google Scholar] [CrossRef]

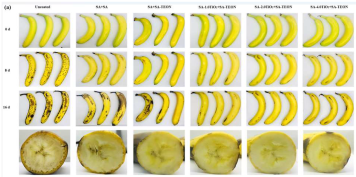

- Yang, Z.; Li, M.; Zhai, X.; Zhao, L.; Tahir, H.E.; Shi, J.; Zou, X.; Huang, X.; Li, Z.; Xiao, J. Development and characterization of sodium alginate/tea tree essential oil nanoemulsion active film containing TiO2 nanoparticles for banana packaging. Int. J. Biol. Macromol. 2022, 213, 145–154. [Google Scholar] [CrossRef]

- Alfi, A.A.; Al-Qahtani, S.D.; Alatawi, N.M.; Attar, R.M.S.; Abu Al-Ola, K.; Habeebullah, T.M.; El-Metwaly, N.M. Simple preparation of novel photochromic polyvinyl alcohol/carboxymethyl cellulose security barcode incorporated with lanthanide-doped aluminate for anticounterfeiting applications. Luminescence 2022, 37, 1152–1161. [Google Scholar] [CrossRef]

- Wang, Z.L.; Cao, C.L.; Yu, H.T. Design and Implementation of Kiwifruit Seedling Tracing System Based on QR Code and Electronic Label. In Proceedings of the 16th IEEE International Wireless Communications and Mobile Computing Conference (IEEE IWCMC), Electr Network, Limassol, Cyprus, 27 July 2020; pp. 2190–2193. [Google Scholar]

- Du, Y.; Yang, F.; Yu, H.; Cheng, Y.; Guo, Y.; Yao, W.; Xie, Y. Fabrication of novel self-healing edible coating for fruits preservation and its performance maintenance mechanism. Food Chem. 2021, 351, 129284. [Google Scholar] [CrossRef]

- Wang, S.Y.; Ma, Y.; Wang, F.J.; Lu, C.H.; Liu, Y.C.; Zhang, S.Z.; Ma, S.F.; Wang, L.Q. Development of cellulose-based self-healing hydrogel smart packaging for fish preservation and freshness indication. Carbohydr. Polym. 2025, 348, 122806. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.Q.; Zhai, X.D.; Yin, L.T.; Shi, J.Y.; Zou, X.B.; Li, Z.H.; Huang, X.W.; Ma, X.D.; Povey, M. A smart bilayer film containing zein/gelatin/carvacrol and polyvinyl alcohol/chitosan/anthocyanin for Lateolabrax japonicus preservation and freshness monitoring. J. Food Meas. Charact. 2023, 17, 6470–6483. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Z.Y.; Dong, Y.; Wang, Y.X. Effect of chitosan coating incorporated with Torreya grandis essential oil on the quality and physiological attributes of loquat fruit. J. Food Meas. Charact. 2022, 16, 2820–2830. [Google Scholar] [CrossRef]

- Riahi, Z.; Rhim, J.-W.; Bagheri, R.; Pircheraghi, G.; Lotfali, E. Carboxymethyl cellulose-based functional film integrated with chitosan-based carbon quantum dots for active food packaging applications. Prog. Org. Coat. 2022, 166, 106794. [Google Scholar] [CrossRef]

- He, Y.; Fei, X.; Li, H. Carboxymethyl cellulose-based nanocomposites reinforced with montmorillonite and ε-poly-l-lysine for antimicrobial active food packaging. J. Appl. Polym. Sci. 2019, 137, 48782. [Google Scholar] [CrossRef]

- Wang, C.; Chang, T.; Dong, S.; Zhang, D.; Ma, C.; Chen, S.; Li, H. Biopolymer films based on chitosan/potato protein/linseed oil/ZnO NPs to maintain the storage quality of raw meat. Food Chem. 2020, 332, 127375. [Google Scholar] [CrossRef]

- Song, W.; Zhai, X.; Shi, J.; Zou, X.; Xue, Y.; Sun, Y.; Sun, W.; Zhang, J.; Huang, X.; Li, Z.; et al. A ratiometric fluorescence amine sensor based on carbon quantum dot-loaded electrospun polyvinylidene fluoride film for visual monitoring of food freshness. Food Chem. 2024, 434, 137423. [Google Scholar] [CrossRef]

- Shen, C.; Chen, W.Q.; Li, C.Z.; Chen, X.C.; Cui, H.Y.; Lin, L. Pickering emulsion stabilized by gliadin/soybean polysaccharide composite colloidal nanoparticle: Physicochemical properties and its application on washing of fresh-cut cabbage. Food Res. Int. 2022, 161, 111886. [Google Scholar] [CrossRef]

- Yu, S.S.; Huang, X.Y.; Wang, L.; Wang, Y.N.; Jiao, X.Y.; Chang, X.H.; Tian, X.Y.; Ren, Y.; Zhang, X.R. Characterization of the volatile flavor profiles of black garlic using nanomaterial-based colorimetric sensor array, HS-SPME-GC/MS coupled with chemometrics strategies. Food Chem. 2024, 458, 140213. [Google Scholar] [CrossRef]

- Liang, N.N.; Hu, X.T.; Li, W.T.; Mwakosya, A.W.; Guo, Z.; Xu, Y.W.; Huang, X.W.; Li, Z.H.; Zhang, X.A.; Zou, X.B.; et al. Fluorescence and colorimetric dual-mode sensor for visual detection of malathion in cabbage based on carbon quantum dots and gold nanoparticles. Food Chem. 2021, 343, 128494. [Google Scholar] [CrossRef]

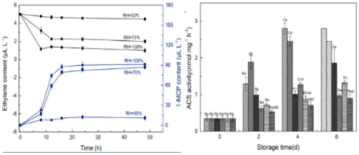

- Wu, W.N.; Ni, X.Y.; Shao, P.; Gao, H.Y. Novel packaging film for humidity-controlled manipulating of ethylene for shelf-life extension of Agaricus bisporus. Lwt-Food Sci. Technol. 2021, 145, 111331. [Google Scholar] [CrossRef]

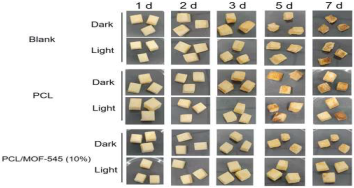

- Zhao, X.; Shi, T.J.; Liu, Y.Y.; Chen, L.J. Porphyrinic Metal-Organic Framework-Loaded Polycaprolactone Composite Films with a High Photodynamic Antibacterial Activity for the Preservation of Fresh-Cut Apples. ACS Appl. Polym. Mater. 2022, 5, 560–566. [Google Scholar] [CrossRef]

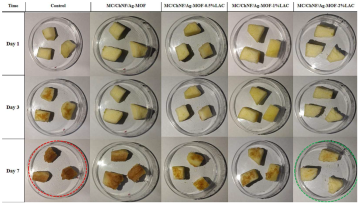

- Tavassoli, M.; Khezerlou, A.; Sani, M.A.; Hashemi, M.; Firoozy, S.; Ehsani, A.; Khodaiyan, F.; Adibi, S.; Noori, S.M.A.; McClements, D.J. Methylcellulose/chitosan nanofiber-based composites doped with lactoferrin-loaded Ag-MOF nanoparticles for the preservation of fresh apple. Int. J. Biol. Macromol. 2024, 259, 129182. [Google Scholar] [CrossRef] [PubMed]

- Xie, D.; Huang, G.; Yang, M.; Yi, S.; Zheng, X.; Zhu, M.; Zhai, H. Bionic modified atmosphere film Inspired by plant stomata with curcumin as controllable gas “Switches” for fruit preservation. Chem. Eng. J. 2024, 500, 156741. [Google Scholar] [CrossRef]

- Ding, K.; Xie, Y.; Xu, H.; Xu, S.; Ge, S.; Li, H.; Chang, X.; Chen, J.; Wang, R.; Shan, Y.; et al. Visible light-responsive TiO2-based hybrid nanofiller reinforced multifunctional chitosan film for effective fruit preservation. Food Chem. 2024, 460, 140539. [Google Scholar] [CrossRef]

- Li, Q.; Chen, Q.; Yang, K.; Liu, H.; Xu, D.; Gu, Y.; Sun, L.; Lei, P.; Wang, R.; Xu, H. ε-Poly-L-lysine/rhamnolipid bifunctional coating based on green electrostatic assembly technology for fruit packaging and preservation. Chem. Eng. J. 2025, 503, 158425. [Google Scholar] [CrossRef]

- Jiang, F.; Liang, Y.; Liu, L.; Zhang, Y.; Deng, Y.; Wei, F.; Xu, C.; Fu, L.; Lin, B. One-pot co-crystallized hexanal-loaded ZIF-8/quaternized chitosan film for temperature-responsive ethylene inhibition and climacteric fruit preservation. Int. J. Biol. Macromol. 2024, 265, 130798. [Google Scholar] [CrossRef]

- Moggia, C.; Sepúlveda, D.; Valdés, M.; Araya, C.M.; Pacheco, P.; Diaz, V.; Lobos, G.A.; Beaudry, R.; Lorca-Alvarez, J. Dangler for Accelerated Dehydration: A Novel System for Assessing the Impacts of Relative Humidity on Fruit Water Loss During Cold Storage of Blueberries. Hortscience 2023, 58, 717–721. [Google Scholar] [CrossRef]

- Nie, X.L.; Shi, H.; Wang, F.; You, C.Q.; Zhang, D.H.; Xiao, Z.H.; Li, X. Biodegradable chitosan-based biofilms incorporated with Camellia oleifera residue protein for food packaging. Food Hydrocoll. 2024, 157, 110436. [Google Scholar] [CrossRef]

- Regmi, S.; Janaswamy, S. Biodegradable films from soyhull cellulosic residue with UV protection and antioxidant properties improve the shelf-life of post-harvested raspberries. Food Chem. 2024, 460, 140672. [Google Scholar] [CrossRef]

- Salamat, R.; Ghassemzadeh, H.R.; Ranjbar, F.; Jalali, A.; Mahajan, P.; Herppich, W.B.; Mellmann, J. The effect of additional packaging barrier, air moment and cooling rate on quality parameters of button mushroom (Agaricus bisporus). Food Packag. Shelf Life 2020, 23, 100448. [Google Scholar] [CrossRef]

- Amin, U.; Khan, M.K.I.; Maan, A.A.; Nazir, A.; Riaz, S.; Khan, M.U.; Sultan, M.; Munekata, P.E.S.; Lorenzo, J.M. Biodegradable active, intelligent, and smart packaging materials for food applications. Food Packag. Shelf Life 2022, 33, 100903. [Google Scholar] [CrossRef]

- Seretloa, S.; Alatise, M. Development of Data Acquisition System for Real-Time Monitoring Using a Smartphone. In Proceedings of the 5th International Conference on Artificial Intelligence, Big Data, Computing and Data Communication Systems (ICABCD), Durban, South Africa, 4–5 August 2022. [Google Scholar]

- Lamberty, A.; Kreyenschmidt, J. Ambient Parameter Monitoring in Fresh Fruit and Vegetable Supply Chains Using Internet of Things-Enabled Sensor and Communication Technology. Foods 2022, 11, 1777. [Google Scholar] [CrossRef] [PubMed]

- Dwibedi, V.; Kaur, G.; George, N.; Rana, P.; Ge, Y.H.; Sun, T. Research progress in the preservation and packaging of fruits and vegetables: From traditional methods to innovative technologies. Food Packag. Shelf Life 2024, 46, 101385. [Google Scholar] [CrossRef]

- Perumal, A.B.; Huang, L.X.; Nambiar, R.B.; He, Y.; Li, X.L.; Sellamuthu, P.S. Application of essential oils in packaging films for the preservation of fruits and vegetables: A review. Food Chem. 2022, 375, 131810. [Google Scholar] [CrossRef]

- Pham, T.T.; Nguyen, L.L.; Dam, M.S.; Baranyai, L. Application of Edible Coating in Extension of Fruit Shelf Life: Review. Agriengineering 2023, 5, 520–536. [Google Scholar] [CrossRef]

- Ding, F.Y.; Long, S.M.; Huang, X.W.; Shi, J.Y.; Povey, M.; Zou, X.B. Emerging Pickering emulsion films for bio-based food packaging applications. Food Packag. Shelf Life 2024, 42, 101242. [Google Scholar] [CrossRef]

- Rehman, A.; Liang, Q.F.; Karim, A.; Assadpour, E.; Jafari, S.M.; Rasheed, H.A.; Virk, M.S.; Qayyum, A.; Suleria, H.A.R.; Ren, X.F. Pickering high internal phase emulsions stabilized by biopolymeric particles: From production to high-performance applications. Food Hydrocoll. 2024, 150, 109751. [Google Scholar] [CrossRef]

- Li, H.X.; Zhou, M.; Mohammed, A.A.Y.; Chen, L.; Zhou, C. From fruit and vegetable waste to degradable bioplastic films and advanced materials: A review. Sustain. Chem. Pharm. 2022, 30, 100859. [Google Scholar] [CrossRef]

| Type | Material | Response Factor | Result | Reference |

|---|---|---|---|---|

| Temperature and humidity smart label | Metal ion | Humidity, temperature | Color variation: Light green-blue; green-red:  | [70] |

| Cresol red/thymol blue | Humidity | Color variation: lilac-yellow:  | [71] | |

| PDA, nanoparticles | Temperature | Fruits and vegetables: AgNPs produce color changes with temperature changes to monitor fruit and vegetable quality. color variation: purple–red.  | [72] | |

| Type | Smart material | Response factor | Result | Reference |

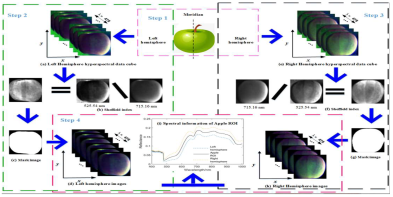

| Integrated smart label | Visible near-infrared spectroscopy (Vis-NIR), hyperspectral imaging technique | Fruit and vegetable appearance | Apple: The method of variable iterative space contraction combined with stepwise regression was used to manage the origin and quality of apples.  | [73] |

| RFID optical sensor | Color | Atlas acquisition:  | [72] | |

| No RFID traceability system | Position tracking | Fruit and vegetable: Use a combination of innovative RF technologies, such as RFID and NFC, and key international standards, such as EPC global, to track information about products purchased by consumers  | [74] | |

| Type | Smart material | Response factor | Result | Reference |

| Smart indicating label | PEG-400 | Steam | Sewant mushrooms: the freshness of fruits and vegetables is indicated by their sensitivity to water vaporcolor change: Completely opaque–transparent:  | [75] |

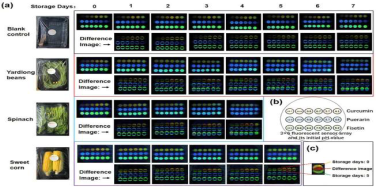

| curcumin, puerarin, and fisetin | Volatile organic compounds | Green beans, spinach, sweet corn: development and application of a 3 × 6 fluorescent sensor array that exhibits pH-sensitive properties, utilizing curcumin, puerarin, and fisetin. Volatile components are measured by this sensor.  | [65] | |

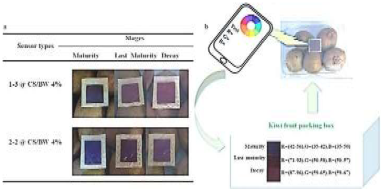

| Methyl red/bromocresol purple | Aldehyde | Kiwi fruit: developed an in-package colorimetric paper to monitor the ripeness of kiwifruit by detecting the release of aldehydes. Color changes: blue-deep red–red.  | [76] | |

| Type | Smart material | Response factor | Result | Reference |

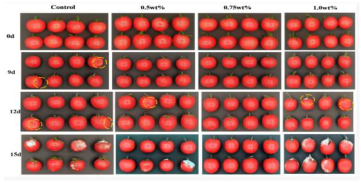

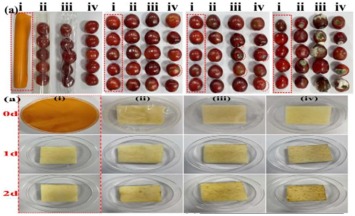

| Active freshness-keeping packaging | Clove Essential Oil | Microorganism | Cherry tomatoes: using the antioxidant and antibacterial properties of clove essential oil, it can effectively extend the freshness life of fruits and vegetables.  | [77] |

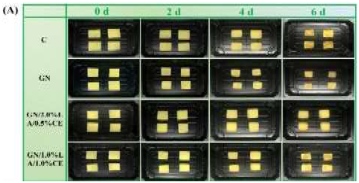

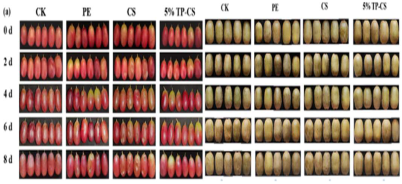

| L. lactis | Bacteria | Fresh-cut apples, potatoes: the incorporation of Lactococcus lactis (LA) significantly enhanced the antibacterial activity of the film, extending the shelf life of fruits and vegetables.  | [78] | |

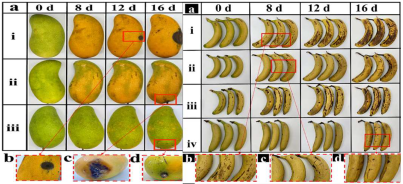

| Tree essential oil, TiO2 | Fungus | Banana: Tea tree essential oil has anti-fungal and DPPH scavenging activity, which can effectively improve the quality of bananas.  | [79] |

| Packaging | Purpose | Object | Reference |

|---|---|---|---|

| Ethylene-humidity regulation | Delay the softening, browning, and weight loss of mushrooms | Agaricus bisporus:  | [93] |

| Porphyrinic metal–organic framework | High photodynamic antibacterial activity | Fresh-cut apples:  | [94] |

| Ag-MOF nanoparticles | Preservation | Fresh apple:  | [95] |

| Bionic-modified atmosphere film | Preservation | Cherries and fresh-cut apple slices:  | [96] |

| Smart packaging | Purpose | Object | Reference |

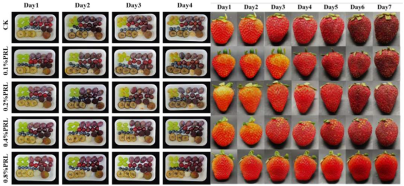

| Photocatalytic multifunctional film | Reduces respiration and transpiration and slows browning | Grapes and kiwifruit:  | [97] |

| Dual-functional coatings | Anti-fog and antibacterial | Different fresh fruits and strawberries:  | [98] |

| Multifunctional nanocomposite film | Antibacterial, UV resistance, and water retention properties | banana and mango:  | [99] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, L.; Huang, X.; Li, Z.; Qin, Z.; Zhang, N.; Zhai, X.; Shi, J.; Zhang, J.; Shen, T.; Zhang, R.; et al. Application of Smart Packaging in Fruit and Vegetable Preservation: A Review. Foods 2025, 14, 447. https://doi.org/10.3390/foods14030447

Du L, Huang X, Li Z, Qin Z, Zhang N, Zhai X, Shi J, Zhang J, Shen T, Zhang R, et al. Application of Smart Packaging in Fruit and Vegetable Preservation: A Review. Foods. 2025; 14(3):447. https://doi.org/10.3390/foods14030447

Chicago/Turabian StyleDu, Liuzi, Xiaowei Huang, Zhihua Li, Zhou Qin, Ning Zhang, Xiaodong Zhai, Jiyong Shi, Junjun Zhang, Tingting Shen, Roujia Zhang, and et al. 2025. "Application of Smart Packaging in Fruit and Vegetable Preservation: A Review" Foods 14, no. 3: 447. https://doi.org/10.3390/foods14030447

APA StyleDu, L., Huang, X., Li, Z., Qin, Z., Zhang, N., Zhai, X., Shi, J., Zhang, J., Shen, T., Zhang, R., & Wang, Y. (2025). Application of Smart Packaging in Fruit and Vegetable Preservation: A Review. Foods, 14(3), 447. https://doi.org/10.3390/foods14030447