Advances in Processing Techniques and Determinants of Sweet Potato Starch Gelatinization

Abstract

1. Introduction

2. Processing Techniques for Gelatinization of Sweet Potato Starch

2.1. Moist Heat Processing

2.2. Steaming

2.3. Baking

2.4. Frying

2.5. Microwave Processing

2.6. Extrusion Processing

2.7. High Hydrostatic Pressure

2.8. Spray Drying

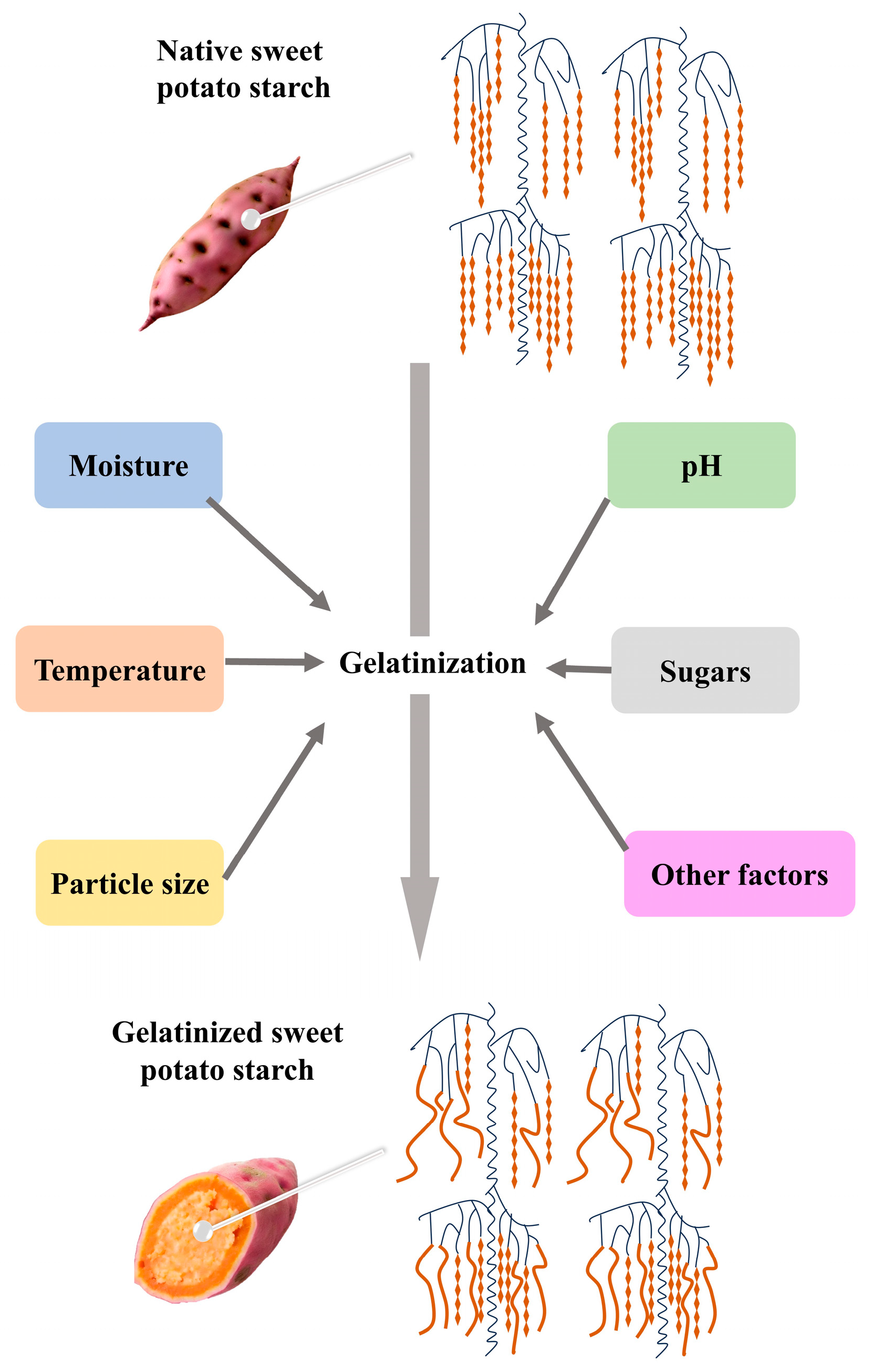

3. Determinants of Gelatinization in Sweet Potato Starch

3.1. Moisture Content

3.2. Temperature

3.3. Amylose/Amylopectin Ratio

3.4. Particle Size

3.5. pH

3.6. Sugars

4. Applications of Gelatinized Sweet Potato Starch in Food

5. Conclusions and Future Perspective

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alam, M.K. A comprehensive review of sweet potato (Ipomoea batatas [L.] Lam): Revisiting the associated health benefits. Trends Food Sci. Technol. 2021, 115, 512–529. [Google Scholar] [CrossRef]

- Alam, M.K.; Rana, Z.H.; Islam, S.N. Comparison of the proximate composition, total carotenoids and total polyphenol content of nine orange-fleshed sweet potato varieties grown in bangladesh. Foods 2016, 5, 64. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Zhao, L.; Bian, X.; Guo, K.; Zhou, L.; Wei, C. Characterization and comparative study of starches from seven purple sweet potatoes. Food Hydrocoll. 2018, 80, 168–176. [Google Scholar] [CrossRef]

- Lan, M.-Y.; Lin, J.-A.; Chen, S.-Y.; Yen, G.-C. Effect of multi-processing technologies on the quality of sweet potato starch and associated starch pearl products. Food Biosci. 2024, 62, 105286. [Google Scholar] [CrossRef]

- Sudheesh, C.; Varsha, L.; Sunooj, K.V.; Pillai, S. Influence of crystalline properties on starch functionalization from the perspective of various physical modifications: A review. Int. J. Biol. Macromol. 2024, 280, 136059. [Google Scholar] [CrossRef]

- Shrivastava, A.; Gupta, R.K.; Srivastav, P.P. Exploring novel frontiers of advancements in purple yam (Dioscorea alata L.) starch extraction, modification, characterization, applications in food and other industries. Meas. Food 2024, 15, 100196. [Google Scholar] [CrossRef]

- Yan, X.; McClements, D.J.; Luo, S.; Liu, C.; Ye, J. Recent advances in the impact of gelatinization degree on starch: Structure, properties and applications. Carbohydr. Polym. 2024, 340, 122273. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Zhang, L.; Liu, W.; Liu, Q.; Wang, F.; Zhang, H.; Hu, H.; Blecker, C. Physicochemical and structural characterization of potato starch with different degrees of gelatinization. Foods 2021, 10, 1104. [Google Scholar] [CrossRef]

- Shigematsu, T.; Furukawa, N.; Takaoka, R.; Hayashi, M.; Sasao, S.; Ueno, S.; Nakajima, K.; Kido, M.; Nomura, K.; Iguchi, A. Effect of high pressure on the saccharification of starch in the tuberous root of sweet potato (Ipomoea batatas). Biophys. Chem. 2017, 231, 105–110. [Google Scholar] [CrossRef]

- de Oliveira, M.M.; Tribst, A.A.L.; de CastroLeite Júnior, B.R.; de Oliveira, R.A.; Cristianini, M. Effects of high pressure processing on cocoyam, peruvian carrot, and sweet potato: Changes in microstructure, physical characteristics, starch, and drying rate. Innov. Food Sci. Emerg. Technol. 2015, 31, 45–53. [Google Scholar] [CrossRef]

- Kumar, Y.; Singh, L.; Sharanagat, V.S.; Patel, A.; Kumar, K. Effect of microwave treatment (low power and varying time) on potato starch: Microstructure, thermo-functional, pasting and rheological properties. Int. J. Biol. Macromol. 2020, 155, 27–35. [Google Scholar] [CrossRef] [PubMed]

- Xia, H.; Li, Y.; Gao, Q. Preparation and properties of rs4 citrate sweet potato starch by heat-moisture treatment. Food Hydrocoll. 2016, 55, 172–178. [Google Scholar] [CrossRef]

- Huang, T.-T.; Zhou, D.-N.; Jin, Z.-Y.; Xu, X.-M.; Chen, H.-Q. Effect of repeated heat-moisture treatments on digestibility, physicochemical and structural properties of sweet potato starch. Food Hydrocoll. 2016, 54, 202–210. [Google Scholar] [CrossRef]

- Guclu, G.; Dagli, M.M.; Aksay, O.; Keskin, M.; Kelebek, H.; Selli, S. Comparative elucidation on the phenolic fingerprint, sugars and antioxidant activity of white, orange and purple-fleshed sweet potatoes (Ipomoea batatas L.) as affected by different cooking methods. Heliyon 2023, 9, e18684. [Google Scholar] [CrossRef]

- Musilová, J.; Franková, H.; Fedorková, S.; Lidiková, J.; Vollmannová, A.; Sulírová, K.; Árvay, J.; Kasal, P. Comparison of polyphenols, phenolic acids, and antioxidant activity in sweet potato (Ipomoea batatas L.) tubers after heat treatments. J. Agric. Food Res. 2024, 18, 101271. [Google Scholar] [CrossRef]

- Rahman, M.H.; Zhang, M.; Sun, H.-N.; Mu, T.-H. Comparative study of thermo-mechanical, rheological, and structural properties of gluten-free model doughs from high hydrostatic pressure treated maize, potato, and sweet potato starches. Int. J. Biol. Macromol. 2022, 204, 725–733. [Google Scholar] [CrossRef]

- Wang, T.; Chen, B.; Shen, Y.; Wong, J.; Yang, C.; Lin, T. Influences of superheated steaming and roasting on the quality and antioxidant activity of cooked sweet potatoes. Int. J. Food Sci. Technol. 2012, 47, 1720–1727. [Google Scholar] [CrossRef]

- Sinoda, O.; Kodera, S.; Oya, C. The chemistry of cooking: The chemical changes of carbohydrates in the sweet potato according to various methods of cooking. Biochem. J. 1931, 25, 1973–1976. [Google Scholar] [CrossRef] [PubMed]

- Saleh, M.; Lee, Y.; Obeidat, H. Effects of incorporating nonmodified sweet potato (Ipomoea batatas) flour on wheat pasta functional characteristics. J. Texture Stud. 2018, 49, 512–519. [Google Scholar] [CrossRef]

- Somaratne, G.; Ye, A.; Nau, F.; Ferrua, M.J.; Dupont, D.; Singh, R.P.; Singh, J. Role of biochemical and mechanical disintegration on β-carotene release from steamed and fried sweet potatoes during in vitro gastric digestion. Food Res. Int. 2020, 136, 109481. [Google Scholar] [CrossRef] [PubMed]

- Kako, Y.; Llave, Y.; Sakai, N.; Fukuoka, M. Computer simulation of microwave cooking of sweet potato—Kinetics analysis of reactions in the maltose production process and their modeling. J. Food Eng. 2023, 349, 111469. [Google Scholar] [CrossRef]

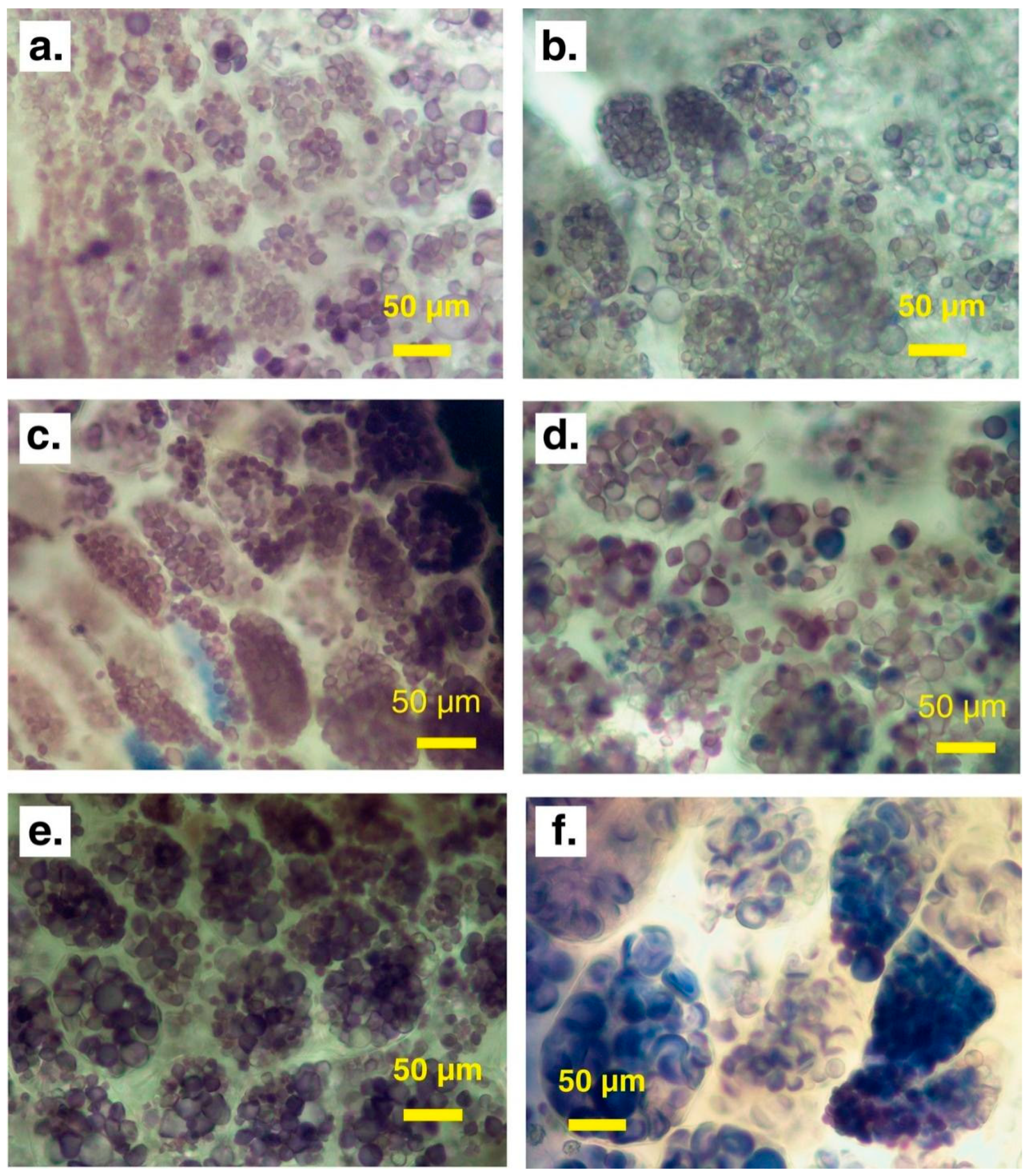

- Han, H.; Hou, J.; Yang, N.; Zhang, Y.; Chen, H.; Zhang, Z.; Shen, Y.; Huang, S.; Guo, S. Insight on the changes of cassava and potato starch granules during gelatinization. Int. J. Biol. Macromol. 2019, 126, 37–43. [Google Scholar] [CrossRef]

- Kim, H.W.; Kim, J.B.; Cho, S.M.; Chung, M.N.; Lee, Y.M.; Chu, S.M.; Che, J.H.; Kim, S.N.; Kim, S.Y.; Cho, Y.S.; et al. Anthocyanin changes in the korean purple-fleshed sweet potato, shinzami, as affected by steaming and baking. Food Chem. 2012, 130, 966–972. [Google Scholar] [CrossRef]

- Bedin, A.C.; Lacerda, L.G.; Bach, D.; Demiate, I.M.; Junges, M.F.D. Influence of cooking method on the in vitro digestibility of starch from sweet potato roots. Braz. Arch. Biol. Technol. 2023, 66, e23230872. [Google Scholar] [CrossRef]

- Chan, C.-F.; Chiang, C.-M.; Lai, Y.-C.; Huang, C.-L.; Kao, S.-C.; Liao, W.C. Changes in sugar composition during baking and their effects on sensory attributes of baked sweet potatoes. J. Food Sci. Technol. 2014, 51, 4072–4077. [Google Scholar] [CrossRef]

- Ravli, Y.; Da Silva, P.; Moreira, R.G. Two-stage frying process for high-quality sweet-potato chips. J. Food Eng. 2013, 118, 31–40. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, Y.; Cao, Y.; Xia, W.; Jiang, Q. Application of simultaneous combination of microwave and steam cooking to improve nutritional quality of cooked purple sweet potatoes and saving time. Innov. Food Sci. Emerg. Technol. 2016, 36, 303–310. [Google Scholar] [CrossRef]

- Liao, L.; Huihui, L.; Wu, W. Processability and physical-functional properties of purple sweet potato powder as influenced by explosion puffing drying. J. Food Meas. Charact. 2021, 15, 944–952. [Google Scholar] [CrossRef]

- Liu, Y.; Olajide, T.; Sun, M.; Ji, M.; Yoong, J.; Weng, X. Physicochemical properties of red palm oil extruded potato and sweet potato snacks. Grasas Aceites 2021, 72, e412. [Google Scholar] [CrossRef]

- Iwe, M.O.; Van Zuilichem, D.J.; Ngoddy, P.O. Extrusion cooking of blends of soy flour and sweet potato flour on specific mechanical energy (sme), extrudate, temperature and torque. J. Food Process. Preserv. 2001, 25, 251–266. [Google Scholar] [CrossRef]

- Cui, R.; Zhu, F. Physicochemical properties and bioactive compounds of different varieties of sweetpotato flour treated with high hydrostatic pressure. Food Chem. 2019, 299, 125129. [Google Scholar] [CrossRef]

- dos Santos, T.P.R.; Franco, C.M.L.; do Carmo, E.L.; Jane, J.-L.; Leonel, M. Effect of spray-drying and extrusion on physicochemical characteristics of sweet potato starch. J. Food Sci. Technol. 2019, 56, 376–383. [Google Scholar] [CrossRef] [PubMed]

- Jiang, H.; Ling, B.; Zhou, X.; Wang, S. Effects of combined radio frequency with hot water blanching on enzyme inactivation, color and texture of sweet potato. Innov. Food Sci. Emerg. Technol. 2020, 66, 102513. [Google Scholar] [CrossRef]

- Mao, C.; Ye, P.; Liu, T.; Song, M.; Xie, Y.; Pang, H.; Wang, Y.; Chen, X.; Wang, K.; Wang, Y. Evaluation of mechanical properties, heating rate and radio frequency explosive puffing (rfep) quality of purple sweet potato under different moisture contents and moisture equilibrium process. Innov. Food Sci. Emerg. Technol. 2024, 93, 103611. [Google Scholar] [CrossRef]

- Imaizumi, T.; Tanaka, F.; Sato, Y.; Yoshida, Y.; Uchino, T. Evaluation of electrical and other physical properties of heated sweet potato. J. Food Process Eng. 2017, 40, e12490. [Google Scholar] [CrossRef]

- Li, C.Y.; Zhang, R.Q.; Fu, K.Y.; Li, C.; Li, C. Effects of high temperature on starch morphology and the expression of genes related to starch biosynthesis and degradation. J. Cereal Sci. 2017, 73, 25–32. [Google Scholar] [CrossRef]

- Hari, P.K.; Garg, S.K. Gelatinization of starch and modified starch. Starch-Starke 1989, 41, 88–91. [Google Scholar] [CrossRef]

- Chen, X.; Zhu, L.; Zhang, H.; Zhang, Y.; Cheng, L.; Wu, G. Influence of cell-wall permeability on starch digestion in sweet potato cells. Food Hydrocoll. 2025, 159, 110718. [Google Scholar] [CrossRef]

- Shin, M.S.; Ahn, S.Y. Degree of gelatinization of cooked sweet potatoes by different cooking methods. Appl. Biol. Chem. 1986, 29, 372–374. [Google Scholar]

- Wong, J.J.; Chin, M.H.; Wang, T.C.; Yang, C.C. Effects of superheated steam and roasting treatment on quality and antioxidant capacity of sweet potatoes. Taiwan. J. Agric. Chem. Food Sci. 2010, 48, 11–18. [Google Scholar]

- Xu, A.; Guo, K.; Liu, T.; Bian, X.; Zhang, L.; Wei, C. Effects of different isolation media on structural and functional properties of starches from root tubers of purple, yellow and white sweet potatoes. Molecules 2018, 23, 2135. [Google Scholar] [CrossRef] [PubMed]

- Wei, X.; Ren, G.; Liu, W.; Zhao, M.; Xu, D. Effects of component ratios on the properties of sweet potato–oat composite dough and the quality of its steamed cake. J. Food Sci. 2024, 89, 3248–3259. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Zhang, R.; Jia, R.; Deng, Y.; Wang, Z. Impact of different cooking methods on the chemical profile of orange-fleshed sweet potato (Ipomoea batatas L.). LWT 2023, 173, 114288. [Google Scholar] [CrossRef]

- Jiao, Q.; Lin, B.; Mao, Y.; Jiang, H.; Guan, X.; Li, R.; Wang, S. Effects of combined radio frequency heating with oven baking on product quality of sweet potato. Food Control 2022, 139, 109097. [Google Scholar] [CrossRef]

- Freitas, D.; Gómez-Mascaraque, L.G.; Le Feunteun, S.; Brodkorb, A. Boiling vs. baking: Cooking-induced structural transformations drive differences in the in vitro starch digestion profiles that are consistent with the in vivo glycemic indexes of white and sweet potatoes. Food Struct. 2023, 38, 100355. [Google Scholar] [CrossRef]

- Desnilasari, D.; Afifah, N.; Indrianti, N. Physicochemical, baking quality, and sensory evaluation of gluten free bread made from modified sweet potato flour with addition of nuts flour. In Proceedings of the 5th International Symposium on Applied Chemistry (ISAC), Tangerang, Indonesia, 23–24 October 2019; AIP Conference Proceedings: Melville, NY, USA, 2019; Volume 2175. [Google Scholar] [CrossRef]

- Wu, K.-L.; Sung, W.-C.; Yang, C.-H. Characteristics of dough and bread as affected by the incorporation of sweet potato paste in the formulation. J. Mar. Sci. Technol. 2009, 17, 13–22. [Google Scholar] [CrossRef]

- Chikpah, S.K.; Korese, J.K.; Hensel, O.; Sturm, B.; Pawelzik, E. Rheological properties of dough and bread quality characteristics as influenced by the proportion of wheat flour substitution with orange-fleshed sweet potato flour and baking conditions. LWT 2021, 147, 111515. [Google Scholar] [CrossRef]

- Allan, M.C.; Johanningsmeier, S.D.; Nakitto, M.; Guambe, O.; Abugu, M.; Pecota, K.V.; Yencho, G.C. Baked sweetpotato textures and sweetness: An investigation into relationships between physicochemical and cooked attributes. Food Chem. X 2024, 21, 101072. [Google Scholar] [CrossRef] [PubMed]

- Kwaw, E.; Osae, R.; Apaliya, M.T.; Sackey, A.S.; Alolga, R.N.; Kaburi, S.A.; Hinson, M.; Bediako, G.; Botwe, A.K.; Pitcher, V.M. Effect of different pre-treatments on the physical properties, frying kinetics and organoleptic physiognomies of fried sweet potato (Ipomoea batatas) chips. Food Humanit. 2024, 3, 100351. [Google Scholar] [CrossRef]

- Liu, T.; Dodds, E.; Leong, S.Y.; Eyres, G.T.; Burritt, D.J.; Oey, I. Effect of pulsed electric fields on the structure and frying quality of “kumara” sweet potato tubers. Innov. Food Sci. Emerg. Technol. 2017, 39, 197–208. [Google Scholar] [CrossRef]

- Vilpoux, O.F. Chapter 4—Roots and tubers processing for cooking purposes: Ready-to-eat, vacuum and frozen products, french fries, and chips. In Traditional Starch Food Products; Cereda, M.P., Vilpoux, O.F., Eds.; Academic Press: Cambridge, MA, USA, 2025; pp. 75–110. [Google Scholar]

- Li, Y.; Wang, Y.; Li, X.; Chen, H. Effect of freezing-assisted treatment on the formation of stable vii-type complex of fried sweet potato starch and its mechanism. J. Food Sci. 2022, 87, 543–553. [Google Scholar] [CrossRef]

- Shi, M.; Li, D.; Yan, Y.; Liu, Y. Effect of moisture content on structure and properties of fried potato starch. Starch-Starke 2018, 70, 1800012. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Ramanathan, S.; Basak, T. Microwave food processing—A review. Food Res. Int. 2013, 52, 243–261. [Google Scholar] [CrossRef]

- Monteiro, R.L.; de Moraes, J.O.; Gomide, A.I.; Carciofi, B.A.M.; Laurindo, J.B. Temperature control for high-quality oil-free sweet potato chips produced by microwave rotary drying under vacuum. LWT 2022, 157, 113047. [Google Scholar] [CrossRef]

- Monteiro, R.L.; de Moraes, J.O.; Domingos, J.D.; Carciofi, B.A.M.; Laurindo, J.B. Evolution of the physicochemical properties of oil-free sweet potato chips during microwave vacuum drying. Innov. Food Sci. Emerg. Technol. 2020, 63, 102317. [Google Scholar] [CrossRef]

- Basílio, L.S.P.; Nunes, A.; Minatel, I.O.; Diamante, M.S.; Di Lázaro, C.B.; e Silva, A.C.A.F.; Vargas, P.F.; Vianello, F.; Maraschin, M.; Lima, G.P.P. The phytochemical profile and antioxidant activity of thermally processed colorful sweet potatoes. Horticulturae 2023, 10, 18. [Google Scholar] [CrossRef]

- Dawkins, N.L.; Lu, J.Y. Physico-chemical properties and acceptability of flour prepared from microwave blanched sweet potatoes. J. Food Process. Preserv. 1991, 15, 115–124. [Google Scholar] [CrossRef]

- Tüfekçi, S.; Özkal, S.G. The optimization of hybrid (microwave–conventional) drying of sweet potato using response surface methodology (rsm). Foods 2023, 12, 3003. [Google Scholar] [CrossRef]

- Fan, K.; Zhang, M.; Bhandari, B. Osmotic-ultrasound dehydration pretreatment improves moisture adsorption isotherms and water state of microwave-assisted vacuum fried purple-fleshed sweet potato slices. Food Bioprod. Process. 2019, 115, 154–164. [Google Scholar] [CrossRef]

- Zhang, T.; Yu, S.; Pan, Y.; Li, H.; Liu, X.; Cao, J. Properties of texturized protein and performance of different protein sources in the extrusion process: A review. Food Res. Int. 2023, 174, 113588. [Google Scholar] [CrossRef]

- Ye, J.; Hu, X.; Luo, S.; Liu, W.; Chen, J.; Zeng, Z.; Liu, C. Properties of starch after extrusion: A review. Starch-Starke 2018, 70, 1700110. [Google Scholar] [CrossRef]

- Ascerhi, J.L.R.; Bernal-Gomez, M.E.; Carvalho, C.W.P. Production of snacks from blends of broken rice and sweet potato using thermoplastic extrusion: Part i. Chemical characterization, expansion index, and apparent density. Alimentaria 1998, 35, 70–77. [Google Scholar]

- Pérez Ramos, K.; Elías Peñafiel, C.; Delgado Soriano, V. Bocadito con alto contenido proteico: Un extruido a partir de quinua (Chenopodium quinoa Willd.), tarwi (Lupinus mutabilis Sweet) y camote (Ipomoea batatas L.). Sci. Agropecu. 2017, 8, 377–388. [Google Scholar] [CrossRef]

- Liu, X.; Yang, L.; Zhao, S.; Zhang, H. Characterization of the dough rheological and steamed bread fortified with extruded purple sweet potato flour. Int. J. Food Prop. 2020, 23, 765–776. [Google Scholar] [CrossRef]

- Pérez, I.C.; Mu, T.; Zhang, M.; Ji, L. Effect of high hydrostatic pressure to sweet potato flour on dough properties and characteristics of sweet potato-wheat bread. Int. J. Food Sci. Technol. 2018, 53, 1087–1094. [Google Scholar] [CrossRef]

- Ahmed, J.; Thomas, L.; Arfat, Y.A. Effects of high hydrostatic pressure on functional, thermal, rheological and structural properties of β-d-glucan concentrate dough. LWT 2016, 70, 63–70. [Google Scholar] [CrossRef]

- Li, W.; Tian, X.; Liu, L.; Wang, P.; Wu, G.; Zheng, J.; Ouyang, S.; Luo, Q.; Zhang, G. High pressure induced gelatinization of red adzuki bean starch and its effects on starch physicochemical and structural properties. Food Hydrocoll. 2015, 45, 132–139. [Google Scholar] [CrossRef]

- Khan, N.M.; Mu, T.-H.; Zhang, M.; Arogundade, L.A. The effects of pH and high hydrostatic pressure on the physicochemical properties of a sweet potato protein emulsion. Food Hydrocoll. 2014, 35, 209–216. [Google Scholar] [CrossRef]

- Verma, A.; Singh, S.V. Spray drying of fruit and vegetable juices—A review. Crit. Rev. Food Sci. Nutr. 2015, 55, 701–719. [Google Scholar] [CrossRef]

- Majzoobi, M.; Radi, M.; Farahnaky, A.; Jamalian, J.; Tongtang, T.; Mesbahi, G. Physicochemical properties of pre-gelatinized wheat starch produced by a twin drum drier. J. Agric. Sci. Technol. 2011, 13, 193–202. [Google Scholar]

- dos Santos, T.P.R.; Franco, C.M.L.; Leonel, M. Gelatinized sweet potato starches obtained at different preheating temperatures in a spray dryer. Int. J. Biol. Macromol. 2019, 149, 1339–1346. [Google Scholar] [CrossRef]

- dos Santos, T.P.R.; Franco, C.M.L.; Mischan, M.M.; Leonel, M. Behavior of sweet potato starch after spray-drying under different pretreatment conditions. Starch-Starke 2019, 71, 1800245. [Google Scholar] [CrossRef]

- Arebo, M.A.; Feyisa, J.D.; Tafa, K.D.; Satheesh, N. Optimization of spray-drying parameter for production of better quality orange fleshed sweet potato (Ipomoea batatas L.) powder: Selected physiochemical, morphological, and structural properties. Heliyon 2023, 9, e13078. [Google Scholar] [CrossRef]

- Cho, S.; Yoo, B. Comparison of the effect of sugars on the viscoelastic properties of sweet potato starch pastes. Int. J. Food Sci. Technol. 2010, 45, 410–414. [Google Scholar] [CrossRef]

- Zhou, D.-N.; Zhang, B.; Chen, B.; Chen, H.-Q. Effects of oligosaccharides on pasting, thermal and rheological properties of sweet potato starch. Food Chem. 2017, 230, 516–523. [Google Scholar] [CrossRef]

- Grabowski, J.; Truong, V.-D.; Daubert, C. Nutritional and rheological characterization of spray dried sweetpotato powder. LWT-Food Sci. Technol. 2008, 41, 206–216. [Google Scholar] [CrossRef]

- Valetudie, J.C.; Gallant, D.J.; Bouchet, B.; Colonna, P.; Champ, M. Influcence of cooking procedures on structure and biochemical changes in sweet potato. Starch-Starke 1999, 51, 389–397. [Google Scholar] [CrossRef]

- Li, C. Recent progress in understanding starch gelatinization—An important property determining food quality. Carbohydr. Polym. 2022, 293, 119735. [Google Scholar] [CrossRef]

- Yu, J.H.; Lee, H.W.; Shin, T.H.; Jo, Y.J.; Chung, M.N.; Jang, K.I.; Lee, J.; Jeong, H.S. Quality characteristics of sweet potato paste varieties prepared by different heating methods. J. Korean Soc. Food Sci. Nutr. 2022, 51, 969–975. [Google Scholar] [CrossRef]

- Lv, Z.; Yu, K.; Jin, S.; Ke, W.; Fei, C.; Cui, P.; Lu, G. Starch granules size distribution of sweet potato and their relationship with quality of dried and fried products. Starch-Starke 2019, 71, 1800175. [Google Scholar] [CrossRef]

- Kalb, A.J.; Sterling, C. Role of hydrogen ion concentration in retrogradation of starch sols. J. Appl. Polym. Sci. 1962, 6, 571–574. [Google Scholar] [CrossRef]

- Fang, F.; Luo, X.; Fei, X.; Mathews, M.A.A.; Lim, J.; Hamaker, B.R.; Campanella, O.H. Stored gelatinized waxy potato starch forms a strong retrograded gel at low pH with the formation of intermolecular double helices. J. Agric. Food Chem. 2020, 68, 4036–4041. [Google Scholar] [CrossRef]

- Allan, M.C.; Rajwa, B.; Mauer, L.J. Effects of sugars and sugar alcohols on the gelatinization temperature of wheat starch. Food Hydrocoll. 2018, 84, 593–607. [Google Scholar] [CrossRef]

- Li, C.; Gong, B. Insights into chain-length distributions of amylopectin and amylose molecules on the gelatinization property of rice starches. Int. J. Biol. Macromol. 2020, 155, 721–729. [Google Scholar] [CrossRef]

- Li, C.; Wu, A.; Yu, W.; Hu, Y.; Li, E.; Zhang, C.; Liu, Q. Parameterizing starch chain-length distributions for structure-property relations. Carbohydr. Polym. 2020, 241, 116390. [Google Scholar] [CrossRef]

- Chiotelli, E.; Pilosio, G.; Le Meste, M. Effect of sodium chloride on the gelatinization of starch: A multimeasurement study. Biopolymers 2002, 63, 41–58. [Google Scholar] [CrossRef]

- Donmez, D.; Pinho, L.; Patel, B.; Desam, P.; Campanella, O.H. Characterization of starch–water interactions and their effects on two key functional properties: Starch gelatinization and retrogradation. Curr. Opin. Food Sci. 2021, 39, 103–109. [Google Scholar] [CrossRef]

- Wang, S.; Wang, J.; Yu, J.; Wang, S. Effect of fatty acids on functional properties of normal wheat and waxy wheat starches: A structural basis. Food Chem. 2016, 190, 285–292. [Google Scholar] [CrossRef]

- Abdel-Aal, E.-S.M.; Hernandez, M.; Rabalski, I.; Hucl, P. Composition of hairless canary seed oil and starch-associated lipids and the relationship between starch pasting and thermal properties and its lipids. LWT 2020, 125, 109257. [Google Scholar] [CrossRef]

- Jangchud, K.; Phimolsiripol, Y.; Haruthaithanasan, V. Physicochemical properties of sweet potato flour and starch as affected by blanching and processing. Starch-Starke 2003, 55, 258–264. [Google Scholar] [CrossRef]

- Huang, C.-C.; Lai, P.; Chen, I.-H.; Liu, Y.-F.; Wang, C.-C. Effects of mucilage on the thermal and pasting properties of yam, taro, and sweet potato starches. LWT-Food Sci. Technol. 2010, 43, 849–855. [Google Scholar] [CrossRef]

- Dong, X.; Huang, Y.; Pan, Y.; Wang, K.; Prakash, S.; Zhu, B. Investigation of sweet potato starch as a structural enhancer for three-dimensional printing of Scomberomorus niphonius surimi. J. Texture Stud. 2019, 50, 316–324. [Google Scholar] [CrossRef] [PubMed]

- Jia, R.; Katano, T.; Yoshimoto, Y.; Gao, Y.; Watanabe, Y.; Nakazawa, N.; Osako, K.; Okazaki, E. Sweet potato starch with low pasting temperature to improve the gelling quality of surimi gels after freezing. Food Hydrocoll. 2018, 81, 467–473. [Google Scholar] [CrossRef]

- Collado, L.S.; Corke, H. Pasting properties of commercial and experimental starch pearls. Carbohydr. Polym. 1998, 35, 89–96. [Google Scholar] [CrossRef]

- Noda, T.; Kobayashi, T.; Suda, I. Effect of soil temperature on starch properties of sweet potatoes. Carbohydr. Polym. 2001, 44, 239–246. [Google Scholar] [CrossRef]

- Srichuwong, S.; Sunarti, T.C.; Mishima, T.; Isono, N.; Hisamatsu, M. Starches from different botanical sources I: Contribution of amylopectin fine structure to thermal properties and enzyme digestibility. Carbohydr. Polym. 2005, 60, 529–538. [Google Scholar] [CrossRef]

- Katayama, K.; Komae, K.; Kohyama, K.; Kato, T.; Tamiya, S.; Komaki, K. New sweet potato line having low gelatinization temperature and altered starch structure. Starch-Starke 2002, 54, 51–57. [Google Scholar] [CrossRef]

- Srichuwong, S.; Orikasa, T.; Matsuki, J.; Shiina, T.; Kobayashi, T.; Tokuyasu, K. Sweet potato having a low temperature-gelatinizing starch as a promising feedstock for bioethanol production. Biomass Bioenergy 2012, 39, 120–127. [Google Scholar] [CrossRef]

- Nakamura, Y.; Ohara-Takada, A.; Kuranouchi, T.; Masuda, R.; Katayama, K. Mechanism for maltose generation by heating in the storage roots of sweet potato cultivar “quick sweet” containing starch with a low pasting temperature. J. Jpn. Soc. Food Sci. Technol.-Nippon Shokuhin Kagaku Kogaku Kaishi 2014, 61, 62–69. [Google Scholar] [CrossRef]

- Wang, W.; Hu, A.; Li, Y.; Yan, J.; Liu, S.; Zheng, J. Effect of multiple short-time repeated microwave treatments on the structure and physicochemical properties of sweet potato starch. Starch-Starke 2023, 75, 2200231. [Google Scholar] [CrossRef]

- Zhou, W.; Yang, J.; Hong, Y.; Liu, G.; Zheng, J.; Gu, Z.; Zhang, P. Impact of amylose content on starch physicochemical properties in transgenic sweet potato. Carbohydr. Polym. 2015, 122, 417–427. [Google Scholar] [CrossRef]

- Kitahara, K.; Fukunaga, S.; Katayama, K.; Takahata, Y.; Nakazawa, Y.; Yoshinaga, M.; Suganuma, T. Physicochemical properties of sweetpotato starches with different gelatinization temperatures. Starch-Starke 2005, 57, 473–479. [Google Scholar] [CrossRef][Green Version]

- Zhu, F.; Yang, X.; Cai, Y.; Bertoft, E.; Corke, H. Physicochemical properties of sweetpotato starch. Starch-Starke 2011, 63, 249–259. [Google Scholar] [CrossRef]

- Noda, T.; Kimura, T.; Otani, M.; Ideta, O.; Shimada, T.; Saito, A.; Suda, I. Physicochemical properties of amylose-free starch from transgenic sweet potato. Carbohydr. Polym. 2002, 49, 253–260. [Google Scholar] [CrossRef]

- Duan, W.; Zhang, H.; Xie, B.; Wang, B.; Zhang, L. Impacts of nitrogen fertilization rate on the root yield, starch yield and starch physicochemical properties of the sweet potato cultivar jishu 25. PLoS ONE 2019, 14, e0221351. [Google Scholar] [CrossRef] [PubMed]

- Noda, T.; Takahata, Y.; Sato, T.; Suda, I.; Morishita, T.; Ishiguro, K.; Yamakawa, O. Relationships between chain length distribution of amylopectin and gelatinization properties within the same botanical origin for sweet potato and buckwheat. Carbohydr. Polym. 1998, 37, 153–158. [Google Scholar] [CrossRef]

- Ye, F.; Li, J.; Zhao, G. Physicochemical properties of different-sized fractions of sweet potato starch and their contributions to the quality of sweet potato starch. Food Hydrocoll. 2020, 108, 106023. [Google Scholar] [CrossRef]

- Zhang, T.; Oates, C. Relationship between α-amylase degradation and physico-chemical properties of sweet potato starches. Food Chem. 1999, 65, 157–163. [Google Scholar] [CrossRef]

- Aina, A.J.; Falade, K.O.; Akingbala, J.O.; Titus, P. Physicochemical properties of twenty-one caribbean sweet potato cultivars. Int. J. Food Sci. Technol. 2009, 44, 1696–1704. [Google Scholar] [CrossRef]

- Hasjim, J.; Li, E.; Dhital, S. Milling of rice grains: Effects of starch/flour structures on gelatinization and pasting properties. Carbohydr. Polym. 2013, 92, 682–690. [Google Scholar] [CrossRef]

- Eliasson, A.; Karlsson, R. Gelatinization properties of different size classes of wheat starch granules measured with differential scanning calorimetry. Starch-Starke 1983, 35, 130–133. [Google Scholar] [CrossRef]

- Hu, H.; Zhou, X.-Y.; Wang, Y.-S.; Zhang, Y.-X.; Zhou, W.-H.; Zhang, L. Effects of particle size on the structure, cooking quality and anthocyanin diffusion of purple sweet potato noodles. Food Chem. X 2023, 18, 100672. [Google Scholar] [CrossRef]

- Ice, J.R.; Hamann, D.D.; Purcell, A.E. Effects of ph, enzymes, and storage time on the rheology of sweet potato puree. J. Food Sci. 1980, 45, 1614–1618. [Google Scholar] [CrossRef]

- Lee, S.Y.; Lee, K.Y.; Lee, H.G. Effect of different pH conditions on the in vitro digestibility and physicochemical properties of citric acid-treated potato starch. Int. J. Biol. Macromol. 2018, 107, 1235–1241. [Google Scholar] [CrossRef] [PubMed]

- Renzetti, S.; van den Hoek, I.A.; van der Sman, R.G. Mechanisms controlling wheat starch gelatinization and pasting behaviour in presence of sugars and sugar replacers: Role of hydrogen bonding and plasticizer molar volume. Food Hydrocoll. 2021, 119, 106880. [Google Scholar] [CrossRef]

- Kohyama, K.; Nishinari, K. Effect of soluble sugars on gelatinization and retrogradation of sweet potato starch. J. Agric. Food Chem. 1991, 39, 1406–1410. [Google Scholar] [CrossRef]

- Perry, P.; Donald, A. The effect of sugars on the gelatinisation of starch. Carbohydr. Polym. 2002, 49, 155–165. [Google Scholar] [CrossRef]

- Wang, H.; Yang, Q.; Ferdinand, U.; Gong, X.; Qu, Y.; Gao, W.; Ivanistau, A.; Feng, B.; Liu, M. Isolation and characterization of starch from light yellow, orange, and purple sweet potatoes. Int. J. Biol. Macromol. 2020, 160, 660–668. [Google Scholar] [CrossRef]

- Wang, H.; Yang, Q.; Gao, L.; Gong, X.; Qu, Y.; Feng, B. Functional and physicochemical properties of flours and starches from different tuber crops. Int. J. Biol. Macromol. 2020, 148, 324–332. [Google Scholar] [CrossRef]

- Moorthy, S.; Sajeev, M.; Ambrose, R.; Anish, R. Applications of tuber starches. In Tropical Tuber Starches: Structural and Functional Characteristics; CABI: Wallingford, UK, 2021; pp. 214–227. [Google Scholar] [CrossRef]

- Menon, R.; Padmaja, G.; Sajeev, M. Cooking behavior and starch digestibility of nutriose® (resistant starch) enriched noodles from sweet potato flour and starch. Food Chem. 2015, 182, 217–223. [Google Scholar] [CrossRef]

- Chen, Z.; Schols, H.A.; Voragen, A.G.J. The use of potato and sweet potato starches affects white salted noodle quality. J. Food Sci. 2003, 68, 2630–2637. [Google Scholar] [CrossRef]

- Kexue, Z.J.S.; Industry, T.O.F. Study on the properties of blending wheat flour with purple sweet potato flour and application in noodles. Sci. Technol. Food Ind. 2011, 94–96+101. [Google Scholar] [CrossRef]

- Lase, V.A.; Julianti, E.; Lubis, L.M. Bihon type noodles from heat moisture treated starch of four varieties of sweet potato. J. Teknol. Ind. Pangan 2013, 24, 89–96. [Google Scholar] [CrossRef]

- Monthe, O.C.; Grosmaire, L.; Nguimbou, R.M.; Dahdouh, L.; Ricci, J.; Tran, T.; Ndjouenkeu, R. Rheological and textural properties of gluten-free doughs and breads based on fermented cassava, sweet potato and sorghum mixed flours. LWT 2019, 101, 575–582. [Google Scholar] [CrossRef]

- Chittrakorn, S.; Bora, G.C. Production of pregelatinized sweet potato flour and its effect on batter and cake properties. J. Food Process. Preserv. 2021, 45, e16019. [Google Scholar] [CrossRef]

- Li, S.; Ye, F.; Zhou, Y.; Lei, L.; Zhao, G. Rheological and textural insights into the blending of sweet potato and cassava starches: In hot and cooled pastes as well as in fresh and dried gels. Food Hydrocoll. 2019, 89, 901–911. [Google Scholar] [CrossRef]

- Paixão e Silva, G.D.L.; Bento, J.A.C.; Ribeiro, G.O.; Lião, L.M.; Soares Júnior, M.S.; Caliari, M. Application potential and technological properties of colored sweet potato starches. Starch-Starke 2021, 73, 2000100. [Google Scholar] [CrossRef]

- Zhang, Q.; Huang, L.; Li, H.; Zhao, D.; Cao, J.; Song, Y.; Liu, X. Mimic pork rinds from plant-based gel: The influence of sweet potato starch and konjac glucomannan. Molecules 2022, 27, 3103. [Google Scholar] [CrossRef]

- Mason, W.R. Chapter 20—Starch use in foods. In Starch, 3rd ed.; BeMiller, J., Whistler, R., Eds.; Academic Press: San Diego, CA, USA, 2009; pp. 745–795. [Google Scholar]

- Lee, Y.Y.; Lee, S.; Ham, S.H.; Lee, M.G.; Hahn, J.; Kim, Y.; Choi, Y.J. Relationship between sensory attributes and instrumental texture properties in meat analog patty system substituted with sweet potato stem. J. Sci. Food Agric. 2024, 104, 7002–7012. [Google Scholar] [CrossRef]

- Lyu, R.; Ahmed, S.; Fan, W.; Yang, J.; Wu, X.; Zhou, W.; Zhang, P.; Yuan, L.; Wang, H. Engineering properties of sweet potato starch for industrial applications by biotechnological techniques including genome editing. Int. J. Mol. Sci. 2021, 22, 9533. [Google Scholar] [CrossRef]

- Rashwan, A.K.; Younis, H.A.; Abdelshafy, A.M.; Osman, A.I.; Eletmany, M.R.; Hafouda, M.A.; Chen, W. Plant starch extraction, modification, and green applications: A review. Environ. Chem. Lett. 2024, 22, 2483–2530. [Google Scholar] [CrossRef]

| Treatment | Parameters | Influence | References |

|---|---|---|---|

| Moist heat processing | 60–80 °C | Cassava starch shows slight swelling and 8.5% amylose leaching, while potato starch swells rapidly with 51.05% amylose leaching | [22] |

| Steaming | 140 °C | High gelatinization (up to 95%) without charring | [17] |

| Steaming | 121 °C, 10 min | Maintained high antioxidant levels, preventing charring and increasing phenolic content | [23] |

| Baking | 200 °C, 20 min | As maltose levels increase, starch levels decrease | [24] |

| Baking | 200 °C, 40–50 min | Baking only slightly reduced the total anthocyanin content | [23] |

| Baking | 200 °C, 90 min | Increased maltose content and sweetness, enhancing sensory acceptability | [25] |

| Frying | 130 °C | Lower oil content by 15% compared to single-stage frying, improved texture and appearance | [26] |

| Microwave and Steaming | microwaving (1000 W) and steaming (1700 W) | Enhanced antioxidant activity, reduced cooking time | [27] |

| Explosion puffing drying | 80 °C, 5 min | Enhanced anthocyanin retention and improved crispness, beneficial for gelatinization quality | [28] |

| Extrusion processing | 150–155 °C | High sensory score and micronutrient retention, with optimal expansion | [29] |

| Extrusion processing | 100 °C | Die diameter has a greater impact on product temperature than screw speed and feed composition | [30] |

| High hydrostatic pressure (HHP) | 200–600 Mpa, 15min | Enhancing digestibility and bioactive compound extractability | [31] |

| Spray drying | Inlet temperature (130 °C), outlet temperature (105 °C) | Complete starch gelatinization is suitable for applications requiring rapid solubility and low final viscosity | [32] |

| Radio frequency blanching | 90 °C | Improved enzyme inactivation, better color and texture retention | [33] |

| Treatment | Mechanism | Advantages | Limitations | Applications | References |

|---|---|---|---|---|---|

| Moist heat processing | High temperature and abundant water cause starch granules to swell | Efficient gelatinization improves viscosity and gel-forming ability | High nutrient loss, high energy consumption | Sweet potato pearls | [22] |

| Steaming | Gradual moisture penetration, uniform gelatinization, retains more nutrients, lower degree of gelatinization than boiling | Better nutrient retention | Lower degree of gelatinization, higher equipment costs | Steamed pastries | [17,23] |

| Baking | Provides slow, uniform heating, suitable for baked products like bread and cakes, and improves texture and mouthfeel | Versatile for various baked goods | Dependent on other ingredients (additives and wheat flour), high energy consumption | Baked products like bread and cakes | [24,25] |

| Frying | Partial gelatinization through high oil temperature forms a crispy outer layer with a soft interior, suitable for foods like sweet potato balls and fries | Unique texture (crispy exterior, soft interior), fast processing | Partial gelatinization, increased fat content | Fried sweet potato balls, french fries | [26] |

| Microwave heating | Rapid energy transfer for quick gelatinization retains more nutrients but may face uneven heating challenges | High energy efficiency, good nutrient retention | Uneven heating, industrial scaling challenges | Rapid dehydration and texture improvement products | [27] |

| Extrusion processing | High pressure and temperature with mechanical shear induce gelatinization | Efficient gelatinization | High equipment costs, complex operation | Puffed sweet potato products | [29] |

| High hydrostatic pressure | Low-temperature treatment prevents nutrient degradation, enhances starch viscosity and gel properties, retains natural flavor and color | Preserves nutrients and sensory qualities | Longer overall processing time | Products requiring retained nutrition and sensory attributes | [31] |

| Spray drying | Atomizes starch slurry into droplets for quick drying into powder, improves solubility and viscosity, convenient for storage and application | Convenient powder form, enhanced solubility, and rheological properties | High energy consumption | Instant food ingredients, thickening agents, or stabilizers in various food applications | [32] |

| Influencing Factors | Mechanism | References |

|---|---|---|

| Moisture content | Adequate water facilitates the hydration and swelling of starch granules, disrupting crystalline structure. Insufficient moisture leads to incomplete gelatinization | [79,80] |

| Temperature | Higher temperatures break crystalline structures, accelerating gelatinization. Excessive heat can degrade starch, reducing viscosity and gel strength | [80,81] |

| Particle Size | Smaller particles increase surface area, allowing faster water absorption and heat transfer, leading to efficient gelatinization | [82] |

| pH | Acidic or alkaline conditions alter hydrogen bonding and starch structure, affecting water absorption and gelatinization. Extreme pH can cause hydrolysis and reduce functional properties | [83,84] |

| Sugars | Compete with starch for water, reducing swelling and delaying gelatinization. Increase gelatinization temperature and improve stability in final products | [77,85] |

| Amylose/Amylopectin ratio | Higher amylose content increases gelatinization temperature and affects texture. Amylopectin-rich starches gelatinize more easily | [86,87] |

| Salts | Stabilize starch granules and enhance water availability through ionic interactions, influencing gelatinization degree | [88,89] |

| Lipids | Interact with starch to form complexes, reducing water availability and potentially inhibiting gelatinization | [90,91] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.; Hu, W.; Qiao, S.; Song, W.; Tan, W. Advances in Processing Techniques and Determinants of Sweet Potato Starch Gelatinization. Foods 2025, 14, 545. https://doi.org/10.3390/foods14040545

Yang S, Hu W, Qiao S, Song W, Tan W. Advances in Processing Techniques and Determinants of Sweet Potato Starch Gelatinization. Foods. 2025; 14(4):545. https://doi.org/10.3390/foods14040545

Chicago/Turabian StyleYang, Songtao, Wentao Hu, Shuai Qiao, Wei Song, and Wenfang Tan. 2025. "Advances in Processing Techniques and Determinants of Sweet Potato Starch Gelatinization" Foods 14, no. 4: 545. https://doi.org/10.3390/foods14040545

APA StyleYang, S., Hu, W., Qiao, S., Song, W., & Tan, W. (2025). Advances in Processing Techniques and Determinants of Sweet Potato Starch Gelatinization. Foods, 14(4), 545. https://doi.org/10.3390/foods14040545