The Aroma, Taste Contributions, and Flavor Evaluation Based on GC-IMS, E-Nose, and E-Tongue in Soybean Pastes: A Comparative Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Establishment of Fuzzy Mathematics Model

2.2.1. Sensory Evaluation

2.2.2. Determination of Sensory Factor Set and Comment Set

2.2.3. Determination of Fuzzy Matrix

2.3. Analysis of Volatile Compounds by HS-GC-IMS

2.4. Analysis of E-Nose

2.5. Analysis of E-Tongue

2.6. Statistical Analysis

3. Results and Discussion

3.1. Result of Sensory Evaluation

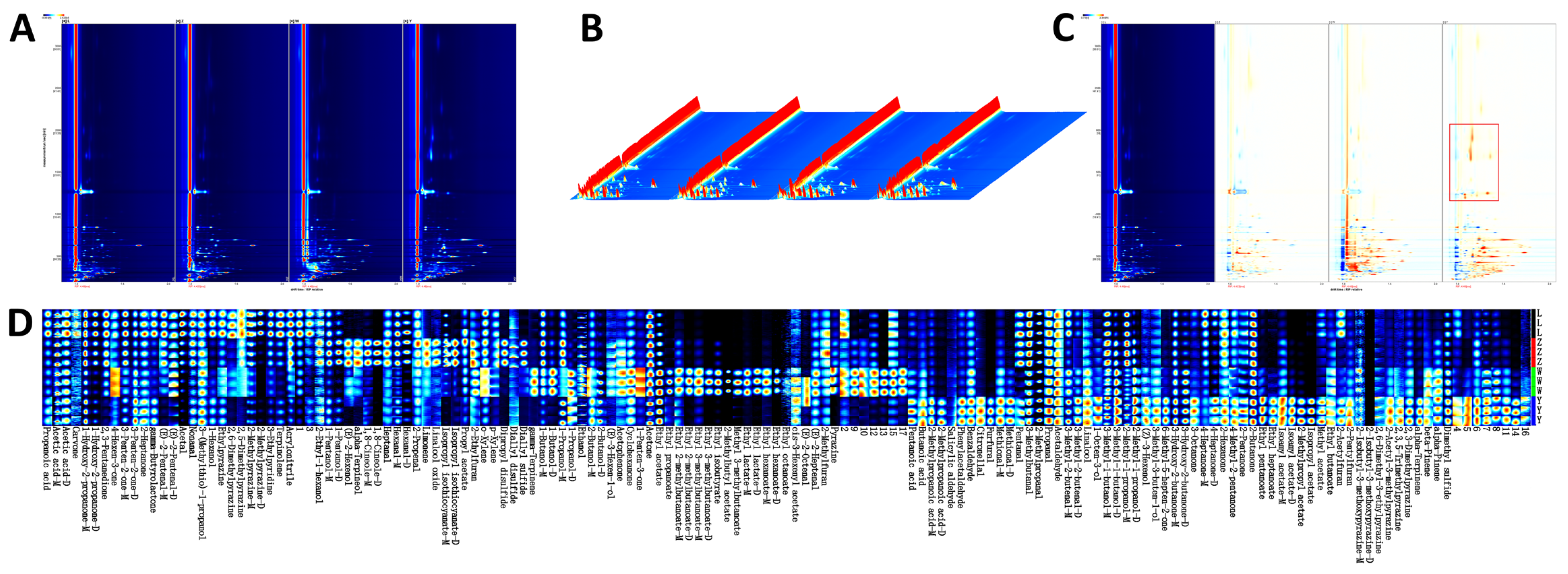

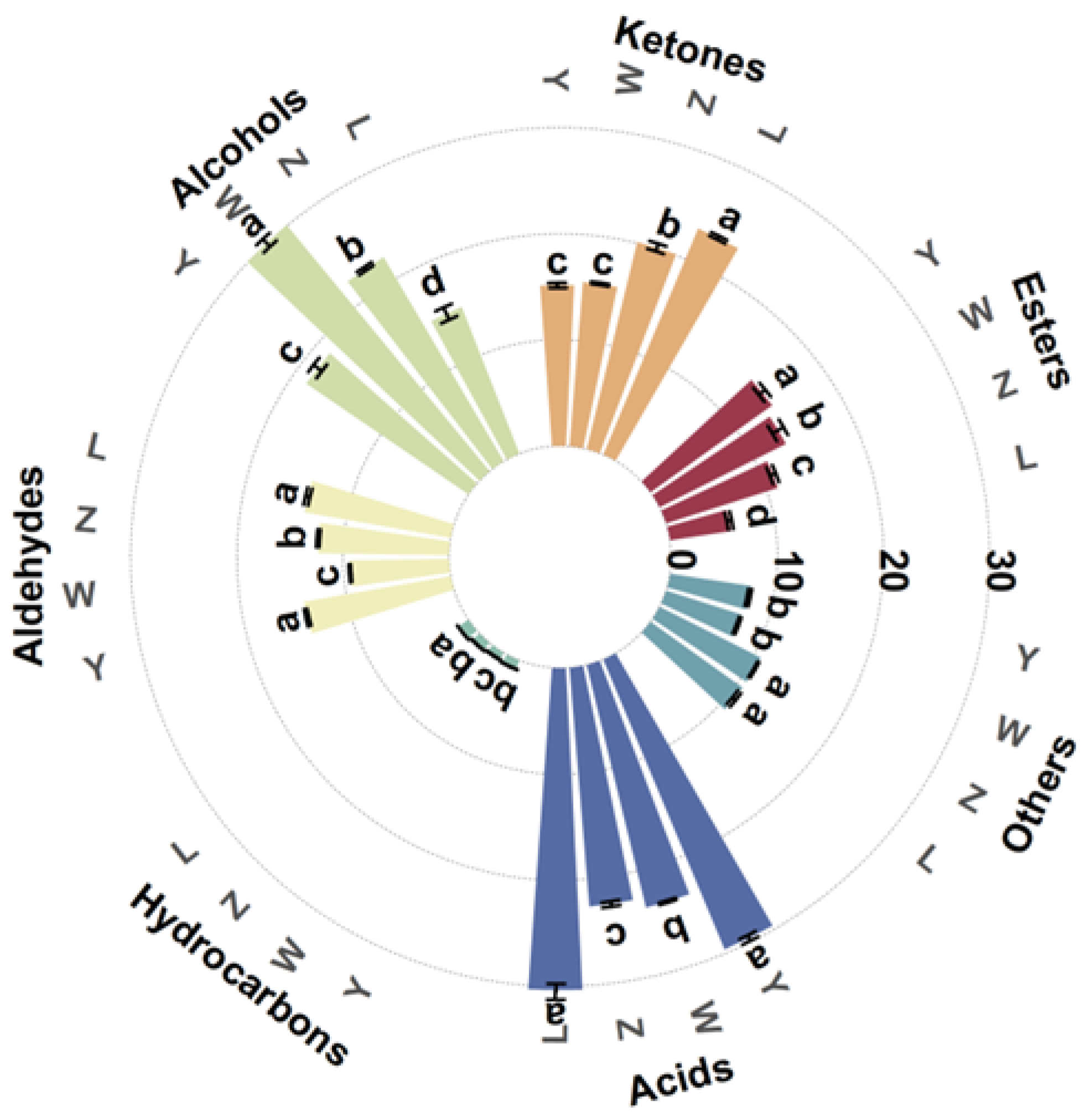

3.2. HS-GC-IMS Analysis

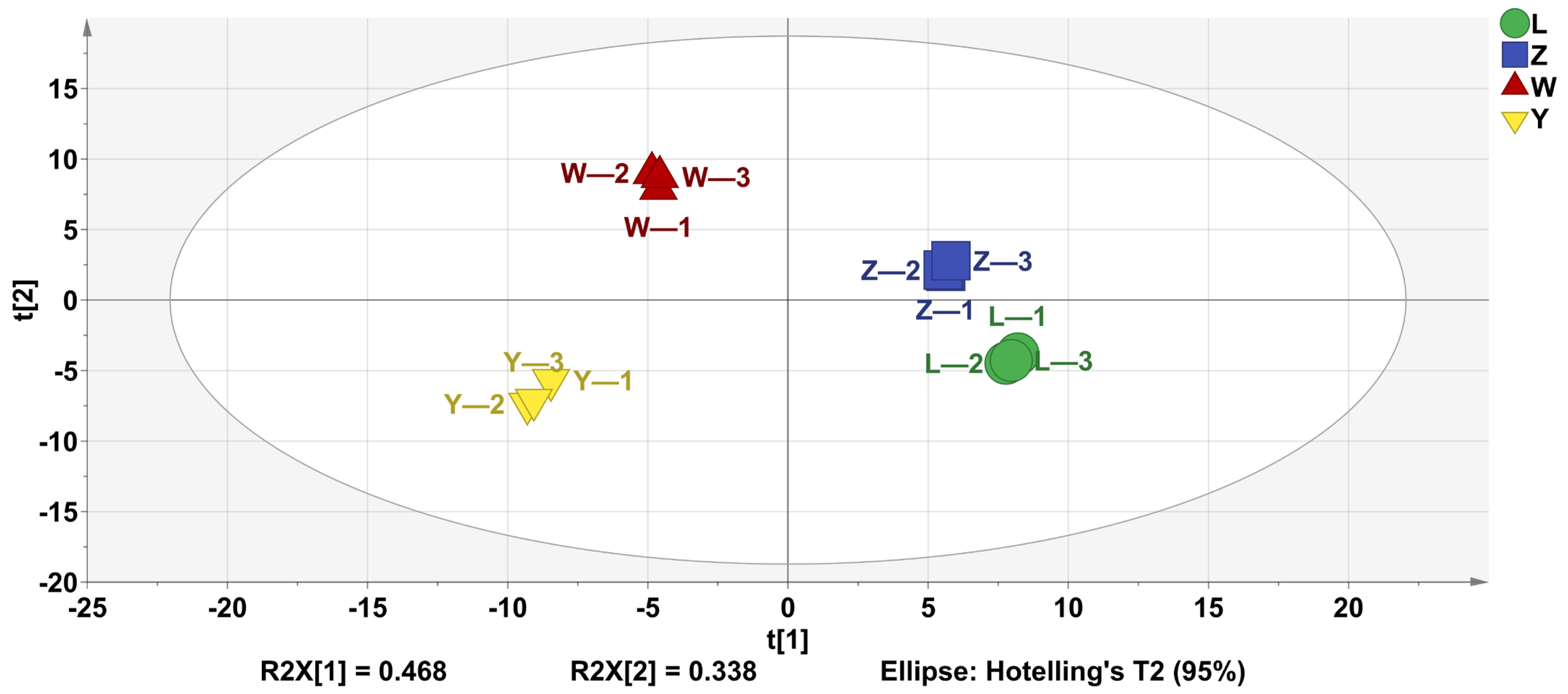

3.3. PLS-DA and Model Evaluation Analysis

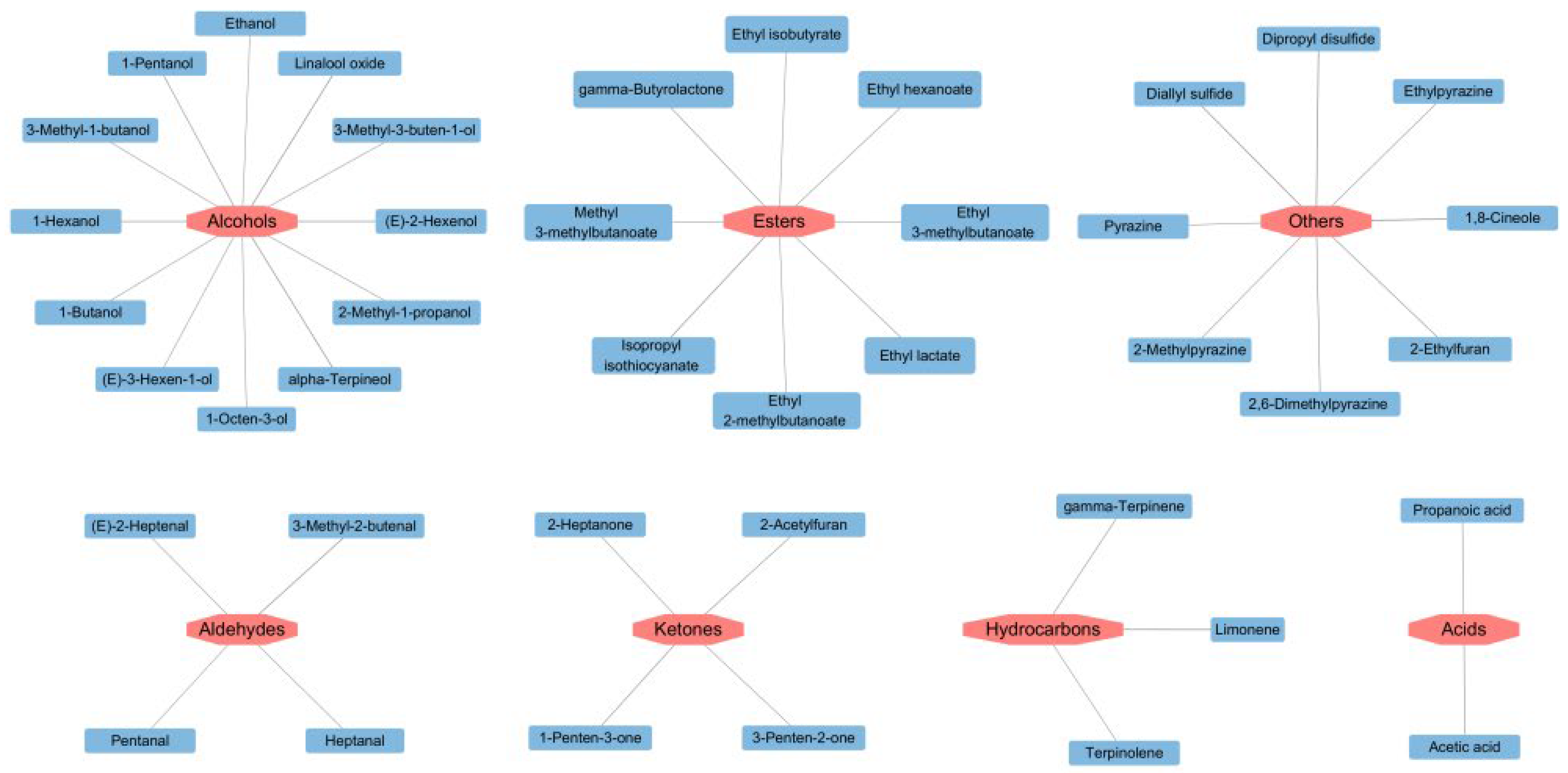

3.4. Key Volatile Substances

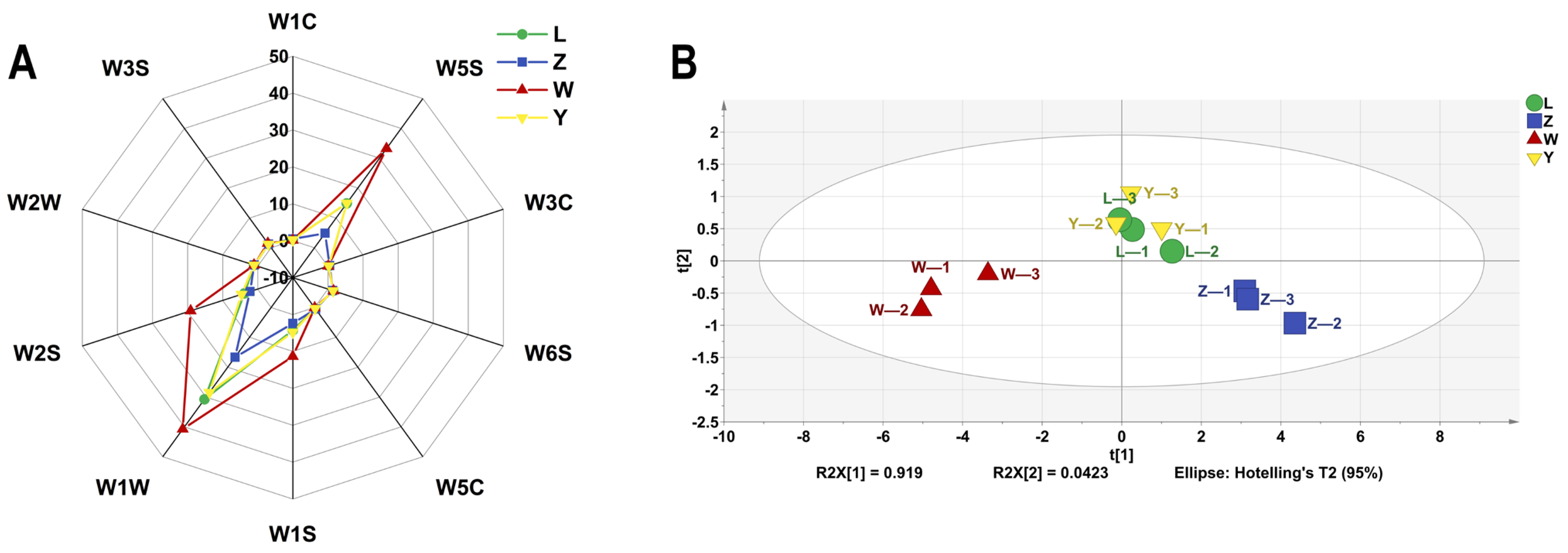

3.5. E-Nose Analysis

3.6. E-Tongue Analysis

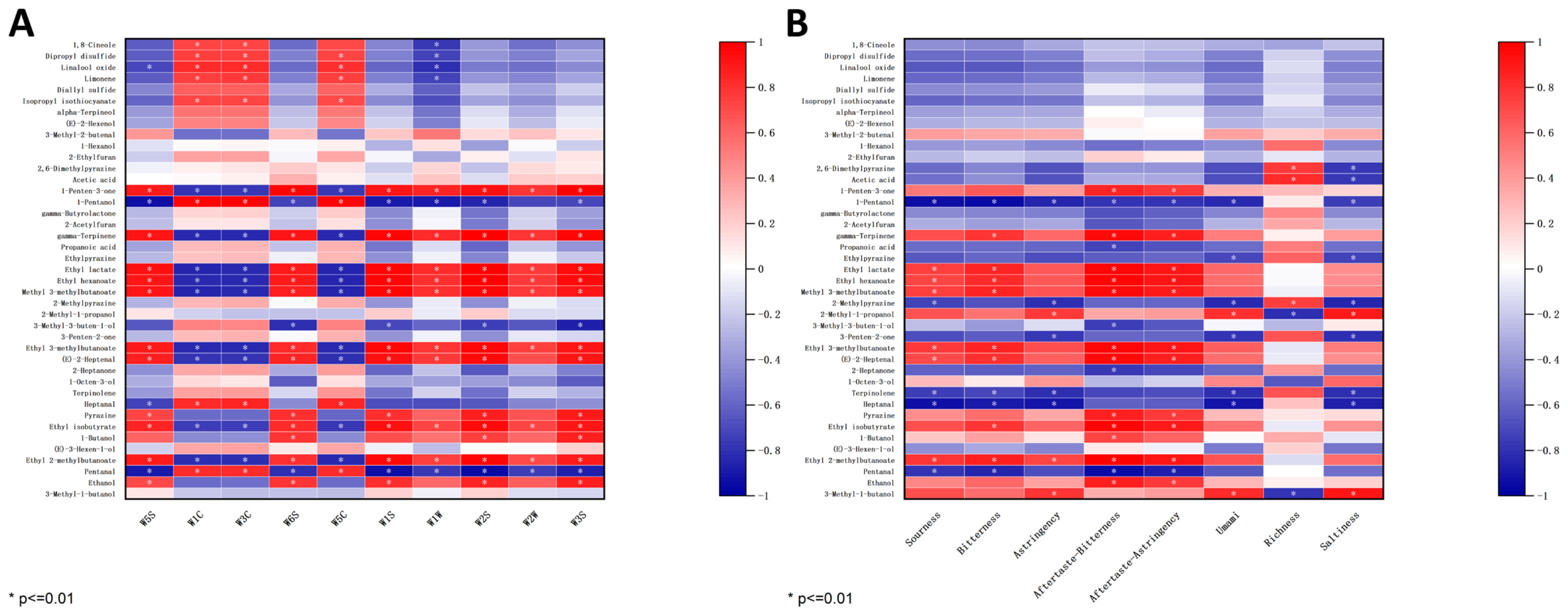

3.7. Correlation Analysis

3.7.1. Correlation Between E-Nose and GC–IMS

3.7.2. Correlation Between E-Tongue and GC–IMS

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lu, Y.; Chi, Y.; Lv, Y.; Yang, G.; He, Q. Evolution of the volatile flavor compounds of Chinese horse bean-chili-paste. LWT 2019, 102, 131–135. [Google Scholar] [CrossRef]

- Cao, Z.-H.; Green-Johnson, J.M.; Buckley, N.D.; Lin, Q.-Y. Bioactivity of soy-based fermented foods: A review. Biotechnol. Adv. 2019, 37, 223–238. [Google Scholar] [CrossRef] [PubMed]

- Bahuguna, A.; Shukla, S.; Lee, J.S.; Bajpai, V.K.; Kim, S.Y.; Huh, Y.S.; Han, Y.K.; Kim, M. Garlic augments the functional and nutritional behavior of Doenjang, a traditional Korean fermented soybean paste. Sci. Rep. 2019, 9, 5436. [Google Scholar] [CrossRef]

- Hao, Y.; Sun, B. Analysis of bacterial diversity and biogenic amines content during fermentation of farmhouse sauce from Northeast China. Food Control 2020, 108, 106861. [Google Scholar] [CrossRef]

- Kim, M.J.; Kwak, H.S.; Kim, S.S. Effects of salinity on bacterial communities, Maillard reactions, isoflavone composition, antioxidation and antiproliferation in Korean fermented soybean paste (doenjang). Food Chem. 2018, 245, 402–409. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.; Yu, X.; Fang, J.; Lu, Y.; Liu, P.; Xing, Y.; Wang, Q.; Che, Z.; He, Q. Flavor Compounds in Pixian Broad-Bean Paste: Non-Volatile Organic Acids and Amino Acids. Molecules 2018, 23, 1299. [Google Scholar] [CrossRef]

- Wu, J.; Tian, T.; Liu, Y.; Shi, Y.; Tao, D.; Wu, R.; Yue, X. The dynamic changes of chemical components and microbiota during the natural fermentation process in Da-Jiang, a Chinese popular traditional fermented condiment. Food Res. Int. 2018, 112, 457–467. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, P.; Xie, M.; An, F.; Qiu, B.; Wu, R. Metaproteomics of Microbiota in Naturally Fermented Soybean Paste, Da-jiang. J. Food Sci. 2018, 83, 1342–1349. [Google Scholar] [CrossRef]

- Singracha, P.; Niamsiri, N.; Visessanguan, W.; Lertsiri, S.; Assavanig, A. Application of lactic acid bacteria and yeasts as starter cultures for reduced-salt soy sauce (moromi) fermentation. LWT 2017, 78, 181–188. [Google Scholar] [CrossRef]

- Xie, C.; Zeng, H.; Wang, C.; Xu, Z.; Qin, L. Volatile flavour components, microbiota and their correlations in different sufu, a Chinese fermented soybean food. J. Appl. Microbiol. 2018, 125, 1761–1773. [Google Scholar] [CrossRef]

- Huang, X.; Yu, S.; Han, B.; Chen, J. Bacterial community succession and metabolite changes during sufu fermentation. LWT 2018, 97, 537–545. [Google Scholar] [CrossRef]

- Saeed, F.; Afzaal, M.; Shah, Y.A.; Khan, M.H.; Hussain, M.; Ikram, A.; Ateeq, H.; Noman, M.; Saewan, S.A.; Khashroum, A.O. Miso: A traditional nutritious & health-endorsing fermented product. Food Sci. Nutr. 2022, 10, 4103–4111. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Liu, X.; Tamura, T.; Kyouno, N.; Zhang, H.; Chen, J.Y. Effect of volatile compounds on the quality of miso (traditional Japanese fermented soybean paste). LWT 2021, 139, 110573. [Google Scholar] [CrossRef]

- Wang, C.; Chen, J.; Tian, W.; Han, Y.; Xu, X.; Ren, T.; Tian, C.; Chen, C. Natto: A medicinal and edible food with health function. Chin. Herb. Med. 2023, 15, 349–359. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Lu, Y.; Zhao, A.; Wu, Y.; Zhang, Y.; Yang, X. Quantitative analyses for several nutrients and volatile components during fermentation of soybean by Bacillus subtilis natto. Food Chem. 2022, 374, 131725. [Google Scholar] [CrossRef]

- Lee, S.; Lee, S.; Singh, D.; Oh, J.Y.; Jeon, E.J.; Ryu, H.S.; Lee, D.W.; Kim, B.S.; Lee, C.H. Comparative evaluation of microbial diversity and metabolite profiles in doenjang, a fermented soybean paste, during the two different industrial manufacturing processes. Food Chem. 2017, 221, 1578–1586. [Google Scholar] [CrossRef] [PubMed]

- Jeong, D.-W.; Heo, S.; Lee, B.; Lee, H.; Jeong, K.; Her, J.-Y.; Lee, K.-G.; Lee, J.-H. Effects of the predominant bacteria from meju and doenjang on the production of volatile compounds during soybean fermentation. Int. J. Food Microbiol. 2017, 262, 8–13. [Google Scholar] [CrossRef]

- Romulo, A.; Surya, R. Tempe: A traditional fermented food of Indonesia and its health benefits. Int. J. Gastron. Food Sci. 2021, 26, 100413. [Google Scholar] [CrossRef]

- Wu, Z.; Chao, J.; Tang, H.; Liu, T.; Jiang, L.; Liu, Y. Characterization of key aroma-active compounds in different types of Douchi based on molecular sensory science approaches. Food Chem. X 2024, 21, 101170. [Google Scholar] [CrossRef]

- Wang, Q.; Li, L.; Ding, W.; Zhang, D.; Wang, J.; Reed, K.; Zhang, B. Adulterant identification in mutton by electronic nose and gas chromatography-mass spectrometer. Food Control 2019, 98, 431–438. [Google Scholar] [CrossRef]

- Guo, X.; Schwab, W.; Ho, C.-T.; Song, C.; Wan, X. Characterization of the aroma profiles of oolong tea made from three tea cultivars by both GC–MS and GC-IMS. Food Chem. 2022, 376, 131933. [Google Scholar] [CrossRef]

- Nie, S.; Li, L.; Wang, Y.; Wu, Y.; Li, C.; Chen, S.; Zhao, Y.; Wang, D.; Xiang, H.; Wei, Y. Discrimination and characterization of volatile organic compound fingerprints during sea bass (Lateolabrax japonicas) fermentation by combining GC-IMS and GC-MS. Food Biosci. 2022, 50, 102048. [Google Scholar] [CrossRef]

- Ma, M.; Chen, Z.; Huang, B.; Chen, X.; Liu, H.; Peng, Z.; Dong, P.; Lu, J.; Wu, D. Characterizing the key aroma compounds of barley malt from different origins using GC-E-Nose, HS-SPME-GC-MS, and HS-GC-IMS. Food Biosci. 2024, 58, 103707. [Google Scholar] [CrossRef]

- Miao, X.; Zhang, R.; Jiang, S.; Song, Z.; Du, M.; Liu, A. Volatile flavor profiles of douchis from different origins and varieties based on GC-IMS and GC-O-QTOF/MS analysis. Food Chem. 2024, 460, 140717. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Cai, X.; Liu, J.; Yuan, C.; Yi, Y.; Qiao, M. Investigation of different ingredients affected the flavor changes of Yu-Shiang shredded pork by using GC-IMS and GC-MS combined with E-nose and E-tongue. Heliyon 2024, 10, e31486. [Google Scholar] [CrossRef] [PubMed]

- Meng, X.; Ye, D.; Pan, Y.; Zhang, T.; Liang, L.; Liu, Y.; Ma, Y. Optimisation of Not-from-Concentrate Goji Juice Processing Using Fuzzy Mathematics and Response Surface Methodology and Its Quality Assessment. Appl. Sci. 2024, 14, 8393. [Google Scholar] [CrossRef]

- Zhai, H.; Dong, W.; Tang, Y.; Hu, R.; Yu, X.; Chen, X. Characterization of the volatile flavour compounds in Yunnan Arabica coffee prepared by different primary processing methods using HS-SPME/GC-MS and HS-GC-IMS. LWT 2024, 192, 115717. [Google Scholar] [CrossRef]

- Zheng, X.; Ji, H.; Zhang, D.; Zhang, Z.; Liu, S.; Song, W. The identification of three phospholipid species roles on the aroma formation of hot-air-dried shrimp (Litopenaeus vannamei) by gas chromatography–ion mobility spectrometry and gas chromatography- mass spectrometry. Food Res. Int. 2022, 162, 112191. [Google Scholar] [CrossRef]

- Liu, L.; Chen, X.; Hao, L.; Zhang, G.; Jin, Z.; Li, C.; Yang, Y.; Rao, J.; Chen, B. Traditional fermented soybean products: Processing, flavor formation, nutritional and biological activities. Crit. Rev. Food Sci. Nutr. 2020, 62, 1971–1989. [Google Scholar] [CrossRef]

- Xu, Y.; Zhao, J.; Liu, X.; Zhang, C.; Zhao, Z.; Li, X.; Sun, B. Flavor mystery of Chinese traditional fermented baijiu: The great contribution of ester compounds. Food Chem. 2022, 369, 130920. [Google Scholar] [CrossRef]

- Zhang, J.; Han, Z.; Chen, H.; Wang, S.; Sun, J.; Zhang, N.; Zhang, H. Characterization and correlations of dominant microorganisms and volatile compounds in fermentation process of Yangjiang douchi. J. Sci. Food Agric. 2024, 104, 7397–7407. [Google Scholar] [CrossRef] [PubMed]

- Xie, J.; Wang, L.; Deng, Y.; Yuan, H.; Zhu, J.; Jiang, Y.; Yang, Y. Characterization of the key odorants in floral aroma green tea based on GC-E-Nose, GC-IMS, GC-MS and aroma recombination and investigation of the dynamic changes and aroma formation during processing. Food Chem. 2023, 427, 136641. [Google Scholar] [CrossRef] [PubMed]

- Jia, W.; Liang, G.; Tian, H.; Sun, J.; Wan, C. Electronic Nose-Based Technique for Rapid Detection and Recognition of Moldy Apples. Sensors 2019, 19, 1526. [Google Scholar] [CrossRef] [PubMed]

| Items | V1 | V2 | V3 | V4 |

|---|---|---|---|---|

| Color | Reddish-brown, bright, and shiny. | Reddish brown, shiny. | Dull surface color and low gloss. | The surface is not shiny, the color is gray and dull. |

| Flavor | Harmonious smell and strong sauce flavor. | Harmonious smell and sauce flavor. | Light sauce flavor, no bad flavor. | Light sauce flavor, peculiar flavor. |

| Texture | The sauce is medium consistency, uniform, no impurities. | The sauce is medium consistency, no impurities. | Paste consistency is not appropriate, no impurities. | Paste consistency is not appropriate and there are impurities. |

| Taste | Full taste, and mellow, and appropriate salinity. | Umami and appropriate salinity. | Slightly umami, slightly salty or light. | Burnt, too salty or too light. |

| Sensor Number | Sensors Name | Sensitive Substance |

|---|---|---|

| 1 | W1C | Aromatic compounds |

| 2 | W5S | Nitrogen oxides |

| 3 | W3C | Ammonia, aromatic molecule |

| 4 | W6S | Hydrides |

| 5 | W5C | Olefin, aromatic components, and polar molecules |

| 6 | W1S | Alkanes |

| 7 | W1W | Sulfides |

| 8 | W2S | Alcohols and some aromatic compounds |

| 9 | W2W | Aromatic components and organic sulfides |

| 10 | W3S | Aliphatic series |

| Sample | Color | Flavor | Texture | Taste | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| V1 | V2 | V3 | V4 | V1 | V2 | V3 | V4 | V1 | V2 | V3 | V4 | V1 | V2 | V3 | V4 | |

| 1 | 5 | 7 | 8 | 0 | 14 | 6 | 0 | 0 | 15 | 4 | 1 | 0 | 17 | 2 | 1 | 0 |

| 2 | 13 | 7 | 0 | 0 | 7 | 8 | 5 | 0 | 11 | 4 | 5 | 0 | 11 | 7 | 2 | 0 |

| 3 | 16 | 4 | 0 | 0 | 8 | 7 | 5 | 0 | 9 | 9 | 2 | 0 | 6 | 10 | 4 | 0 |

| 4 | 2 | 6 | 12 | 0 | 3 | 4 | 8 | 5 | 1 | 9 | 10 | 0 | 4 | 10 | 6 | 0 |

| Compounds (111) | MW | RI | Rt (s) | Dt (ms) | Relative Amount (%) | |||

|---|---|---|---|---|---|---|---|---|

| L | Z | W | Y | |||||

| Esters (21) | ||||||||

| Methyl acetate | 74.1 | 851.8 | 256.877 | 1.19121 | 0.32 ± 0.022 b | 0.14 ± 0.008 c | 0.12 ± 0.005 c | 0.46 ± 0.022 a |

| Ethyl acetate | 88.1 | 896.8 | 283.395 | 1.33437 | 1.31 ± 0.152 d | 1.88 ± 0.100 c | 4.07 ± 0.061 a | 3.30 ± 0.450 b |

| Isopropyl acetate | 102.1 | 957.6 | 323.64 | 1.47496 | 0.14 ± 0.028 b | 0.05 ± 0.001 b | 0.02 ± 0.003 b | 1.87 ± 0.140 a |

| Ethyl propanoate | 102.1 | 974.5 | 335.737 | 1.44596 | 0.03 ± 0.001 c | 0.05 ± 0.004 c | 0.23 ± 0.032 a | 0.09 ± 0.012 b |

| Ethyl isobutyrate | 116.2 | 982.3 | 341.553 | 1.55668 | 0.02 ± 0.001 c | 0.27 ± 0.038 b | 1.46 ± 0.156 a | 0.07 ± 0.010 c |

| Propyl acetate | 102.1 | 995.1 | 351.196 | 1.47584 | 0.21 ± 0.890 ab | 0.28 ± 0.103 a | 0.18 ± 0.007 ab | 0.12 ± 0.018 b |

| 2-Methylpropyl acetate | 116.2 | 1030.6 | 388.863 | 1.60889 | 0.02 ± 0.000 b | 0.03 ± 0.004 b | 0.07 ± 0.014 b | 0.70 ± 0.084 a |

| Ethyl butanoate | 116.2 | 1038.3 | 397.602 | 1.19963 | 0.10 ± 0.003 c | 0.14 ± 0.009 b | 0.18 ± 0.012 a | 0.18 ± 0.008 a |

| Methyl 3-methylbutanoate | 116.2 | 1054.2 | 416.278 | 1.55364 | 0.01 ± 0.000 b | 0.01 ± 0.001 b | 0.17 ± 0.032 a | 0.02 ± 0.000 b |

| Ethyl 2-methylbutanoate-M | 130.2 | 1069.5 | 434.968 | 1.25521 | 0.05 ± 0.001 d | 0.15 ± 0.013 c | 0.32 ± 0.011 a | 0.18 ± 0.005 b |

| Ethyl 2-methylbutanoate-D | 130.2 | 1069.5 | 434.968 | 1.25521 | 0.02 ± 0.003 b | 0.04 ± 0.008 b | 0.65 ± 0.096 a | 0.04 ± 0.003 b |

| Ethyl 3-methylbutanoate-M | 130.2 | 1082.4 | 451.541 | 1.27458 | 0.02 ± 0.002 c | 0.09 ± 0.008 b | 0.50 ± 0.037 a | 0.09 ± 0.008 b |

| Ethyl 3-methylbutanoate-D | 130.2 | 1082.4 | 451.541 | 1.27458 | 0.02 ± 0.001 b | 0.01 ± 0.001 b | 0.23 ± 0.051 a | 0.01 ± 0.001 b |

| 2-Methylbutyl acetate | 130.2 | 1110.1 | 492.504 | 1.72463 | 0.04 ± 0.003 c | 0.07 ± 0.004 b | 0.13 ± 0.01 a | 0.07 ± 0.002 b |

| Isopropyl isothiocyanate-M | 101.2 | 1134.6 | 535.618 | 1.09185 | 0.96 ± 0.133 b | 3.99 ± 0.028 a | 0.88 ± 0.013 b | 0.19 ± 0.019 c |

| Isopropyl isothiocyanate-D | 101.2 | 1134.6 | 535.618 | 1.09185 | 0.19 ± 0.007 d | 2.20 ± 0.024 a | 0.37 ± 0.032 b | 0.28 ± 0.010 c |

| Isoamyl acetate-M | 130.2 | 1138.2 | 542.35 | 1.30144 | 0.14 ± 0.014 d | 0.34 ± 0.02 b | 0.40 ± 0.027 b | 0.84 ± 0.011 a |

| Isoamyl acetate-D | 130.2 | 1138.2 | 542.35 | 1.30144 | 0.03 ± 0.004 c | 0.14 ± 0.011 b | 0.20 ± 0.039 b | 1.36 ± 0.10 a |

| Ethyl pentanoate | 130.2 | 1163.2 | 590.92 | 1.2857 | 0.27 ± 0.009 c | 0.20 ± 0.008 d | 0.97 ± 0.026 b | 2.75 ± 0.020 a |

| Ethyl hexanoate-M | 144.2 | 1247 | 729.499 | 1.34328 | 0.01 ± 0.001 b | 0.02 ± 0.001 b | 0.15 ± 0.012 a | 0.02 ± 0.000 b |

| Ethyl hexanoate-D | 144.2 | 1247 | 729.499 | 1.34328 | 0.02 ± 0.002 b | 0.01 ± 0.001 bc | 0.03 ± 0.002 a | 0.01 ± 0.001 c |

| cis-3-Hexenyl acetate | 142.2 | 1331.7 | 870.734 | 1.32866 | 0.02 ± 0.003 a | 0.02 ± 0.003 a | 0.02 ± 0.001 a | 0.01 ± 0.002 a |

| Ethyl lactate-M | 118.1 | 1362.8 | 931.32 | 1.15595 | 0.06 ± 0.004 c | 0.07 ± 0.004 b | 1.00 ± 0.006 a | 0.05 ± 0.004 c |

| Ethyl lactate-D | 118.1 | 1362.8 | 931.32 | 1.15595 | 0.03 ± 0.003 b | 0.03 ± 0.004 b | 0.25 ± 0.006 a | 0.03 ± 0.000 b |

| Ethyl heptanoate | 158.2 | 1366.6 | 939.048 | 1.42191 | 0.05 ± 0.003 b | 0.03 ± 0.003 c | 0.04 ± 0.001 c | 0.16 ± 0.005 a |

| Ethyl octanoate | 172.3 | 1455.7 | 1138.39 | 1.48435 | 0.05 ± 0.006 a | 0.05 ± 0.004 a | 0.05 ± 0.005 ab | 0.04 ± 0.003 b |

| gamma-Butyrolactone | 86.1 | 1714.4 | 1990.701 | 1.09373 | 1.71 ± 0.082 a | 0.72 ± 0.015 c | 0.61 ± 0.010 d | 1.18 ± 0.007 b |

| Total | 5.82 ± 0.242 d | 11.02 ± 0.303 c | 13.28 ± 0.598 b | 14.09 ± 0.388 a | ||||

| Ketones (19) | ||||||||

| Acetone | 58.1 | 836 | 248.138 | 1.11374 | 7.04 ± 0.181 a | 7.10 ± 0.170 a | 6.42 ± 0.037 b | 4.73 ± 0.116 c |

| 2-Butanone | 72.1 | 917.3 | 296.352 | 1.24426 | 3.71 ± 0.040 a | 3.42 ± 0.064 b | 2.79 ± 0.007 c | 2.87 ± 0.095 c |

| 2-Pentanone | 86.1 | 1000.9 | 356.942 | 1.36668 | 0.24 ± 0.037 b | 0.22 ± 0.021 b | 0.19 ± 0.009 b | 0.32 ± 0.040 a |

| 4-Methyl-2-pentanone | 100.2 | 1027.9 | 385.85 | 1.18531 | 0.19 ± 0.030 a | 0.14 ± 0.010 b | 0.11 ± 0.005 b | 0.18 ± 0.010 a |

| 1-Penten-3-one | 84.1 | 1044.6 | 404.834 | 1.08174 | 0.05 ± 0.004 b | 0.04 ± 0.004 c | 0.08 ± 0.002 a | 0.03 ± 0.002 d |

| 2,3-Pentanedione | 100.1 | 1066.5 | 431.266 | 1.20009 | 1.15 ± 0.073 a | 0.88 ± 0.088 b | 0.48 ± 0.042 c | 0.19 ± 0.007 d |

| 2-Hexanone | 100.2 | 1101.6 | 478.392 | 1.19714 | 0.07 ± 0.002 a | 0.06 ± 0.005 b | 0.03 ± 0.001 d | 0.06 ± 0.003 c |

| 3-Penten-2-one-M | 84.1 | 1117 | 504.36 | 1.0948 | 1.05 ± 0.017 a | 0.85 ± 0.021 b | 0.59 ± 0.020 c | 0.44 ± 0.022 d |

| 3-Penten-2-one-D | 84.1 | 1117 | 504.36 | 1.0948 | 0.57 ± 0.063 b | 0.43 ± 0.029 c | 0.60 ± 0.016 b | 0.77 ± 0.026 a |

| 4-Heptanone-M | 114.2 | 1170.5 | 605.731 | 1.24066 | 0.41 ± 0.108 a | 0.26 ± 0.013 b | 0.16 ± 0.002 c | 0.15 ± 0.022 c |

| 4-Heptanone-D | 114.2 | 1170.5 | 605.731 | 1.24066 | 0.08 ± 0.030 b | 0.04 ± 0.002 c | 0.04 ± 0.001 c | 0.12 ± 0.013 a |

| 2-Heptanone | 114.2 | 1196.3 | 657.814 | 1.26308 | 0.11 ± 0.005 a | 0.08 ± 0.005 c | 0.06 ± 0.006 d | 0.09 ± 0.004 b |

| 4-Hexen-3-one | 98.1 | 1200.3 | 663.297 | 1.1127 | 0.09 ± 0.004 a | 0.06 ± 0.002 b | 0.04 ± 0.002 d | 0.04 ± 0.001 c |

| 3-Octanone | 128.2 | 1239.3 | 718.122 | 1.30231 | 0.04 ± 0.009 b | 0.03 ± 0.002 bc | 0.03 ± 0.000 c | 0.09 ± 0.006 a |

| 3-Hydroxy-2-butanone-M | 98.1 | 1301.3 | 815.436 | 1.16314 | 0.97 ± 0.026 b | 0.99 ± 0.012 b | 0.97 ± 0.020 b | 1.22 ± 0.013 a |

| 3-Hydroxy-2-butanone-D | 88.1 | 1301.3 | 815.436 | 1.09028 | 0.20 ± 0.013 c | 0.21 ± 0.008 c | 0.49 ± 0.012 b | 0.52 ± 0.016 a |

| Cyclohexanone | 88.1 | 1301.3 | 815.436 | 1.09028 | 0.11 ± 0.008 c | 0.13 ± 0.007 b | 0.18 ± 0.003 a | 0.12 ± 0.009 bc |

| 1-Hydroxy-2-propanone-M | 74.1 | 1316.6 | 842.849 | 1.09589 | 3.48 ± 0.086 a | 2.91 ± 0.023 b | 1.32 ± 0.045 d | 1.79 ± 0.001 c |

| 1-Hydroxy-2-propanone-D | 74.1 | 1316.6 | 842.849 | 1.09589 | 2.66 ± 0.111 a | 1.66 ± 0.047 b | 0.44 ± 0.021 d | 0.63 ± 0.011 c |

| 6-Methyl-5-hepten-2-one | 126.2 | 1349.8 | 905.563 | 1.17761 | 0.04 ± 0.006 bc | 0.05 ± 0.008 b | 0.04 ± 0.001 c | 0.16 ± 0.004 a |

| 2-Acetylfuran | 110.1 | 1544.3 | 1378.468 | 1.13048 | 0.54 ± 0.013 a | 0.14 ± 0.005 c | 0.13 ± 0.004 c | 0.42 ± 0.040 b |

| Acetophenone | 120.2 | 1817.9 | 2489.778 | 1.17898 | 0.15 ± 0.019 c | 0.23 ± 0.009 b | 0.26 ± 0.014 a | 0.13 ± 0.007 c |

| Carvone | 150.2 | 1889.8 | 2908.024 | 1.31286 | 0.18 ± 0.005 a | 0.15 ± 0.009 b | 0.12 ± 0.005 c | 0.12 ± 0.008 c |

| Total | 23.1 ± 0.181 a | 20.09 ± 0.378 b | 15.54 ± 0.114 c | 15.16 ± 0.210 c | ||||

| Alcohols (17) | ||||||||

| Ethanol | 46.1 | 944.9 | 314.734 | 1.13563 | 7.23 ± 0.388 c | 10.43 ± 0.161 b | 17.14 ± 0.35 a | 5.14 ± 0.288 d |

| 2-Butanol-M | 74.1 | 1041.2 | 400.917 | 1.15331 | 0.32 ± 0.006 c | 0.28 ± 0.004 d | 0.55 ± 0.011 a | 0.44 ± 0.009 b |

| 2-Butanol-D | 74.1 | 1041.2 | 400.917 | 1.15331 | 0.09 ± 0.007 b | 0.10 ± 0.001 b | 0.28 ± 0.002 a | 0.30 ± 0.017 a |

| 1-Propanol-M | 60.1 | 1057.2 | 419.901 | 1.11458 | 0.58 ± 0.056 b | 0.91 ± 0.015 a | 0.50 ± 0.023 c | 0.48 ± 0.019 c |

| 1-Propanol-D | 60.1 | 1057.2 | 419.901 | 1.11458 | 0.12 ± 0.007 d | 0.17 ± 0.005 c | 0.83 ± 0.024 b | 0.88 ± 0.009 a |

| 2-Methyl-1-propanol-M | 74.1 | 1111.4 | 494.743 | 1.17746 | 1.57 ± 0.089 b | 2.03 ± 0.007 a | 1.07 ± 0.014 c | 1.11 ± 0.090 c |

| 2-Methyl-1-propanol-D | 74.1 | 1111.4 | 494.743 | 1.17746 | 0.45 ± 0.031 d | 1.44 ± 0.031 c | 2.69 ± 0.028 b | 3.5 ± 0.024 a |

| 1-Butanol-M | 74.1 | 1162.3 | 588.996 | 1.18533 | 1.03 ± 0.081 a | 1.13 ± 0.085 a | 1.09 ± 0.008 a | 0.41 ± 0.029 b |

| 1-Butanol-D | 74.1 | 1162.3 | 588.996 | 1.18533 | 0.13 ± 0.025 c | 0.23 ± 0.037 b | 0.92 ± 0.015 a | 0.11 ± 0.002 c |

| 3-Methyl-1-butanol-M | 88.1 | 1223.1 | 694.821 | 1.2444 | 1.26 ± 0.061 b | 1.61 ± 0.008 a | 1.19 ± 0.011 c | 1.13 ± 0.030 c |

| 3-Methyl-1-butanol-D | 88.1 | 1223.1 | 694.821 | 1.2444 | 0.59 ± 0.065 d | 1.65 ± 0.027 c | 2.49 ± 0.023 b | 3.61 ± 0.024 a |

| 3-Methyl-3-buten-1-ol | 86.1 | 1266.5 | 759.065 | 1.17761 | 0.04 ± 0.002 b | 0.04 ± 0.001 b | 0.02 ± 0.003 c | 0.05 ± 0.001 a |

| 1-Pentanol-M | 88.1 | 1268 | 761.297 | 1.2556 | 0.34 ± 0.013 b | 0.44 ± 0.015 a | 0.14 ± 0.007 d | 0.25 ± 0.005 c |

| 1-Pentanol-D | 88.1 | 1268 | 761.297 | 1.2556 | 0.04 ± 0.005 b | 0.06 ± 0.005 a | 0.02 ± 0.001 d | 0.03 ± 0.004 c |

| 1-Hexanol | 102.2 | 1373.7 | 953.405 | 1.33276 | 0.35 ± 0.012 a | 0.07 ± 0.002 d | 0.09 ± 0.002 c | 0.18 ± 0.007 b |

| (E)-3-Hexen-1-ol | 100.2 | 1389.2 | 985.898 | 1.22993 | 0.02 ± 0.001 c | 0.03 ± 0.004 a | 0.02 ± 0.001 b | 0.01 ± 0.002 d |

| (E)-2-Hexenol | 100.2 | 1395.1 | 998.58 | 1.32876 | 0.03 ± 0.003 c | 0.14 ± 0.005 a | 0.07 ± 0.012 b | 0.03 ± 0.014 c |

| (Z)-3-Hexenol | 100.2 | 1405.8 | 1022 | 1.25723 | 0.04 ± 0.002 b | 0.03 ± 0.002 b | 0.04 ± 0.003 b | 0.06 ± 0.005 a |

| Linalool oxide | 170.3 | 1443.9 | 1109.719 | 1.23909 | 0.04 ± 0.004 b | 0.11 ± 0.009 a | 0.03 ± 0.001 c | 0.04 ± 0.002 bc |

| 1-Octen-3-ol | 128.2 | 1487.7 | 1219.784 | 1.16307 | 0.04 ± 0.003 c | 0.06 ± 0.002 b | 0.04 ± 0.003 c | 0.15 ± 0.012 a |

| 2-Ethyl-1-hexanol | 130.2 | 1542.1 | 1371.811 | 1.43037 | 0.09 ± 0.010 a | 0.09 ± 0.006 a | 0.05 ± 0.011 b | 0.06 ± 0.004 b |

| Linalool | 154.3 | 1639.9 | 1694.692 | 1.2236 | 0.34 ± 0.028 c | 0.38 ± 0.011 b | 0.43 ± 0.017 a | 0.42 ± 0.023 a |

| alpha-Terpineol | 154.3 | 1829.7 | 2553.831 | 1.23986 | 0.15 ± 0.014 c | 0.90 ± 0.071 a | 0.37 ± 0.059 b | 0.14 ± 0.025 c |

| Total | 14.86 ± 0.637 d | 22.33 ± 0.168 b | 30.07 ± 0.484 a | 18.51 ± 0.481 c | ||||

| Aldehydes (18) | ||||||||

| Acetaldehyde | 44.1 | 762.5 | 211.375 | 1.02953 | 2.39 ± 0.176 a | 2.06 ± 0.058 b | 1.76 ± 0.048 c | 1.84 ± 0.024 c |

| Propanal | 58.1 | 816.1 | 237.591 | 1.14237 | 1.76 ± 0.056 a | 1.68 ± 0.076 ab | 1.42 ± 0.014 c | 1.62 ± 0.013 b |

| 2-Methylpropanal | 72.1 | 826.4 | 243.015 | 1.28047 | 0.64 ± 0.013 b | 0.55 ± 0.014 c | 0.47 ± 0.005 d | 0.76 ± 0.026 a |

| 2-Propenal | 56.1 | 880 | 273.149 | 1.06574 | 0.15 ± 0.006 a | 0.16 ± 0.015 a | 0.11 ± 0.003 b | 0.10 ± 0.014 b |

| 3-Methylbutanal | 86.1 | 930.6 | 305.091 | 1.40594 | 4.24 ± 0.041 a | 3.89 ± 0.027 b | 2.55 ± 0.005 d | 3.57 ± 0.078 c |

| Pentanal | 86.1 | 1003.8 | 359.935 | 1.41773 | 0.67 ± 0.137 a | 0.63 ± 0.054 a | 0.13 ± 0.011 b | 0.60 ± 0.041 a |

| Hexanal-M | 100.2 | 1103.1 | 480.797 | 1.30243 | 0.66 ± 0.088 a | 0.7 ± 0.020 a | 0.34 ± 0.009 c | 0.49 ± 0.008 b |

| Hexanal-D | 100.2 | 1103.1 | 480.797 | 1.30243 | 0.09 ± 0.023 a | 0.1 ± 0.003 a | 0.03 ± 0.002 c | 0.06 ± 0.006 b |

| (E)-2-Pentenal-M | 84.1 | 1151.4 | 567.357 | 1.1076 | 0.68 ± 0.032 a | 0.62 ± 0.037 b | 0.26 ± 0.006 c | 0.08 ± 0.002 d |

| (E)-2-Pentenal-D | 84.1 | 1151.4 | 567.357 | 1.1076 | 0.25 ± 0.03 a | 0.21 ± 0.026 b | 0.24 ± 0.005 ab | 0.07 ± 0.003 c |

| Heptanal | 114.2 | 1198.8 | 661.241 | 1.36488 | 0.06 ± 0.006 b | 0.07 ± 0.003 a | 0.03 ± 0.004 c | 0.03 ± 0.001 c |

| 3-Methyl-2-butenal-M | 84.1 | 1217.3 | 686.598 | 1.09215 | 0.49 ± 0.018 a | 0.17 ± 0.012 c | 0.35 ± 0.018 b | 0.35 ± 0.022 b |

| 3-Methyl-2-butenal-D | 84.1 | 1217.3 | 686.598 | 1.09215 | 0.12 ± 0.009 c | 0.07 ± 0.004 d | 0.15 ± 0.017 b | 0.27 ± 0.022 a |

| (E)-2-Heptenal | 112.2 | 1334.3 | 875.744 | 1.25747 | 0.06 ± 0.006 b | 0.06 ± 0.006 b | 0.10 ± 0.003 a | 0.06 ± 0.003 b |

| Nonanal | 142.2 | 1408.9 | 1028.773 | 1.50194 | 0.12 ± 0.002 a | 0.11 ± 0.006 b | 0.07 ± 0.004 d | 0.07 ± 0.004 c |

| (E)-2-Octenal | 126.2 | 1441.1 | 1102.937 | 1.33782 | 0.05 ± 0.004 ab | 0.04 ± 0.003 b | 0.06 ± 0.014 a | 0.04 ± 0.014 b |

| Citronellal | 154.3 | 1488.2 | 1221.009 | 1.22339 | 0.06 ± 0.003 bc | 0.08 ± 0.006 b | 0.05 ± 0.005 c | 0.28 ± 0.024 a |

| Furfural | 96.1 | 1497.3 | 1245.303 | 1.3369 | 0.10 ± 0.010 b | 0.08 ± 0.008 b | 0.11 ± 0.032 b | 1.30 ± 0.178 a |

| Benzaldehyde | 106.1 | 1554.9 | 1410.351 | 1.15785 | 0.46 ± 0.012 b | 0.4 ± 0.013 c | 0.49 ± 0.016 b | 0.61 ± 0.014 a |

| Salicylic aldehyde | 122.1 | 1735.8 | 2084.855 | 1.13761 | 0.23 ± 0.010 b | 0.19 ± 0.016 c | 0.17 ± 0.009 c | 0.37 ± 0.04 a |

| Phenylacetaldehyde | 120.2 | 1770.3 | 2246.508 | 1.26985 | 0.71 ± 0.098 b | 0.53 ± 0.022 c | 0.50 ± 0.033 c | 1.47 ± 0.097 a |

| Total | 13.98 ± 0.209 a | 12.37 ± 0.137 b | 9.38 ± 0.081 c | 14.03 ± 0.153 a | ||||

| Hydrocarbons (8) | ||||||||

| alpha-Pinene | 136.2 | 1031.2 | 389.466 | 1.28974 | 0.04 ± 0.002 d | 0.09 ± 0.007 c | 0.18 ± 0.009 a | 0.13 ± 0.011 b |

| beta-Pinene | 136.2 | 1124.8 | 518.021 | 1.21216 | 0.04 ± 0.002 c | 0.05 ± 0.001 b | 0.09 ± 0.006 a | 0.09 ± 0.006 a |

| p-Xylene | 106.2 | 1147.6 | 560.143 | 1.07808 | 0.25 ± 0.010 a | 0.24 ± 0.003 a | 0.12 ± 0.003 b | 0.07 ± 0.003 c |

| o-Xylene | 106.2 | 1192.2 | 652.332 | 1.09215 | 0.18 ± 0.020 a | 0.18 ± 0.001 a | 0.10 ± 0.001 b | 0.09 ± 0.004 b |

| alpha-Terpinene | 136.2 | 1193.2 | 653.703 | 1.22665 | 0.08 ± 0.011 b | 0.06 ± 0.003 bc | 0.05 ± 0.006 c | 0.32 ± 0.025 a |

| Limonene | 136.2 | 1207.3 | 672.765 | 1.21574 | 0.02 ± 0.002 b | 0.07 ± 0.001 a | 0.02 ± 0.003 b | 0.02 ± 0.001 b |

| gamma-Terpinene | 136.2 | 1255.9 | 742.793 | 1.21637 | 0.03 ± 0.001 b | 0.02 ± 0.002 bc | 0.15 ± 0.010 a | 0.01 ± 0.001 c |

| Terpinolene | 136.2 | 1281.1 | 781.856 | 1.20423 | 0.54 ± 0.012 a | 0.21 ± 0.010 b | 0.07 ± 0.003 d | 0.16 ± 0.013 c |

| Total | 1.17 ± 0.012 a | 0.92 ± 0.021 b | 0.76 ± 0.031 c | 0.89 ± 0.026 b | ||||

| Acids (5) | ||||||||

| Acetic acid-M | 60.1 | 1505.2 | 1266.879 | 1.06157 | 16.06 ± 0.393 a | 13.57 ± 0.176 b | 13.65 ± 0.07 b | 11.09 ± 0.278 c |

| Acetic acid-D | 60.1 | 1505.2 | 1266.879 | 1.06157 | 7.21 ± 0.488 a | 3.91 ± 0.110 c | 4.23 ± 0.050 bc | 4.57 ± 0.097 b |

| 2-Methylpropanoic acid-M | 88.1 | 1637.8 | 1687.06 | 1.15633 | 3.31 ± 0.236 b | 2.64 ± 0.038 c | 2.60 ± 0.035 c | 7.90 ± 0.308 a |

| 2-Methylpropanoic acid-D | 88.1 | 1637.8 | 1687.06 | 1.15633 | 0.26 ± 0.021 b | 0.21 ± 0.012 b | 0.19 ± 0.013 b | 1.20 ± 0.142 a |

| Propanoic acid | 74.1 | 1640.1 | 1695.379 | 1.12238 | 2.05 ± 0.054 a | 0.99 ± 0.048 c | 0.73 ± 0.016 d | 1.35 ± 0.054 b |

| Butanoic acid | 88.1 | 1713.4 | 1986.541 | 1.17542 | 0.50 ± 0.045 d | 0.62 ± 0.019 c | 0.92 ± 0.041 b | 1.51 ± 0.079 a |

| Pentanoic acid | 102.1 | 1910.3 | 3039.964 | 1.23887 | 0.98 ± 0.087 c | 0.65 ± 0.081 d | 1.22 ± 0.023 b | 2.01 ± 0.122 a |

| Total | 30.36 ± 0.744 a | 22.59 ± 0.250 c | 23.54 ± 0.111 b | 29.62 ± 0.300 a | ||||

| Others (23) | ||||||||

| Dimethyl sulfide | 62.1 | 792.7 | 225.753 | 0.95459 | 0.98 ± 0.150 c | 0.83 ± 0.081 c | 1.26 ± 0.071 b | 1.57 ± 0.120 a |

| 2-Methylfuran | 82.1 | 884 | 275.56 | 0.97226 | 0.08 ± 0.010 ab | 0.09 ± 0.018 a | 0.09 ± 0.012 a | 0.06 ± 0.008 b |

| Acetal | 118.2 | 905.5 | 288.819 | 1.02363 | 1.94 ± 0.094 a | 1.13 ± 0.033 b | 0.52 ± 0.030 c | 0.38 ± 0.059 d |

| 2-Ethylfuran | 96.1 | 1004.6 | 360.718 | 1.31692 | 0.24 ± 0.010 c | 0.55 ± 0.034 a | 0.39 ± 0.026 b | 0.20 ± 0.046 d |

| Acrylonitrile | 53.1 | 1033 | 391.575 | 1.04889 | 2.06 ± 0.097 a | 1.77 ± 0.031 b | 0.95 ± 0.026 c | 0.64 ± 0.116 d |

| Diallyl sulfide | 114.2 | 1165.5 | 595.438 | 1.1204 | 0.06 ± 0.002 c | 0.68 ± 0.045 a | 0.18 ± 0.006 b | 0.03 ± 0.002 c |

| 1,8-Cineole-M | 154.3 | 1214.8 | 683.171 | 1.30978 | 0.18 ± 0.028 d | 1.50 ± 0.016 a | 0.35 ± 0.007 c | 0.49 ± 0.021 b |

| 1,8-Cineole-D | 154.3 | 1214.8 | 683.171 | 1.30978 | 0.04 ± 0.003 d | 0.23 ± 0.006 a | 0.07 ± 0.002 c | 0.08 ± 0.004 b |

| Pyrazine | 80.1 | 1229.4 | 703.73 | 1.05292 | 0.21 ± 0.004 c | 0.33 ± 0.024 b | 0.64 ± 0.018 a | 0.08 ± 0.012 d |

| 2-Pentylfuran | 138.2 | 1246.3 | 728.402 | 1.25187 | 0.04 ± 0.004 b | 0.05 ± 0.002 b | 0.05 ± 0.007 b | 0.14 ± 0.011 a |

| 2-Methylpyrazine-M | 94.1 | 1281.5 | 782.541 | 1.08094 | 1.21 ± 0.020 a | 0.72 ± 0.007 b | 0.42 ± 0.005 c | 0.38 ± 0.011 d |

| 2-Methylpyrazine-D | 94.1 | 1281.5 | 782.541 | 1.08094 | 0.83 ± 0.049 a | 0.13 ± 0.004 b | 0.04 ± 0.003 c | 0.09 ± 0.008 b |

| 2,5-Dimethylpyrazine | 108.1 | 1331.1 | 869.576 | 1.12858 | 0.07 ± 0.001 a | 0.05 ± 0.002 b | 0.02 ± 0.001 c | 0.01 ± 0.000 d |

| 2,6-Dimethylpyrazine | 108.1 | 1339.7 | 886.023 | 1.12577 | 0.19 ± 0.014 a | 0.05 ± 0.003 b | 0.05 ± 0.002 b | 0.02 ± 0.000 c |

| Ethylpyrazine | 108.1 | 1354.6 | 914.964 | 1.12692 | 0.14 ± 0.011 a | 0.07 ± 0.005 b | 0.06 ± 0.003 c | 0.07 ± 0.007 b |

| 2,3-Dimethylpyrazine | 108.1 | 1370.7 | 947.22 | 1.12358 | 0.07 ± 0.002 d | 0.08 ± 0.002 c | 0.10 ± 0.004 b | 0.17 ± 0.013 a |

| Dipropyl disulfide | 150.3 | 1383.6 | 974.026 | 1.25638 | 0.04 ± 0.002 bc | 0.34 ± 0.008 a | 0.05 ± 0.007 b | 0.03 ± 0.004 c |

| 3-Ethylpyridine | 107.2 | 1389.4 | 986.446 | 1.12353 | 0.48 ± 0.022 a | 0.30 ± 0.008 b | 0.13 ± 0.005 c | 0.13 ± 0.007 c |

| 2,3,5-Trimethylpyrazine | 122.2 | 1409.5 | 1030.233 | 1.17033 | 0.03 ± 0.006 b | 0.03 ± 0.004 b | 0.03 ± 0.002 b | 0.05 ± 0.003 a |

| 2,6-Dimethyl-3-ethylpyrazine | 136.2 | 1473.3 | 1182.384 | 1.23338 | 0.03 ± 0.007 a | 0.03 ± 0.003 a | 0.03 ± 0.006 a | 0.04 ± 0.002 a |

| Methional-M | 104.2 | 1478.3 | 1195.143 | 1.09197 | 0.24 ± 0.016 d | 0.32 ± 0.013 c | 0.51 ± 0.019 b | 0.86 ± 0.02 a |

| Methional-D | 104.2 | 1478.3 | 1195.143 | 1.09197 | 0.04 ± 0.001 c | 0.04 ± 0.003 c | 0.06 ± 0.006 b | 0.15 ± 0.009 a |

| Diallyl disulfide | 146.3 | 1520.7 | 1309.958 | 1.20671 | 0.08 ± 0.016 a | 0.09 ± 0.009 a | 0.04 ± 0.002 b | 0.03 ± 0.002 b |

| 2-Isobutyl-3-methoxypyrazine-M | 166.2 | 1547.7 | 1388.648 | 1.29017 | 0.23 ± 0.021 ab | 0.25 ± 0.024 a | 0.23 ± 0.008 ab | 0.20 ± 0.025 b |

| 2-Isobutyl-3-methoxypyrazine-D | 166.2 | 1547.7 | 1388.648 | 1.29017 | 0.09 ± 0.008 a | 0.09 ± 0.007 a | 0.07 ± 0.002 b | 0.07 ± 0.000 b |

| 2-Acetyl-3-methylpyrazine | 136.2 | 1694.6 | 1907.511 | 1.17118 | 0.37 ± 0.018 c | 0.42 ± 0.017 c | 0.65 ± 0.016 b | 1.20 ± 0.103 a |

| 3-(Methylthio)-1-propanol | 106.2 | 1803.4 | 2412.623 | 1.10649 | 0.70 ± 0.035 a | 0.49 ± 0.083 b | 0.44 ± 0.067 b | 0.51 ± 0.016 b |

| Total | 10.68 ± 0.193 a | 10.66 ± 0.091 a | 7.42 ± 0.108 b | 7.69 ± 0.155 b | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, B.; Wang, H.; Cao, Z.; Yan, J.; Dong, Z.; Ren, F.; Zhang, W.; Chen, L. The Aroma, Taste Contributions, and Flavor Evaluation Based on GC-IMS, E-Nose, and E-Tongue in Soybean Pastes: A Comparative Study. Foods 2025, 14, 1178. https://doi.org/10.3390/foods14071178

Yang B, Wang H, Cao Z, Yan J, Dong Z, Ren F, Zhang W, Chen L. The Aroma, Taste Contributions, and Flavor Evaluation Based on GC-IMS, E-Nose, and E-Tongue in Soybean Pastes: A Comparative Study. Foods. 2025; 14(7):1178. https://doi.org/10.3390/foods14071178

Chicago/Turabian StyleYang, Bing, Heng Wang, Zhenxia Cao, Jing Yan, Zijie Dong, Fazheng Ren, Wanli Zhang, and Lishui Chen. 2025. "The Aroma, Taste Contributions, and Flavor Evaluation Based on GC-IMS, E-Nose, and E-Tongue in Soybean Pastes: A Comparative Study" Foods 14, no. 7: 1178. https://doi.org/10.3390/foods14071178

APA StyleYang, B., Wang, H., Cao, Z., Yan, J., Dong, Z., Ren, F., Zhang, W., & Chen, L. (2025). The Aroma, Taste Contributions, and Flavor Evaluation Based on GC-IMS, E-Nose, and E-Tongue in Soybean Pastes: A Comparative Study. Foods, 14(7), 1178. https://doi.org/10.3390/foods14071178