Optimization of High-Moisture Meat Analog Production with the Addition of Isolated Mung Bean Protein Using Response Surface Methodology

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. High-Moisture Extrusion Process

2.3. Water Holding Capacity (WHC)

2.4. Water Absorption Capacity (WAC) and Oil Absorption Capacity (OAC)

2.5. Integrity Index and Nitrogen Solubility Index (NSI)

2.6. Texture Profile Analysis (TPA) and Cuttings Strength

2.7. Design and Statistics Analysis

3. Results

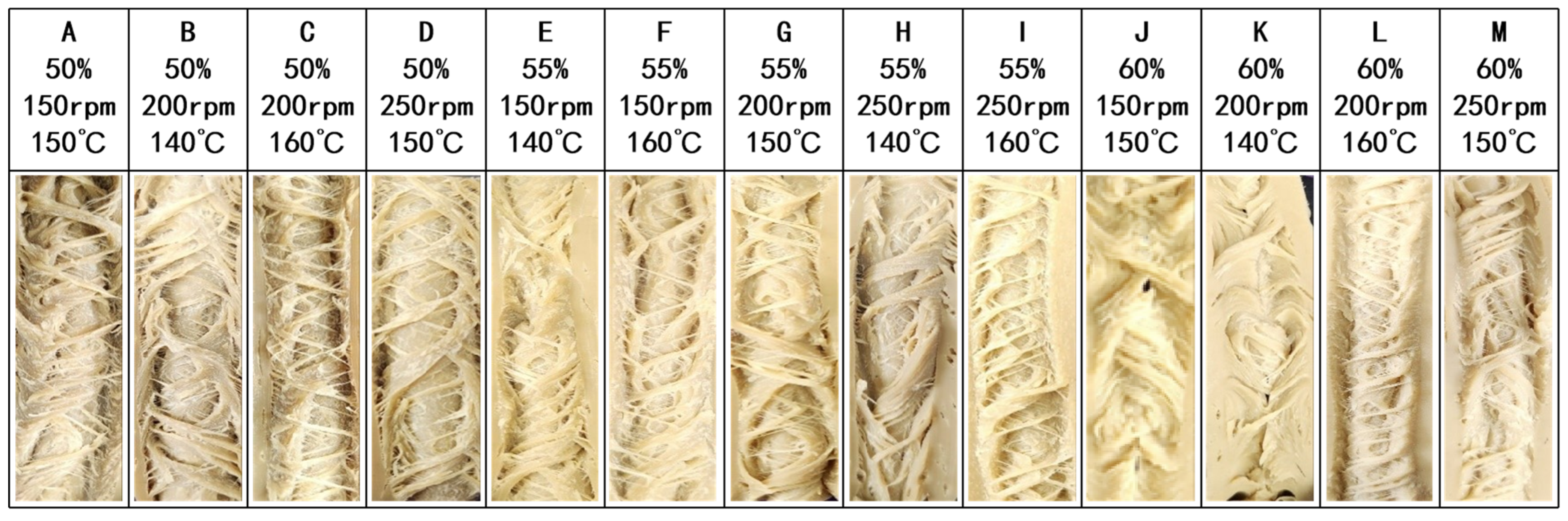

3.1. Fiber Structure

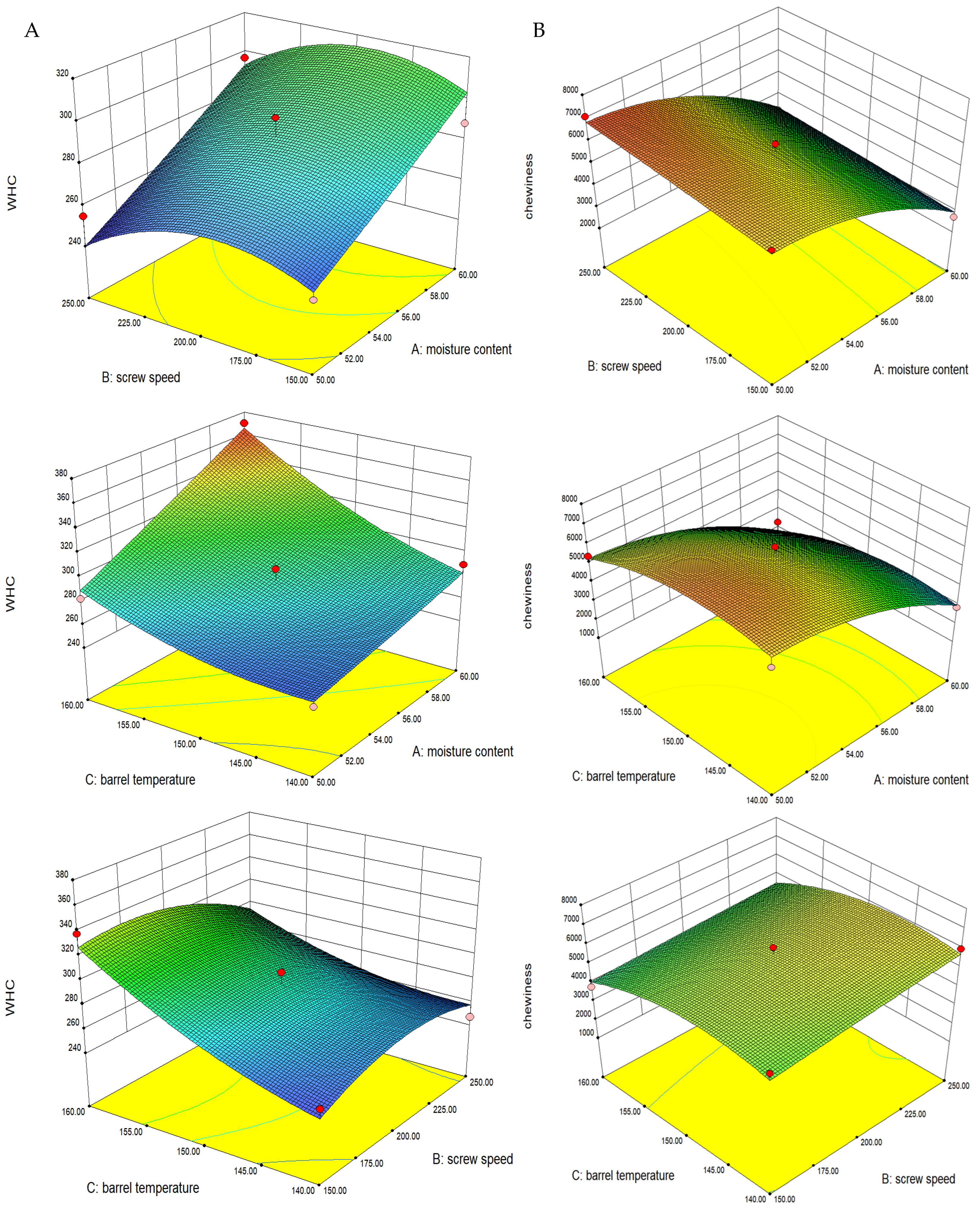

3.2. Water Holding Capacity (WHC)

3.3. Water Absorption Capacity (WAC) and Oil Absorption Capacity (OAC)

3.4. Integrity Index and Nitrogen Solubility Index (NSI)

3.5. Texture Profile Analysis and Cutting Strength

3.6. Optimization of Process Variables

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Malav, O.P.; Talukder, S.; Gokulakrishnan, P.; Chand, S. Meat Analog: A Review. Crit. Rev. Food Sci. Nutr. 2015, 55, 1241–1245. [Google Scholar] [CrossRef] [PubMed]

- Intelligence, A.A. Global Plant-Based Meat Market Report Insights; Arizton: Chicago, IL, USA, 2022. [Google Scholar]

- Kumar, P.; Chatli, M.K.; Mehta, N.; Singh, P.; Malav, O.P.; Verma, A.K. Meat Analogues: Health Promising Sustainable Meat Substitutes. Crit. Rev. Food Sci. Nutr. 2017, 57, 923–932. [Google Scholar] [CrossRef]

- Bohrer, B.M. An Investigation of the Formulation and Nutritional Composition of Modern Meat Analogue Products. Food Sci. Hum. Wellness 2019, 8, 320–329. [Google Scholar] [CrossRef]

- Grand View Research. Plant-Based Meat Market Size, Share & Trends Report, 2030; Grand View Research: San Francisco, CA, USA, 2022. [Google Scholar]

- Handral, H.K.; Tay, S.H.; Chan, W.W.; Choudhury, D. 3D Printing of Cultured Meat Products. Crit. Rev. Food Sci. Nutr. 2022, 62, 272–281. [Google Scholar] [CrossRef]

- Lee, D.Y.; Lee, S.Y.; Jung, J.W.; Kim, J.H.; Oh, D.H.; Kim, H.W.; Kang, J.H.; Choi, J.S.; Kim, G.-D.; Joo, S.-T.; et al. Review of Technology and Materials for the Development of Cultured Meat. Crit. Rev. Food Sci. Nutr. 2023, 63, 8591–8615. [Google Scholar] [CrossRef] [PubMed]

- Grabowska, K.J.; Tekidou, S.; Boom, R.M.; van der Goot, A.-J. Shear Structuring as a New Method to Make Anisotropic Structures from Soy–Gluten Blends. Food Res. Int. 2014, 64, 743–751. [Google Scholar] [CrossRef] [PubMed]

- Krintiras, G.A.; Göbel, J.; van der Goot, A.J.; Stefanidis, G.D. Production of Structured Soy-Based Meat Analogues Using Simple Shear and Heat in a Couette Cell. J. Food Eng. 2015, 160, 34–41. [Google Scholar] [CrossRef]

- Cheftel, J.C.; Kitagawa, M.; Quéguiner, C. New Protein Texturization Processes by Extrusion Cooking at High Moisture Levels. Food Rev. Int. 1992, 8, 235–275. [Google Scholar] [CrossRef]

- Osen, R.; Toelstede, S.; Wild, F.; Eisner, P.; Schweiggert-Weisz, U. High Moisture Extrusion Cooking of Pea Protein Isolates: Raw Material Characteristics, Extruder Responses, and Texture Properties. J. Food Eng. 2014, 127, 67–74. [Google Scholar] [CrossRef]

- Pietsch, V.L.; Werner, R.; Karbstein, H.P.; Emin, M.A. High Moisture Extrusion of Wheat Gluten: Relationship between Process Parameters, Protein Polymerization, and Final Product Characteristics. J. Food Eng. 2019, 259, 3–11. [Google Scholar] [CrossRef]

- Torio, M.A.O.; Itoh, T.; Garcia, R.N.; Maruyama, N.; Utsumi, S.; Tecson-Mendoza, E.M. Introduction of Sulfhydryl Groups and Disulfide Linkage to Mungbean 8Sα Globulin and Effects on Physicochemical and Functional Properties. Food Res. Int. 2012, 45, 277–282. [Google Scholar] [CrossRef]

- Dahiya, P.K.; Linnemann, A.R.; Van Boekel, M.A.J.S.; Khetarpaul, N.; Grewal, R.B.; Nout, M.J.R. Mung Bean: Technological and Nutritional Potential. Crit. Rev. Food Sci. Nutr. 2015, 55, 670–688. [Google Scholar] [CrossRef] [PubMed]

- Calcinai, L.; Prandi, B.; Faccini, A.; Puxeddu, I.; Tedeschi, T. Molecular Characterization and Allergenicity Assessment of Different Samples of Mung Bean. Food Chem. X 2023, 20, 100980. [Google Scholar] [CrossRef]

- Du, M.; Xie, J.; Gong, B.; Xu, X.; Tang, W.; Li, X.; Li, C.; Xie, M. Extraction, Physicochemical Characteristics and Functional Properties of Mung Bean Protein. Food Hydrocoll. 2018, 76, 131–140. [Google Scholar] [CrossRef]

- Seetapan, N.; Raksa, P.; Limparyoon, N.; Srirajan, S.; Makmoon, T.; Israkarn, K.; Gamonpilas, C.; Methacanon, P.; Fuongfuchat, A. High Moisture Extrusion of Meat Analogues Using Mung Bean (Vigna Radiata L.) Protein and Flour Blends: Investigations on Morphology, Texture and Rheology. Int. J. Food Sci. Technol. 2023, 58, 1922–1930. [Google Scholar] [CrossRef]

- Brishti, F.H.; Chay, S.Y.; Muhammad, K.; Ismail-Fitry, M.R.; Zarei, M.; Saari, N. Texturized Mung Bean Protein as a Sustainable Food Source: Effects of Extrusion on Its Physical, Textural and Protein Quality. Innov. Food Sci. Emerg. Technol. 2021, 67, 102591. [Google Scholar] [CrossRef]

- Brishti, F.H.; Chay, S.Y.; Muhammad, K.; Ismail-Fitry, M.R.; Zarei, M.; Karthikeyan, S.; Saari, N. Effects of Drying Techniques on the Physicochemical, Functional, Thermal, Structural and Rheological Properties of Mung Bean (Vigna radiata) Protein Isolate Powder. Food Res. Int. 2020, 138, 109783. [Google Scholar] [CrossRef]

- Hossain Brishti, F.; Chay, S.Y.; Muhammad, K.; Rashedi Ismail-Fitry, M.; Zarei, M.; Karthikeyan, S.; Caballero-Briones, F.; Saari, N. Structural and Rheological Changes of Texturized Mung Bean Protein Induced by Feed Moisture during Extrusion. Food Chem. 2021, 344, 128643. [Google Scholar] [CrossRef]

- Lin, S.; Huff, H.; Hsieh, F. Extrusion Process Parameters, Sensory Characteristics, and Structural Properties of a High Moisture Soy Protein Meat Analog. J. Food Sci. 2002, 67, 1066–1072. [Google Scholar] [CrossRef]

- Samard, S.; Ryu, G.-H. Physicochemical and Functional Characteristics of Plant Protein-Based Meat Analogs. J. Food Process. Preserv. 2019, 43, e14123. [Google Scholar] [CrossRef]

- Gu, B.Y.; Ryu, G.H. Effects of Moisture Content and Screw Speed on Physical Properties of Extruded Soy Protein Isolate. J. Korean Soc. Food Sci. Nutr. 2017, 46, 751–758. [Google Scholar] [CrossRef]

- Căpriță, R.; Căpriță, A.; Crețescu, I. Protein Solubility as Quality Index for Processed Soybean. Sci. Pap. Anim. Sci. Biotechnol. 2010, 43, 375. [Google Scholar]

- Starcher, B. A Ninhydrin-Based Assay to Quantitate the Total Protein Content of Tissue Samples. Anal. Biochem. 2001, 292, 125–129. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Hsieh, F.-H. Protein–Protein Interactions during High-Moisture Extrusion for Fibrous Meat Analogues and Comparison of Protein Solubility Methods Using Different Solvent Systems. J. Agric. Food Chem. 2008, 56, 2681–2687. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Liu, L.; Jiang, Y.; Faisal, S.; Wang, Q. A New Insight into the High-Moisture Extrusion Process of Peanut Protein: From the Aspect of the Orders and Amount of Energy Input. J. Food Eng. 2020, 264, 109668. [Google Scholar] [CrossRef]

- Maung, T.T.; Gu, B.Y.; Ryu, G.H. Influence of Extrusion Process Parameters on Specific Mechanical Energy and Physical Properties of High-Moisture Meat Analog. Int. J. Food Eng. 2021, 17, 149–157. [Google Scholar] [CrossRef]

- Mazaheri Tehrani, M.; Ehtiati, A.; Sharifi Azghandi, S. Application of Genetic Algorithm to Optimize Extrusion Condition for Soy-Based Meat Analogue Texturization. J. Food Sci. Technol. 2017, 54, 1119–1125. [Google Scholar] [CrossRef]

- Li, J.; Fu, J.; Ma, Y.; He, Y.; Fu, R.; Qayum, A.; Jiang, Z.; Wang, L. Low Temperature Extrusion Promotes Transglutaminase Cross-Linking of Whey Protein Isolate and Enhances Its Emulsifying Properties and Water Holding Capacity. Food Hydrocoll. 2022, 125, 107410. [Google Scholar] [CrossRef]

- Zhang, T.; Dou, W.; Zhang, X.; Zhao, Y.; Zhang, Y.; Jiang, L.; Sui, X. The Development History and Recent Updates on Soy Protein-Based Meat Alternatives. Trends Food Sci. Technol. 2021, 109, 702–710. [Google Scholar] [CrossRef]

- Palanisamy, M.; Franke, K.; Berger, R.G.; Heinz, V.; Töpfl, S. High Moisture Extrusion of Lupin Protein: Influence of Extrusion Parameters on Extruder Responses and Product Properties. J. Sci. Food Agric. 2019, 99, 2175–2185. [Google Scholar] [CrossRef]

- Guerrero, P.; Beatty, E.; Kerry, J.P.; de la Caba, K. Extrusion of Soy Protein with Gelatin and Sugars at Low Moisture Content. J. Food Eng. 2012, 110, 53–59. [Google Scholar] [CrossRef]

- Chen, F.L.; Wei, Y.M.; Zhang, B. Chemical Cross-Linking and Molecular Aggregation of Soybean Protein during Extrusion Cooking at Low and High Moisture Content. LWT Food Sci. Technol. 2011, 44, 957–962. [Google Scholar] [CrossRef]

- Asgar, M.; Fazilah, A.; Huda, N.; Bhat, R.; Karim, A.A. Nonmeat Protein Alternatives as Meat Extenders and Meat Analogs. Compr. Rev. Food Sci. Food Saf. 2010, 9, 513–529. [Google Scholar] [CrossRef]

- Schmid, E.-M.; Farahnaky, A.; Adhikari, B.; Torley, P.J. High Moisture Extrusion Cooking of Meat Analogs: A Review of Mechanisms of Protein Texturization. Compr. Rev. Food Sci. Food Saf. 2022, 21, 4573–4609. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Huang, H.-M.; Lin, C.-C.; Lin, F.-Y.; Chan, Y.-C. Effect of Temperature on Hydrophobic Interaction between Proteins and Hydrophobic Adsorbents: Studies by Isothermal Titration Calorimetry and the van’t Hoff Equation. Langmuir 2003, 19, 9395–9403. [Google Scholar] [CrossRef]

- Kaleda, A.; Talvistu, K.; Vaikma, H.; Tammik, M.-L.; Rosenvald, S.; Vilu, R. Physicochemical, Textural, and Sensorial Properties of Fibrous Meat Analogs from Oat-Pea Protein Blends Extruded at Different Moistures, Temperatures, and Screw Speeds. Future Foods 2021, 4, 100092. [Google Scholar] [CrossRef]

- Chen, F.L.; Wei, Y.M.; Zhang, B.; Ojokoh, A.O. System Parameters and Product Properties Response of Soybean Protein Extruded at Wide Moisture Range. J. Food Eng. 2010, 96, 208–213. [Google Scholar] [CrossRef]

- Lin, S.; Huff, H.; Hsieh, F. Texture and Chemical Characteristics of Soy Protein Meat Analog Extruded at High Moisture. J. Food Sci. 2000, 65, 264–269. [Google Scholar] [CrossRef]

- Zahari, I.; Purhagen, J.K.; Rayner, M.; Ahlström, C.; Helstad, A.; Landers, M.; Müller, J.; Eriksson, J.; Östbring, K. Extrusion of High-Moisture Meat Analogues from Hempseed Protein Concentrate and Oat Fibre Residue. J. Food Eng. 2023, 354, 111567. [Google Scholar] [CrossRef]

| X1 | X2 | X3 |

|---|---|---|

| Moisture Content (%) | Screw Speed (rpm) | Barrel Temperature (°C) |

| 50 | 150 | 150 |

| 50 | 200 | 140 |

| 50 | 200 | 160 |

| 50 | 250 | 150 |

| 55 | 150 | 140 |

| 55 | 150 | 160 |

| 55 | 200 | 150 |

| 55 | 200 | 150 |

| 55 | 200 | 150 |

| 55 | 250 | 140 |

| 55 | 250 | 160 |

| 60 | 150 | 150 |

| 60 | 200 | 140 |

| 60 | 200 | 160 |

| 60 | 250 | 150 |

| X1 | X2 | X3 | Water Holding Capacity (%) | Water Absorption Capacity (%) | Oil Absorption Capacity (%) | Integrity Index (%) | Nitrogen Solubility Index (%) |

|---|---|---|---|---|---|---|---|

| M.C (%) | S.S (rpm) | B.T (°C) | |||||

| 50 | 150 | 150 | 248.92 ± 19.53 d | 298.51 ± 3.14 h | 130.61 ± 5.12 h | 82.96 ± 1.46 d | 27.72 ± 0.95 gh |

| 50 | 200 | 140 | 251.66 ± 11.88 d | 312.52 ± 6.48 g | 156.63 ± 7.94 ef | 86.62 ± 0.14 bc | 26.60 ± 1.13 h |

| 50 | 200 | 160 | 282.26 ± 23.70 c | 319.97 ± 2.98 g | 161.87 ± 4.88 e | 79.66 ± 3.23 ef | 34.16 ± 1.58 cd |

| 50 | 250 | 150 | 255.03 ± 20.54 d | 316.65 ± 11.37 g | 138.91 ± 1.36 gh | 87.85 ± 0.81 bc | 31.19 ± 1.03 def |

| 55 | 150 | 140 | 255.00 ± 10.44 d | 336.78 ± 5.95 f | 174.27 ± 7.91 cd | 85.11 ± 2.47 cd | 30.03 ± 1.81 efg |

| 55 | 150 | 160 | 337.99 ± 5.97 b | 348.38 ± 3.53 e | 183.27 ± 4.18 abc | 63.17 ± 3.56 g | 46.13 ± 2.01 a |

| 55 | 200 | 150 | 282.21 ± 12.98 c | 346.43 ± 8.65 ef | 191.34 ± 4.32 ab | 88.12 ± 0.39 bc | 31.11 ± 1.91 def |

| 55 | 200 | 150 | 296.54 ± 4.97 c | 362.01 ± 1.78 d | 192.17 ± 6.42 ab | 88.76 ± 1.15 b | 29.45 ± 2.07 fgh |

| 55 | 200 | 150 | 283.84 ± 8.87 c | 359.50 ± 1.89 d | 186.13 ± 4.85 ab | 88.02 ± 0.11 bc | 29.69 ± 0.52 fgh |

| 55 | 250 | 140 | 246.85 ± 8.80 d | 352.50 ± 8.34 de | 164.67 ± 7.12 de | 96.47 ± 0.97 a | 28.61 ± 0.62 fgh |

| 55 | 250 | 160 | 287.12 ± 7.39 c | 359.51 ± 1.39 d | 193.56 ± 9.27 a | 78.86 ± 1.99 f | 33.07 ± 0.70 cde |

| 60 | 150 | 150 | 288.33 ± 9.00 c | 401.50 ± 4.30 b | 167.16 ± 9.82 de | 78.49 ± 1.65 f | 31.86 ± 1.63 def |

| 60 | 200 | 140 | 289.56 ± 10.68 c | 385.21 ± 5.38 c | 159.06 ± 5.11 e | 79.71 ± 1.26 ef | 35.69 ± 3.08 c |

| 60 | 200 | 160 | 370.47 ± 8.65 a | 425.66 ± 6.67 a | 147.98 ± 5.77 fg | 62.67 ± 2.56 g | 42.80 ± 2.77 b |

| 60 | 250 | 150 | 297.03 ± 23.80 c | 377.13 ± 7.03 c | 181.26 ± 5.22 bc | 82.52 ± 0.61 de | 36.00 ± 1.70 c |

| Run Order | X1 | X2 | X3 | Texture Profile Analysis | Cutting Strength (g cm−2) | |||

|---|---|---|---|---|---|---|---|---|

| M.C (%) | S.S (rpm) | B.T (°C) | Springiness (%) | Cohesiveness (%) | Chewiness (g) | Vertical Direction | Parallel Direction | |

| 1 | 50 | 150 | 150 | 94.62 ± 0.53 cde | 85.63 ± 0.69 abc | 6286.45 ± 213.80 b | 1318.25 ± 120.46 bc | 1026.07 ± 160.41 a |

| 2 | 50 | 200 | 140 | 93.78 ± 1.14 ef | 86.27 ± 2.45 ab | 5625.87 ± 212.10 c | 1164.16 ± 81.50 d | 797.62 ± 33.81 d |

| 3 | 50 | 200 | 160 | 92.57 ± 0.55 g | 87.11 ± 0.91 a | 5415.51 ± 378.55 cd | 1595.01 ± 102.28 a | 1027.58 ± 73.89 a |

| 4 | 50 | 250 | 150 | 94.73 ± 1.15 bcde | 86.33 ± 0.76 ab | 7089.33 ± 168.53 a | 1348.36 ± 67.40 b | 912.56 ± 56.78 bc |

| 5 | 55 | 150 | 140 | 95.26 ± 1.13 abcd | 85.33 ± 0.97 abc | 5321.18 ± 209.94 d | 996.66 ± 55.12 fg | 705.42 ± 21.31 de |

| 6 | 55 | 150 | 160 | 92.73 ± 1.16 fg | 85.72 ± 0.78 abc | 3818.07 ± 272.59 f | 1206.44 ± 164.38 cd | 994.04 ± 76.62 abc |

| 7 | 55 | 200 | 150 | 95.40 ± 1.35 abc | 84.49 ± 3.25 abc | 5315.10 ± 287.43 d | 1137.43 ± 115.36 de | 896.58 ± 60.60 c |

| 8 | 55 | 200 | 150 | 95.26 ± 0.77 abcd | 85.20 ± 1.44 abc | 5986.49 ± 184.81 b | 1198.23 ± 46.79 cd | 1007.57 ± 64.20 ab |

| 9 | 55 | 200 | 150 | 96.41 ± 0.78 a | 84.38 ± 3.73 abc | 5646.54 ± 166.51 c | 1272.55 ± 99.09 bcd | 911.55 ± 79.80 bc |

| 10 | 55 | 250 | 140 | 95.99 ± 0.82 ab | 85.50 ± 1.11 abc | 5993.87 ± 400.22 b | 928.05 ± 117.87 fg | 645.00 ± 84.31 e |

| 11 | 55 | 250 | 160 | 95.44 ± 0.73 abc | 86.08 ± 0.95 abc | 4206.93 ± 204.52 e | 1190.59 ± 67.34 cd | 1020.59 ± 92.47 a |

| 12 | 60 | 150 | 150 | 94.03 ± 0.72 de | 83.79 ± 0.96 bc | 2703.68 ± 62.74 h | 945.09 ± 148.90 fg | 923.99 ± 61.13 abc |

| 13 | 60 | 200 | 140 | 96.07 ± 1.07 a | 83.37 ± 4.68 c | 2796.72 ± 358.25 h | 755.79 ± 176.35 h | 678.92 ± 75.20 e |

| 14 | 60 | 200 | 160 | 96.32 ± 0.85 a | 85.80 ± 1.21 abc | 2301.10 ± 166.41 i | 1030.82 ± 76.18 ef | 675.79 ± 129.54 e |

| 15 | 60 | 250 | 150 | 95.76 ± 1.32 abc | 86.13 ± 1.37 abc | 3250.06 ± 192.44 g | 867.42 ± 71.90 gh | 780.04 ± 43.84 d |

| Source | Water Holding Capacity | p Value | Chewiness | |

|---|---|---|---|---|

| p Value | Significant | Significant | ||

| Model | 0.0179 | * | 0.0065 | ** |

| X1-moisture content | 0.0041 | ** | 0.0003 | ** |

| X2-screw speed | 0.3344 | 0.1581 | ||

| X3- barrel temperature | 0.0024 | ** | 0.0375 | * |

| X1 X2 | 0.9329 | 0.8129 | ||

| X1 X3 | 0.1463 | 0.7297 | ||

| X2X3 | 0.2043 | 0.7935 | ||

| X1 2 | 0.9229 | 0.0308 | * | |

| X22 | 0.0901 | 0.9442 | ||

| X32 | 0.2387 | 0.0311 | * | |

| Lack of Fit | 0.1674 | 0.2447 | ||

| R2 | 0.9335 | 0.9569 | ||

| Adj R2 | 0.8139 | 0.8792 | ||

| C.V. % | 5.14 | 10.73 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Gu, B.-J.; Hwang, N.-k.; Ryu, G.-H. Optimization of High-Moisture Meat Analog Production with the Addition of Isolated Mung Bean Protein Using Response Surface Methodology. Foods 2025, 14, 1323. https://doi.org/10.3390/foods14081323

Zhang Y, Gu B-J, Hwang N-k, Ryu G-H. Optimization of High-Moisture Meat Analog Production with the Addition of Isolated Mung Bean Protein Using Response Surface Methodology. Foods. 2025; 14(8):1323. https://doi.org/10.3390/foods14081323

Chicago/Turabian StyleZhang, Yu, Bon-Jae Gu, Nam-ki Hwang, and Gi-Hyung Ryu. 2025. "Optimization of High-Moisture Meat Analog Production with the Addition of Isolated Mung Bean Protein Using Response Surface Methodology" Foods 14, no. 8: 1323. https://doi.org/10.3390/foods14081323

APA StyleZhang, Y., Gu, B.-J., Hwang, N.-k., & Ryu, G.-H. (2025). Optimization of High-Moisture Meat Analog Production with the Addition of Isolated Mung Bean Protein Using Response Surface Methodology. Foods, 14(8), 1323. https://doi.org/10.3390/foods14081323