Plant-Based Alternatives to Meat Products

Abstract

1. Introduction

2. Sources of Plant Proteins

3. Techno-Functional Properties and Nutritional Equivalency of Plant Proteins for Meat Alternatives

| Ingredients that Are Used for the Formulation of Meat Analogues | Function | Possible Sources |

|---|---|---|

| Colourings | Helps in the achievement of a good appearance and the enhancement of visual appeal. | Annatto, beet juice extract, caramel colours, carotene, cumin, soy leghaemoglobin, malt, and turmeric. |

| Fat | The enhancement of flavour via the synthesis of volatile and non-volatile flavour constituents. They give the juiciness and tenderness to meat analogues, as well as contribute to the structure formation in meat analogues. | Various oils, such as Canola oil, coconut oil, sunflower oil, corn oil, sesame oil, cocoa butter, olive oil, palm oil, soybean oil, and flaxseed oil. |

| Flavourings | Contribute towards the enhancement of flavour, as well as act as a preservative for shelf-life extension and mask the flavours of legume proteins. | Various seasonings, natural spices, and herbs, such as basil, fennel, garlic, onion, pepper, and thyme; various precursors, such as amino acids; thiamine; reducing sugars; nucleotides; and yeast extract. |

| Polysaccharides | Play a key role in the formation of flavour in the presence of amino acids as a result of the Maillard reaction and caramelization occurring in the presence of heat. | Starches and flour, binding agents, and gums, such as methylcellulose, acacia gum, xanthan gum, and carrageenan. |

| Water | Normally used as a source of hydration for all the other dry ingredients. Water affects the functional qualities, such as viscosity, swelling, emulsification, gelation, and foaming, and also helps with the achievement of juiciness and mouthfeel of the final product and also plays an important role in the determination of the viscosity during the extrusion process. | N/A |

| Product | Calories | Total Fat | Saturated Fat | Fibre | Protein | Sodium |

|---|---|---|---|---|---|---|

| Beef: serving size 100 g | ||||||

| Conventional Minced Beef | 332 | 30 g | 11 g | 0 g | 14 g | 67 mg |

| Beyond Burger Beyond Meat | 196 | 12 g | 2.9 g | 1.2 g | 16 g | 300 mg |

| This Isn’t Beef Plant-Based Burgers | 224 | 15.4 g | 5 g | 3.0 g | 14.3 g | 400 mg |

| Vivera Plant Steaks | 200 | 10 g | 4.7 g | 4.9 g | 18 g | 440 mg |

| Chicken: serving size 100 g | ||||||

| Traditional Chicken Nuggets; Waitrose Frozen Breaded Chicken Breast Chunks | 210 | 8.1 g | 1 g | 1.1 g | 19.8 g | 292 mg |

| Quorn Vegetarian Chicken Style Nuggets | 190 | 8.3 g | 0.8 g | 4.5 g | 9.4 g | 480 mg |

| Tesco Plant Chef No-Chicken Nuggets | 230 | 10.2 g | 0.9 g | 7.2 g | 11.1 g | 264 mg |

| Protein Type * | Formulation | Key Outcome | Reference |

|---|---|---|---|

| YPPI + RPC | 50:50 | Texturization via HME. | [83] |

| SPI + WG SPI + PPI SPI + RBP SPI + FPI SPI + SPPI | 70:30 | SPI-WG and SPI-PPI exhibited superior fibre. | [70] |

| SPI + WG | 70:30, 50:50, 30:70 | SPI-WG 50:50 exhibits the best fibrous structure. | [63] |

| SPI + WG | 80:20, 35:65, 50:50, 65:35, 20:80 | Rheology of SPI- and WG-phases determine structure formation. | [84] |

| SPI + WG | 10%, 20%, 30% WG with soy (+oil, starch, salt, pumpkin powder) | 30% WG addition exhibited fibrous structures interconnected with much smaller fibres. | [85] |

| SPI + PkPC | 90:10, 80:20, 70:30, 60:40 (corn starch was added to all concentrations) | More pumpkin protein produces a less aligned structure. | [86] |

| SPI + PPI | 90:10 | SPI-PPI gel predicts HME texture, PPI weakened structure. | [87] |

| PPI + WG | 100:10, 70:30, 50:50, 30:70 | 30% WG resulted in the highest fibrous structure. | [88] |

| HPC + WG HPC + CPC | 90:10, 70:30, 50:50 50:50 | 90:10 hemp–WG best structure and better sensory with higher hemp fibrous degree. | [61] |

| PP + WG | 90:10 | PP-CP-WG > PP + WG > PP-SPI-WG; hardness PP-CP-WG > PP + WG ~ PP-SPI-WG; chewiness PPI-CP-WG > PP + WG ~ PPI-SPI-WG fibrous degree PP-CP-WG > PP + WG > PP-SPI-WG; hardness PP-CP-WG > PP + WG ~ PP-SPI- WG; chewiness PP-CP-WG > PP + WG ~ PP-SPI-WG. | [89] |

| PP + SPI + WG | 80:10:10 | ||

| PP + CP + WG | 80:10:10 | ||

| PPI + FPC | 93.84:3, 90.84:6, 88.84:8 (3.16% salt added to all) | Noticeable change in the nature of fibre formation due to FPC addition. | [90] |

| HPI + PPC HPI + SPC HPC + PPC HPC + SPC | 80:20, 50:50, 20:80 | Hemp protein isolate was not able to extrude on its own; extrusion could be performed using hemp protein concentrate and by adding soy or pea proteins. | [91] |

| SPI | Added insoluble dietary fibre (IDF) | IDF facilitates the formation of filamentous structures and enhances the mechanical anisotropy of extrudates. | [92] |

| SPI and SPC | Added inulin | Inulin facilitates the formation of lamellar structures and improves the fibrous structure and protein digestibility. | [93] |

| SPI | Added dietary fibre (DF) from soy | Protein–DF ratio affected extrudate texture, (micro) structure, and protein reactivity. | [94] |

| SPI + WG | Added alginate, xanthan gum, and maltodextrin (1–5% for each) | The polysaccharides increased the water distribution of extrudates by enhancing protein–water interactions through hydrogen bonding. | [95] |

| PPI | Amylopectin and stearic acid | Amylopectin and stearic acid synergistically contributed to improving the fibrous structures and fibrous degree in pea protein extrudate. | [96] |

| SPI | High-acyl gellan gum, low-acyl gellan gum, high-methoxy pectin, low-methoxy pectin, and xanthan (2% for each, with salt) | The addition of hydrocolloids and salts increased the crosslink bonds and structural compactness at the microscopic level and enhanced the fibrous structure. | [97] |

4. Protein Texturization for Plant-Based Meat Alternatives

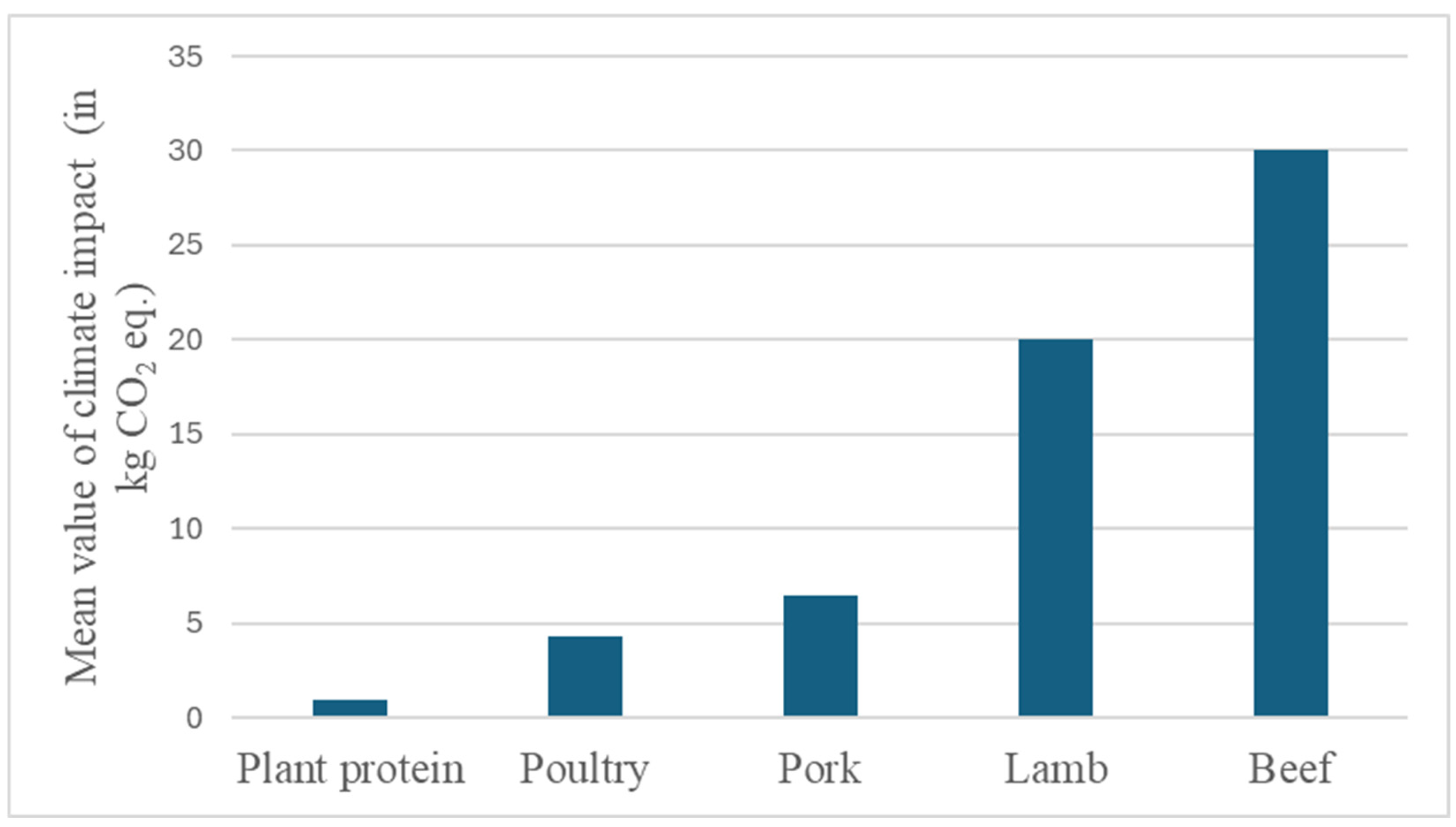

5. Environmental Sustainability of Plant-Based Alternatives to Meat Products

6. Market, Innovation, and Supply Chain of Plant-Based Meat Alternatives

7. Challenges and Opportunities for Plant-Based Meat Alternatives

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Munialo, C.D.; Stewart, D.; Campbell, L.; Euston, S.R. Extraction, characterisation and functional applications of sustainable alternative protein sources for future foods: A review. Futur. Foods 2022, 6, 100152. [Google Scholar] [CrossRef]

- Duluins, O.; Baret, P.V. A Systematic Review of the Definitions, Narratives and Paths Forwards for a Protein Transition in High-Income Countries. Nat. Food 2024, 5, 28–36. [Google Scholar] [CrossRef] [PubMed]

- Munialo, C.D.; Vriesekoop, F. Plant-based Foods as Meat and Fat Substitutes. Food Sci. Nutr. 2023, 11, 4898–4911. [Google Scholar] [CrossRef]

- Baig, M.A.; Ajayi, F.F.; Hamdi, M.; Baba, W.; Brishti, F.H.; Khalid, N.; Zhou, W.; Maqsood, S. Recent Research Advances in Meat Analogues: A Comprehensive Review on Production, Protein Sources, Quality Attributes, Analytical Techniques used, and Consumer Perception. Food Rev. Int. 2024, 41, 236–267. [Google Scholar] [CrossRef]

- Lindberg, L.; McCann, R.R.; Smyth, B.; Woodside, J.V.; Nugent, A.P. The Environmental Impact, Ingredient Composition, Nutritional and Health Impact of Meat Alternatives: A Systematic Review. Trends Food Sci. Technol. 2024, 149, 104483. [Google Scholar] [CrossRef]

- Kozicka, M.; Havlík, P.; Valin, H.; Wollenberg, E.; Deppermann, A.; Leclère, D.; Lauri, P.; Moses, R.; Boere, E.; Frank, S. Feeding Climate and Biodiversity Goals with Novel Plant-Based Meat and Milk Alternatives. Nat. Commun. 2023, 14, 5316. [Google Scholar] [CrossRef]

- Kyriakopoulou, K.; Keppler, J.K.; van Der Goot, A.J. Functionality of Ingredients and Additives in Plant-Based Meat Analogues. Foods 2021, 10, 600. [Google Scholar] [CrossRef]

- Safdar, B.; Zhou, H.; Li, H.; Cao, J.; Zhang, T.; Ying, Z.; Liu, X. Prospects for Plant-Based Meat: Current Standing, Consumer Perceptions, and Shifting Trends. Foods 2022, 11, 3770. [Google Scholar] [CrossRef]

- Flint, M.; Bowles, S.; Lynn, A.; Paxman, J.R. Novel Plant-Based Meat Alternatives: Future Opportunities and Health Considerations. Proc. Nutr. Soc. 2023, 82, 370–385. [Google Scholar] [CrossRef]

- Tyndall, S.M.; Maloney, G.R.; Cole, M.B.; Hazell, N.G.; Augustin, M.A. Critical Food and Nutrition Science Challenges for Plant-Based Meat Alternative Products. Crit. Rev. Food Sci. Nutr. 2024, 64, 638–653. [Google Scholar] [CrossRef]

- Andreani, G.; Sogari, G.; Marti, A.; Froldi, F.; Dagevos, H.; Martini, D. Plant-Based Meat Alternatives: Technological, Nutritional, Environmental, Market, and Social Challenges and Opportunities. Nutrients 2023, 15, 452. [Google Scholar] [CrossRef] [PubMed]

- Ye, Y.; Zhou, J.; Guan, X.; Sun, X. Commercialization of Cultured Meat Products: Current Status, Challenges, and Strategic Prospects. Futur. Foods 2022, 6, 100177. [Google Scholar] [CrossRef]

- Yi, L.; Lakemond, C.M.; Sagis, L.M.; Eisner-Schadler, V.; Van Huis, A.; van Boekel, M.A. Extraction and Characterisation of Protein Fractions from Five Insect Species. Food Chem. 2013, 141, 3341–3348. [Google Scholar] [CrossRef] [PubMed]

- Jepson, L.M.; Daniel, R.; Nyambayo, I.; Munialo, C.D. The Isolation and Characterisation of Protein from Nine Edible Insect Species. J. Food Sci. Technol. 2024, 61, 1998–2007. [Google Scholar] [CrossRef]

- Lonchamp, J.; Akintoye, M.; Clegg, P.S.; Euston, S.R. Sonicated Extracts from the Quorn Fermentation Co-Product as Oil-Lowering Emulsifiers and Foaming Agents. Eur. Food Res. Technol. 2020, 246, 767–780. [Google Scholar] [CrossRef]

- Lonchamp, J.; Stewart, K.; Munialo, C.D.; Evans, L.; Akintoye, M.; Gordon, S.; Clegg, P.S.; Willoughby, N.; Euston, S.R. Mycoprotein as Novel Functional Ingredient: Mapping of Functionality, Composition and Structure Throughout the Quorn Fermentation Process. Food Chem. 2022, 396, 133736. [Google Scholar] [CrossRef]

- Bomkamp, C.; Skaalure, S.C.; Fernando, G.F.; Ben-Arye, T.; Swartz, E.W.; Specht, E.A. Scaffolding Biomaterials for 3D Cultivated Meat: Prospects and Challenges. Adv. Sci. 2022, 9, 2102908. [Google Scholar] [CrossRef]

- Rasmussen, M.K.; Gold, J.; Kaiser, M.W.; Moritz, J.; Räty, N.; Rønning, S.B.; Ryynänen, T.; Skrivergaard, S.; Ström, A.; Therkildsen, M. Critical Review of Cultivated Meat from a Nordic Perspective. Trends Food Sci. Technol. 2024, 144, 104336. [Google Scholar] [CrossRef]

- Michel, F.; Hartmann, C.; Siegrist, M. Consumers’ Associations, Perceptions and Acceptance of Meat and Plant-Based Meat Alternatives. Food Qual. Prefer. 2021, 87, 104063. [Google Scholar] [CrossRef]

- McClements, D.J.; Grossmann, L. Next-Generation Plant-Based Foods: Challenges and Opportunities. Annu. Rev. Food Sci. Technol. 2024, 15, 79–101. [Google Scholar] [CrossRef]

- Deprá, M.C.; Dias, R.R.; Sartori, R.B.; de Menezes, C.R.; Zepka, L.Q.; Jacob-Lopes, E. Nexus on Animal Proteins and the Climate Change: The Plant-Based Proteins are Part of the Solution? Food Bioprod. Process. 2022, 133, 119–131. [Google Scholar] [CrossRef]

- Mazumder, M.A.R.; Panpipat, W.; Chaijan, M.; Shetty, K.; Rawdkuen, S. Role of Plant Protein on the Quality and Structure of Meat Analogs: A New Perspective for Vegetarian Foods. Futur. Foods 2023, 8, 100280. [Google Scholar] [CrossRef]

- Ashaolu, T.J. Applications of Soy Protein Hydrolysates in the Emerging Functional Foods: A Review. Int. J. Food Sci. Technol. 2020, 55, 421–428. [Google Scholar] [CrossRef]

- Lian, Z.; Yang, S.; Dai, S.; Tong, X.; Liao, P.; Cheng, L.; Qi, W.; Wang, Y.; Wang, H.; Jiang, L. Relationship between Flexibility and Interfacial Functional Properties of Soy Protein Isolate: Succinylation Modification. J. Sci. Food Agric. 2022, 102, 6454–6463. [Google Scholar] [CrossRef]

- Galus, S. Functional Properties of Soy Protein Isolate Edible Films as Affected by Rapeseed Oil Concentration. Food Hydrocoll. 2018, 85, 233–241. [Google Scholar] [CrossRef]

- Munialo, C.D.; van der Linden, E.; de Jongh, H.H. The Ability to Store Energy in Pea Protein Gels is Set by Network Dimensions Smaller than 50 Nm. Food Res. Int. 2014, 64, 482–491. [Google Scholar] [CrossRef]

- Chang, L.; Lan, Y.; Bandillo, N.; Ohm, J.; Chen, B.; Rao, J. Plant Proteins from Green Pea and Chickpea: Extraction, Fractionation, Structural Characterization and Functional Properties. Food Hydrocoll. 2022, 123, 107165. [Google Scholar] [CrossRef]

- Stone, A.K.; Avarmenko, N.A.; Warkentin, T.D.; Nickerson, M.T. Functional Properties of Protein Isolates from Different Pea Cultivars. Food Sci. Biotechnol. 2015, 24, 827–833. [Google Scholar] [CrossRef]

- Ivanov, M.; Munialo, C.D. The Investigation of the Functional Properties of Single and Mixed Milk/Lupine Protein Systems. Int. J. Food Sci. Technol. 2023, 58, 5728–5737. [Google Scholar] [CrossRef]

- Lo, B.; Kasapis, S.; Farahnaky, A. Improving Functional Properties of Lupin Protein by Physical Modification: High Pressure Homogenisation. Int. J. Food Sci. Technol. 2024, 59, 1443–1455. [Google Scholar] [CrossRef]

- Krause, M.; Sørensen, J.C.; Petersen, I.L.; Duque-Estrada, P.; Cappello, C.; Tlais, A.Z.A.; Di Cagno, R.; Ispiryan, L.; Sahin, A.W.; Arendt, E.K. Associating Compositional, Nutritional and Techno-Functional Characteristics of Faba Bean (Vicia faba L.) Protein Isolates and their Production Side-Streams with Potential Food Applications. Foods 2023, 12, 919. [Google Scholar] [CrossRef] [PubMed]

- Stone, A.K.; Shi, D.; Marinangeli, C.P.; Carlin, J.; Nickerson, M.T. Current Review of Faba Bean Protein Fractionation and its Value-added Utilization in Foods. Sustain. Food Proteins 2024, 2, 101–124. [Google Scholar] [CrossRef]

- Mir, N.A.; Riar, C.S.; Singh, S. Improvement in the Functional Properties of Quinoa (Chenopodium ouinoa) Protein Isolates After the Application of Controlled Heat-Treatment: Effect on Structural Properties. Food Struct. 2021, 28, 100189. [Google Scholar] [CrossRef]

- Steffolani, M.E.; Villacorta, P.; Morales-Soriano, E.R.; Repo-Carrasco, R.; León, A.E.; Pérez, G.T. Physicochemical and Functional Characterization of Protein Isolated from Different Quinoa Varieties (Chenopodium ouinoa Willd.). Cereal Chem. 2016, 93, 275–281. [Google Scholar] [CrossRef]

- Elsohaimy, S.A.; Refaay, T.M.; Zaytoun, M. Physicochemical and Functional Properties of Quinoa Protein Isolate. Ann. Agric. Sci. 2015, 60, 297–305. [Google Scholar] [CrossRef]

- Flory, J.; Xiao, R.; Li, Y.; Dogan, H.; Talavera, M.J.; Alavi, S. Understanding Protein Functionality and its Impact on Quality of Plant-Based Meat Analogues. Foods 2023, 12, 3232. [Google Scholar] [CrossRef]

- Benković, M.; Jurinjak Tušek, A.; Sokač Cvetnić, T.; Jurina, T.; Valinger, D.; Gajdoš Kljusurić, J. An Overview of Ingredients used for Plant-Based Meat Analogue Production and their Influence on Structural and Textural Properties of the Final Product. Gels 2023, 9, 921. [Google Scholar] [CrossRef]

- Zahari, I.; Östbring, K.; Purhagen, J.K.; Rayner, M. Plant-Based Meat Analogues from Alternative Protein: A Systematic Literature Review. Foods 2022, 11, 2870. [Google Scholar] [CrossRef]

- Lyu, B.; Li, J.; Meng, X.; Fu, H.; Wang, W.; Ji, L.; Wang, Y.; Guo, Z.; Yu, H. The Protein Composition Changed the Quality Characteristics of Plant-Based Meat Analogues Produced by a Single-Screw Extruder: Four Main Soybean Varieties in China as Representatives. Foods 2022, 11, 1112. [Google Scholar] [CrossRef]

- Zhu, Z.; Pius Bassey, A.; Cao, Y.; Ma, Y.; Huang, M.; Yang, H. Food Protein Aggregation and its Application. Food Res. Int. 2022, 160, 111725. [Google Scholar] [CrossRef]

- Wu, C.; Wang, T.; Ren, C.; Ma, W.; Wu, D.; Xu, X.; Wang, L.; Du, M. Advancement of Food-derived Mixed Protein Systems: Interactions, Aggregations, and Functional Properties. Compr. Rev. Food Sci. Food Saf. 2021, 20, 627–651. [Google Scholar] [CrossRef] [PubMed]

- Amaral, D.F.; de Souza Ferreira Filho, J.B.; Chagas, A.L.S.; Adami, M. Expansion of Soybean Farming into Deforested Areas in the Amazon Biome: The Role and Impact of the Soy Moratorium. Sustain. Sci. 2021, 16, 1295–1312. [Google Scholar] [CrossRef]

- Carson, J.A.S.; Lichtenstein, A.H.; Anderson, C.A.; Appel, L.J.; Kris-Etherton, P.M.; Meyer, K.A.; Petersen, K.; Polonsky, T.; Van Horn, L. Dietary Cholesterol and Cardiovascular Risk: A Science Advisory from the American Heart Association. Circulation 2020, 141, e39–e53. [Google Scholar] [CrossRef]

- Ishwarya Shankaran, P.; Kumari, P. Nutritional Analysis of Plant-Based Meat: Current Advances and Future Potential. Appl. Sci. 2024, 14, 4154. [Google Scholar] [CrossRef]

- Yeo, M.T.Y.; Bi, X.; Henry, C.J. Are plant-based meat analogues richer in minerals than their meat counterparts? Food Humanit. 2023, 1, 670–674. [Google Scholar] [CrossRef]

- Arbach, C.T.; Alves, I.A.; Serafini, M.R.; Stephani, R.; Perrone, Í.T.; de Carvalho da Costa, J. Recent Patent Applications in Beverages Enriched with Plant Proteins. npj Sci. Food 2021, 5, 28. [Google Scholar] [CrossRef]

- Soh, B.X.P.; Smith, N.W.; von Hurst, P.R.; McNabb, W.C. Evaluation of Protein Adequacy from Plant-Based Dietary Scenarios in Simulation Studies: A Narrative Review. J. Nutr. 2024, 154, 300–313. [Google Scholar] [CrossRef]

- Montgomery, A. Physiochemical, Microbial and Sensory Attributes of a Purple Hull Peas Meat Substitute. Master’s Thesis, Tuskegee University, Tuskegee, AL, USA, 2023. [Google Scholar]

- Webb, D.; Dogan, H.; Li, Y.; Alavi, S. Physico-Chemical Properties and Texturization of Pea, Wheat and Soy Proteins using Extrusion and their Application in Plant-Based Meat. Foods 2023, 12, 1586. [Google Scholar] [CrossRef]

- Nikbakht Nasrabadi, M.; Sedaghat Doost, A.; Mezzenga, R. Modification Approaches of Plant-Based Proteins to Improve their Techno-Functionality and use in Food Products. Food Hydrocoll. 2021, 118, 106789. [Google Scholar] [CrossRef]

- Wang, Z.; Tian, Y.; Lou, F.; Guo, Z. Effect of Pea Protein Isolate–Soybean Meal Ratio on Fiber Structure and Texture Properties of High-Moisture Meat Analogs. Foods 2024, 13, 3818. [Google Scholar] [CrossRef]

- Siddiqui, S.A.; Khalifa, I.; Yin, T.; Morsy, M.K.; Khoder, R.M.; Salauddin, M.; Farzana, W.; Sharma, S.; Khalid, N. Valorization of Plant Proteins for Meat Analogues Design—A Comprehensive Review. Eur. Food Res. Technol. 2024, 250, 2479–2513. [Google Scholar] [CrossRef]

- Jarunglumlert, T.; Chantanuson, R.; Hayashi, R.; Katano, Y.; Kusakari, T.; Nagamine, S.; Matsumiya, K.; Kobayashi, T.; Nakagawa, K. Techno-Economic Assessment of Plant-Based Meat Analogue Produced by the Freeze Alignment Technique. Future Foods 2023, 8, 100269. [Google Scholar] [CrossRef]

- Chandran, A.S.; Kashyap, P.; Thakur, M. Effect of Extraction Methods on Functional Properties of Plant Proteins: A Review. eFood 2024, 5, e151. [Google Scholar] [CrossRef]

- Tang, W.; Pan, Q.; He, J.; Liu, J. Plant-Based Meat: The Influence on Texture by Protein-Polysaccharide Interactions and Processing Techniques. Food Res. Int. 2025, 202, 115673. [Google Scholar] [CrossRef]

- Galanakis, C.M. Sustainable Meat Production and Processing; Academic Press: Cambridge, MA, USA, 2018. [Google Scholar]

- Chao, C.; Park, H.J.; Kim, H.W. Effect of L-Cysteine on Functional Properties and Fibrous Structure Formation of 3D-Printed Meat Analogs from Plant-Based Proteins. Food Chem. 2024, 439, 137972. [Google Scholar] [CrossRef]

- Kumar, P.; Sharma, N.; Ahmed, M.A.; Verma, A.K.; Umaraw, P.; Mehta, N.; Abubakar, A.A.; Hayat, M.N.; Kaka, U.; Lee, S. Technological Interventions in Improving the Functionality of Proteins during Processing of Meat Analogs. Front. Nutr. 2022, 9, 1044024. [Google Scholar] [CrossRef]

- Plattner, B. Extrusion Techniques for Meat Analogues. Cereal Foods World 2020, 65, 43. [Google Scholar]

- Zahari, I.; Ferawati, F.; Helstad, A.; Ahlström, C.; Östbring, K.; Rayner, M.; Purhagen, J.K. Development of High-Moisture Meat Analogues with Hemp and Soy Protein using Extrusion Cooking. Foods 2020, 9, 772. [Google Scholar] [CrossRef]

- Mazaheri Tehrani, M.; Ehtiati, A.; Sharifi Azghandi, S. Application of Genetic Algorithm to Optimize Extrusion Condition for Soy-Based Meat Analogue Texturization. J. Food Sci. Technol. 2017, 54, 1119–1125. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, Y.; Zhang, T.; Zhang, Y.; Jiang, L.; Sui, X. High Moisture Extrusion of Soy Protein and Wheat Gluten Blend: An Underlying Mechanism for the Formation of Fibrous Structures. LWT 2022, 163, 113561. [Google Scholar] [CrossRef]

- Zhang, X.; Shen, A.; Zhang, Z.; Zhang, T.; Jiang, L.; Zhou, W.; Zhang, Y.; Sui, X. Advancing Molecular Understanding in High Moisture Extrusion for Plant-Based Meat Analogs: Challenges and Perspectives. Food Chem. 2024, 460, 140458. [Google Scholar] [CrossRef] [PubMed]

- Akharume, F.U.; Aluko, R.E.; Adedeji, A.A. Modification of Plant Proteins for Improved Functionality: A Review. Compr. Rev. Food Sci. Food Saf. 2021, 20, 198–224. [Google Scholar] [CrossRef] [PubMed]

- Kyriakopoulou, K.; Dekkers, B.; van der Goot, A.J. Plant-based meat analogues. In Sustainable Meat Production and Processing; Academic Press: Amsterdam, The Netherlands, 2019; pp. 103–126. [Google Scholar]

- Nasrollahzadeh, F.; Alexi, N.; Skov, K.B.; Roman, L.; Sfyra, K.; Martinez, M.M. Texture Profiling of Muscle Meat Benchmarks and Plant-Based Analogues: An Instrumental and Sensory Design Approach with Focus on Correlations. Food Hydrocoll. 2024, 151, 109829. [Google Scholar] [CrossRef]

- Ravishankar, G.A.; Rao, A.R.; Tahergorabi, R.; Mohan, A. Handbook of Plant-Based Meat Analogs: Innovation, Technology and Quality; Elsevier Science & Technology: Amsterdam, The Netherlands, 2024. [Google Scholar]

- Ramos-Diaz, J.M.; Oksanen, S.; Kantanen, K.; Edelmann, J.M.; Suhonen, H.; Sontag-Strohm, T.; Piironen, V.; Jouppila, K. Characterization of Texturized Meat Analogues Containing Native Lupin Flour and Lupin Protein Concentrate/Isolate. Heliyon 2023, 9, e20503. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, K.; Zhang, X.; Zhang, T.; Zhao, J.; Jiang, L.; Sui, X. Protein Blend Extrusion: Crafting Meat Analogues with Varied Textural Structures and Characteristics. Food Chem. 2024, 460, 140709. [Google Scholar] [CrossRef]

- Lee, P.Y.; Leong, S.Y.; Oey, I. The Role of Protein Blends in Plant-Based Milk Alternative: A Review through the Consumer Lens. Trends Food Sci. Technol. 2024, 143, 104268. [Google Scholar] [CrossRef]

- Wang, T.; Xu, P.; Chen, Z.; Wang, R. Mechanism of Structural Interplay between Rice Proteins and Soy Protein Isolates to Design Novel Protein Hydrocolloids. Food Hydrocoll. 2018, 84, 361–367. [Google Scholar] [CrossRef]

- Yan, G.; Li, Y.; Wang, H.; Cui, S.; Li, Y.; Zhang, L.; Yan, J. Multiscale Approach to the Characterization of the Interfacial Properties of Micellar Casein and Whey Protein Blends and their Effects on Recombined Dairy Creams. Food Res. Int. 2024, 188, 114453. [Google Scholar] [CrossRef]

- Jang, J.; Lee, D. Advancements in Plant Based Meat Analogs Enhancing Sensory and Nutritional Attributes. npj Sci. Food 2024, 8, 50. [Google Scholar] [CrossRef]

- Gidley, M.J.; Yakubov, G.E. Functional Categorisation of Dietary Fibre in Foods: Beyond ‘Soluble’ vs ‘Insoluble’. Trends Food Sci. Technol. 2019, 86, 563–568. [Google Scholar] [CrossRef]

- Gastaldello, A.; Giampieri, F.; De Giuseppe, R.; Grosso, G.; Baroni, L.; Battino, M. The Rise of Processed Meat Alternatives: A Narrative Review of the Manufacturing, Composition, Nutritional Profile and Health Effects of Newer Sources of Protein, and their Place in Healthier Diets. Trends Food Sci. Technol. 2022, 127, 263–271. [Google Scholar] [CrossRef]

- Grillo, A.; Salvi, L.; Coruzzi, P.; Salvi, P.; Parati, G. Sodium Intake and Hypertension. Nutrients 2019, 11, 1970. [Google Scholar] [CrossRef] [PubMed]

- McClements, D.J. Ultraprocessed Plant-based Foods: Designing the Next Generation of Healthy and Sustainable Alternatives to Animal-based Foods. Compr. Rev. Food Sci. Food Saf. 2023, 22, 3531–3559. [Google Scholar] [CrossRef] [PubMed]

- Butola, L.K.; Kute, P.K.; Anjankar, A.; Dhok, A.; Gusain, N.; Vagga, A. Vitamin B12-do You Know Everything. J. Evol. Med. Dent. Sci. 2020, 9, 3139–3147. [Google Scholar] [CrossRef]

- Tachie, C.; Nwachukwu, I.D.; Aryee, A.N. Trends and Innovations in the Formulation of Plant-Based Foods. Food Prod. Process Nutr. 2023, 5, 16. [Google Scholar] [CrossRef]

- Toh, D.W.K.; Fu, A.S.; Mehta, K.A.; Lam, N.Y.L.; Haldar, S.; Henry, C.J. Plant-Based Meat Analogs and their Effects on Cardiometabolic Health: An 8-Week Randomized Controlled Trial Comparing Plant-Based Meat Analogs with their Corresponding Animal-Based Foods. Am. J. Clin. Nutr. 2024, 119, 1405–1416. [Google Scholar] [CrossRef]

- Toh, D.W.K.; Srv, A.; Henry, C.J. Unknown Impacts of Plant-Based Meat Alternatives on Long-Term Health. Nat. Food 2022, 3, 90–91. [Google Scholar] [CrossRef]

- Zahari, I.; Rinaldi, S.; Ahlstrom, C.; Östbring, K.; Rayner, M.; Purhagen, J. High Moisture Meat Analogues from hemp–The Effect of Co-Extrusion with Wheat Gluten and Chickpea Proteins on the Textural Properties and Sensorial Attributes. LWT 2023, 189, 115494. [Google Scholar] [CrossRef]

- Dekkers, B.L.; Boom, R.M.; van der Goot, A.J. Structuring Processes for Meat Analogues. Trends Food Sci. Technol. 2018, 81, 25–36. [Google Scholar] [CrossRef]

- Chiang, J.H.; Loveday, S.M.; Hardacre, A.K.; Parker, M.E. Effects of Soy Protein to Wheat Gluten Ratio on the Physicochemical Properties of Extruded Meat Analogues. Food Struct. 2019, 19, 100102. [Google Scholar] [CrossRef]

- Choi, H.W.; Hahn, J.; Kim, H.; Choi, Y.J. Thermorheological Properties and Structural Characteristics of Soy and Pumpkin Seed Protein Blends for High-Moisture Meat Analogs. Food Chem. 2025, 464, 141768. [Google Scholar] [CrossRef] [PubMed]

- Choi, H.W.; Choi, M.; Ryoo, C.; Hahn, J.; Choi, Y.J. Viscometry-Based Prediction of Structural Properties of High-Moisture Meat Analogues using Gelation Properties of Soy and Pea Isolate Protein Blends. Food Hydrocoll. 2024, 151, 109870. [Google Scholar] [CrossRef]

- Zhao, Y.; Peng, N.; Li, Y.; Liang, Y.; Guo, Z.; Wang, C.; Wang, Z.; Wang, C.; Ren, X. Physicochemical Properties, Structural Characteristics and Protein Digestibility of Pea Protein-Wheat Gluten Composited Meat Analogues Prepared Via High-Moisture Extrusion. Food Hydrocoll. 2024, 156, 110283. [Google Scholar] [CrossRef]

- Jiang, W.; Feng, J.; Yang, X.; Li, L. Structure of Pea Protein-Based Complexes on High-Moisture Extrusion: Raw Materials and Extrusion Zones. LWT 2024, 194, 115823. [Google Scholar] [CrossRef]

- Riazi, F.; Tehrani, M.M.; Lammers, V.; Heinz, V.; Savadkoohi, S. Unexpected Morphological Modifications in High Moisture Extruded Pea-Flaxseed Proteins: Part I, Topological and Conformational Characteristics, Textural Attributes, and Viscoelastic Phenomena. Food Hydrocoll. 2023, 136, 108304. [Google Scholar] [CrossRef]

- Amagliani, L.; van de Langerijt, T.M.; Morgenegg, C.; Bovetto, L.; Schmitt, C. Influence of Charged and Non-Charged Co-Solutes on the Heat-Induced Aggregation of Soy and Pea Proteins at pH 7.0. Food Hydrocoll. 2023, 137, 108392. [Google Scholar] [CrossRef]

- Deng, Q.; Wang, Z.; Fu, L.; He, Z.; Zeng, M.; Qin, F.; Chen, J. High-Moisture Extrusion of Soy Protein: Effects of Insoluble Dietary Fiber on Anisotropic Extrudates. Food Hydrocoll. 2023, 141, 108688. [Google Scholar]

- Zhang, W.; Hui, B.; Li, X.; Guo, Z.; Li, J. Elucidating the Mechanism of Inulin-Induced Improvement in the Structural and Functional Properties of High-Moisture Extruded Products. Food Hydrocoll. 2024, 157, 110449. [Google Scholar] [CrossRef]

- Li, J.; Janssen, F.; Verfaillie, D.; Brijs, K.; Delcour, J.A.; Gunes, D.Z.; Cardinaels, R.; Van Royen, G.; Wouters, A.G. The Interplay between Soy Proteins and Dietary Fiber in Determining the Structure and Texture of High Moisture Extrudates. Food Hydrocoll. 2024, 156, 110256. [Google Scholar] [CrossRef]

- Wang, F.; Gao, Y.; Gu, X.; Luan, B.; Zhu, Y.; Huang, Y.; Zhu, X. High-Moisture Extrusion Cooking on Soybean-Wheat Protein Mixtures: Effect of Sodium Alginate/Xanthan Gum/Maltodextrin on Promoting a Fibrous Structure. Front. Nutr. 2023, 9, 1077601. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, J.; Liu, H.; Li, T.; Wang, Q. Mechanism of High-Moisture Extruded Protein Fibrous Structure Formation Based on the Interactions among Pea Protein, Amylopectin, and Stearic Acid. Food Hydrocoll. 2023, 136, 108254. [Google Scholar] [CrossRef]

- Taghian Dinani, S.; Zhang, Y.; Vardhanabhuti, B.; Jan van der Goot, A. Enhancing Textural Properties in Plant-Based Meat Alternatives: The Impact of Hydrocolloids and Salts on Soy Protein-Based Products. Curr. Res. Food Sci. 2023, 7, 100571. [Google Scholar] [CrossRef] [PubMed]

- Ozturk, O.K.; Hamaker, B.R. Texturization of Plant Protein-Based Meat Alternatives: Processing, Base Proteins, and Other Constructional Ingredients. Futur. Foods 2023, 8, 100248. [Google Scholar] [CrossRef]

- De Angelis, D.; van der Goot, A.J.; Pasqualone, A.; Summo, C. Advancements in Texturization Processes for the Development of Plant-Based Meat Analogs: A Review. Curr. Opin. Food Sci. 2024, 58, 101192. [Google Scholar] [CrossRef]

- Arora, S.; Kataria, P.; Nautiyal, M.; Tuteja, I.; Sharma, V.; Ahmad, F.; Haque, S.; Shahwan, M.; Capanoglu, E.; Vashishth, R. Comprehensive Review on the Role of Plant Protein as a Possible Meat Analogue: Framing the Future of Meat. ACS Omega 2023, 8, 23305–23319. [Google Scholar] [CrossRef]

- Grossmann, L.; Weiss, J. Alternative Protein Sources as Technofunctional Food Ingredients. Annu. Rev. Food Sci. Technol. 2021, 12, 93–117. [Google Scholar] [CrossRef]

- GFI. Plant-Based Meat: Anticipating 2030 Production Requirements. 2024. Available online: https://gfi.org/resource/anticipating-plant-based-meat-production-requirements-2030/ (accessed on 12 December 2024).

- Troya, M.; Kurawadwala, H.; Byrne, B.; Dowdy, R.; Weston, Z. Plant Based Meat: Anticipating 2030 Production Requirements; Good Food Institute: Washington, DC, USA, 2022. [Google Scholar]

- Cornet, S.H.; Snel, S.J.; Schreuders, F.K.; van der Sman, R.G.; Beyrer, M.; van der Goot, A.J. Thermo-Mechanical Processing of Plant Proteins using Shear Cell and High-Moisture Extrusion Cooking. Crit. Rev. Food Sci. Nutr. 2022, 62, 3264–3280. [Google Scholar] [CrossRef]

- Hülsebusch, L.; Heyn, T.R.; Amft, J.; Schwarz, K. Extrusion of Plant Proteins: A Review of Lipid and Protein Oxidation and their Impact on Functional Properties. Food Chem. 2024, 470, 142607. [Google Scholar] [CrossRef]

- Alonso, R.; Orue, E.; Zabalza, M.J.; Grant, G.; Marzo, F. Effect of Extrusion Cooking on Structure and Functional Properties of Pea and Kidney Bean Proteins. J. Sci. Food Agric. 2000, 80, 397–403. [Google Scholar] [CrossRef]

- Chan, E.; Rodas-Gonzalez, A.; Tulbek, M.; Koksel, F. Effects of Protein Formula and Extrusion Cooking Conditions on the Techno-Functional Properties of Texturised Pea Proteins. Int. J. Food Sci. Technol. 2024, 59, 584–595. [Google Scholar] [CrossRef]

- Dinali, M.; Liyanage, R.; Silva, M.; Newman, L.; Adhikari, B.; Wijesekara, I.; Chandrapala, J. Fibrous Structure in Plant-Based Meat: High-Moisture Extrusion Factors and Sensory Attributes in Production and Storage. Food Rev. Int. 2024, 40, 2940–2968. [Google Scholar] [CrossRef]

- Sui, X.; Zhang, T.; Zhang, X.; Jiang, L. High-Moisture Extrusion of Plant Proteins: Fundamentals of Texturization and Applications. Annu. Rev. Food Sci. Technol. 2024, 15, 125–149. [Google Scholar] [CrossRef] [PubMed]

- van der Sman, R.G.M.; van der Goot, A.J. Hypotheses Concerning Structuring of Extruded Meat Analogs. Curr. Res. Food Sci. 2023, 6, 100510. [Google Scholar] [CrossRef] [PubMed]

- Gasparre, N.; van den Berg, M.; Oosterlinck, F.; Sein, A. High-Moisture Shear Processes: Molecular Changes of Wheat Gluten and Potential Plant-Based Proteins for its Replacement. Molecules 2022, 27, 5855. [Google Scholar] [CrossRef]

- Hu, X.; Xiang, X.; Ju, Q.; Li, S.; Julian McClements, D. Impact of Lipid Droplet Characteristics on the Rheology of Plant Protein Emulsion Gels: Droplet Size, Concentration, and Interfacial Properties. Food Res. Int. 2024, 191, 114734. [Google Scholar] [CrossRef]

- Mitchell, J.R. Structural Changes in Biopolymers during Extrusion. In Food Extrusion Science and Technology; Marcel Dekker: New York, NY, USA, 1991. [Google Scholar]

- Murillo, J.S.; Osen, R.; Hiermaier, S.; Ganzenmüller, G. Towards Understanding the Mechanism of Fibrous Texture Formation during High-Moisture Extrusion of Meat Substitutes. J. Food Eng. 2019, 242, 8–20. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, Y.; Li, K.; Shen, S.; Li, J. Exploring the Mechanism of Amylose/Amylopectin Improving Formation of Yeast-Soy Protein High-Moisture Extrudates Based on Small and Large Amplitude Oscillatory Shear Rheology. Food Hydrocoll. 2024, 153, 110062. [Google Scholar] [CrossRef]

- Chutinara, C.; Sagis, L.M.; Landman, J. Interfacial Rheological Properties of Pepsin-Hydrolyzed Lentil Protein Isolate at Oil-Water Interfaces. Food Hydrocoll. 2024, 155, 110201. [Google Scholar] [CrossRef]

- Meng, A.; Chen, F.; Zhao, D.; Wei, Y.; Zhang, B. Identifying Changes in Soybean Protein Properties during High-Moisture Extrusion Processing using Dead-Stop Operation. Food Chem. 2022, 395, 133599. [Google Scholar] [CrossRef]

- Wittek, P.; Zeiler, N.; Karbstein, H.P.; Emin, M.A. High Moisture Extrusion of Soy Protein: Investigations on the Formation of Anisotropic Product Structure. Foods 2021, 10, 102. [Google Scholar] [CrossRef]

- Maningat, C.C.; Jeradechachai, T.; Buttshaw, M.R. Textured Wheat and Pea Proteins for Meat Alternative Applications. Cereal Chem. 2022, 99, 37–66. [Google Scholar] [CrossRef]

- Ferawati, F.; Zahari, I.; Barman, M.; Hefni, M.; Ahlström, C.; Witthöft, C.; Östbring, K. High-Moisture Meat Analogues Produced from Yellow Pea and Faba Bean Protein Isolates/Concentrate: Effect of Raw Material Composition and Extrusion Parameters on Texture Properties. Foods 2021, 10, 843. [Google Scholar] [CrossRef] [PubMed]

- Kantanen, K.; Oksanen, A.; Edelmann, M.; Suhonen, H.; Sontag-Strohm, T.; Piironen, V.; Ramos Diaz, J.M.; Jouppila, K. Physical Properties of Extrudates with Fibrous Structures made of Faba Bean Protein Ingredients using High Moisture Extrusion. Foods 2022, 11, 1280. [Google Scholar] [CrossRef]

- Kuijpers, S.A.; Goudappel, G.; Huppertz, T.; van Duynhoven, J.P.; Terenzi, C. Quantification of Phase Separation in High Moisture Soy Protein Extrudates by NMR and MRI. Food Res. Int. 2024, 197, 115225. [Google Scholar] [CrossRef]

- Peng, Y.; Zhao, D.; Li, M.; Wen, X.; Ni, Y. The Interactions of Soy Protein and Wheat Gluten for the Development of Meat-Like Fibrous Structure. Molecules 2023, 28, 7431. [Google Scholar] [CrossRef]

- Schreuders, F.K.G.; Sagis, L.M.C.; Bodnár, I.; Erni, P.; Boom, R.M.; van der Goot, A.J. Mapping the Texture of Plant Protein Blends for Meat Analogues. Food Hydrocoll. 2021, 118, 106753. [Google Scholar] [CrossRef]

- Yuliarti, O.; Kiat Kovis, T.J.; Yi, N.J. Structuring the Meat Analogue by using Plant-Based Derived Composites. J. Food Eng. 2021, 288, 110138. [Google Scholar] [CrossRef]

- Krintiras, G.A.; Göbel, J.; Van der Goot, A.J.; Stefanidis, G.D. Production of Structured Soy-Based Meat Analogues using Simple Shear and Heat in a Couette Cell. J. Food Eng. 2015, 160, 34–41. [Google Scholar] [CrossRef]

- Ismail, B.P.; Senaratne-Lenagala, L.; Stube, A.; Brackenridge, A. Protein Demand: Review of Plant and Animal Proteins used in Alternative Protein Product Development and Production. Anim. Front. 2020, 10, 53–63. [Google Scholar] [CrossRef]

- Marczak, A.; Mendes, A.C. Dietary Fibers: Shaping Textural and Functional Properties of Processed Meats and Plant-Based Meat Alternatives. Foods 2024, 13, 1952. [Google Scholar] [CrossRef]

- Wen, Y.; Chao, C.; Che, Q.T.; Kim, H.W.; Park, H.J. Development of Plant-Based Meat Analogs using 3D Printing: Status and Opportunities. Trends Food Sci. Technol. 2023, 132, 76–92. [Google Scholar] [CrossRef]

- da Trindade, L.G.; Zanchet, L.; Bonsanto, F.P.; Braga, A.R.C. Spinning a Sustainable Future: Electrospun Polysaccharide–Protein Fibers for Plant-Based Meat Innovation. Foods 2024, 13, 2962. [Google Scholar] [CrossRef] [PubMed]

- Jia, X.; Qin, Z.; Xu, J.; Kong, B.; Liu, Q.; Wang, H. Preparation and Characterization of Pea Protein Isolate-Pullulan Blend Electrospun Nanofiber Films. Int. J. Biol. Macromol. 2020, 157, 641–647. [Google Scholar]

- Aguilar-Vázquez, G.; Ortiz-Frade, L.; Figueroa-Cárdenas, J.D.; López-Rubio, A.; Mendoza, S. Electrospinnability Study of Pea (Pisum sativum) and Common Bean (Phaseolus vulgaris L.) using the Conformational and Rheological Behavior of their Protein Isolates. Polym. Test. 2020, 81, 106217. [Google Scholar] [CrossRef]

- Mattice, K.D.; Marangoni, A.G. Physical Properties of Plant-Based Cheese Products Produced with Zein. Food Hydrocoll. 2020, 105, 105746. [Google Scholar] [CrossRef]

- Miller, O.; Scarlett, C.J.; Akanbi, T.O. Plant-Based Meat Analogues and Consumer Interest in 3D-Printed Products: A Mini-Review. Foods 2024, 13, 2314. [Google Scholar] [CrossRef]

- Ramachandraiah, K. Potential Development of Sustainable 3d-Printed Meat Analogues: A Review. Sustainability 2021, 13, 938. [Google Scholar] [CrossRef]

- Vignesh, K.; Yadav, D.K.; Wadikar, D.D.; Semwal, A.D. Exploring Sustenance: Cereal Legume Combinations for Vegan Meat Development. Sustain. Food Technol. 2024, 2, 32–47. [Google Scholar] [CrossRef]

- Atkinson, W.T. Meat-like Protein Food Product. U.S. Patent US3488770A, 6 January 1970. [Google Scholar]

- Consolacion, F.I.; Jelen, P. Freeze Texturation of Proteins: Effect of the Alkali, Acid and Freezing Treatments on Texture Formation. Food Struct. 1986, 5, 5. [Google Scholar]

- Lugay, J.C.; Kim, M.K. Freeze alignment: A novel method for protein texturization. In Utilization of Protein Resources (USA); Food & Nutrition Press: Trumbull, CT, USA, 1978. [Google Scholar]

- Pulivarthi, M.K.; Buenavista, R.M.; Bangar, S.P.; Li, Y.; Pordesimo, L.O.; Bean, S.R.; Siliveru, K. Dry Fractionation Process Operations in the Production of Protein Concentrates: A Review. Compr. Rev. Food Sci. Food Saf. 2023, 22, 4670–4697. [Google Scholar] [CrossRef]

- Assatory, A.; Vitelli, M.; Rajabzadeh, A.R.; Legge, R.L. Dry Fractionation Methods for Plant Protein, Starch and Fiber Enrichment: A Review. Trends Food Sci. Technol. 2019, 86, 340–351. [Google Scholar] [CrossRef]

- Nájera Espinosa, S.; Hadida, G.; Jelmar Sietsma, A.; Alae-Carew, C.; Turner, G.; Green, R.; Pastorino, S.; Picetti, R.; Scheelbeek, P. Mapping the Evidence of Novel Plant-Based Foods: A Systematic Review of Nutritional, Health, and Environmental Impacts in High-Income Countries. Nutr. Rev. 2024, nuae031. [Google Scholar] [CrossRef] [PubMed]

- Azarkamand, S.; Ríos, A.F.; Batlle-Bayer, L.; Bala, A.; Sazdovski, I.; Roca, M.; Margallo, M.; Aldaco, R.; Laso, J.; Puig, R. Calculating the True Costs of Protein Sources by Integrating Environmental Costs and Market Prices. Sustain. Prod. Consum. 2024, 49, 28–41. [Google Scholar] [CrossRef]

- Shanmugam, K.; Bryngelsson, S.; Östergren, K.; Hallström, E. Climate Impact of Plant-Based Meat Analogues: A Review of Life Cycle Assessments. Sustain. Prod. Consum. 2023, 36, 328–337. [Google Scholar] [CrossRef]

- Reis, G.G.; Villar, E.G.; Ryynänen, T.; Rodrigues, V.P. David Vs Goliath: The Challenges for Plant-Based Meat Companies Competing with Animal-Based Meat Producers. J. Clean. Prod. 2023, 423, 138705. [Google Scholar] [CrossRef]

- van der Weele, C.; Feindt, P.; Jan van der Goot, A.; van Mierlo, B.; van Boekel, M. Meat Alternatives: An Integrative Comparison. Trends Food Sci. Technol. 2019, 88, 505–512. [Google Scholar] [CrossRef]

- Alexander, P.; Brown, C.; Arneth, A.; Dias, C.; Finnigan, J.; Moran, D.; Rounsevell, M.D.A. Could Consumption of Insects, Cultured Meat Or Imitation Meat Reduce Global Agricultural Land use? Glob. Food Secur. 2017, 15, 22–32. [Google Scholar] [CrossRef]

- Caputo, V.; Sun, J.; Staples, A.J.; Taylor, H. Market Outlook for Meat Alternatives: Challenges, Opportunities, and New Developments. Trends Food Sci. Technol. 2024, 148, 104474. [Google Scholar] [CrossRef]

- Mylan, J.; Andrews, J.; Maye, D. The Big Business of Sustainable Food Production and Consumption: Exploring the Transition to Alternative Proteins. Proc. Natl. Acad. Sci. USA 2023, 120, e2207782120. [Google Scholar] [CrossRef]

- GFI Europe. Alternative Protein, R&D Priorities. 2024. Available online: https://gfieurope.org/wp-content/uploads/2023/04/Scitech-research-priority-briefing_GFI-Europe_January-2025.pdf (accessed on 12 December 2024).

- GFI. Reimagining Protein. 2024. Available online: https://www.energy.gov/sites/default/files/2023-10/Tessa%20Hale_Reimagining%20Proteins.pdf (accessed on 12 December 2024).

- Deloitte. Plant-Based Alternatives Driving Industry M&A. 2019. Available online: https://oceanium.world/wp-content/uploads/2021/05/plant-based-alternatives.pdf (accessed on 12 December 2024).

- Lurie-Luke, E. Alternative Protein Sources: Science Powered Startups to Fuel Food Innovation. Nat. Commun. 2024, 15, 4425. [Google Scholar] [CrossRef]

- Tziva, M.; Negro, S.O.; Kalfagianni, A.; Hekkert, M.P. Understanding the Protein Transition: The Rise of Plant-Based Meat Substitutes. Environ. Innov. Soc. Transit. 2020, 35, 217–231. [Google Scholar] [CrossRef]

- Bulah, B.M.; Negro, S.O.; Beumer, K.; Hekkert, M.P. Institutional Work as a Key Ingredient of Food Innovation Success: The Case of Plant-Based Proteins. Environ. Innov. Soc. Transit. 2023, 47, 100697. [Google Scholar] [CrossRef]

- Imran, M.; Liyan, Z. Production of Plant-Based Meat: Functionality, Limitations and Future Prospects. Eur. Food Res. Technol. 2023, 249, 2189–2213. [Google Scholar] [CrossRef]

- Curtain, F.; Grafenauer, S. Plant-Based Meat Substitutes in the Flexitarian Age: An Audit of Products on Supermarket Shelves. Nutrients 2019, 11, 2603. [Google Scholar] [CrossRef]

- GFI. Reducing the Price of Alternative. Proteins. 2021, pp. 1–14. Available online: https://gfi.org/reducing-the-price-of-alternative-proteins/ (accessed on 12 December 2024).

- Yule, J.A.; Cummings, K.H. Conservative Consumer Disinterest in Plant-Based Meat: A Problem of Message Incongruence. Appetite 2023, 187, 106574. [Google Scholar] [CrossRef]

- Food Consumer Observatory. Consumer Perceptions Unwrapped: Ultra-Processed Foods (UPF). 2024. Available online: https://www.eitfood.eu/files/Consumer-Perceptions-Unwrapped_Consumer-Observatory-Report-1.pdf (accessed on 12 December 2024).

- Petrus, R.R.; do Amaral Sobral, P.J.; Tadini, C.C.; Gonçalves, C.B. The NOVA Classification System: A Critical Perspective in Food Science. Trends Food Sci. Technol. 2021, 116, 603–608. [Google Scholar] [CrossRef]

- Marshall, D.; Bano, F.; Banas, K. A Meaty Issue: The Effect of Meat-Related Label Terminology on the Willingness to Eat Vegetarian Foods. Food Qual. Prefer. 2022, 96, 104413. [Google Scholar] [CrossRef]

| Material Composition (%w/w) | Protein Ingredient | Functionality | The Type of Application in Meat Analogues | ||

|---|---|---|---|---|---|

| Structuring Process | Role | Products | |||

| ~70% protein | Soy concentrate | Possesses excellent texturization properties. | Extrusion and shear cell technology | As a binding ingredient, a source of protein, and in the enhancement of texture. | Most burger patties, minced meat analogues, muscle-type products, and plant-based sausages. |

| ~90% protein | Soy isolates extracted by the use of alkaline/acid precipitation | Possess excellent gelation and emulsification potential, as well as good solubility propensity. | Extrusion, shear cell technology, spinning, and freeze structuring. | Used as the base for the formulation of fat substitutes, as a binder, as a protein source, emulsifier, and for texture enhancement. | Most burger patties, minced meat analogues, and plant-based sausages. |

| ~90% protein that is mainly denatured due to heat treatment | Soy isolates that are extracted from soy that has been heat treated or toasted isolate | There is a general decrease in solubility, an increase in water-holding capacity, and good gelling propensity. | Extrusion, shear cell | Used as a protein source, texture, binder, a base for fat substitutes. | Used in the formulation of burger patties, minced meat analogues, and plant-based sausages. |

| ~43–56% protein, ~0.5–9% fat, ~3–7% crude fibre, and >30% total carbohydrate | Defatted soy flour/meal | They display good water-binding capacity and fat-retention properties. | Extrusion | Used as a binding ingredient and in texture modification. | Used in the formulation of burger patties, minced meat analogues, in the production of muscle-type products, and in plant-based sausages. |

| >45% protein, ~30% fat | Spray-dried soymilk powder | Tend to be highly soluble and possess good emulsification properties. | Mainly used in freeze structuring | Used as an emulsifier and in texture modification. | Used in the production of tofu and Yuba. |

| ~85% protein | Pea isolates | Possesses good water- and fat-binding properties, emulsification, and results in a firm texture after thermal/heat processing. | Used in extrusion, shear cell technology and in spinning | Used as a binder, emulsifier, and texture enhancement. | Used in the formulation of burger patties, the production of minced-meat analogues, the formulation of muscle-type products, and plant-based sausages. |

| 75–80% protein, 15–17% carbohydrates, 5–8% fat | Wheat gluten isolate | Possess good binding ability, low solubility, is involved in the formation of dough, and has a high crosslinking capacity via S-S bridges. | Used in extrusion, shear cell technology | Used in functions that require adhesion properties and in the enhancement of the textural properties of meat analogues. | Used in the formulation of burger patties and in the formulation of muscle-type products. |

| 56% protein | Dry, fractionated faba | Possesses good water-binding properties, gelation, and results in a firm texture after thermal/heat processing. | Used in high-moisture extrusion | Used in the enhancement of textural properties. | Used in the formulation of burger patties, the production of minced meat analogues, the formulation of muscle-type products, and plant-based sausages |

| ~37% protein | 30% native lupine flour blended with 70% different blend ratios of lupine protein concentrate and isolate | Possesses a reduced water-absorption capacity and gelation and results in a firm texture after thermal/heat processing. | Used in extrusion | Used in the enhancement of textural properties. | Used in the fabrication of texturized meat analogues with fibrous structures. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Munialo, C.D.; Baeghbali, V.; Acharya, P. Plant-Based Alternatives to Meat Products. Foods 2025, 14, 1396. https://doi.org/10.3390/foods14081396

Munialo CD, Baeghbali V, Acharya P. Plant-Based Alternatives to Meat Products. Foods. 2025; 14(8):1396. https://doi.org/10.3390/foods14081396

Chicago/Turabian StyleMunialo, Claire Darizu, Vahid Baeghbali, and Parag Acharya. 2025. "Plant-Based Alternatives to Meat Products" Foods 14, no. 8: 1396. https://doi.org/10.3390/foods14081396

APA StyleMunialo, C. D., Baeghbali, V., & Acharya, P. (2025). Plant-Based Alternatives to Meat Products. Foods, 14(8), 1396. https://doi.org/10.3390/foods14081396