Improving Cull Cow Meat Quality Using Vacuum Impregnation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Material and Sample Preparation

2.2. Isotonic Solution Preparation

2.3. Analytical Methods

2.4. Vacuum Impregnation Experiments

2.5. Scanning Electron Microscopy

2.6. Statistical Analysis

3. Results and Discussion

3.1. Analytical Results

3.2. Volume of Brine Impregnated in the Meat with Vacuum Impregnation

3.3. Volume Deformation of Cull Cow Meat Subjected to Vacuum Impregnation

3.4. Changes in the Sample Effective Porosity of Meat

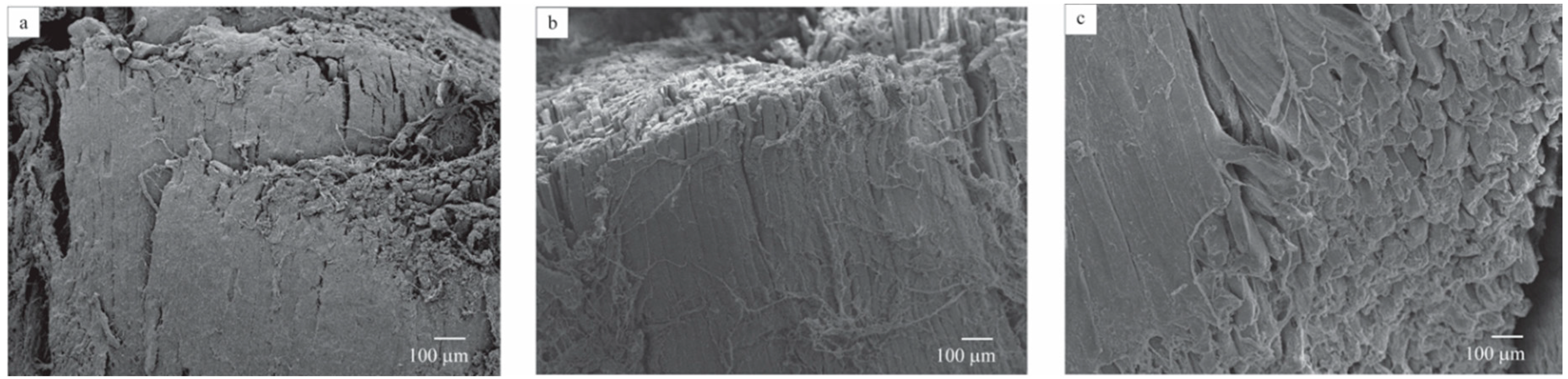

3.5. Microstructural Analysis of Meat Vacuum Impregnated

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Hoffman, L. Sensory and physical characteristics of enhanced vs. Non-enhanced meat from mature cows. Meat Sci. 2006, 72, 195–202. [Google Scholar] [CrossRef] [PubMed]

- Smith, D.P.; Acton, J.C. Marination, cooking, and curing of poultry products. In Poultry Meat Processing; Sams, A.R., Ed.; Taylor & Francis Group LLC: Boca Raton, FL, USA, 2001; pp. 257–280. [Google Scholar]

- Feiner, G. Meat Products Handbook Practical Science and Technology; Publishing Limited: Cambridge, UK, 2006. [Google Scholar]

- Vihavainen, E.J.; Björkroth, K.J. Spoilage of value-added, high-oxygen modified-atmosphere packaged raw beef steaks by leuconostoc gasicomitatum and leuconostoc gelidum. Int. J. Food Microbiol. 2007, 119, 340–345. [Google Scholar] [CrossRef] [PubMed]

- Belitz, H.; Grosch, W.; Schieberle, P. Food Chemistry; Springer: Berlin, Germany, 2009. [Google Scholar]

- Huff-Lonergan, E.; Lonergan, S.M. Mechanisms of water-holding capacity of meat: The role of postmortem biochemical and structural changes. Meat Sci. 2005, 71, 194–204. [Google Scholar] [CrossRef] [PubMed]

- Uttaro, B.; Aalhus, J. Effect of thawing rate on distribution of an injected salt and phosphate brine in beef. Meat Sci. 2007, 75, 480–486. [Google Scholar] [CrossRef] [PubMed]

- Uttaro, B.; Badoni, M.; Zawadski, S.; Gill, C. Effects of the pressure, flow rate and delivered volume of brine on the distributions of brine and bacteria in brine-injected meat. Food Control 2011, 22, 180–185. [Google Scholar] [CrossRef]

- Cárcel, J.A.; Benedito, J.; Bon, J.; Mulet, A. High intensity ultrasound effects on meat brining. Meat Sci. 2007, 76, 611–619. [Google Scholar] [CrossRef] [PubMed]

- Leal-Ramos, M.Y.; Alarcon-Rojo, A.D.; Mason, T.J.; Paniwnyk, L.; Alarjah, M. Ultrasound-enhanced mass transfer in halal compared with non-halal chicken. J. Sci. Food Agric. 2011, 91, 130–133. [Google Scholar] [CrossRef] [PubMed]

- Siró, I.; Vén, C.; Balla, C.; Jónás, G.; Zeke, I.; Friedrich, L. Application of an ultrasonic assisted curing technique for improving the diffusion of sodium chloride in porcine meat. J. Food Eng. 2009, 91, 353–362. [Google Scholar] [CrossRef]

- Stadnik, J.; Dolatowski, Z.J.; Baranowska, H.M. Effect of ultrasound treatment on water holding properties and microstructure of beef (m. Semimembranosus) during ageing. LWT-Food Sci. Technol. 2008, 41, 2151–2158. [Google Scholar] [CrossRef]

- Lakshmanan, R.; Parkinson, J.A.; Piggott, J.R. High-pressure processing and water-holding capacity of fresh and cold-smoked salmon (salmo salar). LWT-Food Sci. Technol. 2007, 40, 544–551. [Google Scholar] [CrossRef]

- Villacís, M.; Rastogi, N.; Balasubramaniam, V. Effect of high pressure on moisture and NaCl diffusion into turkey breast. LWT-Food Sci. Technol. 2008, 41, 836–844. [Google Scholar] [CrossRef]

- Yashoda, K.; Rao, R.J.; Mahendrakar, N.; Rao, D.N. Marination of sheep muscles under pressure and its effect on meat texture quality. J. Muscle Foods 2005, 16, 184–191. [Google Scholar] [CrossRef]

- Barat, J.M.; Grau, R.; Fito, P.; Chiralt, A. Vacuum salting treatment for the accelerated processing of dry-cured ham. In Advanced Technologies for Meat Processing; Nollet, L.M.L., Toldrá, F., Eds.; Taylor & Francis Group LLC: Boca Raton, FL, USA, 2006; pp. 353–370. [Google Scholar]

- Barat, J.; Andujar, G.; Andrés, A.; Arguelles, A.; Fito, P. Salting studies during tasajo making. In Osmotic Dehydration and Vacuum Impregnation Applications in Food Industries; Fito, P., Chiralt, A., Barat, J.M., Spiess, W.E.L., Behsnilian, D., Eds.; Technomic Publishing Company Inc.: Lancaster, PA, USA, 2001; pp. 171–183. [Google Scholar]

- Deumier, F.; Trystram, G.; Collignan, A.; Guédider, L.; Bohuon, P. Pulsed vacuum brining of poultry meat: Interpretation of mass transfer mechanisms. J. Food Eng. 2003, 58, 85–93. [Google Scholar] [CrossRef]

- Bugueño, G.; Escriche, I.; Chiralt, A.; Pérez-Juan, M.; Serra, J.A.; Camacho, M.M. Use of vacuum impregnation in smoked salmon manufacturing. In Osmotic Dehydration & Vacuum Impregnation Applications in Food Industries; Fito, P., Chiralt, A., Barat, J.M., Spiess, W.E.L., Behsnilian, D., Eds.; Technomic Publishing Company, Inc.: Lancaster, PA, USA, 2001; pp. 195–206. [Google Scholar]

- Larrazábal-Fuentes, M.J.; Escriche-Roberto, I.; Camacho-Vidal, M.d.M. Use of immersion and vacuum impregnation in marinated salmon (salmo salar) production. J. Food Process. Preserv. 2009, 33, 635–650. [Google Scholar] [CrossRef]

- Salvatori, D.; Andres, A.; Chiralt, A.; Fito, P. The response of some properties of fruits to vacuum impregnation. J. Food Process Eng. 1998, 21, 59–73. [Google Scholar] [CrossRef]

- Valdez-Fragoso, A.; Sáenz-Hernández, C.; Welti-Chanes, J.; Mújica-Paz, H. Cherry pepper pickling: Mass transport and firmness parameters and stability indicators. J. Food Eng. 2009, 95, 648–655. [Google Scholar] [CrossRef]

- Fito, P.; Chiralt, A. Vacuum impregnation of plant tissues. In Minimally Processed Fruits and Vegetables; Alzamora, S.M., Tapia, M.S., López-Malo, A., Eds.; Aspen Publication Inc.: Frederick, MD, USA, 2000; pp. 189–201. [Google Scholar]

- Graiver, N.; Pinotti, A.; Califano, A.; Zaritzky, N. Diffusion of sodium chloride in pork tissue. J. Food Eng. 2006, 77, 910–918. [Google Scholar] [CrossRef]

- Chiralt, A.; Fito, P.; Barat, J.M.; Andrés, A.; González-Martínez, C.; Escriche, I.; Camacho, M.M. Use of vacuum impregnation in food salting process. J. Food Eng. 2001, 49, 141–151. [Google Scholar] [CrossRef]

- USDA. Institutional Meat Purchasing Specifications for Fresh Beef; Serv, A.M., Ed.; USDA: Washington, DC, USA, 2014.

- Cunnif, P. Official Methods of Analysis of Aoac International, 16th ed.; Association of Official Analytical Chemists International: Arlington, VA, USA, 1998. [Google Scholar]

- Rahman, M.S. Mass-volume-area-related properties of foods. In Engineering Properties of Foods; Rao, M.A., Rizvi, S.S.H., Datta, A.K., Eds.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2005; pp. 1–40. [Google Scholar]

- Fito, P.; Andrés, A.; Chiralt, A.; Pardo, P. Coupling of hydrodynamic mechanism and deformation-relaxation phenomena during vacuum treatments in solid porous food-liquid systems. J. Food Eng. 1996, 27, 229–240. [Google Scholar] [CrossRef]

- Dykstra, M.J. A Manual of Applied Techniques for Biological Electron Microscopy; Springer Science & Business Media: New York, NY, USA, 1993; p. 78. [Google Scholar]

- Buford, M.; Calkins, C.; Johnson, D.; Gwartney, B. Cow Muscle Profiling: Processing Traits of 21 Muscles from Beef and Dairy Cow Carcasses; University of Nebraska-Lincoln: Lincoln, NE, USA, 2003. [Google Scholar]

- Patten, L.; Hodgen, J.; Stelzleni, A.; Calkins, C.; Johnson, D.; Gwartney, B. Chemical properties of cow and beef muscles: Benchmarking the differences and similarities 1 2. J. Anim. Sci. 2008, 86, 1904–1916. [Google Scholar] [CrossRef] [PubMed]

- Lewicki, P.P. Data and models of water activity II: Solid foods. In Food Properties Handbook; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2009. [Google Scholar]

- Hildrum, K.I.; Wold, J.P.; Segtnan, V.H.; Renou, J.P.; Dufour, E. New spectroscopic techniques for online monitoring of meat quality. In Advanced Technologies for Meat Processing; Nollet, L.M.L., Toldrá, F., Eds.; CRC Press and Taylor & Francis Group: Boca Raton, FL, USA, 2006; pp. 88–123. [Google Scholar]

- Malterre, C.; Jones, S.D.M. Meat production from heifers and cull cows. In Beef Cattle Production (World Animal Science. C: Production-Approach 5); Jarrige, R., Beéranger, C., Eds.; Elsevier Scince Publishers: Holland, The Netherlands, 1992; pp. 357–375. [Google Scholar]

- Andres, A.; Salvatori, D.; Albors, A.; Chiralt, A.; Fito, P. Vacuum impregnation viability of some fruits and vegetables. In Osmotic Dehydration & Vacuum Impregnation: Aplications in Food Industries; Fito, P., Chiralt, A., Barat, J.M., Spiess, W.E., Behsnilian, D., Eds.; Technomic Publishing Company Inc.: Lancaster, PA, USA, 2001; pp. 53–60. [Google Scholar]

- Lawrie, R.A.; Ledward, D.A. Lawries’s Meat Science; CRC Press LLC: Boca Raton, FL, USA, 2006. [Google Scholar]

- Desmond, E. Reducing salt: A challenge for the meat industry. Meat Sci. 2006, 74, 188–196. [Google Scholar] [CrossRef] [PubMed]

- Lepetit, J. A theoretical approach of the relationships between collagen content, collagen cross-links and meat tenderness. Meat Sci. 2007, 76, 147–159. [Google Scholar] [CrossRef] [PubMed]

- Saurel, R. The use of vacuum technology to improve processed fruit and vegetables. In Fruit and Vegetable Processing Improving Quality; Jongen, W., Ed.; CRC Press LLC: Boca Raton, FL, USA, 2002; pp. 363–380. [Google Scholar]

- Derossi, A.; De Pilli, T.; Severini, C. Reduction in the ph of vegetables by vacuum impregnation: A study on pepper. J. Food Eng. 2010, 99, 9–15. [Google Scholar] [CrossRef]

| Properties | Mean ± SD |

|---|---|

| Meat | |

| Moisture (g/100 g meat) * | 75.5 ± 3.0 |

| Protein (g/100 g meat) * | 20.2 ± 0.4 |

| Fat (g/100 g meat) * | 3.5 ± 2.5 |

| Ash (g/100 g meat) * | 1.2 ± 0.0 |

| pH | 5.8 ± 0.2 |

| Water activity | 0.98 ± 0.0 |

| (g/cm3) | 1.07 ± 0.0 |

| Isotonic solution | |

| Water activity | 0.98 ± 0.0 |

| (g/cm3) | 1.02 ± 0.01 |

| Paraffin wax | |

| (g/cm3) | 0.76 ± 0.01 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leal-Ramos, M.Y.; Alarcón-Rojo, A.D.; Gutiérrez-Méndez, N.; Mújica-Paz, H.; Rodríguez-Almeida, F.; Quintero-Ramos, A. Improving Cull Cow Meat Quality Using Vacuum Impregnation. Foods 2018, 7, 74. https://doi.org/10.3390/foods7050074

Leal-Ramos MY, Alarcón-Rojo AD, Gutiérrez-Méndez N, Mújica-Paz H, Rodríguez-Almeida F, Quintero-Ramos A. Improving Cull Cow Meat Quality Using Vacuum Impregnation. Foods. 2018; 7(5):74. https://doi.org/10.3390/foods7050074

Chicago/Turabian StyleLeal-Ramos, Martha Y., Alma D. Alarcón-Rojo, Néstor Gutiérrez-Méndez, Hugo Mújica-Paz, Felipe Rodríguez-Almeida, and Armando Quintero-Ramos. 2018. "Improving Cull Cow Meat Quality Using Vacuum Impregnation" Foods 7, no. 5: 74. https://doi.org/10.3390/foods7050074

APA StyleLeal-Ramos, M. Y., Alarcón-Rojo, A. D., Gutiérrez-Méndez, N., Mújica-Paz, H., Rodríguez-Almeida, F., & Quintero-Ramos, A. (2018). Improving Cull Cow Meat Quality Using Vacuum Impregnation. Foods, 7(5), 74. https://doi.org/10.3390/foods7050074