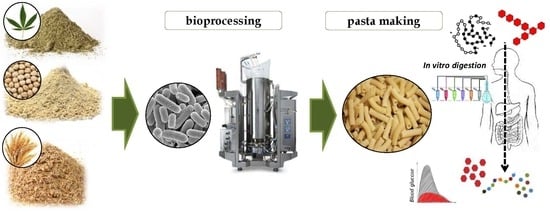

Use of Fermented Hemp, Chickpea and Milling By-Products to Improve the Nutritional Value of Semolina Pasta

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials, Bacterial Strains and Enzymes

2.2. Proximate Chemical Composition of Raw Materials

2.3. Bioprocessing

2.4. Determination of the Protein Degradation

2.5. Microbiological and Biochemical Characterization of Fermented Doughs

2.6. Pasta Making

2.7. In vitro Protein Digestibility (IVPD)

2.8. Pasta Characterization

2.8.1. Hydration Test, Cooking Time, Cooking Loss and Water Absorption

2.8.2. Chemical and Nutritional Profile

2.8.3. Texture and Color Analysis

2.8.4. Sensory Analysis

2.9. Statistical Analysis

3. Results

3.1. Proximate Composition of the Raw Materials

3.2. Proteolysis and Set-Up of the Bioprocessing

3.3. Chemical Characterization of Doughs

3.4. Chemical, Technological and Structural Properties of Pasta

3.5. Nutritional Properties of Pasta

3.6. Sensory Analysis

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kc, K.B.; Dias, G.M.; Veeramani, A.; Swanton, C.J.; Fraser, D.; Steinke, D.; Lee, E.; Wittman, H.; Farber, J.M.; Dunfield, K.; et al. When too much isn’t enough: Does current food production meet global nutritional needs? PLoS ONE 2018, 13, e0205683. [Google Scholar] [CrossRef] [PubMed]

- Banovic, M.; Arvola, A.; Pennanen, K.; Duta, D.E.; Brückner-Gühmann, M.; Lähteenmäki, L.; Grunert, K.G. Foods with increased protein content: A qualitative study on European consumer preferences and perceptions. Appetite 2018, 125, 233–243. [Google Scholar] [CrossRef] [PubMed]

- Mannar, M.V.; Hurrell, R.F. Food Fortification in a Globalized World, 1st ed.; Academic Press: New York, NY, USA, 2018. [Google Scholar]

- Spinelli, S.; Padalino, L.; Costa, C.; Del Nobile, M.A.; Conte, A. Food by-products to fortified pasta: A new approach for optimization. J. Clean. Prod. 2019, 215, 985–991. [Google Scholar] [CrossRef]

- Foschia, M.; Horstmann, S.W.; Arendt, E.K.; Zannini, E. Legumes as Functional Ingredients in Gluten-Free Bakery and Pasta Products. Annu. Rev. Food Sci. Technol. 2017, 8, 75–96. [Google Scholar] [CrossRef] [PubMed]

- Marconi, E.; Graziano, M.; Cubadda, R. Composition and Utilization of Barley Pearling By-Products for Making Functional Pastas Rich in Dietary Fiber and β-Glucans. Cereal Chem. J. 2000, 77, 133–139. [Google Scholar] [CrossRef]

- Rizzello, C.G.; Verni, M.; Koivula, H.; Montemurro, M.; Seppa, L.; Kemell, M.; Katina, K.; Coda, R.; Gobbetti, M. Influence of fermented faba bean flour on the nutritional, technological and sensory quality of fortified pasta. Food Funct. 2017, 8, 860–871. [Google Scholar] [CrossRef]

- Cankurtaran, T.; Bilgiçli, N. Influence of wheat milling by-products on some physical and chemical properties of filled and unfilled fresh pasta. J. Food Sci. Technol. 2019, 56, 2845–2854. [Google Scholar] [CrossRef]

- International Pasta Organization. The World Pasta Industry Status Report 2014; International Pasta Organization: Rome, Italy, 2014. [Google Scholar]

- Foschia, M.; Peressini, D.; Sensidoni, A.; Brennan, M.A.; Brennan, C.S. How combinations of dietary fibres can affect physicochemical characteristics of pasta. LWT 2015, 61, 41–46. [Google Scholar] [CrossRef]

- Lu, X.; Brennan, M.A.; Serventi, L.; Liu, J.; Guan, W.; Brennan, C.S. Addition of mushroom powder to pasta enhances the antioxidant content and modulates the predictive glycaemic response of pasta. Food Chem. 2018, 264, 199–209. [Google Scholar] [CrossRef]

- Martínez, M.L.; Marín, M.A.; Gili, R.D.; Penci, M.C.; Ribotta, P.D. Effect of defatted almond flour on cooking, chemical and sensorial properties of gluten-free fresh pasta. Int. J. Food Sci. Technol. 2017, 52, 2148–2155. [Google Scholar] [CrossRef]

- Parvathy, U.; Bindu, J.; Joshy, C.G. Development and optimization of fish-fortified instant noodles using response surface methodology. Int. J. Food Sci. Technol. 2017, 52, 608–616. [Google Scholar] [CrossRef]

- Roy, A.; Kucukural, A.; Zhang, Y. I-TASSER: A unified platform for automated protein structure and function prediction. Nat. Protoc. 2010, 5, 725–738. [Google Scholar] [CrossRef] [PubMed]

- Krishnaiah, D.; Sarbatly, R.; Nithyanandam, R. A review of the antioxidant potential of medicinal plant species. Food Bioprod. Process. 2011, 89, 217–233. [Google Scholar] [CrossRef]

- Teh, S.-S.; Bekhit, A.E.-D.A.; Carne, A.; Birch, J. Antioxidant and ACE-inhibitory activities of hemp (Cannabis sativa L.) protein hydrolysates produced by the proteases AFP, HT, Pro-G, actinidin and zingibain. Food Chem. 2016, 203, 199–206. [Google Scholar] [CrossRef]

- Rizzello, C.G.; Nionelli, L.; Coda, R.; Di Cagno, R.; Gobbetti, M. Use of sourdough fermented wheat germ for enhancing the nutritional, texture and sensory characteristics of the white bread. Eur. Food Res. Technol. 2009, 230, 645–654. [Google Scholar] [CrossRef]

- Coda, R.; Di Cagno, R.; Gobbetti, M.; Rizzello, C.G. Sourdough lactic acid bacteria: Exploration of non-wheat cereal-based fermentation. Food Microbiol. 2014, 37, 51–58. [Google Scholar] [CrossRef]

- Gobbetti, M.; De Angelis, M.; Di Cagno, R.; Calasso, M.; Archetti, G.; Rizzello, C.G. Novel insights on the functional/nutritional features of the sourdough fermentation. Int. J. Food Microbiol. 2019, 302, 103–113. [Google Scholar] [CrossRef]

- Montemurro, M.; Coda, R.; Rizzello, C.G. Recent Advances in the Use of Sourdough Biotechnology in Pasta Making. Foods 2019, 8, 129. [Google Scholar] [CrossRef]

- Rizzello, C.G.; Nionelli, L.; Coda, R.; De Angelis, M.; Gobbetti, M. Effect of sourdough fermentation on stabilisation, and chemical and nutritional characteristics of wheat germ. Food Chem. 2010, 119, 1079–1089. [Google Scholar] [CrossRef]

- AACC. Approved Methods of Analysis. 2010. Available online: http://methods.aaccnet.org/ (accessed on 18 December 2015).

- Mariotti, F.; Tomé, D.; Mirand, P.P. Converting Nitrogen into Protein—Beyond 6.25 and Jones’ Factors. Crit. Rev. Food Sci. Nutr. 2008, 48, 177–184. [Google Scholar] [CrossRef]

- FAO Food and Nutrition paper 77. Food Energy—Methods of Analysis and Conversion Factors. In Proceedings of the Food and Agriculture Organization of the United Nations Technical Workshop Report, Rome, Italy, 3–6 December 2002.

- Weiss, W.; Vogelmeier, C.; Görg, A. Electrophoretic characterization of wheat grain allergens from different cultivars involved in bakers’ asthma. Electrophoresis 1993, 14, 805–816. [Google Scholar] [CrossRef] [PubMed]

- Church, F.C.; Swaisgood, H.E.; Porter, D.H.; Catignani, G.L. Spectrophotometric Assay Using o-Phthaldialdehyde for Determination of Proteolysis in Milk and Isolated Milk Proteins. J. Dairy Sci. 1983, 66, 1219–1227. [Google Scholar] [CrossRef]

- Rizzello, C.G.; Cassone, A.; Coda, R.; Gobbetti, M. Antifungal activity of sourdough fermented wheat germ used as an ingredient for bread making. Food Chem. 2011, 127, 952–959. [Google Scholar] [CrossRef] [PubMed]

- Akeson, W.R.; Stahmann, M.A. A Pepsin Pancreatin Digest Index of Protein Quality Evaluation. J. Nutr. 1964, 83, 257–261. [Google Scholar] [CrossRef]

- Rizzello, C.G.; Calasso, M.; Campanella, D.; De Angelis, M.; Gobbetti, M. Use of sourdough fermentation and mixture of wheat, chickpea, lentil and bean flours for enhancing the nutritional, texture and sensory characteristics of white bread. Int. J. Food Microbiol. 2014, 180, 78–87. [Google Scholar] [CrossRef]

- Bradford, M.M. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal. Biochem. 1976, 72, 248–254. [Google Scholar] [CrossRef]

- Marti, A.; Fongaro, L.; Rossi, M.; Lucisano, M.; Pagani, A.M. Quality characteristics of dried pasta enriched with buckwheat flour. Int. J. Food Sci. Technol. 2011, 46, 2393–2400. [Google Scholar] [CrossRef]

- Schoenlechner, R.; Drausinger, J.; Ottenschlaeger, V.; Jurackova, K.; Berghofer, E. Functional Properties of Gluten-Free Pasta Produced from Amaranth, Quinoa and Buckwheat. Plant Foods Hum. Nutr. 2010, 65, 339–349. [Google Scholar] [CrossRef]

- D’egidio, M.G.; Mariani, B.M.; Nardi, S.; Novaro, P.; Cubadda, R. Chemical and technological variables and their relationships: A predictive equation for pasta cooking quality. Cereal Chem. 1990, 67, 275–281. [Google Scholar]

- Iametti, S.; Bonomi, F.; Pagani, M.A.; Zardi, M.; Cecchini, C.; D’Egidio, M.G. Properties of the Protein and Carbohydrate Fractions in Immature Wheat Kernels. J. Agric. Food Chem. 2006, 54, 10239–10244. [Google Scholar] [CrossRef]

- Hagerman, A.E. Acid Buthanol Assay for Proanthocyanidins. In The Tannin Handbook 2002; Hagerman, A.E., Ed.; Miami University: Oxford, UK, 2002. [Google Scholar]

- De Angelis, M.; Damiano, N.; Rizzello, C.G.; Cassone, A.; Di Cagno, R.; Gobbetti, M. Sourdough fermentation as a tool for the manufacture of low-glycemic index white wheat bread enriched in dietary fibre. Eur. Food Res. Technol. 2009, 229, 593–601. [Google Scholar] [CrossRef]

- Capriles, V.D.; Arêas, J.A.G. Effects of prebiotic inulin-type fructans on structure, quality, sensory acceptance and glycemic response of gluten-free breads. Food Funct. 2013, 4, 104–110. [Google Scholar] [CrossRef] [PubMed]

- Rizzello, C.G.; De Angelis, M.; Di Cagno, R.; Camarca, A.; Silano, M.; Losito, I.; De Vincenzi, M.; De Bari, M.D.; Palmisano, F.; Maurano, F.; et al. Highly Efficient Gluten Degradation by Lactobacilli and Fungal Proteases during Food Processing: New Perspectives for Celiac Disease. Appl. Environ. Microbiol. 2007, 73, 4499–4507. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Arte, E.; Rizzello, C.G.; Verni, M.; Nordlund, E.; Katina, K.; Coda, R. Impact of Enzymatic and Microbial Bioprocessing on Protein Modification and Nutritional Properties of Wheat Bran. J. Agric. Food Chem. 2015, 63, 8685–8693. [Google Scholar] [CrossRef] [PubMed]

- Gänzle, M.G.; Loponen, J.; Gobbetti, M. Proteolysis in sourdough fermentations: Mechanisms and potential for improved bread quality. Trends Food Sci. Technol. 2008, 19, 513–521. [Google Scholar] [CrossRef]

- Torres, A.; Frias, J.; Granito, M.; Vidal-Valverde, C. Fermented Pigeon Pea (Cajanus cajan) Ingredients in Pasta Products. J. Agric. Food Chem. 2006, 54, 6685–6691. [Google Scholar] [CrossRef] [PubMed]

- EFSA Panel on Dietetic Products, Nutrition and Allergies (NDA). Scientific Opinion on the substantiation of a health claim related to cocoa flavanols and maintenance of normal endothelium-dependent vasodilation pursuant to Article 13(5) of Regulation (EC) No 1924/2006. EFSA J. 2012, 10, 2809. [Google Scholar] [CrossRef] [Green Version]

- Vieira, B.; Caramori, J.; Oliveira, C.; Correa, G. Combination of phytase and organic acid for broilers: Role in mineral digestibility and phytic acid degradation. World’s Poult. Sci. J. 2018, 74, 711–726. [Google Scholar] [CrossRef]

- Coda, R.; Kianjam, M.; Pontonio, E.; Verni, M.; Di Cagno, R.; Katina, K.; Rizzello, C.G.; Gobbetti, M. Sourdough-type propagation of faba bean flour: Dynamics of microbial consortia and biochemical implications. Int. J. Food Microbiol. 2017, 248, 10–21. [Google Scholar] [CrossRef] [Green Version]

- Waters, D.M.; Mauch, A.; Coffey, A.; Arendt, E.K.; Zannini, E. Lactic acid bacteria as a cell factory for the delivery of functional biomolecules and ingredients in cereal-based beverages: A review. Crit. Rev. Food Sci. Nutr. 2015, 55, 503–520. [Google Scholar] [CrossRef]

- Filannino, P.; Di Cagno, R.; Gobbetti, M. Metabolic and functional paths of lactic acid bacteria in plant foods: Get out of the labyrinth. Curr. Opin. Biotechnol. 2018, 49, 64–72. [Google Scholar] [CrossRef] [PubMed]

| pH | pC | pWGB | pHF | pCF | pWGBF | pCT | |

|---|---|---|---|---|---|---|---|

| Semolina (%) | 70.2 | 70.2 | 70.2 | 70.2 | 70.2 | 70.2 | 77 |

| Water (%) | 19.8 | 19.8 | 12.8 | 19.8 | 19.8 | 12.8 | 23 |

| Fermented dough (%) 1 | - | - | - | 11 | 11 | 17 | - |

| Unfermented dough (%) 1 | 11 | 11 | 17 | - | - | - | - |

| Hemp | Chickpea | Wheat germ:bran (1:4) | |

|---|---|---|---|

| Protein (%) | 36.9 ± 0.1 a | 25.2 ± 0.4 b | 17.8 ± 0.5 c |

| Fat (%) | 11.9 ± 0.2 a | 3.9 ± 0.1 c | 8.6 ± 0.7 b |

| Available carbohydrates (%) | 4.2 ± 0.1 | 48.9 ± 1.9 | 34.2 ± 2.1 |

| Total dietary fiber (%) | 39.7 ± 0.1 a | 24.3 ± 0.3 b | 37.8 ± 1.1 a |

| Ash (%) | 7.6 ± 0.2 a | 2.9 ± 0.9 b | 2.0 ± 0.4 b |

| H | C | WGB | HF | CF | WGBF | |

|---|---|---|---|---|---|---|

| pH | 6.4 ± 0.2 a | 6.1 ± 0.1 a | 6.3 ± 0.5 a | 4.5 ± 0.3 b,c | 4.4 ± 0.2 c | 4.9 ± 0.2 b |

| Total titratable acidity (TTA) (mL NaOH 0.1M) | 4.2 ± 0.3 c | 4.1 ± 0.2 c | 4.0 ± 0.1 c | 35.8 ± 0.6 a | 28.6 ± 0.8 b | 29.1 ± 0.7 b |

| Lactic acid (mmol/Kg) | 3.3 ± 0.2 d | 4.1 ± 0.2 c | 4.1 ± 0.5 c | 214.9 ± 5.8 b | 180.7 ± 4.3 c | 246.4 ± 6.2 a |

| Acetic acid (mmol/Kg) | 1.8 ± 0.9 d | 1.1 ± 0.3 d | 2.6 ± 0.4 c | 43.9 ± 0.9 a | 42.7 ± 0.7 a | 31.6 ± 0.3 b |

| Fermentation quotient (FQ) | 1.8 | 3.7 | 1.6 | 4.7 | 4.3 | 7.8 |

| Total free amino acid (TFAA) (mg/Kg) | 990 ± 8 d | 1972 ± 12 c | 802 ± 5 e | 1799 ± 11 c | 2457 ± 16 a | 1929 ± 13 b |

| Peptides (g/Kg) | 0.62 ± 0.05 c | 2.60 ± 0.60 a | 0.81 ± 0.09 b | 0.49 ± 0.59 c | 0.75 ± 0.20 b,c | 0.77 ± 0.10 b,c |

| pH | pC | pWGB | pHF | pCF | pWGBF | pCT | |

|---|---|---|---|---|---|---|---|

| Chemical Properties | |||||||

| pH | 6.41 ± 0.10 a | 6.37 ± 0.21 a | 6.42 ± 0.31 a | 5.12 ± 0.11 b | 5.16 ± 0.05 b | 5.06 ± 0.08 b | 6.47 ± 0.24 a |

| TTA (mL NaOH 0.1M) | 3.01 ± 0.13 c | 2.05 ± 0.41 d | 1.82 ± 0.09 d | 6.61 ± 1.01 a | 4.01 ± 0.61 b | 4.45 ± 0.91 b | 2.01 ± 0.37 d |

| TFAA (mg/Kg) | 238 ± 9 e | 400 ± 8 d | 203 ± 4 f | 1018 ± 11 b | 743 ± 7 c | 1529 ± 12 a | 102 ± 10 g |

| Technological Properties | |||||||

| Optimal Cooking Time (OCT) (min) | 7.0 ± 0.2 c | 6.3 ± 0.1 d | 8.0 ± 0.2 b | 6.3 ± 0.1 d | 6.0 ± 0.1 e | 7.0 ± 0.1 c | 10.0 ± 0.1 a |

| Water absorption (%) | 94.4 ± 3.7 c | 105.4 ± 3.2 b | 110.6 ± 2.9 b | 105.3 ± 4.5 a | 99.6 ± 3.6 b | 98.4 ± 3.2 b | 125.1 ± 4.1 a |

| Cooking loss (% of d.m.) | 4.7 ± 0.1 d | 4.6 ± 0.1 d | 6.3 ± 0.1 b | 5.1 ± 0.1 c | 5 ± 0.2 c | 6.8 ± 0.1 a | 4.1 ± 0.1 e |

| Structural Properties | |||||||

| Hardness (N) | 7.99 ± 0.51 b | 7.34 ± 0.29 b,c | 11.6 ± 0.31 a | 7.13 ± 0.42 b | 4.60 ± 0.17 d | 6.98 ± 0.18 c | 4.24 ± 0.15 e |

| Chewiness (N) | 2.00 ± 0.10 b | 1.46 ± 0.05 c | 2.07 ± 0.08 b | 1.14 ± 0.08 d | 2.03 ± 0.15 b | 2.22 ± 0.13 b | 2.86 ± 0.07 a |

| Cohesiveness | 0.33 ± 0.03 b | 0.27 ± 0.04 b,c | 0.26 ± 0.02 c | 0.29 ± 0.02 b,c | 0.43 ± 0.06 a | 0.45 ± 0.04 a | 0.44 ± 0.04 a |

| Color Analysis | |||||||

| L | 52.1 ± 2.4 c | 65.5 ± 4 a,b | 62.8 ± 3.1 b | 51.2 ± 1.9 c | 65.6 ± 4.3 a | 63.2 ± 2.1 b | 70.8 ± 1.2 a |

| a | 0.6 ± 0.1 c | 0.8 ± 0.2 c | 1.4 ± 0.4 a,b | 0.6 ± 0.4 b,c | 0.3 ± 0.2 c | 2.1 ± 0.6 a | −0.6 ± 0.2 d |

| b | 9.3 ± 1.7 c | 18.5 ± 1.6 a | 19.9 ± 2.7 a | 9.6 ± 0.9 c | 22.9 ± 3.2 a | 14.7 ± 1.5 b | 17.7 ± 2.4 a |

| ΔE | 42.9 ± 1.2 a | 31.7 ± 4.2 b | 35.7 ± 1.9 b | 41.9 ± 1.1 a | 34.7 ± 0.6 b | 33.4 ± 2.4 b | 26.7 ± 2.3 c |

| pH | pC | pWGB | pHF | pCF | pWGBF | pCT | |

|---|---|---|---|---|---|---|---|

| Protein (%) | 14.77 ± 0.31 a | 13.50 ± 0.27 b | 13.32 ± 0.19 b | 14.54 ± 0.29 a | 12.95 ± 0.31 | 13.54 ± 0.24 b | 12.32 ± 0.28 c |

| Fat (%) | 2.61 ± 0.06 b | 3.94 ± 0.02 a | 2.01 ± 0.02 c | 2.53 ± 0.02 b | 4.02 ± 0.06 a | 1.99 ± 0.04 | 1.58 ± 0.01 d |

| Available carbohydrates (%) | 74.16 ± 1.02 | 75.48 ± 1.01 | 76.99 ± 0.97 | 73.98 ± 1.07 | 75.66 ± 0.98 | 77.11 ± 0.99 | 81.94 ± 0.67 |

| Total dietary fibers (%) | 6.71 ± 0.25 a | 5.89 ± 0.31 b | 6.10 ± 0.24 b | 6.84 ± 0.33 a | 6.10 ± 0.36 b | 5.96 ± 0.32 b | 3.05 ± 0.18 c |

| Ash (%) | 1.75 ± 0.10 a | 1.27 ± 0.13 b | 1.58 ± 0.12 a,b | 1.81 ± 0.13 a | 1.34 ± 0.17 b | 1.67 ± 0.19 a | 1.11 ± 0.10 b |

| Phytic acid (g/100g) | 1.01 ± 0.05 a | 0.35 ± 0.01 c | 0.12 ± 0.02 d | 0.62 ± 0.06 b | 0.03 ± 0.01 e | 0.12 ± 0.02 d | n.d. |

| Raffinose (g/Kg) | 0.11 ± 0.02 c | 0.33 ± 0.02 a | 0.17 ± 0.02 b | 0.05 ± 0.01 d | 0.11 ± 0.01 c | 0.17 ± 0.02 b | n.d. |

| Condensed tannins (g/Kg) | 3.43 ± 0.10 a | 4.08 ± 0.91 a | 2.21 ± 0.03 c | 2.61 ± 0.09 b | 1.96 ± 0.02 d | 0.90 ± 0.01 e | n.d. |

| HI (%) | 75.71 ±6.52 a | 70.73 ± 4.91 a | 60.62 ± 4.18 b | 72.92 ± 5.17 a | 55.61 ± 3.05 b | 42.4 ± 3.96 c | 75.9 ± 2.18 a |

| IVPD (%) | 58.5 ± 0.6 d | 65.61 ± 0.7 b | 55.01 ± 0.4 e | 64.63 ± 0.8 c | 73.80 ± 0.7 a | 66.83 ± 0.6 b | 45.1 ± 0.4 f |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schettino, R.; Pontonio, E.; Rizzello, C.G. Use of Fermented Hemp, Chickpea and Milling By-Products to Improve the Nutritional Value of Semolina Pasta. Foods 2019, 8, 604. https://doi.org/10.3390/foods8120604

Schettino R, Pontonio E, Rizzello CG. Use of Fermented Hemp, Chickpea and Milling By-Products to Improve the Nutritional Value of Semolina Pasta. Foods. 2019; 8(12):604. https://doi.org/10.3390/foods8120604

Chicago/Turabian StyleSchettino, Rosa, Erica Pontonio, and Carlo Giuseppe Rizzello. 2019. "Use of Fermented Hemp, Chickpea and Milling By-Products to Improve the Nutritional Value of Semolina Pasta" Foods 8, no. 12: 604. https://doi.org/10.3390/foods8120604

APA StyleSchettino, R., Pontonio, E., & Rizzello, C. G. (2019). Use of Fermented Hemp, Chickpea and Milling By-Products to Improve the Nutritional Value of Semolina Pasta. Foods, 8(12), 604. https://doi.org/10.3390/foods8120604