Pre-Hydrated Berry Pomace in Wheat Bread: An Approach Considering Requisite Water in Fiber Enrichment

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Bread-Making Procedure

2.3. Dough Analysis

2.4. Bread Analysis

2.5. Statistical Analysis

3. Results and Discussion

3.1. Hydration Properties

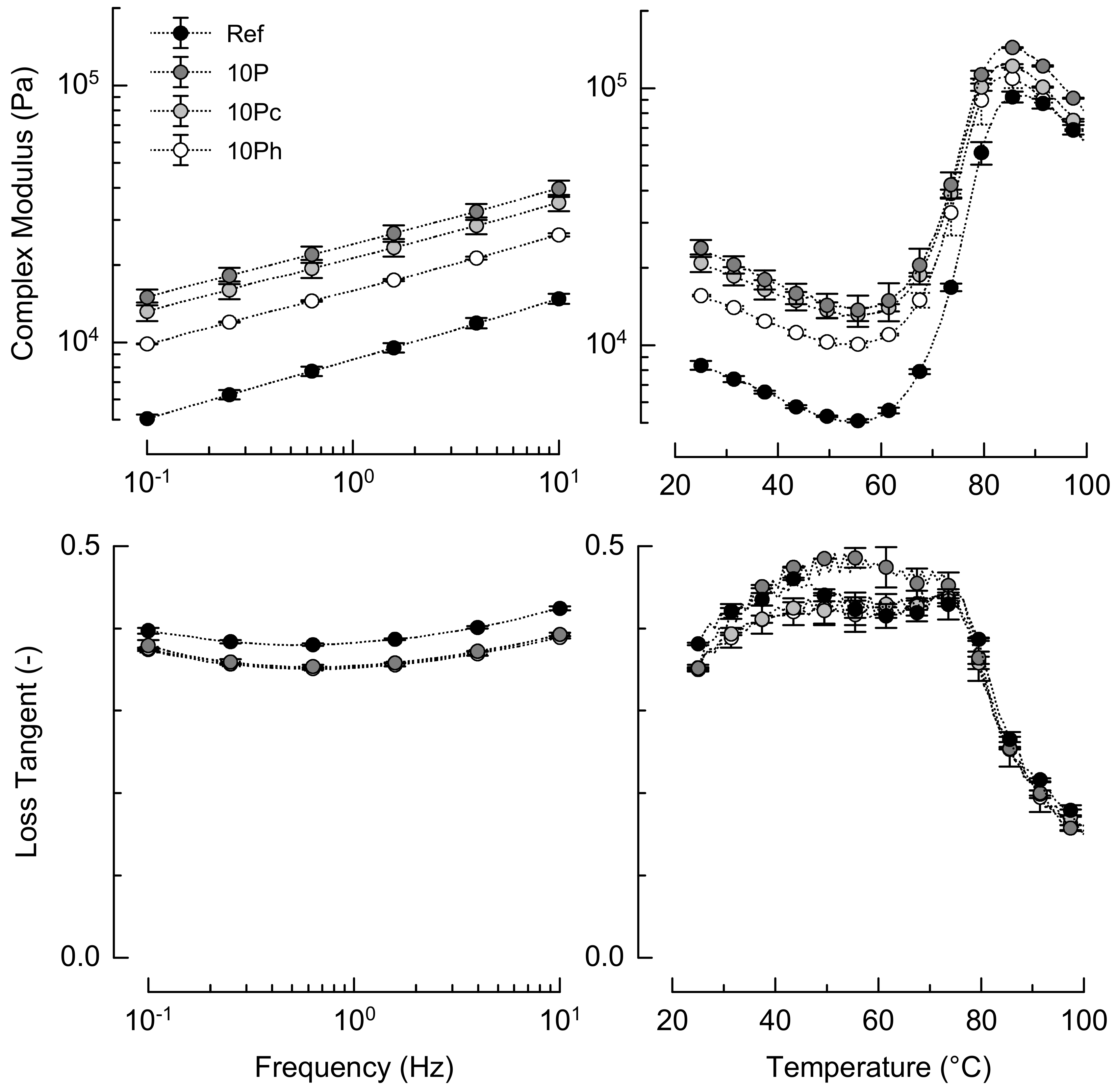

3.2. Rheology during Simulated Baking

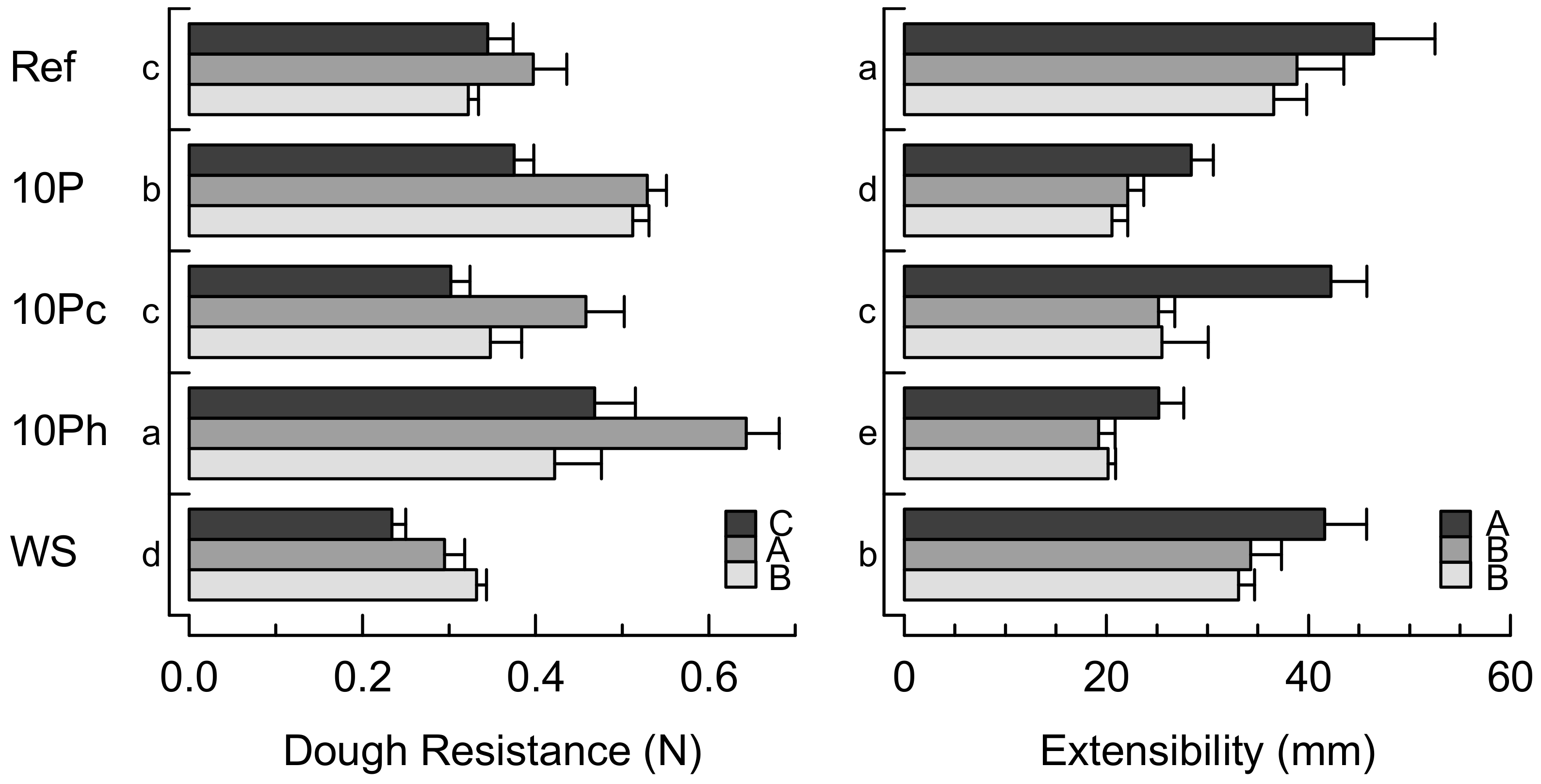

3.3. Changes in Dough Properties during Proofing

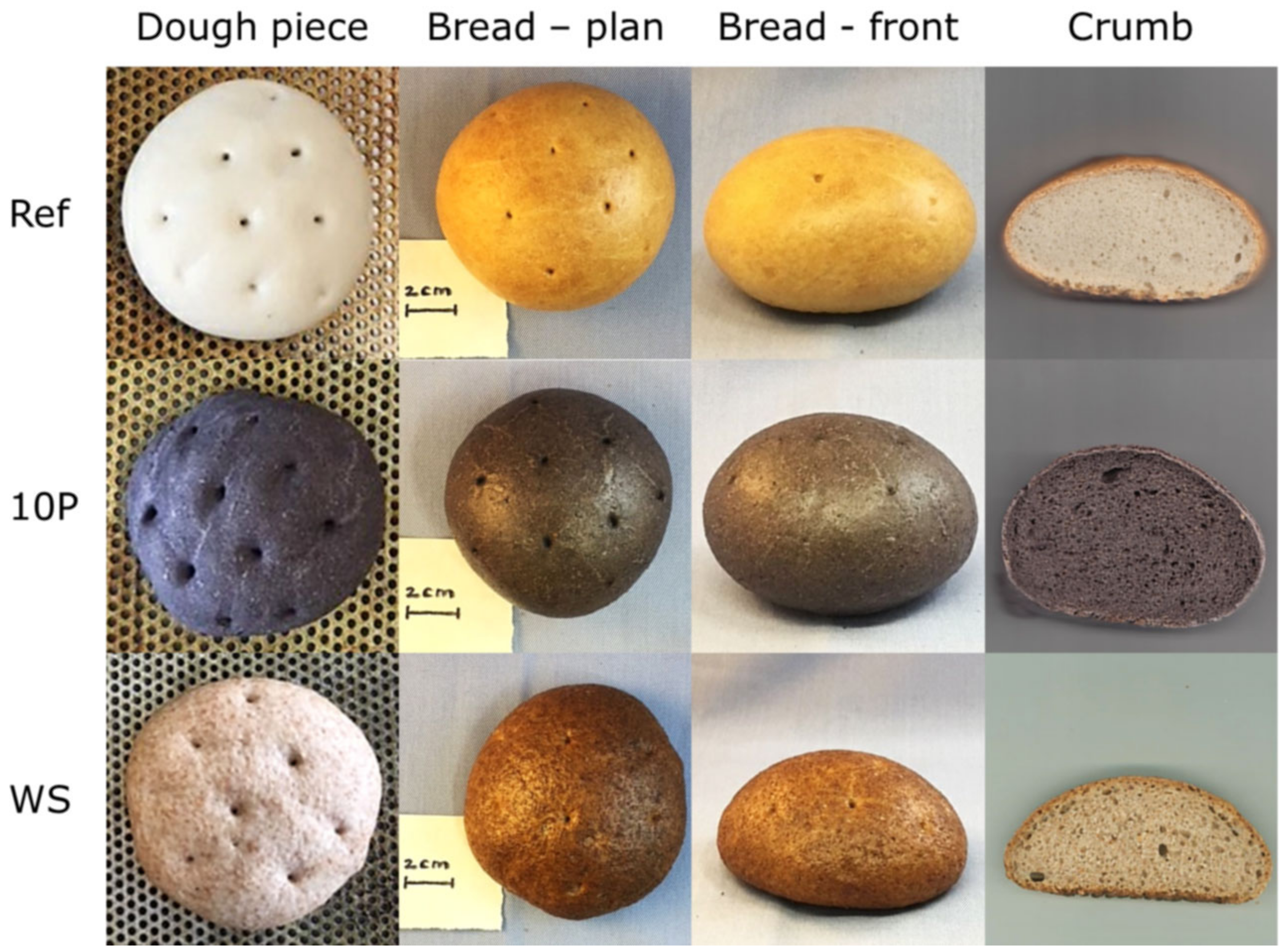

3.4. Effects on Bread Characteristics

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Alba, K.; MacNaughtan, W.; Laws, A.P.; Foster, T.J.; Campbell, G.M.; Kontogiorgos, V. Fractionation and characterisation of dietary fibre from blackcurrant pomace. Food Hydrocoll. 2018, 81, 398–408. [Google Scholar] [CrossRef]

- Reißner, A.-M.; Al-Hamimi, S.; Quiles, A.; Schmidt, C.; Struck, S.; Hernando, I.; Turner, C.; Rohm, H. Composition and physicochemical properties of dried berry pomace: Composition and technofunctional properties of berry pomace. J. Sci. Food Agric. 2018, 99, 1284–1293. [Google Scholar] [CrossRef] [PubMed]

- Rohm, H.; Brennan, C.; Turner, C.; Günther, E.; Campbell, G.; Hernando, I.; Struck, S.; Kontogiorgos, V. Adding value to fruit processing waste: Innovative ways to incorporate fibers from berry pomace in baked and extruded cereal-based foods—A SUSFOOD project. Foods 2015, 4, 690–697. [Google Scholar] [CrossRef] [PubMed]

- Martins, Z.E.; Pinho, O.; Ferreira, I.M.P.L.V.O. Food industry by-products used as functional ingredients of bakery products. Trends Food Sci. Technol. 2017, 67, 106–128. [Google Scholar] [CrossRef]

- Struck, S.; Straube, D.; Zahn, S.; Rohm, H. Interaction of wheat macromolecules and berry pomace in model dough: Rheology and microstructure. J. Food Eng. 2018, 223, 109–115. [Google Scholar] [CrossRef]

- Guarda, A.; Rosell, C.; Benedito, C.; Galotto, M. Different hydrocolloids as bread improvers and antistaling agents. Food Hydrocoll. 2004, 18, 241–247. [Google Scholar] [CrossRef]

- Wang, J.; Rosell, C.M.; Benedito de Barber, C. Effect of the addition of different fibres on wheat dough performance and bread quality. Food Chem. 2002, 79, 221–226. [Google Scholar] [CrossRef]

- Lazaridou, A.; Duta, D.; Papageorgiou, M.; Belc, N.; Biliaderis, C.G. Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. J. Food Eng. 2007, 79, 1033–1047. [Google Scholar] [CrossRef]

- Gómez, M.; Ronda, F.; Blanco, C.A.; Caballero, P.A.; Apesteguía, A. Effect of dietary fibre on dough rheology and bread quality. Eur. Food Res. Technol. 2003, 216, 51–56. [Google Scholar] [CrossRef]

- Alba, K.; Rizou, T.; Paraskevopoulou, A.; Campbell, G.M.; Kontogiorgos, V. Effects of blackcurrant fibre on dough physical properties and bread quality characteristics. Food Biophys. 2020, 15, 313–322. [Google Scholar] [CrossRef]

- Hemdane, S.; Jacobs, P.J.; Dornez, E.; Verspreet, J.; Delcour, J.A.; Courtin, C.M. Wheat (Triticum aestivum L.) bran in bread making: A critical review. Compr. Rev. Food Sci. Food Saf. 2016, 15, 28–42. [Google Scholar] [CrossRef]

- Mildner-Szkudlarz, S.; Bajerska, J.; Zawirska-Wojtasiak, R.; Górecka, D. White grape pomace as a source of dietary fibre and polyphenols and its effect on physical and nutraceutical characteristics of wheat biscuits: Addition of white grape pomace to wheat biscuits. J. Sci. Food Agric. 2013, 93, 389–395. [Google Scholar] [CrossRef] [PubMed]

- Schmidt, C.; Geweke, I.; Struck, S.; Zahn, S.; Rohm, H. Blackcurrant pomace from juice processing as partial flour substitute in savoury crackers: Dough characteristics and product properties. Int. J. Food Sci. Technol. 2018, 53, 237–245. [Google Scholar] [CrossRef]

- Freund, W. Handbuch Backwaren-Technologie, 4th ed.; Behr’s Verlag: Hamburg, Germany, 2003. [Google Scholar]

- ICC. Determination of the Moisture Content of Cereals and Cereal Products (Practical Method); Standard 110/1; International Association for Cereal Science and Technology: Vienna, Austria, 1976. [Google Scholar]

- ICC. Method for Using the Brabender Farinograph; Standard 115/1; International Association for Cereal Science and Technology: Vienna, Austria, 1992. [Google Scholar]

- Verheyen, C.; Jekle, M.; Becker, T. Effects of Saccharomyces cerevisiae on the structural kinetics of wheat dough during fermentation. LWT-Food Sci. Technol. 2014, 58, 194–202. [Google Scholar] [CrossRef]

- Balestra, F. Empirical and Fundamental Mechanical Tests in the Evaluation of Dough and Bread Rheological Properties. Ph.D. Thesis, Universita di Bologna, Bologna, Italy, 2014. [Google Scholar]

- AACC. Guidelines for Measurement of Volume by Rapeseed Displacement. AACC Method 10-05.01. In Approved Methods of Analysis, 11th ed.; AACC International: St. Paul, MN, USA, 2009. [Google Scholar]

- AACC. Staleness/Texture. AACC Method 74-09.01. In Approved Methods of Analysis, 11th ed.; AACC International: ST. Paul, MN, USA, 2009. [Google Scholar]

- Rohm, H.; Jaros, D. Colour of hard cheese: 1. Description of colour properties and effects of maturation. Z. Lebensm. Unters. Forsch. 1996, 203, 241–244. [Google Scholar] [CrossRef]

- Frakolaki, G.; Giannou, V.; Topakas, E.; Tzia, C. Chemical characterization and breadmaking potential of spelt versus wheat flour. J. Cereal Sci. 2018, 79, 50–56. [Google Scholar] [CrossRef]

- Peressini, D.; Sensidoni, A. Effect of soluble dietary fibre addition on rheological and breadmaking properties of wheat doughs. J. Cereal Sci. 2009, 49, 190–201. [Google Scholar] [CrossRef]

- Dreese, P.C.; Faubion, J.M.; Hoseney, R.C. Dynamic rheological properties of flour, gluten, and gluten-starch doughs. I. Temperature-dependent changes during heating. Cereal Chem. 1988, 65, 348–353. [Google Scholar]

- Rosell, C.; Rojas, J.; Benedito de Barber, C. Influence of hydrocolloids on dough rheology and bread quality. Food Hydrocoll. 2001, 15, 75–81. [Google Scholar] [CrossRef]

- Sudha, M.L.; Baskaran, V.; Leelavathi, K. Apple pomace as a source of dietary fiber and polyphenols and its effect on the rheological characteristics and cake making. Food Chem. 2007, 104, 686–692. [Google Scholar] [CrossRef]

- Jekle, M.; Becker, T. Dough microstructure: Novel analysis by quantification using confocal laser scanning microscopy. Food Res. Int. 2011, 44, 984–991. [Google Scholar] [CrossRef]

- Belghith Fendri, L.; Chaari, F.; Maaloul, M.; Kallel, F.; Abdelkafi, L.; Ellouz Chaabouni, S.; Ghribi-Aydi, D. Wheat bread enrichment by pea and broad bean pods fibers: Effect on dough rheology and bread quality. LWT–Food Sci. Technol. 2016, 73, 584–591. [Google Scholar] [CrossRef]

- Cauvain, S. Functional Ingredients. In Technology of Breadmaking, 3rd ed.; Springer International Publishing: Cham, Switzerland, 2015; p. 90. [Google Scholar]

- Rathnayake, H.A.; Navaratne, S.B.; Navaratne, C.M. Porous crumb structure of leavened baked products. Int. J. Food Sci. 2018, 8187318. [Google Scholar] [CrossRef]

- Karnopp, A.R.; Figueroa, A.M.; Los, P.R.; Teles, J.C.; Simões, D.R.S.; Barana, A.C.; Kubiaki, F.T.; de Oliveira, J.G.B.; Granato, D. Effects of whole-wheat flour and bordeaux grape pomace (Vitis labrusca L.) on the sensory, physicochemical and functional properties of cookies. Food Sci. Technol. Camp. 2015, 35, 750–756. [Google Scholar] [CrossRef]

- Kotoki, D.; Deka, S.C. Baking loss of bread with special emphasis on increasing water holding capacity. J. Food Sci. Technol. 2010, 47, 128–131. [Google Scholar] [CrossRef]

- Kučerová, J.; Šottníková, V.; Nedomová, Š. Influence of dietary fibre addition on the rheological and sensory properties of dough and bakery products. Czech J. Food Sci. 2013, 31, 340–346. [Google Scholar] [CrossRef]

- Tańska, M.; Zadernowski, R.; Konpka, I. The quality of wheat bread supplemented with dried carrot pomace. Pol. J. Nat. Sci. 2007, 27, 126–136. [Google Scholar] [CrossRef]

- Skendi, A.; Biliaderis, C.G.; Papageorgiou, M.; Izydorczyk, M.S. Effects of two barley β-glucan isolates on wheat flour dough and bread properties. Food Chem. 2010, 119, 1159–1167. [Google Scholar] [CrossRef]

- Holmes, J.T.; Hoseney, R.C. Chemical leavening: Effect of pH and certain ions on breadmaking properties. Cereal Chem. 1987, 64, 343–348. [Google Scholar]

| Component (g/100 g) | Blackcurrant Pomace 1 | Wheat Flour | 90% Wheat Flour + 10% Pomace | Wholegrain Spelt Flour |

|---|---|---|---|---|

| Carbohydrates | 2.2 | 81.2 | 73.3 | 70.4 |

| Dietary fiber | 59.1 | 2.7 | 8.3 | 9.3 |

| Protein | 15.7 | 15.1 | 15.1 | 15.7 |

| Fat | 20.2 | 0.9 | 2.9 | 2.1 |

| Ash | 2.7 | 0.7 | 0.9 | 0.9 |

| Sample 1 | Dough Stickiness (N) (n = 20) 2 | Dough pH (-) (n = 6) 2 | Bread pH (-) (n = 4) 2 | Baking Loss (%) (n = 8) 2 | Bread Volume (mL) (n = 8) 2 | Crumb Moisture (g/100 g) (n = 6) 2 |

|---|---|---|---|---|---|---|

| Ref | 0.49 ± 0.03 a | 5.77 ± 0.01 a | 5.90 ± 0.01 a | 15.59 ± 0.38 b | 181.83 ± 4.50 a | 41.41 ± 0.15 d |

| 10P | 0.35 ± 0.05 b | 5.11 ± 0.01 d | 5.01 ± 0.01 c | 14.34 ± 0.20 cd | 162.19 ± 5.89 c | 41.68 ± 0.18 c |

| 10Pc | 0.35 ± 0.04 b | 5.15 ± 0.01 c | 5.01 ± 0.01 c | 14.61 ± 0.36 c | 163.45 ± 2.33 c | 42.09 ± 0.19 b |

| 10Ph | 0.32 ± 0.05 b | 5.15 ± 0.01 c | 5.01 ± 0.01 c | 14.10 ± 0.28 d | 171.71 ± 7.89 b | 42.78 ± 0.11 a |

| WS | 0.50 ± 0.05 a | 5.74 ± 0.01 b | 5.72 ± 0.01 b | 17.45 ± 0.24 a | 141.25 ± 0.45 d | 42.85 ± 0.09 a |

| Sample 1 | Crust Firmness (N) (n = 32) 2 | Crumb Firmness (N) (n = 16) 3 | Crumb Cell Density (cells/cm2) (n = 4) 2 | Total Cell Area (mm2/100 mm2) (n = 4) 2 |

|---|---|---|---|---|

| Ref | 20.87 ± 1.40 b | 5.49 ± 1.46 bc | 26.31 ± 4.45 b | 25.80 ± 3.15 c |

| 10P | 22.09 ± 2.81 ab | 5.01 ± 0.59 bc | 35.97 ± 4.31 a | 33.53 ± 2.29 b |

| 10Pc | 22.20 ± 3.33 ab | 4.81 ± 0.79 c | 32.75 ± 5.53 ab | 38.18 ± 2.70 a |

| 10Ph | 22.57 ± 3.53 ab | 6.02 ± 0.88 b | 34.92 ± 5.31 a | 36.45 ± 2.65 ab |

| WS | 23.51 ± 3.30 a | 13.71 ± 3.32 a | 26.06 ± 0.39 b | 32.98 ± 2.24 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reißner, A.-M.; Beer, A.; Struck, S.; Rohm, H. Pre-Hydrated Berry Pomace in Wheat Bread: An Approach Considering Requisite Water in Fiber Enrichment. Foods 2020, 9, 1600. https://doi.org/10.3390/foods9111600

Reißner A-M, Beer A, Struck S, Rohm H. Pre-Hydrated Berry Pomace in Wheat Bread: An Approach Considering Requisite Water in Fiber Enrichment. Foods. 2020; 9(11):1600. https://doi.org/10.3390/foods9111600

Chicago/Turabian StyleReißner, Anne-Marie, Amanda Beer, Susanne Struck, and Harald Rohm. 2020. "Pre-Hydrated Berry Pomace in Wheat Bread: An Approach Considering Requisite Water in Fiber Enrichment" Foods 9, no. 11: 1600. https://doi.org/10.3390/foods9111600

APA StyleReißner, A.-M., Beer, A., Struck, S., & Rohm, H. (2020). Pre-Hydrated Berry Pomace in Wheat Bread: An Approach Considering Requisite Water in Fiber Enrichment. Foods, 9(11), 1600. https://doi.org/10.3390/foods9111600