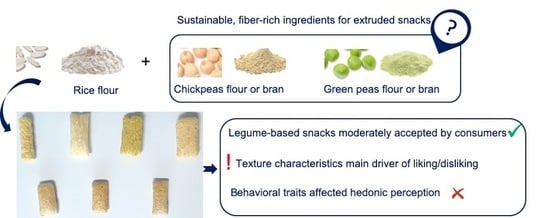

Legume Flour or Bran: Sustainable, Fiber-Rich Ingredients for Extruded Snacks?

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Instrumental Texture Analysis

2.3. Sensory Evaluations

2.3.1. Subjects

2.3.2. Hedonic Evaluation

2.3.3. Sensory Descriptive Evaluation

2.3.4. Questionnaires

Food Neophobia Scale

Food Technology Neophobia Scale

2.3.5. Experimental Procedure

2.4. Data Analysis

3. Results

3.1. Hardness

3.2. Hedonic Evaluation

3.3. Sensory Descriptive Evaluation

3.4. Food Neophobia

3.5. Food Technology Neophobia

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- FAO. The Future of Food and Agriculture: Trends and Challenges; FAO: Rome, Italy, 2017; ISBN 978925109551. [Google Scholar]

- Nemecek, T.; Von Richthofen, J.S.; Dubois, G.; Casta, P.; Charles, R.; Pahl, H. Environmental impacts of introducing grain legumes into European crop rotations. Eur. J. Agron. 2008, 28, 380–393. [Google Scholar] [CrossRef]

- Preissel, S.; Reckling, M.; Schläfke, N.; Zander, P. Magnitude and farm-economic value of grain legume pre-crop benefits in Europe: A review. Field Crops Res. 2015, 175, 64–79. [Google Scholar] [CrossRef]

- Patras, A.; Oomah, B.D.; Gallagher, E. By-product utilization. In Pulse Foods: Processing, Quality and Nutraceutical Applications; Academic Press: London, UK, 2011; pp. 325–362. [Google Scholar]

- Buttriss, J.L.; Stokes, C.S. Dietary fibre and health: An overview. Nutr. Bull. 2008, 33, 186–200. [Google Scholar] [CrossRef]

- Cummings, J.H.; Bingham, S.A.; Heaton, K.W.; Eastwood, M.A. Fecal weight, colon cancer risk, and dietary intake of nonstarch polysaccharides (dietary fiber). Gastroenterology 1992, 103, 1783–1789. [Google Scholar] [CrossRef]

- Zheng, B.; Shen, H.; Han, H.; Han, T.; Qin, Y. Dietary fiber intake and reduced risk of ovarian cancer: A meta-analysis. Nutr. J. 2018, 17, 99. [Google Scholar] [CrossRef]

- Miyazawa, I.; for the NIPPON DATA80 Research Group; Miura, K.; Miyagawa, N.; Kondo, K.; Kadota, A.; Okuda, N.; Fujiyoshi, A.; Chihara, I.; Nakamura, Y.; et al. Relationship between carbohydrate and dietary fibre intake and the risk of cardiovascular disease mortality in Japanese: 24-year follow-up of NIPPON DATA80. Eur. J. Clin. Nutr. 2020, 74, 67–76. [Google Scholar] [CrossRef]

- Yang, Y.; Zhao, L.G.; Wu, Q.J.; Ma, X.; Xiang, Y.B. Association between dietary fiber and lower risk of all-cause mortality: A meta-analysis of cohort studies. Am. J. Epidemiol. 2015, 181, 83–91. [Google Scholar] [CrossRef]

- Blüher, M. Obesity: Global epidemiology and pathogenesis. Nat. Rev. Endocrinol. 2019, 15, 288–298. [Google Scholar] [CrossRef]

- Koç, F.; Mills, S.; Strain, C.; Ross, R.P.; Stanton, C. The public health rationale for increasing dietary fibre: Health benefits with a focus on gut microbiota. Nutr. Bull. 2020, 45, 294–308. [Google Scholar] [CrossRef]

- Vaz Patto, M.C.; Amarowicz, R.; Aryee, A.N.; Boye, J.I.; Chung, H.J.; Martín-Cabrejas, M.A.; Domoney, C. Achievements and challenges in improving the nutritional quality of food legumes. Crit. Rev. Plant Sci. 2015, 34, 105–143. [Google Scholar] [CrossRef]

- Saint-Eve, A.; Granda, P.; Legay, G.; Cuvelier, G.; Delarue, J. Consumer acceptance and sensory drivers of liking for high plant protein snacks. J. Sci. Food Agric. 2019, 99, 3983–3991. [Google Scholar] [CrossRef]

- Alava, C.; Verdú, S.; Barat, J.M.; Grau, R. Enrichment of chips with fibre from a tiger-nut (Cyperus esculentus) milk co-product at ‘source of fibre foods’ and ‘high fibre content foods’ levels: Impact on processing, physico-chemical and sensory properties. Int. J. Food Sci. Technol. 2019, 54, 908–915. [Google Scholar] [CrossRef]

- Bortnowska, G.; Krudos, A.; Schube, V.; Krawczyńska, W.; Krzemińska, N.; Mojka, K. Effects of waxy rice and tapioca starches on the physicochemical and sensory properties of white sauces enriched with functional fibre. Food Chem. 2016, 202, 31–39. [Google Scholar] [CrossRef]

- Wang, Y.; Trani, A.; Knaapila, A.; Hietala, S.; Coda, R.; Katina, K.; Maina, N.H. The effect of in situ produced dextran on flavour and texture perception of wholegrain sorghum bread. Food Hydrocoll. 2020, 106, 105913. [Google Scholar] [CrossRef]

- Sivam, A.S.; Sun-Waterhouse, D.; Quek, S.; Perera, C.O. Properties of bread dough with added fiber polysaccharides and phenolic antioxidants: A review. J. Food Sci. 2010, 75, R163–R174. [Google Scholar] [CrossRef] [PubMed]

- Rakhesh, N.; Fellows, C.M.; Sissons, M. Evaluation of the technological and sensory properties of durum wheat spaghetti enriched with different dietary fibres. J. Sci. Food Agric. 2015, 95, 2–11. [Google Scholar] [CrossRef] [PubMed]

- Millar, K.A.; Barry-Ryan, C.; Burke, R.; Hussey, K.; McCarthy, S.; Gallagher, E. Effect of pulse flours on the physiochemical characteristics and sensory acceptance of baked crackers. Int. J. Food Sci. Technol. 2017, 52, 1155–1163. [Google Scholar] [CrossRef]

- Venkatachalam, K.; Nagarajan, M. Physicochemical and sensory properties of savory crackers incorporating green gram flour to partially or wholly replace wheat flour. Ital. J. Food Sci. 2017, 29, 599–612. [Google Scholar]

- Pliner, P.; Hobden, K. Development of a scale to measure the trait of food neophobia in humans. Appetite 1992, 19, 105–120. [Google Scholar] [CrossRef]

- Cox, D.N.; Evans, G. Construction and validation of a psychometric scale to measure consumers’ fears of novel food technologies: The food technology neophobia scale. Food Qual. Prefer. 2008, 19, 704–710. [Google Scholar] [CrossRef]

- Schutz, H.G.; Cardello, A.V. A labeled affective magnitude (lam) scale for assessing food liking/disliking. J. Sens. Stud. 2001, 16, 117–159. [Google Scholar] [CrossRef]

- Ares, G.; Deliza, R.; Barreiro, C.; Giménez, A.; Gámbaro, A. Comparison of two sensory profiling techniques based on consumer perception. Food Qual. Prefer. 2010, 21, 417–426. [Google Scholar] [CrossRef]

- Jaeger, S.R.; Beresford, M.K.; Paisley, A.G.; Antúnez, L.; Vidal, L.; Cadena, R.S.; Giménez, A.; Ares, G. Check-all-that-apply (CATA) questions for sensory product characterization by consumers: Investigations into the number of terms used in CATA questions. Food Qual. Prefer. 2015, 42, 154–164. [Google Scholar] [CrossRef]

- Meyners, M.; Castura, J.C. Randomization of CATA attributes: Should attribute lists be allocated to assessors or to samples? Food Qual. Prefer. 2016, 48, 210–215. [Google Scholar] [CrossRef]

- Meyners, M.; Castura, J.C.; Carr, B.T. Existing and new approaches for the analysis of CATA data. Food Qual. Prefer. 2013, 30, 309–319. [Google Scholar] [CrossRef]

- Bresciani, A.; Marti, A. Using pulses in baked products: Lights, shadows, and potential solutions. Foods 2019, 8, 451. [Google Scholar] [CrossRef] [PubMed]

- De Palma, G.; Nadal, I.; Collado, M.C.; Sanz, Y. Effects of a gluten-free diet on gut microbiota and immune function in healthy adult human subjects. Br. J. Nutr. 2009, 102, 1154–1160. [Google Scholar] [CrossRef]

- Campagna, G.; Tatangelo, R.; La Fratta, I.; Rizzuto, A.; Ballerini, P.; Cocco, D.; Savi, S.; Rotunno, A.; Rotunno, P.F.; Speranza, L.; et al. Insights in the evaluation of gluten dietary avoidance in healthy subjects. J. Am. Coll. Nutr. 2020, 39, 178–186. [Google Scholar] [CrossRef]

- Laleg, K.; Cassan, D.; Barron, C.; Prabhasankar, P.; Micard, V. Structural, culinary, nutritional and anti-nutritional properties of high protein, gluten free, 100% legume pasta. PLoS ONE 2016, 11, e0160721. [Google Scholar] [CrossRef]

- Brennan, M.A.; Derbyshire, E.; Tiwari, B.K.; Brennan, C.S. Ready-to-eat snack products: The role of extrusion technology in developing consumer acceptable and nutritious snacks. Int. J. Food Sci. Technol. 2013, 48, 893–902. [Google Scholar] [CrossRef]

- Singh, S.; Gamlath, S.; Wakeling, L. Nutritional aspects of food extrusion: A review. Int. J. Food Sci. Technol. 2007, 42, 916–929. [Google Scholar] [CrossRef]

- Leonard, W.; Zhang, P.; Ying, D.; Fang, Z. Application of extrusion technology in plant food processing byproducts: An overview. Compr. Rev. Food Sci. Food Saf. 2020, 19, 218–246. [Google Scholar] [CrossRef]

- Balasubramanian, S.; Borah, A.; Singh, K.K.; Patil, R.T. Rheological and nutritional quality of selected dehulled legumes blended rice extrudates. J. Food Sci. Technol. 2012, 49, 632–637. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Lazou, A.; Krokida, M.; Tzia, C. Sensory properties and acceptability of corn and lentil extruded puffs. J. Sens. Stud. 2010, 25, 838–860. [Google Scholar] [CrossRef]

- Monnet, A.F.; Laleg, K.; Michon, C.; Micard, V. Legume enriched cereal products: A generic approach derived from material science to predict their structuring by the process and their final properties. Trends Food Sci. Technol. 2019, 86, 131–143. [Google Scholar] [CrossRef]

- Stagnari, F.; Maggio, A.; Galieni, A.; Pisante, M. Multiple benefits of legumes for agriculture sustainability: An overview. Chem. Biol. Technol. Agric. 2017, 4, 2. [Google Scholar] [CrossRef]

- Tassoni, A.; Tedeschi, T.; Zurlini, C.; Cigognini, I.M.; Petrusan, J.-I.; Rodríguez, Ó.; Neri, S.; Celli, A.; Sisti, L.; Cinelli, P.; et al. State-of-the-Art Production Chains for Peas, Beans and Chickpeas—Valorization of Agro-Industrial Residues and Applications of Derived Extracts. Molecules 2020, 25, 1383. [Google Scholar] [CrossRef]

- Grigor, J.M.; Brennan, C.S.; Hutchings, S.C.; Rowlands, D.S. The sensory acceptance of fibre-enriched cereal foods: A meta-analysis. Int. J. Food Sci. Technol. 2016, 51, 3–13. [Google Scholar] [CrossRef]

- Phimolsiripol, Y.; Mukprasirt, A.; Schoenlechner, R. Quality improvement of rice-based gluten-free bread using different dietary fibre fractions of rice bran. J. Cereal Sci. 2012, 56, 389–395. [Google Scholar] [CrossRef]

- Han, J.J.; Janz, J.A.; Gerlat, M. Development of gluten-free cracker snacks using pulse flours and fractions. Food Res. Int. 2010, 43, 627–633. [Google Scholar] [CrossRef]

- Guinard, J.X.; Mazzucchelli, R. The sensory perception of texture and mouthfeel. Trends Food Sci. Technol. 1996, 7, 213–219. [Google Scholar] [CrossRef]

- Laureati, M.; Sandvik, P.; Almli, V.L.; Sandell, M.; Zeinstra, G.; Methven, L.; Wallner, M.; Jilani, H.; Alfaro, B.; Proserpio, C. Individual differences in texture preferences among European children: Development and validation of the Child Food Texture Preference Questionnaire (CFTPQ). Food Qual. Prefer. 2020, 80, 103828. [Google Scholar] [CrossRef]

- Szczesniak, A.S. Texture is a sensory property. Food Qual. Prefer. 2002, 13, 215–225. [Google Scholar] [CrossRef]

- Pasqualone, A.; Costantini, M.; Coldea, T.E.; Summo, C. Use of legumes in extrusion cooking: A review. Foods 2020, 9, 958. [Google Scholar] [CrossRef] [PubMed]

- Tuorila, H.; Hartmann, C. Consumer responses to novel and unfamiliar foods. Curr. Opin. Food Sci. 2020, 33, 1–8. [Google Scholar] [CrossRef]

- Proserpio, C.; Almli, V.; Sandvik, P.; Sandell, M.; Methven, L.; Wallner, M.; Jilani, H.; Zeinstra, G.; Alfaro, B.; Laureati, M. Cross-national differences in child food neophobia: A comparison of five European countries. Food Qual. Prefer. 2020, 81, 103861. [Google Scholar] [CrossRef]

- Siegrist, M.; Hartmann, C.; Keller, C. Antecedents of food neophobia and its association with eating behavior and food choices. Food Qual. Prefer. 2013, 30, 293–298. [Google Scholar] [CrossRef]

- Proserpio, C.; Pagliarini, E.; Laureati, M.; Frigerio, B.; Lavelli, V. Acceptance of a new food enriched in β-glucans among adolescents: Effects of food technology neophobia and healthy food habits. Foods 2019, 8, 433. [Google Scholar] [CrossRef]

| Samples | Hardness (N) |

|---|---|

| R | 48.3 cd ± 1.3 |

| C | 85.2 e ± 1.4 |

| C15 | 47.4 c ± 0.8 |

| C30 | 40.1 b ± 0.6 |

| P | 32.8 a ± 0.9 |

| P15 | 46.4 c ± 0.9 |

| P30 | 55.9 d ± 1.1 |

| Factors | Hedonic Ratings (Mean ± SEM) | F | p |

|---|---|---|---|

| Samples | 5.58 | <0.0001 | |

| R | 42.4 a ± 1.9 | ||

| C30 | 49.2 b ± 1.6 | ||

| P30 | 49.8 b ± 1.5 | ||

| P15 | 51.5 bc ± 1.6 | ||

| C | 53.0 bc ± 1.9 | ||

| C15 | 55.2 c ± 1.6 | ||

| P | 56.0 c ± 2.3 | ||

| Gender | 5.25 | 0.02 | |

| Females | 49.3 a ± 0.9 | ||

| Males | 52.7 b ± 1.1 | ||

| Age | 5.95 | 0.01 | |

| ≤26 years old | 52.8 a ± 0.9 | ||

| >27 years old | 49.2 b ± 1.0 |

| Sensory Attributes | Samples | ||||||

|---|---|---|---|---|---|---|---|

| R | C30 | P30 | P15 | C | C15 | P | |

| Appearance | |||||||

| Dark yellow *** | 1 a | 34 e | 25 cde | 12 abc | 18 bcd | 9 ab | 31 de |

| Light yellow *** | 58 c | 13 a | 12 a | 31 b | 40 b | 37 b | 12 a |

| Green *** | 0 a | 0 a | 0 a | 0 a | 0 a | 1 a | 24 b |

| Odor | |||||||

| Strong ** | 0 a | 2 ab | 4 ab | 2 ab | 6 ab | 1 a | 9 b |

| Mild n.s. | 32 | 31 | 30 | 27 | 28 | 37 | 27 |

| Toasted *** | 2 a | 20 b | 19 b | 17 b | 10 ab | 17 b | 9 ab |

| Rice *** | 16 c | 7 abc | 4 ab | 13 bc | 1 a | 14 bc | 4 ab |

| Legume *** | 3 a | 6 ab | 11 abc | 3 a | 18 c | 6 ab | 17 bc |

| Flavor | |||||||

| Mild *** | 39 c | 28 bc | 34 bc | 38 c | 12 a | 38 c | 19 ab |

| Strong *** | 1 a | 9 a | 2 a | 2 a | 31 b | 0 a | 24 b |

| Chickpea *** | 5 a | 7 a | 5 a | 3 a | 31 b | 9 a | 13 a |

| Rice *** | 33 c | 12 ab | 24 bc | 27 bc | 5 a | 34 c | 5 a |

| Pea *** | 0 a | 5 a | 2 a | 3 a | 10 a | 0 a | 44 b |

| Spicy *** | 2 a | 6 a | 5 a | 7 a | 22 b | 1 a | 7 a |

| Whole-wheat *** | 2 a | 40 bc | 46 c | 27 b | 3 a | 39 bc | 4 a |

| Taste | |||||||

| Bitter n.s. | 3 | 6 | 4 | 2 | 8 | 1 | 8 |

| Salty n.s. | 8 | 6 | 10 | 8 | 13 | 8 | 13 |

| Sweet *** | 10 ab | 27 c | 7 a | 21 bc | 8 a | 6 a | 12 ab |

| Texture | |||||||

| Crumbly *** | 26 ab | 48 c | 34 bc | 46 c | 16 a | 43 c | 48 c |

| Sticky *** | 41 b | 15 a | 41 b | 32 b | 3 a | 37 b | 6 a |

| Hard *** | 54 b | 9 a | 13 a | 10 a | 62 b | 15 a | 14 a |

| Porous *** | 39 b | 37 b | 33 b | 38 b | 8 a | 41 b | 45 b |

| Dry n.s. | 54 | 44 | 49 | 43 | 47 | 44 | 40 |

| Hardness (N) | Crumbly | Hard | Porous | Sticky | Dry | |

|---|---|---|---|---|---|---|

| Hardness (N) | 1 | |||||

| Crumbly | −0.87 * | 1 | ||||

| Hard | 0.71 (*) | −0.92 ** | 1 | |||

| Porous | −0.96 ** | 0.79 * | −0.67 | 1 | ||

| Sticky | −0.20 | 0.04 | −0.18 | 0.42 | 1 | |

| Dry | 0.39 | −0.71 (*) | 0.64 | −0.26 | 0.53 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Proserpio, C.; Bresciani, A.; Marti, A.; Pagliarini, E. Legume Flour or Bran: Sustainable, Fiber-Rich Ingredients for Extruded Snacks? Foods 2020, 9, 1680. https://doi.org/10.3390/foods9111680

Proserpio C, Bresciani A, Marti A, Pagliarini E. Legume Flour or Bran: Sustainable, Fiber-Rich Ingredients for Extruded Snacks? Foods. 2020; 9(11):1680. https://doi.org/10.3390/foods9111680

Chicago/Turabian StyleProserpio, Cristina, Andrea Bresciani, Alessandra Marti, and Ella Pagliarini. 2020. "Legume Flour or Bran: Sustainable, Fiber-Rich Ingredients for Extruded Snacks?" Foods 9, no. 11: 1680. https://doi.org/10.3390/foods9111680

APA StyleProserpio, C., Bresciani, A., Marti, A., & Pagliarini, E. (2020). Legume Flour or Bran: Sustainable, Fiber-Rich Ingredients for Extruded Snacks? Foods, 9(11), 1680. https://doi.org/10.3390/foods9111680