1. Introduction

3D printing (3DP) refers to an advanced production technology category characterized by layer-by-layer material deposition for creating personalized objects from pre-designed digital models. It has evolved significantly throughout the last three decades and 3D printers (the associated machine systems) are currently able to utilize a wide range of raw materials, including food ingredients. Until recently, the idea of automated food personalization was only associated with science fiction. 3D food printing, which integrates 3DP technology and digital gastronomy [

1], has the potential to make this a reality. Even though the first 3D food printer patent was filed in 2001 [

2], the technology remained under-researched until the inception of the first prototype at Cornell University in 2006 [

3,

4,

5]. Since then, its academic relevance has increased substantially. The identified application areas of 3D food printing presently range all the way from domestic and restaurant kitchens to spaceships [

6,

7,

8]. Moreover, the associated ingredients portfolio is expanding from naturally printable food ingredients [

3] like sugar, hummus, chocolate, and cheese to healthier and more sustainable food ingredients including plant-based proteins [

9,

10].

Conventional food value chains, which involve centralized factory production, promote mass standardization of food products. However, this often results in over-exploitation of resources, high emissions, and food waste [

11,

12]. With globalization, food supply chains are increasingly becoming complex and less transparent. Shipping of pre-processed food from a centralized factory to different parts of the world not only entails a profusion of air miles, but also requires food additives to preserve the flavor and appearance. Consumer desirability of such standardized food products is gradually diminishing. 3D food printing, still in its nascent state, has the potential to address many of the challenges associated with traditional food production practices. It could make the existing food value chains more sustainable and consumer-desirable by facilitating on-demand food production, reducing food waste, and enabling automated food personalization [

11,

12].

3D food printing offers the leeway to tailor contents of food products to match an individual’s health and activity level as well as their personal taste preferences. Therefore, in addition to shape customization (

Figure 1), nutritional content and texture of the food can be fine-tuned. While the potential of 3D food printing is clearly evident, its use is still limited to the academic arena, catering, and confectionery sectors [

7,

8]. Most existing systems are not designed for large volume applications and lack functional value propositions, well defined customer segments, and profit mechanisms. However, the scarcity of commercial success stories of 3D food printing does not point to a lack of market for the technology. BIS Research, for example, has predicted the 3D food printing market to reach

$525.6 million globally by 2023 [

13].

Since 3D food printing is a relatively recent innovation, there are several technological challenges to overcome before it can be adopted by the mainstream food industry [

14]. For instance, matching food ingredients with suitable 3DP technologies as well as the selection and optimization of food ingredients are two major avenues that are currently being tackled [

15,

16]. Studies reveal that the ingredient choice for 3D food printing has a significant impact on mixing efficiency, printing speed, geometric accuracy, and compatibility with conventional post-processing techniques such as baking [

1,

16,

17,

18,

19]. In addition to understanding the 3D printability of traditional food ingredients [

15,

18,

20], there are investigations focused on the applicability of novel-alternative and healthy food ingredients for 3D food printing [

9]. Despite the progress made, the functional potential of 3D food printing remains largely unrealized on a commercial level.

Researchers argue that 3D food printing will not completely replace the traditional food production process, but would diversify the food product offering [

6,

19]. Various application areas are identified, but the techno-economic feasibility and consumer desirability of the use cases remain unclear. Digital platforms, for example, have become an integral part of the present-day consumer experience. Previous studies have examined the possible interactions between 3DP and digital platforms [

21,

22], but have been mostly limited to the specialty goods sector. Identifying potentially desirable attributes of the hardware-software system for 3D food printing is expected to have a positive impact on the market acceptance of the technology. This knowledge should also help entrepreneurs and academics in the field to effectively channel their developmental activities. Additionally, a breakthrough of 3D food printing into commercial arenas may not only be dependent on the progress of technology R&D, but also on innovative business models [

23,

24,

25].

The motivation behind this study was to update the business outlook of 3D food printing beyond general excitement in order to direct R&D efforts needed for the realization of commercial 3D food printing applications. It aimed at addressing the identified knowledge gaps through three research objectives, which are (a) gathering expert perspectives on the maturity level of 3D food printing along with the key attributes of its hardware-software system, (b) identifying use cases for 3D food printing that are techno-economically feasible as well as desirable to consumers, and (c) investigating the potential of 3D food printing in creating profitable businesses until the year 2024 by using an approach alternative to methodologies of market research, i.e., business modelling [

26].

2. Methodology

The study utilized a three-phase Mixed Methods Research (MMR) process, as illustrated in

Figure 2. MMR is a subset of multimethodology [

27] that systematically integrates qualitative and quantitative data as part of a study or a group of related studies [

28,

29]. The three associated phases are (1) exploratory phase, (2) evaluation phase, and (3) development phase, respectively. Exploratory phase included two sets of interviews with experts from within the 3D food printing value chain. While the first set of interviews aimed at gathering expert insights on use cases and potential attributes of 3D food printer systems [

30,

31], the second set of interviews focused on understanding the maturity level of the technology for industry-scale utilization. The second phase involved screening for the most potential use-cases utilizing an expert survey [

31] and consumer focus group discussions. Here, perspectives from academia, industry, and consumers are considered for evaluating techno-economic feasibility and desirability of the use cases. In the third phase, a business modelling workshop was organized to sketch and evaluate value propositions for the selected use cases.

2.1. Exploratory Phase: Interviews with Experts

The first set of interviews were organized during autumn 2017, and covered topics including change drivers for 3D food printing, its hardware and software platform, key customization parameters, novel use cases, and future scenarios (

Appendix A). A semi-structured and open-ended format was followed to provide enough flexibility to both the interviewer and the experts interviewed. A total of fifteen interviews with participants from Finland (10), Spain (2), Netherlands (2), and England (1) were conducted. Due to the multidisciplinary nature of the topic, a diverse interview pool was required for amassing fresh data from multiple perspectives. The participating experts represented research organizations, academia, food producers, food processing brands, food distributers, future-foresight consultancy, 3D food printing businesses, software providers, and hardware providers. While face-to-face sessions were conducted for participants from Finland, Skype was utilized as a platform for the international interviews. All the interviews were recorded (~600 min) and were later transcribed into text format. Data were visualized and analyzed using affinity diagrams [

32], which facilitated organizing the ideas and opinions into categories based on their natural relationships.

A second set of semi-structured and open-ended interviews was carried-out in autumn 2018. These interviews focused on the technological feasibility of the key elements of the 3D food printing process, i.e., 3D food printing technologies, ingredients and recipes, equipment hardware and software, post-processing, and automation of printing systems. The participants either had hands-on R&D experience in the field of 3D food printing or were actively following the field with business interests. In total, 10 experts were individually interviewed from the research sector and industry in Finland, covering all the key elements of 3D food printing process. The duration of a typical interview was one hour, and the objective was to obtain a worthwhile perspective of the current feasibility of the technology, as well as its prospect feasibility within the next five years. The interviews were supplemented by findings in the literature to further define the maturity and readiness level of the specific technology or process part in question.

2.2. Evaluation Phase: Expert Survey and Consumer Focus Groups

2.2.1. Survey Design

In order to evaluate and generalize the results of the first set of interviews, an expert survey was conducted during autumn 2017. The quantitative survey was designed following the exploratory sequential model proposed by Curry et al. [

33], as shown in

Figure 3. Data were gathered systematically from a pre-established target audience utilizing an online questionnaire [

34]. This method was selected because of the design flexibility it allows for the researcher, convenience for the respondents, and the ease of data handling. The questionnaire was prepared in a professional electronic survey system Webropol [

35], with an approximate completion time of 15 min. It consisted of multiple-choice closed-ended questions arranged into various sections, i.e., taxonomy and background information, platform for 3D food printing, use cases for 3D food printing platform, and contact information.

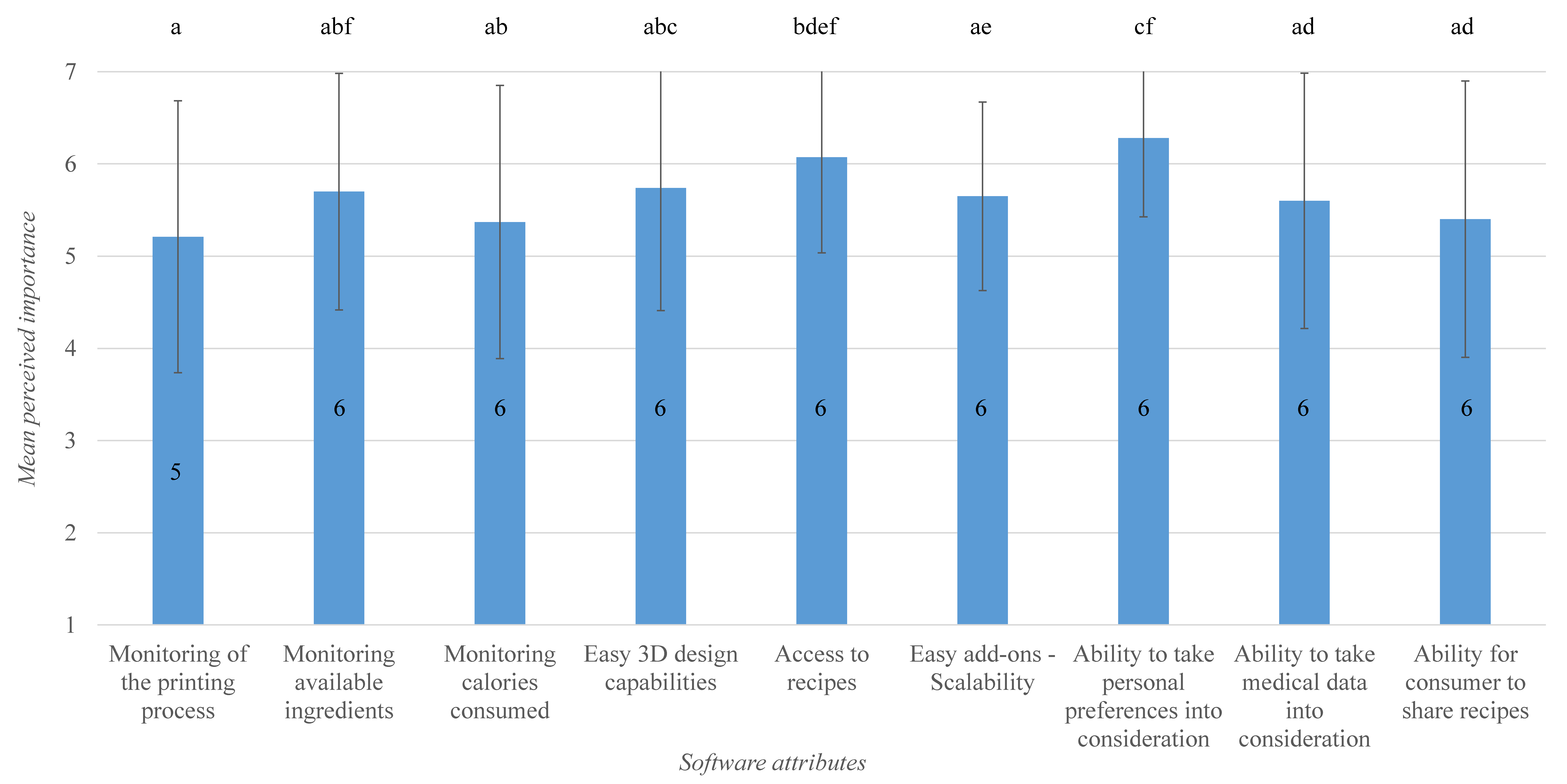

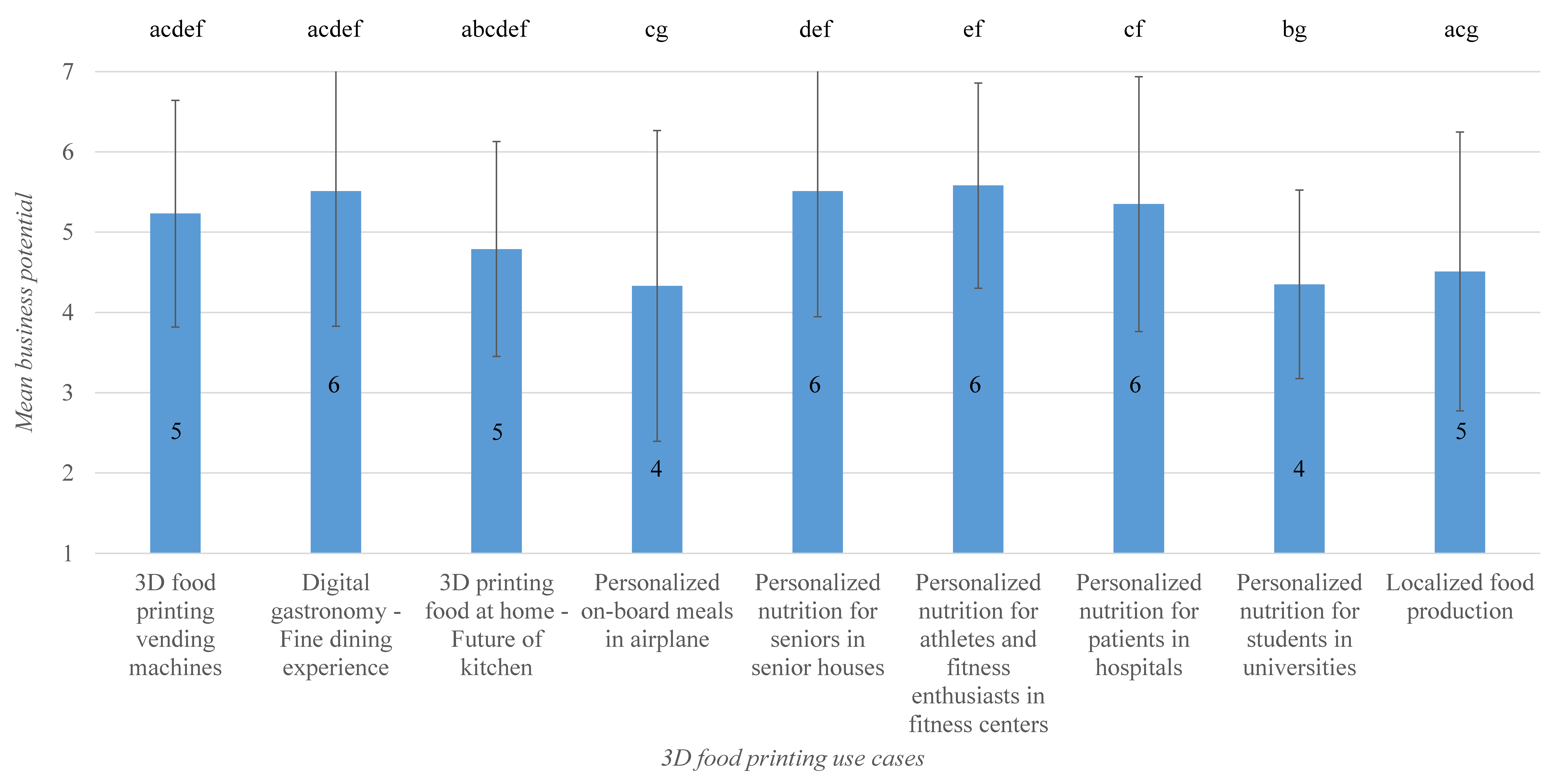

A 7-point Likert scale was used in the survey, with questions structured in a matrix form. The targeted experts were asked to rate (1) attributes of 3D food printing hardware, (2) attributes of 3D food printing software, (3) use-cases based on business potential, and (4) use-cases based on techno-economic feasibility. ‘1’ on the Likert scale denoted least importance/techno-economic feasibility/business potential, and ‘7’ denoted most importance/techno-economic feasibility/business potential. Additionally, an ‘I don’t know’ option was added for the participants who were unsure of how to rate. After logically structuring all the questions, the framework was tested and refined in a pilot study. It was then privately sent out to 85 experts associated with different facets of 3D food printing, with a customized invitation letter. These experts included authors of 3D food printing-related research papers, participants of previously conducted qualitative study, and representatives from 3D food printing businesses globally.

2.2.2. Statistical Analysis of Survey Data

Some of the respondents constantly selected the ‘I don’t know’ option in the survey. Such responses were treated as unreliable and were removed before exporting the data to Statistical Product and Service Solutions (SPSS) software for detailed statistical analysis.

Table 1 shows the number of responses (N) that were analyzed in SPSS for each of the four questions. Since the dependent variable in the questions is ordinal, non-parametric statistical analysis using a Friedman test was conducted. The test provided χ2 value (Chi-square), degrees of freedom (df), and the significance value (Asymp. Sig.,

p-value), thereby revealing any statistically significant differences between the mean ratings of related groups. While the Friedman test shows whether there are overall differences (

p < 0.05), it doesn’t pinpoint which of the analyzed groups differ significantly from each other [

36,

37]. Post hoc Wilcoxon signed-rank tests were carried out on different combinations of the related groups to examine where the differences occur [

38]. The test statistics gave the

Z-scores and the corresponding Asymp. Sig. (2-sided

p) values. These p-values were then manually compared with Bonferroni-adjusted significance level for examining the statistical significance. Bonferroni adjustment was made by dividing the initially used significance level (in this case, 0.05) with the number of tests performed [

39]. The significance level was set at

p ≤ 0.001 for all the post-hoc pair-wise comparisons.

2.2.3. Consumer Focus Groups

Focus group discussions were conducted to gain insight into consumer attitude towards 3D food printing and its associated products/services. Focus groups took place in Finland and Belgium. The reasoning behind the selection of these two countries was that they do not have similar traditions in food and eating, and therefore should bring diversity to the study. There were four focus groups in Finland and three in Belgium, with 6–8 participants per group, aged between 24 and 65 years. The main criterion for the selection of participants was that they should not work or study in the fields of food production, home appliance production, and consumer/market research. The focus group discussions were conducted during spring 2018. In the discussions (

Appendix B), attention was paid to participants’ spontaneous reactions to 3D food printing, their beliefs, perceptions, fears towards the technology, and potential ways of using it. The discussions also included evaluation of the potential use cases (referred to as concepts in the focus groups) that were identified in the previous research phase. The discussions were tape-recorded, and detailed notes were made throughout, which included participants’ perceptions about the potential use-cases and further development ideas. Before the discussions, all the participants provided written informed consent to take part in the study.

2.3. Development Phase: Business Modelling

A business model provides a holistic picture on how a firm creates and captures value. It gives answers to questions in four dimensions [

26]: (1) market domain—who are the target customers and what are their needs? (2) the value proposition of the firm—what will be offered to the customers? (3) technical domain—how is the value proposition created? and (4) description of profit mechanism—how does the business model generate profit? The creation of business models forces us to simultaneously consider both the feasibility of the technology required for value creation, and the potential attractiveness of value proposals in markets for capturing value. This approach has an advantage over the typical technological feasibility or market research studies where researchers focus on either one of the subjects, neglecting the other.

Business modelling was carried out during spring 2019 by means of two separate workshops with experts (business model ideation workshop and business model evaluation workshop, as illustrated in

Figure 2). Design criteria were defined beforehand to guide the ideation process, which included one criterion for each of the four dimensions of a business model. An additional criterion related to overall sustainability was also established. The results of the second set of expert interviews were utilized at this stage, on which to base the technological aspects associated with value creation. During the first workshop (business model ideation workshop), ideas for value proposition were generated by taking the findings from evaluation phase into account. These were then rendered into business model sketches that take technological feasibility aspects and market potential into account. The participants of the first workshop were the same experts who took part in the second set of interviews.

After the business model ideation workshop, three business model ideas that best demonstrated the versatility of 3D food printing were selected for further development. During the second workshop (business model evaluation workshop), initial sketches of these three selected business models were presented, evaluated, and enriched. Most of the experts that participated in the second set of interviews and the first business modelling workshop also took part in the second workshop. The evaluation was performed against the defined design criteria, technological feasibility, and business potential. The second workshop resulted in a polished set of three business models for 3D food printing.

4. Discussion

3D food printing has gained a lot of interest in the recent past and is considered as a field with high expectations. The aim of this study was to update the outlook of 3D food printing beyond its general anticipation by addressing the identified knowledge gaps in the field. The results generated should help the industry and academia to channel their research and developmental activities to best exploit the functional value of 3D food printing. Firstly, the results provided an update on the maturity level of the technology for industrial-scale utilization. Additionally, the key attributes of 3D food printer hardware-software system were put together. Secondly, the study discerned prospective use cases for 3D food printing that are techno-economically feasible for businesses to implement, and desirable to the consumers. Lastly, three business models were provided together with value chain sketches to aid various commercialization efforts.

The short feasibility study with experts pointed out that 3D food printing technology at component level is mature enough for industrial utilization. This means that individual aspects of the technology, such as the state of engineering in 3D food printing, ingredient portfolio, and post-processing options can presently be utilized on an incremental basis. One of the associated challenges, identified from the literature [

14,

15,

16], is the matching of food ingredients with suitable 3D printing techniques. However, out of the techniques applicable in 3D printing food (i.e., material extrusion, selective laser sintering, hot air sintering, and liquid binding), material extrusion provides the most versatility in terms of applicable ingredients [

8,

15,

43,

44]. In agreement with this, experts considered extrusion-based techniques to have the most potential for industrial scaling.

Godoi et al. have categorized extrusion-based 3D food printing techniques into soft-material extrusion, melting extrusion, and hydrogel-forming extrusion [

15]. The experts favored soft-material (paste) extrusion, and were keen on multi-material printing possibilities. The reason for this favoring could be due to the fact that such multi-material systems are already well developed [

45] and are commercially available [

46]. Additionally, the available literature pinpoints a variety of healthy and alternate base paste ingredients that could be used with soft-material extrusion [

10,

44]. However, the quality of the extruded food product depends on critical material parameters, such as rheological properties, particle size, mechanical properties, etc., as well as processing parameters like nozzle diameter, temperature, extrusion rate, solidification rate, etc. [

15,

20]. Regarding post-processing, experts raised concerns about shape retention and compatibility of traditional methods including baking and freeze-drying. The latest research addresses this challenge. Lille et al., for example, managed to significantly improve the shape retention of milk formulations by using rye flour as an additive [

10].

Hardware and software attributes were evaluated by the survey participants for its importance, only on a generic level. Industry/academia must examine these attributes for its relevance in the context of the use case they have in hand. For example, a use case related to 3D chocolate printing would benefit more from having better printing precision rather than multi-material compatibility. Additionally, integrated cooking system is not a relevant hardware attribute for such a use case. Previous studies [

21,

22] focused on the specialty goods sector points out the significant role that an intuitive software platform plays in leveraging functional value of a technology like 3D printing. The attributes and customization parameters identified as part of this study could be utilized by 3D food printer manufacturers for developing systems that are connected, data-driven, collaborative and transparent.

Regarding survey results on the techno-economic feasibility and business potential of identified use cases, the ones related to personalized nutrition (of athletes, patients at hospitals, and seniors) were very well-received. However, the use case of personalized nutrition for students in universities was an exception. This could be due to the fact that athletes, patients, and senior citizens are more specific target groups compared to students, and hence the implementation process would be comparatively easier. The study results additions to the existing knowledge regarding personalized nutrition as an application area of 3D food printing [

47,

48,

49]. Interestingly, the 3D food printing vending machine use case was not rated significantly different from personalized nutrition (of athletes, patients at hospitals, and seniors) use cases in terms of techno-economic feasibility. This, however, does not mean that 3D food vending is equally feasible as the latter use cases. The reason for this higher rating could be its novelty value, and that the survey participants might have had different perceptions regarding its implementation.

According to the literature, already taking consumer perspectives into account during the early development phase will have a positive impact on the market acceptance of novel food technologies [

50]. The results of this study reflected the novelty of 3D food printing to consumers and highlighted the importance of introducing the technology in markets via services that are realistic, and with appropriate target groups. Focus group results indicated that consumers desire personalization and convenience over special eating experience. It is not advised to brand the technology as 3D food printing, as the term ‘printing’ drew adverse associations in consumers’ minds that are against the current food trends related to naturalness and healthiness. In general, the focus group results confirmed the finding of Mantihal et al., that consumer awareness of 3D food printing is still very limited [

8]. 3D food printing enterprises should invest resources to address this issue, since consumers ultimately decide whether 3D food printing will make a commercial breakthrough or not.

The results from the exploratory phase and the evaluation phase were utilized in creating the three business models. Although the presented models would not be realized as such, they include elements that could be used when designing other models. It should be noted that only an upper-level business model sketching is carried out to answer how firms could create and capture value utilizing the identified use-cases. The next step would be to create machine design concepts for the selected models and to test them with end-users. Refined machine design concepts could then be translated to working prototypes.

5. Conclusions

This study investigated the techno-economic prospects as well as consumer desirability of 3D food printing utilizing a mixed methods approach. The data obtained from expert interviews were evaluated using an expert survey and consumer focus groups. The results provided perceptions on the key hardware-software attributes and use cases for 3D food printing. Both experts and consumers supported 3D food printer (hardware-software) platforms that could offer functional value in terms of health, nutrition, and convenience. The research results were translated into three business models for 3D food printing, namely, customized design chocolates, personalized snacks at semi-public spaces, and 3D food printing in kitchen department of hospitals. The first model could easily be implemented presently by small businesses around the niche, with minimal resources. However, the latter models involving the 3D printing of personalized meals/snacks for large consumer segments, would offer higher business prospects. Although no technological and scientific breakthroughs are necessary, the development efforts required to make these business models real and profitable should not be underestimated. The personalized snacks model incorporates the novel machine concept of 3D food vending, and therefore would demand (high) risk taking to start the development efforts. If such risks are taken and if those attempts are successful, 3D printed food could indeed become a part of our daily life. If not, 3D food printing might remain in niche with models such as customized design chocolate, which target small and specific segments.