3.2. pH and Water Activity

The effect of the addition of olive extracts on the pH and a

w of beef patties is shown in

Table 2. All treatments had the same pH value at Day 0 (5.7). This pH value is similar to those reported by Hayes et al. [

2], in beef patties with olive leaf extract, and Gómez et al. [

27], in beef patties with grape seed extract.

Patties packaged in OW had pH values lower than those obtained in patties packaged in MAP at Day 2. During the rest of the days of refrigerated storage, the packaging did not affect the pH of the beef patties (p > 0.05).

There were significant differences among treatments (

p < 0.05) for pH values from Day 8. The beef patties with sulfites kept their pH stable during the refrigerated storage, due to its antimicrobial and antifungal effect. However, the pH of the control patties and those with olive extract decreased from the 8th day of storage due to the lactic acid bacteria’s growth [

29]. These results are in accordance with those found by Hayes et al. [

3] in patties with and without olive leaf extract. Therefore, the addition of OE in the doses used in the present study does not affect the pH of the beef patties. The a

w values of the beef patties were not affected by packaging and type of antioxidant (

p > 0.05) during the refrigerated store.

3.3. Color

Consumers’ acceptability is greatly affected by meat color. The combined effect of the addition of olive extract and the packaging method on the lightness (L*), redness (a*) and yellowness (b*) of beef patties refrigerated for 15 days is shown in

Table 3.

Packaging affected the L* parameter (

p < 0.05) from Day 8 and the lowest L* values were reached for the overwrap packages during the refrigerated storage. Thus, OW conditions led to a decrease in the L* parameter in beef patties. These results are in agreement with those obtained by Gómez and Lorenzo in foal meat [

30]. Moreover, there was no observed effect for the antioxidant type used in the L* values (

p > 0.05).

There were no significant differences among treatments (

p > 0.05) for L* values during the refrigerated storage, except for the C-MAP treatment that had an increase in lightness until Day 12. Fernández-López et al. [

31] also reported an increase in lightness during storage of ostrich steaks.

Redness is the most important parameter in red meat, since the bright red color is highly appreciated by the consumer. The packaging method significantly affected (

p< 0.05) the a* parameter through all the days of the study. In MAP conditions, a* values were higher than those obtained in OW packaging up to 8 days of refrigerated storage. From the 12th day, the a* values in the MAP samples were lower than those obtained for the OW ones. These results agree with those found by several authors describing a faster decrease in a* when using MAP instead of overwrap conditions by the end of refrigerated storage [

30,

32].

The a* values showed significant differences (

p < 0.05) among both packaging methods according to the antioxidant used. Thus, in the OW treatment, the OE did not allow to keep the redness of the meat since the samples with OE1 and OE2 showed similar values of the a* parameter than the control samples. However, if the addition of OE is combined with MAP, the redness preservation is achieved up to day 8 for the OE1 samples and 12 for OE2, respectively, since the a* values in the C treatments were lower than those obtained in treatments with OE added. There were no significant differences (

p < 0.05) between the patties elaborated with the two doses studied for the a* parameter and, therefore, the lowest dose (150 mg/kg) would be enough in order to preserve the redness of the beef patties. These findings were in agreement with those reported earlier by Hayes et al. [

3], who reported that the addition of an olive leaf extract improved the color stability in raw beef patties stored aerobically and in MAP for 12 days.

Moreover, all treatments showed a significant decrease (

p < 0.001) in redness (around 66%) through the refrigeration storage time due to the pigment oxidation of meat products [

2]. It should be noted that the C-OW treatment was the sample whose redness decreased faster. From Day 2, the sample had the same a* value observed for the rest of the refrigerated period.

The yellowness showed significant differences (

p < 0.05) between the packaging conditions. The b* values were higher in the treatments packaged in the MAP conditions than those packaged in the OW ones. Thus, the MAP enhanced the b* stability in beef patties. Similar behavior was found by Gómez and Lorenzo [

30] in foal meat.

The OE added at the doses studied protected the yellowness of the beef patties up to 5 days in the OW samples. However, in the MAP samples, no effect related to OE addition was noted.

Moreover, the yellowness was mainly affected by storage time (p < 0.001) and the b* values decreased during refrigerated storage of the beef patties.

As reflected in

Table 4 the color differences found between the control patties and the patties with sulfites and the olive extracts were in general higher than 2.3. That means that consumers could detect the differences in color between the C-OW and C-MAP samples and their respective patties with antioxidants from Day 0 (with the exception of S-OW and OE1-OW) and over all the storage time.

The highest ΔE* values were found at Days 2 for the OW patties whereas in the MAP samples the highest values were reached at Day 8. An effect of the packaging or the antioxidant used was not found for this parameter, which means that consumers would not detect differences in color between the samples with sulfites or OE regardless of the packaging method used.

Table 5 shows the ΔE* values between the patties at Day 0 and the rest of the days. In this case, the ΔE* values were significantly higher than those found in

Table 4, which means that the storage time clearly affect to the color of the patties due to the lipid oxidation and protein degradation. An effect of the storage time was found in all the patties except for C-OW and OE2-MAP. In the OE1-OW and OE2-OW patties, the color differences increased until Day 5 and then kept constant until Day 15. Meanwhile, the ΔE* values of the rest of the treatments increased until Day 8 and then kept constant. Therefore, the sulfite would protect the color more than the OE in OW conditions. Moreover, the MAP would enhance the color stability in beef patties in relation to the OW conditions, regardless of the use or not of antioxidants in the formulation.

3.4. Microbiological Analysis

Microbial spoilage usually reduces the shelf-life of raw meat.

Table 6 reflects the effect of the addition of antioxidants and the packaging method on the total viable counts (TVC) of beef patties for refrigerated storage for 15 days. The initial TVC at Day 0 was 4.35 log10 cfu/g, a value similar to those obtained in raw beef patties at Day 0 [

3]. The mincing process could contribute to the relatively high initial TVC in minced beef [

3]. The addition of sulfite inhibited the growth of TVC (

p < 0.05) from Day 8 of storage under both packaging conditions. This is related to the well-known antimicrobial effect of sulfite, one of the reasons for its use in the meat industry [

7]. Conversely, the olive extract assayed did not show a bacteriostatic effect. Only a slight effect was observed at the higher doses used (250 mg/Kg) from Day 8. These results contrast with those reported by Hayes et al. [

3], who found antimicrobial activity of an olive leaf extract in raw beef patties under aerobic and MAP storage. The different phenolic composition of the extracts studied, the doses added and the source, one from the olive fruit (the present study) and the other from the olive leaf [

3], could explain why olive leaf extract was more effective against microorganisms than the olive extract.

Storage time had a significant effect on the TVCs of beef patties packaged in both the MAP and OW conditions, with an increase in TVC values (

p < 0.001) observed over the 15 days of the refrigerated storage. The counts at which the meat becomes unacceptable by consumers, implying spoilage of the meat, is 7 log

10 cfu/g [

33]. Therefore, the shelf-life of beef patties without antioxidant (C) and with OE (150 or 250 mg OE/kg) stored under both MAP and OW conditions would be 8 days. The addition of sulfites would extend the shelf-life up to 12 or 15 days in MAP and aerobic storage, respectively. The microbiological results are correlated with the pH values as previously explained. The beef patties with sulfites had the highest pH values probably due to the lower proliferation of lactic bacteria and, therefore, a lower production of lactic acid.

Moreover, in spite of the presence of CO

2, the MAP packaging did not inhibit microbial growth probably due to the growth of lactic bacteria, which are the predominant microorganisms in meat packaged in MAP [

34].

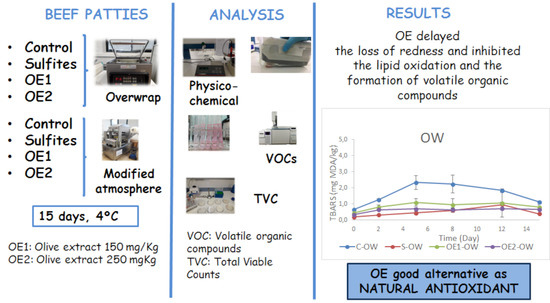

3.5. Lipid Oxidation

Table 7 shows the effect of the addition of antioxidants and packaging method on lipid oxidation during 15 days at 4 °C. The results are expressed as mg MDA/Kg of product. An effect of the antioxidant, the packaging method and the time of storage was observed for this parameter (

p < 0.05).

The initial value of the TBARS ranged from 0.20 to 0.66 (p < 0.05). This range of values at Day 0 can be related to the differences in the fat content among the samples.

Regarding the packaging method, the TBARS values of the samples packaged in MAP were higher than those packaged in OW conditions (

p > 0.05), regardless of the antioxidant used or the day of refrigerated storage. These higher TBARS values are due to the higher oxygen content in the samples packaged in MAP (80%), which leads to an increased susceptibility of minced beef to lipid oxidation, with associated adverse effects on color [

35].

With respect to the antioxidant added, in patties packaged in MAP conditions, the TBARS values of the patties with OE added (OE1-MA and OE2-MA) were lower than those obtained in patties with sulfite (S-MAP) or without additives (C-MAP) from Day 5 of treatment. Likewise, the higher dose of OE, the higher protection against lipid oxidation, was observed in MAP beef patties. The sulfites did not protect the beef patties from the rancidity since the TBARS values of the patties with (S-MAP) or without antioxidants (C-MAP) were similar. These results can be partially explained by the self-oxidation from the sulfite to a sulfate that can be accelerated by several factors, such as iron, a heme group of myoglobin and the partial pressure of oxygen [

36]. Furthermore, Lizada and Yang [

37] reported that sulfite could induce the direct oxidation of linoleic acid, one of the fatty acids present in beef, to low molecular weight compounds. This lipid oxidation needs oxygen and occurs together with the oxidation of sulfite to sulfate, which explains why the TBARS values in patties with sulfite in MAP (S-MAP) were so high.

The presence of OE also protects the patties from lipid oxidation in the samples packed in overwrap conditions (

p < 0.05) through the storage time. The OE can slow TBARS formation due to its antioxidant activity as a consequence of its phenolic compounds, which act as free radical scavengers. The efficacy of the OE to delay the lipid oxidation in foal patties refrigerated for 6 days has been showed in a previous study [

38]. Moreover, the treatment with sulfite (S-OW) had similar TBARS values to the treatments with OE throughout the refrigerated storage. This antioxidant activity of sulfites is due to its ability to break down hydroperoxides without producing radicals [

39]. Likewise, sulfites can scavenge reactive oxygen species (ROS), ending the radical termination processes. In addition to this, sulfites might reduce other pro-oxidants, such as H

2O

2, and avoid the accumulation of protein radicals that could act as lipid pro-oxidants [

23]. An interaction of packaging and antioxidant was found for this parameter during all storage times (

p ≤ 0.05), except for Day 0 (

p = 0.495).

The limit of detection for the rancidity for beef acceptability to consumers has been set at 2 mg MDA/kg meat [

40]. Taking this value into account, this level of rancidity was reached by the control patties packaged in MAP conditions (C-MAP) at Day 2 (2.17 mg MDA/kg) and the control patties packaged in OW conditions (C-OW) at Day 5 (2.33 mg MDA/kg). Patties with sulfites and packaged in OW conditions (S-OW) had TBARS values lower than 2 mg MDA/kg during the 15 days of refrigerated storage. However, the combination of the addition of sulfites with MAP packing led to TBARS values similar to those obtained from patties without antioxidant added (C-MAP). It should be noted that the OE delayed the lipid oxidation in the MAP and OW conditions, and the higher the dose used, the higher the antioxidant activity. The OE-containing samples showed mean TBARS values lower than 2 mg MDA/kg during the 15 days of refrigerated storage, except the OE1-MAP at Day 15. Therefore, the combination of 250 mg/kg OE with 25% polyphenols and 15% hydroxytyrosol, and MAP packaging, would be effective against lipid oxidation up to 15 days.

3.6. Volatile Organic Compounds

Fatty acids, amino acids, peptides, lipids and proteins are important contributors to meat flavor through hydrolysis, oxidation of lipids proteolysis and Maillard reactions [

41]. In this sense, it is well-known that lipid oxidation involves the formation of free radicals and hydroperoxides whose decomposition can result in the formation of volatile compounds (aldehydes, alcohols, ketones, etc.). Many of these volatile compounds have an unpleasant flavor and are responsible for the rancid odors present in meat products during storage [

21]; thus, these compounds are reliable parameters for monitoring the shelf-life of meat products. Among these VOCs, aldehydes, and mainly hexanal, are extensively recognized as markers of lipid oxidation in meat products. Other VOCs that are also related to the formation of rancid odors are alcohols, 2,3-octanedione and 2-pentylfuran [

22].

Table 8 shows the following VOCs studied: hexanal, 2-pentyl-furan, 1-pentanol, 2,3-octanedione, hexanol, nonanal and 1-octen-2-ol.

According to the TBARS results, the OE delayed the formation of all the volatile compounds studied, since in general the patties had significantly lower amounts of all the VOCs evaluated at Days 5, 8 and 12 than the control samples in both methods of packaging studied. An effect of the dose added was also found, so the higher the amount of OE added the higher the antioxidant effect. The addition of 250 mg of OE/kg of product inhibited the formation of 2-pentylfural and nonanal over the storage time studied. An effect of the type of packaging was also found, mainly after Day 5 of treatment, except for the compounds 1-octen-2-ol and 2,3-octanedione. The OW control samples showed higher concentrations of hexanal, 2,3-octanedione and 1-octen-2-ol than those of the MAP control patties, but lower concentrations than the other four volatile compounds studied. However, in all the cases, the antioxidant effect of the OE was higher in the samples packaged in OW conditions than in MAP with a high oxygen content. A combination effect of the packaging and antioxidant employed was also found (p ≤ 0.05), with the exception of nonanal.

These results also showed higher effectiveness of the OE than sulfites, highlighting the high potential of this OE as an antioxidant in beef patties stored in OW or MAP. It was expected that the sulfites show significantly lower levels of hexanal, as well as the rest of the VOCs studied, than the control samples due to its antioxidant activity [

39]; however in the present study, sulfites only delayed the formation of 2-pentylfuran, 2,3 octanedione and 1-pentanol in both kinds of packaging methods studied, and hexanol and 1-octen-2-ol in the OW samples. These results agree with those previously discussed for the TBARS values.

Regarding to the evolution of the VOC analyzed, the general trend was an increase during the first 8–12 days of storage, after which the concentration decreased. In those cases where an effect of storage time was not observed, the level of the volatile compound studied remained constant. This finding agrees with the results found by Tateo et al. [

42], who reported that the amount of many volatile compounds of foal meat packaged under vacuum conditions decreased after 9 days of storage. This decrease during the storage time can be related to the fact that hexanal and the other VOCs are formed in the early stages of the oxidation process and undergo further reactions that can be responsible of their decrease [

43]. Interactions between proteins and lipid oxidation products can take place from Shiff bases via condensation reactions [

44]. The antioxidant effect of an olive extract on volatile organic compounds formed during lipid oxidation of beef meat can be due to the polyphenols present in the extract; however, this is the first study of such an approach in the literature. It should be taken into account that the most important polyphenol present in olive oil and its wastes is hydroxytyrosol, which is a phenolic compound with a high antioxidant activity [

45]. The antioxidant mechanisms of polyphenols are usually ascribed to their capacity to donate electrons to free radicals formed during lipid oxidation and to their capacity to stabilize their structure by resonance delocalization of an electron within their aromatic ring [

4]. Other products with a high phenolic content, such as wine pomace or herbs and spices, have also showed the ability to protect meat products from lipid oxidation [

7,

46].