Use of a Taguchi Design in Hibiscus sabdariffa Extracts Encapsulated by Spray-Drying

Abstract

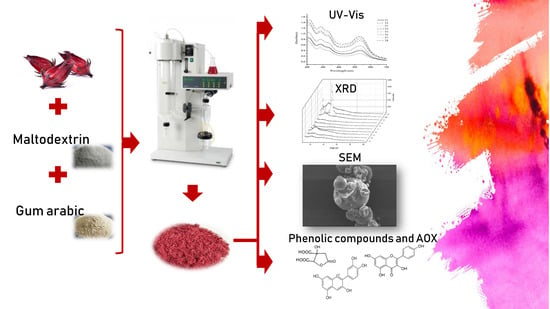

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Design

2.3. Sample Preparation and Spray-Drying of Hibiscus Extracts

2.4. Physicochemical Properties

2.4.1. Encapsulation Yield (EY)

2.4.2. Encapsulation Efficiency (EE)

2.4.3. Moisture, Aater Activity (Aw), pH, Solubility, Wettability and, Bulk Density Analysis

2.5. Scanning Electron Microscopy (SEM)

2.6. Absorption Spectrum

2.7. X-ray Diffraction (XRD)

2.8. Total Soluble Polyphenols (TSP) Content and AOX Assays.

2.9. Identification of PC by HPLC-DAD

2.10. Data Analysis

3. Results and Discussion

3.1. Physicochemical Properties

3.2. Scanning Electron Microscopy (SEM)

3.3. Absorption Spectrume

3.4. X-ray Diffraction

3.5. PC Content and AOX in Hibiscus Encapsulates

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Borrás-Linares, I.; Fernández-Arroyo, S.; Arráez-Roman, D.; Palmeros-Suárez, P.A.; Del Val-Díaz, R.; Andrade-Gonzáles, I.; Fernández-Gutiérrez, A.; Gómez-Leyva, J.F.; Segura-Carretero, A. Characterization of phenolic compounds, anthocyanidin, antioxidant and antimicrobial activity of 25 varieties of Mexican Roselle (Hibiscus sabdariffa). Ind. Crops Prod. 2015, 69, 385–394. [Google Scholar] [CrossRef]

- Sáyago-Ayerdi, S.G.; Arranz, S.; Serrano, J.; Goñi, I. Dietary fiber content and associated antioxidant compounds in roselle flower (Hibiscus sabdariffa L.) beverage. J. Agric. Food Chem. 2007, 55, 7886–7890. [Google Scholar] [CrossRef] [PubMed]

- Duarte-Valenzuela, Z.N.; Zamora-Gasga, V.M.; Montalvo-González, E.; Sáyago-Ayerdi, S.G. Caracterización Nutricional de 20 Variedades Mejoradas de jamaica (Hibiscus sabdariffa L.) Cultivadas en México. Rev. Fitotec. Mex. 2016, 39, 199–206. [Google Scholar]

- Bakowska-Barczak, A.M.; Kolodziejczyk, P.P. Black currant polyphenols: Their storage stability and microencapsulation. Ind. Crops Prod. 2010, 34, 1301–1309. [Google Scholar] [CrossRef]

- Tolun, A.; Altintas, Z.; Artik, N. Microencapsulation of grape polyphenols using maltodextrin and gum arabic as two alternative coating materials: Development and characterization. J. Biotechnol. 2016, 239, 23–33. [Google Scholar] [CrossRef]

- De Moura, S.C.; Berling, C.L.; Germer, S.P.; Alvim, I.D.; Hubinger, M.D. Encapsulating anthocyanins from Hibiscus sabdariffa L. calyces by ionic gelation: Pigment stability during storage of microparticles. Food Chem. 2018, 241, 317–327. [Google Scholar] [CrossRef]

- Gonzalez-Palomares, S.; Estarrón-Espinosa, M.; Gómez-Leyva, J.F.; Andrade-González, I. Effect of the temperature on the spray drying of roselle extracts (Hibiscus sabdariffa L.). Plant Foods Hum. Nutr. 2009, 64, 62–67. [Google Scholar] [CrossRef]

- Díaz-Bandera, D.; Villanueva-Carvajal, A.; Dublán-García, O.; Quintero-Salazar, B.; Dominguez-López, A. Assessing release kinetics and dissolution of spray-dried Roselle (Hibiscus sabdariffa L.) extract encapsulated with different carrier agents. LWT Food Sci. Technol. 2015, 64, 693–698. [Google Scholar]

- Gómez-Aldapa, C.A.; Castro-Rosas, J.; Rangel-Vargas, E.; Navarro-Cortez, R.O.; Cabrera-Canales, Z.E.; Díaz-Batalla, L.; Martínez-Bustos, F.; Guzmán-Ortiz, F.A.; Falfan-Cortes, R.N. A modified Achira (Canna indica L.) starch as a wall material for the encapsulation of Hibiscus sabdariffa extract using spray drying. Food Res. Int. 2019, 119, 547–553. [Google Scholar] [CrossRef]

- Tjantelé, M. Parameter design using the Taguchi methodology. Microelectron. Eng. 1991, 10, 277–286. [Google Scholar] [CrossRef]

- Ravanfar, R.; Tamadon, A.M.; Niakousari, M. Optimization of ultrasound assisted extraction of anthocyanins from red cabbage using Taguchi design method. J. Food Sci. Technol. 2015, 52, 8140–8147. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Assadpour, E.; Jafari, S.M. Spray drying of folic acid within nano-emulsions: Optimization by Taguchi approach. Dry. Technol. 2017, 35, 1152–1160. [Google Scholar] [CrossRef]

- Sharif, K.M.; Rahman, M.M.; Azmir, J.; Mohamed, A.; Jahurul, M.H.A.; Sahena, F.; Zaidul, I.S.M. Experimental design of supercritical fluid extraction—A review. J. Food Eng. 2014, 124, 105–116. [Google Scholar] [CrossRef]

- Oztop, M.H.; Sahin, S.; Sumnu, G. Optimization of microwave frying of potato slices by using Taguchi technique. J. Food Eng. 2007, 79, 83–91. [Google Scholar] [CrossRef]

- Rao, R.S.; Kumar, C.G.; Prakasham, R.S.; Hobbs, P.J. The Taguchi methodology as a statistical tool for biotechnological applications: A critical appraisal. Biotechnol. J. 2008, 3, 510–523. [Google Scholar] [CrossRef]

- Ahi, M.; Hatamipour, M.S.; Goodarzi, A. Optimization of leavening activity of baker’s yeast during the spray-drying process. Dry. Technol. 2010, 28, 490–494. [Google Scholar] [CrossRef]

- Rombaut, N.; Savoire, R.; Thomasset, B.; Castello, J.; Van Hecke, E.; Lanoisellé, J.L. Optimization of oil yield and oil total phenolic content during grape seed cold screw pressing. Ind. Crops Prod. 2015, 63, 26–33. [Google Scholar] [CrossRef]

- Mandal, V.; Mohan, Y.; Hemalatha, S. Microwave assisted extraction of curcumin by sample–solvent dual heating mechanism using Taguchi L9 orthogonal design. J. Pharm. Biomed. Anal. 2008, 46, 322–327. [Google Scholar] [CrossRef]

- Ç>am, M.; İçyer, N.C.; Erdoğan, F. Pomegranate peel phenolics: Microencapsulation, storage stability and potential ingredient for functional food development. LWT Food Sci. Technol. 2014, 55, 117–123. [Google Scholar]

- Fang, Z.; Bhandari, B. Effect of spray drying and storage on the stability of bayberry polyphenols. Food Chem. 2011, 129, 1139–1147. [Google Scholar] [CrossRef]

- Idham, Z.; Muhamad, I.I.; Sarmidi, M.R. Degradation kinetics and color stability of spray-dried encapsulated anthocyanins from Hibiscus sabdariffa. J. Food Process Eng. 2012, 35, 522–542. [Google Scholar] [CrossRef]

- Mahdavi, S.A.; Jafari, S.M.; Assadpoor, E.; Dehnad, D. Microencapsulation optimization of natural anthocyanins with maltodextrin, gum Arabic and gelatin. Int. J. Biol. Macromol. 2016, 85, 379–385. [Google Scholar] [CrossRef] [PubMed]

- Fazaeli, M.; Emam-Djomeh, Z.; Ashtari, A.K.; Omid, M. Effect of spray drying conditions and feed composition on the physical properties of black mulberry juice powder. Food Bioprod. Process. 2012, 90, 667–675. [Google Scholar] [CrossRef]

- Cilek, B.; Luca, A.; Hasirci, V.; Sahin, S.; Sumnu, G. Microencapsulation of phenolic compounds extracted from sour cherry pomace: Effect of formulation, ultrasonication time and core to coating ratio. Eur. Food Res. Technol. 2012, 235, 587–596. [Google Scholar] [CrossRef]

- AOAC. Official Method of Analysis of AOAC, 20th ed.; Association of Official Analytical Chemists: Arlington, VA, USA, 2012. [Google Scholar]

- Al-kahtani, H.A.; Hassan, B.H. Spray drying of roselle (Hibiscus sabdariffa L.) extract. J. Food Sci. 1990, 55, 1073–1076. [Google Scholar] [CrossRef]

- Cano-Chauca, M.; Stringheta, P.C.; Ramos, A.M.; Cal-Vidal, J. Effect of the carriers’ on the microstructure of mango powder obtained by spray drying and its functional characterization. Innov. Food Sci. Emerg. 2005, 6, 420–428. [Google Scholar] [CrossRef]

- Fuchs, M.; Turchiuli, C.; Bohin, M.; Cuvelier, M.E.; Ordonnaud, C.; Peyrat-Maillard, M.N.; Dumoulin, E. Encapsulation of oil in powder using spray drying and fluidised bed agglomeration. J. Food Eng. 2006, 75, 27–35. [Google Scholar] [CrossRef]

- Goula, A.M.; Adamopoulos, K.G. Effect of maltodextrin addition during spray drying of tomato pulp in dehumidified air: II. Powder properties. Dry. Technol. 2008, 26, 726–737. [Google Scholar] [CrossRef]

- Pérez-Jiménez, J.; Arranz, S.; Tabernero, M.; Díaz-Rubio, M.E.; Serrano, J.; Goñi, I.; Saura-Calixto, F. Updated methodology to determine antioxidant capacity in plant foods, oils and beverages: Extraction, measurement and expression of results. Food Res. Int. 2008, 41, 274–285. [Google Scholar] [CrossRef]

- Montreau, F.R. Sur le dosage des composés phénoliques totaux dans les vins par la methode Folin-Ciocalteau. Connaiss. Vigne Vin 1972, 24, 397–404. [Google Scholar]

- Prior, R.L.; Wu, X.; Schaich, K.M. Standardized methods for the determination of antioxidant capacity and phenolics in foods and dietary supplements. J. Agric. Food Chem. 2005, 53, 4290–4302. [Google Scholar] [CrossRef] [PubMed]

- Alvarez-Parrilla, E.; De la Rosa, L.A.; Amarowicz, R.; Sahidi, F. Antioxidant activity of fresh and processed Jalapeño and Serrano peppers. J. Agric. Food Chem. 2010, 59, 163–173. [Google Scholar] [CrossRef] [PubMed]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- Benzie, I.F.; Strain, J.J. The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: The FRAP assay. Anal. Biochem. 1996, 239, 70–76. [Google Scholar] [CrossRef] [Green Version]

- Blancas-Benitez, F.J.; Pérez-Jiménez, J.; Montalvo-González, E.; González-Aguilar, G.A.; Sáyago-Ayerdi, S.G. In vitro evaluation of the kinetics of the release of phenolic compounds from guava (Psidium guajava L.) fruit. J. Funct. Foods 2018, 43, 139–145. [Google Scholar] [CrossRef]

- Dantas, D.; Pasquali, M.A.; Cavalcanti-Mata, M.; Duarte, M.E.; Lisboa, H.M. Influence of spray drying conditions on the properties of avocado powder drink. Food Chem. 2018, 266, 284–291. [Google Scholar] [CrossRef]

- Alves, S.F.; Borges, L.L.; Dos-Santos, T.O.; De Paula, J.R.; Conceição, E.C.; Bara, M.T. Microencapsulation of essential oil from fruits of Pterodon emarginatus using gum arabic and maltodextrin as wall materials: Composition and stability. Dry. Technol. 2014, 32, 96–105. [Google Scholar] [CrossRef]

- De Barros-Fernandes, R.V.; Borges, S.V.; Botrel, D.A. Gum arabic/starch/maltodextrin/inulin as wall materials on the microencapsulation of rosemary essential oil. Carbohydr. Polym. 2014, 101, 524–532. [Google Scholar] [CrossRef]

- Cuq, B.; Rondet, E.; Abecassis, J. Food powders engineering, between know how and science: Constraints, stakes and opportunities. Powder Technol. 2011, 208, 244–251. [Google Scholar] [CrossRef]

- Tonon, R.V.; Brabet, C.; Hubinger, M.D. Anthocyanin stability and antioxidant activity of spray-dried açai (Euterpe Oleracea mart.) juice produced with different carrier agents. Food Res. Int. 2010, 43, 907–914. [Google Scholar] [CrossRef]

- De Andrade, D.P.; Ramos, C.L.; Botrel, D.A.; Borges, S.V.; Schwan, R.F.; Ribeiro-Dias, D. Stability of microencapsulated lactic acid bacteria under acidic and bile juice conditions. Int. J. Food Sci. Technol. 2019, 54, 2355–2362. [Google Scholar] [CrossRef]

- Aboulwafa, M.M.; Youssef, F.S.; Gad, H.A.; Sarker, S.D.; Nahar, L.; Al-Azizi, M.M.; Ashour, M.L. Authentication and discrimination of green tea samples using UV–vis, FTIR and HPLC techniques coupled with chemometrics analysis. J. Pharm. Biomed. Anal. 2019, 164, 653–658. [Google Scholar] [CrossRef] [PubMed]

- Jakobek, L. Interactions of polyphenols with carbohydrates, lipids and proteins. Food Chem. 2015, 175, 556–567. [Google Scholar] [CrossRef] [PubMed]

- Sáyago-Ayerdi, S.G.; Velázquez-López, C.; Montalvo-González, E.; Goñi, I. By-product from decoction process of Hibiscus sabdariffa L. calyces as a source of polyphenols and dietary fiber. J. Sci. Food Agric. 2014, 94, 898–904. [Google Scholar] [CrossRef] [PubMed]

- Mercado-Mercado, G.; Blancas-Benitez, F.J.; Velderrain-Rodríguez, G.R.; Montalvo-González, E.; González-Aguilar, G.A.; Alvarez-Parrilla, E.; Sáyago-Ayerdi, S.G. Bioaccessibility of polyphenols released and associated to dietary fibre in calyces and decoction residues of Roselle (Hibiscus sabdariffa L.). J. Funct. Foods 2015, 18, 171–181. [Google Scholar] [CrossRef]

- Mohd, N.; Hern, F.S.; Ismail, A.; Yee, C.L. Antioxidant activity in different parts of roselle (Hibiscus sabdariffa L.) extracts and potential exploitation of the seeds. Food Chem. 2010, 122, 1055–1060. [Google Scholar] [CrossRef]

- Pérez-González, A.; Rebollar-Zepeda, A.M.; León-Carmona, J.R.; Galano, A. Reactivity indexes and O-H bond dissociation energies of a large series of polyphenols: Implications for their free radical scavenging activity. J. Mex. Chem. Soc. 2012, 56, 241–249. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Marshall-Breton, C.; Leser, M.E.; Sher, A.A.; McClements, D.J. Fabrication of ultrafine edible emulsions: Comparison of high-energy and low-energy homogenization methods. Food Hydrocoll. 2012, 29, 398–406. [Google Scholar] [CrossRef]

- Brown, J.E.; Khodr, H.; Hider, R.C.; Rice-Evans, C.A. Structural dependence of flavonoid interactions with Cu+2 ions: Implications for their antioxidant properties. Biochem. J. 1998, 330, 1173–1178. [Google Scholar] [CrossRef]

| Hibiscus Concentration (%) | Solvent of Extraction | Decoction (°C/min) | Extract: Carrier Ratio (w/w) | Carriers Ratio (MD + GA) 2 (%) | Homogenization (rpm) | Inlet Temperature (°C) | |

|---|---|---|---|---|---|---|---|

| T1 | 1 | Ethanol 20% | 100/5 | 1:1 | 90:10 | 10,000 | 110 |

| T2 | 2.5 | Water | 100/5 | 1:2 | 90:10 | 5000 | 110 |

| T3 | 1 | Water | NA | 1:1 | 80:20 | 5000 | 110 |

| T4 | 2.5 | Water | 100/5 | 1:1 | 80:20 | 10,000 | 150 |

| T5 | 1 | Water | NA | 1:2 | 90:10 | 10,000 | 150 |

| T6 | 1 | Ethanol 20% | 100/5 | 1:2 | 80:20 | 5000 | 150 |

| T7 | 2.5 | Ethanol 20% | NA | 1:2 | 80:20 | 10,000 | 110 |

| T8 | 2.5 | Ethanol 20% | NA | 1:1 | 90:10 | 5000 | 150 |

| Treatment | EY 2 (%) | EE 3 (%) | Moisture (%) | Aw | pH | Solubility (%) | Wettability (min) | Bulk Density (g/cm3) |

|---|---|---|---|---|---|---|---|---|

| T1 | 61.88 ± 0.93 b | 86.58± 0.95 bc | 4.89 ± 0.87 abc | 0.27 ± 0 b | 3.09 ± 0.01 e | 89.22 ± 2.0 a | 5.14 ± 0.03 ab | 0.35 ± 0.02 f |

| T2 | 89.38 ± 1.04 g | 85.45± 4.47 bc | 5.97 ± 0.86 c | 0.23 ± 0 a | 2.75 ± 0.01 c | 77.11 ± 5.97 a | 4.76 ± 0.42 ab | 0.44 ± 0.01 cde |

| T3 | 73.53 ± 1.01 a | 87.93± 2.94 c | 9.55 ± 0.41 f | 0.38 ± 0 h | 2.70 ± 0.01 b | 83.82 ± 3.24 a | 2.95 ± 0.16 a | 0.43 ± 0.03 bcd |

| T4 | 86.34 ± 0.05 f | 86.70± 2.23 bc | 5.19 ± 0.62 bc | 0.35 ± 0 e | 2.65 ± 0.01 a | 86.06 ±0.33 a | 3.08 ± 1.51 a | 0.48 ± 0.03 e |

| T5 | 69.01 ± 0.42 c | 88.48± 0.73 c | 8.06 ± 0.66 e | 0.36 ± 0 f | 2.65 ± 0.01 a | 82.23 ± 3.05 a | 3.92 ± 0.46 a | 0.46 ± 0.03 de |

| T6 | 74.80 ± 0.68 d | 82.61± 0.18 ab | 4.49 ± 0.58 ab | 0.29 ± 0 d | 3.55 ± 0.01 g | 90.82 ± 1.42 a | 6.19 ± 2.97 ab | 0.42 ± 0.03 abc |

| T7 | 84.40 ± 0.28 e | 80.95± 1.13 a | 3.76 ± 0.35 ad | 0.28 ± 0 c | 3.19 ± 0.01 f | 89.71 ± 2.01 a | 7.72 ± 0.42 b | 0.40 ± 0.01 ab |

| T8 | 72.53 ± 0.59 a | 85.36± 2.02 abc | 2.77 ± 0.84 d | 0.37 ± 0 g | 2.80 ± 0.01 d | 90.76 ± 0.76 a | 4.83 ± 2.23 ab | 0.38 ± 0.02 af |

| Treatment | TSP | AOX | ||

|---|---|---|---|---|

| (mg GAE/g DW) 2 | (mmol TE/g DW) 3 | |||

| ABTS | DPPH | FRAP | ||

| T1 | 16.00 ± 0.56 d | 103.16 ± 3.79 b | 28.60 ± 3.30 ab | 220.06 ± 2.27 a |

| T2 | 21.23 ± 0.17 e | 139.64 ± 12.13 c | 57.61 ± 5.19 e | 258.43 ± 1.13 f |

| T3 | 30.51 ± 0.41 g | 201.80 ± 0.05 e | 89.15 ± 11.00 d | 271.95 ± 6.63 g |

| T4 | 32.13 ± 0.06 h | 216.28 ± 5.24 f | 87.78 ± 2.76 cd | 231.41 ± 0.13 e |

| T5 | 25.69 ± 0.11 f | 155.16 ± 0.12 d | 80.12 ± 4.78 c | 224.45 ±1.29 a |

| T6 | 7.16 ± 0.05 a | 24.27 ± 0.01 a | 21.29 ± 0.02 b | 67.97 ± 1.29 b |

| T7 | 9.14 ± 0.03 b | 24.42 ± 0.11 a | 30.67 ± 0.42 a | 140.56 ± 0.83 c |

| T8 | 13.73 ± 0.21 c | 24.04 ± 0.04 a | 33.02 ± 0.04 a | 154.09 ± 0.20 d |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Navidad-Murrieta, M.S.; Pérez-Larios, A.; Sanchéz-Burgos, J.A.; Ragazzo-Sánchez, J.A.; Luna-Bárcenas, G.; Sáyago-Ayerdi, S.G. Use of a Taguchi Design in Hibiscus sabdariffa Extracts Encapsulated by Spray-Drying. Foods 2020, 9, 128. https://doi.org/10.3390/foods9020128

Navidad-Murrieta MS, Pérez-Larios A, Sanchéz-Burgos JA, Ragazzo-Sánchez JA, Luna-Bárcenas G, Sáyago-Ayerdi SG. Use of a Taguchi Design in Hibiscus sabdariffa Extracts Encapsulated by Spray-Drying. Foods. 2020; 9(2):128. https://doi.org/10.3390/foods9020128

Chicago/Turabian StyleNavidad-Murrieta, Migdalia Sarahy, Alejandro Pérez-Larios, Jorge Alberto Sanchéz-Burgos, Juan Arturo Ragazzo-Sánchez, Gabriel Luna-Bárcenas, and Sonia G. Sáyago-Ayerdi. 2020. "Use of a Taguchi Design in Hibiscus sabdariffa Extracts Encapsulated by Spray-Drying" Foods 9, no. 2: 128. https://doi.org/10.3390/foods9020128

APA StyleNavidad-Murrieta, M. S., Pérez-Larios, A., Sanchéz-Burgos, J. A., Ragazzo-Sánchez, J. A., Luna-Bárcenas, G., & Sáyago-Ayerdi, S. G. (2020). Use of a Taguchi Design in Hibiscus sabdariffa Extracts Encapsulated by Spray-Drying. Foods, 9(2), 128. https://doi.org/10.3390/foods9020128