Developing New Health Material: The Utilization of Spray Drying Technology on Avocado (Persea Americana Mill.) Seed Powder

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Solution Preparation and Stability Test

2.2.1. Solution Preparation

2.2.2. Brix and pH Value

2.2.3. Total Phenolic Content

2.2.4. Reducing Power

2.2.5. ABTS Method(2,2′-azino-bis[3-ethylbenzothiazoline-6-sulfonate])

2.2.6. DPPH Method

2.3. Spray Drying

2.4. Regression Model and Statistical Analysis

2.5. Avocado Seed Powder Analysis

2.5.1. Powder Yield

2.5.2. Moisture Analysis

2.5.3. Water Activity Analysis

2.5.4. Solubility Analysis

2.5.5. Color Analysis

2.5.6. Scanning Electron Microscopy (SEM)

2.6. Statistical Analysis

3. Results and Discussion

3.1. Solution Stability

3.2. Regression Model and Statistical Analysis

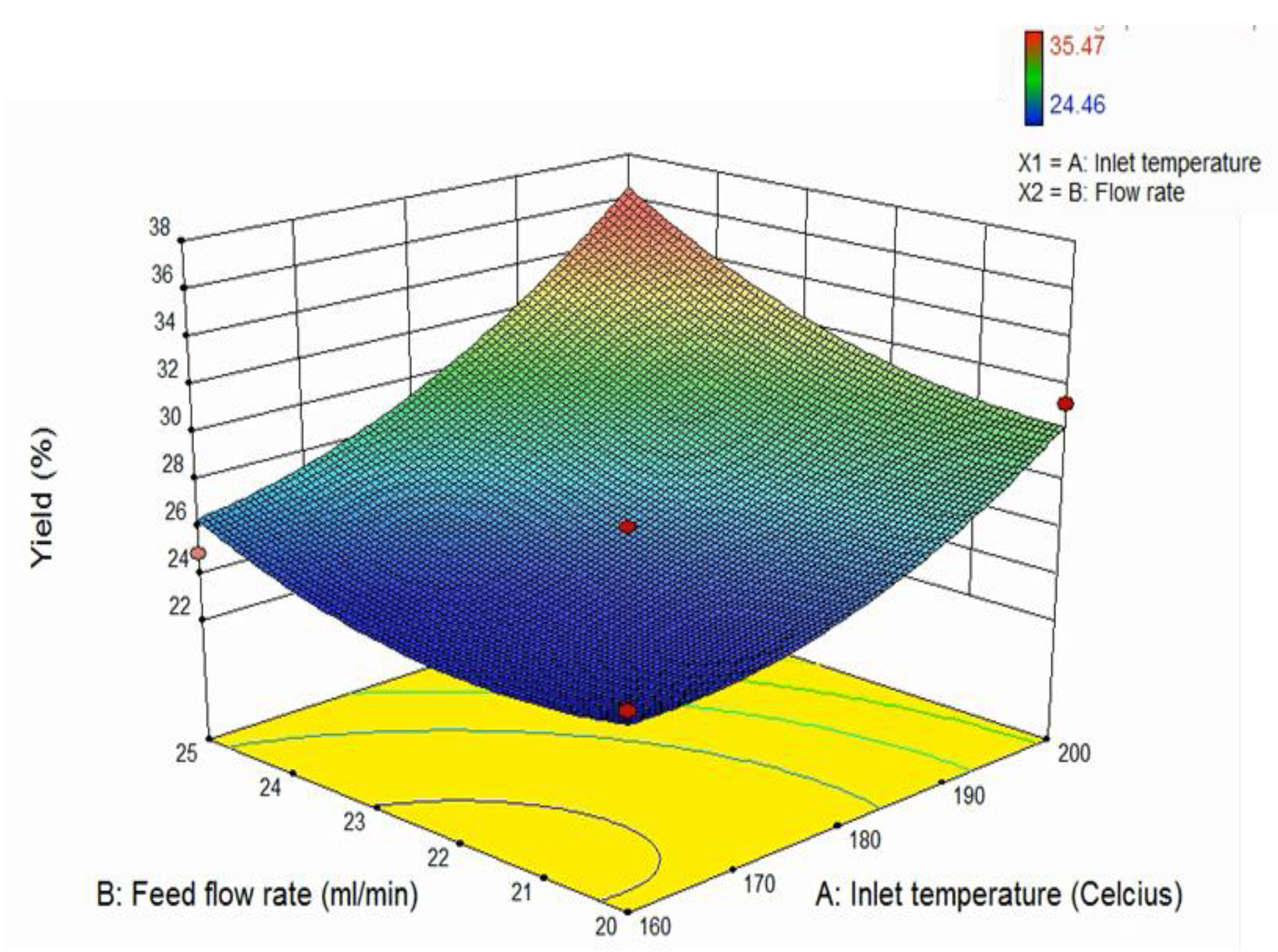

3.3. Powder Yield

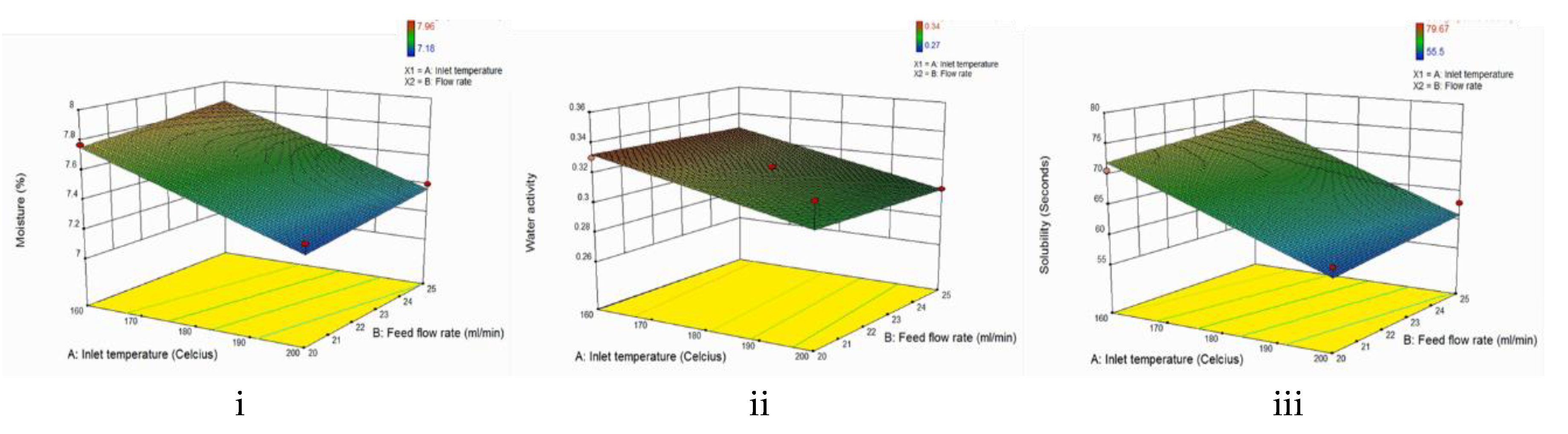

3.4. Moisture Content

3.5. Water Activity

3.6. Solubility

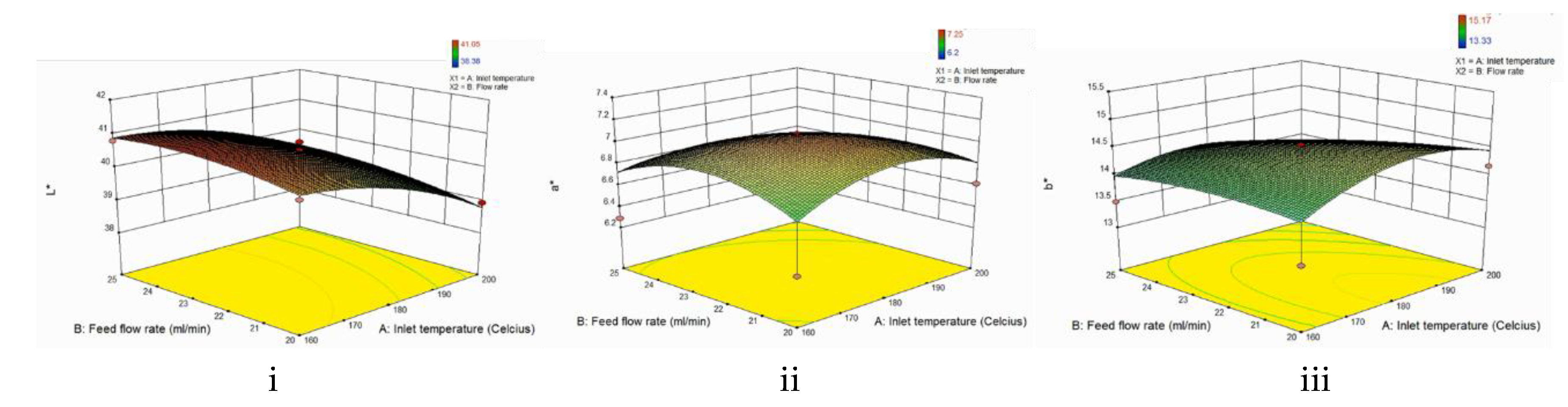

3.7. Color Analysis

3.8. Scanning Electron Microscopy (SEM)

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Villa-Rodriguez, J.A.; Yahia, E.M.; González-León, A.; Ifie, I.; Robles-Zepeda, R.E.; Domínguez-Avila, J.A.; González-Aguilar, G.A. Ripening of ‘Hass’ Avocado Mesocarp Alters Its Phytochemical Profile and the in Vitro Cytotoxic Activity of Its Methanolic Extracts. South African J. Bot. 2020, 128, 1–8. [Google Scholar] [CrossRef]

- Dantas, D.; Pasquali, M.A.; Cavalcanti-Mata, M.; Duarte, M.E.; Lisboa, H.M. Influence of Spray Drying Conditions on the Properties of Avocado Powder Drink. Food Chem. 2018, 266, 284–291. [Google Scholar] [CrossRef] [PubMed]

- Araújo, R.G.; Rodriguez-Jasso, R.M.; Ruiz, H.A.; Pintado, M.M.E.; Aguilar, C.N. Avocado By-Products: Nutritional and Functional Properties. Trends Food Sci. Technol. 2018, 80, 51–60. [Google Scholar] [CrossRef]

- Dabas, D.; Shegog, R.; Ziegler, G.; Lambert, J. Avocado (Persea Americana) Seed as a Source of Bioactive Phytochemicals. Curr. Pharm. Des. 2013, 19, 6133–6140. [Google Scholar] [CrossRef] [PubMed]

- Leite, J.J.G.; Brito, É.H.S.; Cordeiro, R.A.; Brilhante, R.S.N.; Sidrim, J.J.C.; Bertini, L.M.; De Morais, S.M.; Rocha, M.F.G. Chemical Composition, Toxicity and Larvicidal and Antifungal Activities of Persea Americana (Avocado) Seed Extracts. Rev. Soc. Bras. Med. Trop. 2009, 42, 110–113. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dabas, D.; Elias, R.J.; Lambert, J.D.; Ziegler, G.R. A Colored Avocado Seed Extract as a Potential Natural Colorant. J. Food Sci. 2011, 76, C1335–C1341. [Google Scholar] [CrossRef] [PubMed]

- Alhassan, A.J.; Sule, M.S.; Atiku, M.K.; Wudil, A.M.; Abubakar, H.; Mohammed, S.A. Effects of Aqueous Avocado Pear (Persea Americana) Seed Extract on Alloxan Induced Diabetes Rats. Greener J. Med. Sci. 2012, 2, 5–11. [Google Scholar] [CrossRef] [Green Version]

- Figueroa, J.G.; Borrás-Linares, I.; Lozano-Sánchez, J.; Segura-Carretero, A. Comprehensive Characterization of Phenolic and other Polar Compounds in the Seed and Seed Coat of Avocado by HPLC-DAD-ESI-QTOF-MS. Food Res. Int. 2018, 105, 752–763. [Google Scholar] [CrossRef]

- Geissman, T.A.; Dittmar, H.F.K. A Proanthocyanidin from Avocado Seed. Phytochemistry 1965, 4, 359–368. [Google Scholar] [CrossRef]

- Wong, C.W.; Teoh, C.; Putri, C. Effect of Enzymatic Processing, Inlet Temperature, and Maltodextrin Concentration on the Rheological and Physicochemical Properties of Spray-dried Banana (Musa Acuminata) Powder. J. Food Process. Preserv. 2017, 42. [Google Scholar] [CrossRef]

- Quek, S.Y.; Chok, N.K.; Swedlund, P. The Physicochemical Properties of Spray-Dried Watermelon Powders. Chem. Eng. Process. Process Intensif. 2007, 46, 386–392. [Google Scholar] [CrossRef]

- Goula, A.M.; Adamopoulos, K.G. Effect of Maltodextrin Addition during Spray Drying of Tomato Pulp in Dehumidified Air: II. Powder Properties. Dry. Technol. 2008, 26, 726–737. [Google Scholar] [CrossRef]

- Jittanit, W.; Niti-Att, D.; Techanuntachaikul, O. Study of Spray Drying of Pineapple Juice Using Maltodextrin as an Adjunct. Chiang Mai J. Sci. 2010, 37, 498–506. [Google Scholar]

- Ferrari, C.C.; Germer, S.P.M.; de Aguirre, J.M. Effects of Spray-Drying Conditions on the Physicochemical Properties of Blackberry Powder. Dry. Technol. 2012, 30, 154–163. [Google Scholar] [CrossRef]

- Thirugnanasambandham, K.; Sivakumar, V. Influence of Process Conditions on the Physicochemical Properties of Pomegranate Juice in Spray Drying Process: Modelling and Optimization. J. Saudi Soc. Agric. Sci. 2017, 16, 358–366. [Google Scholar] [CrossRef] [Green Version]

- Philip, J.P.; Madhumitha, G.; Mary, S.A. Free Radical Scavenging and Reducing Power of Lawsonia Inermis L. Seeds. Asian Pac. J. Trop. Med. 2011, 4, 457–461. [Google Scholar] [CrossRef] [Green Version]

- Obeng, E.; Kpodo, F.M.; Tettey, C.O.; Essuman, E.K.; Adzinyo, O.A. Antioxidant, Total Phenols and Proximate Constituents of Four Tropical Leafy Vegetables. Sci. African 2020, 7, e00227. [Google Scholar] [CrossRef]

- Arnao, M.B.; Cano, A.; Acosta, M. The Hydrophilic and Lipophilic Contribution to Total Antioxidant Activity. Food Chem. 2001, 73, 239–244. [Google Scholar] [CrossRef]

- Akbari, S.; Abdurahman, N.H.; Yunus, R.M.; Alara, O.R.; Abayomi, O.O. Extraction, Characterization and Antioxidant Activity of Fenugreek (Trigonella-Foenum Graecum) Seed Oil. Mater. Sci. Energy Technol. 2019, 2, 349–355. [Google Scholar] [CrossRef]

- Cornell, J.A.; Khuri, A.I. Response Surfaces: Designs and Analyses; Marcel Dekker, Inc.: New York, NY, USA, 1987. [Google Scholar]

- Bezerra, M.; Santelli, R.; Oliveira, E.; Villar, L.; Escaleira, L. Response Surface Methodology (RSM) as a Tool for Optimization in Analytical Chemistry. Talanta 2008, 76, 965–977. [Google Scholar] [CrossRef]

- Tonon, R.V.; Brabet, C.; Hubinger, M.D. Influence of Process Conditions on the Physicochemical Properties of Açai (Euterpe Oleraceae Mart.) Powder Produced by Spray Drying. J. Food Eng. 2008, 88, 411–418. [Google Scholar] [CrossRef]

- Jangam, S.; Thorat, B. Optimization of Spray Drying of Ginger Extract. Dry. Technol. 2010, 28, 1426–1434. [Google Scholar] [CrossRef]

- Tsai, C.-E.; Lin, L.-H. PPH Scavenging Capacity of Extracts from Camellia Seed Dregs Using Polyol Compounds as Solvents. Heliyon 2019, 5, e02315. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Y.; Huang, S.; Shao, S.; Qian, L.; Xu, P. Studies on Bioactivities of Tea (Camellia Sinensis L.) Fruit Peel Extracts: Antioxidant Activity and Inhibitory Potential against α-Glucosidase and α-Amylase in Vitro. Ind. Crops Prod. 2012, 37, 520–526. [Google Scholar] [CrossRef]

- Alkhalafa, M.I.; Alansari, W.S.; Ibrahim, E.A.; ELhalwagy, M.E.A. Anti-Oxidant, Anti-Inflammatory and Anti-Cancer Activities of Avocado (Persea Americana) Fruit and Seed Extract. J. King Saud Univ. 2019, 31, 1358–1362. [Google Scholar] [CrossRef]

- Tontul, I.; Topuz, A. Spray-Drying of Fruit and Vegetable Juices: Effect of Drying Conditions on the Product Yield and Physical Properties. Trends Food Sci. Technol. 2017, 63, 91–102. [Google Scholar] [CrossRef]

- Santana, A.A.; Cano-Higuita, D.M.; DeOliveira, R.A.; Telis, V.R.N. Influence of Different Combinations of Wall Materials on the Microencapsulation of Jussara Pulp (Euterpe Edulis) by Spray Drying. Food Chem. 2016, 212, 1–9. [Google Scholar] [CrossRef]

- Phisut, N. Spray Drying Technique of Fruit Juice Powder: Some Factors Influencing the Properties of Product. Int. Food Res. J. 2012, 19, 1297–1306. [Google Scholar]

- Vardin, H.; Yasar, M. Optimisation of Pomegranate (Punica Granatum L.) Juice Spray-Drying as Affected by Temperature and Maltodextrin Content. Int. J. Food Sci. Technol. 2012, 47, 167–176. [Google Scholar] [CrossRef]

- Fazaeli, M.; Emam-Djomeh, Z.; Kalbasi Ashtari, A.; Omid, M. Effect of Spray Drying Conditions and Feed Composition on the Physical Properties of Black Mulberry Juice Powder. Food Bioprod. Process. 2012, 90, 667–675. [Google Scholar] [CrossRef]

- Shishir, M.R.I.; Taip, F.S.; Aziz, N.A.; Talib, R.A. Physical Properties of Spray-Dried Pink Guava (Psidium Guajava) Powder. Agric. Agric. Sci. Procedia 2014, 2, 74–81. [Google Scholar] [CrossRef] [Green Version]

- Woo, M.W.; Daud, W.R.W.; Tasirin, S.M.; Talib, M.Z.M. Optimization of the Spray Drying Operating Parameters—A Quick Trial-and-Error Method. Dry. Technol. 2007, 25, 1741–1747. [Google Scholar] [CrossRef]

- Ejiofor, N.C.; Ezeagu, I.E.; Ayoola, M.B.; Umera, E.A. Determination of the Chemical Composition of Avocado (Persea Americana) Seed. Adv. Food Technol. Nutr. Sci. Open J. 2018, S51–S55. [Google Scholar] [CrossRef]

- Lewicki, P.P. Water as the Determinant of Food Engineering Properties. A Review. J. Food Eng. 2004, 61, 483–495. [Google Scholar] [CrossRef]

- Angel, R.C.M.; Espinosa-Muñoz, L.C.; Aviles-Aviles, C.; González-García, R.; Moscosa-Santillán, M.; Grajales-Lagunes, A.; Abud-Archila, M. Spray-Drying of Passion Fruit Juice Using Lactose-Maltodextrin Blends as the Support Material. Brazilian Arch. Biol. Technol. 2009, 52, 1011–1018. [Google Scholar] [CrossRef] [Green Version]

- Adams, M.R.; Moss, M.O. Food Microbiology, 3rd ed.; The Royal Society of Chemistry: Cambridge, UK, 2008. [Google Scholar]

- Lewis, M.J. Physical Properties of Foods and Food Processing Systems; Woodhead Publishing: Cambridge, UK, 1990. [Google Scholar]

- Khalilian Movahhed, M.; Mohebbi, M. Spray Drying and Process Optimization of Carrot-Celery Juice. J. Food Process. Preserv. 2015, 40, 212–225. [Google Scholar] [CrossRef]

- Wong, C.W.; Pui, L.; Ng, J.M.L. Production of Spray-Dried Sarawak Pineapple (Ananas Comosus) Powder from Enzyme Liquefied Puree. Int. Food Res. J. 2015, 22, 1631–1636. [Google Scholar]

- Muzaffar, K.; Kumar, P. Parameter Optimization for Spray Drying of Tamarind Pulp Using Response Surface Methodology. Powder Technol. 2015, 279, 179–184. [Google Scholar] [CrossRef]

| Trial * | Inlet Temperature (°C) | Feed Flow Rate (mL/min) |

|---|---|---|

| 1 | 160 | 20 |

| 2 | 200 | 20 |

| 3 | 160 | 25 |

| 4 | 200 | 25 |

| 5 | 152 | 22.5 |

| 6 | 208 | 22.5 |

| 7 | 180 | 19 |

| 8 | 180 | 26 |

| 9 | 180 | 22.5 |

| 10 | 180 | 22.5 |

| 11 | 180 | 22.5 |

| 12 | 180 | 22.5 |

| 13 | 180 | 22.5 |

| Sugar Content (°Brix) | pH Value | Total Phenolic Content (mg GAE/g) | Reducing Power (OD Value) | ABTS (IC50: μg/mL) | DPPH (IC50: μg/mL) | |

|---|---|---|---|---|---|---|

| Avocado seed extract | 1.23 ± 0.047 | 5.76 ± 0.024 | 367.13 | 1.70 ± 0.06 | 2.767 | 65.28 |

| Model | Yield (%) | Moisture (%) | Water Activity | Solubility (s) | Color | ||

|---|---|---|---|---|---|---|---|

| L* | a* | b* | |||||

| Quadratic | Linear | Linear | Linear | Quadratic | |||

| β0 | 26.07 | 7.56 | 0.32 | 66 | 40.52 | 7.08 | 14.54 |

| β1 | 4.06 | −0.25 | −0.015 | −6.81 | −0.81 | −0.066 | 0.02 |

| β11 | 1.78 | - | - | - | −0.39 | −0.21 | −0.39 |

| β2 | 2.07 | 0.050 | −1.464 × 10−3 | 1.21 | 0.24 | −0.11 | −0.21 |

| β22 | −1.53 | - | - | - | −0.22 | −0.21 | −0.11 |

| β12 | 0.98 | - | - | - | 0.075 | −0.11 | −0.17 |

| R2 | 0.96 | 0.97 | 0.51 | 0.93 | 0.978 | 0.44 | 0.48 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alissa, K.; Hung, Y.-C.; Hou, C.Y.; Lim, G.C.W.; Ciou, J.-Y. Developing New Health Material: The Utilization of Spray Drying Technology on Avocado (Persea Americana Mill.) Seed Powder. Foods 2020, 9, 139. https://doi.org/10.3390/foods9020139

Alissa K, Hung Y-C, Hou CY, Lim GCW, Ciou J-Y. Developing New Health Material: The Utilization of Spray Drying Technology on Avocado (Persea Americana Mill.) Seed Powder. Foods. 2020; 9(2):139. https://doi.org/10.3390/foods9020139

Chicago/Turabian StyleAlissa, Karen, Yu-Chi Hung, Chih Yao Hou, GiGi Chin Wen Lim, and Jhih-Ying Ciou. 2020. "Developing New Health Material: The Utilization of Spray Drying Technology on Avocado (Persea Americana Mill.) Seed Powder" Foods 9, no. 2: 139. https://doi.org/10.3390/foods9020139

APA StyleAlissa, K., Hung, Y.-C., Hou, C. Y., Lim, G. C. W., & Ciou, J.-Y. (2020). Developing New Health Material: The Utilization of Spray Drying Technology on Avocado (Persea Americana Mill.) Seed Powder. Foods, 9(2), 139. https://doi.org/10.3390/foods9020139