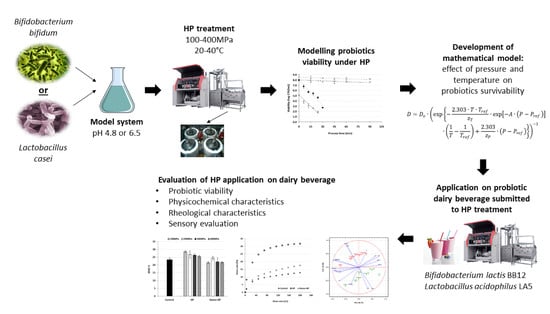

Impact of High-Pressure Process on Probiotics: Viability Kinetics and Evaluation of the Quality Characteristics of Probiotic Yoghurt

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of the Inocula for Kinetics Study

2.2. Yoghurt Preparation

2.3. High-Pressure Processing

2.4. Microbiological Analysis

2.5. Physicochemical Analysis

2.6. Rheological Properties

2.7. Sensory Evaluation

2.8. Data Analysis

2.9. Statistical Analysis

3. Results and Discussion

3.1. Probiotics Viability Loss as a Function of Pressure and Temperature

3.2. Modeling Probiotics Viability Loss as a Function of Temperature and Pressure

3.3. Selection of Optimal HP Conditions-Application in Yoghurt Production

3.3.1. Viability of Starter Culture and Probiotic Bacteria in Yoghurt Samples

3.3.2. Physicochemical/Rheological Characteristics After HP Treatment and During Storage

3.3.3. Sensory Profile of the HP Yoghurts

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Food and Agriculture Organization of the United Nations/World Health Organization (FAO/WHO). Report of a Joint FAO/WHO Working Group on Drafting Guidelines for the Evaluation of Probiotics in Food; Food and Agriculture Organization of the United Nations/World Health Organization: London, ON, Canada, 2002. [Google Scholar]

- Hill, C.; Guarner, F.; Reid, G.; Gibson, G.R.; Merenstein, D.J.; Pot, B.; Morelli, L.; Canani, R.B.; Flint, H.J.; Salminen, S.; et al. The International Scientific Association for Probiotics and Prebiotics consensus statement on the scope and appropriate use of the term probiotic. Nat. Rev. Gastroenterol. Hepatol. 2014, 11, 506–514. [Google Scholar] [CrossRef]

- Şanlier, N.; Gökcen, B.B.; Sezgin, A.C. Health benefits of fermented foods. Crit. Rev. Food Sci. Nutr. 2017, 59, 506–527. [Google Scholar] [CrossRef]

- Collado, M.C.; Isolauri, E.; Salminen, S.; Sanz, Y. The impact of probiotic on gut health. Curr. Drug. Metab. 2008, 10, 68–78. [Google Scholar] [CrossRef] [PubMed]

- Tripathy, M.K.; Giri, S.K. Probiotic functional foods: Survival of probiotics during processing and storage. J. Funct. Foods 2014, 9, 225–241. [Google Scholar] [CrossRef]

- Lucey, J.A. Formation and physical properties of milk protein gels. J. Dairy Sci. 2002, 85, 281–294. [Google Scholar] [CrossRef]

- Leroy, F.; De Vuyst, L. Lactic acid bacteria as functional starter cultures for the food fermentation industry. Trends Food Sci. Technol. 2004, 15, 67–78. [Google Scholar] [CrossRef]

- Trujillo, A.J.; Capellas, M.; Saldo, J.; Gervilla, R.; Guamis, B. Application of high-hydrostatic pressure on milk and dairy products: A review. Innov. Food Sci. Emerg. 2002, 3, 295–307. [Google Scholar] [CrossRef]

- Anema, S.G.; Lauber, S.; Lee, S.K.; Henle, T.; Klostermeyer, H. Rheological properties of acid gels prepared from pressure- and transglutaminase-treated skim milk. Food Hydrocoll. 2006, 19, 879–887. [Google Scholar] [CrossRef]

- Penna, A.L.B.; Subbarao-Gurram, G.V.; Barbosa-Cánovas, G.V. High hydrostatic pressure processing on microstructure of probiotic low-fat yogurt. Food Res. Int. 2007, 40, 510–519. [Google Scholar] [CrossRef]

- Masson, L.M.P.; Rosenthal, A.; Calado, V.M.A.; Dliza, R.; Tashima, L. Effect of ultra-high pressure homogenization on viscosity and shear stress of fermented dairy beverage. LWT-Food Sci. Technol. 2011, 44, 495–501. [Google Scholar] [CrossRef]

- Tsevdou, M.S.; Eleftheriou, E.G.; Taoukis, P.S. Transglutaminase treatment of thermally and high pressure processed milk: Effects on the properties and storage stability of set yoghurt. Innov. Food Sci. Emerg. 2013, 17, 144–152. [Google Scholar] [CrossRef]

- Loveday, S.M.; Sarkar, A.; Singh, H. Innovative yoghurts: Novel processing technologies for improving acid milk gel texture. Trends Food Sci. Technol. 2013, 33, 5–20. [Google Scholar] [CrossRef]

- Tanaka, T.; Hatanaka, K. Application of hydrostatic pressure to yoghurt to prevent its after-acidification. J. Jpn. Soc. Food Sci. 1992, 39, 173–177. [Google Scholar] [CrossRef]

- Krompkamp, J.; Moreira, R.M.; Langeveld, L.P.M.; Van Mil, P.J.J.M. Microorganisms in milk and yoghurt: Selective inactivation by high hydrostatic pressure. In Proceedings of the IDF Symposium Heat Treatments and Alternative Methods, Vienna, Austria, 6–8 September 1995. [Google Scholar]

- de Ancos, B.; Cano, M.P.; Gómez, R. Characteristics of stirred low-fat yoghurt as affected by high pressure. Int. Dairy J. 2000, 10, 105–111. [Google Scholar] [CrossRef]

- Tarmaraj, N.; Shah, N.P. Selective Enumeration of Lactobacillus delbrueckii ssp. bulgaricus, Streptococcus thermophilus, Lactobacillus acidophilus, Bifidobacteria, Lactobacillus casei, Lactobacillus rhamnosus and Propionibacteria. J. Dairy Sci. 2003, 86, 2288–2296. [Google Scholar] [CrossRef]

- International Dairy Federation (IDF). Yogurt: Determination of Titratable Acidity. International IDF Standard, ISO 1991; International Dairy Federation: Vienna, Austria, 1991. [Google Scholar]

- Harte, F.; Luedecke, L.; Swanson, B.; Barbosa-Cánovas, G.V. Low-fat set yogurt made from milk subjected to combinations of high hydrostatic pressure and thermal processing. J. Dairy Sci. 2003, 86, 1074–1082. [Google Scholar] [CrossRef]

- Akhtar, M.; Murray, B.S.; Dickinson, E. Perception of creaminess of model oil-in-water dairy emulsions: Influence of the shear-thinning nature of a viscosity-controlling hydrocolloid. Food Hydrocoll. 2006, 20, 839–847. [Google Scholar] [CrossRef]

- ISO 13300-1. Sensory Analysis—General Guidance for the Staff of a Sensory Evaluation Laboratory—Part 1: Staff Responsibilities; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- ISO 13300-2. Sensory Analysis—General Guidance for the Staff of a Sensory EVALUATION Laboratory—Part 2: Recruitment and Training of Panel Leaders; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- ISO 8589. Sensory Analysis—General Guidance for the Design of Test Rooms; ISO: Geneva, Switzerland, 2007. [Google Scholar]

- Katsaros, G.I.; Tsevdou, M.; Panagiotou, T.; Taoukis, P.S. Kinetic study of high pressure microbial and enzyme inactivation and selection of pasteurization conditions for Valencia Orange Juice. Int. J. Food Sci. Technol. 2010, 45, 1119–1129. [Google Scholar] [CrossRef]

- Kanta, A.; Soukoulis, C.; Tzia, C. Eliciting the Sensory Modalities of Fat Reformulated Yoghurt Ice Cream Using Oligosaccharides. Food Bioprocess Technol. 2018, 11, 885–900. [Google Scholar] [CrossRef]

- Dave, R.I.; Shah, N.P. Effect of Cysteine on the Viability of Yoghurt and Probiotic Bacteria in Yoghurts Made with Commercial Starter Cultures. Int. Dairy J. 1997, 7, 537–545. [Google Scholar] [CrossRef]

- Gomez, A.; Malcata, F. Bifidobacterium spp. and Lactobacillus acidophilus: Biological, biochemical, technological and therapeutical properties relevant for use as a probiotic. Trends Food Sci. Technol. 1999, 10, 139–157. [Google Scholar] [CrossRef]

- Reyns, K.M.F.A.; Sootjens, C.C.F.; Cornelis, K.; Weemars, C.A.; Hendrickx, M.E.; Michiels, C.W. Kinetics analysis and modeling of combined high–pressure–temperature inactivation of the yeast Zygosaccharomyces bailii. Int. J. Food Microbiol. 2000, 56, 199–210. [Google Scholar] [CrossRef]

- Godwart, G.; Kailasapathy, K. Viability and survival of free, encapsulated probiotic bacteria in yoghurt. Milchwissenschaft 2003, 58, 396–399. [Google Scholar]

- Yilmaztekin, M.; Özer, B.H.; Atasoy, F. Survival of Lactobacillus acidophilus LA-5 and Bifidobacterium bifidum BB-02 in white-brined cheese. Int. J. Food Sci. Nutr. 2004, 55, 53–60. [Google Scholar] [CrossRef]

- Özer, B.; Kirmaci, H.A.; Şenel, E.; Atamer, M.; Hayaloğlu, A. Improving the viability of Bifidobacterium bifidum BB-12 and Lactobacillus acidophilus LA-5 in white-brined cheese by microencapsulation. Int. Dairy J. 2009, 19, 22–29. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations/World Health Organization (FAO/WHO). Standard for Fermented Milks, Revised Standard. Codex Alimentarius. STAN 243-2003; Food and Agriculture Organization of the United Nations/World Health Organization: Rome, Italy, 2011. [Google Scholar]

- Senaka Ranadheera, C.; Evans, C.A.; Adams, M.C.; Baines, S.K. Probiotic viability and physico-chemical and sensory properties of plain and stirred fruit yogurts made from goat’s milk. Food Chem. 2012, 135, 1411–1418. [Google Scholar] [CrossRef]

- Jankowska, A.; Grześkiewicz, A.; Wiśniewska, K.; Reps, A. Application of probiotic bacteria in production of yoghurt preserved under high pressure. High Press. Res 2005, 25, 57–62. [Google Scholar] [CrossRef]

- Jankowska, A.; Grześkiewicz, A.; Wiśniewska, K.; Reps, A. Examining the possibilities of applying high pressure to preserve yoghurt supplemented with probiotic bacteria. High Press. Res. 2012, 32, 339–346. [Google Scholar] [CrossRef]

- Oey, I.; Lille, M.; Van Loey, A.; Hendrickx, M. Effect of high pressure processing on colour, texture and flavour of fruit and vegetable-based food products: A review. Trends Food Sci. Technol. 2008, 19, 320–328. [Google Scholar] [CrossRef]

- Barba, F.J.; Esteve, M.J.; Frigola, A. Physicochemical and nutritional characteristics of blueberry juice after high pressure processing. Food Res. Int. 2008, 50, 545–549. [Google Scholar] [CrossRef]

- Liu, X.; Powers, J.R.; Swanson, B.G.; Hill, H.H.; Clark, S. Modification of whey protein concentrate hydrophobicity by high hydrostatic pressure. Innov. Food Sci. Emerg. 2005, 6, 310–317. [Google Scholar] [CrossRef]

- Lee, W.; Clark, S.; Swanson, B.G. Functional properties of high hydrostatic pressure-treated whey protein. J. Food Process. Preserv. 2006, 30, 488–501. [Google Scholar] [CrossRef]

- Soukoulis, C.; Lyroni, E.; Tzia, C. Sensory profiling and hedonic judgement of probiotic ice cream as a function of hydrocolloids, yogurt and milk fat content. LWT-Food Sci. Technol. 2010, 43, 1351–1358. [Google Scholar] [CrossRef]

- Lesme, H.; Rannou, C.; Famelart, M.-H.; Bouhallab, S.; Prost, C. Yogurts enriched with milk proteins: Texture properties, aroma release and sensory perception. Trends Food Sci. Technol. 2020. [Google Scholar] [CrossRef]

- Tsevdou, M.; Soukoulis, C.; Cappellin, L.; Gasperi, F.; Taoukis, P.S.; Biasioli, F. Monitoring and Modeling of Endogenous Flavour Compounds Evolution during Fermentation of Thermally, High Hydrostatic Pressure or Transglutaminase Treated Milk using PTR-TOF-MS. Food Chem. 2013, 138, 2159–2167. [Google Scholar] [CrossRef]

- Soukoulis, C.; Cappellin, L.; Aprea, E.; Costa, F.; Viola, R.; Märk, T.D.; Gasperi, F.; Biasioli, F. PTR-ToF-MS, A Novel, Rapid, High Sensitivity and Non-Invasive Tool to Monitor Volatile Compound Release During Fruit Post-Harvest Storage: The Case Study of Apple Ripening. Food Bioprocess. Technol. 2013, 6, 2831–2843. [Google Scholar] [CrossRef]

| Decimal Reduction Times (D, min) of B. bifidum in pH 4.80 | |||||

| 20 °C | 25 °C | 30 °C | 35 °C | zT (°C) | |

| 100 MPa | 435 (±23) | 400 (± 19) | 263 (± 5.2) | 250 (± 7.3) | 62.2 (± 16) |

| 200 MPa | 313 (±9.0) | 40.3 (± 1.4) | 18.6 (± 2.0) | 16.2 (± 0.7) | 11.9 (± 3.2) |

| 300 MPa | 4.08 (±0.01) | 2.53 (± 0.04) | 1.43 (± 0.1) | 0.71 (± 0.06) | 19.8 (± 1.7) |

| 400 MPa | 0.25 (±0.03) | 0.27 (± 0.01) | 0.24 (± 0.01) | 0.11 (± 0.00) | 37.5 (± 3.4) |

| zP (MPa) | 90.9 (± 5.1) | ||||

| Decimal Reduction Times (D, min) of B. bifidum in pH 6.50 | |||||

| 25 °C | 30 °C | 35 °C | 40 °C | zT (°C) | |

| 100 MPa | - | 526 (± 15) | 333 (± 2.1) | 185 (± 9.0) | 22.1 (± 2.3) |

| 200 MPa | 303 (± 3.0) | 128 (± 10) | 108 (± 9.3) | 95.2 (± 7.0) | 78.4 (± 9.4) |

| 300 MPa | 38.6 (± 2.1) | 36.5 (± 1.9) | 35.2 (± 0.6) | 15.8 (± 2.0) | 39.7 (± 1.6) |

| 400 MPa | 6.47 (± 1.1) | 6.20 (± 0.9) | 2.22 (± 0.3) | 2.09 (± 0.4) | 28.9 (± 1.2) |

| zP (MPa) | 151 (± 8.0) | ||||

| Parameter | Estimated Value pH 4.80 | Estimated Value pH 6.50 |

|---|---|---|

| Pref (MPa) | 200 | 200 |

| Tref (°C) | 25 | 25 |

| Do (min) | 44.5 ± 6.39 | 281 ± 19.7 |

| zT (°C) | 5.91 ± 0.44 | 22.9 ± 3.50 |

| zP (MPa) | 90 (constant) | 140 (constant) |

| A (MPa−1) | 0.016 ± 0.002 | 0.002 ± 0.000 |

| R2 | 0.99 | 0.95 |

| Plain Yoghurt | ||||

|---|---|---|---|---|

| Control * | - | |||

| D + 1 | 8.9 ± 0.2 i | - | - | |

| D + 15 | 8.8 ± 0.1 hi | |||

| D + 28 | 8.7 ± 0.0 gh | |||

| HP | 100 MPa | 200 MPa | 300 MPa | 400 MPa |

| D + 1 | 8.7 ± 0.1 fgh | 8.7 ± 0.1 fgh | 8.4 ± 0.2 bcd | N.D. |

| D + 15 | 8.5 ± 0.1 defg | 8.2 ± 0.3 abc | 8.5 ± 0.1 def | N.D. |

| D + 28 | 8.5 ± 0.1 def | 8.2 ± 0.1 ab | 8.5 ± 0.1 def | N.D. |

| Homo-HP | 100 MPa | 200 MPa | 300 MPa | 400 MPa |

| D + 1 | 8.7 ± 0.2 gh | 8.6 ± 0.1 efgh | 8.6 ± 0.0 defgh | N.D. |

| D + 15 | 8.5 ± 0.0 defgh | 8.1 ± 0.1 a | 8.6 ± 0.0 defgh | N.D. |

| D + 28 | 8.4 ± 0.0 cde | 8.1 ± 0.1 a | 8.5 ± 0.1 defg | N.D. |

| Cherry-Flavored Yoghurt | - | - | - | |

| Control * | - | - | - | - |

| D + 1 | 8.8 ± 0.0 ij | - | - | - |

| D + 15 | 8.4 ± 0.0 bcd | |||

| D + 28 | 8.3 ± 0.1 bc | |||

| HP | 100 MPa | 200 MPa | 300 MPa | 400 MPa |

| D + 1 | 8.9 ± 0.0 j | 8.6 ± 0.0 fgh | 8.5 ± 0.1 cde | N.D. |

| D + 15 | 8.8 ± 0.1 ij | 8.2 ± 0.1 a | 8.3 ± 0.1 b | N.D. |

| D + 28 | 8.5 ± 0.0 def | 8.3 ± 0.1 bc | 8.5 ± 0.1 cde | N.D. |

| Homo-HP | 100 MPa | 200 MPa | 300 MPa | 400 MPa |

| D + 1 | 8.7 ± 0.1 hi | 8.7 ± 0.1 hi | 8.6 ± 0.1 fg | N.D. |

| D + 15 | 8.6 ± 0.0 gh | 8.5 ± 0.0 cde | 8.4 ± 0.0 bc | N.D. |

| D + 28 | 8.5 ± 0.1 efg | 8.3 ± 0.0 b | 8.2 ± 0.0 a | N.D. |

| Plain Yoghurt | ||||

| Control * | - | |||

| D + 1 | 8.2 ± 0.1 jk | - | - | |

| D + 15 | 8.3 ± 0.2 jk | |||

| D + 28 | 8.3 ± 0.1 k | |||

| HP | 100 MPa | 200 MPa | 300 MPa | 400 MPa |

| D + 1 | 8.1 ± 0.1 hijk | 7.9 ± 0.0 fghi | 6.8 ± 0.3 c | N.D. |

| D + 15 | 8.1 ± 0.1 ghijk | 7.8 ± 0.1 fg | 6.3 ± 0.1 ab | N.D. |

| D + 28 | 8.1 ± 0.1 ghijk | 7.8 ± 0.1 fgh | 6.1 ± 0.1 a | N.D. |

| Homo-HP | 100 MPa | 200 MPa | 300 MPa | 400 MPa |

| D + 1 | 8.1 ± 0.1 fghij | 8.0 ± 0.1 fghij | 7.1 ± 0.2 d | N.D. |

| D + 15 | 8.1 ± 0.0 ijk | 7.8 ± 0.3 f | 6.7 ± 0.1 c | N.D. |

| D + 28 | 8.1 ± 0.1 hijk | 7.4 ± 0.1 e | 6.5 ± 0.1 bc | N.D. |

| Cherry-Flavored Yoghurt | - | - | - | |

| Control * | - | - | - | - |

| D + 1 | 8.4 ± 0.0 e | - | - | - |

| D + 15 | 8.2 ± 0.0 d | |||

| D + 28 | 8.1 ± 0.1 d | |||

| HP | 100 MPa | 200 MPa | 300 MPa | 400 MPa |

| D + 1 | 8.2 ± 0.0 d | 7.9 ± 0.0 c | 6.5 ± 0.1 a | N.D. |

| D + 15 | 8.1 ± 0.0 d | 7.7 ± 0.0 bc | 6.5 ± 0.1 a | N.D. |

| D + 28 | 8.1 ± 0.1 d | 7.7 ± 0.1 bc | 6.5 ± 0.2 a | N.D. |

| Homo-HP | 100 MPa | 200 MPa | 300 MPa | 400 MPa |

| D + 1 | 8.2 ± 0.1 d | 7.8 ± 0.0 c | 6.6 ± 0.2 a | N.D. |

| D + 15 | 8.2 ± 0.0 d | 7.8 ± 0.0 c | 6.4 ± 0.2 a | N.D. |

| D + 28 | 8.1 ± 0.1 d | 7.6 ± 0.1 b | 6.4 ± 0.1 a | N.D. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsevdou, M.; Ouli-Rousi, M.; Soukoulis, C.; Taoukis, P. Impact of High-Pressure Process on Probiotics: Viability Kinetics and Evaluation of the Quality Characteristics of Probiotic Yoghurt. Foods 2020, 9, 360. https://doi.org/10.3390/foods9030360

Tsevdou M, Ouli-Rousi M, Soukoulis C, Taoukis P. Impact of High-Pressure Process on Probiotics: Viability Kinetics and Evaluation of the Quality Characteristics of Probiotic Yoghurt. Foods. 2020; 9(3):360. https://doi.org/10.3390/foods9030360

Chicago/Turabian StyleTsevdou, Maria, Maria Ouli-Rousi, Christos Soukoulis, and Petros Taoukis. 2020. "Impact of High-Pressure Process on Probiotics: Viability Kinetics and Evaluation of the Quality Characteristics of Probiotic Yoghurt" Foods 9, no. 3: 360. https://doi.org/10.3390/foods9030360

APA StyleTsevdou, M., Ouli-Rousi, M., Soukoulis, C., & Taoukis, P. (2020). Impact of High-Pressure Process on Probiotics: Viability Kinetics and Evaluation of the Quality Characteristics of Probiotic Yoghurt. Foods, 9(3), 360. https://doi.org/10.3390/foods9030360