Characterisation of Formaggella della Valle di Scalve Cheese Produced from Cows Reared in Valley Floor Stall or in Mountain Pasture: Fatty Acids Profile and Sensory Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Design and Sampling Procedure

2.2. Analyses

2.2.1. Gross Composition and Fatty Acids

2.2.2. Sensory Analysis

2.2.3. Volatile Organic Compound (VOC) analysis

2.3. Statistical Analysis

3. Results and Discussion

3.1. Gross Composition of Formaggella della Valle di Scalve

3.2. Fatty Acids

3.2.1. Comparison among Cheese Produced during Summer Season

3.2.2. Comparison between Cheeses Produced in Winter Season

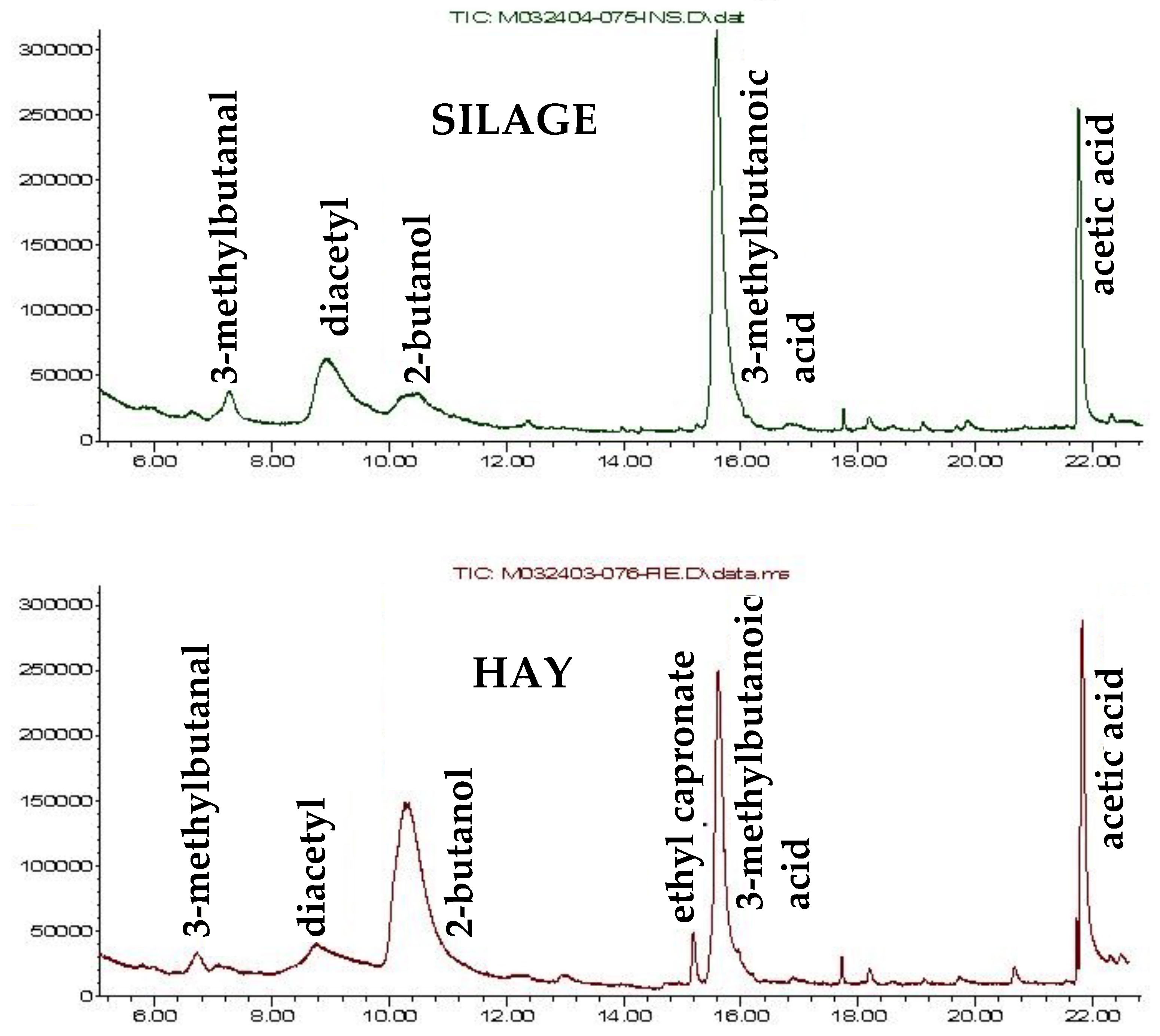

3.3. Sensory and VOC Analyses: Comparison between Cheeses Obtained from Cows Fed Hay and Silage at 30 Days of Ripening

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Romanzin, A.; Corazzin, M.; Piasentier, E.; Bovolenta, S. Effect of rearing system (mountain pasture vs. indoor) of Simmental cows on milk composition and Montasio cheese characteristics. J. Dairy Res. 2013, 80, 390–399. [Google Scholar] [CrossRef] [PubMed]

- Bovolenta, S.; Corazzin, M.; Saccà, E.; Gasperi, F.; Biasioli, F.; Ventura, W. Performance and cheese quality of Brown cows grazing on mountain pasture fed two different levels of supplementation. Livest. Sci. 2009, 124, 58–65. [Google Scholar] [CrossRef]

- Fallico, V.; Chianese, L.; Carpino, S.; Licitra, G. Preliminary evaluation of the influence of pasture feeding on proteolysis of Ragusano cheese. J. Food Technol. 2006, 4, 128–134. [Google Scholar]

- Urbach, G. Effect of feed on flavor in dairy foods. J. Dairy Sci. 1990, 73, 3639–3650. [Google Scholar] [CrossRef]

- Grappin, R.; Beuvier, E. Possible implications of milk pasteurization on the manufacture and sensory quality of ripened cheese. Int. Dairy J. 1997, 7, 751–761. [Google Scholar] [CrossRef]

- Buchin, S.; Delague, V.; Duboz, G.; Berdagué, J.L.; Beuvier, E.; Pochet, S.; Grappin, R. Influence of pasteurization and fat composition of milk on the volatile compounds and flavour characteristics of a semi-hard cheese. J. Dairy Sci. 1998, 81, 3097–3108. [Google Scholar] [CrossRef]

- Malossini, F.; Bovolenta, S.; Piras, C.; Ventura, W. Effect of concentrate supplementation on herbage intake and milk yield of dairy cows grazing an alpine pasture. Livest. Prod. Sci. 1995, 43, 119–128. [Google Scholar] [CrossRef]

- Berry, N.R.; Bueler, T.; Jewell, P.L.; Sutter, F.; Kreuzer, M. The effect of supplementary feeding on composition and renneting properties of milk from cows rotationally grazed at high altitude. Milchwissenschaft 2001, 56, 123–126. [Google Scholar]

- Bugaud, C.; Buchin, S.; Coulon, J.B.; Hauwuy, A.; Dupont, D. Influence of the nature of alpine pastures on plasmin activity, fatty acid and volatile compound composition of milk. Lait 2001, 81, 401–414. [Google Scholar] [CrossRef]

- Panthi, R.R.; Kelly, A.L.; Hennessy, D.; O’Sullivan, M.G.; Kilcawley, K.N.; Mannion, D.T.; Fenelon, M.A.; Sheehan, J.J. Effect of pasture versus indoor feeding regimes on the yield, composition, ripening and sensory characteristics of Maasdam cheese. Int. J. Dairy Technol. 2019, 72, 435–446. [Google Scholar] [CrossRef]

- Coulon, J.-B.; Verdier, I.; Pradel, P. Effect of forage type (hay or grazing) on milk cheesemaking ability. Lait 1996, 76, 479–486. [Google Scholar] [CrossRef]

- Verdier-Metz, I.; Coulon, J.-B.; Pradel, P.; Viallon, C.; Berdagué, J.-L. Effect of forage conservation (hay or silage) and cow breed on the coagulation properties of milks and on the characteristics of ripened cheeses. J. Dairy Res. 1998, 65, 9–21. [Google Scholar] [CrossRef]

- Viallon, C.; Verdier-Metz, I.; Denoyer, C.; Pradel, P.; Coulon, J.B.; Berdagué, J.-L. Desorbed terpenes and sesquiterpenes from forages and cheeses. J. Dairy Res. 1999, 66, 319–326. [Google Scholar] [CrossRef]

- Coppa, M.; Ferlay, A.; Monsallier, F.; Verdier-Metz, I.; Pradel, P.; Didienne, R.; Farruggia, A.; Montel, M.C.; Martin, B. Milk fatty acid composition and cheese texture and appearance from cows fed hay or different grazing systems on upland pastures. J. Dairy Sci. 2011, 94, 1132–1145. [Google Scholar] [CrossRef] [Green Version]

- Martin, B.; Verdier-Metz, I.; Buchin, S.; Hurtaud, C.; Coulon, J.B. How does the nature of forages and pastures diversity influence the sensory quality of dairy livestock products? Anim. Sci. 2005, 81, 205–212. [Google Scholar] [CrossRef]

- Dumont, J.P.; Adda, J. Occurrence of sesqiterpenes in mountain cheese volatiles. J. Agric. Food Chem. 1978, 26, 364–367. [Google Scholar] [CrossRef]

- Bugaud, C.; Buchin, S.; Hauwuy, A.; Coulon, J.B. Relationships between flavour and chemical composition of Abundance cheese derived from different types of pastures. Lait 2001, 81, 757–773. [Google Scholar] [CrossRef]

- Carpino, S.; Mallia, S.; La Terra, S.; Melilli, C.; Licitra, G.; Acree, T.E.; Barbano, D.M.; Van Soest, P.J. Composition and aroma compounds of Ragusano cheese: Native pasture and total mixed rations. J. Dairy Sci. 2004, 87, 816–830. [Google Scholar] [CrossRef]

- Carpino, S.; Horne, J.; Melilli, C.; Licitra, G.; Barbano, D.M.; Van Soest, P.J. Contribution of native pasture to the sensory properties of Ragusano cheese. J. Dairy Sci. 2004, 86, 308–315. [Google Scholar] [CrossRef]

- Kosikowski, F.V.; Mistry, V.V. Cheese and Fermented Milk Foods. Volume 1: Origins and Principles; Kosikowski, F.V., Ed.; LLC: Westport, CT, USA, 1997; Volume 1, p. 379. [Google Scholar]

- Panfili, G.; Manzi, P.; Pizzoferrato, L. High-performance liquid chromatographic method for the simultaneous determination of tocopherols, carotenes, and retinol and its geometric Isomers in Italian cheeses. Analyst 1994, 119, 1161–1165. [Google Scholar] [CrossRef]

- Kilcawley, K.N.; Faulkner, H.; Clarke, H.J.; O’Sullivan, M.G.; Kerry, J.P. Factors influencing the flavour of bovine milk and cheese from grass based versus non-grass based milk production systems. Foods 2018, 7, 37. [Google Scholar] [CrossRef] [Green Version]

- Nozière, P.; Graulet, B.; Lucas, A.; Martin, B.; Grolier, P.; Doreau, M. Carotenoids for ruminants: From forages to dairy products. Anim. Feed Sci. Technol. 2006, 131, 418–450. [Google Scholar] [CrossRef]

- Frétin, M.; Martin, B.; Buchin, S.; Desserre, B.; Lavigne, R.; Tixier, E.; Cirié, C.; Cord, C.; Montel, M.-C.; Delbés, C.; et al. Milk fat composition modifies the texture and appearance of Cantal-type cheeses but not their flavor. J. Dairy Sci. 2019, 102, 1131–1143. [Google Scholar] [CrossRef] [Green Version]

- Corazzin, M.; Romanzin, A.; Sepulcri, A.; Pinosa, M.; Piasentier, E.; Bovolenta, S. Fatty acid profiles of cow’s milk and cheese as affected by mountain pasture type and concentrate supplementation. Animals 2019, 9, 68. [Google Scholar] [CrossRef] [Green Version]

- White, S.L.; Bertrand, J.A.; Wade, M.R.; Washburn, S.P.; Green, J.T.; Jenkins, T.C. Comparison of fatty acid content of milk from Jersey and Holstein cows consuming pasture or a total mixed ration. J. Dairy Sci. 2001, 84, 2295–2301. [Google Scholar] [CrossRef]

- Chilliard, Y.; Glasser, F.; Ferlay, A.; Bernard, L.; Rouel, J.; Doreau, M. Diet, rumen biohydrogenation and nutritional quality of cow and goat milk fat. Eur. J. Lipid Sci. Technol. 2007, 109, 828–855. [Google Scholar] [CrossRef]

- Slots, T.; Butler, G.; Leifert, C.; Kristensen, T.; Skibsted, L.H.; Nielsen, J.N. Potential to differentiate milk composition by different feeding strategies. J. Dairy Sci. 2009, 92, 2057–2066. [Google Scholar] [CrossRef] [Green Version]

- De Noni, I.; Battelli, G. Terpenes and fatty acid profiles of milk fat and “Bitto” cheese as affected by transhumance of cows on different mountain pastures. Food Chem. 2008, 109, 299–309. [Google Scholar] [CrossRef]

- Revello Chion, A.; Tabacco, E.; Giaccone, D.; Peiretti, P.G.; Battelli, G.; Borreani, G. Variation of fatty acid and terpene profiles in mountain milk and “Toma piemontese” cheese as affected by diet composition in different seasons. Food Chem. 2010, 121, 393–399. [Google Scholar] [CrossRef]

- Povolo, M.; Pelizzola, V.; Lombardi, G.; Tava, A.; Contarini, G. Hydrocarbon and fatty acid composition of cheese as affected by the pasture vegetation type. J. Agric. Food Chem. 2012, 60, 299–308. [Google Scholar] [CrossRef] [Green Version]

- Tanaka, K. Occurrence of conjugated linoleic acid in ruminant products and its physiological functions. Anim. Sci. J. 2005, 76, 291–303. [Google Scholar] [CrossRef]

- Dewhurst, R.J.; Shingfield, K.J.; Lee, M.R.F.; Scollan, N.D. Increasing the concentrations of beneficial polyunsaturated fatty acids in milk produced by dairy cows in high-forage systems. Anim. Feed Sci. Technol. 2006, 131, 168–206. [Google Scholar] [CrossRef]

- Summer, A.; Formaggioni, P.; Franceschi, P.; Di Frangia, F.; Righi, F.; Malacarne, M. Cheese as functional food: The example of Parmigiano Reggiano and Grana Padano. Food Technol. Biotechnol. 2017, 55, 277–289. [Google Scholar] [CrossRef]

- Copani, V.; Guarnaccia, P.; Biondi, L.; Lesina, S.C.; Longo, S.; Testa, G.; Cosentino, S.L. Pasture quality and cheese traceability index of Ragusano PDO cheese. Ital. J. Agron. 2015, 10, 667. [Google Scholar] [CrossRef] [Green Version]

- IDF Standard. Milk and Milk Products, Determination of Fat Content, General Guidance on the Use of Butyrometric Methods; International Dairy Federation Standard 152/ISO11870: Brussels, Belgium, 2009. [Google Scholar]

- Formaggioni, P.; Summer, A.; Malacarne, M.; Franceschi, P.; Mucchetti, G. Italian and Italian-style hard cooked cheeses: Predictive formulas for Parmigiano-Reggiano 24 h cheese yield. Int. Dairy J. 2015, 51, 52–58. [Google Scholar] [CrossRef]

- Malacarne, M.; Summer, A.; Franceschi, P.; Formaggioni, P.; Pecorari, M.; Panari, G.; Mariani, P. Free fatty acid profile of Parmigiano-Reggiano cheese throughout ripening: Comparison between the inner and outer regions of the wheel. Int. Dairy J. 2009, 19, 637–641. [Google Scholar] [CrossRef]

- IDF Standard. Milk, Determination of Nitrogen Content, Part 1: Kjeldahl Method; International Dairy Federation Standard 20-1/ISO8968-1: Brussels, Belgium, 2001. [Google Scholar]

- IDF Standard. Cheese and Processed Cheese Products, Determination of Chloride Content, Potentiometric Titration Method; International Dairy Federation Standard 88/ISO5943: Brussels, Belgium, 2006. [Google Scholar]

- IDF Standard. Cheese and Processed Cheese, Determination of the Total Solids Content (Reference Method); International Dairy Federation Standard 4/ISO5534: Brussels, Belgium, 2004. [Google Scholar]

- Association of Official Analytical Chemists [AOAC]. AOAC Official Method no. 996.06. Fat (total, saturated, and unsaturated) in foods; hydrolytic extraction gas chromatographic method. In Official Methods of Analysis of AOAC International, 17th ed.; Horwitz, W., Ed.; AOAC International: Gaithersburg, MD, USA, 2000; pp. 20–24. [Google Scholar]

- Association of Official Analytical Chemists [AOAC]. Fat in milk: Modified Mojonnier ether extraction method. In Official Methods of Analysis of AOAC International; Heldrich, K., Ed.; AOAC International: Arlington, VA, USA, 1990; pp. 811–812. [Google Scholar]

- AOCS. Official Method CE 2-66. Preparation of methyl esters of fatty acids. In Official Methods and Recommended Practices of the AOCS, 6th ed.; Firestone, D., Ed.; AOCS Press: Urbana, IL, USA, 2013. [Google Scholar]

- ISO Standard. Sensory Analysis, Methodology, Triangle Test; International Organization for Standardization Standard ISO4120: Genève, Switzerland, 2004; 15p. [Google Scholar]

- Battelli, G.; Scano, P.; Albano, C.; Cagliani, L.R.; Brasca, M.; Consonni, R. Modifications of the volatile and nonvolatile metabolome of goat cheese due to adjunct of non-starter lactic acid bacteria. LWT 2019, 116, 108576. [Google Scholar] [CrossRef]

- Summer, A.; Franceschi, P.; Formaggioni, P.; Malacarne, M. Characteristics of raw milk produced by free-stall or tie-stall cattle herds in the Parmigiano-Reggiano cheese production area. Dairy Sci. Technol. 2014, 94, 581–590. [Google Scholar] [CrossRef] [Green Version]

- Summer, A.; Lora, I.; Formaggioni, P.; Gottardo, F. Impact of heat stress on milk and meat production. Anim. Front. 2019, 9, 39–46. [Google Scholar] [CrossRef]

- Esposito, G.; Masucci, F.; Napolitano, F.; Braghieri, A.; Romano, R.; Manzo, N.; Di Francia, A. Fatty acid and sensory profiles of Caciocavallo cheese as affected by management system. J. Dairy Sci. 2014, 97, 1918–1928. [Google Scholar] [CrossRef] [Green Version]

- Dhiman, T.R.; Helmink, E.D.; McMahon, D.J.; Fife, R.L.; Pariza, M.W. Conjugated linoleic acid content of milk and cheese from cows fed extruded oilseeds. J. Dairy Sci. 1999, 82, 412–419. [Google Scholar] [CrossRef]

- Carafa, I.; Stocco, G.; Franceschi, P.; Summer, A.; Tuohy, K.M.; Bittante, G.; Franciosi, E. Evaluation of autochthonous lactic acid bacteria as starter and non-starter cultures for the production of Traditional Mountain cheese. Food Res. Int. 2019, 115, 209–218. [Google Scholar] [CrossRef]

- Povolo, M.; Pelizzola, V.; Passolungo, L.; Biazzi, E.; Tava, A.; Contarini, G. Characterization of two agrostis-festuca alpine pastures and their influence on cheese composition. J. Agric. Food Chem. 2013, 61, 447–455. [Google Scholar] [CrossRef]

- Ferlay, A.; Bernard, L.; Meynadier, A.; Malpuech-Brugere, C. Production of trans and conjugated fatty acids in dairy ruminants and their putative effects on human health: A review. Biochimie 2017, 141, 107–120. [Google Scholar] [CrossRef]

- Collomb, M.; Schmid, A.; Sieber, R.; Wechsler, D.; Ryhänen, E.L. Conjugated linoleic acids in milk fat: Variation and physiological effects. Int. Dairy J. 2006, 16, 1347–1361. [Google Scholar] [CrossRef]

- Innocente, N.; Praturlon, D.; Corradini, C. Fatty acid profile of cheese produced with milk from cows grazing on mountain pastures. Ital. J. Food Sci. 2002, 14, 217–224. [Google Scholar]

- Lobos-Ortega, I.; Revilla, I.; González-Martín, M.I.; Hernández-Hierro, J.M.; Vivar-Quintana, A.; González-Pérez, G. Conjugated linoleic acid contents in cheeses of different compositions during six months of ripenin. Czech J. Food Sci. 2012, 30, 220–226. [Google Scholar] [CrossRef] [Green Version]

- Coppa, M.; Verdier-Metz, I.; Ferlay, A.; Pradel, P.; Didienne, R.; Farruggia, A.; Monte, M.C.; Martin, B. Effect of different grazing systems on upland pastures compared with hay diet on cheese sensory properties evaluated at different ripening times. Int. Dairy J. 2011, 21, 815–822. [Google Scholar] [CrossRef]

- Chilliard, Y.; Ferlay, A.; Doreau, M. Effect of different types of forages, animal fat or marine oils in cow’s diet on milk fat secretion and composition, especially conjugated linoleic acid (CLA) and polyunsaturated fatty acids. Livest. Prod. Sci. 2001, 70, 31–48. [Google Scholar] [CrossRef]

- Collomb, M.; Bisig, W.; Bütikofer, U.; Sieber, R.; Bregy, M.; Etter, L. Fatty acid composition of mountains milk from Switzerland: Comparison of organic and integrated farming systems. Int. Dairy J. 2008, 18, 976–982. [Google Scholar] [CrossRef]

- Bouterfa, A.; Bekada, A.; Homrani, A.; Benguendouz, A.; Homrani, A.; Amrane, A.; Zribi, A.; Benakriche, B.; Dahloum, E.H.; Benabdelmoumene, D.; et al. Influence of lactation stage on lipids and fatty acids profile of artisanal Algerian Camembert-type cheese manufactured with cow’s milk. South Asian J. Exp. Biol. 2019, 9, 17–22. [Google Scholar]

- Di Grigoli, A.; Bonanno, A.; Cifuni, G.; Tornambé, G.; Alicata, M. Effetto del regime alimentare delle bovine sulla composizione in acidi grassi del formaggio Caciocavallo Palermitano. Sci. E Tec. Latt. Casearia 2008, 59, 457–461. [Google Scholar]

- Prandini, A.; Sigolo, S.; Cerioli, C.; Piva, G. Survey on conjugated linoleic acid (CLA) content and fatty acid composition of Grana Padano cheese produced in different seasons and areas. Ital. J. Anim. Sci. 2009, 8, 531–540. [Google Scholar] [CrossRef] [Green Version]

- Leiber, F.; Kreuzer, M.; Nigg, D.; Wettstein, H.R.; Scheeder, M.R.L. A study on the causes for the elevated n-3 fatty acids in cows’ milk of alpine origin. Lipids 2005, 40, 191–202. [Google Scholar] [CrossRef]

- Schwendel, B.H.; Morel, P.C.H.; Wester, T.J.; Tavendale, M.H.; Deadman, C.; Fong, B.; Shadbolt, N.M.; Thatcher, A.; Otter, D.E. Fatty acid profile differs between organic and conventionally produced cow milk independent of season or milking time. J. Dairy Sci. 2015, 98, 1411–1425. [Google Scholar] [CrossRef] [Green Version]

- Nagpal, R.; Yadav, H.; Puniya, A.K.; Singh, K.; Jain, S.; Marotta, F. Conjugated linoleic acid: Sources, synthesis and potential health benefits—An overview. Curr. Top. Nutraceut. Res. 2007, 5, 55–65. [Google Scholar]

- Lee, Y.J.; Jenkins, T.C. Biohydrogenation of linolenic acid to stearic acid by the rumen microbial population yields multiple intermediate conjugated diene isomers. J. Nutr. 2011, 141, 1445–1450. [Google Scholar] [CrossRef] [Green Version]

- Nudda, A.; McGuire, M.A.; Battacone, G.; Pulina, G. Seasonal variation in conjugated linoleic acid and vaccenic acid in milk fat of sheep and its transfer to cheese and ricotta. J. Dairy Sci. 2005, 88, 1311–1319. [Google Scholar] [CrossRef] [Green Version]

- Meluchová, B.; Blasko, J.; Kubinec, R.; Górová, R.; Dubravská, J.; Margetín, M.; Soják, L. Seasonal variations in fatty acid composition of pasture forage plants and cla content in ewe milk fat. Small Rumin. Res. 2008, 78, 56–65. [Google Scholar] [CrossRef]

- Cozzi, G.; Ferlito, J.; Pasini, G.; Contiero, B.; Gottardo, F. Application of near-infrared spectroscopy as an alternative to chemical and color analysis to discriminate the production chains of Asiago d’Allevo cheese. J. Agric. Food Chem. 2009, 57, 11449–11454. [Google Scholar] [CrossRef]

- Butler, G.; Nielsen, J.H.; Slots, T.; Seal, C.; Eyre, M.D.; Sanderson, R.; Leifert, C. Fatty acid and fat-soluble antioxidant concentrations in milk from high- and low-input conventional and organic system: Seasonal variation. J. Sci. Food Agric. 2008, 88, 1431–1441. [Google Scholar] [CrossRef]

- Zeppa, G.; Giordano, M.; Gerbi, V.; Arlorio, M. Fatty acid composition of Piedmont “Ossolano” cheese. Lait 2003, 83, 167–173. [Google Scholar] [CrossRef] [Green Version]

- Jahangiri, A.; Leifert, W.R.; McMurchie, E.J. Omega-3 polyunsaturated fatty acids: Recent aspects in relation to health benefits. Food Aust. 2002, 54, 74–77. [Google Scholar]

- Segato, S.; Galaverna, G.; Contiero, B.; Berzaghi, P.; Caligiani, A.; Marseglia, A.; Cozzi, G. Identification of lipid biomarkers to discriminate between the different production systems for Asiago PDO cheese. J. Agric. Food Chem. 2017, 65, 9887–9892. [Google Scholar] [CrossRef]

- Renes, E.; Gómez-Cortés, P.; de la Fuente, M.A.; Fernández, D.; Tornadijo, M.E.; Fresno, J.M. Effect of forage type in the ovine diet on the nutritional profile of sheep milk cheese fat. J. Dairy Sci. 2020, 103, 63–71. [Google Scholar] [CrossRef] [Green Version]

- Schingoethe, D.J.; Voelker, H.H.; Beardsley, G.L.; Parsons, J.G. Rumen volatile fatty acids and milk composition from cows fed hay, haylage, or urea-treated corn silage. J. Dairy Sci. 1976, 59, 894–901. [Google Scholar] [CrossRef]

- Abbey, M.; Nestel, P.J. Plasma cholesteryl ester transfer protein is increased when trans-elaidic acid is substituted for cis-oleic acid in the diet. Atherosclerosis 1994, 106, 99–107. [Google Scholar] [CrossRef]

- Vlaeminck, B.; Fievez, V.; Cabrita, A.R.J.; Fonseca, A.J.M.; Dewhurst, R.J. Factors affecting odd and branched-chain fatty acids in milk: A review. Anim. Feed Sci. Technol. 2006, 131, 389–417. [Google Scholar] [CrossRef]

- Bills, D.D.; Morgan, M.E.; Libbey, M.N.; Day, E.A. Identification of compounds responsible for fruity flavor defect of experimental Cheddar cheeses. J. Dairy Sci. 1965, 48, 1168–1173. [Google Scholar] [CrossRef]

- Mc Gugan, W.A.; Blais, J.A.; Boulet, M.; Giroux, R.N.; Elliott, J.A.; Emmons, D.B. Ethanol, ethyl esters, and volatile fatty acids in fruity Cheddar cheese. Can. Inst. Food Sci. Technol. J. 1975, 8, 196–198. [Google Scholar] [CrossRef]

- Lethuaut, L.; Brossard, C.; Meynier, A.; Rousseau, F.; Llamas, G.; Bousseau, B.; Genot, C. Sweetness and aroma perceptions in dairy desserts varying in sucrose and aroma levels and in textural agent. Int. Dairy J. 2005, 15, 485–493. [Google Scholar] [CrossRef]

- Garel, J.P.; Coulon, J.-B. Effect of feeding and breed of dairy cows on Saint-Nectaire cheesemaking. INRA Prod. Anim. 1990, 3, 127–136. [Google Scholar]

- Biede, S.L.; Hammond, G. Swiss cheese favor. II. Organoleptic analysis. J. Dairy Sci. 1979, 62, 238–248. [Google Scholar] [CrossRef]

| Gross Composition on 100 of Cheese | Gross Composition on 100g of Dry Matter | ||||

|---|---|---|---|---|---|

| Mean | SD | Mean | SD | ||

| Winter: | |||||

| Moisture | g/100g | 42.48 | 3.56 | - | - |

| Protein | g/100g | 25.60 | 0.80 | 44.64 | 3.16 |

| Fat | g/100g | 25.58 | 4.26 | 44.25 | 4.98 |

| Ash | g/100g | 4.04 | 0.16 | 7.05 | 0.71 |

| NaCl | g/100g | 1.61 | 0.21 | 2.82 | 0.50 |

| Summer: | |||||

| Moisture | g/100g | 44.63 | 2.88 | - | - |

| Protein | g/100g | 24.35 | 1.70 | 44.08 | 3.91 |

| Fat | g/100g | 27.24 | 2.95 | 49.12 | 1.27 |

| Ash | g/100g | 3.59 | 0.63 | 6.49 | 1.08 |

| NaCl | g/100g | 1.47 | 0.34 | 2,65 | 0.59 |

| Stall | Valley Pasture | Mountain Pasture | p | |||||

|---|---|---|---|---|---|---|---|---|

| Number of Observations | 5 | 5 | 5 | |||||

| C4—Butiric | % | 2.28 ± 1.15 | 2.25± 0.48 | 2.77 ± 0.92 | NS | |||

| C6—Capronic | % | 1.74 ± 0.86 | 1.55 ± 0.26 | 1.49 ± 0.32 | NS | |||

| C8—Caprilic | % | 1.26 ± 0.52 | 1.04 ± 0.14 | 0.86 ± 0.14 | NS | |||

| C10—Caprinic | % | 3.28 ± 0.97 | b | 2.43 ± 0.30 | ab | 1.83 ± 0.17 | a | * |

| C10:1—Decenoic | % | 0.32 ± 0.12 | 0.26 ± 0.05 | 0.21 ± 0.04 | NS | |||

| C12—Lauric | % | 3.92 ± 0.69 | b | 2.93 ± 0.33 | a | 2.30 ± 0.14 | a | ** |

| C12:1—Lauroleic | % | 0.12 ± 0.02 | b | 0.09 ± 0.02 | a | 0.07 ± 0.02 | a | * |

| C13—Tridecanoic | % | 0.14 ± 0.02 | b | 0.10 ± 0.02 | a | 0.10 ± 0.03 | ab | * |

| C14—Myristic | % | 12.79 ± 0.95 | c | 10.91 ± 0.73 | b | 9.57 ± 0.33 | a | *** |

| C14:1—Myristoleic | % | 1.02 ± 0.12 | b | 0.90 ± 0.14 | ab | 0.80 ± 0.06 | a | * |

| C15—Pentadecanoic | % | 1.31 ± 0.06 | 1.37 ± 0.03 | 1.28 ± 0.12 | NS | |||

| C16—Palmitic | % | 30.58 ± 1.86 | b | 27.44 ± 1.12 | a | 26.64 ± 2.29 | a | * |

| C16:1—Palmitoleic | % | 1.29 ± 0.04 | 1.28 ± 0.07 | 1.26 ± 0.11 | NS | |||

| C17—Eptadecanoic | % | 0.82 ± 0.04 | 0.85 ± 0.07 | 0.87 ± 0.08 | NS | |||

| C17:1—Eptadecenoic | % | 0.25 ± 0.05 | 0.25 ± 0.04 | 0.28 ± 0.03 | NS | |||

| C18—Stearic | % | 10.31 ± 1.21 | a | 12.15 ± 0.98 | b | 13.57 ± 0.53 | b | ** |

| C18:1—Elaidic t-9 | % | 0.50 ± 0.13 | 0.70 ± 0.26 | 0.73 ± 0.33 | NS | |||

| C18:1—Vaccenic t-11 | % | 1.89 ± 0.40 | a | 4.29 ± 0.48 | b | 3.49 ± 0.78 | b | *** |

| C18:1—Oleic | % | 20.63 ± 2.54 | a | 22.70 ± 0.80 | a | 26.03 ± 1.25 | b | ** |

| C18:1—Vaccenic c-11 | % | 0.41 ± 0.07 | 0.41 ± 0.05 | 0.46 ± 0.05 | NS | |||

| C18:2—Linoelaidic t-6 | % | 0.20 ± 0.02 | 0.23 ± 0.01 | 0.21 ± 0.03 | NS | |||

| C18:2—Linoleic | % | 2.62 ± 0.43 | 2.26 ± 0.17 | 2.19 ± 0.69 | NS | |||

| C20—Arachidic | % | 0.18 ± 0.03 | a | 0.20 ± 0.02 | a | 0.25 ± 0.05 | b | * |

| C20:1—Eicosenoic | % | 0.06 ± 0.01 | ab | 0.04 ± 0.01 | a | 0.07 ± 0.01 | b | * |

| C18:3—α-linolenic | % | 0.78 ± 0.07 | a | 1.02 ± 0.07 | b | 0.83 ± 0.21 | a | * |

| C18:2—Rumenic c9,t11 CLA | % | 0.78 ± 0.26 | a | 1.82 ± 0.18 | b | 1.49 ± 0.26 | b | *** |

| C18:2—t10-c12 CLA | % | 0.02 ± 0.03 | 0.04 ± 0.06 | 0.03 ± 0.03 | NS | |||

| SCFA—short chain FA | % | 8.97 ± 3.49 | 7.58 ± 1.04 | 7.18 ± 1.44 | NS | |||

| MCFA—middle chain FA | % | 51.17 ± 2.26 | b | 45.01 ± 2.02 | a | 42.02 ± 2.52 | a | *** |

| LCFA—long chain FA | % | 39.84 ± 4.10 | a | 47.37 ± 2.29 | b | 50.82 ± 1.30 | b | *** |

| OCFA—odd FA | % | 2.69 ± 0.20 | 2.67 ± 0.23 | 2.61 ± 0.23 | NS | |||

| MUFA—monounsaturated FA | % | 26.47 ± 2.52 | a | 30.93 ± 0.99 | b | 33.38 ± 1.57 | b | *** |

| PUFA—polyunsaturated FA | % | 4.66 ± 0.42 | a | 5.62 ± 0.25 | b | 4.96 ± 0.78 | ab | * |

| UFA—unsaturated FA | % | 31.13 ± 2.86 | a | 36.55 ± 1.11 | b | 38.34 ± 0.94 | b | *** |

| SFA—saturated FA | % | 68.85 ± 2.84 | b | 63.41 ± 1.10 | a | 61.68 ± 0.91 | a | *** |

| CLA (conjug. linoleic acids) | % | 0.80 ± 0.28 | a | 1.86 ± 0.21 | b | 1.52 ± 0.27 | b | *** |

| Omega 3 FA | % | 0.83 ± 0.12 | a | 1.09 ± 0.14 | b | 0.86 ± 0.22 | ab | * |

| Omega 6 FA | % | 2.83 ± 0.49 | 2.44 ± 0.21 | 2.37 ± 0.77 | NS | |||

| Silage (I) | Hay (F) | p | ||||

|---|---|---|---|---|---|---|

| Number of Observations | 3 | 3 | ||||

| C4—Butiric | % | 2.85 ± 1.33 | 2.27 ± 0.20 | NS | ||

| C6—Capronic | % | 2.19 ± 1.14 | 1.58 ± 0.36 | NS | ||

| C8—Caprilic | % | 1.52 ± 0.72 | 1.04 ± 0.25 | NS | ||

| C10—Caprinic | % | 3.75 ± 1.35 | 2.53 ± 0.44 | NS | ||

| C10:1—Decenoic | % | 0.41 ± 0.14 | b | 0.26 ± 0.01 | a | * |

| C12—Lauric | % | 4.33 ± 0.90 | 3.21 ± 0.24 | NS | ||

| C12:1—Lauroleic | % | 0.14 ± 0.01 | 0.11 ± 0.03 | NS | ||

| C13—Tridecanoic | % | 0.14 ± 0.01 | 0.12 ± 0.02 | NS | ||

| C14—Myristic | % | 13.22 ± 0.82 | b | 12.18 ± 0.31 | a | * |

| C14:1—Myristoleic | % | 1.15 ± 0.09 | b | 0.94 ± 0.14 | a | * |

| C15—Pentadecanoic | % | 1.30 ± 0.05 | a | 1.42 ± 0.08 | b | * |

| C16—Palmitic | % | 31.29 ± 2.64 | 32.99 ± 2.99 | NS | ||

| C16:1—Palmitoleic | % | 1.31 ± 0.02 | 1.52 ± 0.24 | NS | ||

| C17—Eptadecanoic | % | 0.79 ± 0.10 | a | 0.96 ± 0.02 | b | * |

| C17:1—Eptadecenoic | % | 0.23 ± 0.08 | a | 0.35 ± 0.06 | b | * |

| C18—Stearic | % | 9.02 ± 1.15 | a | 10.81 ± 0.96 | b | * |

| C18:1—Elaidic t-9 | % | 0.68 ± 0.06 | b | 0.48 ± 0.03 | a | ** |

| C18:1—Vaccenic t-11 | % | 1.28 ± 0.24 | a | 1.83 ± 0.17 | b | ** |

| C18:1—Oleic | % | 19.45 ± 1.74 | 20.87 ± 0.35 | NS | ||

| C18:1—Vaccenic c-11 | % | 0.40 ± 0.08 | 0.46 ± 0.02 | NS | ||

| C18:2—Linoelaidic t-6 | % | 0.20 ± 0.01 | a | 0.25 ± 0.02 | b | ** |

| C18:2—Linoleic | % | 2.55 ± 0.20 | b | 1.87 ± 0.17 | a | ** |

| C20—Arachidic | % | 0.16 ± 0.03 | a | 0.21 ± 0.01 | b | * |

| C18:3—α-linolenic | % | 0.87 ± 0.07 | 0.76 ± 0.08 | NS | ||

| C18:2—Rumenic c9,t11 CLA | % | 0.65 ± 0.08 | a | 0.87 ± 0.08 | b | ** |

| C18:2—t10-c12 CLA | % | 0.01 ± 0.00 | 0.02 ± 0.01 | NS | ||

| SCFA—short chain FA | % | 10.70 ± 4.68 | 7.67 ± 1.26 | NS | ||

| MCFA—middle chain FA | % | 52.87 ± 0.89 | 52.47 ± 2.97 | NS | ||

| LCFA—long chain FA | % | 36.39 ± 3.72 | 39.84 ± 1.69 | NS | ||

| OCFA—odd FA | % | 2.45 ± 0.23 | a | 2.85 ± 0.06 | b | * |

| MUFA—monounsaturated FA | % | 25.03 ± 1.84 | 26.80 ± 0.17 | NS | ||

| PUFA—polyunsaturated FA | % | 4.40 ± 0.37 | b | 3.88 ± 0.17 | a | * |

| UFA—unsaturated FA | % | 29.43 ± 2.21 | 30.68 ± 0.35 | NS | ||

| SFA—saturated FA | % | 70.53 ± 2.27 | 69.29 ± 0.36 | NS | ||

| CLA (conjug. linoleic acids) | % | 0.66 ± 0.08 | a | 0.89 ± 0.07 | b | ** |

| Omega 3 FA | % | 0.87 ± 0.07 | 0.76 ± 0.08 | NS | ||

| Omega 6 FA | % | 2.68 ± 0.23 | b | 1.99 ± 0.14 | a | ** |

| Day of Cheesemaking | Difference 1 |

|---|---|

| 1 February | * |

| 16 March | NS |

| 6 January | *** |

| 24 February | NS |

| 26 March | NS |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Formaggioni, P.; Malacarne, M.; Franceschi, P.; Zucchelli, V.; Faccia, M.; Battelli, G.; Brasca, M.; Summer, A. Characterisation of Formaggella della Valle di Scalve Cheese Produced from Cows Reared in Valley Floor Stall or in Mountain Pasture: Fatty Acids Profile and Sensory Properties. Foods 2020, 9, 383. https://doi.org/10.3390/foods9040383

Formaggioni P, Malacarne M, Franceschi P, Zucchelli V, Faccia M, Battelli G, Brasca M, Summer A. Characterisation of Formaggella della Valle di Scalve Cheese Produced from Cows Reared in Valley Floor Stall or in Mountain Pasture: Fatty Acids Profile and Sensory Properties. Foods. 2020; 9(4):383. https://doi.org/10.3390/foods9040383

Chicago/Turabian StyleFormaggioni, Paolo, Massimo Malacarne, Piero Franceschi, Valentina Zucchelli, Michele Faccia, Giovanna Battelli, Milena Brasca, and Andrea Summer. 2020. "Characterisation of Formaggella della Valle di Scalve Cheese Produced from Cows Reared in Valley Floor Stall or in Mountain Pasture: Fatty Acids Profile and Sensory Properties" Foods 9, no. 4: 383. https://doi.org/10.3390/foods9040383

APA StyleFormaggioni, P., Malacarne, M., Franceschi, P., Zucchelli, V., Faccia, M., Battelli, G., Brasca, M., & Summer, A. (2020). Characterisation of Formaggella della Valle di Scalve Cheese Produced from Cows Reared in Valley Floor Stall or in Mountain Pasture: Fatty Acids Profile and Sensory Properties. Foods, 9(4), 383. https://doi.org/10.3390/foods9040383