1. Introduction

Berries are well known for their unique flavor and abundant nutrients, including organic acids, vitamins, sugars, and trace elements, and especially for their large quantity of antioxidants [

1]. Anthocyanins are the main source of antioxidants in berries. Anthocyanins are helpful to reduce cholesterol concentration, alleviate high blood pressure, and improve eyesight. Berries have both nutritional and health functions [

2]. Thus, the Food and Agriculture Organization of the United Nations positioned the berry as a third-generation fruit with health-care functions [

3]. The storage and transportation of berries are quite difficult because they are juicy, fragile, and limited seasonal fruits. Therefore, berries are often processed into products such as jam, juice, and powder [

4]. China has abundant berry resources; the area of berry cultivation is over 45,000 hectares, and the annual output is more than 300,000 tons [

5]. Currently, less than 30% of the total yield of fresh berries are processed into products, so there is a large market space for processed berry products [

6].

The shelf life of fresh berries is 3–4 days at room temperature, due to their moisture content of over 90% (

w.b.) [

7]. In addition to the necessary refrigeration and freezing, drying is one of the most effective methods for the processing and storage of harvested berries [

8]. Conventional hot air drying methods are not suitable for berries [

9]. When dried in high temperature and oxygen conditions for a long time the bioactive ingredients in berries degrade massively and the quality of the product decreases [

10]. Freeze dried products usually have fine quality. However, this process takes a long time, approximately about 24–48 h, which leads to the increase of production costs [

11]. Spray drying is the primary method for producing powders; however, the uniformity of droplets is poor due to the high viscosity of berry puree [

12]. Foam-mat drying is an adaptive method for viscous, sticky, and heat sensitive materials [

13]. In this drying process, the liquid material is converted into a foam material by being whipped after adding an edible foaming agent [

14]. As foam-mat drying is less expensive and less complicated, it has been used to dry mango, papaya, banana, and so on. [

15,

16,

17]. Foam-mat drying combined with microwave heating shortens the drying duration and protects the thermally susceptible nutrients more than when combined with hot air drying, as microwave energy can be instantaneously converted into volumetric heating [

18,

19]. The heat transfer and mass transfer during microwave drying have the same transfer direction from the inside to the outside, which produces high heating speed and a high energy utilization rate [

20]. Microwave-assisted foam-mat drying (MFD) technology makes full use of the advantages of microwave drying and foam-mat drying and is a suitable drying method for berries, including blueberries, raspberries, and other fruits [

21].

The contents and bioactivity of nutrients are important indicators for evaluating the quality of products. Anthocyanins, as a class of polyphenolic pigments, are widely present in plant organs, and they have excellent water solubility and bioactivity [

22]. However, the anthocyanin pigments are unstable when the processing parameters, such as the temperature, pH, oxygen content, and light, change [

23,

24]. The anthocyanin degradation was the maximum in neutral environment at 75 °C, and the degradation was found to follow the first-order kinetics [

25]. Similar results indicated that anthocyanins were stable below 60 °C, whereas they tended to degrade at temperatures higher than 80 °C [

26]. Furfural compounds generated by the thermal degradation of sugars also promoted the degradation of anthocyanins [

27]. Existing studies have focused on the relationship between various single variables and the degradation of anthocyanins, while few studies have comprehensively considered all of the processing factors regarding the stability of anthocyanins during the drying process.

This study aimed to determine the mechanism of anthocyanin degradation in berry puree by considering multiple variables during the MFD. Based on the experimental results in different microwave intensities, path analysis has been implemented to study the effects of multiple variables (temperature, moisture content, drying time and radius) on the anthocyanin degradation content. A multi-physical simulation model was established by using the results of degradation kinetic analysis, which could be a theoretical and technical reference for product quality control.

2. Materials and Methods

2.1. Preparation of Foamed Berry Puree

The drying of blue honeysuckle puree was carried out in a microwave workstation (

Figure 1). Fresh blue honeysuckle (

Lonicera caerulea L.) berries were selected according to their color and maturity (provided by the horticulture station of Northeast Agricultural University, Harbin, China). The uniform and fine berry puree was prepared by grinding in a mixer (JYL-Y5, Jiuyang Ltd., Jinan, China) after removing impurities, cleaning, and wiping off the surface water. The optimal proportion of the foaming agent was 6 g glycerin monostearate (GMS, Jiashili Co., Ltd., Guangzhou, China) and 3 g soy protein isolate (SPI, Linyi Co., Ltd., Linyi, China) dissolved in 100 mL distilled water, and 10 mL of 0.5% carboxymethyl cellulose (CMC, Zhiyuan Co., Ltd., Tianjin, China) was added as a stabilizer. Foaming agent and berry puree were then mixed with a mass ratio of 1: 1. The mixture was stirred evenly with an electric stirrer for 6 min and stored in a water bath (HWS24, Yiheng Co., Ltd., Shanghai, China) at 70 °C for 30 min to generate homogenous foamed berry puree. Foamed berry puree with the density of 600 kg/m

3 has been reported to have the best stability [

28].

2.2. Experimental Process

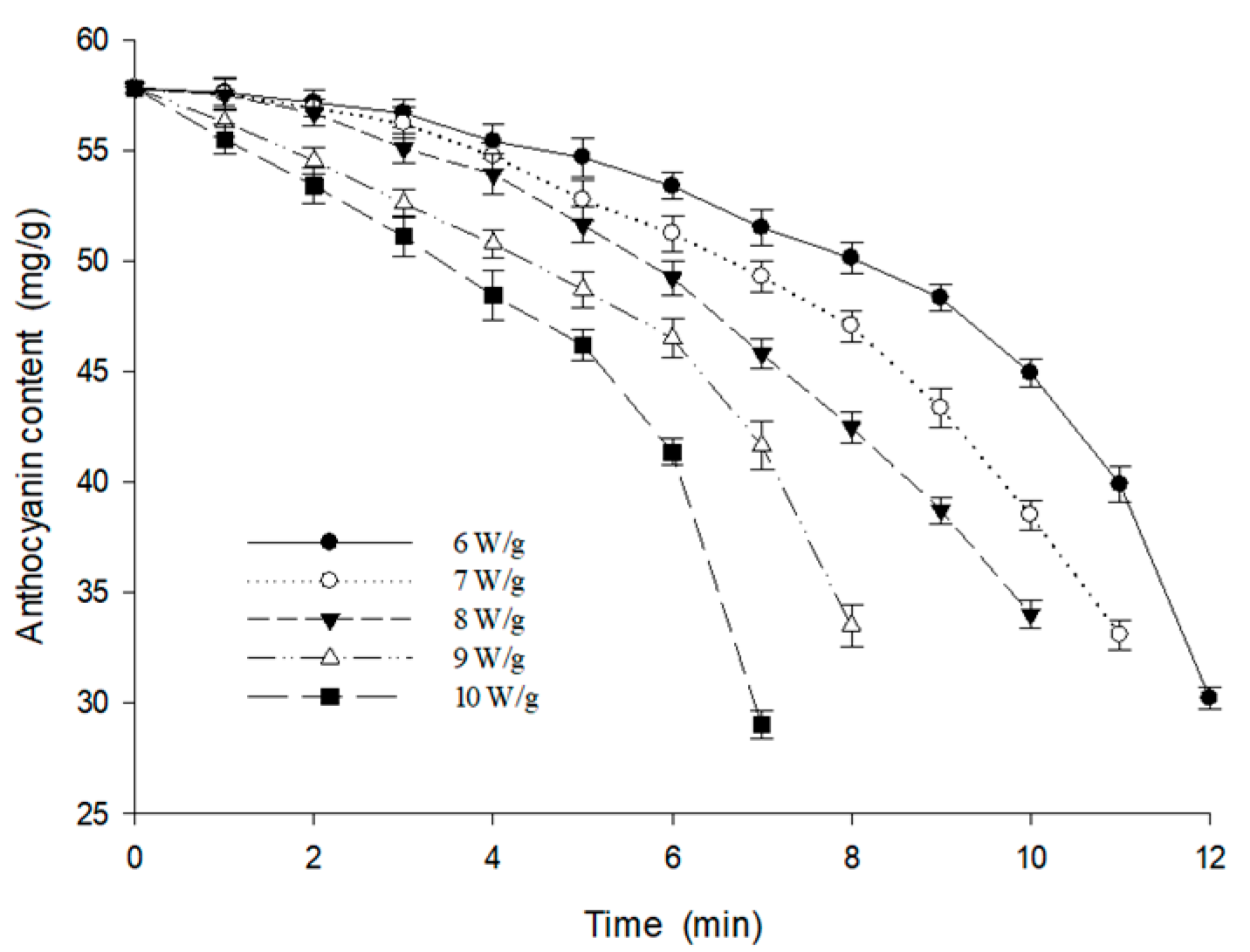

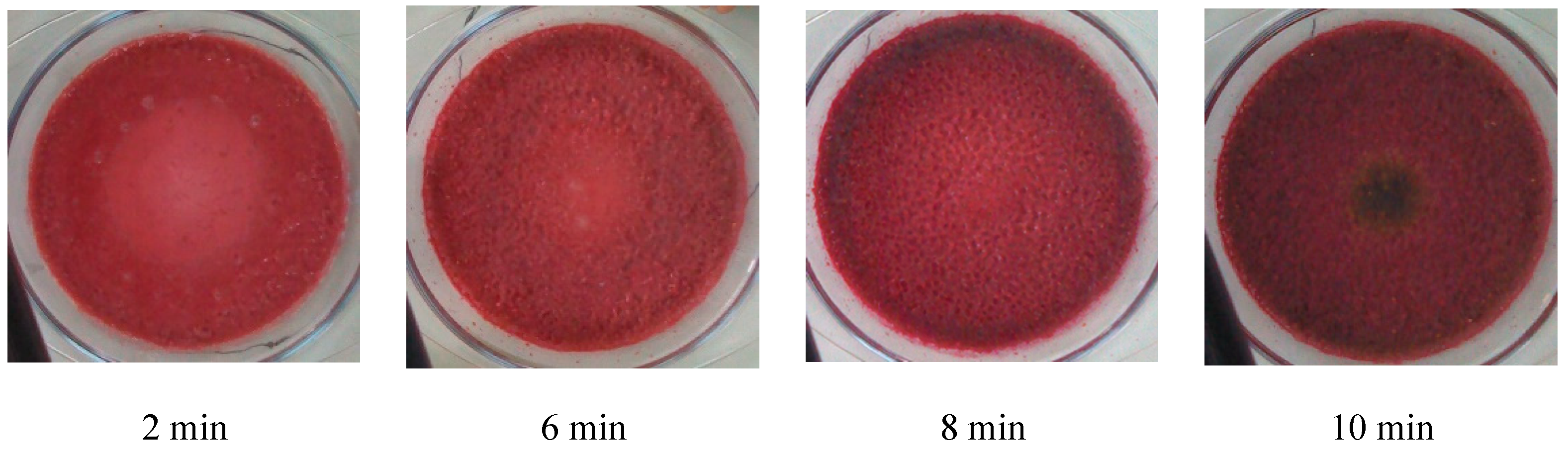

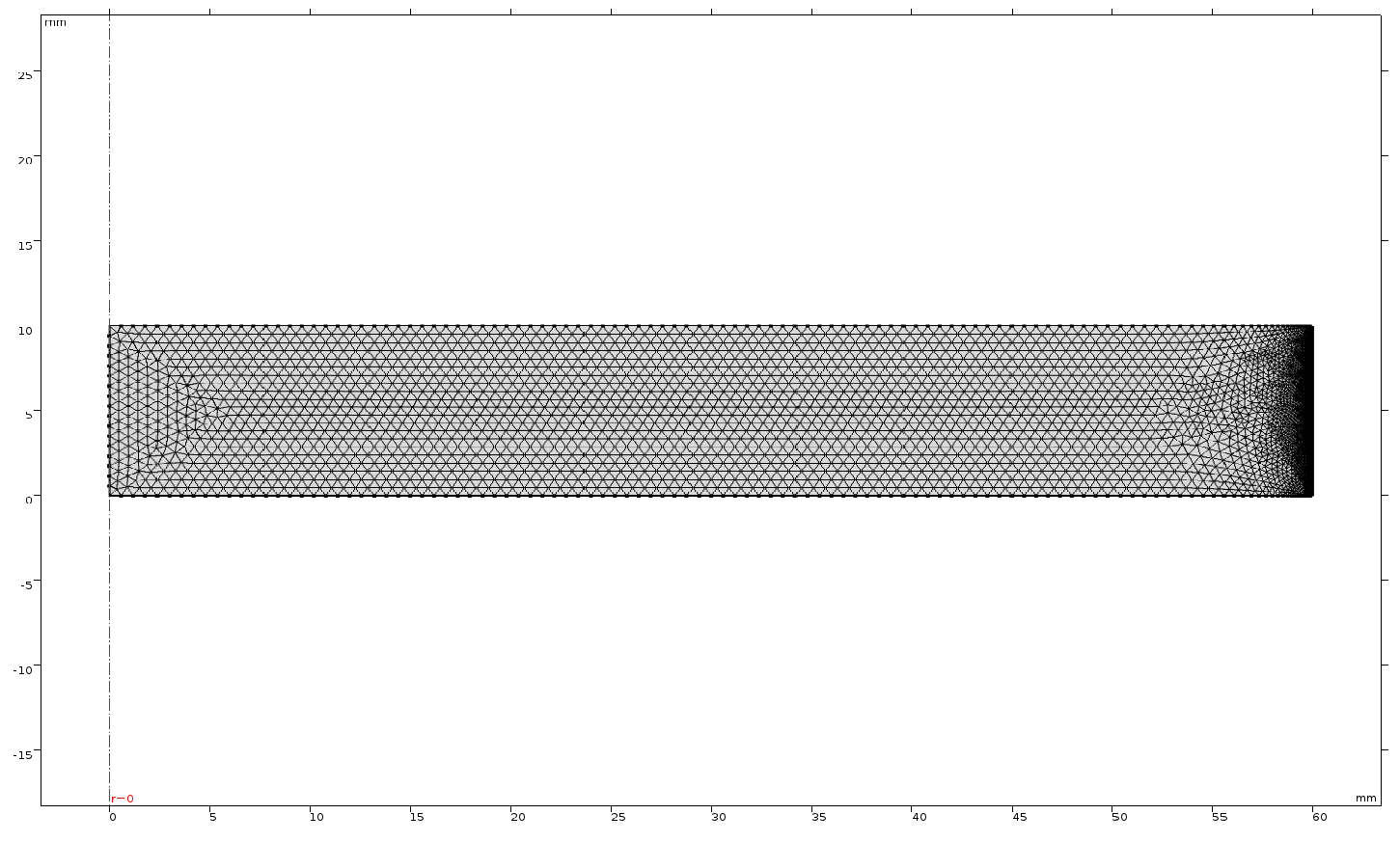

A circular glass-tray containing 100 g of foamed berry puree was loaded on a turntable in the center of a microwave oven. The microwave oven (NN-ST780, Panasonic, Osaka, Japan) was able to supply 10 accurate power levels with a maximum of 1100 W at 2.45 GHz frequency, with internal dimensions of 395 mm (W) × 180 mm (H) × 385 mm (D). The excitation for the microwave oven was through a rectangular waveguide, which was installed on the right wall of the cavity with TE10 as the dominant mode of the transverse electric (TE) waves. The deviation between actual power and rated power was less than 5%, so the rated power was used for calculating the power absorbed by the berry puree in the simulation. The radius of the glass-tray was 8 cm. The temperature, moisture content and anthocyanin content of the berry puree were measured per minute in different positions (radius of 0, 2, 4, 6, 8 cm) when the microwave intensity was set to 6, 7, 8, 9 and 10 W/g. The drying experiments were continued until the moisture content of berry puree was below 15%. Blue honeysuckle powder was obtained by grinding the dried product.

2.3. Determination of Variables

2.3.1. Temperature

An infrared camera (T-420, FLIR Systems Inc., Wilsonville, OR, USA) was used to capture the temperature distribution of the foamed berry puree. FLIR Tools software was used to analyze the infrared image and collect the temperature data of the berry puree. In order to ensure that the distance between the camera and the material was unchanged, the infrared camera was fixed on a tripod. The shooting was completed within 3–4 s to minimize the error caused by the operations.

2.3.2. Moisture Content

The moisture content was determined by the direct drying method (GB 5009.3-2010), and was calculated as the ratio of free water content to the whole weight. The moisture content (%) values were calculated using Equation (1). Dried samples of 2–5 g (0.0001 g) were loaded into an aluminum box and then they were put into a drying oven at 105 °C for 3–4 h until the difference of weight between adjoining samples was less than 2 mg.

where

M is the moisture content (%),

m1 is the weight before drying (g) and

m2 is the constant weight (g).

2.3.3. Total Anthocyanin Content

The total anthocyanin contents were measured by the low concentration of vanillin hydrochloric acid method [

29]. 1–2 g of the dried samples were dissolved in 30 mL of methanol solution. The mixture was centrifuged at 4000 rad/min (LG10-2.4A, Jingli Co., Ltd., Beijing, China). After 15 min of centrifugation, 5 mL chromogenic reagent was added into 1 mL supernatant. The chromogenic reagent was a mixture of 1% (

w/v) vanillin methanol solution and 8% (

w/v) hydrochloric acid methanol solution in a ratio of 1:1. Then, the tube was transferred to a water bath at 30 °C for 30 min. The absorbance of the solution was determined at 520 nm. The concentration of anthocyanin was calculated by using a calibration curve of standard pro-anthocyanin solutions. The anthocyanin content in the berry puree was calculated by using Equation (2).

where

C is the anthocyanin content (mg/g),

V is the constant volume (mL),

D is the concentration of anthocyanin (mg/mL),

n is the dilution multiple and

W is the weight of sample (g).

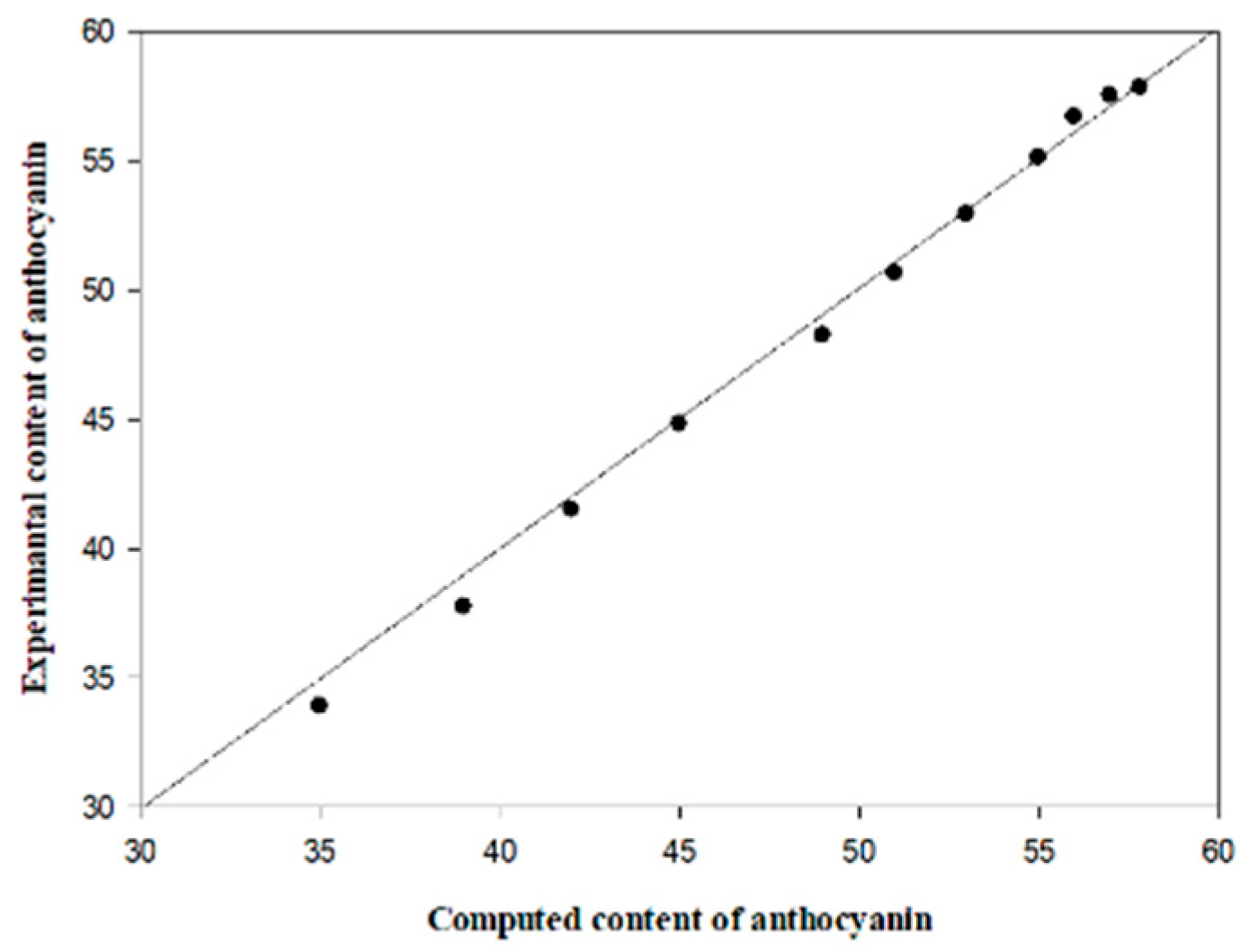

2.4. Statistical Analysis

Regression analysis was performed by Sigmaplot 12.5 (Systat Software Inc., San Jose, CA, USA). The statistical differences among samples were determined by the analysis of variance (ANOVA). The calculation of path analysis was performed by SPSS 24.0 (IBM, Armonk, NY, USA). The multiphysics model of the drying process was simulated by Comsol (Comsol Inc., Stockholm, Stockholm Lan, Sweden). All the data were expressed as mean values of triplicate experiments.